Method for preparing phi7.0mm1770MPa high-strength low-relaxation zinc-coated wire

A 7.0mm1770mpa, galvanized steel wire technology, applied in the direction of manufacturing tools, drawing dies, heat treatment process control, etc., can solve the problems of complex equipment, poor surface quality, poor toughness and plasticity, etc., to achieve high torsion, high linearity, The effect of high toughness and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with typical embodiments.

[0008] The production process of φ7.0mm1770MPa high-strength and low-relaxation galvanized steel wire products for stay cables with torsion: wire rod re-inspection→surface preparation→wire drawing→hot-dip galvanizing→stabilization treatment→inspection. 1. Wire rod re-inspection

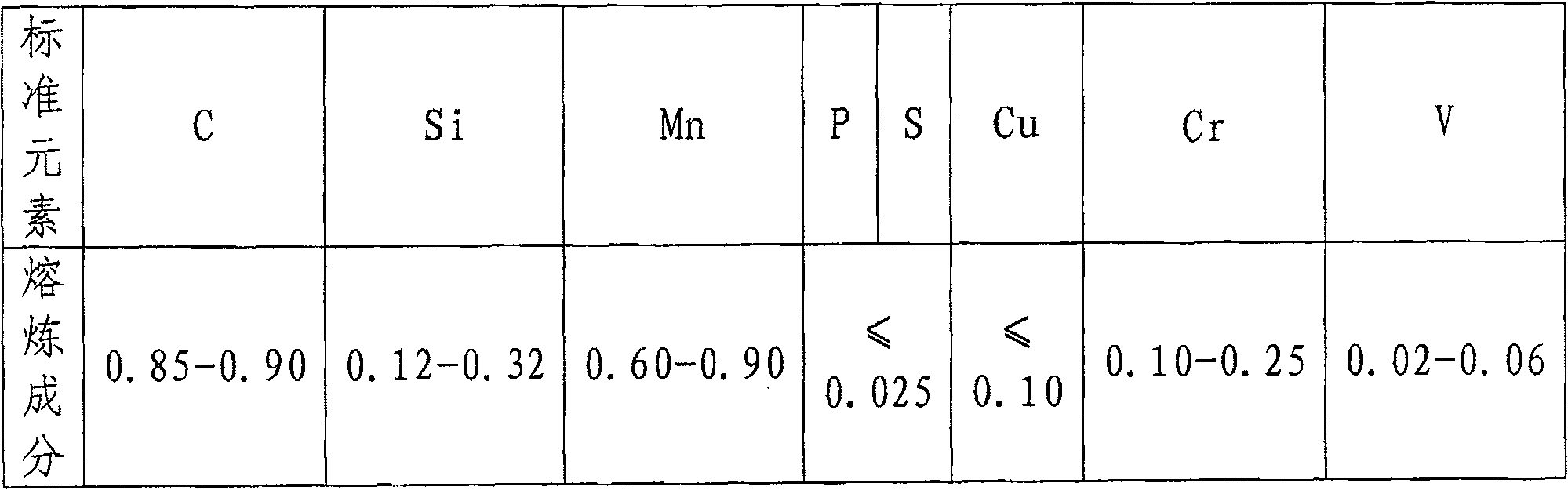

[0009] The φ13.5mm, B87MnQL special wire rod developed by Baosteel is selected, and the main technical conditions are as follows:

[0010] (1) Smelting ingredients:

[0011]

[0012] (2) Mechanical properties: tensile strength 1350±50MPa, section shrinkage ≥ 30% (wire rod ≥ 35% after 14-day aging).

[0013] 2. Surface Preparation

[0014] The iron oxide scale on the surface of the wire rod is removed by pickling, and then the surface of the cleaned wire rod is treated with phosphating and boronizing and dried. Specific process: wire rod → pickling → cleaning (rinsing, rinsing) → phosphating →...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com