High-performance tool joint for transmitting electric power and relevant signals

A related signal and tool joint technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of complex structure, difficult production and use, reduce the stress level and stress concentration of the joint structure, and achieve convenient loading and unloading , improve torsional performance, and the effect of highly intelligent drilling and production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

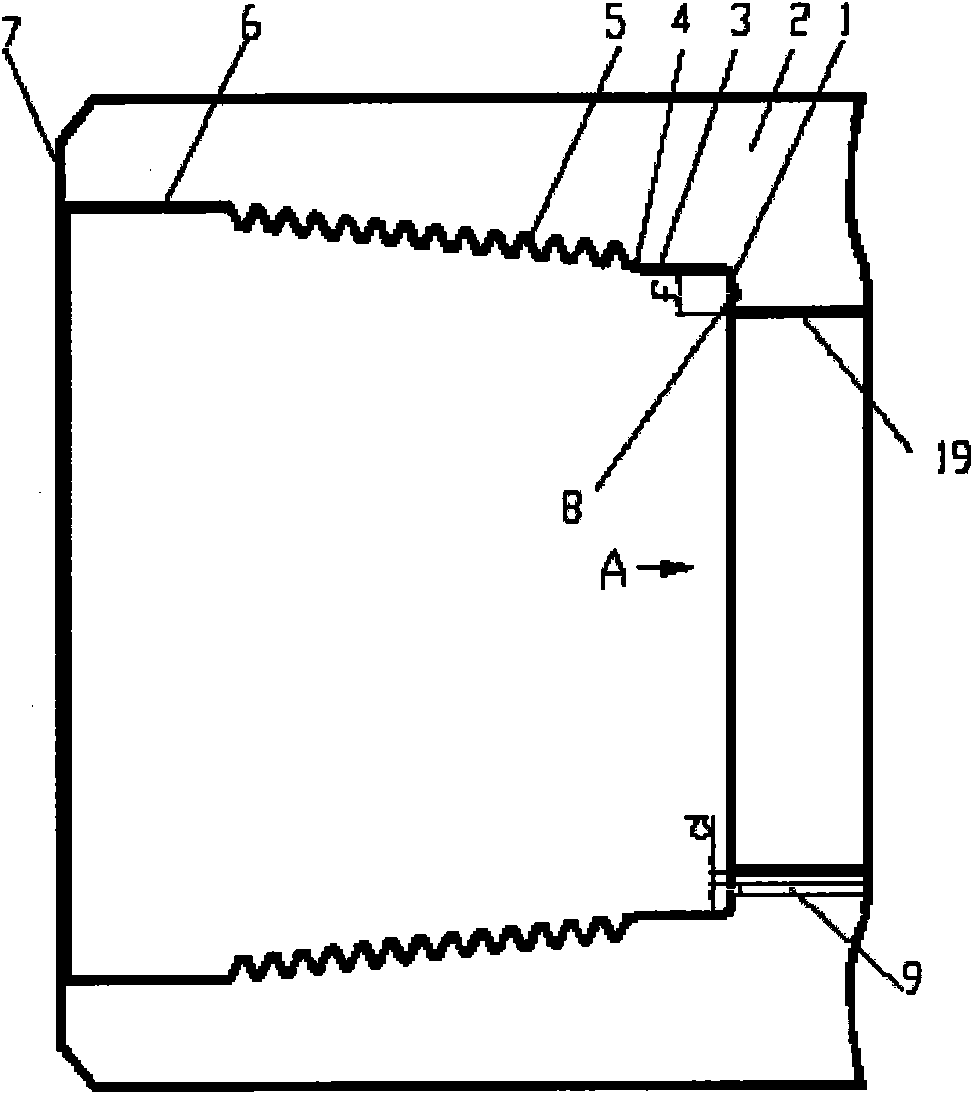

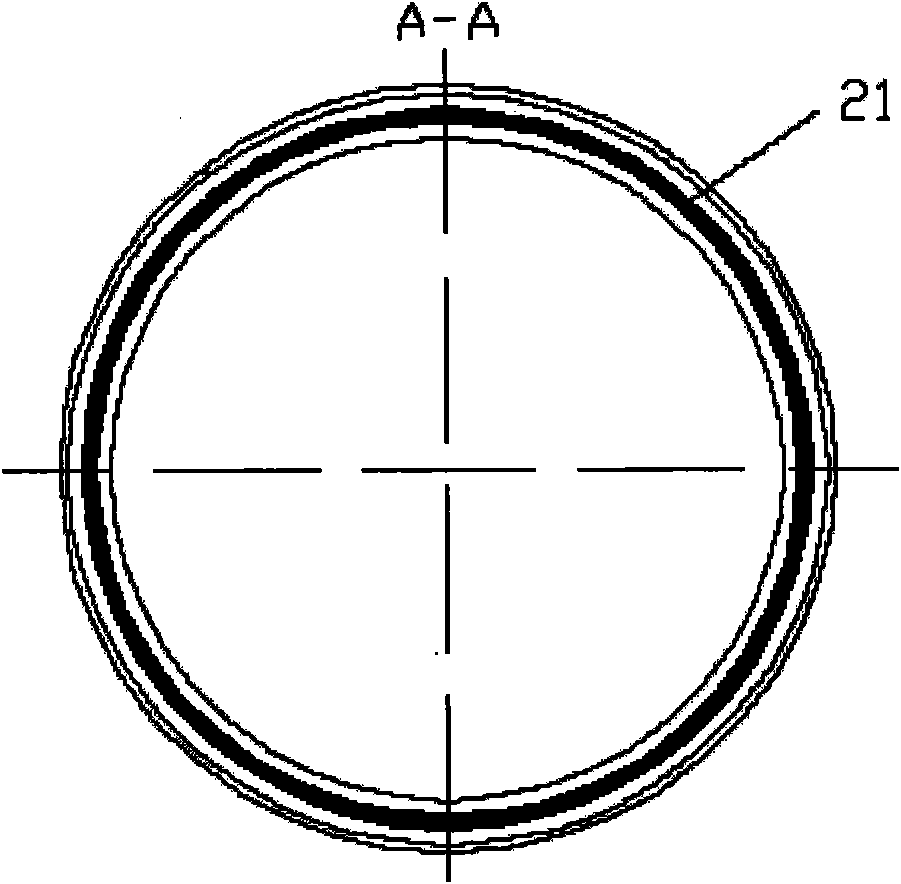

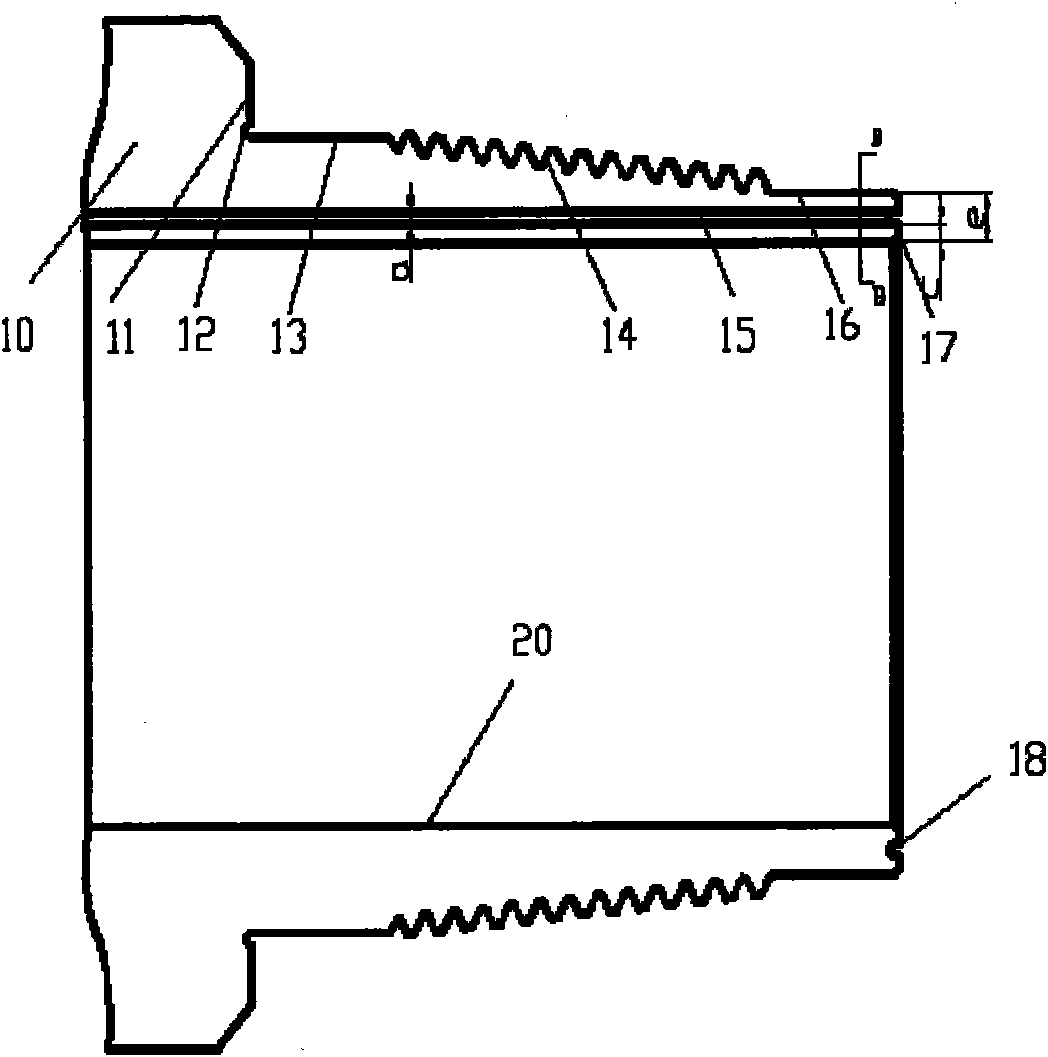

[0035] With the structure of the present invention, its relevant technical parameters: a is 2mm, b is 2.5mm, e is 10mm, f-e is 0.2mm, c is 4mm, and d is 3.5mm. When in use, the internal and external threads can effectively reduce the stress extreme value, and the joint has good connection strength and sealing performance. Through finite element calculation, it can be seen that compared with ordinary joints, the torsional performance is greatly improved. It can effectively improve the stress extreme value and stress distribution of the drill pipe joint, and the torsional performance is very superior. The cross-section of the signal transmission channel is circular, which will not cause stress concentration, and the structure can transmit power and related signals through the signal transmission channel to realize intelligent real-time control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com