Button mounting member

A technology for installing components and buttons, which is applied in the direction of fasteners, buttons, press fasteners, etc., can solve problems such as buckling of button installation components, ridge line pressure, and edge damage, and achieve the effect of suppressing buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

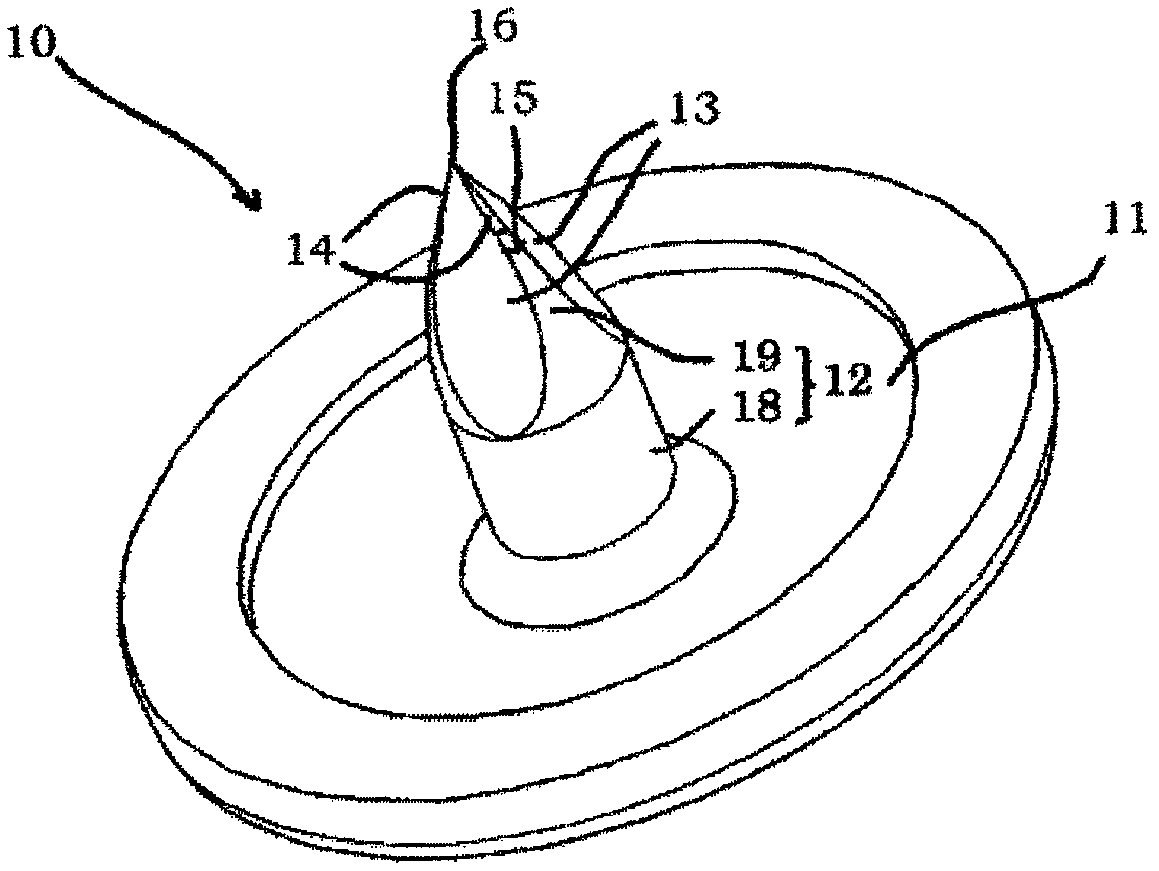

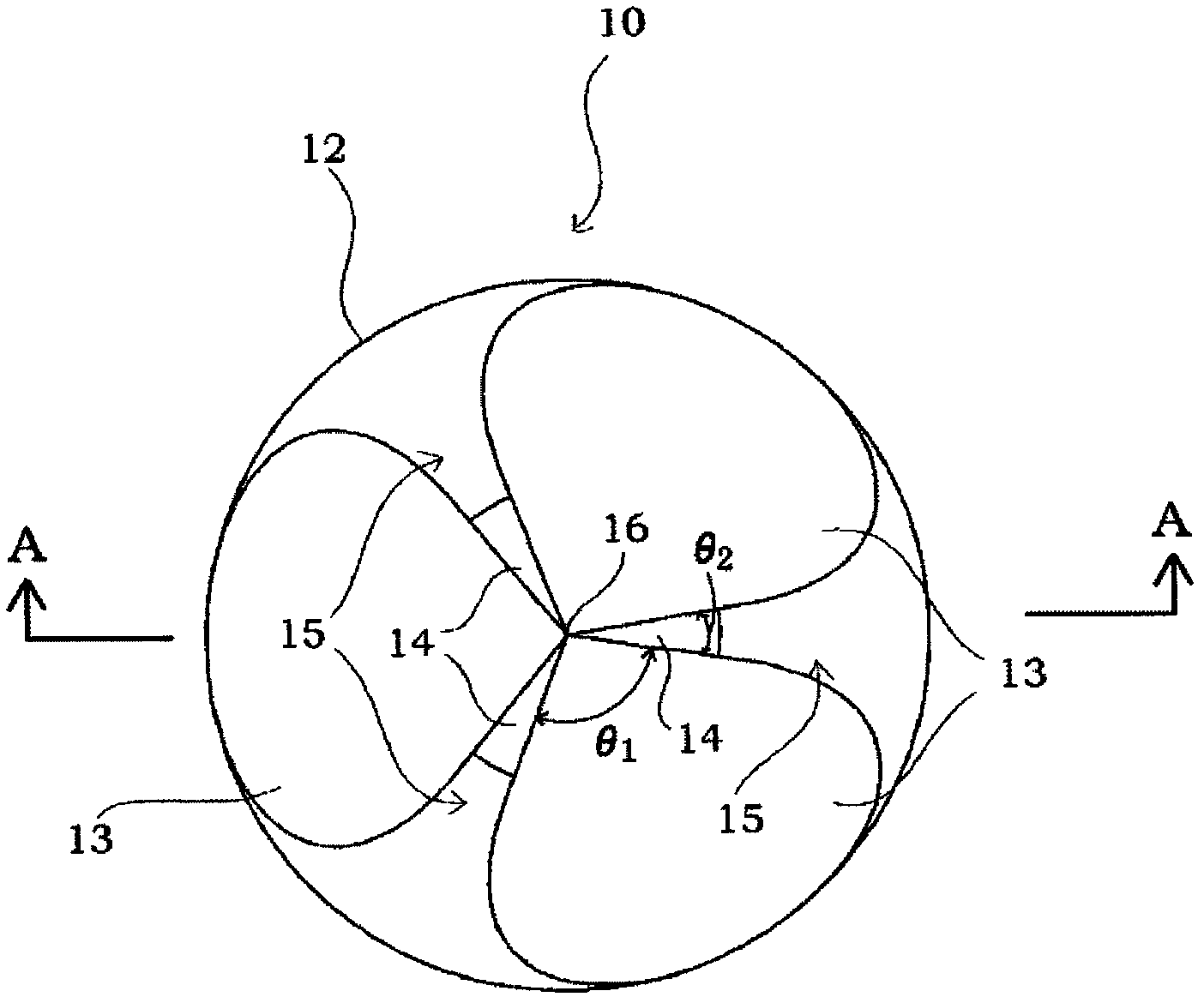

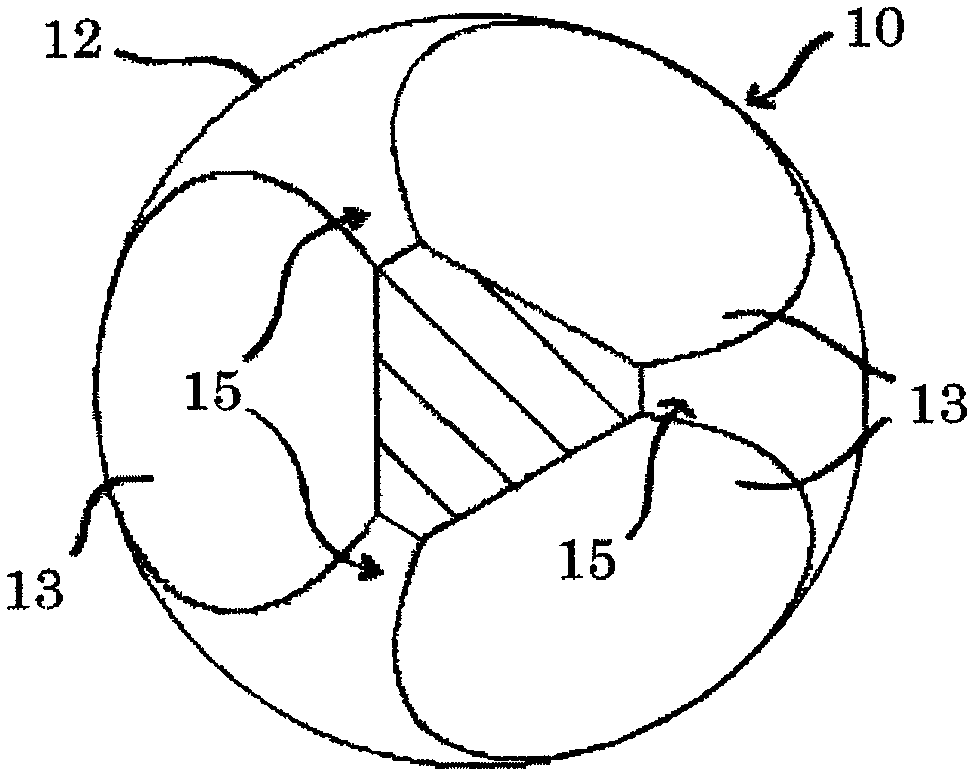

[0047] Structure of button mounting member 10

[0048] figure 1 The perspective view which shows the button attachment member 10 which concerns on 1st Embodiment. figure 2 It shows the top view of the post part 12 of the button attachment member 10. image 3 Indicates the column portion 12 of the button mounting member 10 Figure 4 The B-B horizontal section view. Figure 4 Indicates the column portion 12 of the button mounting member 10 figure 2 A-A cutaway view. Figure 5 A cross-sectional view showing the button attachment member 10 , the flexible base material 40 , and the female snap body 20 before the column portion 12 is inserted.

[0049] The female snap 30 has a button attachment member 10 and a female snap body 20 .

[0050] The button attaching member 10 has a base 11 and a post 12 formed so as to stand up from the approximate center of the surface of the base 11 and used to penetrate a flexible base material 40 such as cloth or the like of clothing. The ...

no. 2 approach

[0071] The button attachment member is not limited to the configuration described in the first embodiment, and may be, for example, a configuration related to the second embodiment described below.

[0072] Figure 10 It shows the top view of the post part 52 of the button attachment member 50 which concerns on 2nd Embodiment. Figure 11 A cross-sectional view showing a column portion 52 of the button attachment member 50 according to the second embodiment.

[0073] The button attaching member 50 has a base (not shown) and a post 52 formed so as to stand up from a substantially central portion of the surface of the base for penetrating flexible substrates such as clothing. The base is formed in a plate shape such as a substantially circular shape or a substantially rectangular shape, for example. The column portion 52 has a column body portion 58 extending from the base surface and a column top portion 59 extending from the front end of the column body portion 58 in a directio...

no. 3 approach

[0080] The button attachment member is not limited to the structures described in the first and second embodiments, and may be, for example, the structure of the third embodiment described below.

[0081] Figure 12 It shows the top view of the post part 62 of the button attachment member 60 which concerns on 3rd Embodiment. Figure 13 It shows the front view seen from the front of the rib part 65 of the post part 62 of the button attachment member 60 which concerns on 3rd Embodiment. Figure 14 It shows the front view seen substantially from the front of the 1st inclined surface 63 of the post part 62 of the button attachment member 60 which concerns on 3rd Embodiment.

[0082] The button attaching member 60 has a base (not shown) and a post 62 formed so as to stand up from a substantially central portion of the surface of the base for penetrating flexible substrates such as clothing. The base is formed in a plate shape such as a substantially circular shape or a substantia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com