Press-fit terminal, connector and press-fit connector continuous body employing same, and wound press-fit connector continuous body

A press-fit, continuum technology, applied in the direction of connection, fixed connection, coupling device, etc., can solve the problem of unstable substrate press-in, prevent substrate damage and contact damage, stabilize insertion force and retention force, and improve reliability. Effects of Sex and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

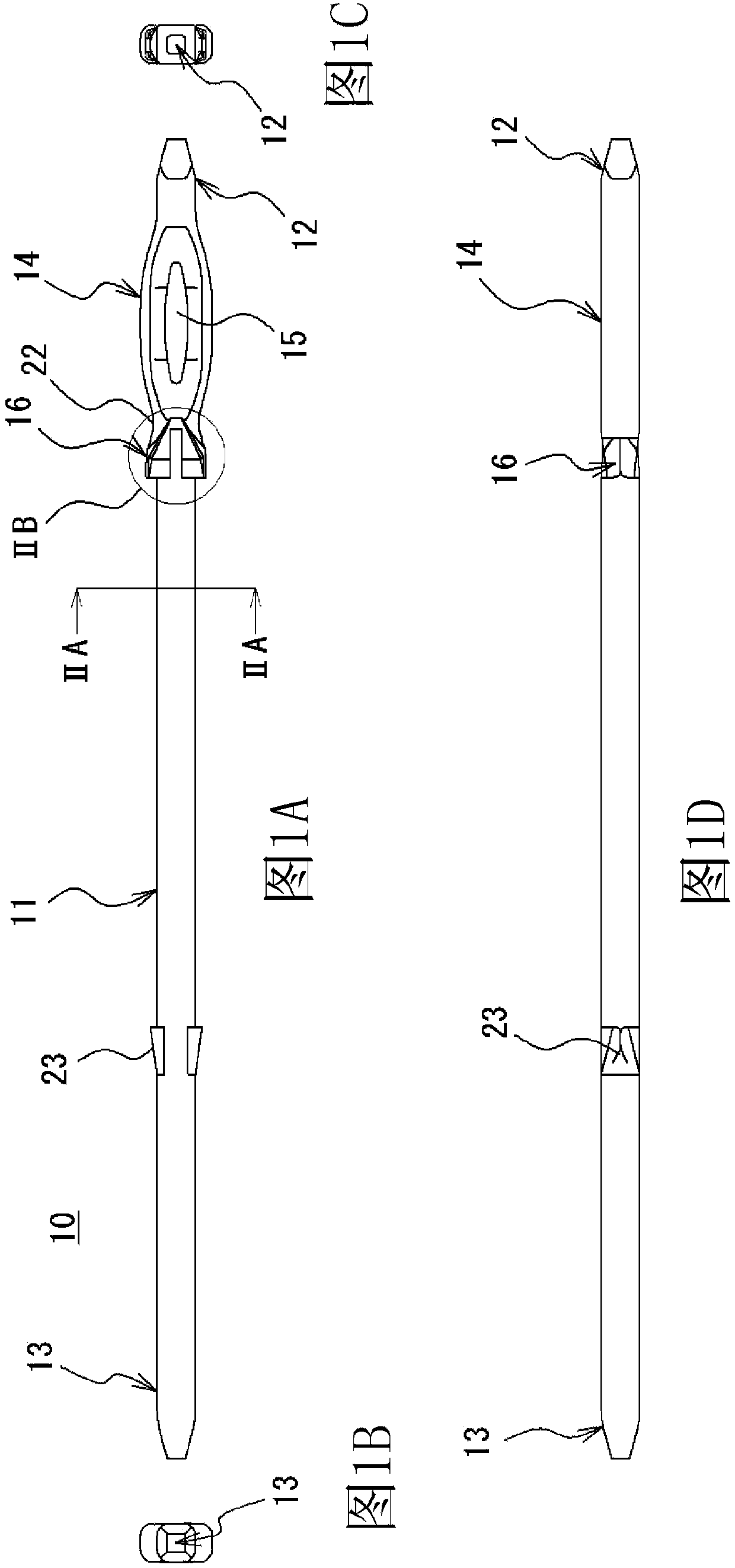

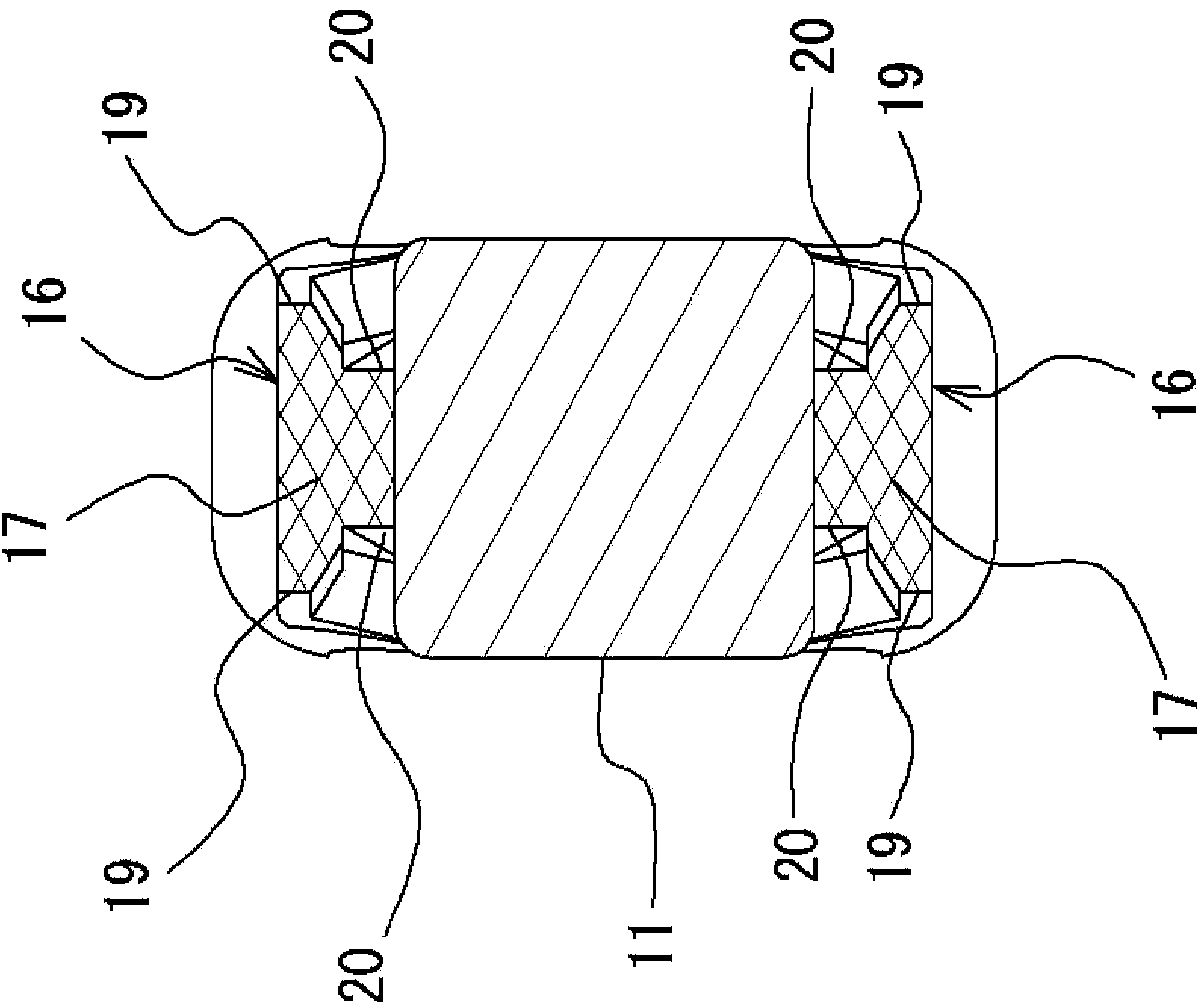

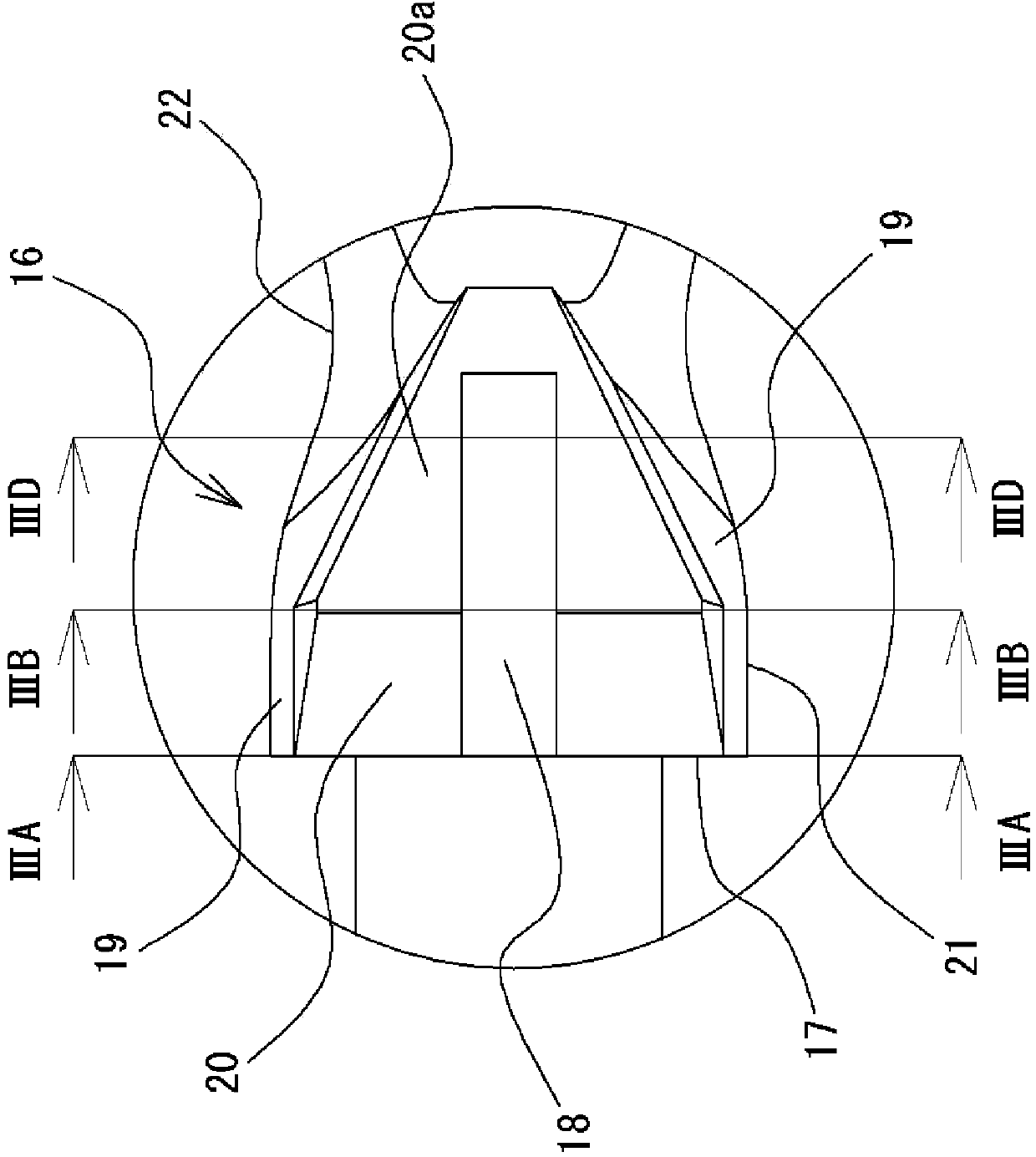

[0059] A press-fit terminal according to an embodiment of the present invention will be described with reference to FIGS. 1 to 3 . With regard to the press-fit terminal (hereinafter referred to as "PF terminal") 10 according to Embodiment 1 of the present invention, the shape of the PF terminal is given at regular intervals on the elongated wire 11A by pressing or the like (see Figure 9A with Figure 9B ), and then, it is divided into a predetermined length of the wire 11, thereby forming a single PF terminal. In this PF terminal 10 , a terminal portion 12 for insertion into a substrate is formed at one end of a wire 11 , and a connection portion 13 for connecting to a counterpart terminal is formed at the other end. In addition, a press-fit portion (hereinafter referred to as “PF portion”) 14 that is press-fitted into the substrate is formed on the end portion 12 side of the wire 11, and the connection portion 13 is formed on the upper portion of the PF portion 14. , a sho...

Embodiment approach 2

[0086] Next, as a second embodiment, a press-fit terminal continuous body (hereinafter referred to as a PF terminal continuous body) 32 in which the PF terminal 10 described in the first embodiment is continuously formed on a wire rod will be described. Also, the same reference numerals are assigned to the same configurations, and detailed descriptions thereof are omitted.

[0087] Such as Figure 9A with Figure 9B As shown, the PF terminal continuous body 32 is a state in which the PF terminal 10 of the first embodiment is continuously formed on the long wire 11A, and is a stage before dividing the PF terminal 10 of the first embodiment as described above into a single body. status.

[0088]At this time, the PF terminal continuous body 32 is formed as a single linear member connecting the ends of the end portion 12 of one PF terminal 10 and the connection portion 13 of the other PF terminal 10 . And the part where this terminal part 12 and the connection part 13 are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com