Load Bearing Frame

a technology of load bearings and frame frames, which is applied in the direction of buildings, towers, walls, etc., can solve the problems of small deformation of the entire frame and sudden collapse of the entire frame, and achieve the effect of improving the load bearing capacity of the entire fram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

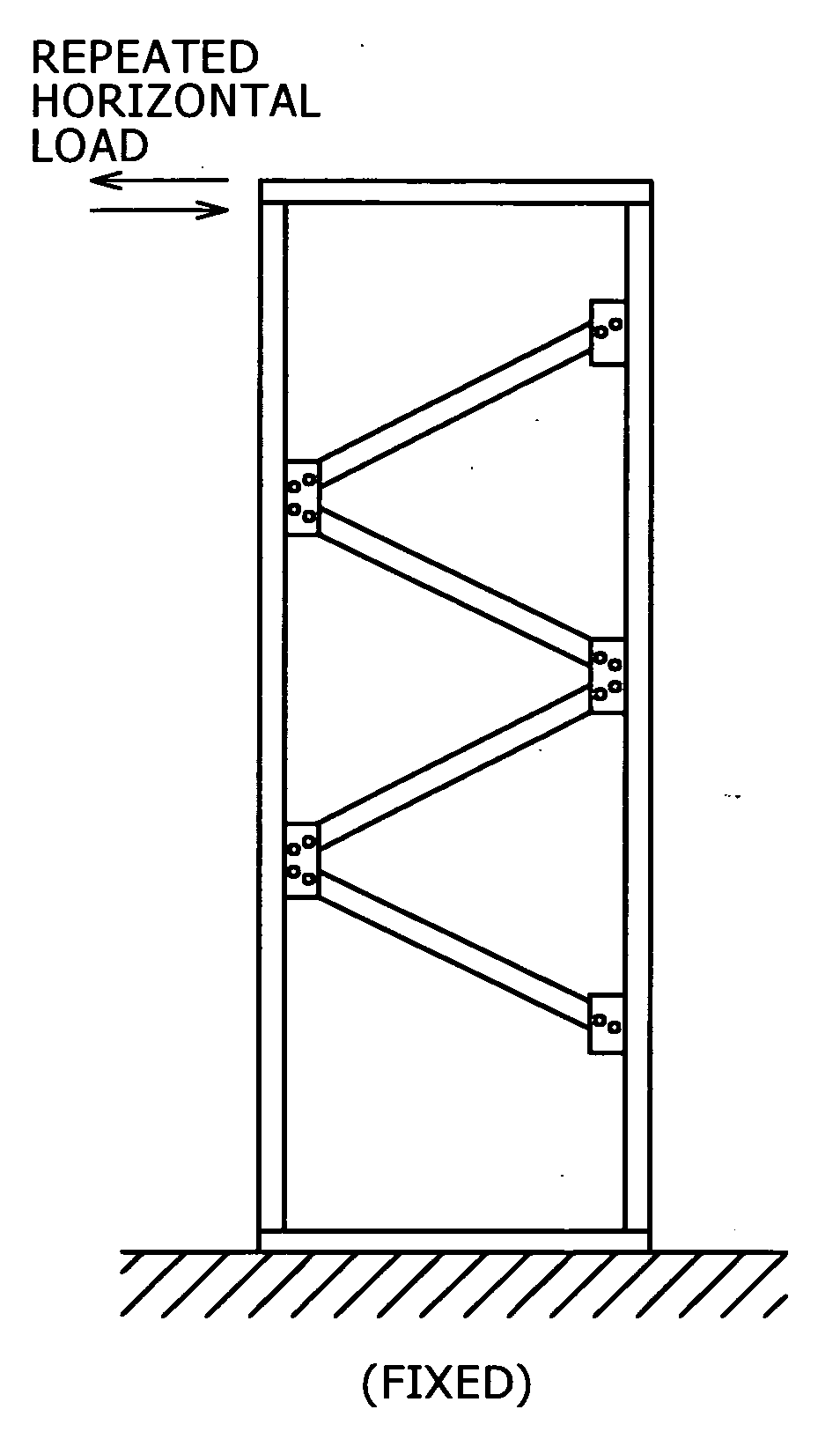

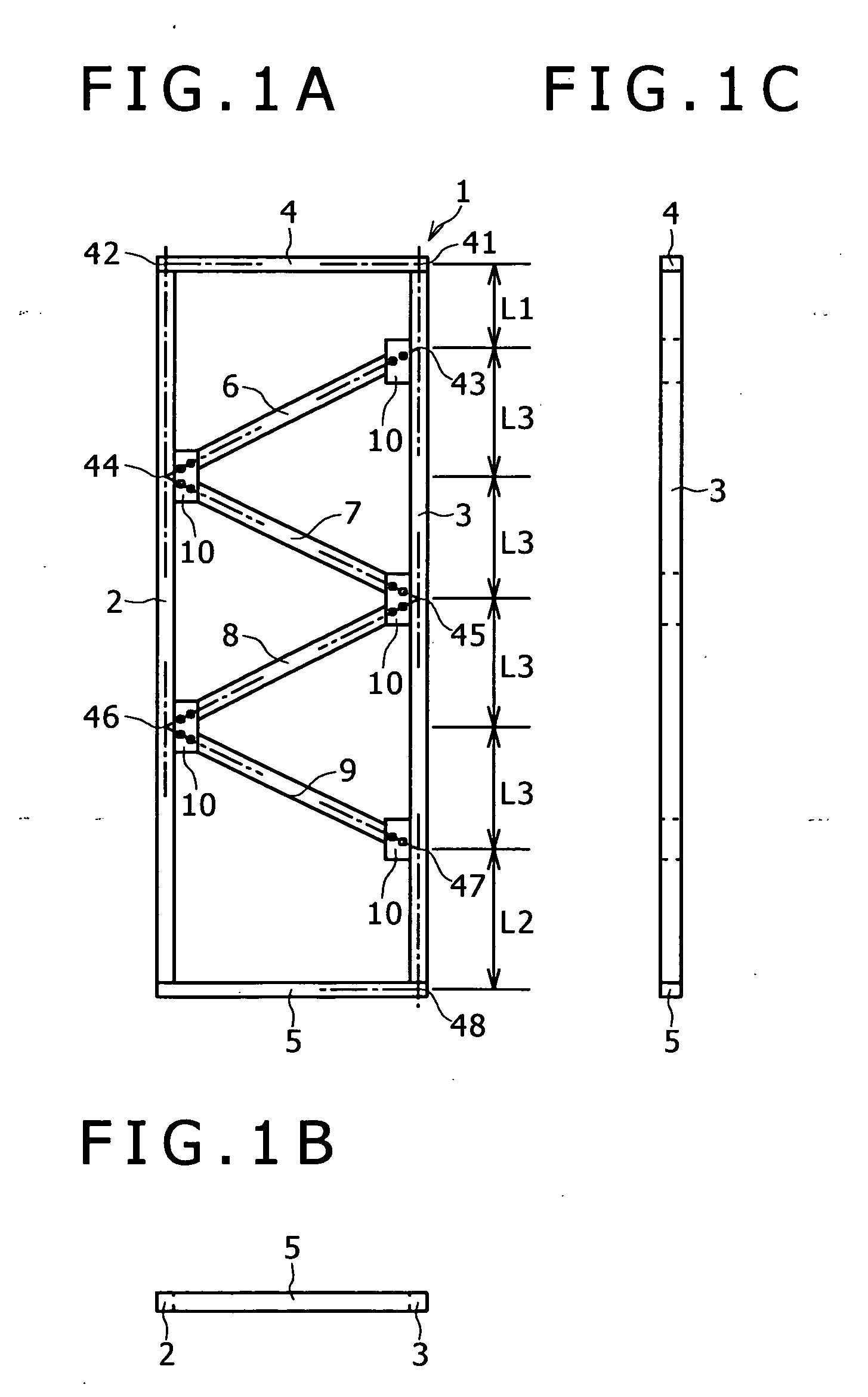

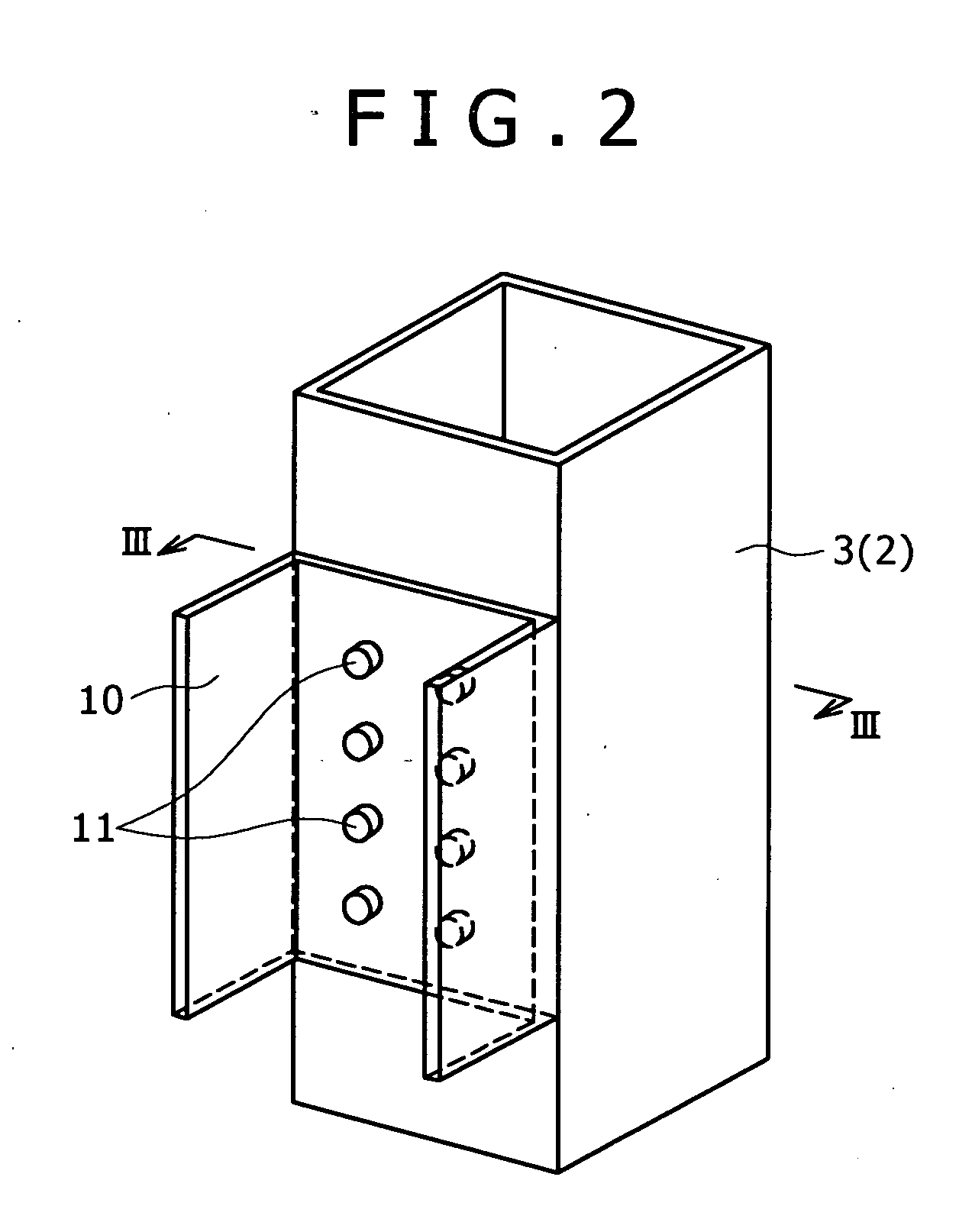

[0028]Hereinafter, a description will be given to preferred embodiments of the present invention with reference to drawings. FIG. 1 is a view showing a schematic configuration of a load bearing frame according to a first embodiment of the present invention. FIG. 1A is a front view, FIG. 1B is a bottom view and FIG. 1C is a side view. FIG. 2 is an enlarged view of the vicinity of a connection part between a pillar material and a connection member. Although FIG. 2 shows the vicinity of a connection part between a pillar material 3 and a connection member 10, a configuration of the vicinity of a connection part between a pillar material 2 and the connection member 10 is the same. FIG. 3 is a sectional view by line III-III of FIG. 2.

[0029]A load bearing frame 1 (hereinafter, referred to as the frame 1) shown in FIG. 1 is a steel frame for a steel house. The frame 1 has two pillar materials 2 and 3, two frame materials 4 and 5 and four diagonal materials 6 to 9. The pillar materials 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com