Nonaqueous electrolyte secondary battery and method for producing the same

A non-aqueous electrolyte, secondary battery technology, applied in secondary battery manufacturing, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as buckling that cannot be avoided, and achieve buckling suppression and excellent cycle life characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

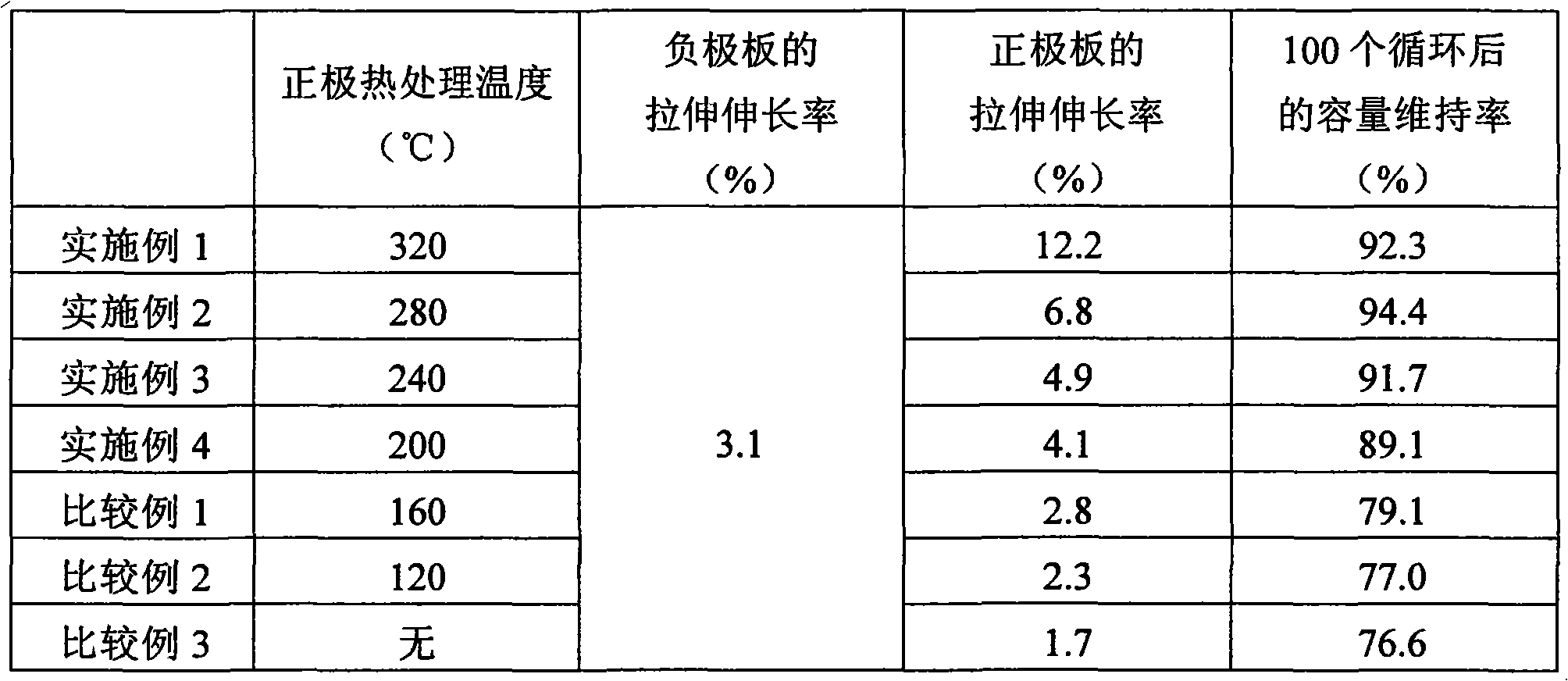

[0075] Hereinafter, examples of the present invention are given to further illustrate the constitution and effect of the present invention, but the present invention is not limited by these examples.

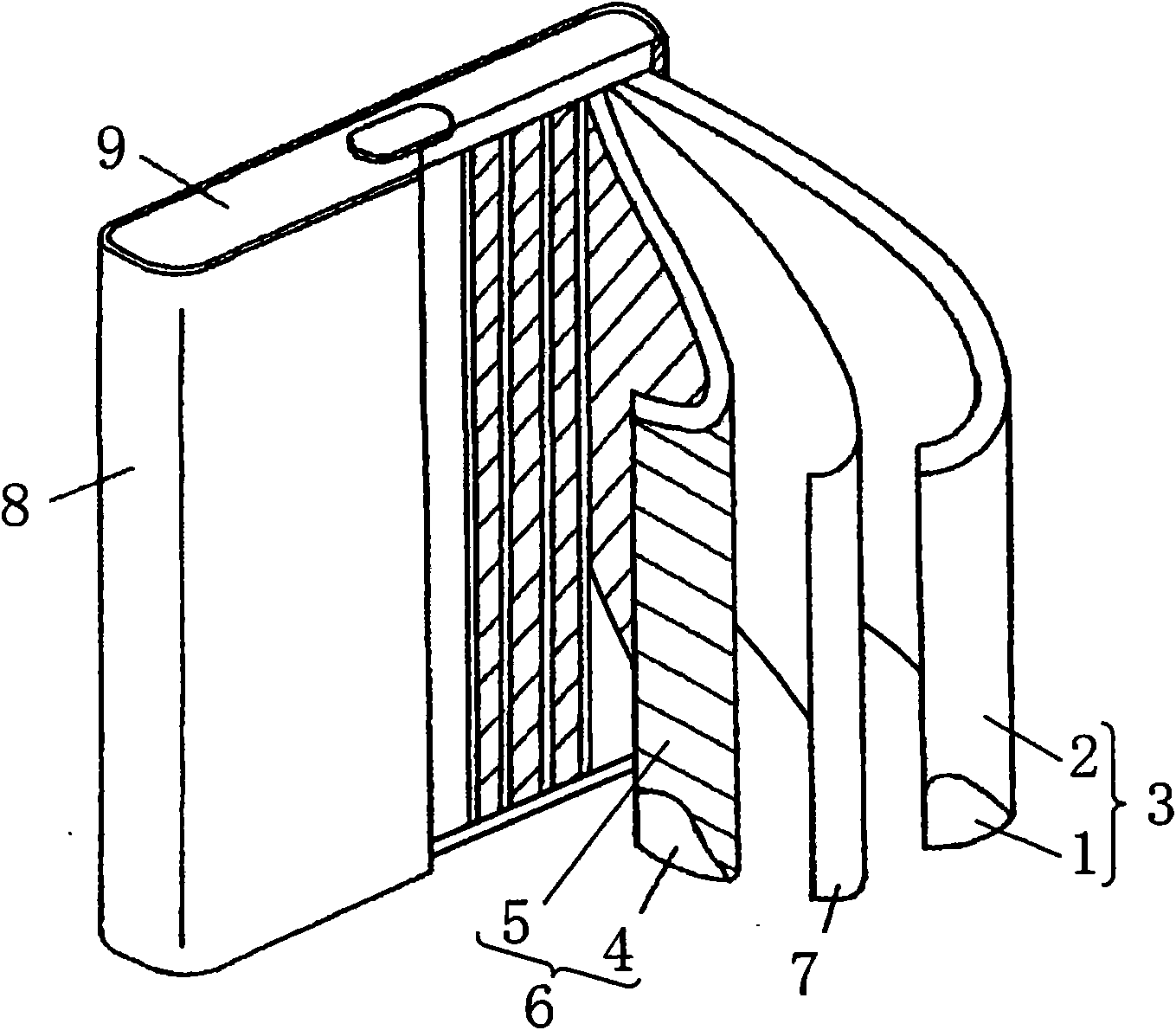

[0076] Make according to the following essentials figure 1 The non-aqueous electrolyte secondary battery shown, and the cycle life characteristics were evaluated.

[0077] (1) Production of negative plate

[0078] A graphite crucible and an electron gun filled with metal Si (purity: 99.999%, manufactured by Furuuchi Chemical Co., Ltd., blank) were installed in a vacuum evaporation apparatus. Electrodeposited copper foil (manufactured by Furukawa Salkittofoil Co., Ltd., thickness 20 μm) as current collector 4 is introduced from a roll into the vacuum evaporation device at a constant speed (5 cm / min), and Oxygen gas with a purity of 99.7% (manufactured by Nippon Oxygen Co., Ltd.) was supplied from the nozzle to the surface of the current collector 4 at a flow rate of 80 sccm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com