Lead sealant film and non-aqueous electrolyte battery

A non-aqueous electrolyte and lead wire sealing technology, which is applied in the manufacture of non-aqueous electrolyte batteries, electrolyte batteries, batteries, etc., and can solve problems such as short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

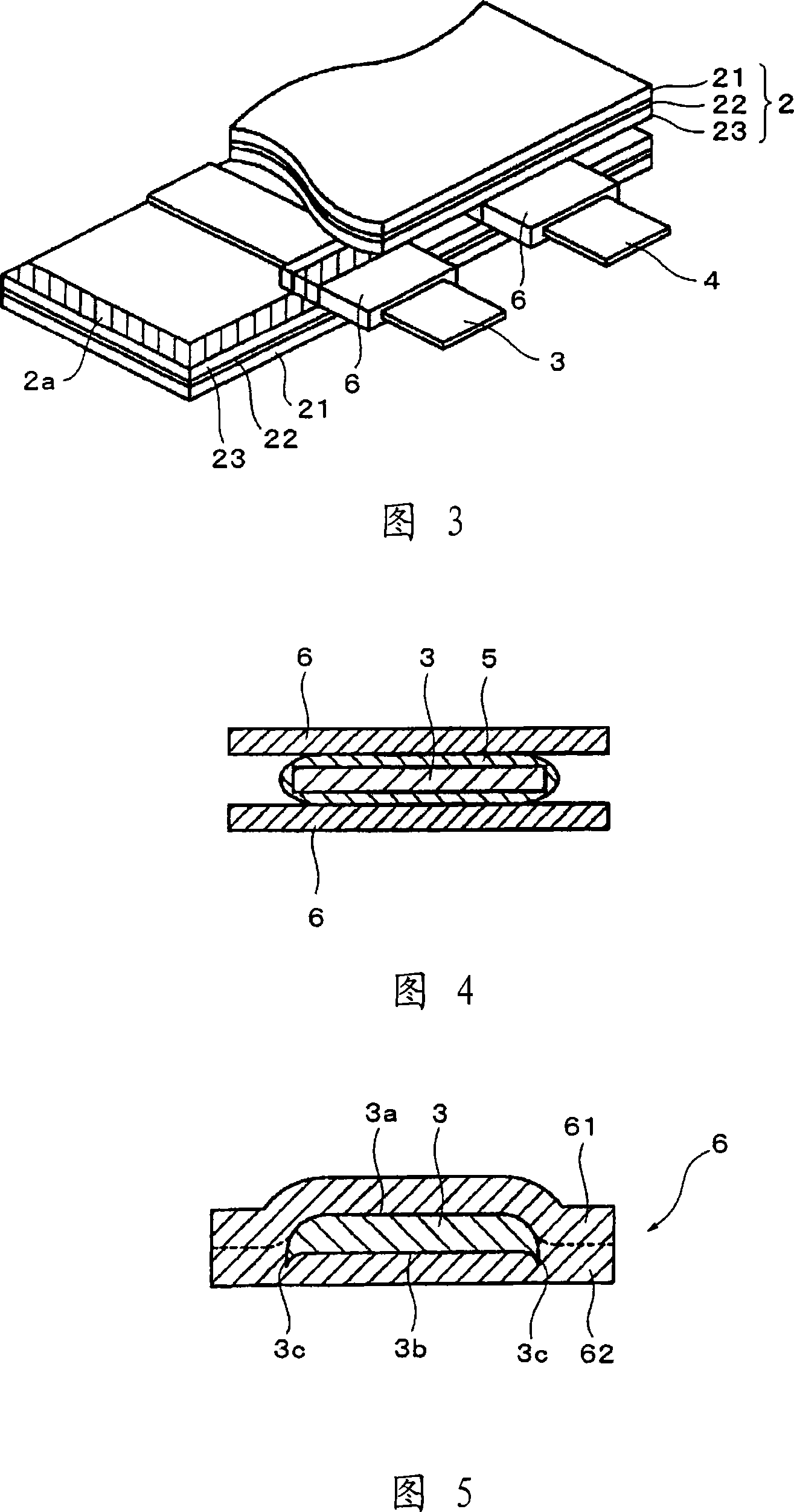

[0113] A lead sealing film having a structure as shown in FIG. 9 was manufactured. 9 is a schematic cross-sectional view of an electrode terminal lead (negative terminal lead 3 or positive terminal lead 4 ) covered by two sealing films 61 , 62 and further heat-sealed by an outer package material 2 .

[0114] In this embodiment, a high melting point (melting point: 168°C) acid-modified polypropylene is set as the intermediate layers 61b, 62b to avoid short circuits, an Al bar or a Ni bar is set as the metal bar constituting the electrode terminal lead 3 or 4, and the Low melting point (melting point: 143°C) acid-modified polypropylene 61c, 62c is used for thermal bonding with the metal strip, and low melting point (melting point: 143°C) acid-modified polypropylene 61a, 62a is used for external packaging The inner layer (CPP layer) 23 of material 2 is thermally bonded, thereby forming a sealing film.

[0115] First, the metal strips (aluminum strips with a width of 4 mm and a t...

Embodiment 2

[0121] For the composition of the lead sealing film, a high melting point (melting point: 168° C.) acid-modified polypropylene is set as an intermediate layer to avoid short circuits, and a low melting point ( Melting point: 143° C.) Acid-modified polypropylene is provided on both sides of the intermediate layer, respectively.

[0122] For the outer packaging material, an aluminum laminated film having a nylon layer as an outer layer, an aluminum layer as a middle layer, and a CPP layer (melting point: 143° C.) as an inner layer was used.

[0123] Next, except for the above-mentioned film composition, substantially the same steps as in Example 1 were repeated to prepare the nonaqueous electrolyte battery of this example. The compositions of the lead sealing film and the outer packaging material film are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com