Driver for circular weaving machine and control method of driver

A control method and technology for circular looms, applied in looms, textile/flexible product manufacturing, textile and other directions, can solve the problems of poor tension control accuracy, uneven winding force, poor winding tension stability, etc. Precise control of winding tension, avoid excessive tension and breakage, and stabilize winding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

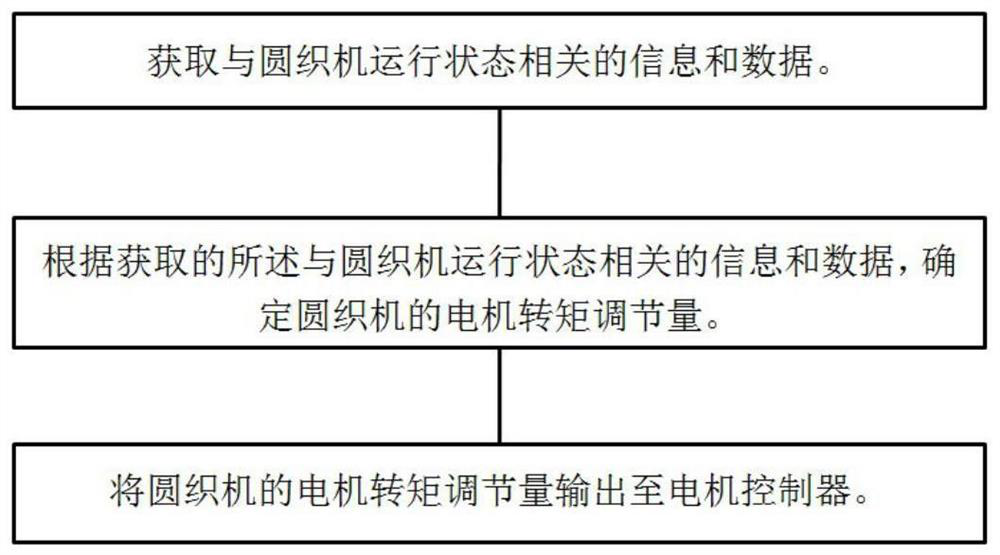

[0091] like Figure 1-2 As shown, the present invention provides a control method for a driver of a circular loom, the method comprising:

[0092] Obtain information and data related to the operating status of the circular loom;

[0093] According to the obtained information and data related to the operating state of the circular loom, determine the motor torque adjustment amount of the circular loom, and the motor torque adjustment amount of the circular loom is used to adjust according to the operating state of the circular loom the torque of the motor;

[0094] Output the motor torque adjustment amount of the circular loom to the motor controller, and then adjust the motor torque to keep the tension of the circular loom constant during winding.

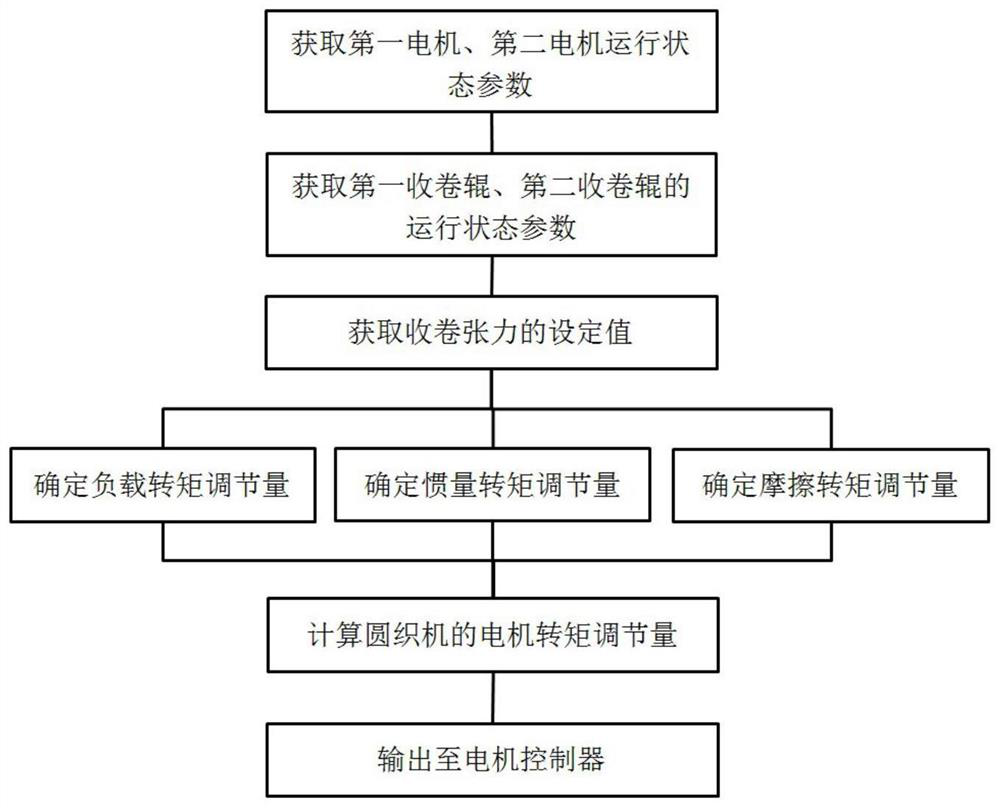

[0095] Further, the acquisition of information and data related to the operating state of the circular loom includes:

[0096] Obtaining the operating state parameters of the first motor, the second motor, the first winding roll...

Embodiment 2

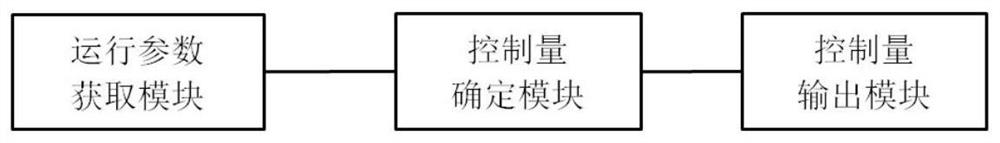

[0157] like image 3 As shown, the present invention provides a driver for a circular loom, the driver comprising:

[0158] The operating parameter acquisition module is used to acquire information and data related to the operating state of the circular loom;

[0159] The control quantity determination module is used to determine the motor torque adjustment quantity of the circular loom according to the acquired information and data related to the operating state of the circular loom, and the motor torque adjustment quantity of the circular loom is used to The running state of the loom to adjust the torque of the motor;

[0160] The control quantity output module is used to output the motor torque adjustment value of the circular loom to the motor controller, and then adjust the motor torque to keep the tension of the circular loom constant during winding.

[0161] Further, the acquisition of information and data related to the operating state of the circular loom includes: ...

Embodiment 3

[0224] like Figure 4 As shown, the present invention provides a computer device, which is characterized in that it includes a memory and a processor; the memory is used to store a computer program; and the processor is used to execute the computer program to realize the above-mentioned embodiment 1 method described. Or, in this embodiment, the computer device can also cooperate with the circular loom as described in Embodiment 2 to form a textile control system, so as to execute the control method as described in Embodiment 1 to achieve precise winding of fabrics operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com