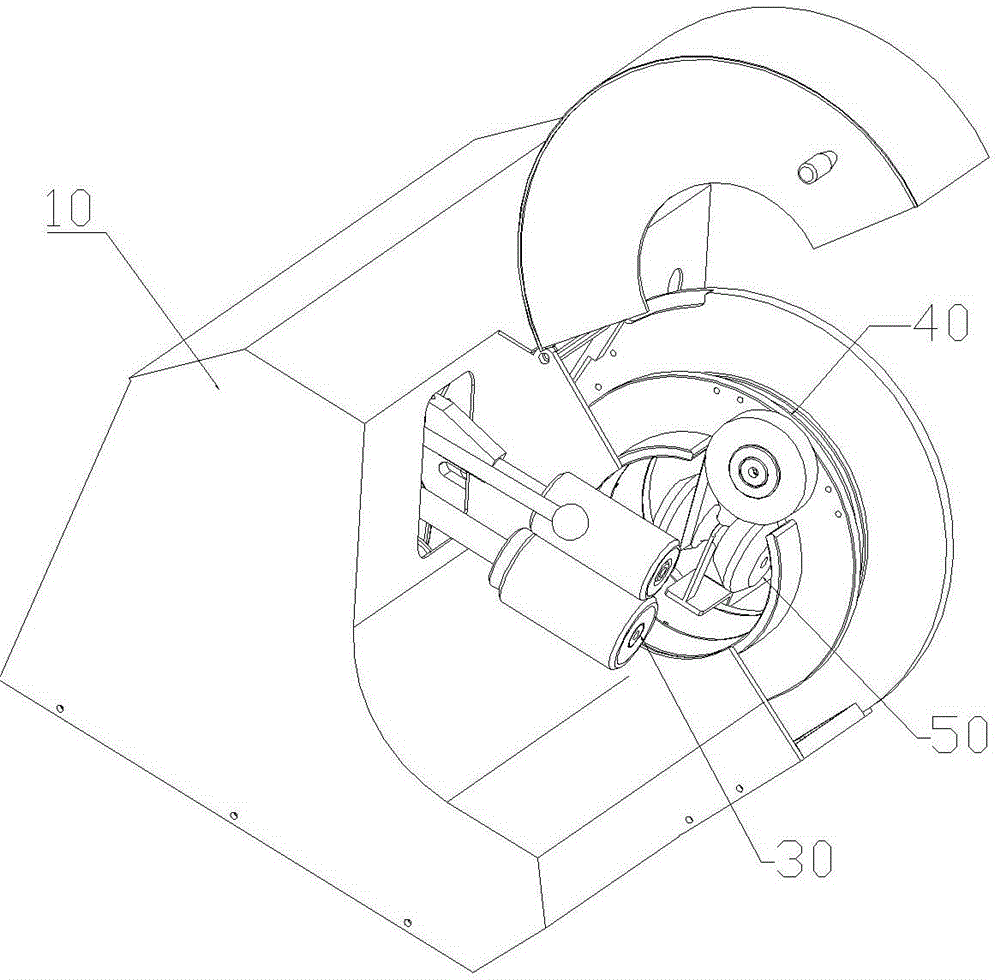

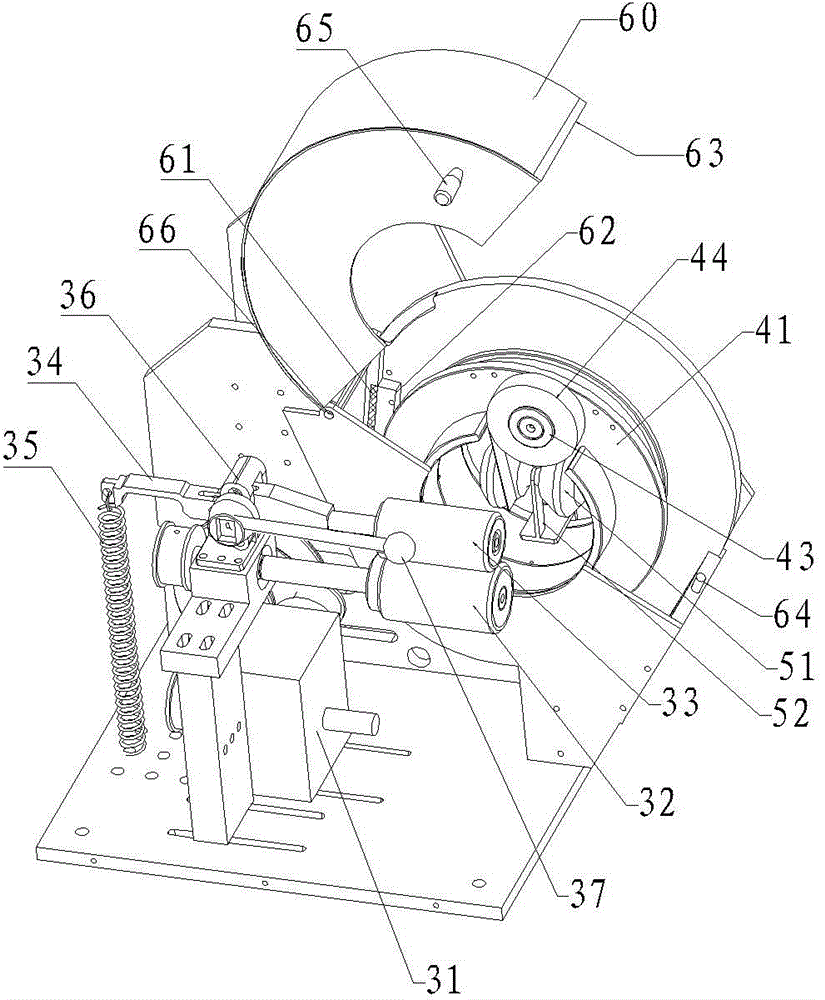

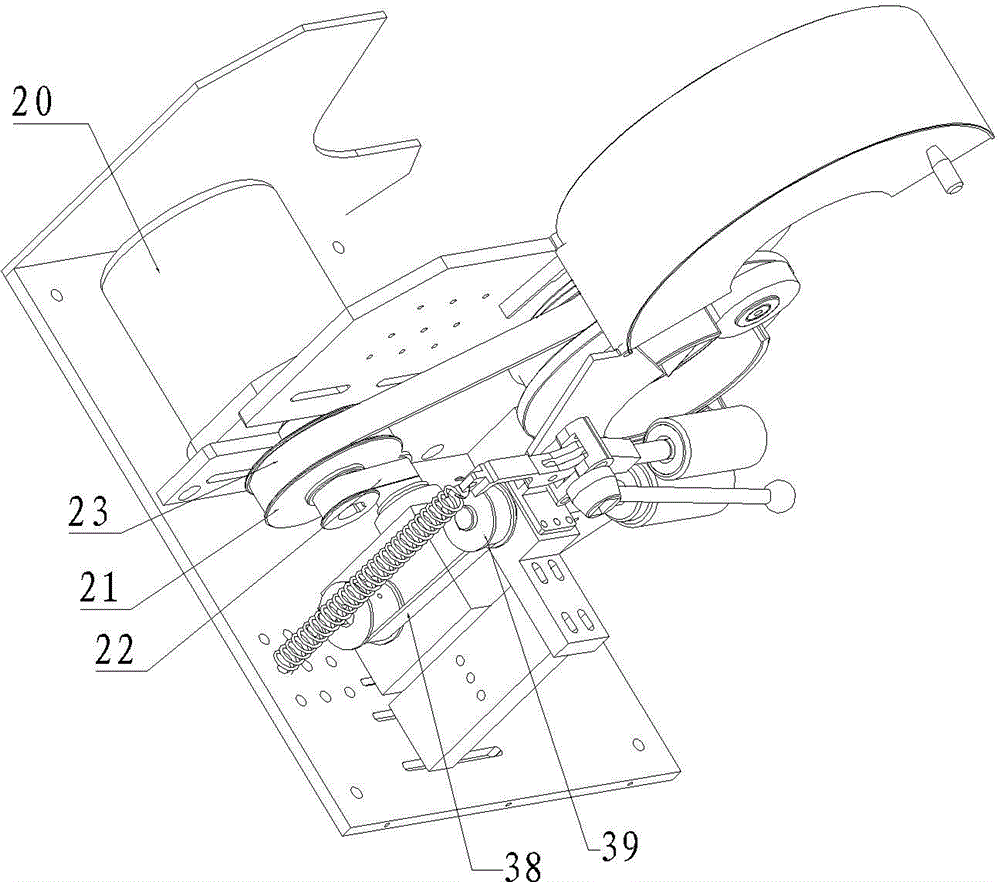

Adhesive tape winding machine

A technology of winding machine and winding mechanism, which is applied to the parts of strapping machinery and strapping materials, etc., can solve the problems of high equipment cost, low equipment efficiency, and large power consumption, and achieve stable and orderly operation, uniform tape winding, and equipment low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0034] The structure of this embodiment is roughly the same as that of Embodiment 1, the difference is that: Figure 6 , the adhesive tape installation device comprises adhesive tape retainer 71 and deck 72, and deck 72 is provided with card slot 73, and tape retainer 71 end is provided with rotating shaft 74, and the other end is connected with card slot 73, and tape retainer 71 is connected with card An elastic pin 76 is arranged at the joint of the groove 73 , a torsion spring is arranged on the rotating shaft 74 , and an adhesive tape installation shaft 75 is arranged on the middle position of the adhesive tape stopper 71 .

[0035] When in use, first press the elastic pin 76, pull the tape stopper 71 upwards, then put the tape on the tape installation shaft 75, loosen the tape stopper 71, and make it under the action of the torsion spring on the rotating shaft 74 Automatically rotate downwards and return to the original position until the adhesive tape stopper 71 snaps in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com