Sensing ring of all-fiber electronic current transformer

A technology of current transformers and sensitive rings, which is applied in the direction of inductors, voltage/current isolation, circuits, etc., can solve the problems of sensitive ring volume, heavy weight, poor field application flexibility, and low reliability, so as to avoid fiber breakage and damage, light weight, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

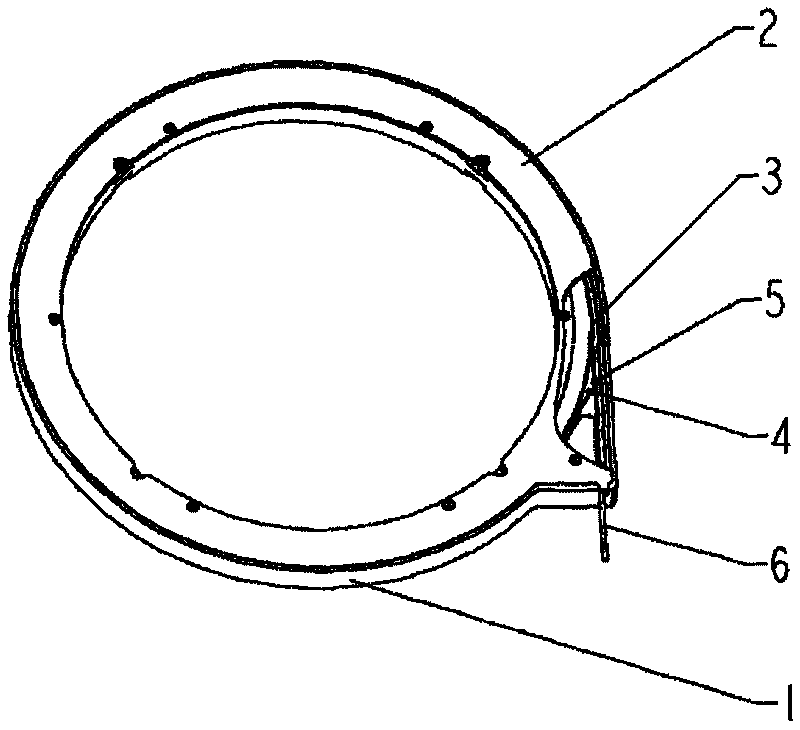

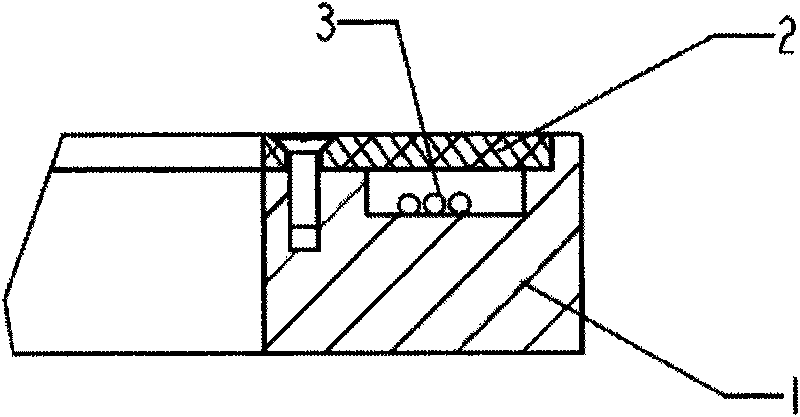

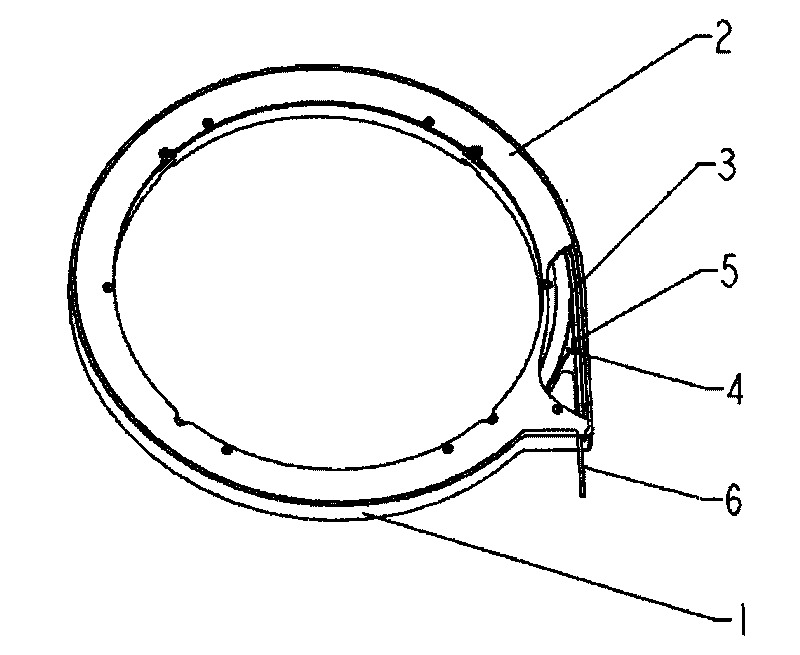

[0029] Firstly, the thermal expansion coefficient is 2.0×10 -5 The sensitive ring body 1 is made into a ring structure with an aluminum alloy material. The outer diameter of the sensitive ring body 1 is 335 mm, the inner diameter is 280 mm, and the thickness is 19 mm. The upper cover 2 of the sensitive ring is prepared to match the structure of the main body 1 of the sensitive ring by using epoxy glass laminated cloth material. The outer diameter of the upper cover 2 of the sensitive ring is 335 mm, the inner diameter is 280 mm, and the thickness is 3 mm. In addition, four threaded holes at an angle of 45° to the horizontal axis are provided on the upper surface of the sensitive ring body 1 for connection with the flange, and the distance between the center of the threaded holes and the axis of the sensitive ring body 1 is 143.5 mm. Seven threaded holes are also provided on the upper surface of the sensitive ring body 1 for connecting with the upper cover 2 of the sensitive ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com