Trimming recycling device of splitting machine

A technology of slitting machine and winding shaft, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of human health damage, large energy waste, and difficult synchronization, etc., to reduce labor intensity, Suitable for a wide range of occasions, the effect of no dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is a further description of the device for collecting waste around the edge of the slitting machine of the present invention in conjunction with the accompanying drawings and specific embodiments:

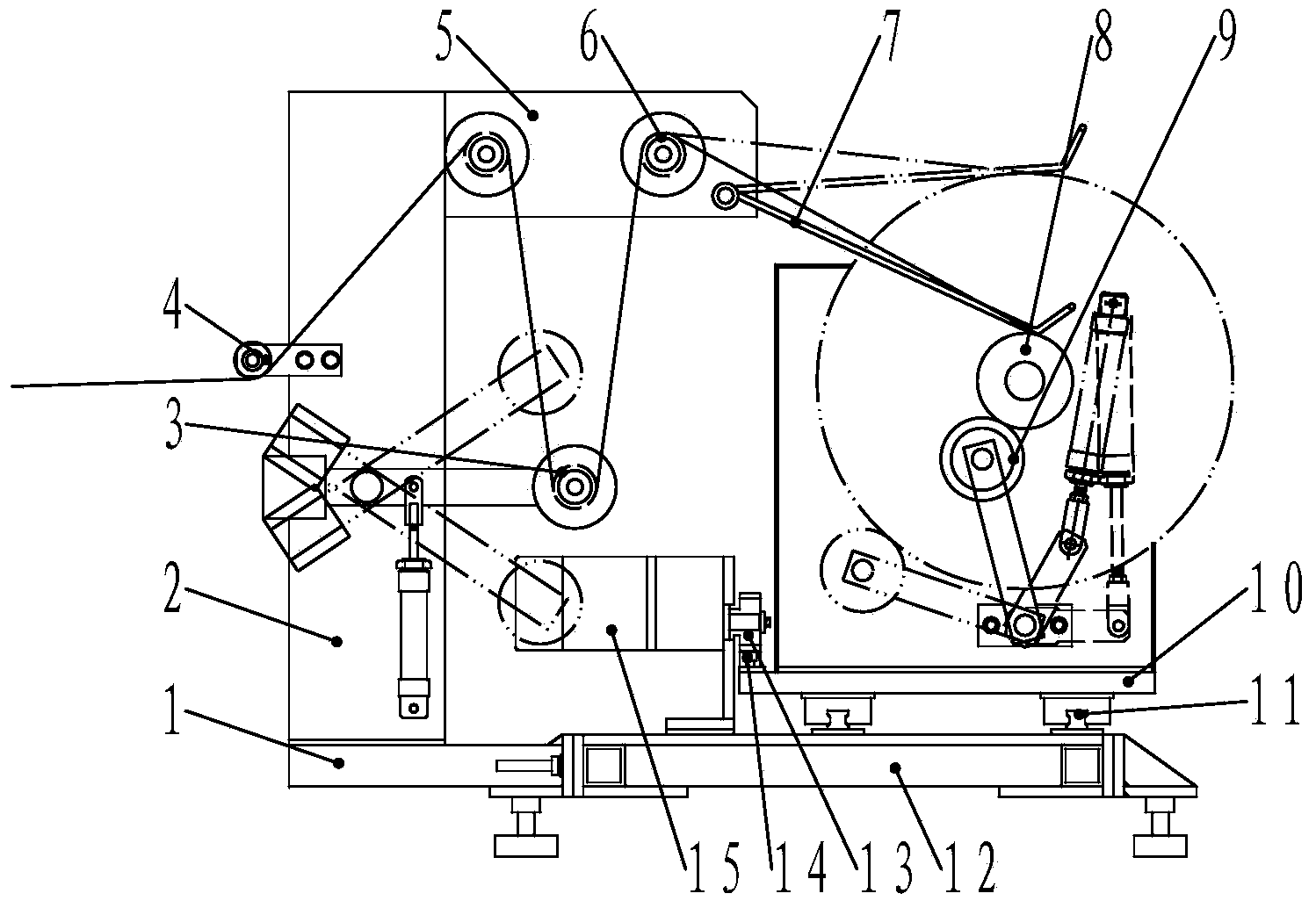

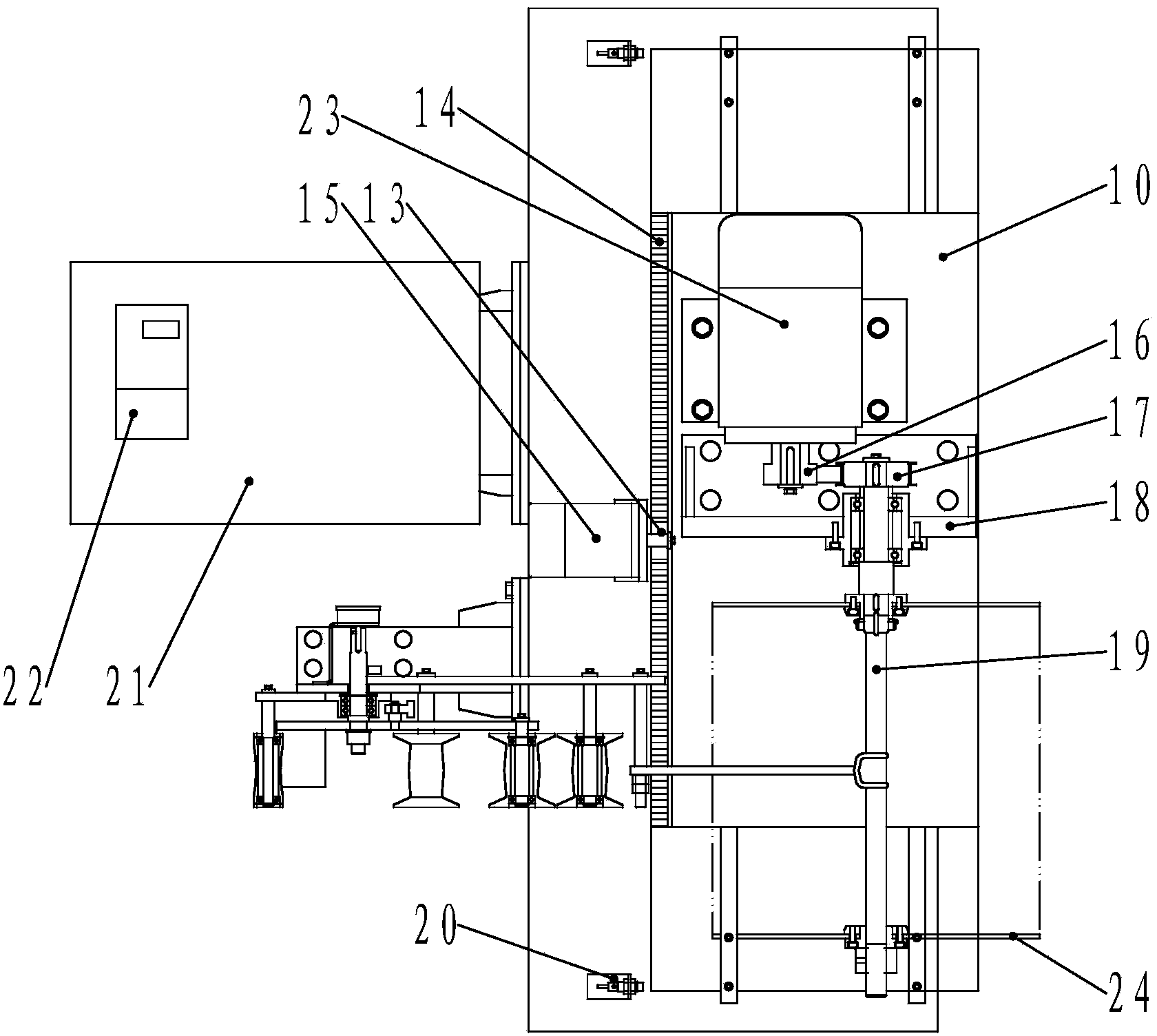

[0015] figure 1 It is a structural schematic diagram of the waste collection device around the edge of the slitting machine of the present invention, figure 2 yes figure 1 top view. In the figure, the waste collection device around the edge of the slitting machine includes a base 12, a support beam 1 is arranged on the base 12, a vertical support 2 is arranged on the support beam 1, and a horizontal support beam 5 is fixed on the vertical support 2, and the vertical support 2 is installed There is a tension pendulum roller mechanism 3 and a material guide wheel 4, and a material passing wheel 6 and a material guide rod 7 are installed on the cross beam 5; a linear guide rail 11 and a single-phase AC stepless variable speed motor 15 are also installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com