Adjustable intelligent thread feeding device for textile machine

A textile machine, adjustable technology, applied in spinning machine, textile and papermaking, continuous winding spinning machine, etc., can solve the problem of difficult to always ensure yarn tightness, reduce the effect of device use, and uneven yarn winding. and other problems, to protect the health of the respiratory tract, reduce the cleaning cycle, and avoid relaxation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

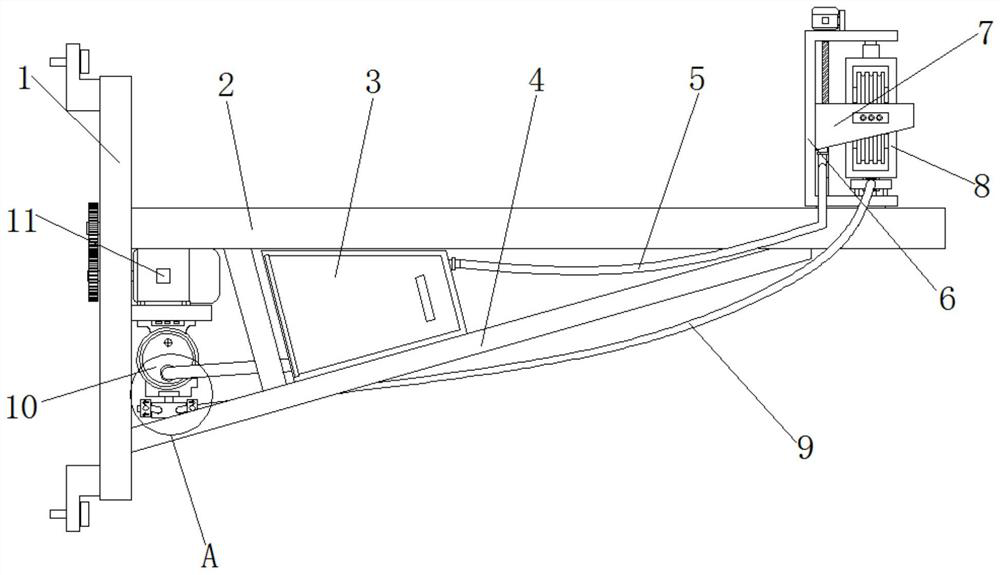

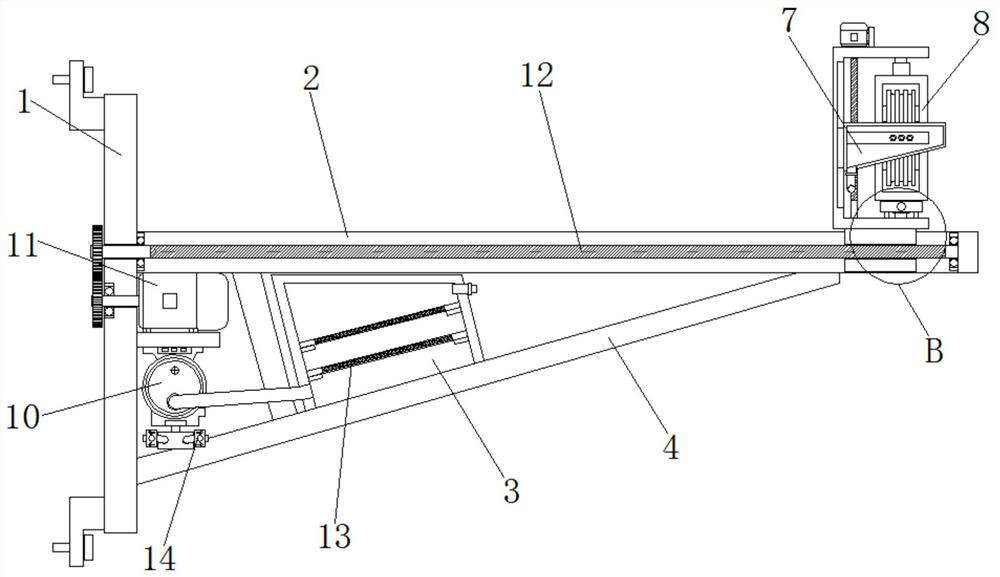

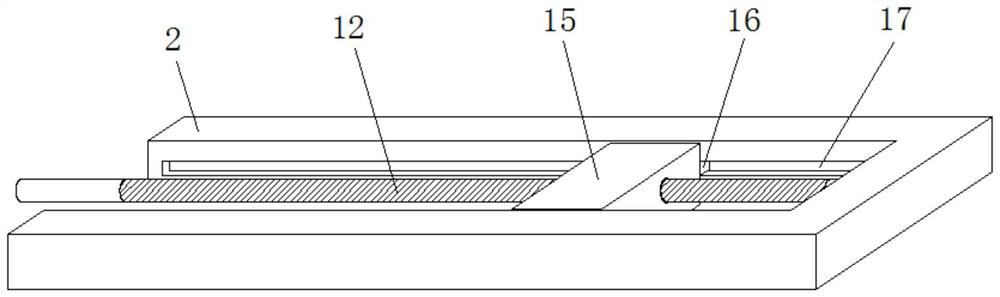

[0041] Example 1, such as figure 1 , 2 , 3, 4, 5, 6, 7 and 10, in the process of winding the yarn onto the spindle, the drive device 11 is first controlled by an external control panel to drive the second threaded rod 12 to rotate forward for a period of time and then reverse To rotate for a period of time, due to the thread effect, the movable block 15 is forced to move back and forth constantly on the inside of the U-shaped frame 2, so that the U-shaped mounting plate 6 and the parts on the inside of the U-shaped mounting plate 6 move back and forth above the U-shaped frame 2 together. The yarn can be evenly and orderly wound on the spindle. When it is necessary to ensure the tightness of the yarn during the winding process, while the U-shaped mounting plate 6 moves back and forth, the servo motor 701 is controlled to drive the first threaded rod 702 to rotate. Utilize the action of the thread to force the pumping chamber 703 to move up and down continuously. At this time, ...

Embodiment 2

[0042] Example 2, such as Figure 1-7 As shown, after the yarn passes through the wire hole 707, the control air pump 10 starts to work, forcing the external control to enter the inside of the filter chamber 3 through the air intake hole 705, the air extraction chamber 703 and the air intake pipe 5 in sequence, and the flow in the process The air will also bring the fine fibers flying out from the wire hole 707 to the inside of the filter chamber 3, the fine fibers are blocked by the filter screen 13, and the filtered air is directly discharged into the external environment, so that the yarn outside can be avoided. The fine fibers broken by friction fly everywhere, which not only reduces the cleaning cycle of the whole device, but also greatly protects the respiratory tract of the operators near the device.

[0043] Working principle: before use, connect the device to the power supply, first pass the yarn through the two sets of guide wheels 804, and then pass the yarn through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com