Patents

Literature

199results about How to "Shorten the cleaning cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modification film of polyvinylidene fluoride and preparation method thereof

The present invention relates to a polyvinylidene flouride modified film and its prparation method. Said invention is prepared by using (by wt%) 14-20% of high-molecular material dissolved in organic solvent and adding 1-6% of organic additive, 0.01-4% of inorganic additive and 0.01-0.9% of titanuim dioxide, whose average grain size is 1-20 nm. Said invention improves the hydrophilic property of polyvinylidene flouride, and the pure water flux of said polyvinylidene flouride film can be raised.

Owner:HARBIN INST OF TECH

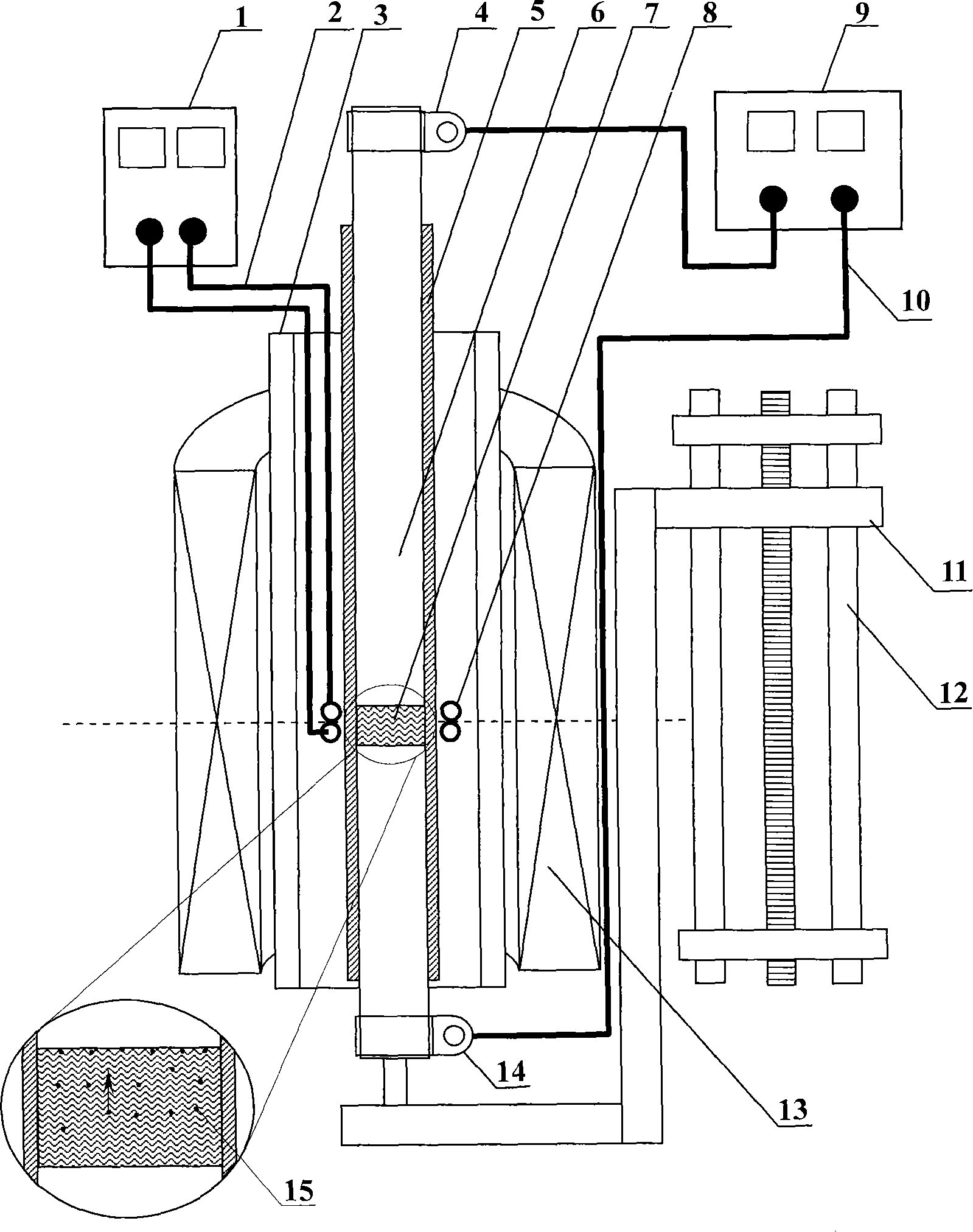

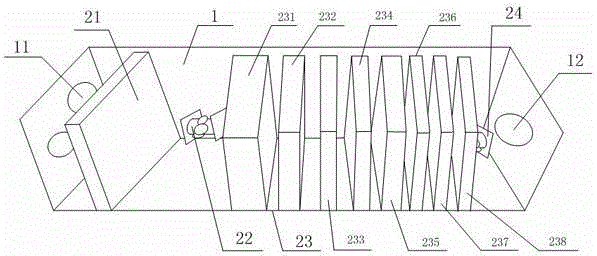

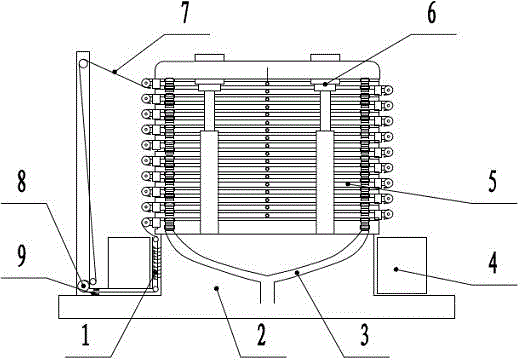

Method for smelting and purifying metal in electro-magnetism composite field and device thereof

The present invention relates to process and apparatus for zone metal melting purification under composite electromagnetic field, and belongs to the field of technology of separating and purifying metal under electromagnetic field. The present invention features that metal or alloy containing mixed metal element is set inside one electromagnetic field comprising parallel magnetic field and electric field in electrically migrating zone melting apparatus, and under the cooperation of the magnetic field and the electric field, the mixed metal element migrates in phase grain form toward the negative pole and the metal or alloy in the lower end is purified. The present invention adopts magnetic field intensity of 0.1-20 T, and DC current density of 10-100 A / aq cm.

Owner:新兴发展集团有限公司

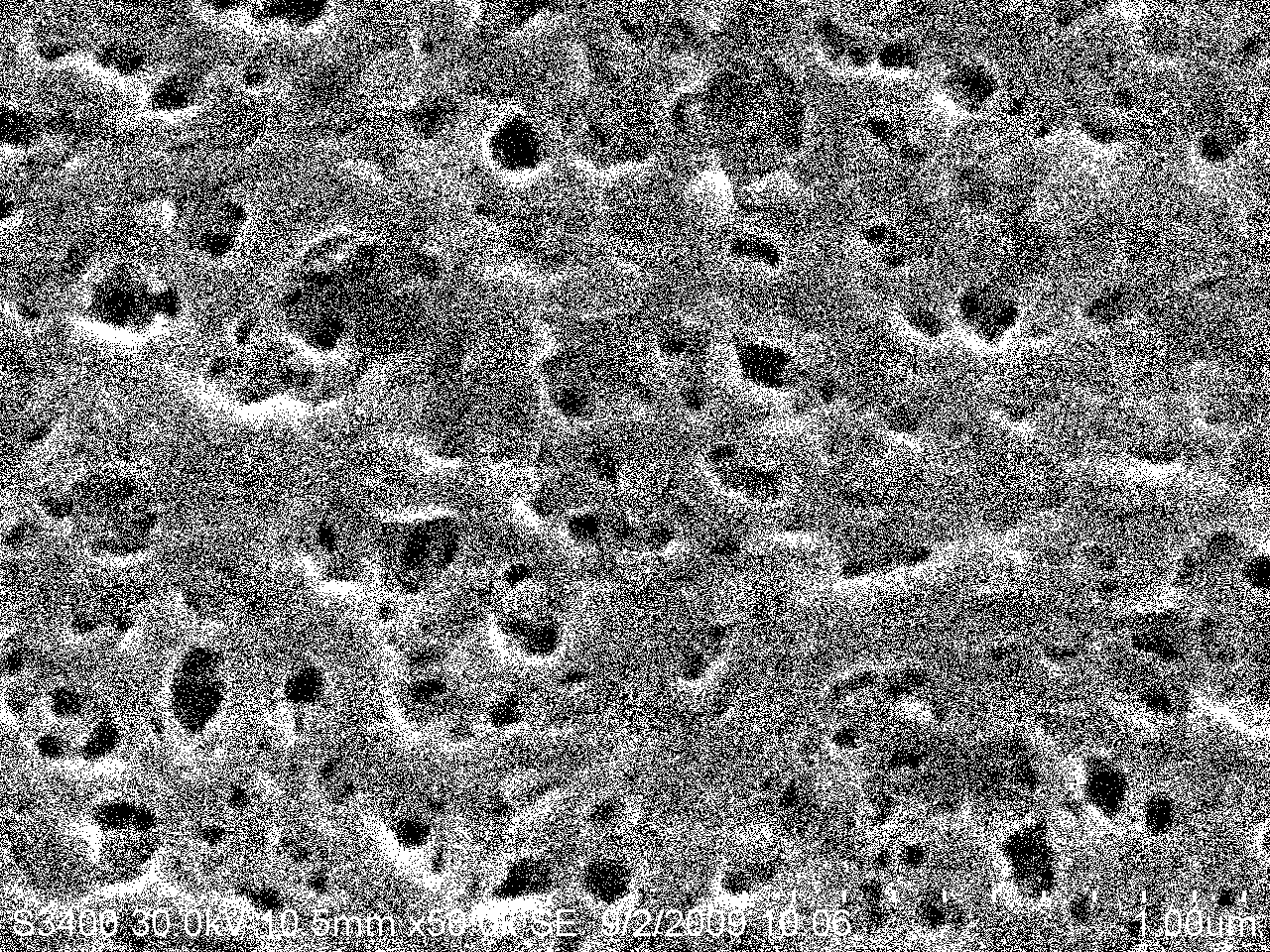

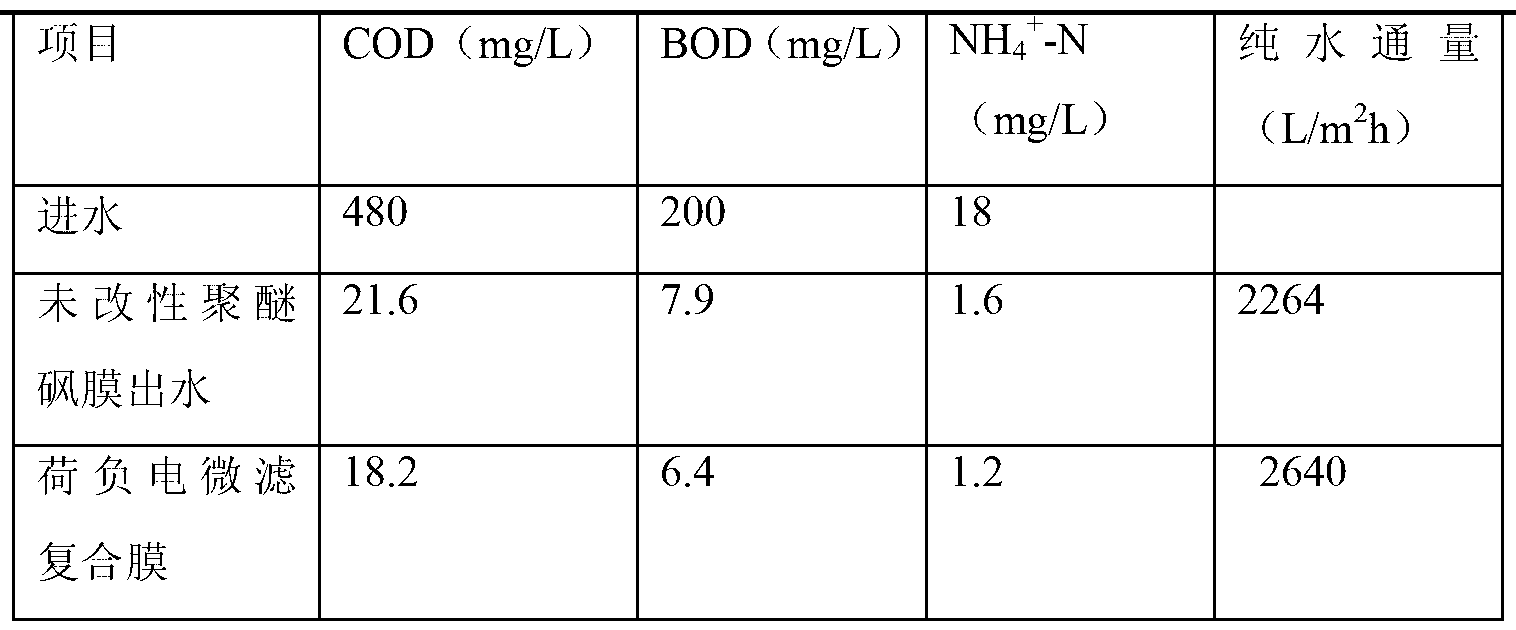

Manufacturing method and application of electronegative composite microfiltration membrane

InactiveCN103272502AGood anti-pollutionShorten the cleaning cycleUltrafiltrationBiological water/sewage treatmentPolyesterOrganic solvent

The invention discloses a manufacturing method of an electronegative composite microfiltration membrane, which comprises the following steps of: (1) dissolving polyether sulfone in an organic solvent, adding an additive and an electronegative reagent, stirring and dissolving sufficiently, filtering an undissolved substance, standing, obtaining membrane casting liquid, (2) casting the memebrane casting liquid onto polyester non-woven cloth, scraping a membrane with a scraper, immersing in a coagulating bath for membrane forming, obtaining a polyether sulfone microfiltration membrane, immersing the polyether sulfone microfiltration membrane in an electronegative reagent solution, taking out for drying, and (3) crosslinking the membrane subjected to electronegative treatment in a crosslinking agent solution, washing to be neutral with deionized water, and obtaining the electronegative composite microfiltration membrane. In addition, the invention provides an application of the electronegative composite microfiltration membrane in a membrane bioreactor. Since bacteria and the surfaces of colloids in the membrane bioreactor are electronegative, the prepared membrane is electronegative, has good hydrophilicity, is not easy to pollute, is not required to be cleaned frequently, has high water flux of stable operation, and lowers the sewage treatment cost.

Owner:NANJING UNIV

Long-lasting self-cleaned coating and preparation method thereof

InactiveCN107312407AReduce the chance of contaminationWash in timeAntifouling/underwater paintsPaints with biocidesSurface cleaningHigh surface

The invention provides a long-lasting self-cleaned coating which comprises the following components in parts by weight: 40-60 parts of a resin, 15-30 parts of a pigment filler, 1-5 parts of aids, 2-8 parts of active components, 20-40 parts of a solvent and 5-20 parts of a curing agent, wherein the aids comprise a dispersing agent, a defoaming agent and a leveling agent. The long-lasting self-cleaned coating provided by the invention has surface properties which are greatly different from those of a common coating, and has relatively high surface energy and humidity. If the coating is affected by external factors such as wind, frost, rain and snow, a relatively great amount of antifouling effective components can be slowly released from the coating continuously, and then surface cleaning of the coating is recovered. In different actual use environments, the long-lasting self-cleaned coating can last for 3-5 years or even longer, and can be applied to inner and outer coating of high-speed rains, vehicle stations and carriages, building aluminum profiles, aluminum veneers, metal curtain walls, glass curtain walls, automobiles, solar panels and decoration fields which require surface cleaning and cannot be frequently maintained or are barely maintained.

Owner:JIANGSU LEE & MAN CHEM +2

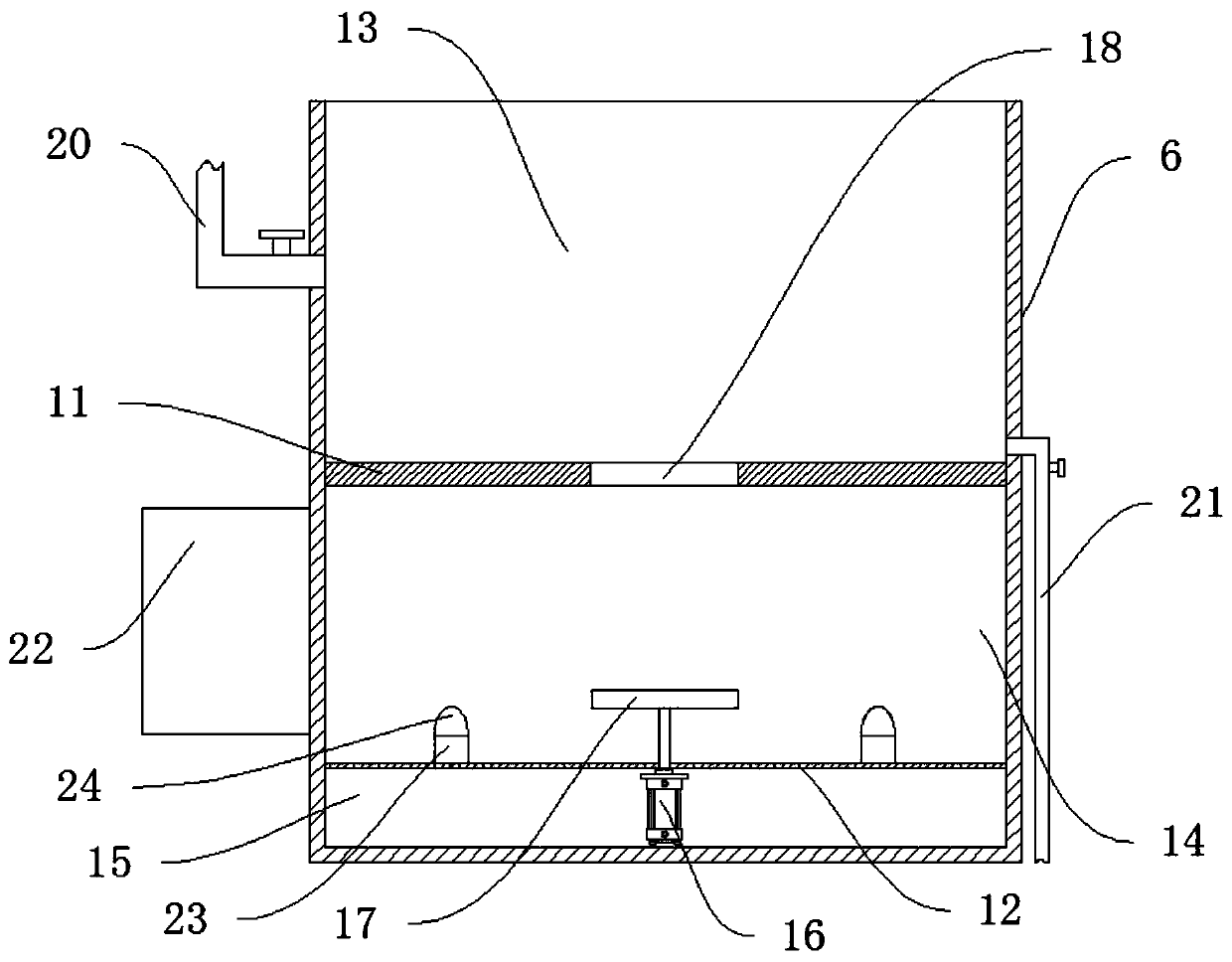

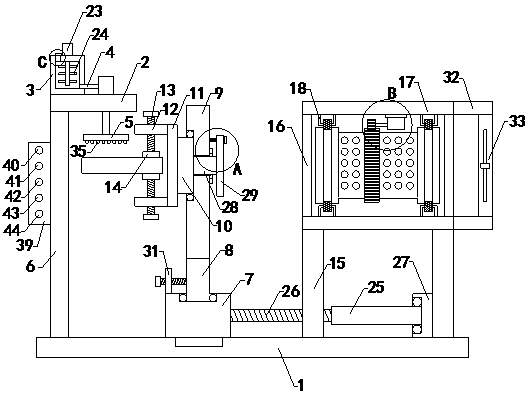

Medical instrument cleaning device for obstetrics and gynecology

InactiveCN109909228AImprove cleaning efficiencyImprove cleaning qualityDrying gas arrangementsCleaning using liquidsObstetric historyPush pull

The invention discloses a medical instrument cleaning device for obstetrics and gynecology. The medical instrument cleaning device comprises a cleaning box and a drying box, wherein a feeding inlet isformed in the side of the cleaning box, a discharging outlet is formed in the other side of the cleaning box, a push-pull bearing plate is arranged at the feeding inlet, a cleaning groove and a clamping mechanism are arranged in the cleaning box, the cleaning groove is used for cleaning medical instruments, and the clamping mechanism is used for clamping the medical instruments and putting the medical instruments into the cleaning groove; a first opening is formed in the side of the drying box, a second opening is formed in the other side of the drying box, a drying device and a disinfectingdevice are arranged in the drying box, the drying device is used for drying the medical instruments, and the disinfecting device is used for disinfecting the medical instruments; and the medical instrument cleaning device further comprises a transmission mechanism, and the transmission mechanism is used for conveying the medical instruments. According to the medical instrument cleaning device, thecleaning box and the drying device are arranged to clean and dry and disinfect the medical instruments, so that the integration of cleaning, drying and disinfection is realized, the cleaning efficiency and the cleaning quality of the medical instruments are greatly improved, and meanwhile the cleaning cycle is reduced.

Owner:什邡市妇幼保健院

High-efficiency cleaning method for novel hydraulic pipeline

InactiveCN107587151AAvoid damageExtended service lifeHollow article cleaningMetallic material coating processesChemical reactionChemical solution

The invention discloses a new type of high-efficiency cleaning method for hydraulic pipes. After the steps of clean water cleaning, derusting cleaning, pipeline passivation treatment and hydraulic oil flushing, the high-efficiency cleaning of the new hydraulic pipes is completed; in the chemical cleaning process of the present invention, weak acid The solution only chemically reacts with oxides, without any damage to the iron crystal of the pipeline itself; after chemical cleaning is used in the present invention, the chemical solution will form a smooth protective film on the inner wall of the pipeline, which increases the usability of the pipeline system and prolongs the life of the pipeline. The service life of the pipeline. The invention adopts the idea that the chemical reaction speed is greater than the physical reaction speed, and uses the chemical agent aqueous solution to remove the oxides on the inner wall of the pipeline, reducing the difficulty of oil leakage in the later stage, which can shorten the cleaning cycle of the hydraulic pipeline, save resource waste, and improve production efficiency.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

Laser cleaning method for oxidation layer of titanium alloy part of aero-engine

InactiveCN108325948ANo pollution in the processReduce pollutionCleaning processes and apparatusLaser beam welding apparatusGalvanometerLength wave

The invention relates to a laser cleaning method for an oxidation layer of a titanium alloy part of an aero-engine. The method comprises the following steps that laser cleaning parameters are selected, wherein according to the thickness and the surface state difference of the titanium alloy oxidation layer, the selected laser pulse width is 10 ns-100 ns, the laser wavelength is 532 nm-1064 nm, theaverage power of the pulse laser is 50 W-300 W, the pulse frequency is 10 kHz-30 kHz, and the linear speed of the rotation of the surface to be cleaned of the part during cleaning is 10-20 mm / s; andthe laser is introduced into a scanning galvanometer or a rotary polygon mirror from a laser device by adopting an optical fiber, spot light spots are shaped into a linear light spot, the length of the linear light spot is 8 mm-40 mm, an annular part and a laser cleaning lens are controlled through a control mechanism, and the linear light spot is enabled to move on the surface of the titanium alloy part oxidation layer. According to the method, the laser cleaning process is efficient and environment-friendly, and the material hydrogen embrittlement risk caused by a traditional acid pickling method is avoided.

Owner:SHANGHAI JUNYI IND AUTOMATION CO LTD

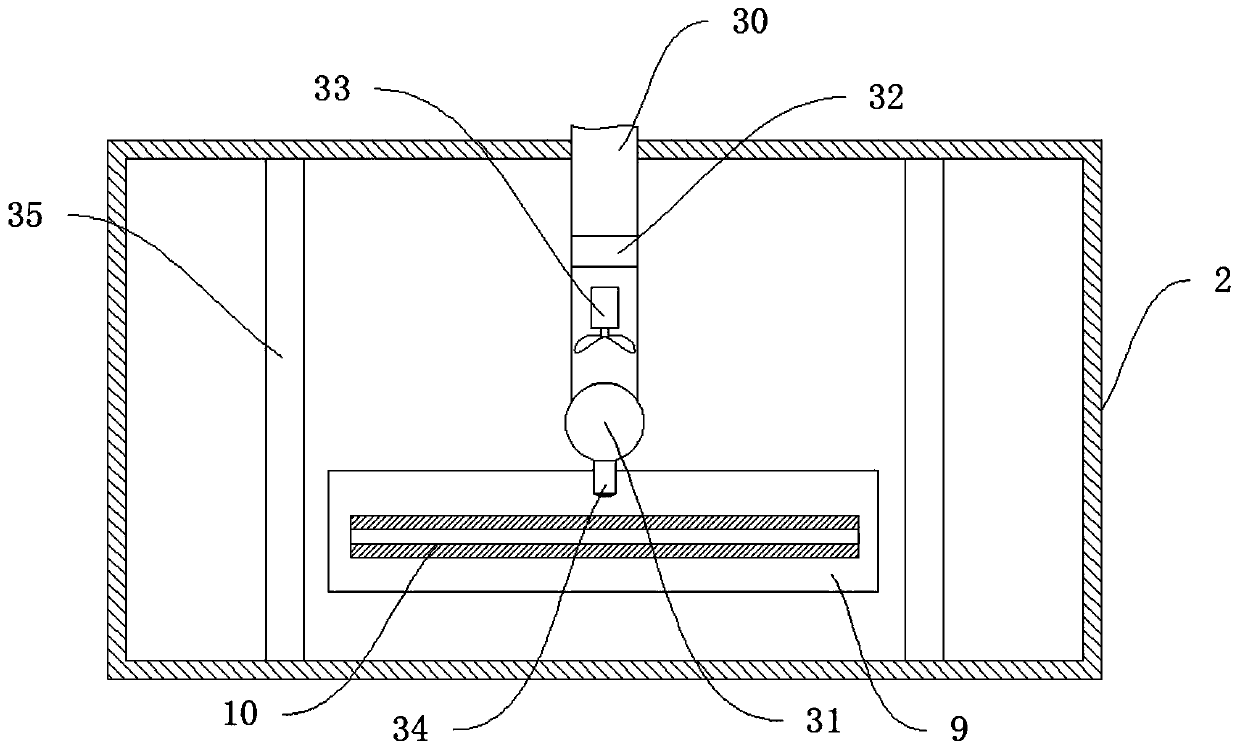

Vapor cooker

InactiveCN102460011AShorten the cleaning cycleImprove ease of useDomestic stoves or rangesSteam generation heating methodsWater reservoirCooker

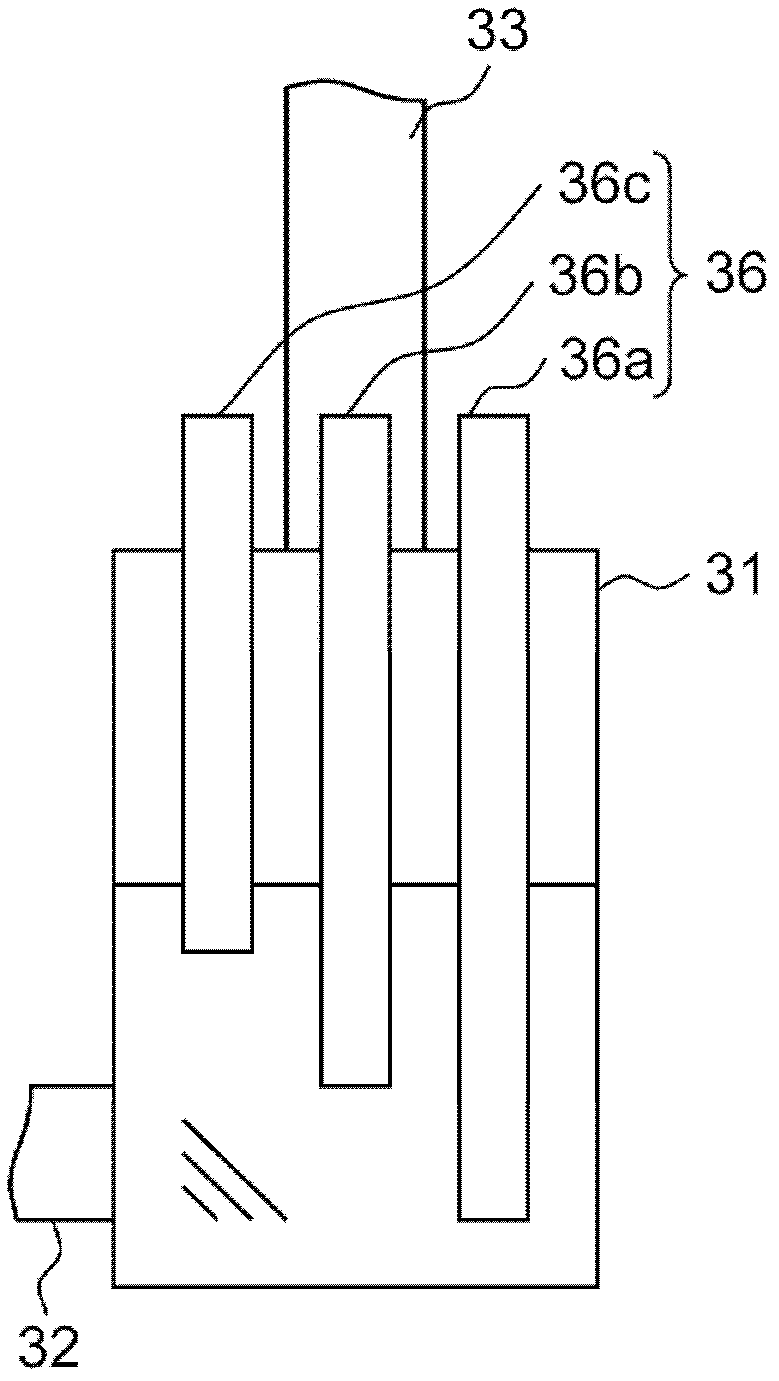

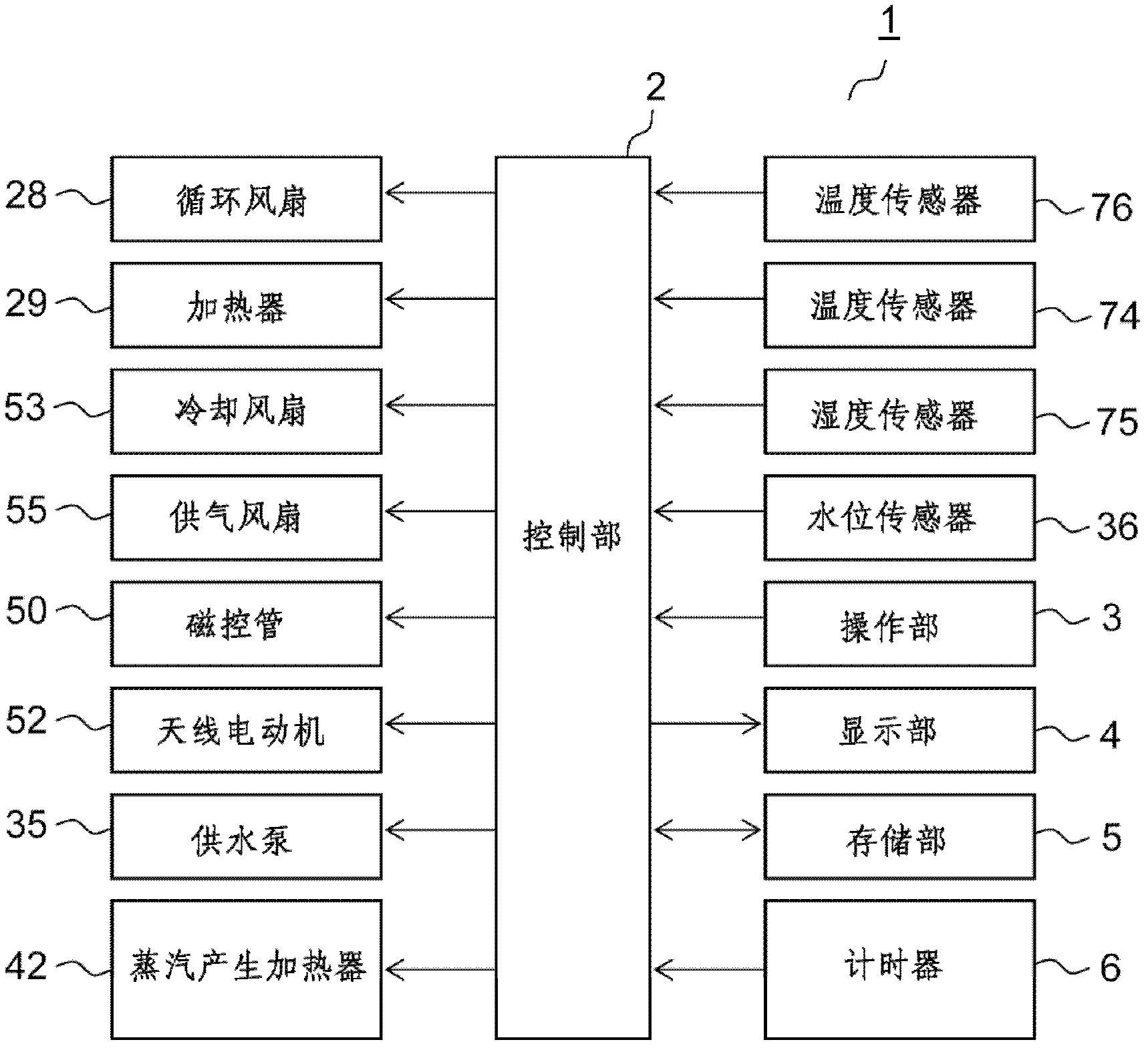

A vapor cooker comprising: a heating chamber (20) for containing an object (90) to be cooked; a removable water tank (30); a vapor generating device (40) having a housing (41) to which water is supplied from the water tank (30) and supplying vapor to the heating chamber (20) by heating the water within the housing (41) by means of a vapor generating heater (42); a hardness detecting section (36) having electrodes (30a-30c) which are immersed in the water tank (30) or in a water reservoir section (31), to which the water tank (30) is connected, and detecting the hardness of the water within the water tank (30) from the resistance values between the electrodes (30a-30c); and a notification section (4) for notifying the timing of cleaning of the vapor generating device (40). When the hardness of the water within the water tank (30) detected by the hardness detection section (36) is high, the frequency of the cleaning of the vapor generating device (40) is set to be lower than that when the hardness of the water within the water tank (30) is low.

Owner:SHARP KK

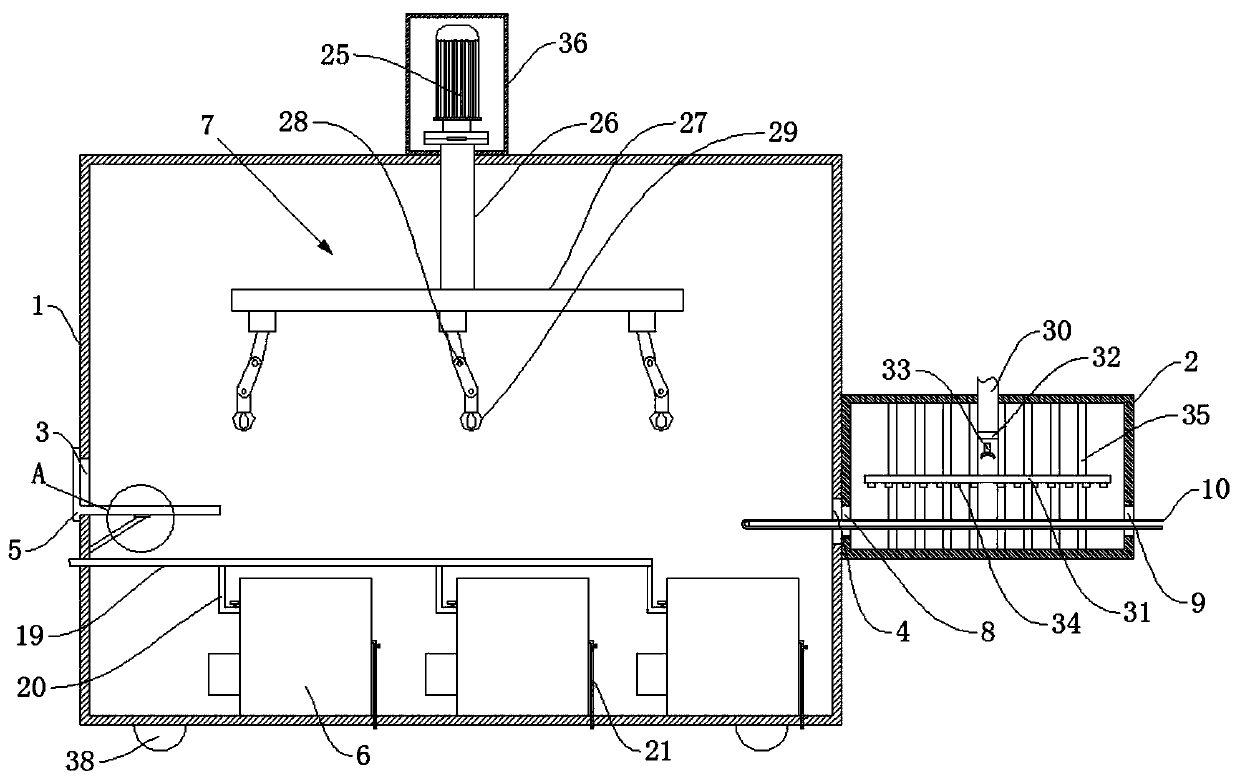

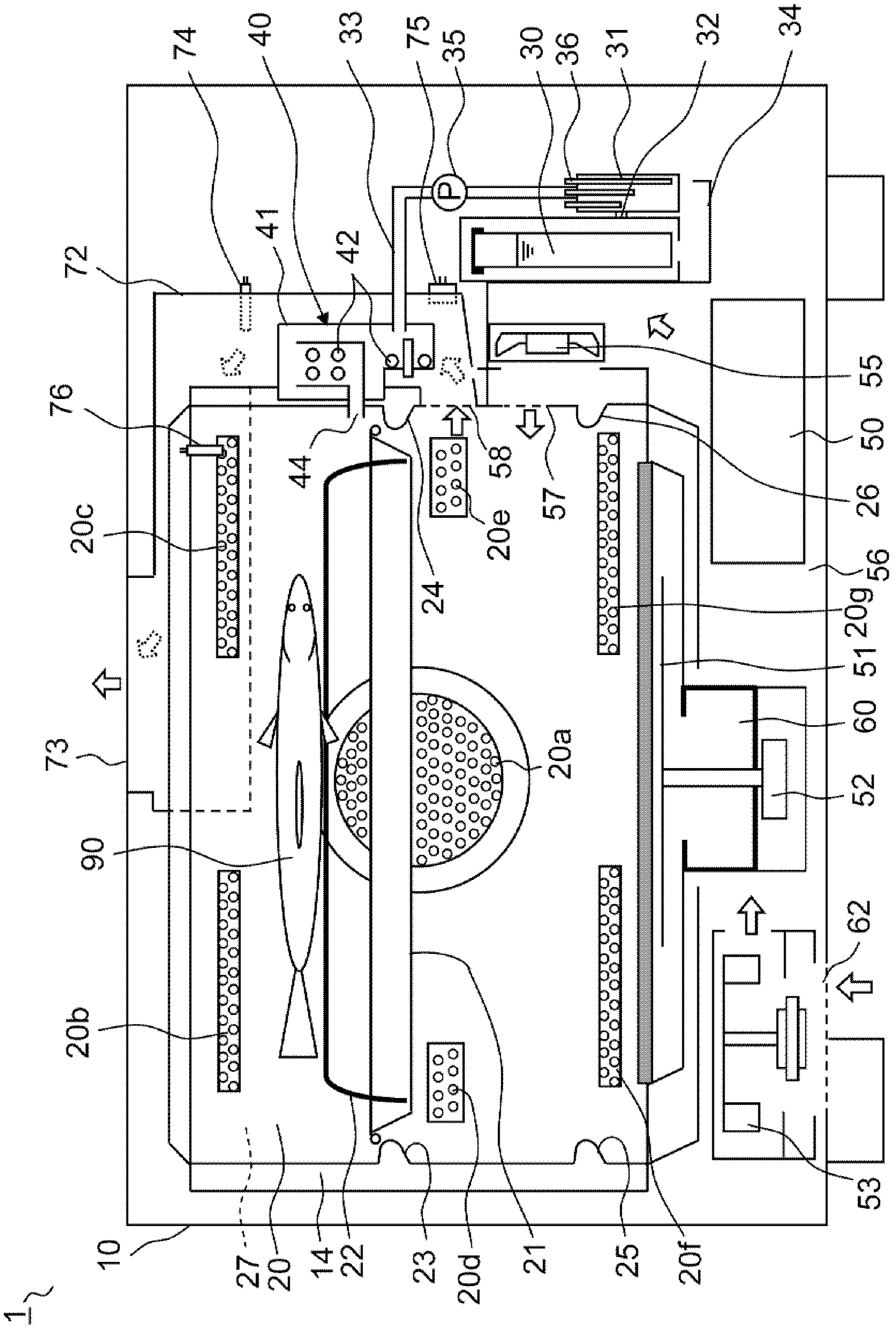

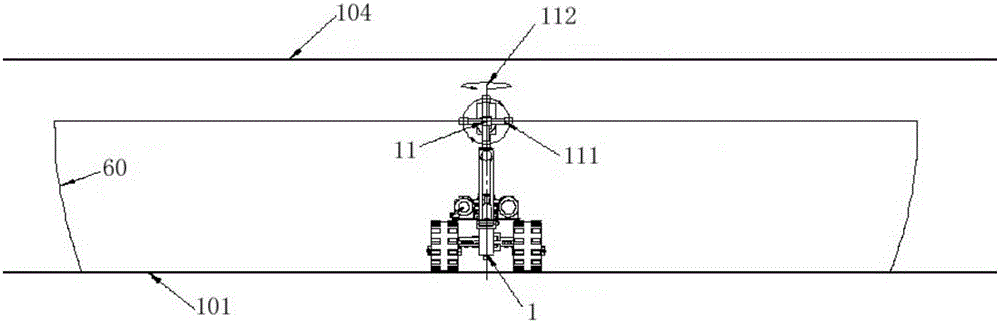

Oil storage tank robot cleaning system and method

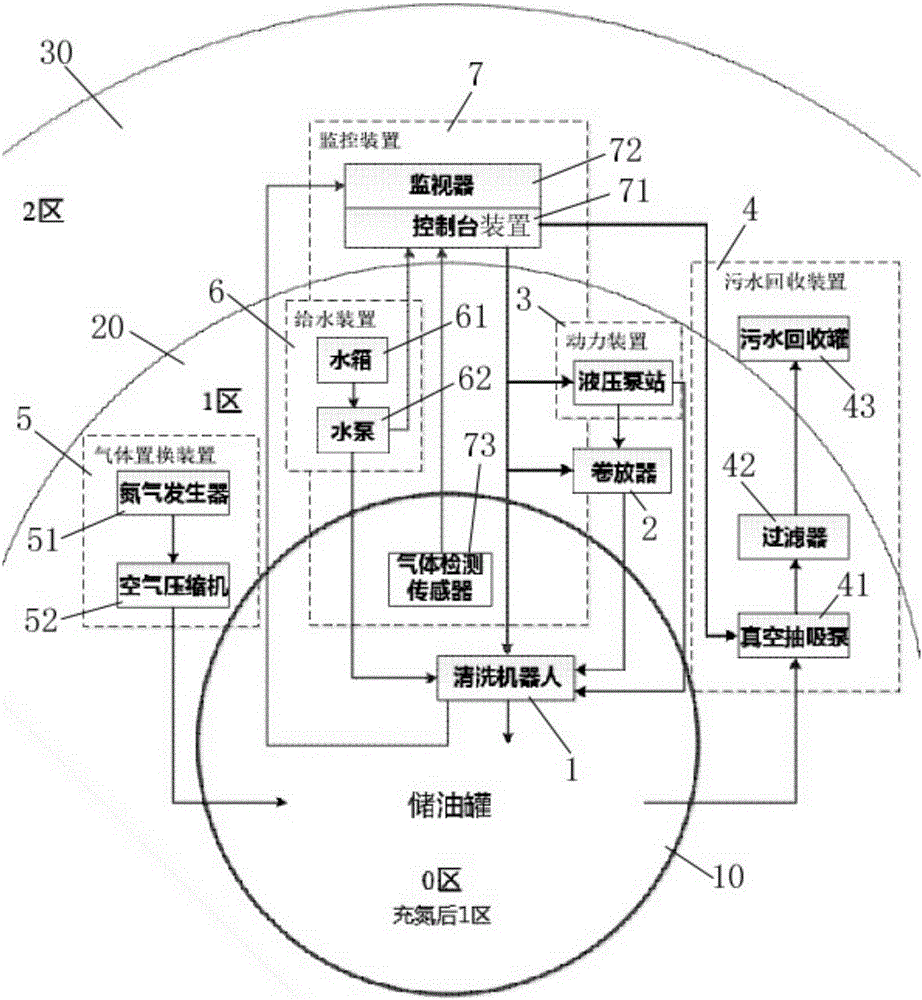

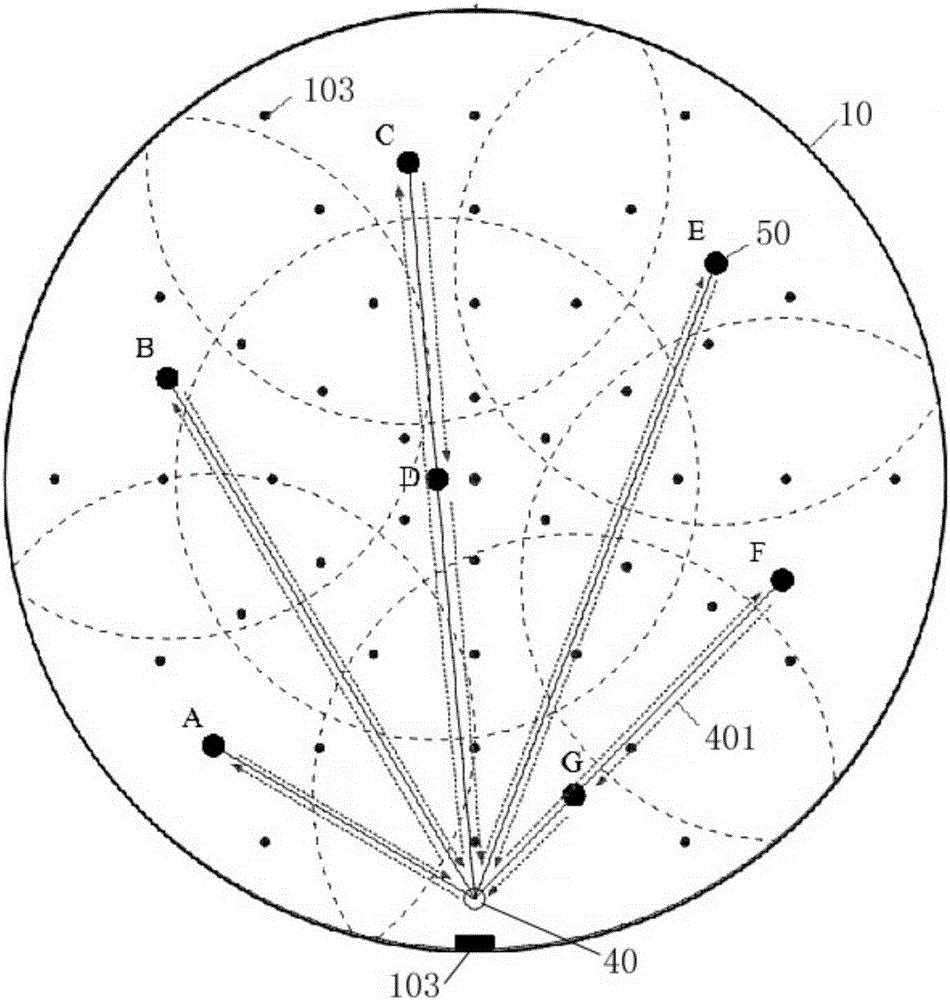

The invention discloses an oil storage tank robot cleaning system and method, and belongs to an oil storage tank cleaning process and system. The cleaning process includes the steps of manhole cover opening, oil product transferring, nitrogen replacing, tank entrance of a robot, oil storage tank cleaning, tank exit of the robot, sewage recovering, ventilating, manual checking and manhole cover installing. The cleaning system comprises the cleaning robot, a reeling and unreeling device, a power device, a monitoring device, a sewage recovering device, a gas replacing device and a water feed device. The cleaning system is characterized in that a 180-degree cleaning mode, a linear turning-back path and a fixed point cleaning scheme are adopted in oil storage tank cleaning, and system equipment has the corresponding explosive-proof grade according to the explosiveness and fatalness region where the system equipment is located. The oil storage tank robot cleaning system is convenient to use, reliable in performance, economical, practical and capable of achieving automatic cleaning without tank entrance of staff.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

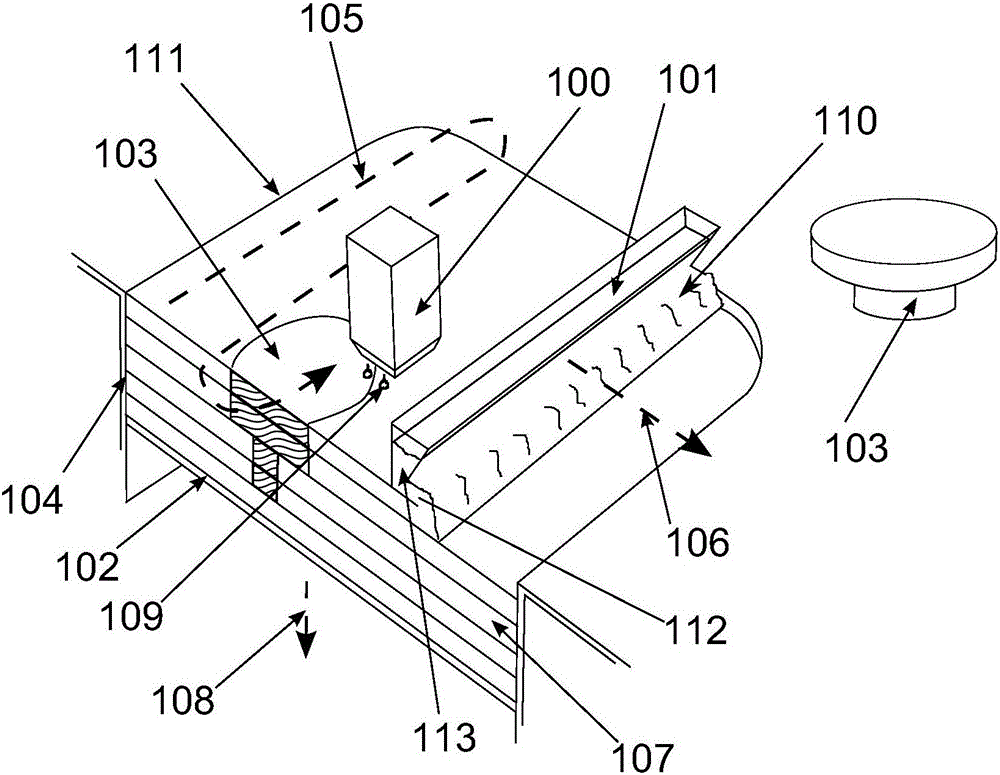

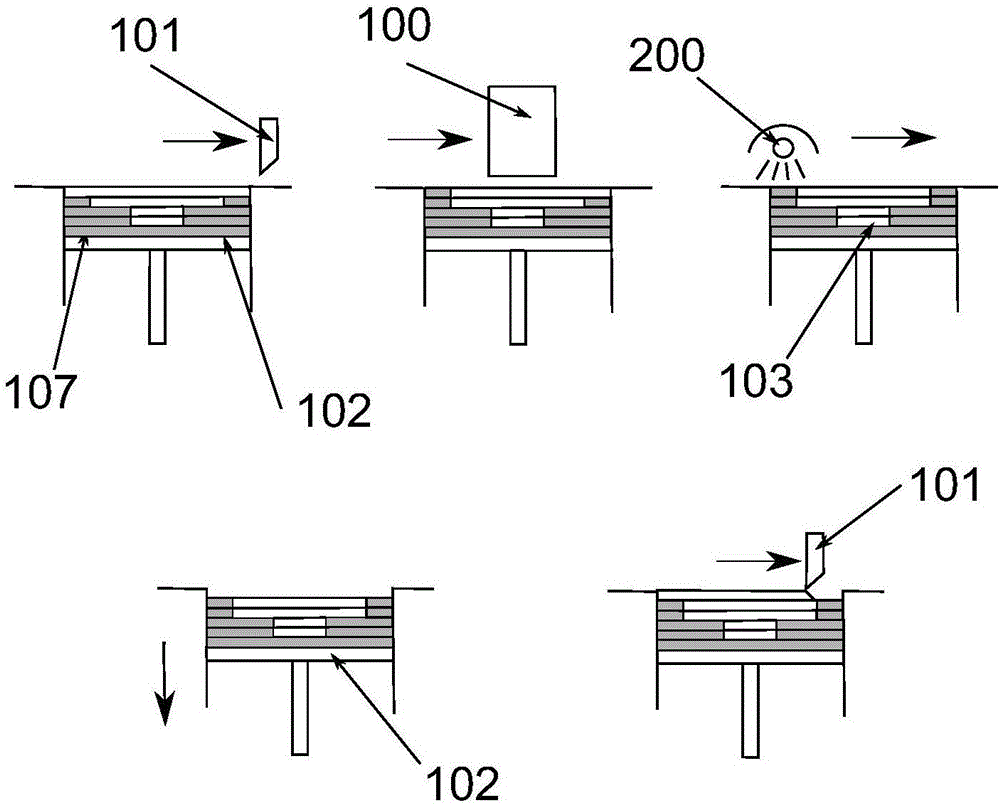

3D reverse image printing method and apparatus

ActiveCN106414040AFavorable material propertiesGood molding propertiesAdditive manufacturing apparatusCeramic shaping apparatusBiomedical engineeringThree dimensional model

Disclosed are a method and an apparatus for making three-dimensional models, wherein joining / binding material is applied layer by layer to a construction platform (102), and agents (100) which delay the joining of the applied material or altogether prevent the applied material from joining are selectively applied.

Owner:VOXELJET AG

Process of carrying out low-temperature chemical cleaning passivation on thermal power plant boiler by utilizing EDTA (Ethylene Diamine Tetraacetic Acid)

InactiveCN102425778AIncrease pHAdjust pH valueBoiler cleaning apparatusMetallic material coating processesEthylene diamineEngineering

The invention relates to a low-temperature chemical cleaning method for a thermal power plant boiler and in particular relate to a process of carrying out low-temperature chemical cleaning passivation by utilizing EDTA (Ethylene Diamine Tetraacetic Acid). The process comprises the following steps: A. connecting a chemical cleaning platform with a system which needs to be cleaned to form a cleaning system, and flushing with circulating water after the connected cleaning system is subjected to a hydraulic test until effluent is transparent and is free from impurities; B. heating the cleaning system cyclically; C. carrying out alkali wash, and flushing; washing by use of EDTA; and passivating. The process has the following characteristics: energy is saved, the consumption is reduced, the cleaning period is shortened, the cleaning cost is reduced, and the boiler can be cleaned and passivated in one step. After the thermal power plant boiler is cleaned by the EDTA at low temperature, a passivation process is added. An alkali substance is added into EDTA cleanout fluid to regulate the pH value of the EDTA cleanout fluid so as to passivate the cleaned boiler. The cleaning process disclosed by the invention is suitable for boilers of various specifications and is beneficial to implementation and popularization on site.

Owner:NINGXIA ELECTRIC POWER RES INST

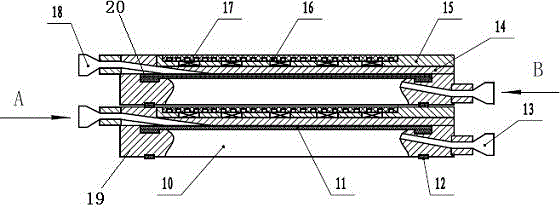

Online detection device for hydraulic pipeline washing oil for ship

InactiveCN103743793AReduce dosageShorten the cleaning cycleTransmissivity measurementsMaterial capacitanceWater contentCheck valve

The invention relates to an online detection device for a hydraulic pipeline washing oil for a ship. According to the innovative points, the online detection device is mounted on a main oil path of a ship pipeline and is located in front of an entrance of a pipeline washing pump station; the online detection device comprises an online sampling assembly, a capacitive sensor module, a photoelectric sensor module and a signal processing system, wherein the online sampling assembly comprises a pair of check valves mounted on the main oil path and a sampling pipe arranged between the liquid outlet sides of the two check valves; the capacitive sensor module is used for detecting the water content; the photoelectric sensor module is used for detecting solid impurities; output signals of a capacitance detection circuit and a photoelectric detection circuit are connected into the signal processing system. The online detection device has the advantages that dielectric constants of various impurities in the washing oil are measured by the capacitive sensor module and the photoelectric sensor module; the cleanliness of the washing oil is calibrated by the processing of the signal processing system so as to judge a washing effect and feed the effect back to workers in time; the use amount of the washing oil is reduced and the washing period is shortened.

Owner:NANTONG UNIVERSITY +1

Marine hydraulic pipeline cleaning-oil online cleaning method

ActiveCN103817117AReduce dosageAvoid detection errorsHollow article cleaningMaterial analysis by optical meansProcess engineeringCapacitance transducer

The invention relates to a marine hydraulic pipeline cleaning-oil online cleaning method. The marine hydraulic pipeline cleaning-oil online cleaning method is characterized in that a sampling point is arranged at the entrance, to a pipeline cleaning pump station, of a main oil circuit of a shipping pipeline; a detectable transparent sampling bypass is arranged at the sampling point, and a capacitance sensor module and a photoelectric sensor module are arranged on the transparent sampling bypass; the shipping pipeline is wholly and circularly cleaned by the aid of hydraulic oil; sampling detection is performed in the manner that during the sampling process, flow rate of the hydraulic oil is controlled to be 6-10m / s, moisture in the hydraulic oil is detected through the capacitance sensor module, scrap iron and oxide impurities in the hydraulic oil are detected through the photoelectric sensor module, calibration display of cleanliness of cleaning oil is performed through processing of a signal processing system, the preset national standard value is compared, and on-off of the pipeline cleaning pump station is controlled. Therefore, cleaning schedule can be fed back to a working staff in time, consumption of the cleaning oil is reduced, cleaning circle is shortened, construction time can be reasonably arranged, and working efficiency can be provided.

Owner:NANTONG UNIVERSITY +1

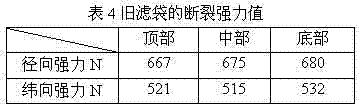

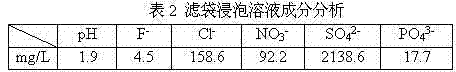

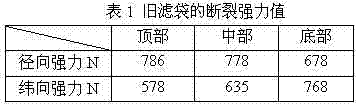

Method for cleaning filter bag for cloth-bag or electric-bag dust collector

ActiveCN102389880ARestoring breathabilityShorten cleaning cycleCleaning using liquidsIonAqueous solution

The invention relates to a method for cleaning a filter bag for a cloth-bag or electric-bag dust collector, which comprises the following steps: (1) clearing surface dust of the filter bag of which the breaking strength is not less than 400N, then, soaking an intercepted small sample into water, measuring the pH value and the ion concentration of soak solution, and if the pH value of the soak solution is less than 5 or in gteater than 9, or F<-> is greater than 2.0mg / l, Cl<-> is greater than 250mg / l, NO3<-> is greater than 30mg / l, SO42<-> is greater than 350mg / l and PO43<-> is greater than 3mg / l in the soak solution, judging that the filter bag needs to the cleaned; (2) firstly, clearing a surface pressed powder layer of the complete filter bag by using compressed air, then, clearing the surface dust by using the dust collector, then, shifting the filter bag into an ultrasonic instrument holding detergent solution for cleaning, washing with the water after the cleaning is completed, and drying in a drying oven. After being cleaned by adopting the method, the filter bag can be recovered in air permeability, the dust clearing period is shortened, corrosive ions remaining in the filter bag are removed, and the service life of the filter bag is prolonged.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

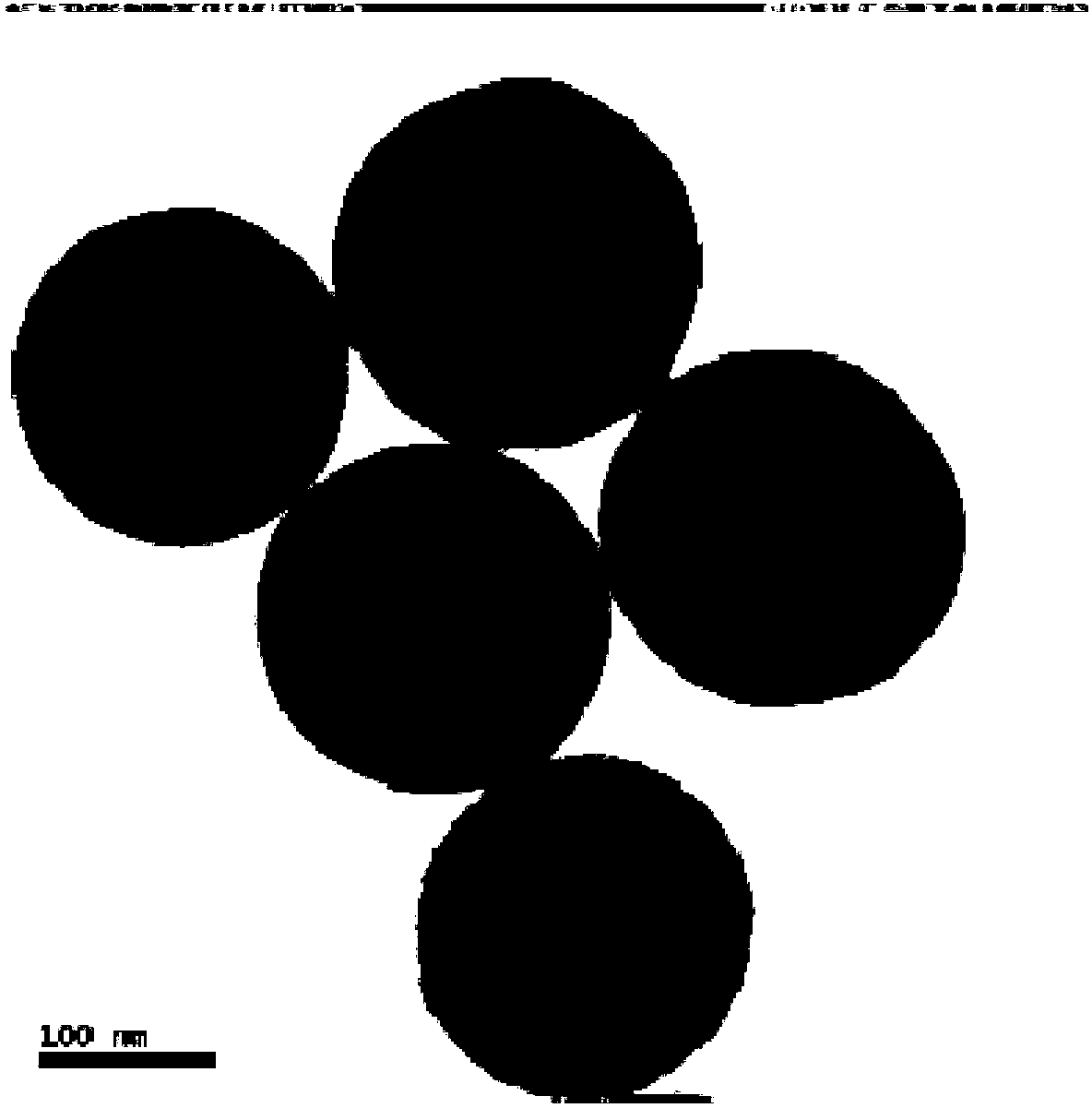

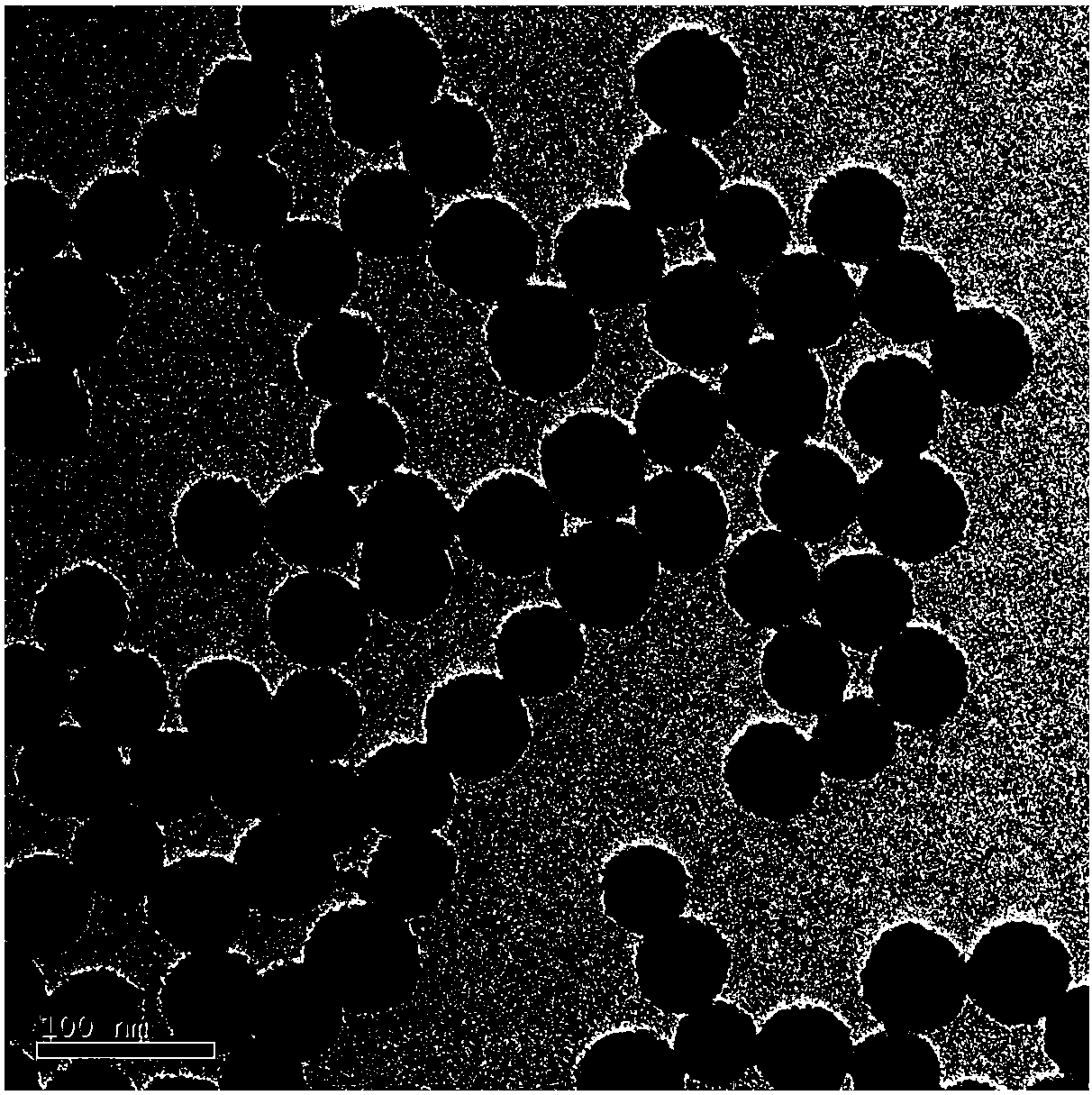

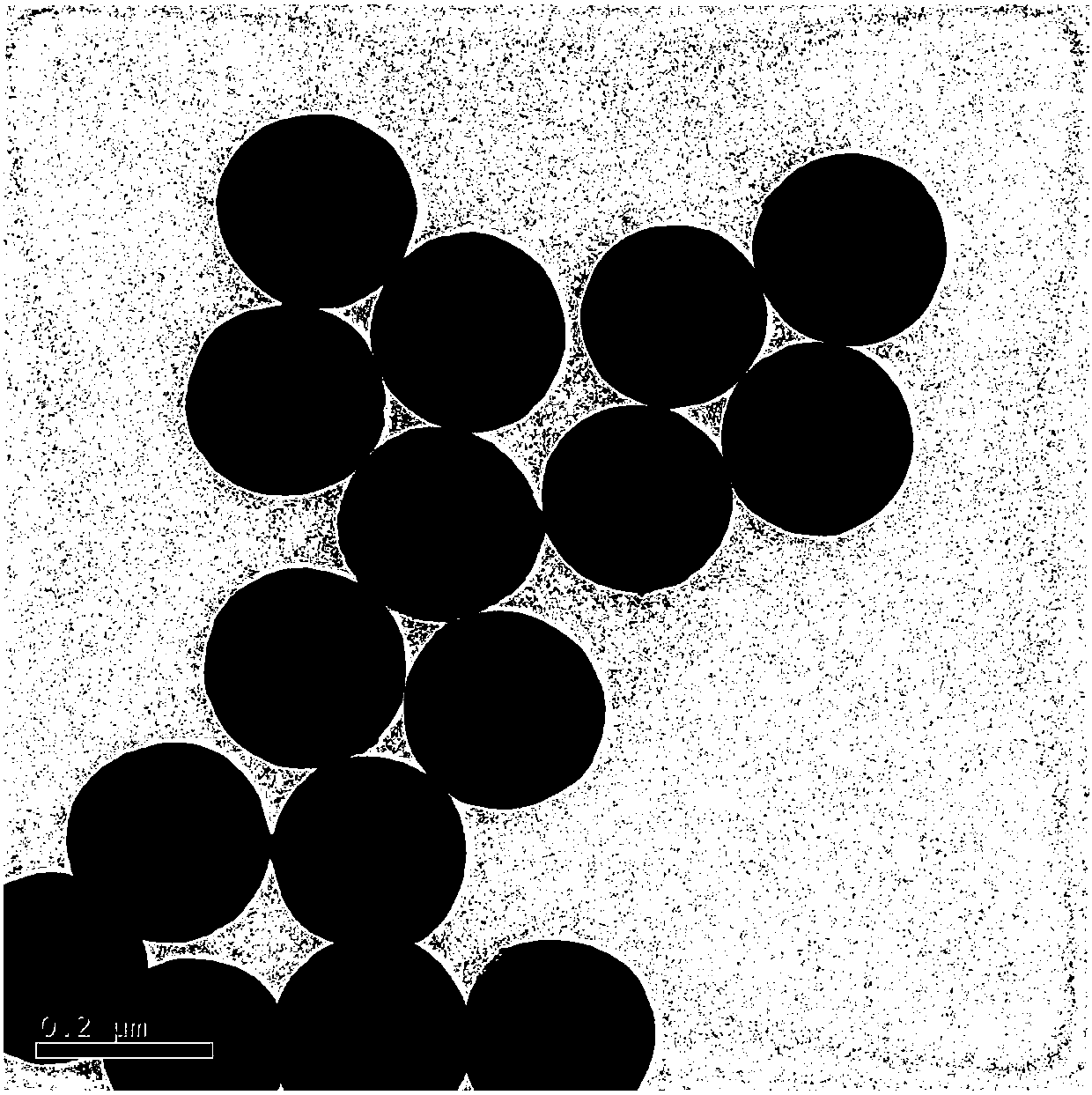

Organic-inorganic hybridized fluorescence nanoparticles capable of emitting color light as well as preparation method thereof

InactiveCN108048074AShorten the cleaning cycleAvoid wastingNanoopticsLuminescent compositionsLuminous intensityUltraviolet lights

The invention provides organic-inorganic hybridized fluorescence nanoparticles capable of emitting color light as well as a preparation method thereof. The luorescence nanoparticles contain inorganicnanoparticles and organic fluorescence carbon points; the carbon points are attached to the surfaces of the inorganic nanoparticles; the particle size of the inorganic nanoparticles is between 30 nm and 280 nm and the mass ratio is between 95 percent and 99.5 percent; the particle size of the carbon points is between 2 nm and 6 nm and the mass ratio is between 0.5 percent and 5 percent; and blue,green or red fluorescence can be emitted under the irradiation of ultraviolet light. The preparation method provided by the invention is simple and short in cycle; and the nanoparticles are bright inlight-emitting color, high in light-emitting intensity, high in light-emitting stability and non-toxic, and avoid environmental pollution.

Owner:HUBEI UNIV

Air purifier

InactiveCN104676776AImprove purification effectImprove adsorption capacityMechanical apparatusLighting and heating apparatusActivated carbon filtrationEngineering

The invention discloses an air purifier. The air purifier comprises a shell, and an air inlet and an air outlet which are arranged on the two ends of the shell. A purifying device is arranged between the air inlet and the air outlet. The purifying device comprises a primary filter, a first air supply device, a filter layer and a second air supply device which are arranged in sequence. The filter layer comprises an ion purifying device layer, a medium efficiency filter layer, a first high efficiency filter layer, an active carbon filtering layer, a cold catalyst filter net, a formaldehyde filter net and an ozone elimination filter net which are arranged in sequence. The air purifying effect of the air purifier is good.

Owner:成都交子新能源科技有限公司

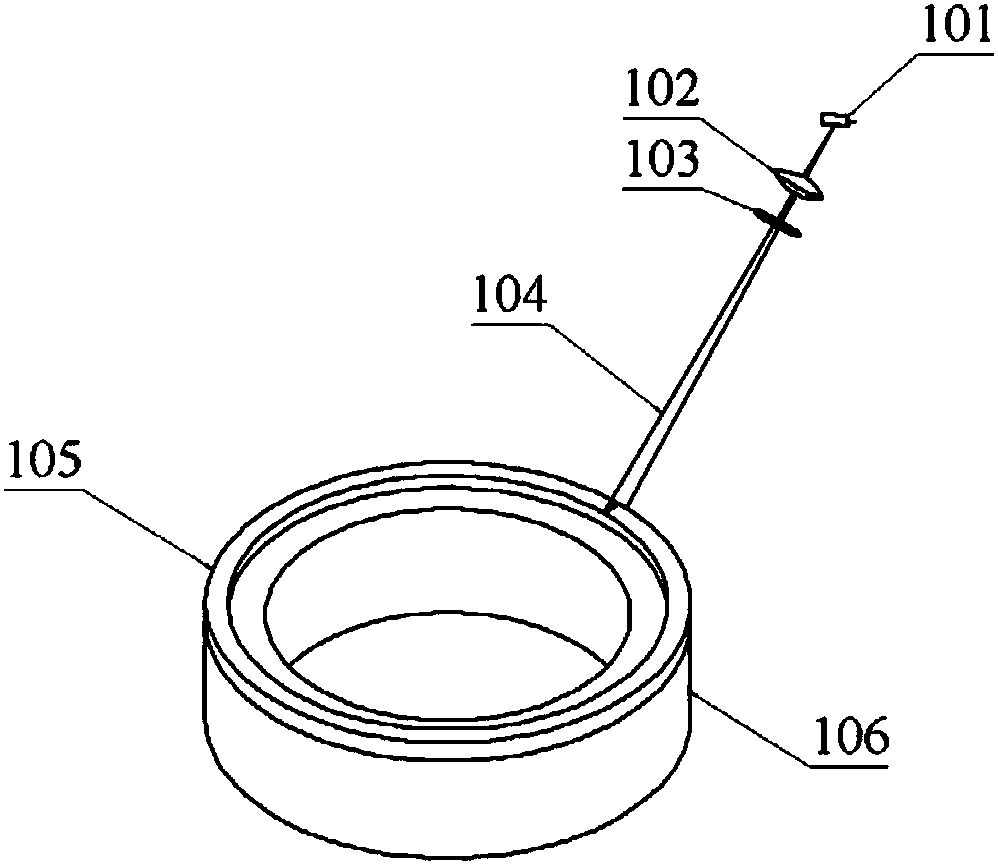

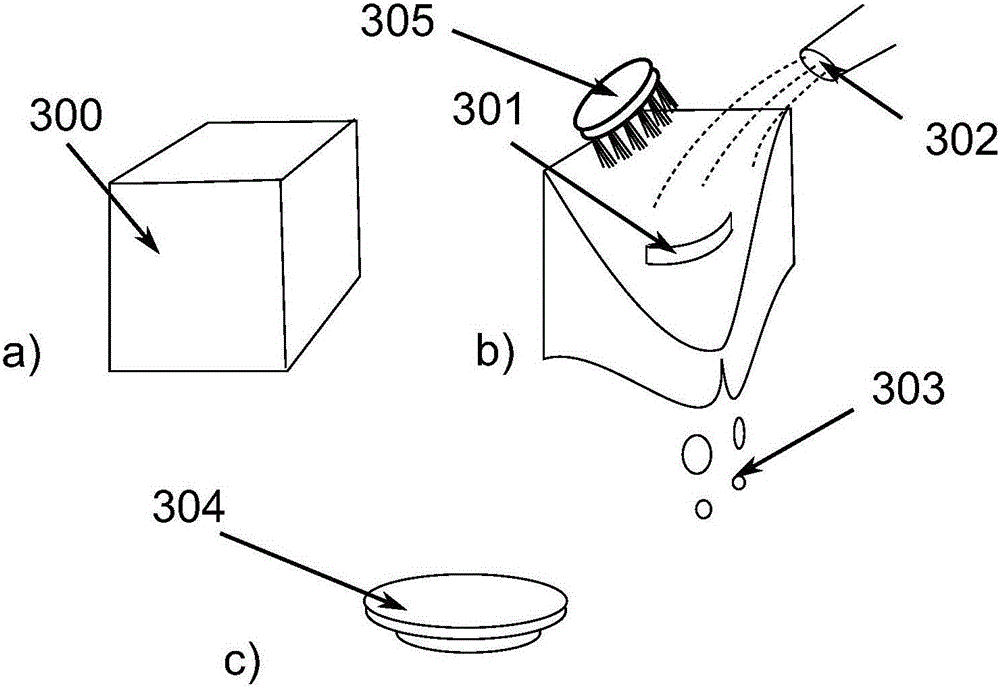

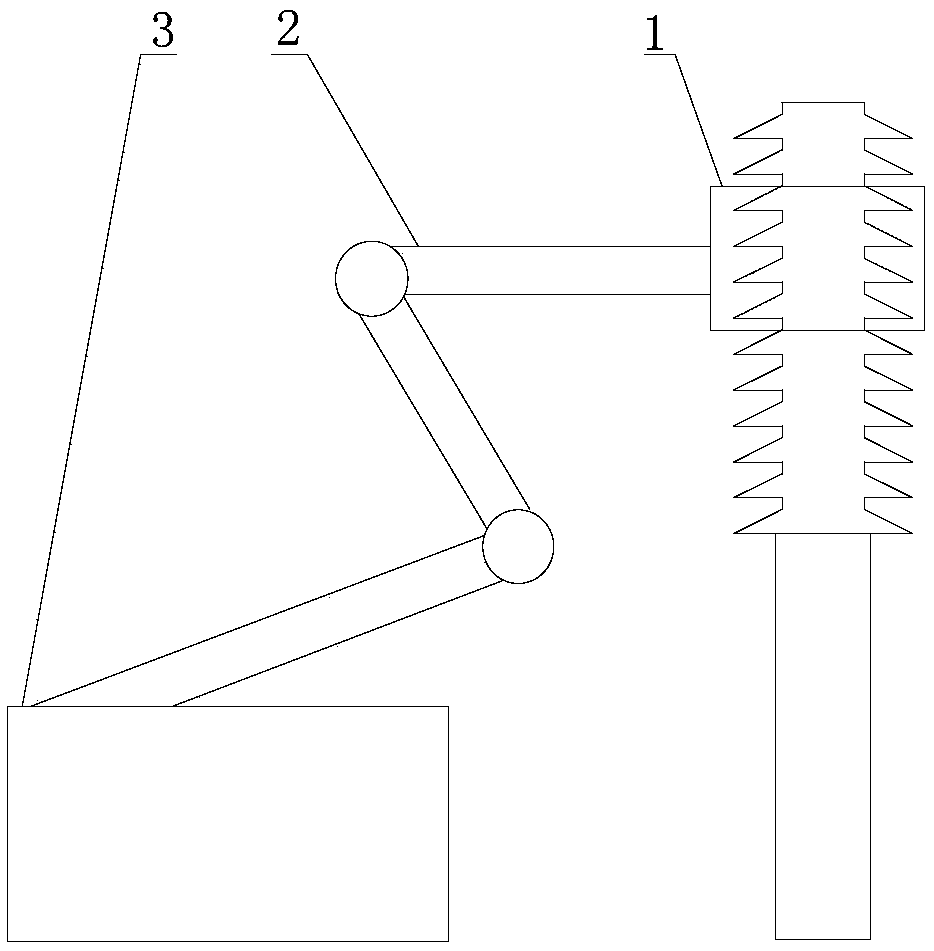

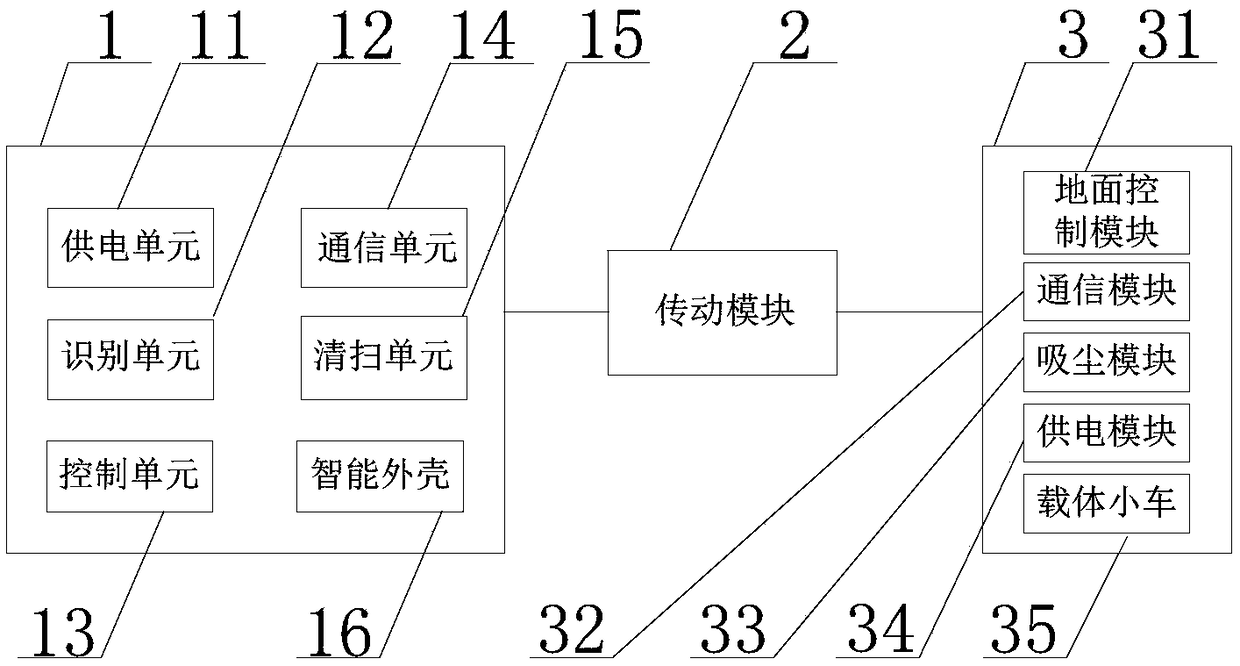

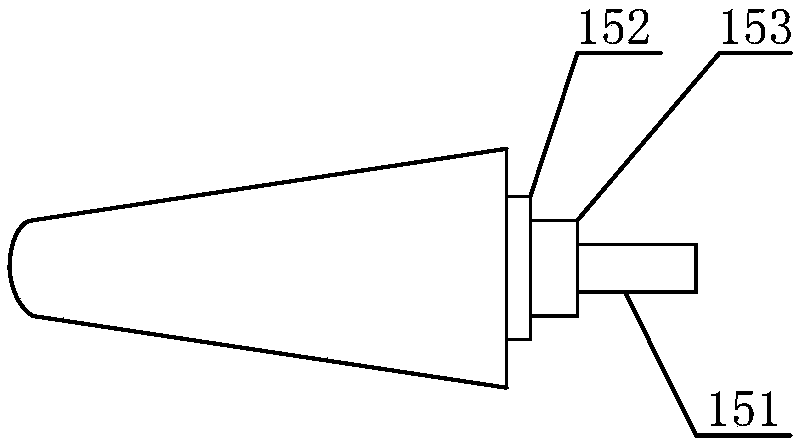

Post insulator electrified sweeping system and method

PendingCN108971043AReduce outage timeImprove power supply reliabilityDirt cleaningCleaning using toolsGround systemMott insulator

The invention discloses a post insulator electrified sweeping system and method. The system comprises a sweeping module, a transmission module and a ground system; the sweeping module comprises an identification unit, a control unit, a sweeping unit and an intelligent shell, the intelligent shell is cylindrical and can be opened and closed along one side of the cylinder wall, the identification unit, the sweeping unit and the intelligent shell are electrically connected with the control unit; one end of the transmission module is fixedly connected with the sweeping module, and the other end ofthe transmission module is fixedly connected with the ground system; the ground system comprises a ground control module and a carrier trolley, the transmission module is electrically connected withthe ground control module, and the control unit is in communication connection with the ground control module. The carrier trolley moves the ground system to the vicinity of a post insulator to be swept, the transmission module drives the sweeping module to move up and down and left and right, the identification unit identifies the relative position of the sweeping module and the post insulator tobe swept, and after alignment is achieved, the sweeping unit is used for sweeping the post insulator to be swept; and according to the system and the method, the power supply can not be influenced when the post insulator is swept, and manpower is saved.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

Modification film of polyvinylidene fluoride and preparation method thereof

InactiveCN1318502CLess likely to affect performanceReduce pollutionOrganic solventMolecular materials

Owner:HARBIN INST OF TECH

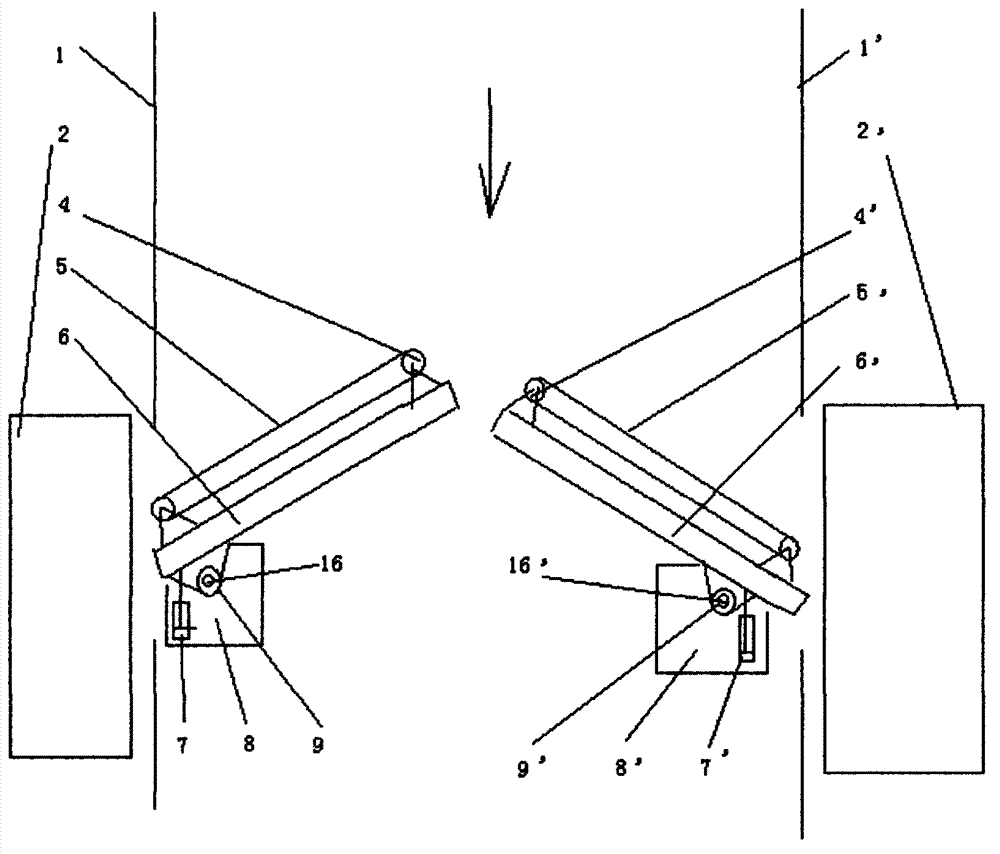

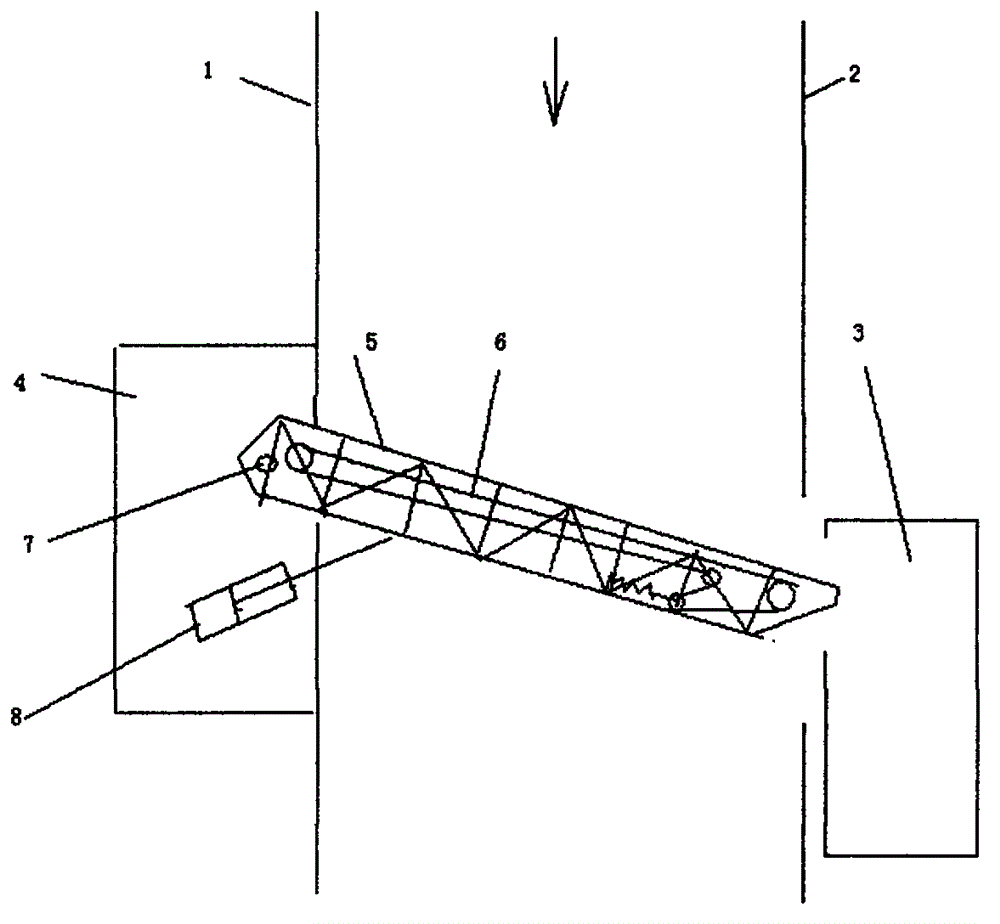

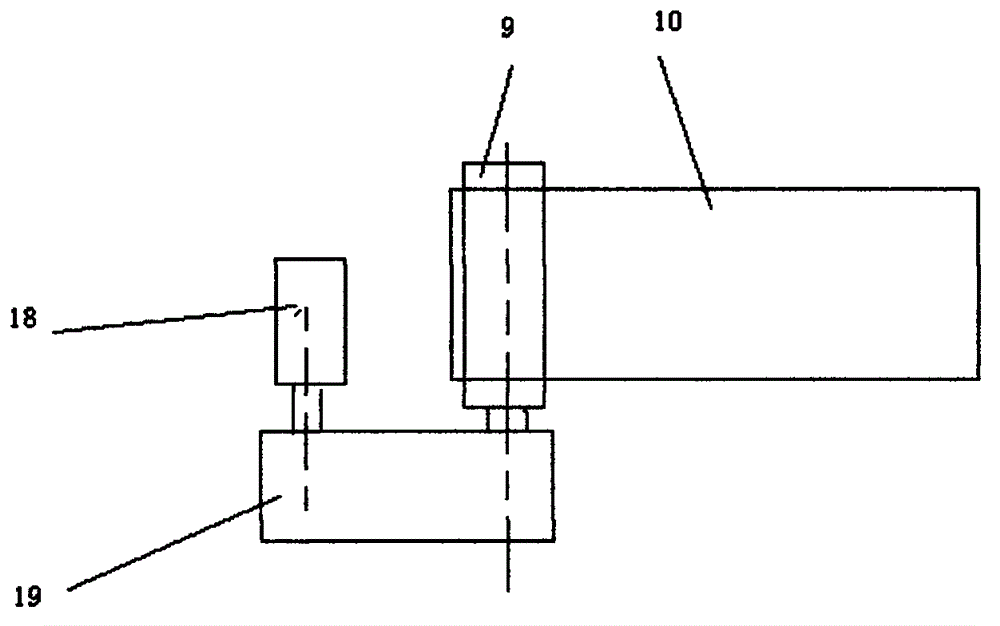

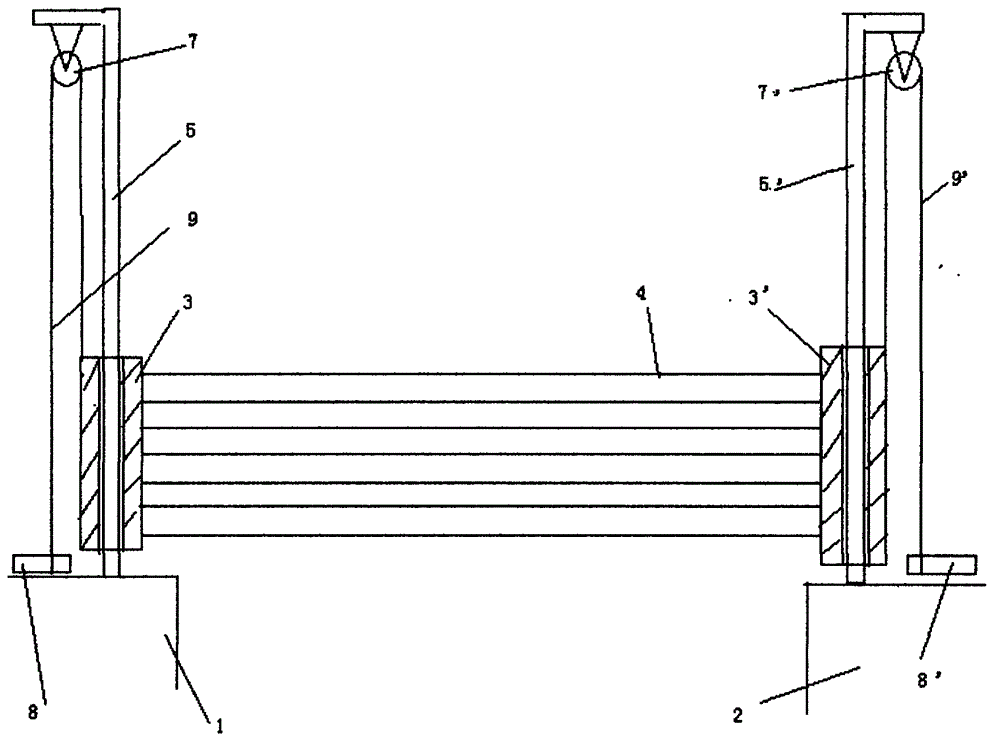

Symmetric riverway automatic trash holding device

ActiveCN104762940AEasy to interceptEasy accessWater cleaningGeneral water supply conservationHydraulic cylinderLeft half

The invention discloses a symmetric riverway automatic trash holding device. The device comprises a left safety pond, a left building concrete work platform and a left stand column which are all arranged on the left bank, wherein the left end of the rear side of a left intercepting plate bottom frame stretching over the left half of a river is hinged to a sleeve, chain wheels are arranged at the two ends of the front side of the left intercepting plate bottom frame, a chain is arranged on the chain wheels, a left hydraulic cylinder is arranged on the left lower side of the left stand column, one end of the left hydraulic cylinder is hinged to the left building concrete work platform, the other end of the left hydraulic cylinder is hinged to the left end of the rear side of the left intercepting plate bottom frame, and a left lifting hydraulic oil cylinder used for lifting the left intercepting plate bottom frame is arranged at the lower end of the sleeve; a right safety pond, a right building concrete work platform, a right stand column, a right intercepting plate bottom frame and the like are arranged on the right bank and symmetrical to the structures on the left bank. By using the symmetric riverway automatic trash holding device, it is not needed that a large amount of manpower and material resources are consumed and ships are adopted for interception and fishing, the device is convenient to use, safe and efficient, the clearing period is greatly shortened, and when no floating objects exist on the upstream, passage of ships in the river is not affected.

Owner:徐州宇之阳市场营销策划有限公司

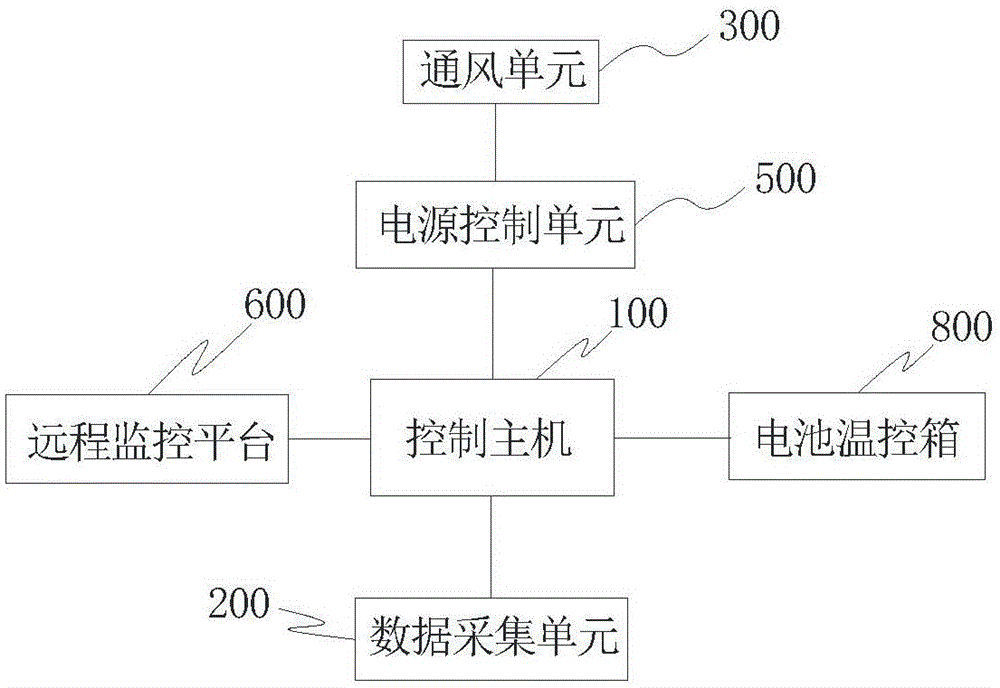

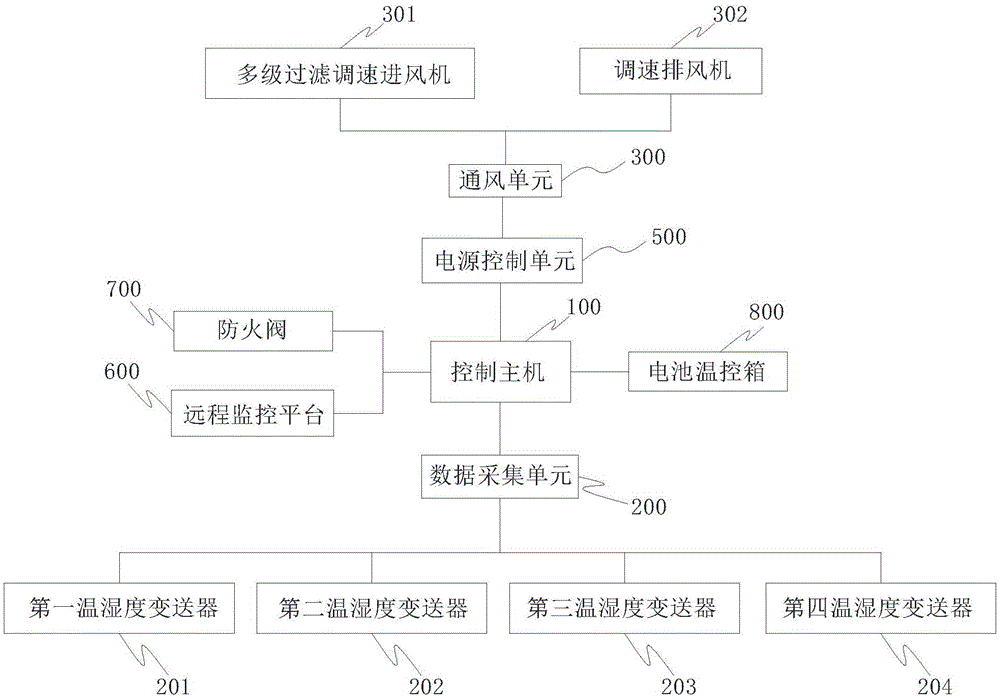

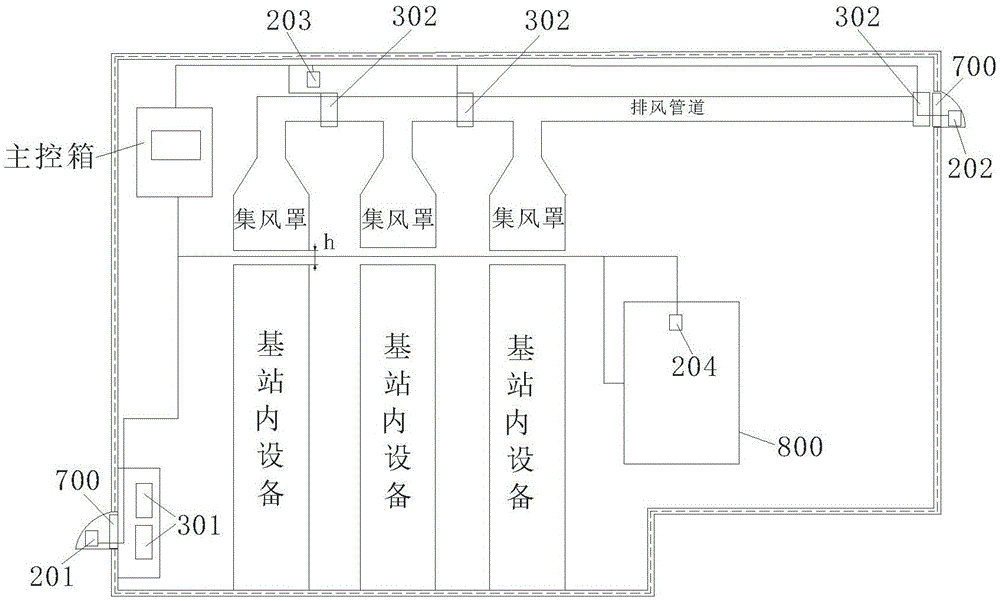

Intelligent base station heat source management energy-saving system

InactiveCN105157187ASave energyReduce demandSpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlControl signal

The invention discloses an intelligent base station heat source management energy-saving system. The system comprises a first temperature and humidity transmitter, a second temperature and humidity transmitter, at least one third temperature and humidity transmitter, a multilevel filtering speed-regulating air inlet blower, a speed-regulating air outlet blower, a plurality of base station special refrigeration devices, a battery temperature control box, a fourth temperature and humidity transmitter and a control host. The control host is used for comparing the indoor temperature and humidity with the outdoor temperature and humidity, controlling the air speed, starting and closure of the multilevel filtering speed-regulating air inlet blower according to a comparative result, and controlling the air speed, starting and closure of the speed-regulating air outlet blower. The control host is further used for sending a control signal to a refrigeration part of the battery temperature control box so as to make the temperature in the battery temperature control box keep constant when the temperature, collected by the fourth temperature and humidity transmitter, in the battery temperature control box is greater than a preset battery constant temperature. According to the system, the intelligent control over the indoor temperature and humidity of a base station is achieved, and the control is accurate, so that the temperature and humidity of the work environment of the base station keep constant. In addition, the energy-saving effect is good and the energy-saving efficiency is high.

Owner:广州金关节能科技发展有限公司

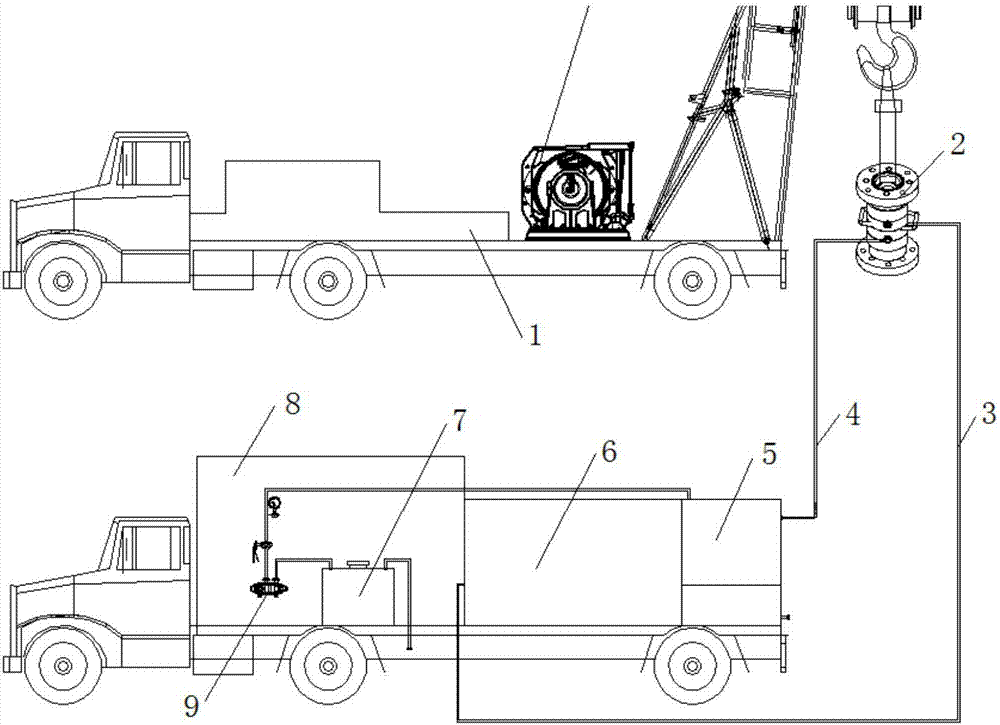

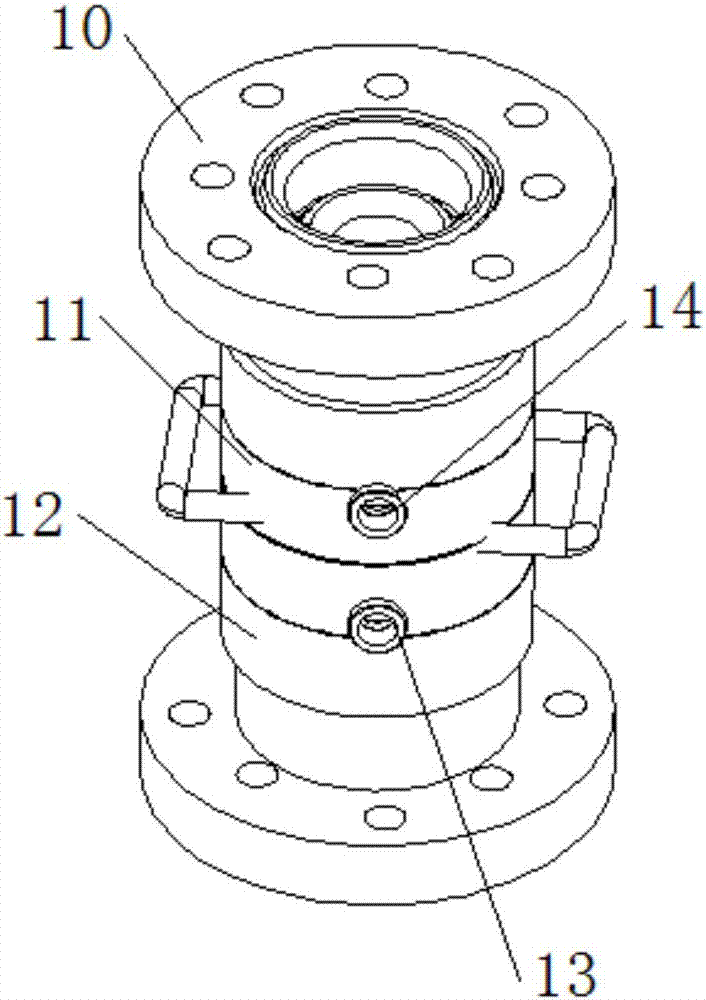

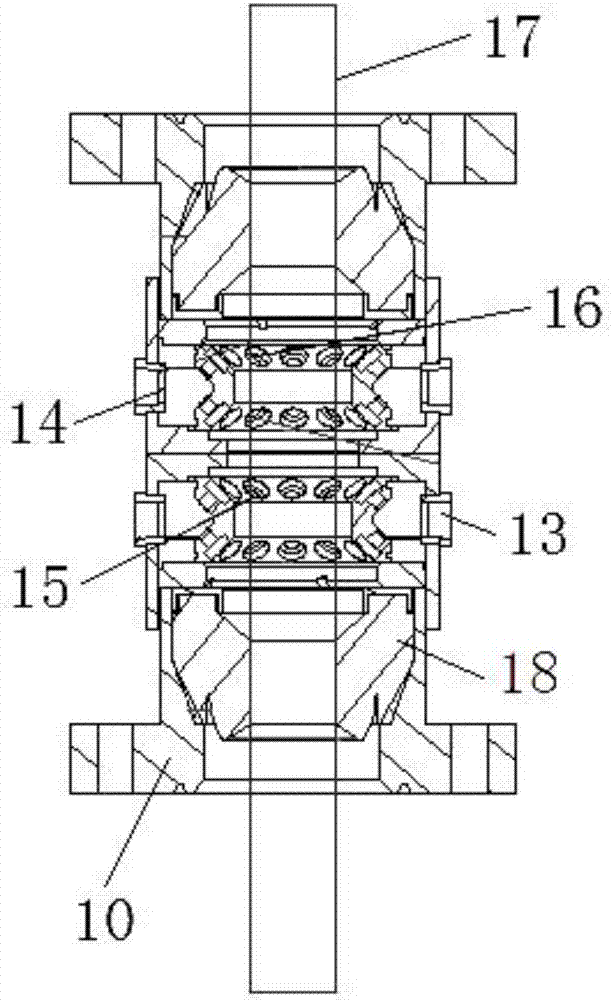

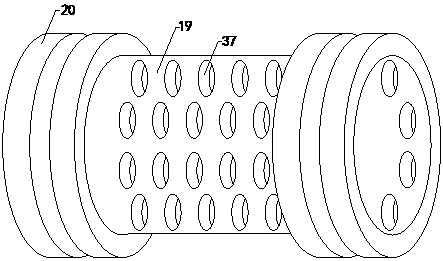

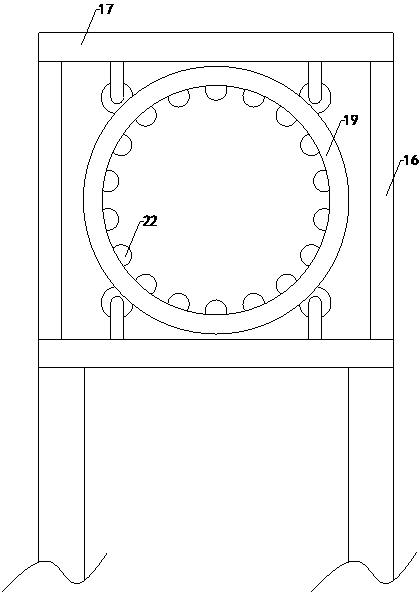

System for cleaning outer wall of oil pipe at wellhead, device and method thereof

PendingCN107201888AAchieve protectionShorten the cleaning cycleCleaning apparatusInsulationWellheadPipe

The invention discloses a system for cleaning an outer wall of an oil pipe at a wellhead, a device and a method thereof; a steam inlet of a well head cleaning device is connected with a steam generating device, and a fluid outlet of the well head cleaning device is connected with a recycling device; the device comprises two shell bodies with the same structure, the inner parts of the shell bodies are hollow and both ends are opened; a spraying ring and an absorbing ring are arranged between the shell bodies, and the spraying ring is in seamless connection with the absorbing ring and one shell body; the absorbing ring is in seamless connection with the spraying ring and the other shell body at the same time. The system, the device and the method adopt the sealed steam cleaning at the wellhead; the steam utilization rate is high, the outer wall of the oil tube can be cleaned rapidly, and the cleaning efficiency is improved; meanwhile, steam cannot be overflowed, and the safety is improved; steam and cleaned materials can be intensively recycled, and free from residue overflow, and can prevent environmental pollution.

Owner:克拉玛依市建业能源股份有限公司

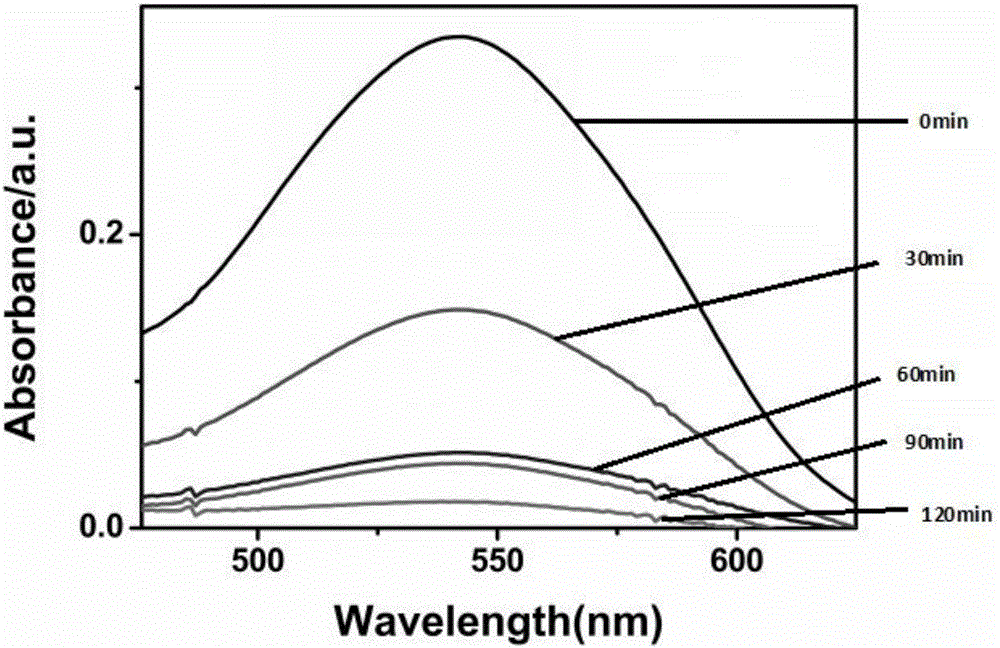

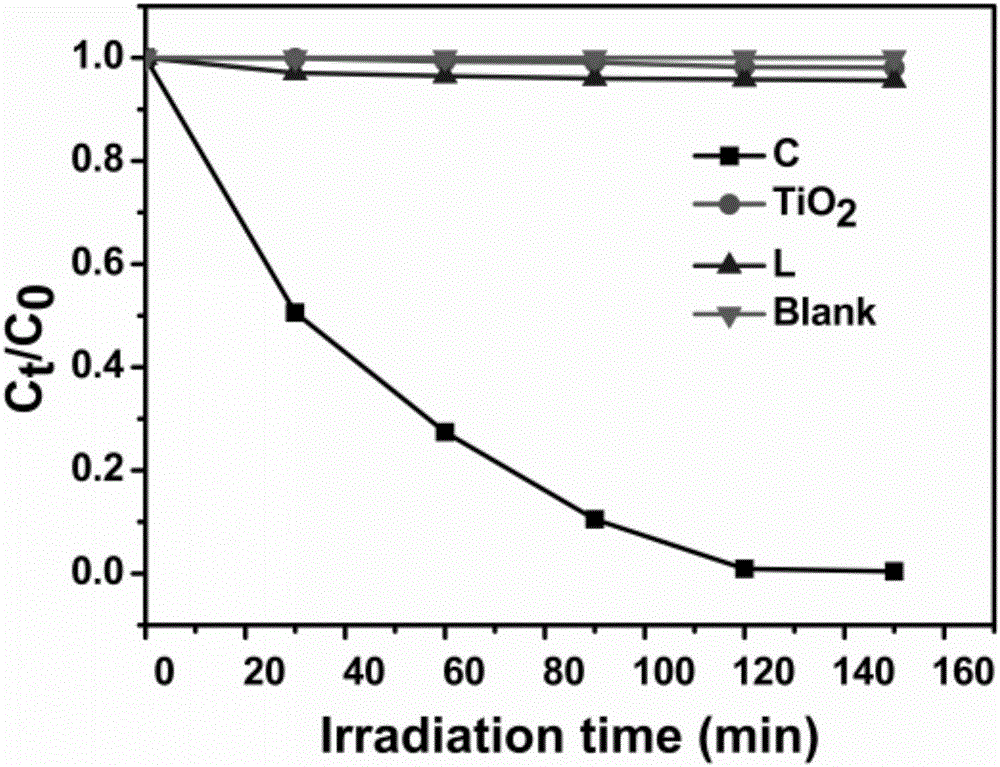

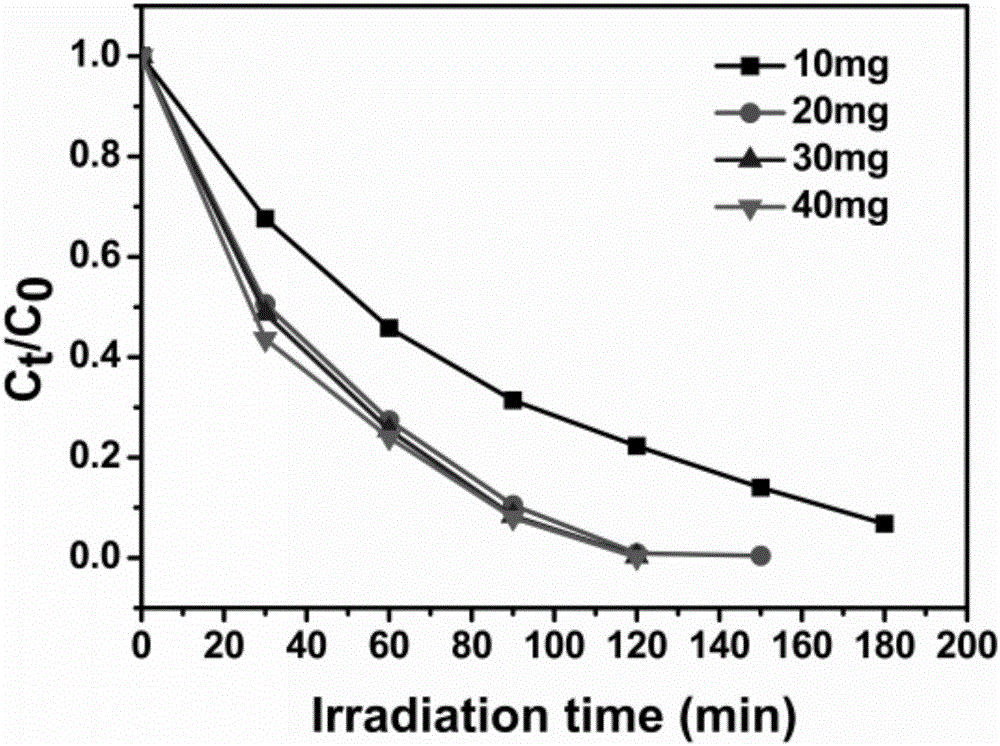

Cuprous selenide cluster supported visible-light-induced catalyst with property of reducing Cr (VI) ions

ActiveCN105944763AShorten the cleaning cycleLow priceWater/sewage treatment by irradiationWater treatment compoundsDecompositionPhysisorption

The invention discloses a cuprous selenide cluster supported visible-light-induced catalyst with a property of reducing Cr (VI) ions. According to the principle of the catalyst, a selenide-containing aromatic nucleus ligand is designed, a cuprous cluster complex of the selenide-containing aromatic nucleus ligand is taken as a sensitizer, the selenide-containing aromatic nucleus ligand is supported to TiO2 through physical absorption step by step, and then the compounds are taken as the catalyst for characterizing optical properties; analysis validation is performed with a diphenylsemicarbazide color developing agent. The invention further discloses a preparation method of the catalyst. The catalyst performs catalysis only under irradiation of a visible light source; chemical conversion of pollutants is fast, and the period of water purification can be shortened; the selected compounds are stable, and secondary pollution caused by decomposition or difficulty in recycle can be avoided; a chemical material for wastewater treatment is abundant, low in cost, non-toxic and environment-friendly.

Owner:NANJING UNIV OF TECH

Part cleaning device for new energy automobile production

ActiveCN109047099AFully dryImprove practicalityDrying machines with non-progressive movementsCleaning using liquidsNew energyEngineering

The invention relates to the technical field of new energy automobile production accessory devices, in particular to a part cleaning device for new energy automobile production. Automobile parts can be well turned over during the cleaning process so as to be cleaned comprehensively, so that the practicability is improved; meanwhile, after being cleaned, the automobile parts can be effectively dried in time, so that the cleaning efficiency is improved, and the use limitation is reduced; and a cleaning solution does not need to be mixed in advance and can be prepared at any time, so that the cleaning period is shortened. The part cleaning device for new energy automobile production comprises a bottom plate, a support plate, a cleaning water tank, a cleaning water pipe, a cleaning nozzle, twogroups of support pillars, an adjusting block, a support shaft, an adjusting plate, a rotary shaft, a right fixed plate, an upper fixed plate, a lower fixed plate, an upper clamping bolt, a lower clamping bolt, an upper clamping plate, a lower clamping plate, four groups of support legs, four groups of support rods, an upper placement plate, a lower placement plate, two groups of upper left supports, two groups of lower left supports, two groups of upper right supports, two groups of lower right supports, a roller, a left rolling ring, a right rolling ring, a gear motor, a mixed motor and multiple groups of stirring blades.

Owner:赖中晶

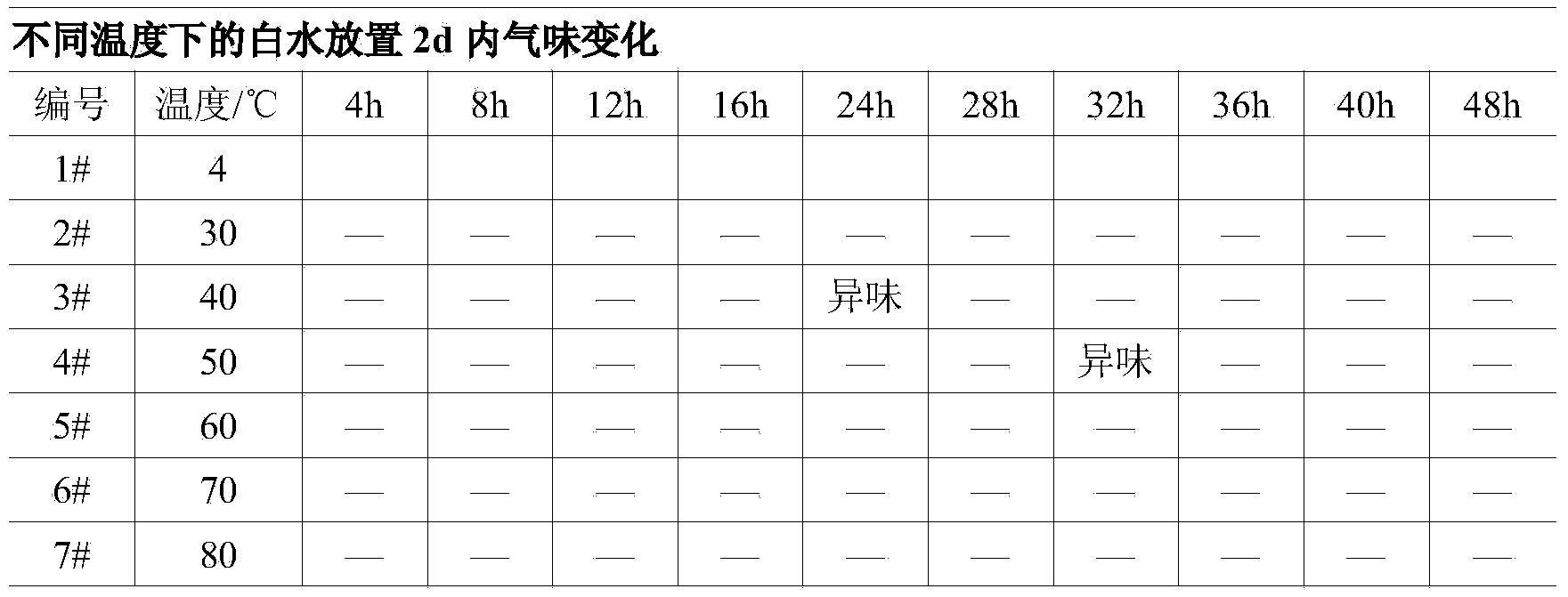

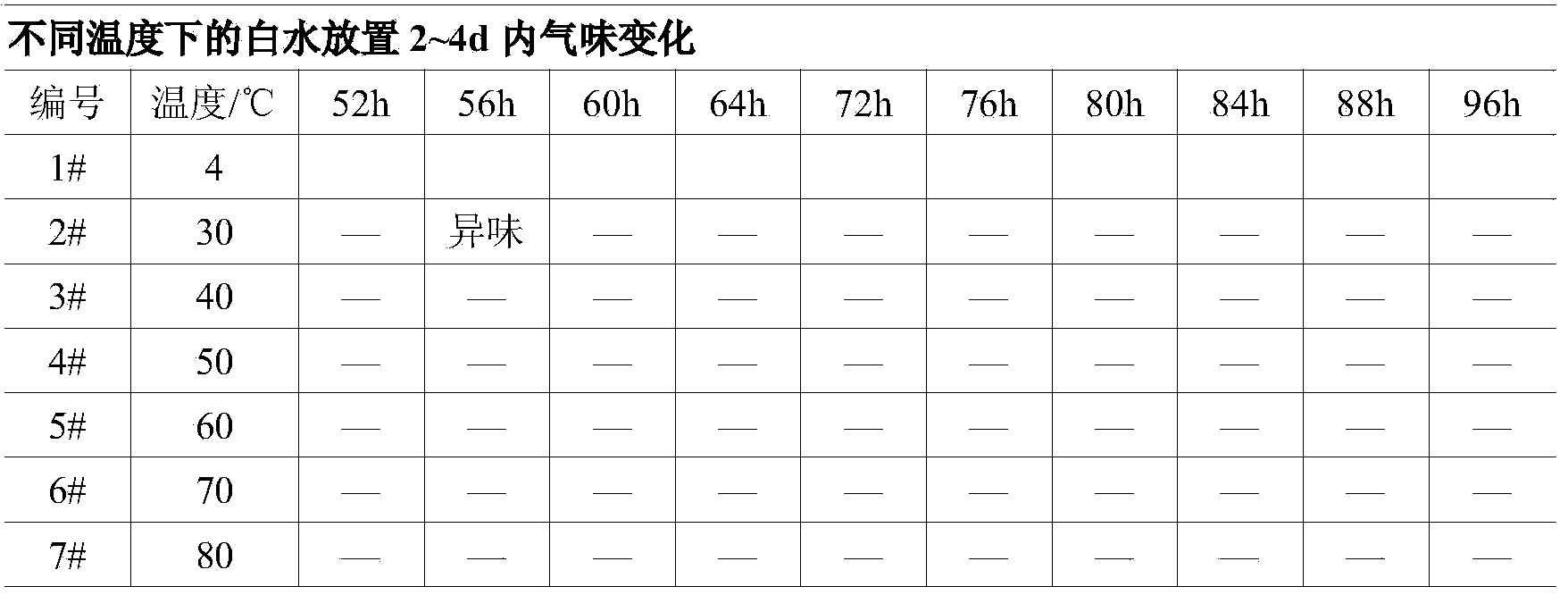

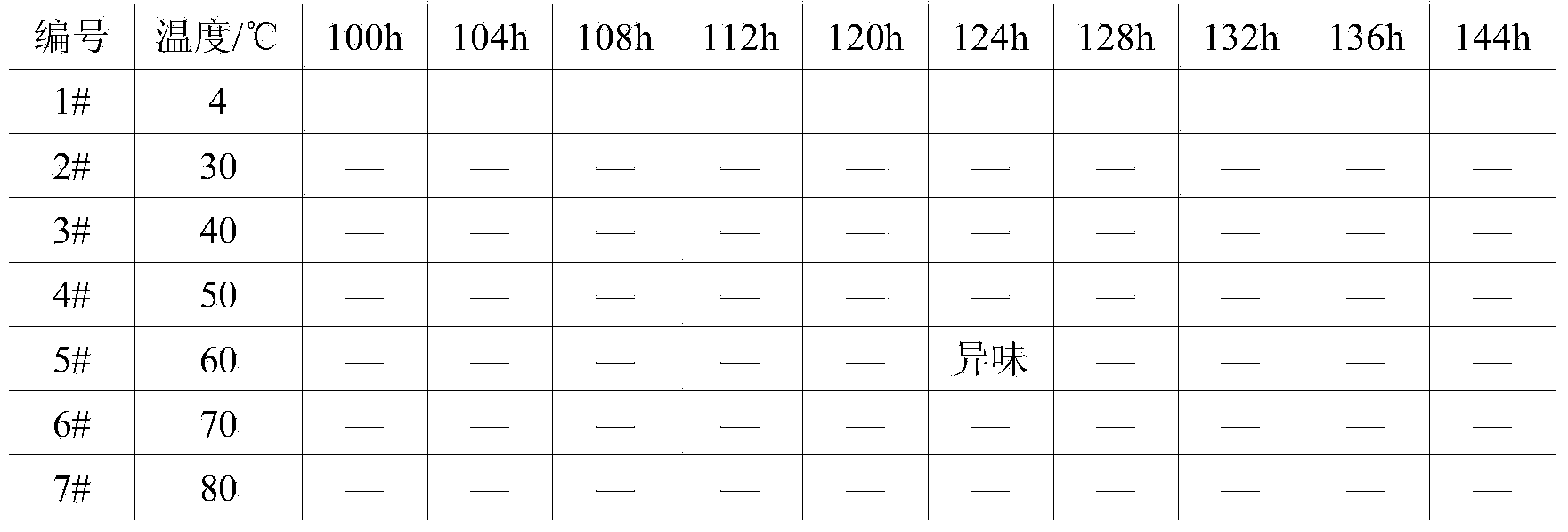

Corrosion-prevention method for paper-making process reconstituted tobacco production white water system

InactiveCN103829365AShorten the cleaning cycleReduce water consumption per tonTobacco preparationTemperature controlWhite water

The invention discloses a corrosion-prevention method for a paper-making process reconstituted tobacco production white water system. The method includes the steps of temperature-control corrosion prevention and bacteriostat corrosion prevention. According to temperature-control corrosion prevention, white water is heated and kept to be 60-100 DEG C, bacteriostats are added into the white water, and the adding amount of the bacteriostats is 20-80 ppm. According to the corrosion-prevention method for the paper-making process reconstituted tobacco production white water system, the method of combining the temperature-control corrosion prevention technology with the bacteriostats is adopted in the paper-making process reconstituted tobacco production process, namely the technology of the combination of controlling the temperature of the white water system to be larger than 60 DEG C and adding bacteriostats to the white water is used as the control means for processing and analyzing microorganisms in the system and is feasible.

Owner:GUANGDONG GOLDEN LEAF TECH DEV +1

Method for cleaning carbon steel casting with weight smaller than 5 tons

The invention relates to a method for cleaning carbon steel casting, in particular to a method for cleaning a carbon steel casting with the weight smaller than 5 tons. The method is characterized by including the steps that high-temperature knockout is firstly carried out; the casting is instantly lifted to a shakeout area after high-temperature knockout is carried out, large sand lumps on the surface of the casting are smashed to fall off; when the casting is cooled to 300 DEG C to 350 DEG C, the casting is lifted to a riser cutting area, and burnt-on sand and porcelain tubes which can influence riser and pouring gate cutting are eliminated; after cleaning of the burnt-on sand and the porcelain tubes is completed, the temperatures of the cutting part and the other parts of the casting are measured respectively, and riser cutting is carried out when the temperature of the cutting part is higher than 150 DEG C, and the temperatures of the other parts are larger than 100 DEG C; after riser cutting is finished, the casting is transferred to the interior of a heat treatment furnace, and furnace charging is carried for performance heat treatment. The method is unique, and the production period is shortened; the problem that riser cutting needs to be carried out through preheating after knockout and shakeout are carried out on the steel casting is solved, and the production cost is reduced.

Owner:KOCEL STEEL

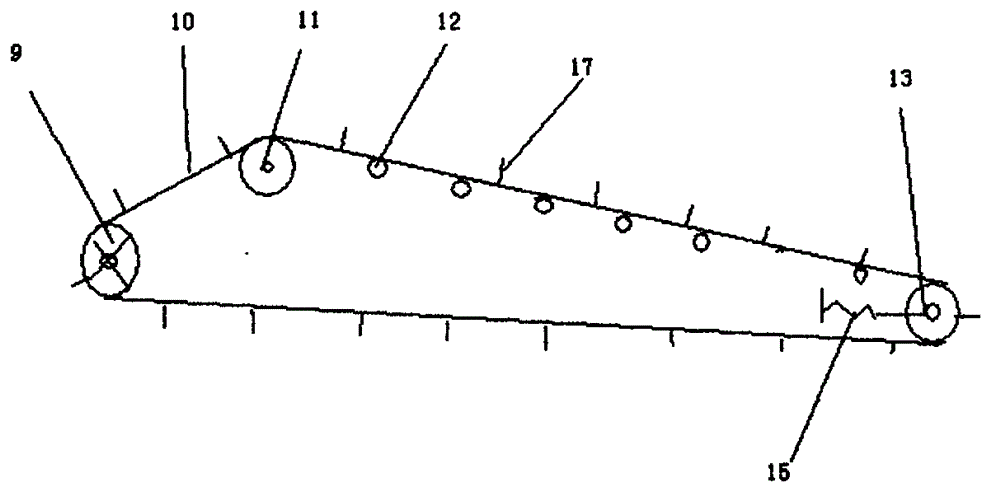

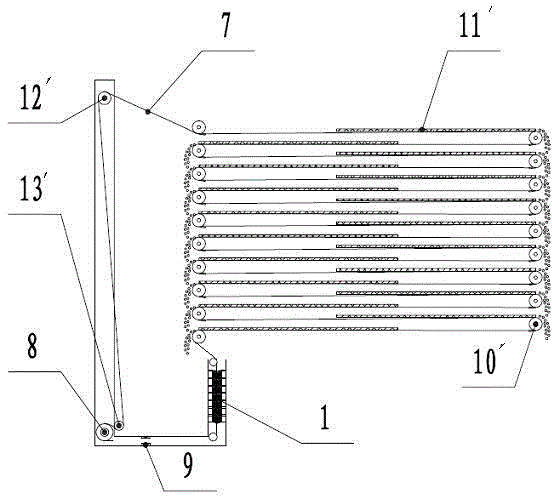

Automatic belt-type riverway trash blocking device

InactiveCN104790367AShorten cleaning cycleAvoid secondary pollutionConveyorsWater cleaningEngineeringMaterial resources

The invention discloses an automatic belt-type riverway trash blocking device. The automatic belt-type riverway trash blocking device comprises a building concrete working platform arranged on the left bank of a river, a floating object treating pond arranged on the right bank of the river and a belt-type conveyer truss stretching across the left bank and the right bank of the river, the front side face of the belt-type conveyer truss is provided with a belt-type conveyer from left to right, the belt surface of a conveying belt of the belt-type conveyer is perpendicular to the water surface, a plurality of rib pieces perpendicular to the belt surface are evenly distributed on the belt surface, the left end of the belt-type conveyer truss is hinged to a sleeve, the sleeve is arranged on a stand pillar of the building concrete working platform in a sleeving mode, one end of a rotation hydraulic cylinder is hinged to the building concrete working platform, and the other end of the rotation hydraulic cylinder is hinged to the belt-type conveyer truss. The automatic belt-type riverway trash blocking device is capable of automatically blocking and removing floating objects or aquatic plants in a riverway, not only is no large amount of manpower and material resources spent on waste cleaning needed, but also the floating objects or the aquatic plants can not accumulate, the cleaning period is greatly shortened, and the secondary pollution can further be avoided.

Owner:SHAOXING UNIVERSITY

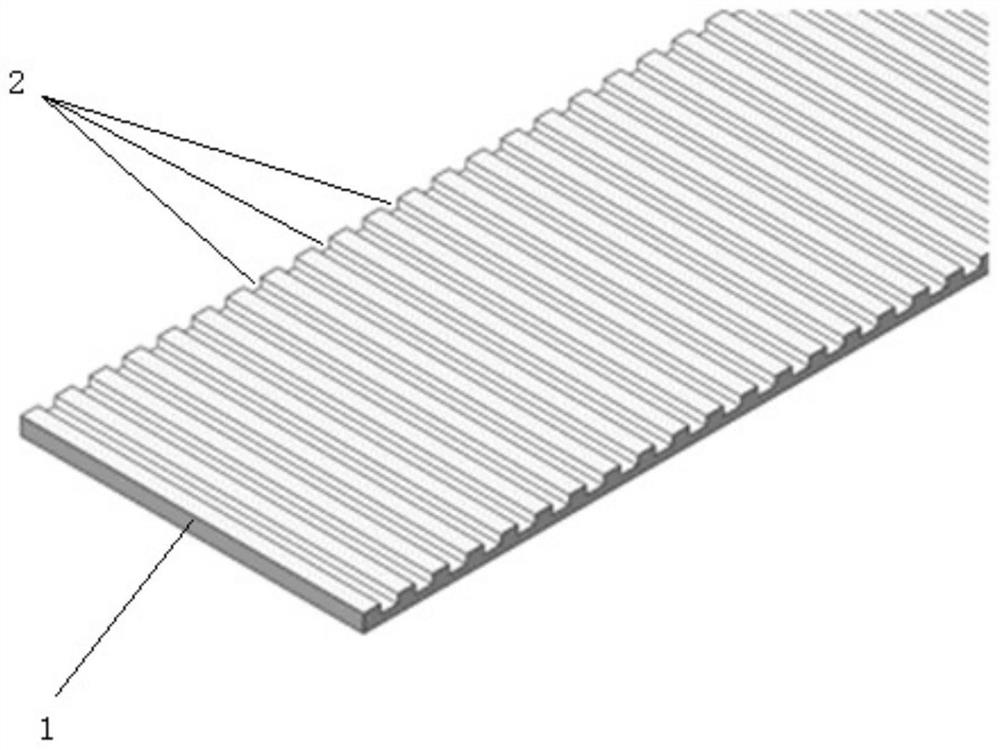

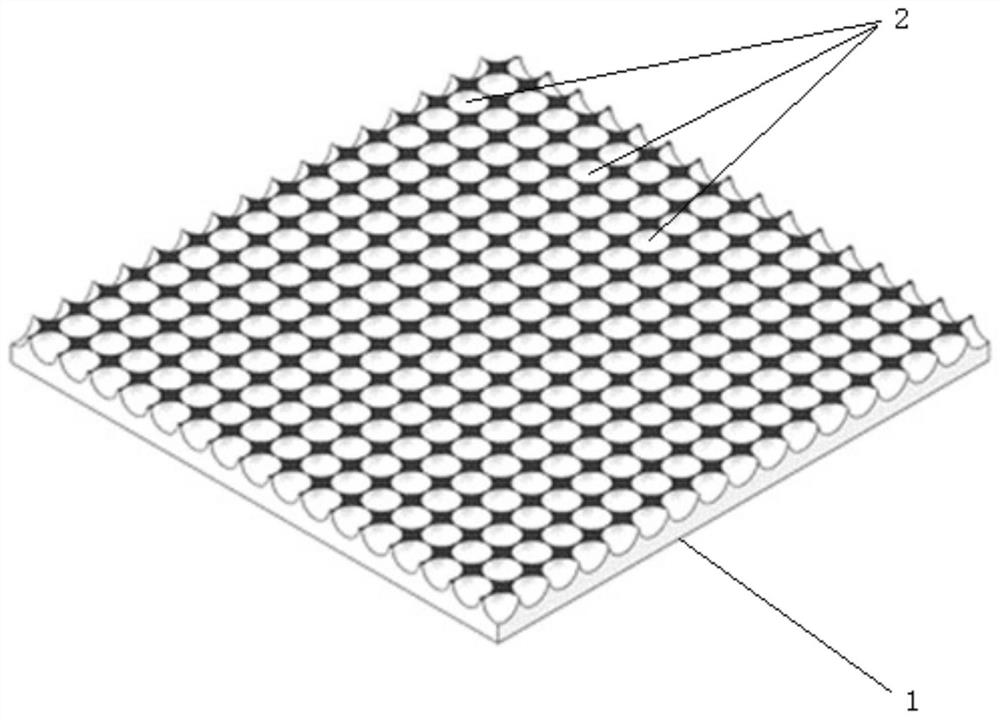

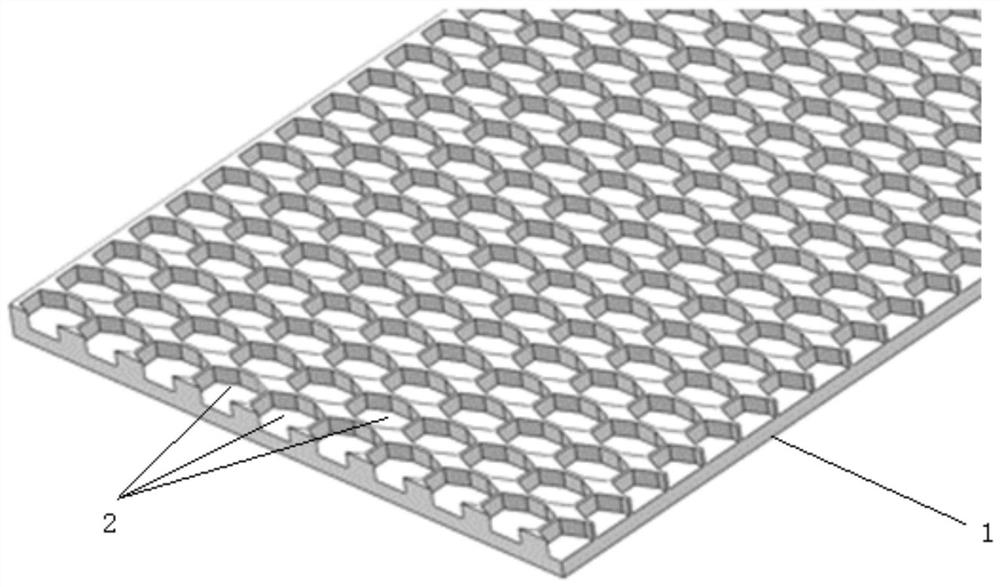

Anti-pollution flat sheet membrane

PendingCN111804147AExtended service lifeReduce pollutionGeneral water supply conservationReverse osmosisChemical treatmentMembrane fouling

According to an anti-pollution flat sheet membrane provided by the invention, physical or chemical treatment is carried out in the membrane preparation process, so that on the surface of the anti-pollution flat sheet membrane, concave parts with a regular shape, a certain size and a certain direction is formed. The structure of the concave parts comprises any one or more of the following characteristics: a strip-shaped groove structure; a dot-shaped concave structure; and a polygonal concave structure; an included angle is formed between the extending direction of the cross section of the concave parts and the water flow direction on the surface of the membrane body. The flat sheet membrane with the regular concave part is prepared; the concave parts can enable inflow water to form a micro-vortex effect, effectively slow down membrane pollution and shorten the cleaning period, so that the service life of the membrane is prolonged, the desalination performance of the flat sheet membranecan be kept unchanged, the membrane pollution can be effectively slowed down, the cleaning period is shortened, the service life of the membrane is prolonged, the adjustable space is large, and the anti-pollution effect is obvious.

Owner:BEIJING ORIGIN WATER FILM TECH

Vertical-type full-automatic filter press based on ultrasonic washing

Owner:JIANGSU XINHONGDA GROUP

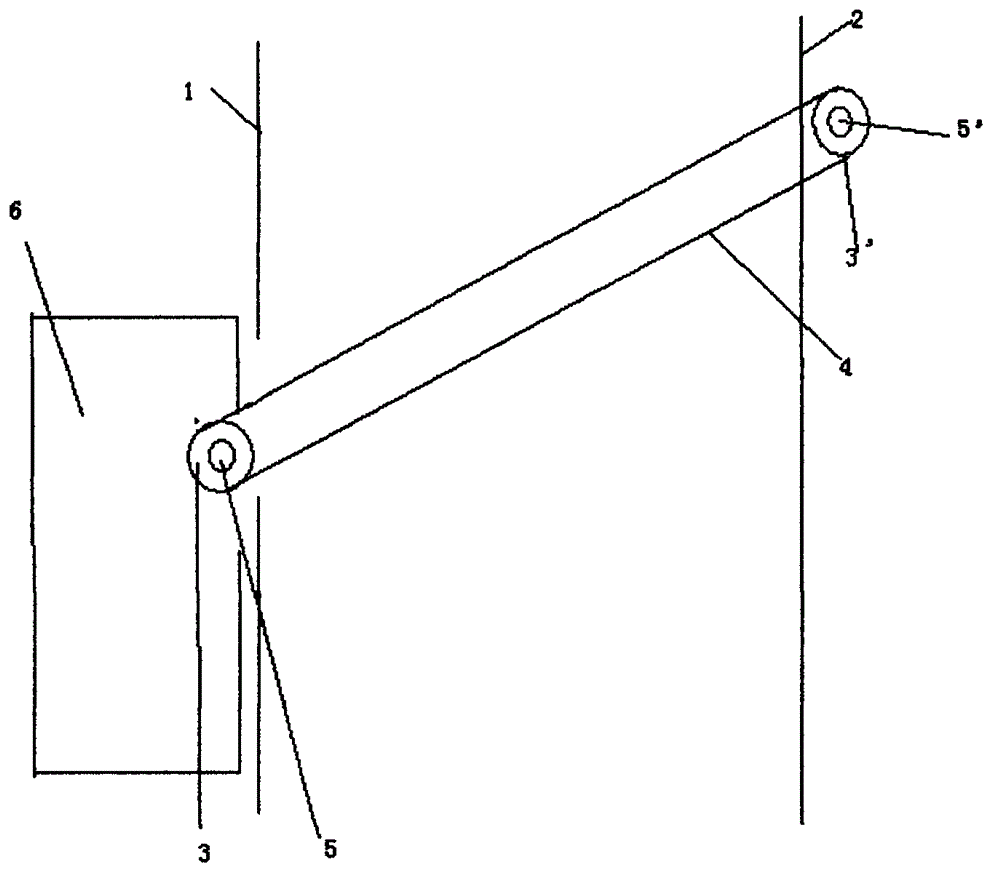

Winch-lifted automatic intercepting device for river floatage

The invention discloses a winch-lifted automatic intercepting device for river floatage. The automatic-lifted automatic intercepting device for river floatage comprises a safe basin arranged at the left bank, a left stand column arranged in the safe basin and a right stand column arranged at the right bank and is located at the upriver of the safe basin. The left stand column and the right stand column are provided with a left pulley and a right pulley respectively. Steel wire rope arrays are arranged on the left pulley and the right pulley in a wound mode. The steel wire rope arrays cross the left bank and the right bank and form an angle of 45 degrees with the water flowing direction. A left winch used for lifting the left pulley along the left stand column and a right winch used for lifting the right pulley along the right pulley are further arranged. According to the winch-lifted automatic intercepting device for river floatage, the floatage or aquatic plants in a riverway can be automatically intercepted and removed. Cleaning conducted by a large amount of manpower and material resource is not needed, the floatage or the aquatic does not pile up, the cleaning period is shortened greatly, and secondary pollution can be avoided.

Owner:SHAOXING UNIVERSITY

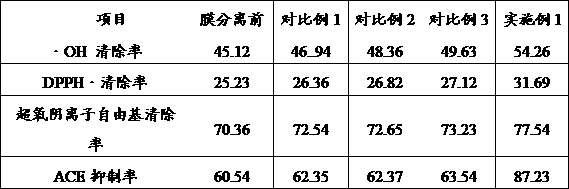

Preparation method of oyster peptide

ActiveCN110129397ASolve pollutionSolve the problem of membrane performance changes such as cloggingUltrafiltrationPeptide preparation methodsFiltration membraneSeparation technology

The invention discloses a preparation method of oyster peptide, belonging to the technical field of biological active components. The method comprises the following steps: (1) carrying out immersion treatment; (2) carrying out sterilization treatment; (3) carrying out enzymatic hydrolysis; (4) carrying out enzyme deactivation; (5) carrying out centrifugal separation; (6) adopting an ultrafiltration overfrequency vibration separation technology, wherein a chitin / graphene oxide / cellulose acetate composite membrane is adopted as a filtration membrane; (7) carrying out spray drying on filtrate obtained in the step (6), packaging and storing to obtain the oyster peptide. The preparation method of the oyster peptide has the beneficial effects that the chitin / graphene oxide / cellulose acetate composite membrane is prepared by using a special preparation method and is matched with the ultrafiltration overfrequency vibration separation technology for use, so that the separating efficiency and effect are improved, and the ACE inhibition activity and antioxidant activity of the oyster peptide are further improved.

Owner:YANTAI YUANLIDE MARINE ORGANISM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com