Laser cleaning method for oxidation layer of titanium alloy part of aero-engine

A technology of aero-engine and laser cleaning, applied in cleaning methods and appliances, chemical instruments and methods, laser welding equipment, etc., can solve problems such as negative effects, achieve the effects of reduced production costs, high adaptability, and the elimination of hydrogen embrittlement risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

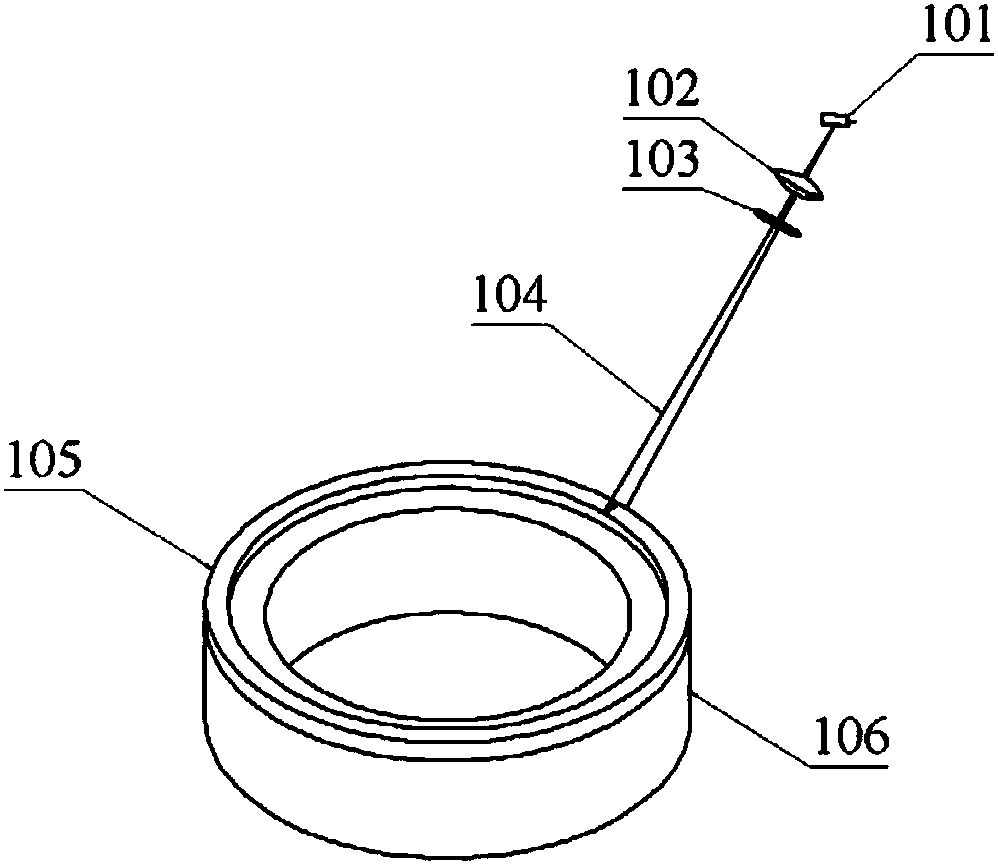

[0028] Such as figure 1 Shown, the laser cleaning method of the oxidized layer of the aero-engine titanium alloy ring part of the present invention comprises the following steps:

[0029] Step 1: Install the titanium alloy part 106 on the chuck of the rotary positioner, and control the distance between the scanning lens and the plane of the part to be cleaned through the mechanical arm, so that the focus of the laser is located near the oxide layer 105 to be cleaned, such as figure 1 shown;

[0030] Step 2: Select the laser cleaning parameters. The average output power of the pulsed laser is 100-250W, the laser wavelength is 1064nm, the pulse frequency is 10kHz, the minimum pulse width is 15ns, the line spot is 25mm, and the line of rotation of the surface of the part to be cleaned is cleaned. The speed is 12mm / s;

[0031] Step 3: Turn on the scanning galvanometer 101 and excite the laser. The laser beam passes through the scanning galvanometer 101 through the focusing lens ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com