Corrosion-prevention method for paper-making process reconstituted tobacco production white water system

A technology of reconstituted tobacco leaves and papermaking method, which is applied in the anticorrosion field of white water system for the production of reconstituted tobacco leaves by papermaking method, which can solve the problems of easily corroded equipment, reduce the number of white water cycles, non-compliance, etc., reduce operating costs, shorten cleaning cycles, and reduce ton consumption The effect of water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

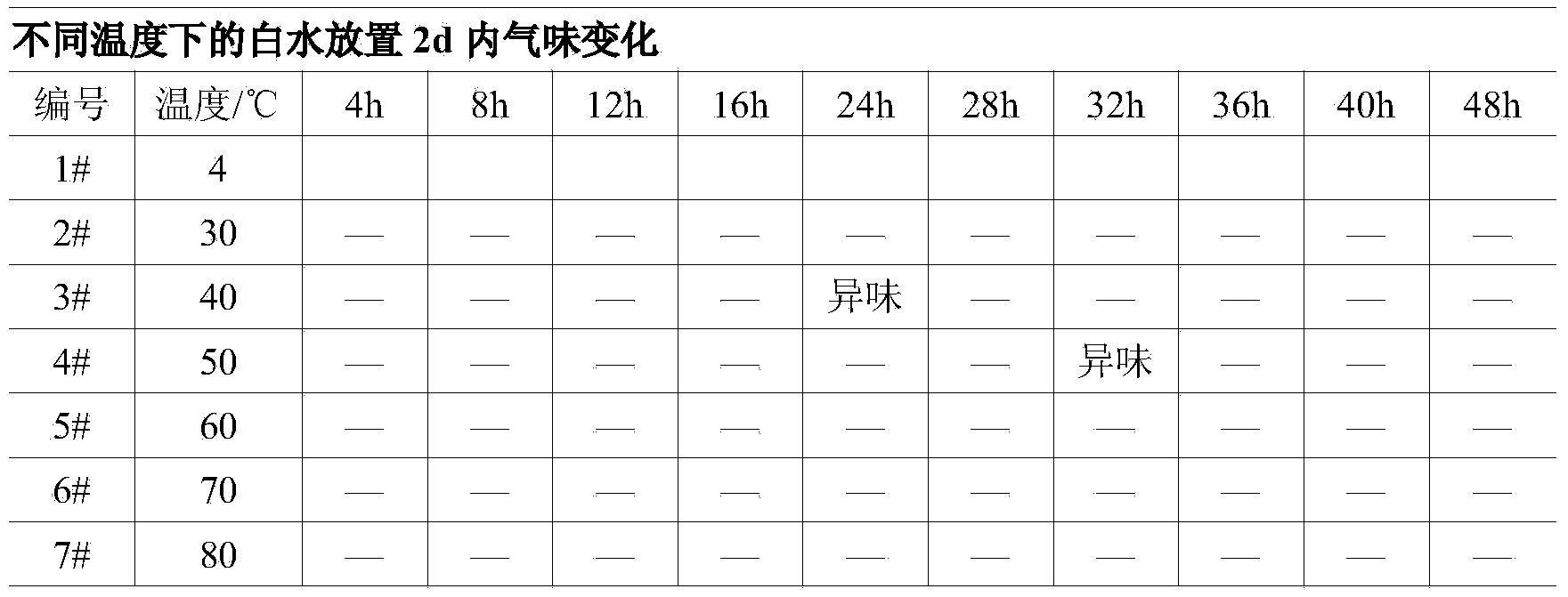

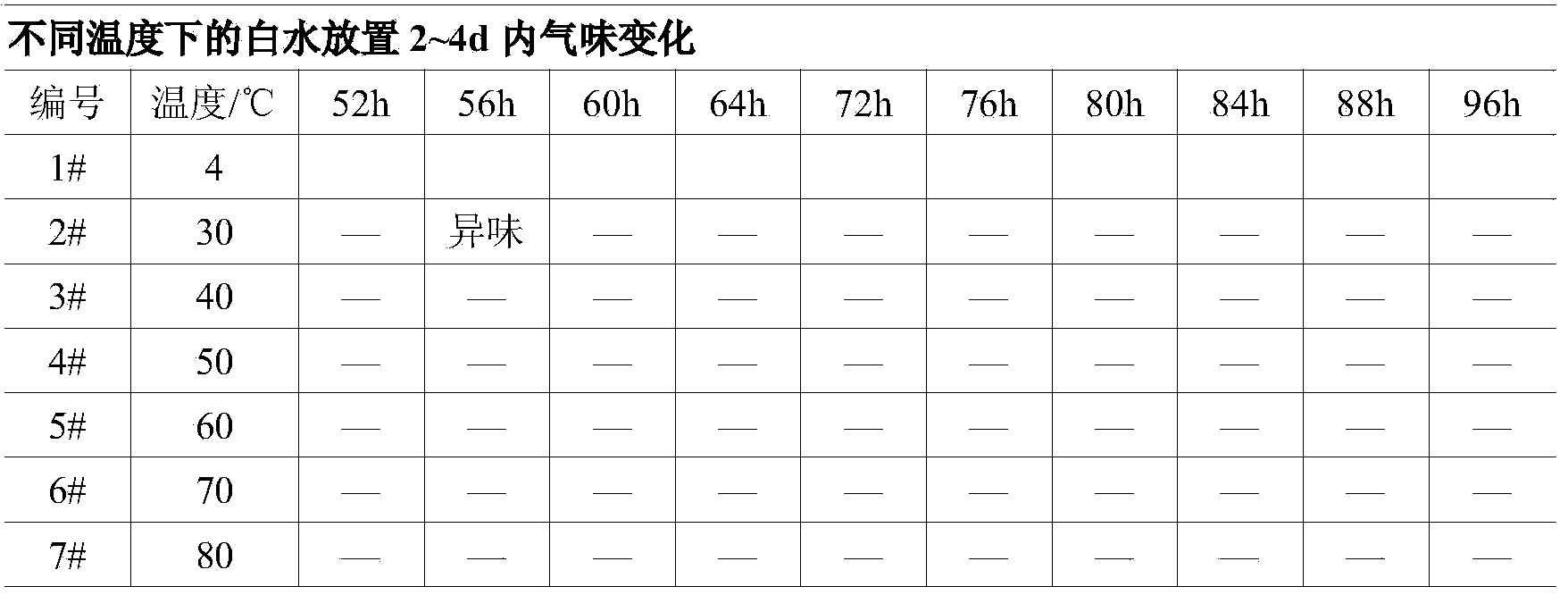

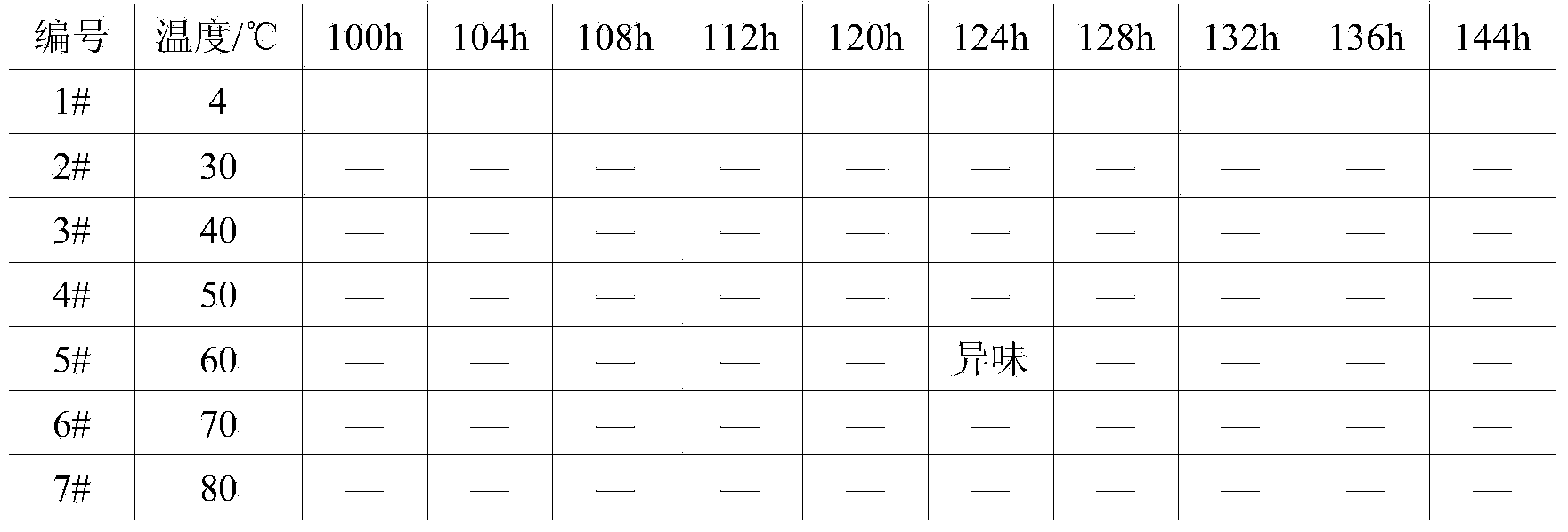

[0017] The white water of the reconstituted tobacco leaf production line by the papermaking method was taken, and the total number of colonies was determined to be 1.0E+07-1.0E+08 cfu / ml through detection. Divide the white water samples into 7 groups, 600mL in each group, and pour them into 7 1000mL sterilized beakers, numbered 1#, 2#, 3#, 4#, 5#, 6#, 7#. Group A was used as a control and placed in a refrigerator at 4°C. Put 2#, 3#, 4#, 5#, 6#, and 7# into the constant temperature magnetic stirrer, and set the temperature at 30°C, 40°C, 50°C, 60°C, 70°C, 80°C ℃, add the rotor (after scrubbing with 75wt% alcohol) and stir evenly. Every once in a while, take out the 1# group sample and compare the smell with the 2#, 3#, 4#, 5#, 6#, 7# group samples, and record whether the sample has deteriorated. After the 1# group sample completes the smell comparison Must be quickly placed in the refrigerator. The above 7 groups of samples were placed with their mouths open. If the water in...

Embodiment 2

[0026] Get the white water identical to embodiment 1, be divided into three parts, each 500ml. The first part is the original white water, and the second part is added with 1ml of diluted bacteriostatic agent (bacteriostatic agent dilution method: take 5ml of bacteriostatic agent with a pipette, add it to a 500ml volumetric flask, and use distilled water to make up the volume. The concentration of antibacterial agent in white water is 1%, that is, 10000ppm), and the concentration of antibacterial agent in white water is 20ppm at this time. In the third part of white water, add 2ml of the diluted bacteriostat, and the concentration of the bacteriostat in the white water is 40ppm. Place three white water samples on a shaker (120rpm, room temperature 20°C) for 4 hours and then take samples to detect the total number of colonies in them respectively. The results are shown in Table 2 below:

[0027] Table 2 The inhibitory effect of azole antibacterial agents on microorganisms

...

Embodiment 3

[0031] Take the same white water as in Example 1, and place it in a system environment with a temperature of 60° C., and add 40 ppm of bacteriostatic agent according to the concentration in Example 2. The critical value of the total number of white water metamorphic colonies is used as a node to investigate the time of white water storage in the system environment. The test results are shown in Table 3.

[0032] Table 3 Temperature bacteriostasis and antibacterial agent integration to investigate the deterioration of white water

[0033]

[0034] The investigation results show that the combination of temperature inhibition and antibacterial agent antibacterial method is used to treat the deterioration of white water in production. According to the critical value of the total number of white water deterioration colonies, the treated white water is recycled for more than 20 days, and the total number of colonies is not higher than 5.8. E+07, indicating that the white water d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com