Anti-pollution flat sheet membrane

A flat membrane, anti-pollution technology, applied in membrane technology, semi-permeable membrane separation, general water supply saving, etc., can solve problems such as limited effect, increased energy consumption, and reduced water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

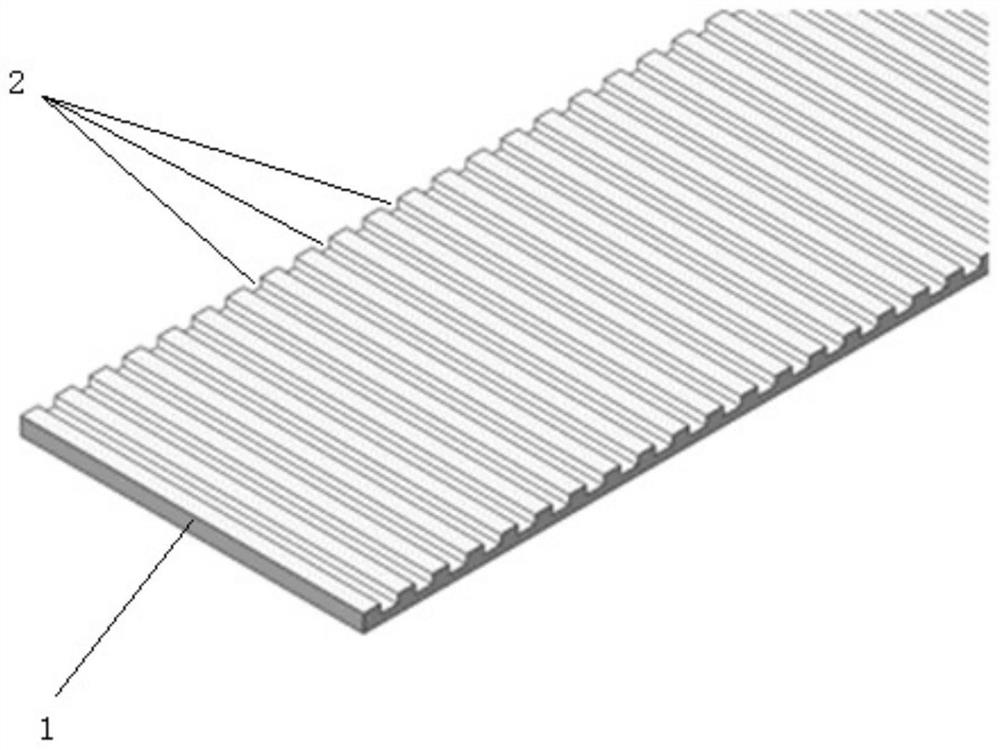

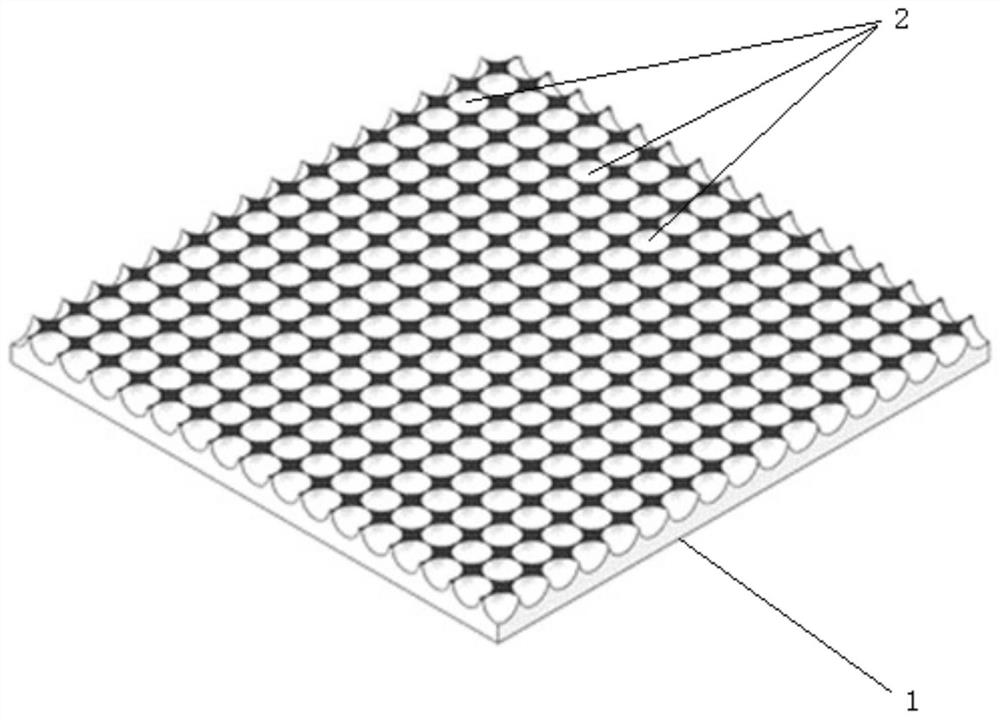

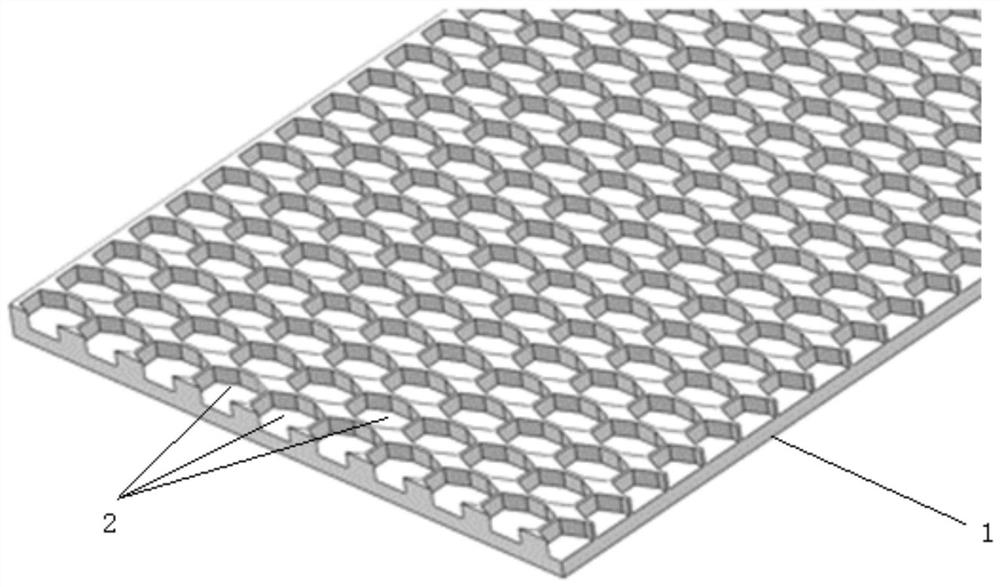

[0035] see Figures 1 to 5 , the present invention provides an anti-pollution flat membrane, comprising a plate-shaped membrane body 1;

[0036] The film body 1 has a plurality of recessed parts 2 with regular-shaped structural features, and the structure of the recessed part 2 includes any one or more of the following features: a strip-shaped groove structure; a dot-shaped recessed structure; a polygonal recessed structure; Among them, such as Figure 5 As shown, the extension direction of the cross section of the concave part 2 of the strip groove structure has an included angle θ with the water flow direction on the surface of the membrane body 1;

[0037] The area where the water flows along the surface of the membrane body 1 to the recessed part 2 is guided by the recessed part 2 to form a vortex.

[0038] The anti-pollution flat film provided by the present invention is subjected to physical or chemical treatment during the film-making process, so that the surface form...

Embodiment 2

[0048] In this example, the reverse osmosis membrane RO-1 with regular grooves on the surface and the reverse osmosis membrane RO-2 with irregular surface morphology were used to conduct a comparative experiment on the anti-fouling performance. The flux and salt rejection performance of the two membranes are the same, both are 38.7LMH, 96.8% (test conditions: 250ppm sodium chloride solution, 60psi). The groove width of the RO-1 diaphragm surface regular shape is 0.38mm, the groove depth h is 0.08mm, and the groove interval b is 0.4mm.

[0049] The anti-scaling test solution uses 787.67mg / L NaHCO 3 and 607.725mg / L CaCl 2 For the mixed solution, the operating condition is cross-flow filtration, the constant flux is 15LMH, and the membrane surface flow velocity is 0.027m / s. The direction of the regular groove of the RO-1 membrane and the cross-flow direction of the test solution are 90°. Inlet pressure changes as Figure 6 As shown, after 102 hours of operation, the inlet pres...

Embodiment 3

[0051] In this example, the nanofiltration membrane NF-1 with regular diamond-shaped depressions on the surface and the nanofiltration membrane NF-2 with irregular surface morphology were used to conduct a comparative experiment of anti-pollution performance. The flux and salt rejection performance of the two membranes are the same, both are 60.5LMH, 98.6% (test conditions: 2000ppm magnesium sulfate solution, 70psi). The surface of the NF-1 diaphragm has a regular shape with a diamond-shaped depression with a side length of 0.45mm, an acute angle of 60°, a depression depth h of 0.05mm, and an interval b of 0.1mm.

[0052] The anti-pollution test solution uses a mixed solution of 16mg / L fulvic acid, 416.3mg / L calcium chloride, 0.198mg / L aluminum chloride and 320mg / L sodium sulfate, and adjusts the pH to 7.8~8, so that there are organic and Inorganic composite pollution. The operating conditions are cross-flow filtration, constant flux 30LMH, and membrane surface flow velocity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com