3D reverse image printing method and apparatus

A printing head, curing reaction technology, applied in the field of manufacturing three-dimensional models, can solve problems such as harming the printing head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

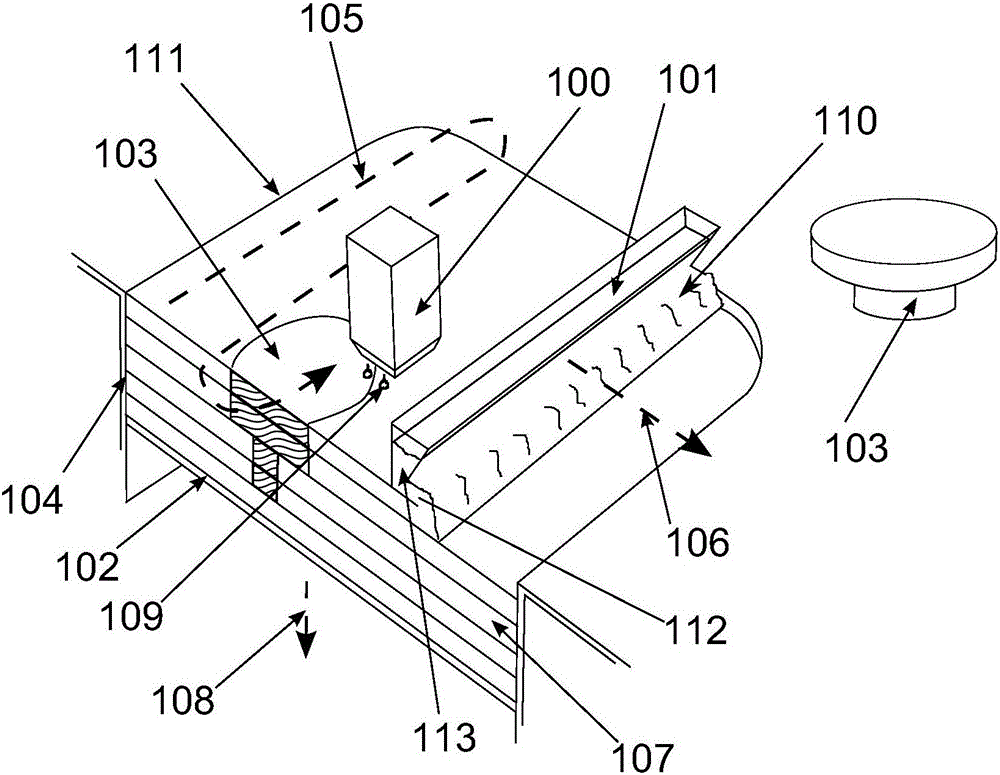

[0081] The system according to the invention makes heavy use of powder-based 3D printing. Extended mechanical engineering to meet the requirements according to the invention.

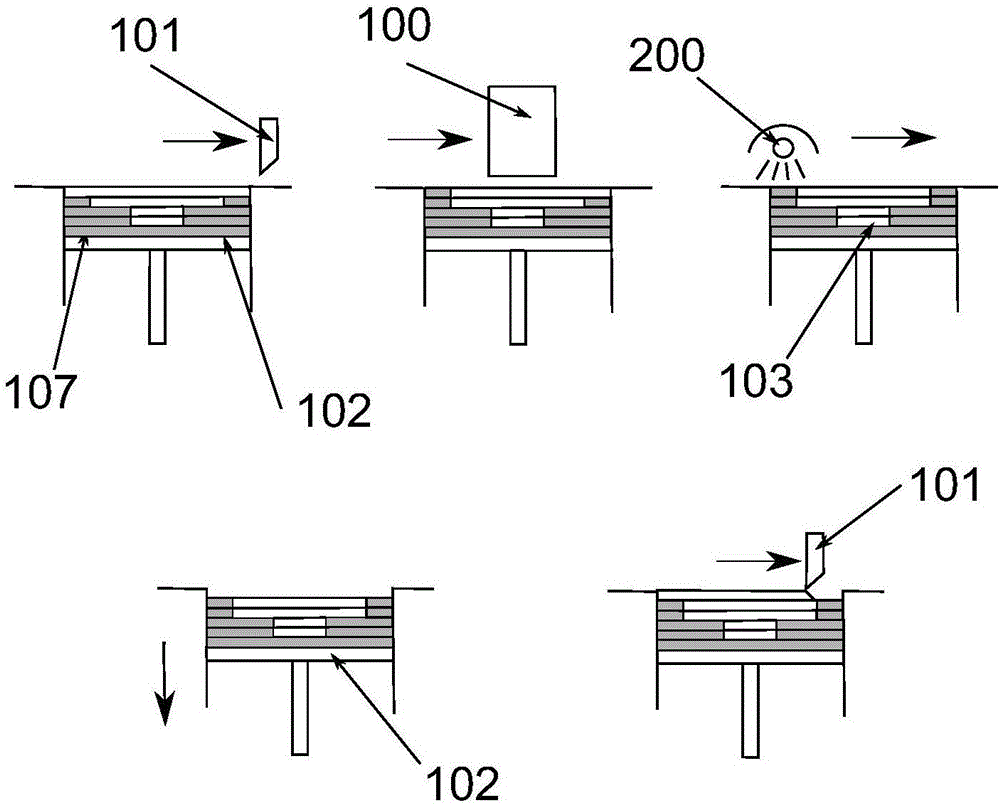

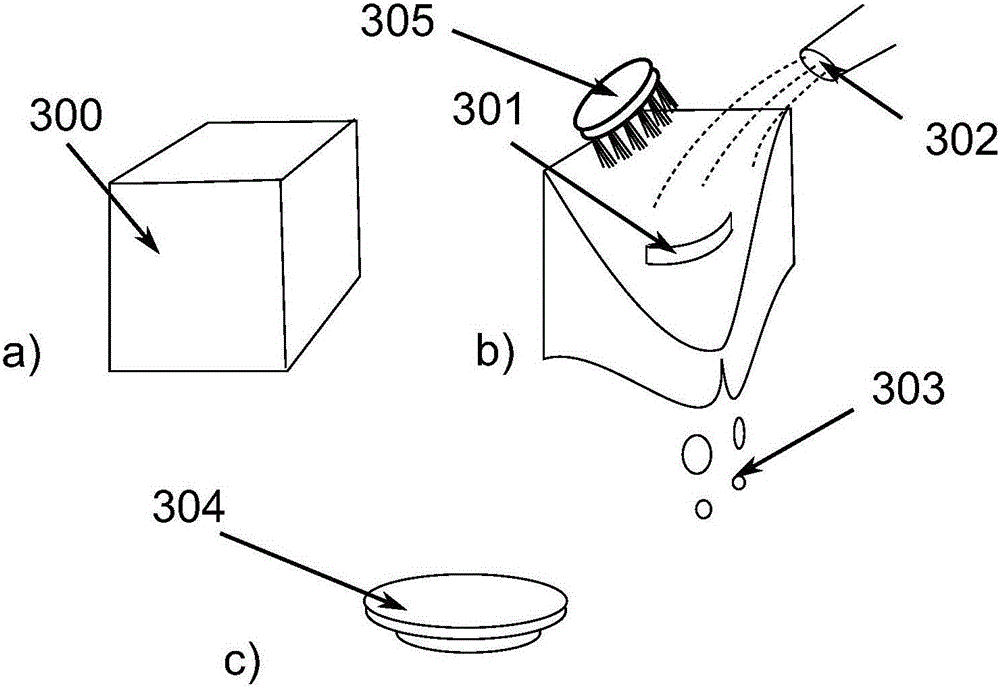

[0082] The device according to the invention comprises a coater (2). The applicator is used to apply pre-mixed granular material or liquid-containing granular material to the build platform (3) and smooth ( figure 2 (a)). The particulate material applied may comprise a wide range of materials. For example, sand, ceramic powder, metal powder, plastic, wood particles, fibrous material, cellulose, lactose powder, etc. may be used. The flow characteristics of these materials can be very different. Different applicator technologies allow layering from dry, free-flowing powders and sticky firm powders to liquid-based dispersions. The height of the powder layer (4) is determined by the build platform (3). It is lowered after applying a layer. During the next coating operation, the resulting volume is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com