Flame-retardant thermoplastic starch material, biocomposite material and preparation method thereof

A thermoplastic starch and flame retardant technology, used in the field of flame retardant thermoplastic starch, can solve the problems of flame retardants such as high temperature resistance, poor processability, and inability to form, and achieve increased toughness, excellent mechanical properties and flame retardant properties. , the effect of improving the overall physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

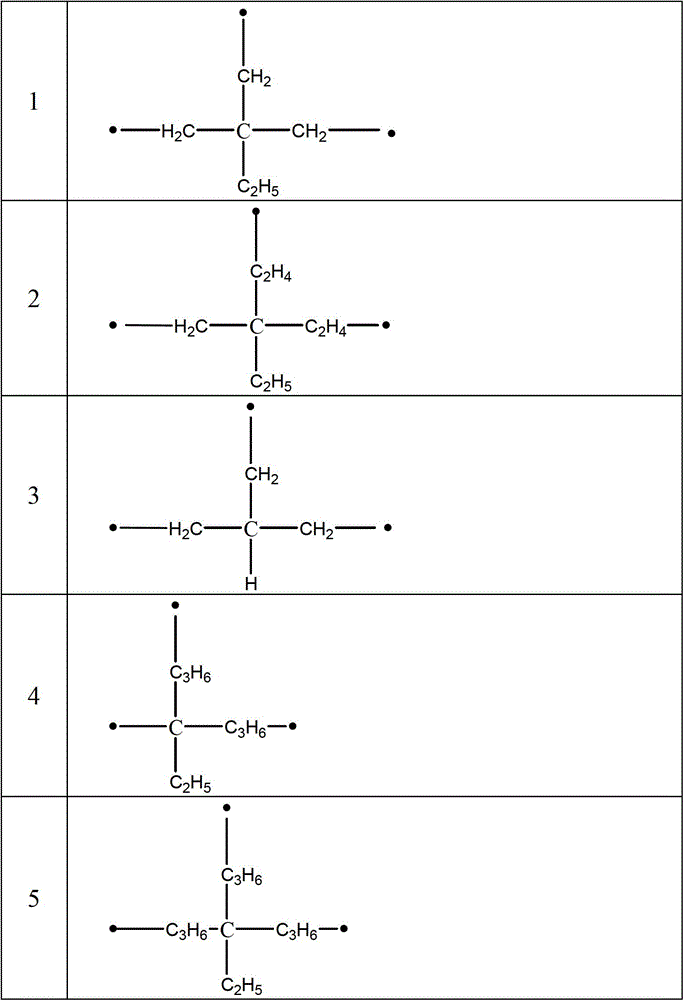

[0031] The present invention provides a method for preparing a flame-retardant thermoplastic starch-based biocomposite. According to the method of the present invention, (A1) 100 parts by weight of starch, (A2) 5 to 75 parts by weight of plasticizer, and ( A3) 5-30 parts by weight of the organic phosphorus flame retardant are mixed and kneaded and plasticized at 60-100°C, preferably 70-90°C, to form a flame-retardant thermoplastic starch material (A).

[0032] Next, mix (A) 5-40 parts by weight of the above-mentioned flame-retardant thermoplastic starch material, (B) 60-90 parts by weight of a thermoplastic polymer, and (C) 3-10 parts by weight of a toughening agent in 170-260 A mixing process is carried out at a temperature of 190-240°C, to form a flame-retardant thermoplastic starch-based biomass composite.

[0033] The flame-retardant thermoplastic starch-based biocomposite material of the present invention comprises: (A) 5-40 parts by weight of flame-retardant thermoplastic sta...

Embodiment 1~17

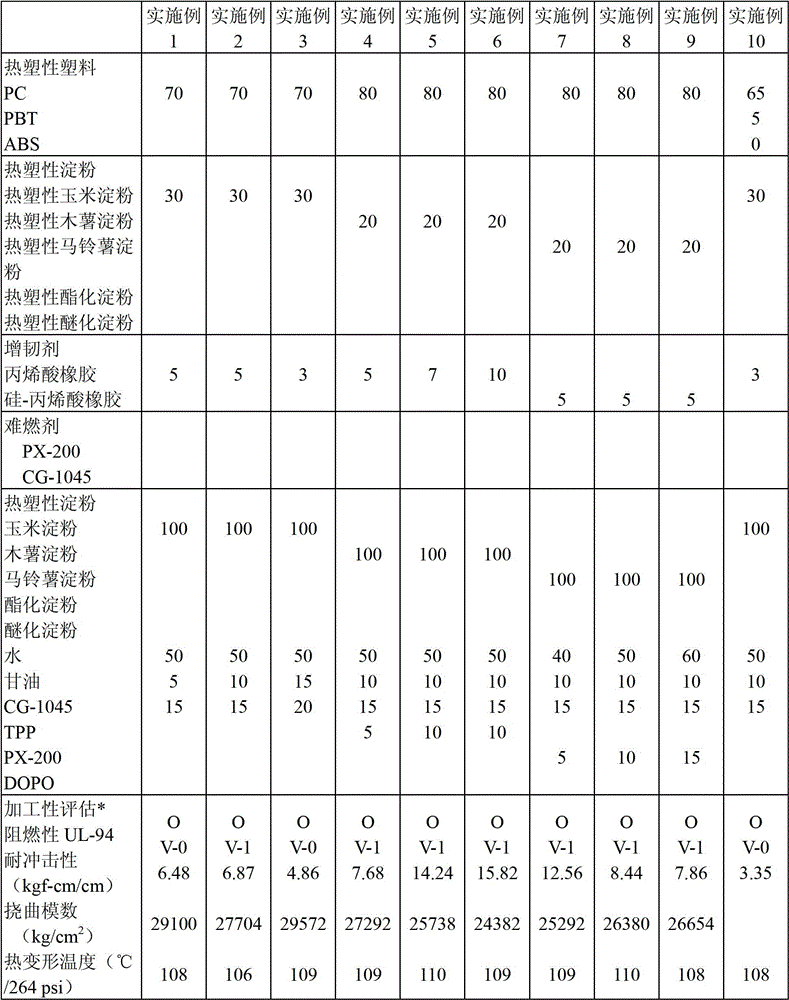

[0040] The preparation methods of the flame-retardant thermoplastic starch-based biocomposite materials of Examples 1-17 are as follows, wherein the composition of each material and the detailed addition ratio are shown in Table 2 and Table 3.

[0041] Combine 100 parts by weight of starch, 30 to 70 parts by weight of water, 5 to 30 parts by weight of glycerin, and 5 to 30 parts by weight of flame retardants, including organic phosphorus flame retardants (Chemguard-1045, ORGANIC PHOSPHONATE, constant Bridge Industry Co., Ltd., Chembridge International Corp.), triphenyl phosphate (TPP), phosphate-based flame retardants (Resorcinol bis(dixylenyl phosphate), PX- 200), or the above-mentioned combination, mix according to the ratio shown in Table 2 and Table 3;

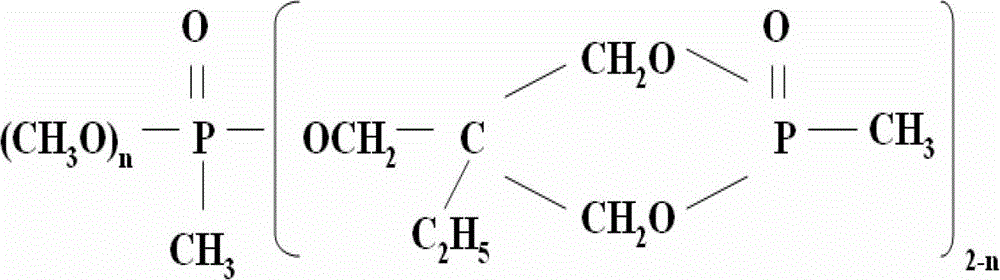

[0042] Chemguard-1045 (CG-1045)

[0043]

[0044] Where n is 1.

[0045] Then, the above-mentioned mixed materials are put into a kneader for plasticization at 60-100°C and a kneading time of 30-80 minutes, and then granulated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com