Composition and shaped body

A composition and compound technology, applied in the direction of wax adhesive, adhesive type, adhesive additive, etc., can solve the problems of reduced productivity, hopper blockage, etc., and achieve improved productivity, good formability, and formed appearance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

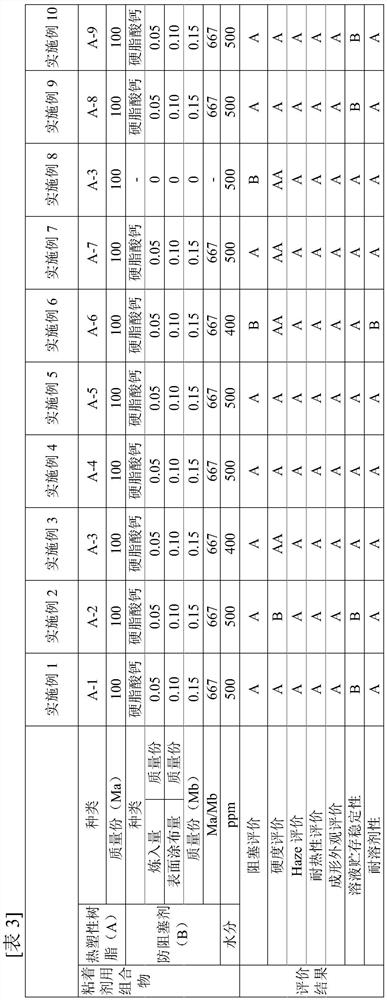

Examples

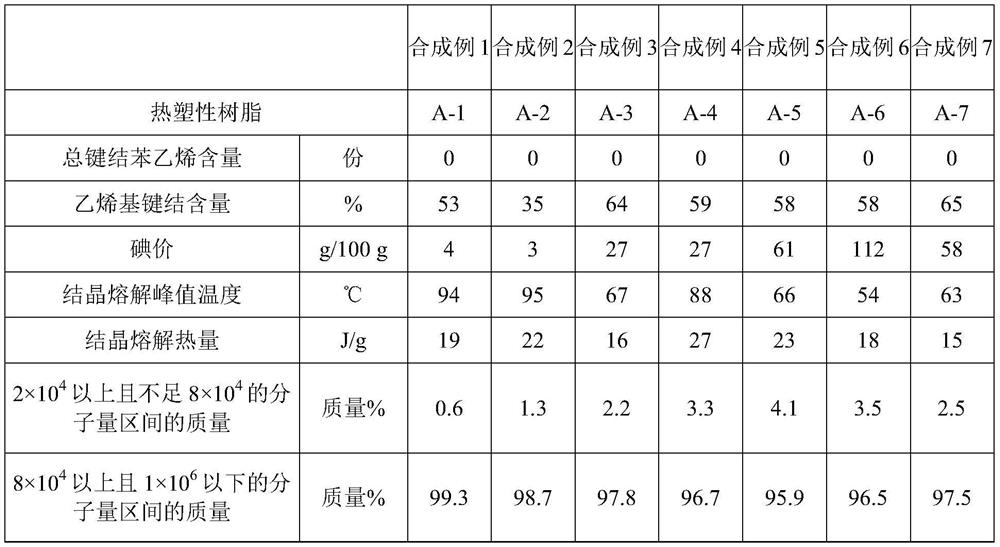

Synthetic example 1

[0114]Put 800 parts of degassed and dehydrated cyclohexane, 20 parts of 1,3-butadiene and 0.03 parts of tetrahydrofuran into a reaction vessel replaced by nitrogen, and add n-butyllithium at the polymerization initiation temperature of 70°C 0.09 parts, for temperature-rising polymerization. After the polymerization conversion rate reached 99% or more, the reaction solution was cooled to 25° C. to prepare a polymer before hydrogenation. Then, 80 parts of 1,3-butadiene and 5 parts of tetrahydrofuran were added, and temperature-rising polymerization was further performed. After the polymerization conversion rate reached 99% or more, 0.06 part of dichloromethylsilane was added, and the temperature-rising polymerization was further performed. Then, 0.04 parts of diethylaluminum chloride and 0.06 parts of bis(cyclopentadienyl)furfuryloxytitanium chloride were put into the reaction container and stirred. The hydrogenation reaction was started at a hydrogen supply pressure of 0.7 MP...

Synthetic example 2

[0116] Put 800 parts of degassed and dehydrated cyclohexane, 20 parts of 1,3-butadiene and 0.03 parts of tetrahydrofuran into a reaction vessel replaced by nitrogen, and add n-butyllithium at the polymerization initiation temperature of 70°C 0.09 parts, for temperature-rising polymerization. After the polymerization conversion rate reached 99% or more, the reaction liquid was cooled to 45° C., 80 parts of 1,3-butadiene and 1 part of tetrahydrofuran were added, and then temperature-rising polymerization was carried out. After the polymerization conversion rate reached 99% or more, 0.06 part of dichloromethylsilane was added, and the temperature-rising polymerization was further performed. Then, 0.04 parts of diethylaluminum chloride and 0.06 parts of bis(cyclopentadienyl)furfuryloxytitanium chloride were put into the reaction container and stirred. Then, a hydrogenation reaction was performed in the same manner as in Synthesis Example 1 to obtain thermoplastic resin A-2.

Synthetic example 3

[0118] The thermoplastic resin A-3 was obtained by the method similar to the synthesis example 1 except having made hydrogenation reaction time into 2 hours.

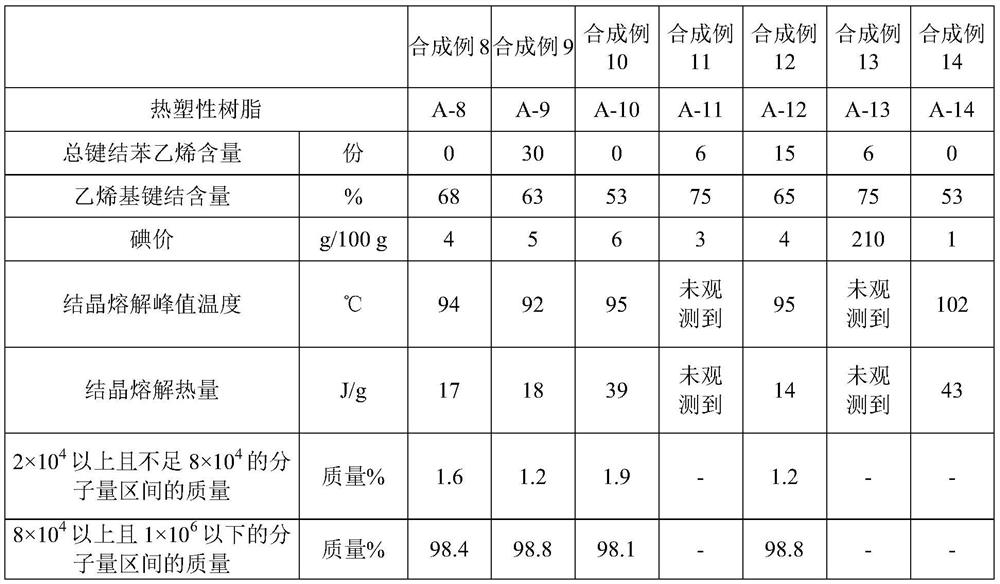

[0119] 3.1.4. Synthesis Example 4, Synthesis Example 5, Synthesis Example 6

[0120] Except having changed the hydrogenation reaction time to 2 hours, 1 hour, and 40 minutes, respectively, thermoplastic resin A-4, thermoplastic resin A-5, and thermoplastic resin A-6 were obtained by the method similar to synthesis example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com