Marine hydraulic pipeline cleaning-oil online cleaning method

A hydraulic pipeline and pipeline cleaning technology, which is applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., can solve the problems of extended delivery cycle of shipyards, waste of hydraulic oil, and long detection cycle, etc., to achieve The effect of shortening the cleaning cycle, avoiding detection errors, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

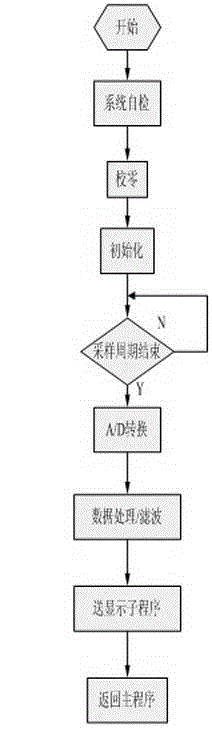

[0014] In the present invention, the online cleaning method of marine hydraulic pipeline cleaning oil is as follows: figure 1 , as shown in 2,

[0015] At first the sampling point is set, and in the present invention, the sampling point is set before the entrance of the pipeline cleaning pump station on the main oil circuit 1 of the ship pipeline; a detachable transparent sampling bypass is set at the sampling point, and the transparent sampling bypass The two ends of the tank are respectively connected to the main oil circuit, and a capacitive sensor module and a photoelectric sensor module connected to the signal processing system are arranged on the transparent sampling bypass.

[0016] As a more specific implementation of the present invention:

[0017] Signal processing system 12 adopts AT89C2051 single-chip microcomputer, and forms signal processing system with peripheral interface circuit MAX1109 type A / D converter, serial port and peripheral chip 74LS164.

[0018] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com