Method for cleaning filter bag for cloth-bag or electric-bag dust collector

A dust collector and filter bag technology, which is applied in the cleaning field of filter bags for cloth bags or electric bag dust collectors, can solve the problems affecting the service life of filter bags, the stable operation of dust collectors, the increase of dust removal resistance/pressure difference of filter bags, and the surface area of filter bags. Too much dust and other problems, to shorten the cleaning cycle, reduce energy consumption, and restore the effect of air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A cleaning method for a filter bag for a cloth bag or electric bag dust collector, which includes the following steps:

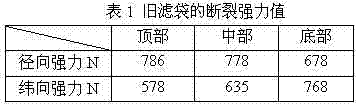

[0017] ① Intercept the old filter bag of suitable size for breaking strength test (test method adopts GB / T3923.1-1997), the results are shown in Table 1. From Table 1, it can be seen that the radial and weft breaking strength are not less than 400N, then You can proceed to the next test step.

[0018]

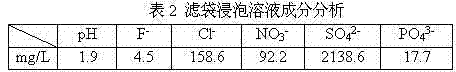

[0019] ②Intercept 100cm 2 The sample of the above-mentioned filter bag was cleaned by the vacuum cleaner until there was no obvious dust on the surface, and then soaked in 250ml of water to determine the pH value and ion concentration of the soaking solution (the ion concentration was measured by plasma emission spectrometer-ICP). The results are shown in Table 2. According to the analysis result, except for Cl - In addition, if all other components are outside the specified range, it is determined that the filter bag needs to be cleaned. The filter bag so...

Embodiment 2

[0025] A cleaning method for a filter bag for a cloth bag or electric bag dust collector, which includes the following steps:

[0026] ①Take an old filter bag of appropriate size for breaking strength test (testing method adopts GB / T3923.1-1997), the results are shown in Table 4. From Table 4, it can be seen that the radial and weft breaking strength are not less than 400N, then You can proceed to the next test step.

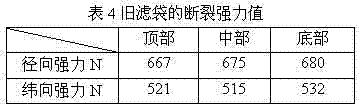

[0027]

[0028] ②Intercept 50cm 2 After cleaning the dust of the above filter bag sample, the vacuum cleaner is soaked in 125ml of water, and the pH value and ion concentration of the soaking solution are measured (the ion concentration is measured by plasma emission spectrometer-ICP). The results are shown in Table 5. According to the analysis result, except for Cl - In addition, if all other components are outside the specified range, it is determined that the filter bag needs to be cleaned. The pH of the filter bag soaking liquid is slightly less than 5.5, and li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com