Patents

Literature

31results about How to "Reduce chemical corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

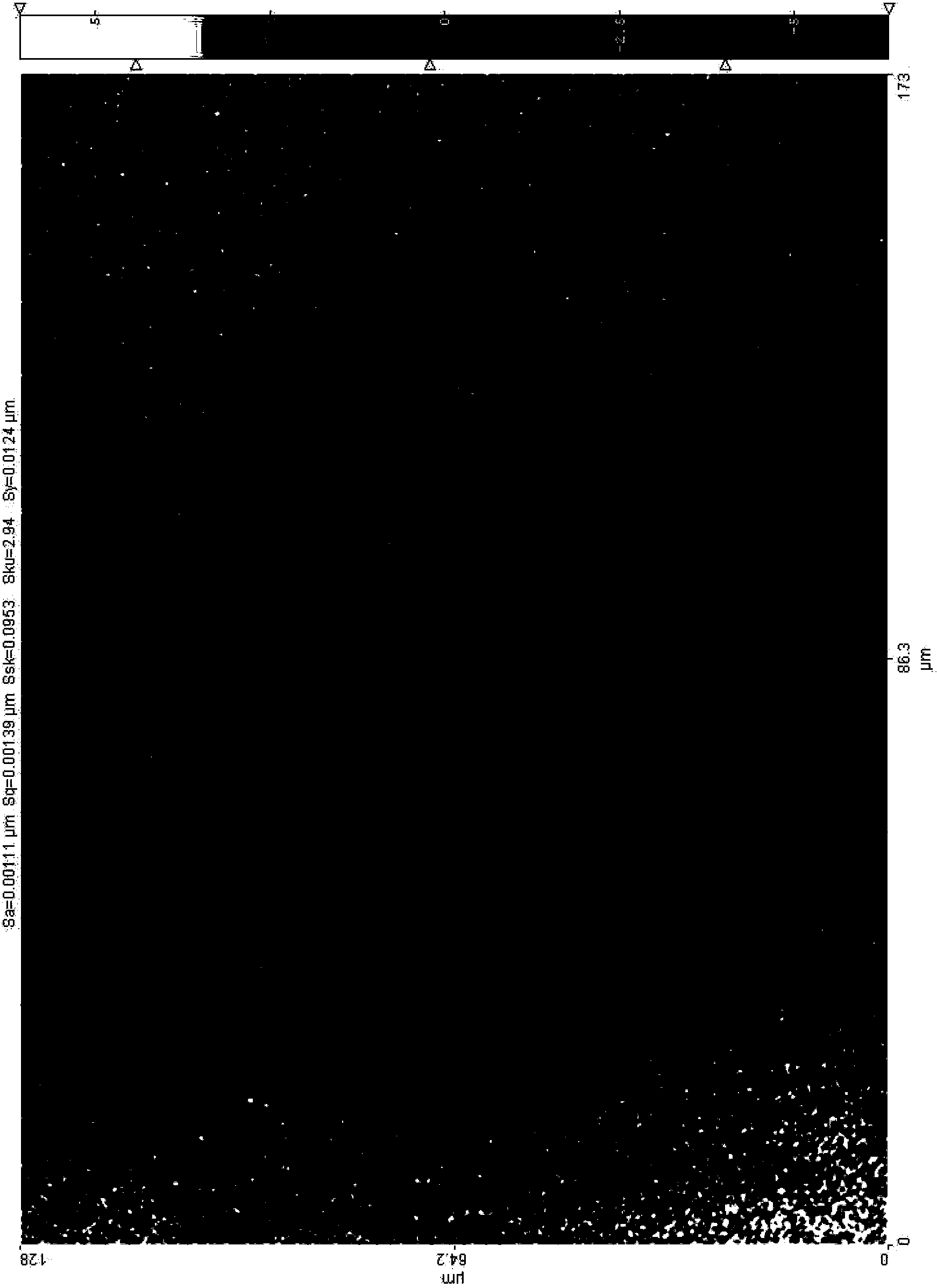

Barium titanate chemico-mechanical polishing aqueous composition and its application

ActiveCN102786879AImprove removal rateReduce concentrationPolishing machinesPolishing compositions with abrasivesBarium titanateSorbent

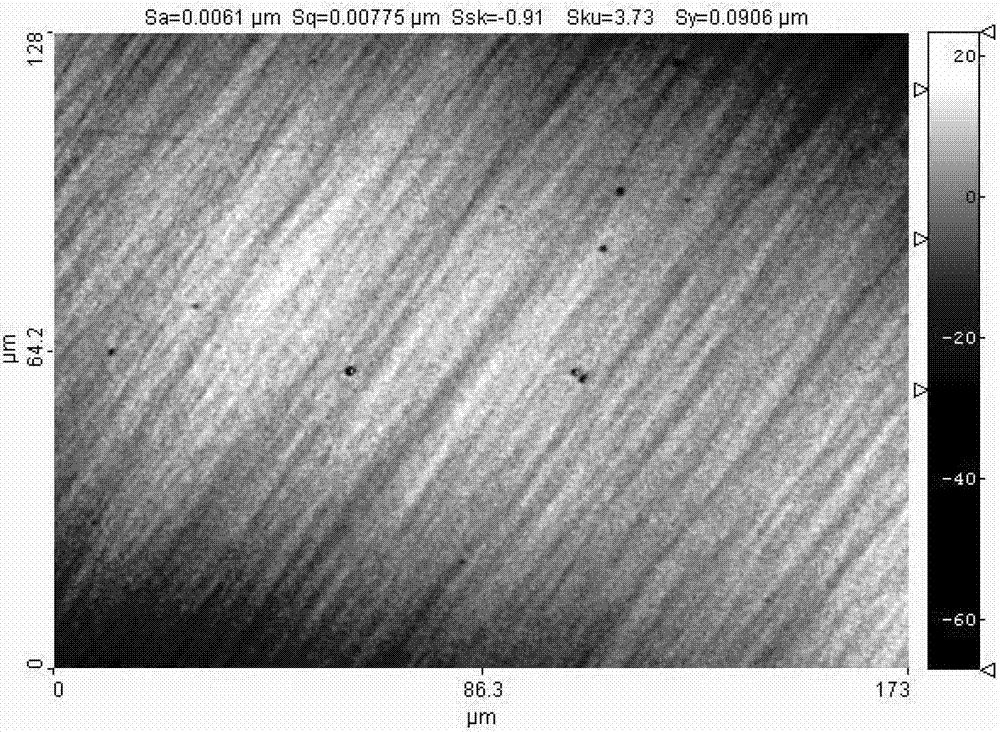

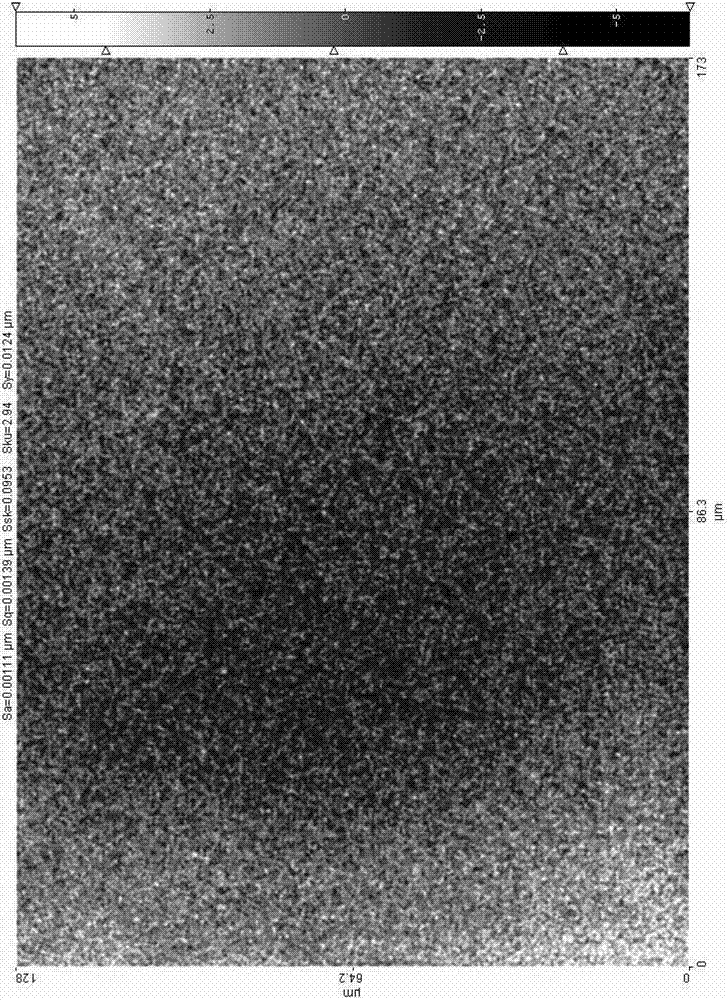

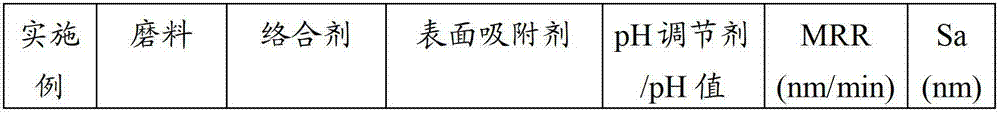

The invention relates to a barium titanate chemico-mechanical polishing aqueous composition and its application. Specifically, the barium titanate chemico-mechanical polishing aqueous composition comprises: 1-20 wt%, preferably 8-15 wt% of an abrasive; 0.5-10 wt%, preferably 1-3 wt% of a complexing agent; and 0.01-5 wt%, preferably 0.1-1 wt% of a surface adsorbent, wherein the barium titanate chemico-mechanical polishing aqueous composition has a pH value of 8.0-12.0, preferably 10.0-11.5. The barium titanate chemico-mechanical polishing aqueous composition provided in the invention can be effectively applied to a barium titanate substrate chemico-mechanical polishing process, thereby being able to effectively obtain a polished barium titanate layer with a high polishing rate and high surface quality.

Owner:TSINGHUA UNIV

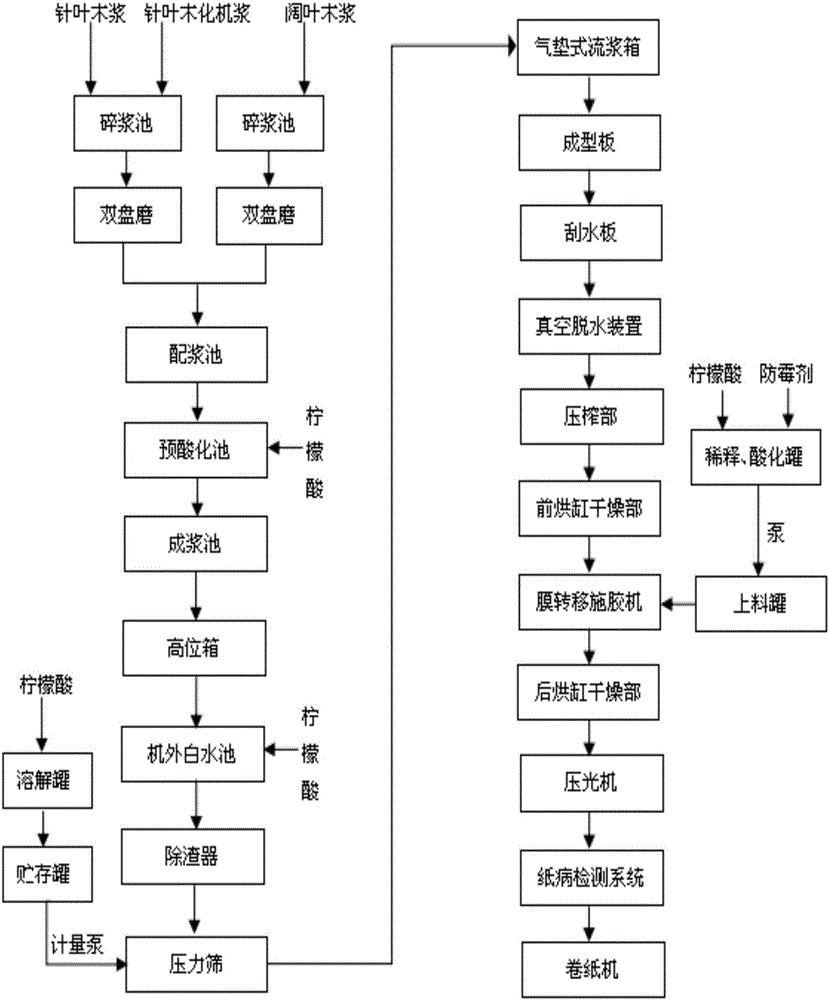

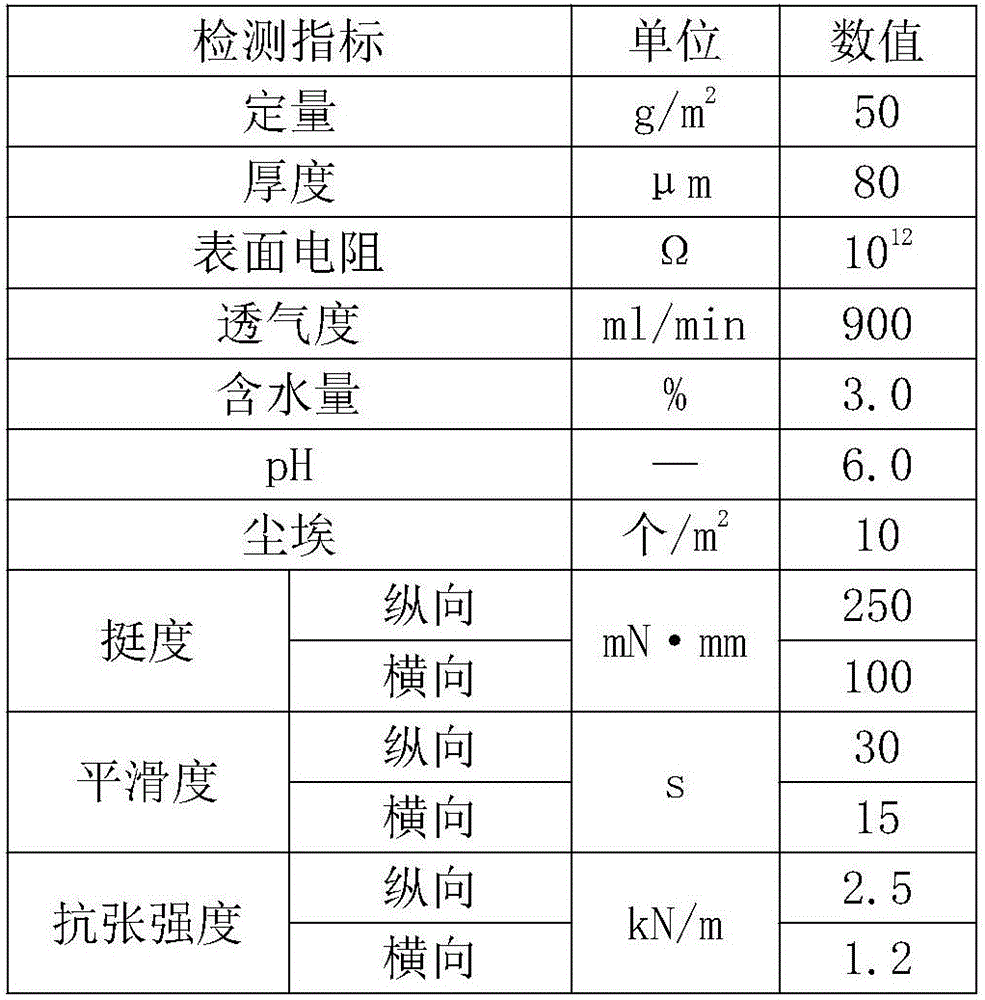

Mildew-proof and anti-bacterium liquid crystal electronic glass partition paper and production technology thereof

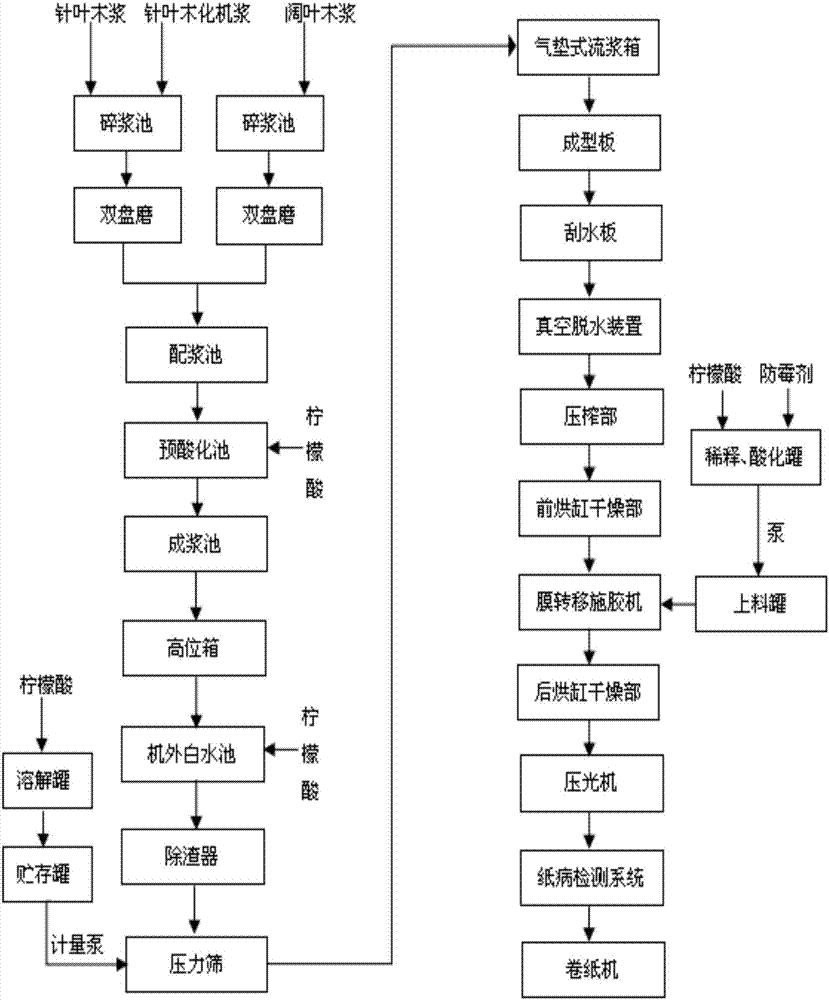

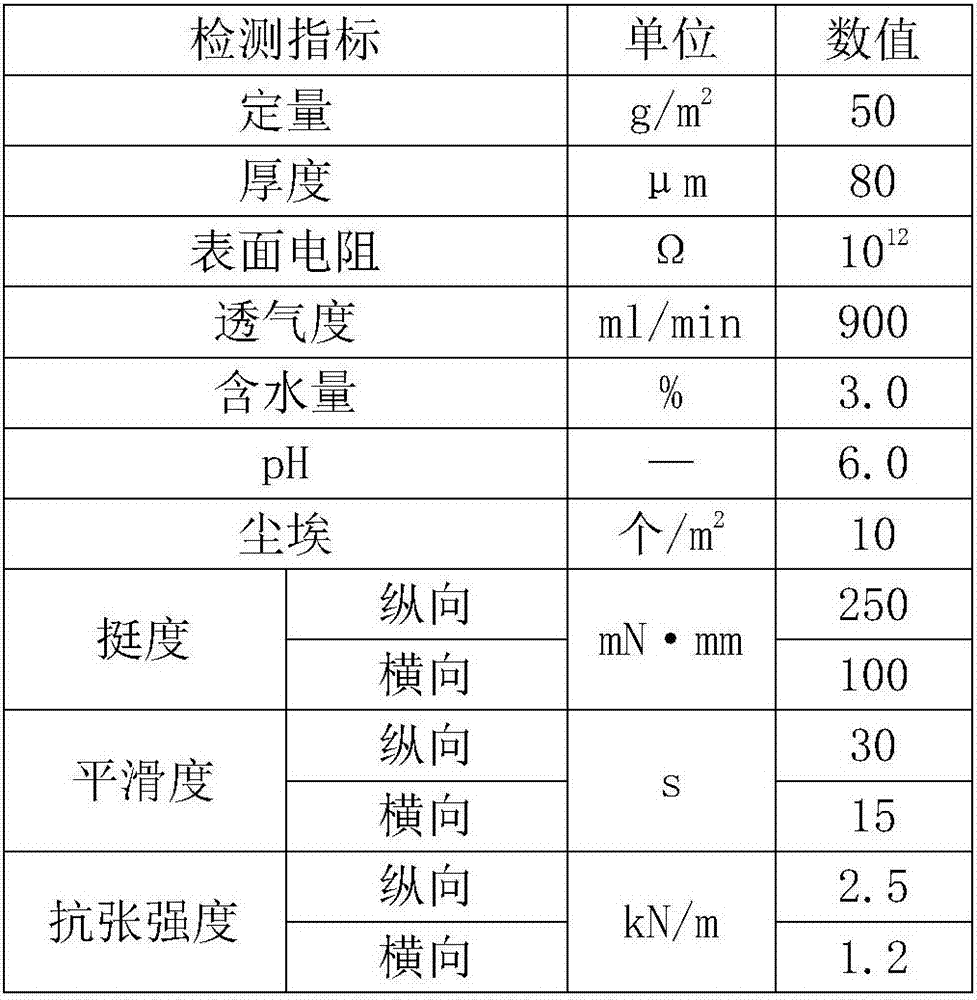

The invention discloses mildew-proof and anti-bacterium liquid crystal electronic glass partition paper and a production technology thereof. Pulp of the partition paper comprises 50% to 70% of original coniferous wood pulp, 10% to 30% of original hardwood pulp and 10% to 20% of coniferous wood chemithermomechanical pulp, wherein the coniferous wood pulp and the coniferous wood chemithermomechanical pulp are pulped in a mixed mode, and the beating degree is 25 degreeSR to 30 degreeSR; the hardwood pulp is independently pulped, the beating degree is 20 degreeSR to 25 degreeSR, the fixed quantity is 30 g / m<2> to 60 g / m<2>, the pH value is 4.5 to 6.5, the moisture content is 1.0% to 4.0%, the surface resistance is larger than or equal to 1,010 omega, and air permeability is larger than or equal to 500 ml / min. The faintly-acid mildew-proof and anti-bacterium liquid crystal electronic glass partition and packaging paper high in stiffness, mechanical strength and air permeability is prepared in combination with various measures, and the paper has the certain separation and protection effects in the storage process and the transportation process of electronic glass, and meanwhile has the mildew-proof function and the moistureproof function.

Owner:YINGGE PULPING & PAPER MAKING LUOHE CITY

Polishing solution for magnesium alloy

The invention provides a polishing solution applied to the magnesium alloy. The polishing solution comprises an abrasive, a strong oxidant, a pH regulator and deionized water; the components are as follows by weight percentage: 10 percent to 40 percent of the abrasive I, 0.1 percent to 3 percent of the strong oxidant, 1 percent to 10 percent of the pH regulator and the balance is deionized water. The polishing solution can be used for polishing treatment of magnesium-alloy surface, effectively improve surface finish of the magnesium alloy, effectively reduce surface scratch after polishing, and reduce surface roughness after polishing; simultaneously, polishing debris is dissolved in the polishing solution, the magnesium-alloy surface is easy to be cleaned, the polishing speed is rapid, the polishing solution has no harm to equipment, and the usage security is high.

Owner:JIANGSU HAIXUN IND GROUP SHARE

High lead-antimony slag type for anode slime smelting process and its use method

ActiveCN101403040AReduce chemical corrosionReduce the amount of dilutionProcess efficiency improvementSmelting processPrecious metal

The invention relates to a high lead-antimony slag type which is used for smelting technique of anode mud and is used by the anode mud in the process of reduction smelting of an oxygen bottom blowing bullion lead furnace in the technique that an oxygen bottom blowing furnace smelts the anode mud and a using method, belonging to the scope of separation and extraction of precious metal and base metal; a formula thereof is the high lead-antimony slag type with low silicon, low calcium and low sodium; all the materials comprises the following ingredients according to mass ratio: 5 to 22 percent of SiO2, 1 to 8 percent of FeO, 0 to 6 percent of Na2O, 0 to 5 percent of CaO, 10 to 35 percent of PbO and 150 to 45 percent of Sb2O3, wherein, the control range of the mass ratio of the PbO and SiO2 is 1.50 to 6.0. The formula not only has good effect for prolonging the service life of a refractory material and improving the continuous operation rate and processing capacity of the bullion lead, but also leads the reduction and volatilization of arsenic and antimony and oxidation and slag formation of lead to be realized simultaneously, reduces the usage of flux and consumption of fuel and effectively separates the valuable metals.

Owner:HENAN YUGUANG GOLD & LEAD

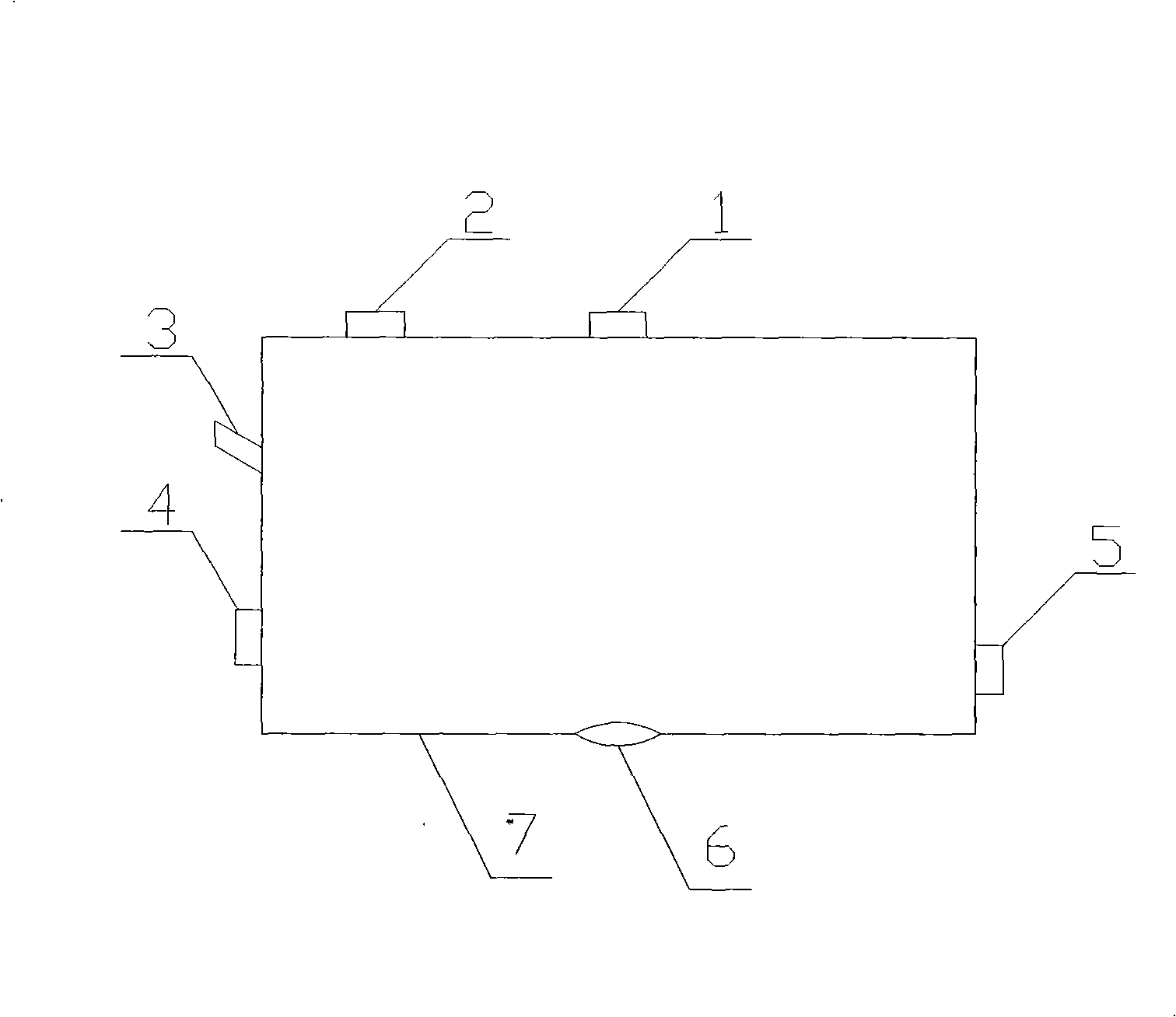

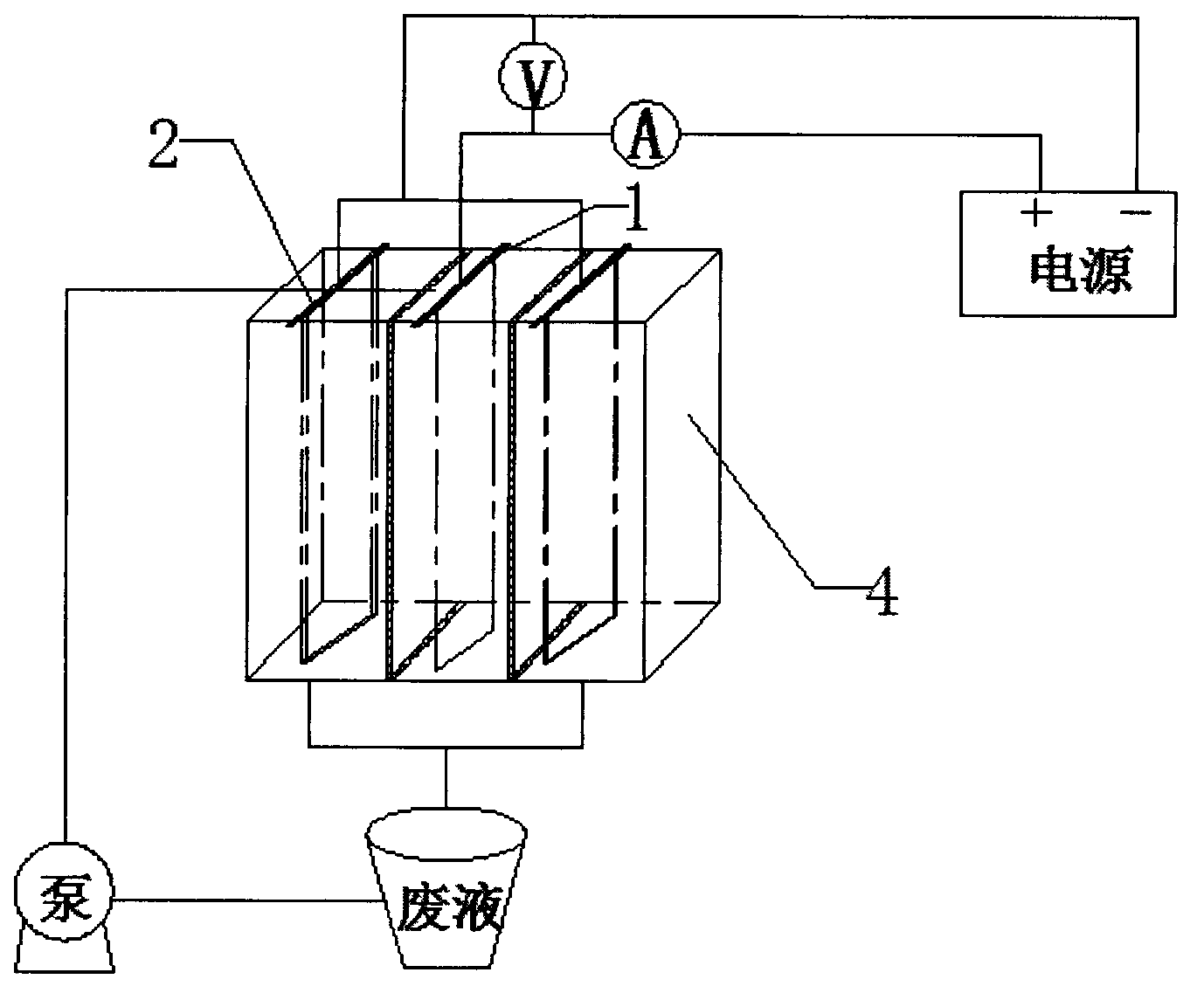

Electrochemical gold dissolving device and method

InactiveCN104294313AReduce pollutionSave the nitrate processPhotography auxillary processesDiaphragmsIridiumElectrochemical dissolution

The invention discloses an electrochemical gold dissolving device and method. An ion exchange membrane electrolytic process is taken as a core technology, the electrochemical gold dissolving method adopting double membranes and double cathode rooms is adopted, a ruthenium iridium titanium-coated basket is taken as an anode, a ruthenium iridium titanium-coated net is taken as a cathode, hydrochloric acid is taken as electrolyte and aqua regia is not used, so that a nitrate removing process is cancelled, process flow is greatly simplified, chemical corrosion on equipment is reduced and environmental pollution is lowered. Besides, an ion exchange membrane is adopted, so that gold dissolved out on the anode can be prevented from entering the cathode region and separating out again on the cathode, and thus, the production efficiency is improved, the energy conservation and emission reduction of production are realized, and great economic benefits and social benefits can be produced.

Owner:CHANGZHOU YIJIN ENVIRONMENTAL PROTECTION TECH

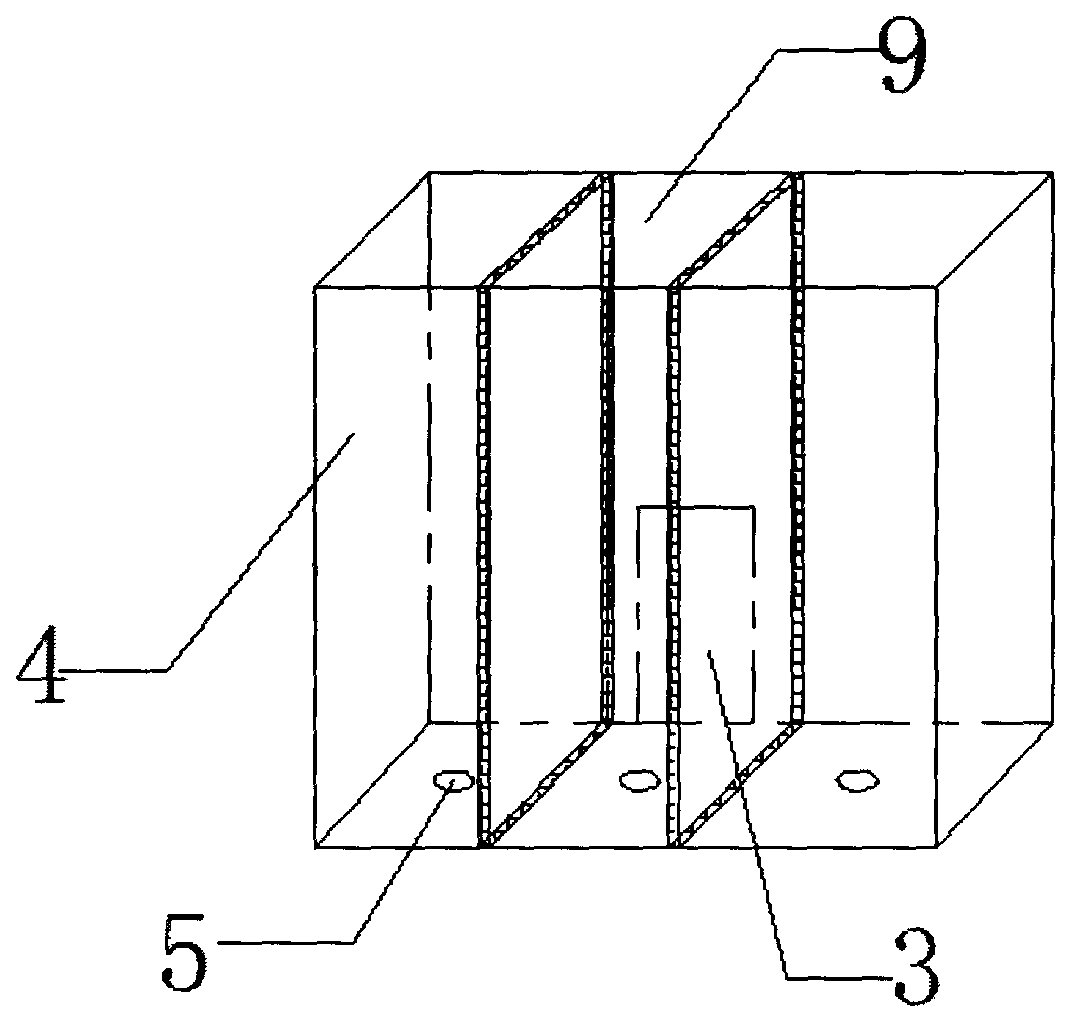

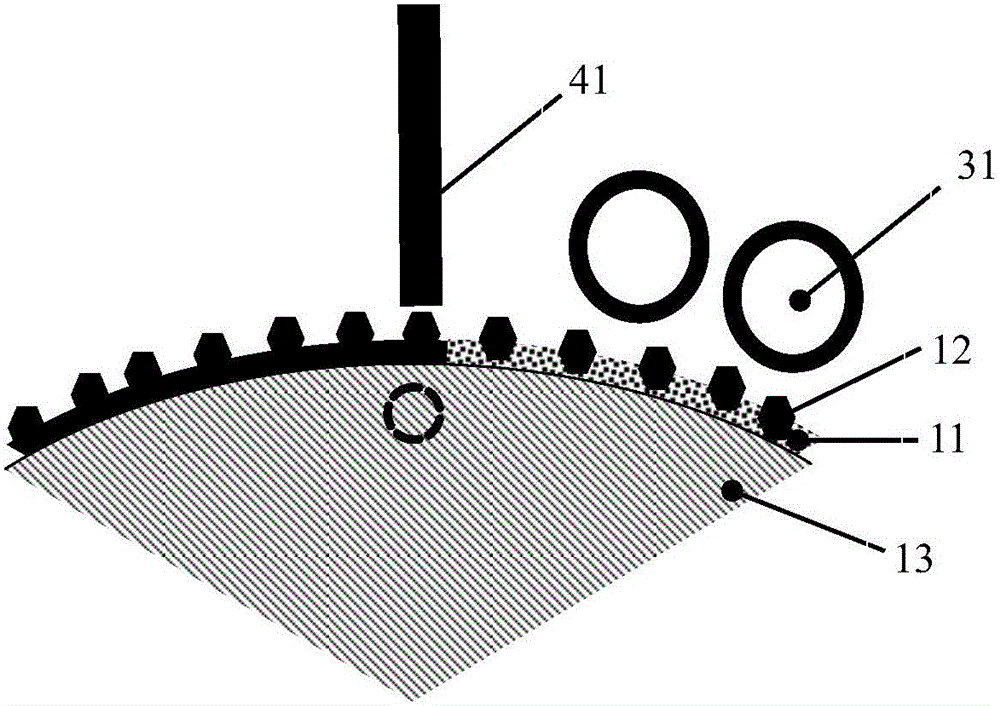

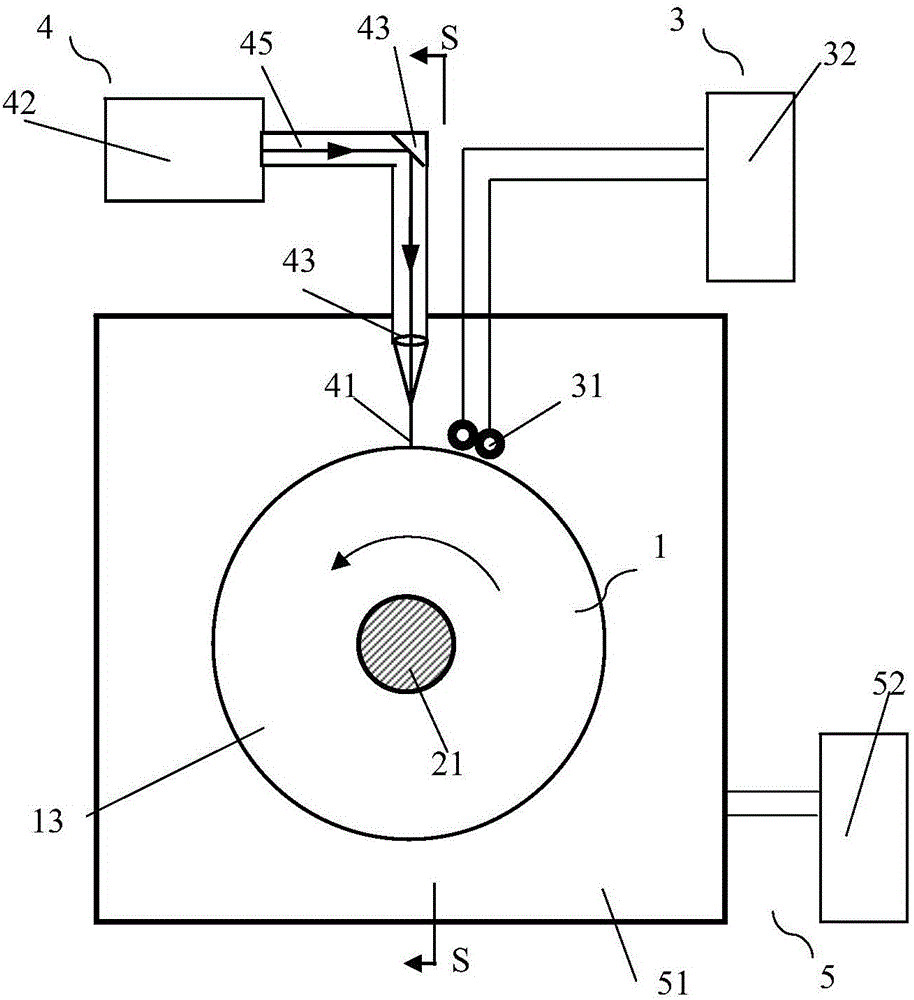

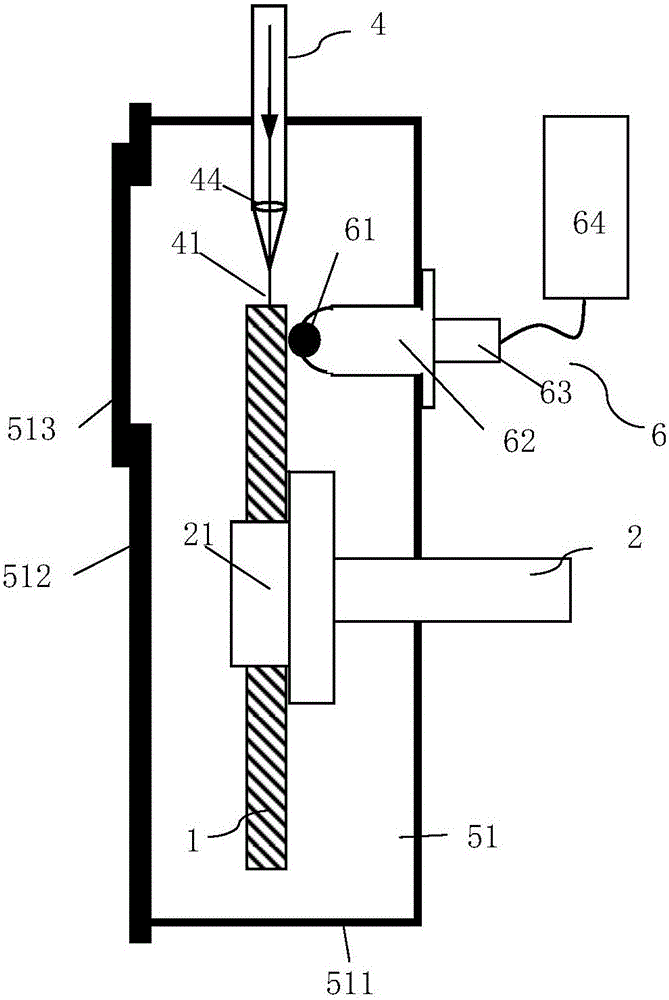

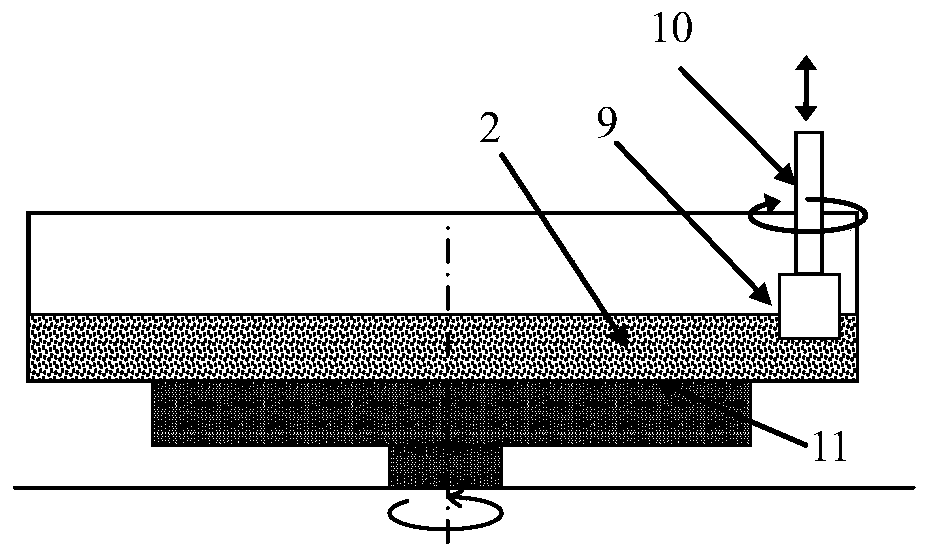

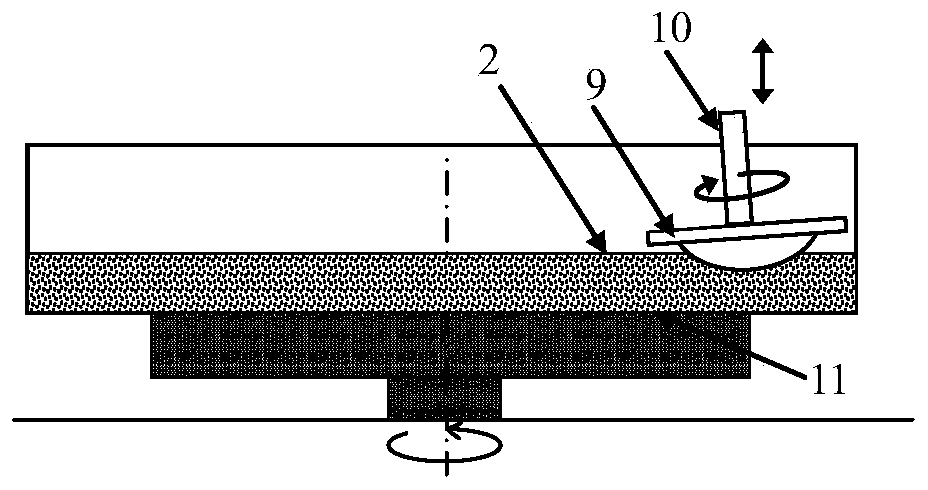

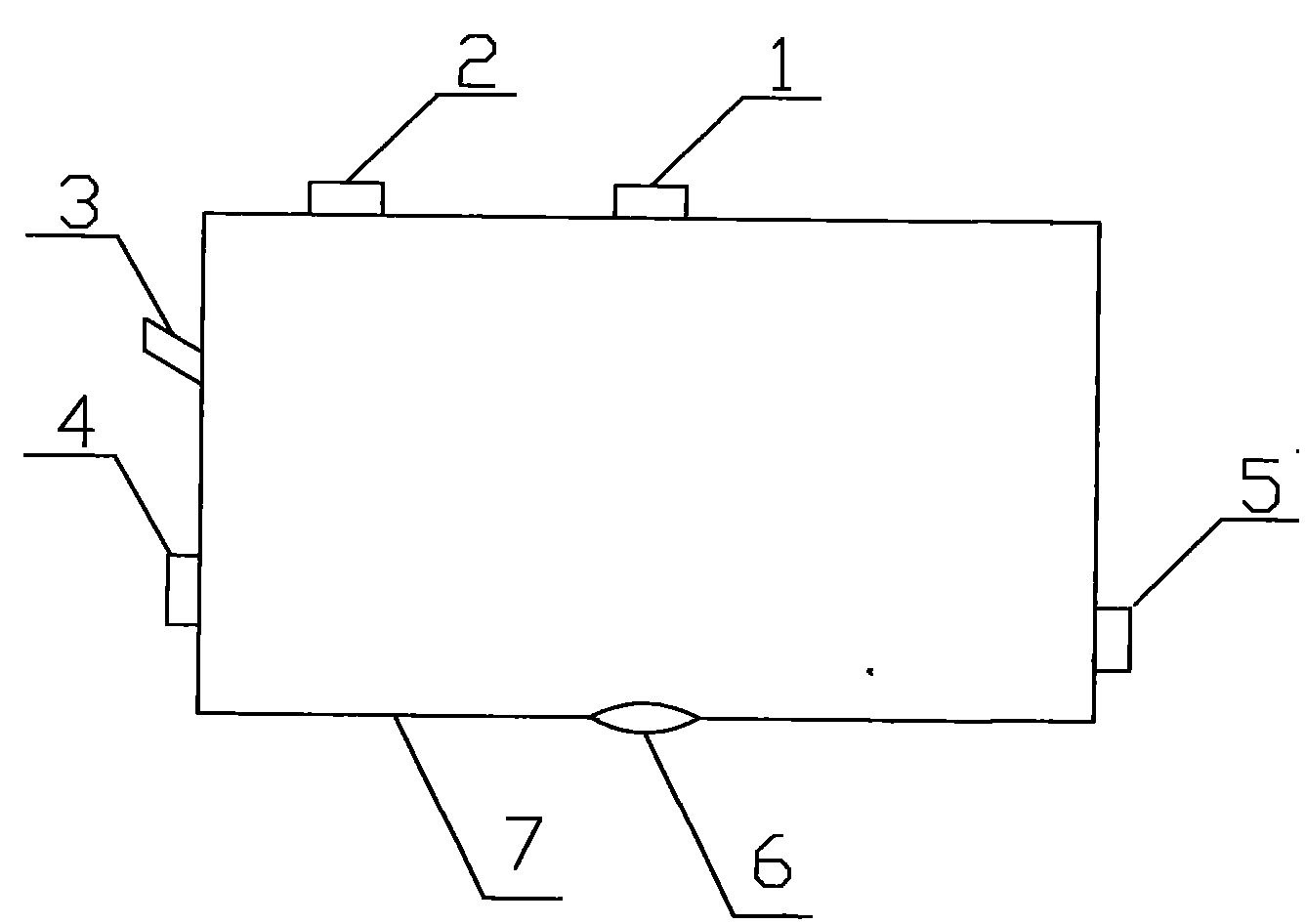

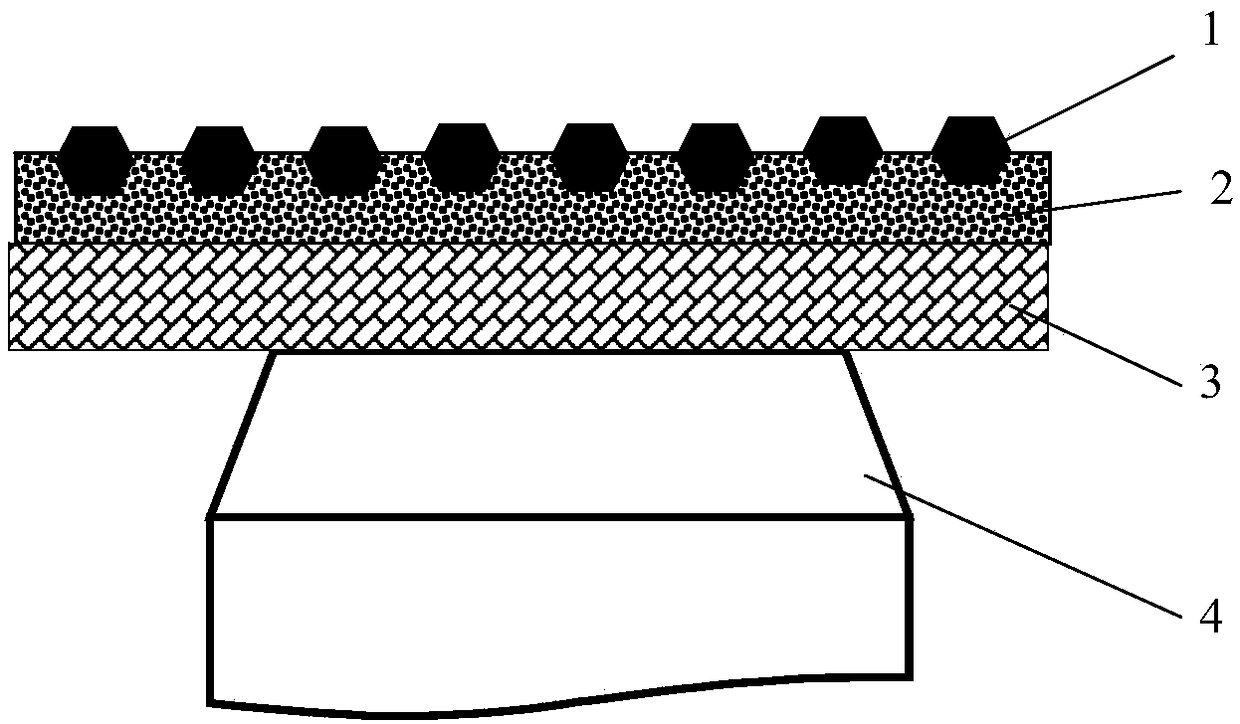

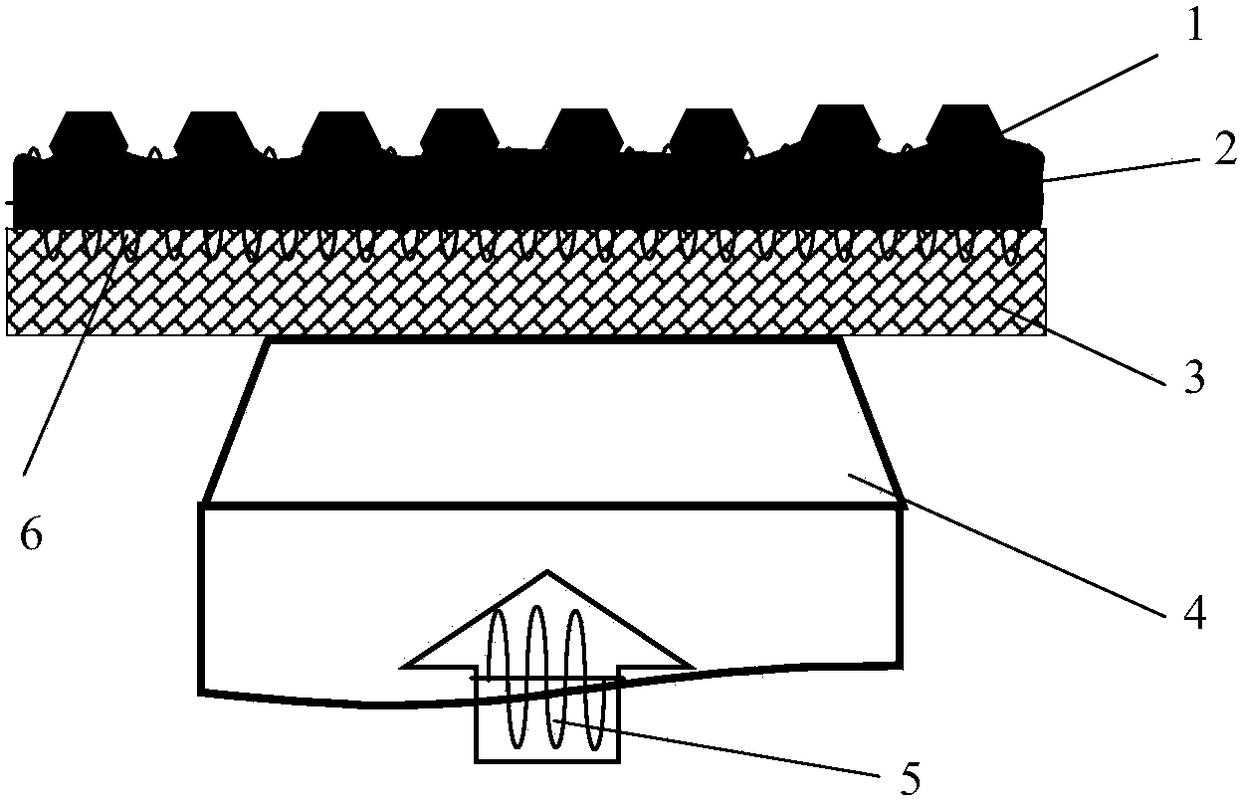

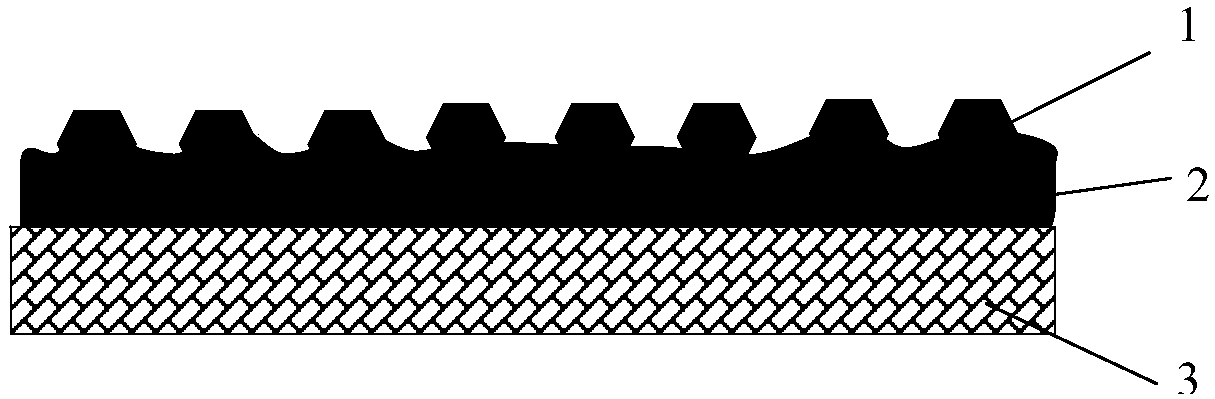

Ultrasonic-assisted induction preheating laser soldering method and device for preparing abrasive particle grinding wheel

InactiveCN105965119AReduce temperature differenceAvoid the disadvantages caused by excessive temperature differenceSoldering auxillary devicesRotational axisLight spot

The invention provides an ultrasonic-assisted induction preheating laser soldering method and device for preparing an abrasive particle grinding wheel. The method comprises the following steps that (1) the to-be-welded grinding wheel coated with an active binding agent and abrasive particles is fixed to a rotary shaft, and the distance between an induction coil and the surface of the to-be-welded grinding wheel is controlled to be within an effective heating distance; laser beam light spots of a laser heating system are adjusted to be focused on the peripheral surface of the to-be-welded grinding wheel and to be located behind the induction coil in the rotation direction of the rotary shaft; and a rolling wheel at the tail end of an ultrasonic amplitude variation rod fixed in an ultrasonic wave loading system is tightly pressed on the side face, of the grinding wheel, in the acting area of the laser beam light spots; and (2) the rotary shaft is made to drive the to-be-welded grinding wheel to rotate, coupling heating is conducted on the surface of the to-be-welded grinding wheel through the induction coil and the laser beam light spots; and chemical bonding and wetting climbing effects of the interface of the active binding agent and the abrasive particles are facilitated through the ultrasonic effect, the abrasive particles leaving a coupling heating area are subjected to high-frequency vibration, and thus thermal stress of the abrasive particles is released effectively.

Owner:HUAQIAO UNIVERSITY

Method for improving oxidation resistance through normal-temperature blackening of rare earth permanent magnet powder

InactiveCN108220946AHigh film forming efficiencyReduce energy consumptionTransportation and packagingMetal-working apparatusRare earthOxidation resistant

The invention provides a method for improving oxidation resistance through normal-temperature blackening of rare earth permanent magnet powder. The method comprises the following steps: the rare earthpermanent magnet powder is dipped in normal-temperature blackening water treatment liquid, prepared by stated steps and containing divalent copper ions, a complexing agent and an oxidizing agent, forreplacement-oxidation reaction under normal temperature; different reaction times are controlled; and after the reaction is finished, magnetic powder is magnetically separated from reaction liquid bya permanent magnet for such steps as solid-liquid separation, distilled water washing, anhydrous ethanol extraction and 50-DEG C low-temperature drying to obtain the magnetic powder coated with a thin and compact oxide film on the surface. The method has the characteristics of simple process operation, low energy consumption, high film forming efficiency, environmental protection and the like; and the treated rare earth permanent magnet powder is more excellent in high-temperature oxidation resistance.

Owner:ZHEJIANG UNIV OF TECH

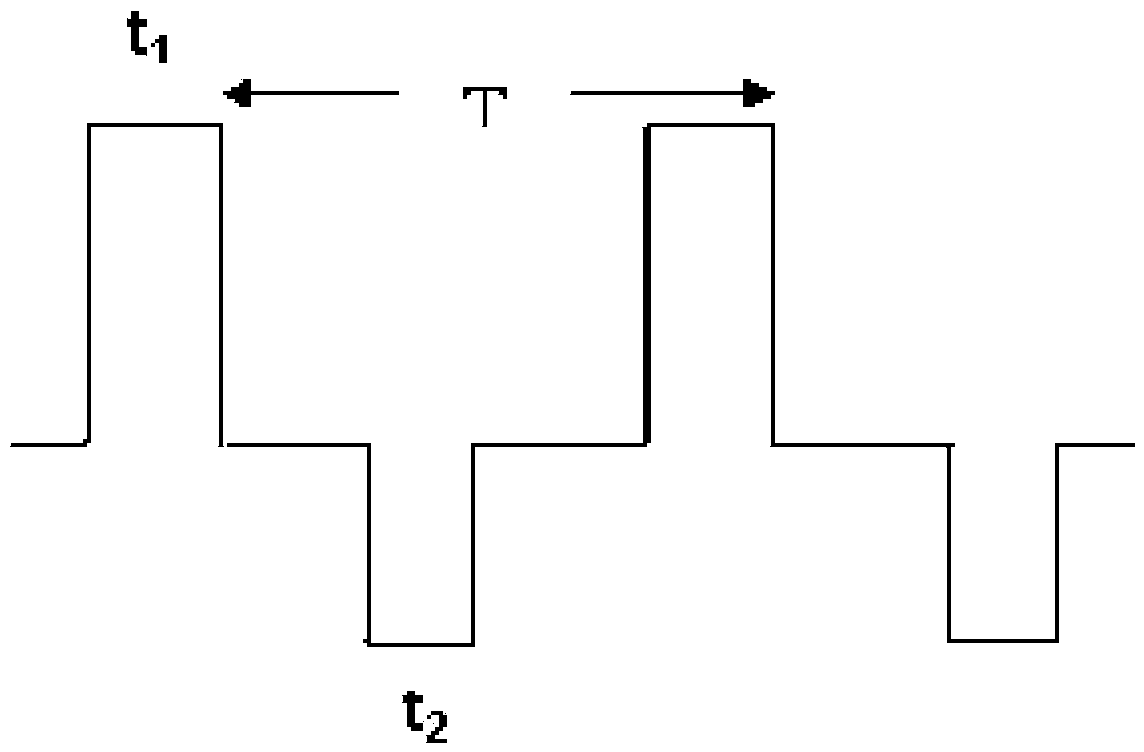

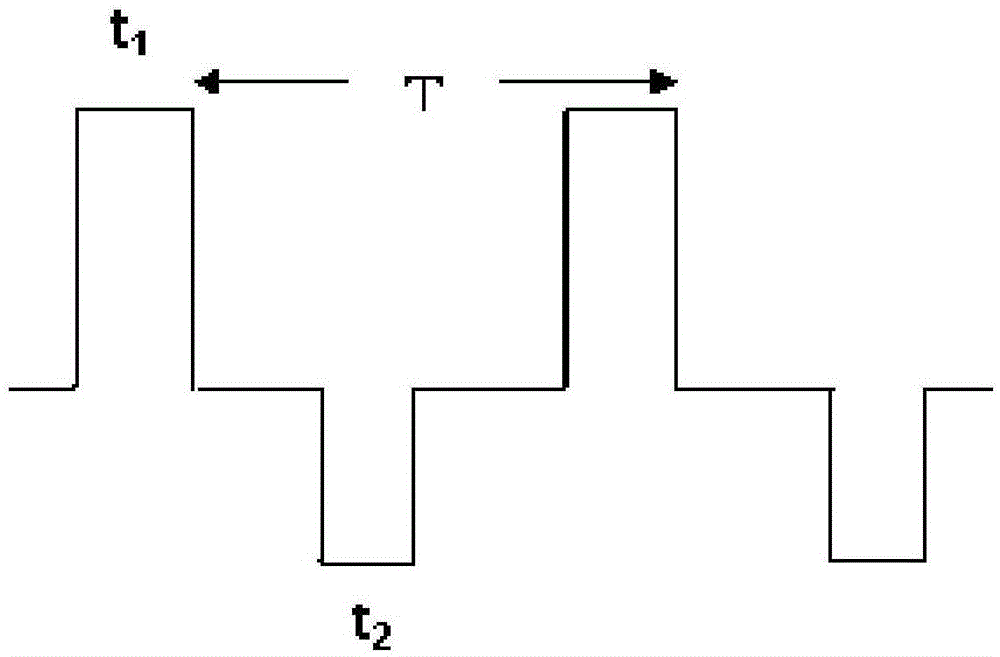

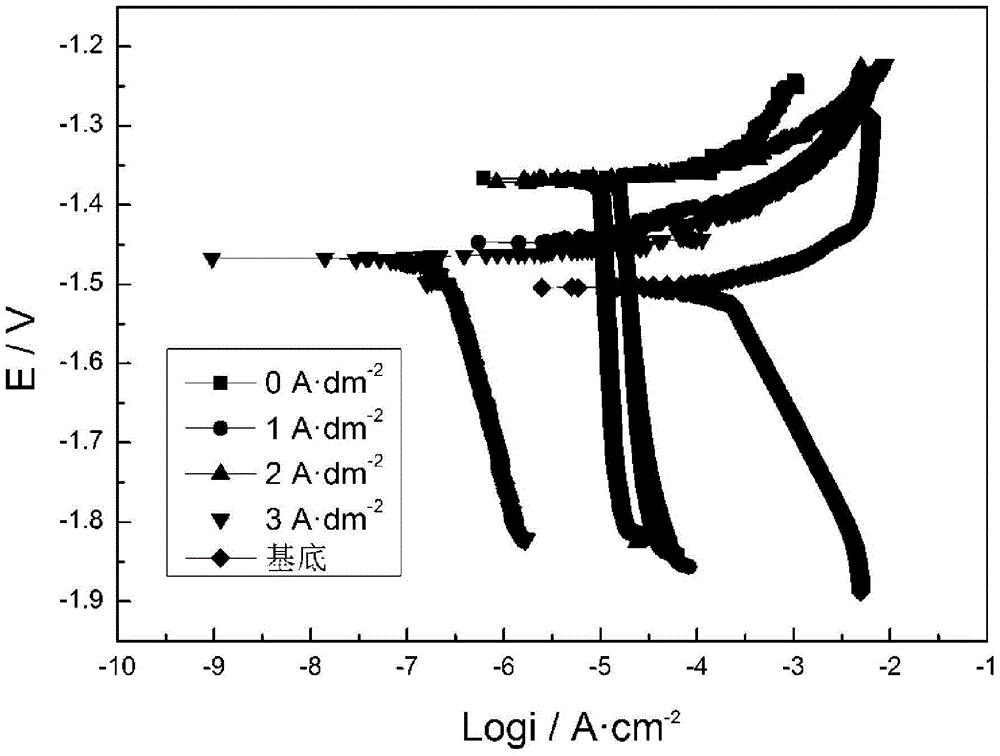

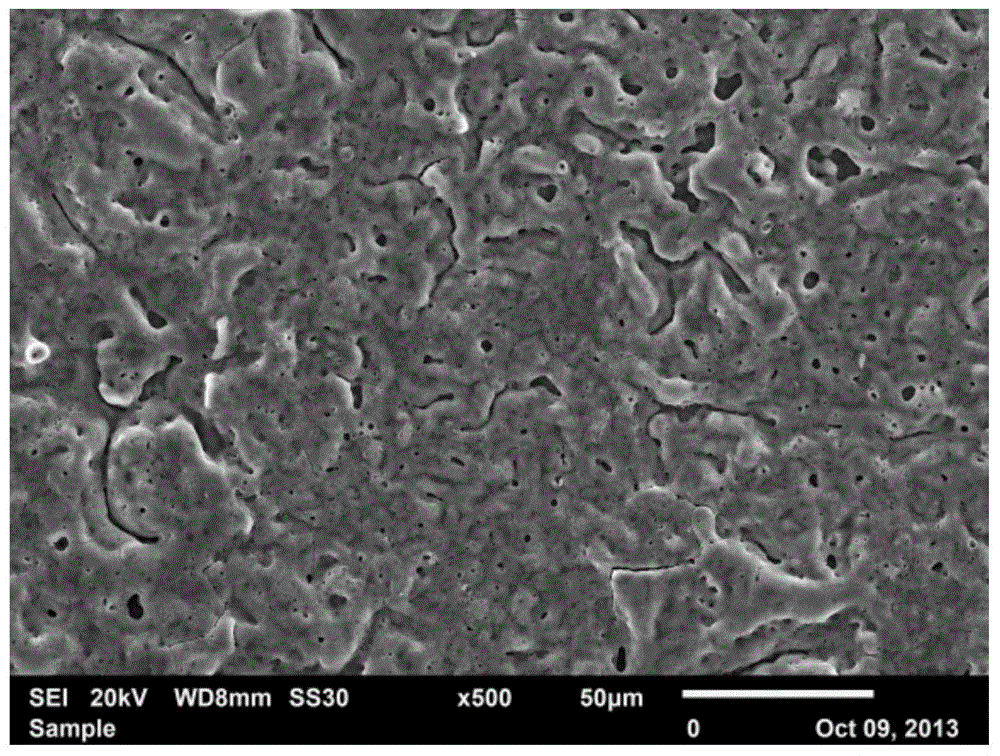

Magnesium alloy anode oxidation method

The invention relates to a magnesium alloy anode oxidation method sequentially comprising degreasing, pickling, alkali corrosion, anodic oxidation and drying steps, and a pulse power supply used in the anodic oxidation step outputs AC square wave pulses. An anodic oxidation film generated in the anodic oxidation process is not burnt and the surface of the oxidation film is smooth.

Owner:JIANGSU ZHONGKE YAMEI NEW MATERIAL CO LTD

High performance water typed edge-rounding agent in use for processing semiconductor wafer

InactiveCN101092584AReduce chemical corrosionImprove the lubrication effectSemiconductor/solid-state device manufacturingAdditivesHigh stressSURFACTANT BLEND

This invention discloses a high-efficiency waterborne edge-rounding solution for processing semiconductor wafer. The edge-rounding solution comprises: penetrant 0.1-10.0 wt.%, lubricant 10-40 wt.%, surfactant 0.1-1.0 wt.%, and deionized water as balance. The penetrant and surfactant are metal ion free, and thus can avoid chemical corrosion caused by metal ions. The edge-rounding solution has such advantages as high lubricity, high heat discharge performance, simple preparation, easy operation and low chemical corrosion, and can prolong the service life of cutters. The edge-rounding solution can solve the problems of impurity contamination, deep damage layer, high stress, and reduced service life faced by microelectronic process.

Owner:天津晶岭电子材料科技有限公司

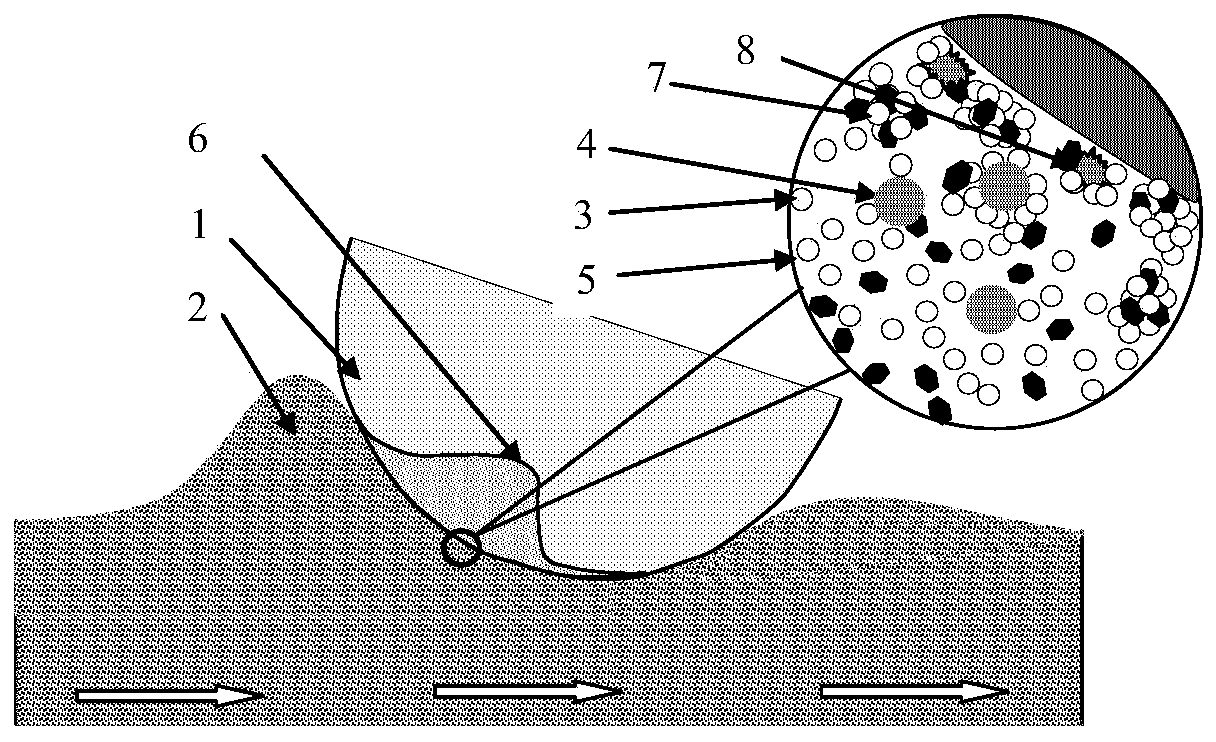

A Mechano-rheological Polishing Method for Fixed-point Release of Chemical Action

Provided is a force rheological polishing method with the chemical action released at a fixed point. A wrapping body containing chemical polishing liquid is added into non-Newtonian fluid polishing liquid with a shearing thickening effect; in the polishing process, along with increasing of the relative movement speed of the polishing liquid and a workpiece, the shearing force caused by the workpiece on the polishing liquid is ceaselessly increased, the polishing liquid generates a rheological phenomenon, and viscosity is fast increased; thus, the acting force of the polishing liquid on the wrapping body dispersed in the polishing liquid is relatively enhanced, the wrapping body is extruded and broken on a face making contact the workpiece, and chemical substances in the wrapping body are released to a polished surface of the workpiece; and the chemical substances bear high speed and high pressure effects, a chemical reaction fast happens with the surface of the workpiece, chemical reactants formed on the surface of the workpiece are efficiently removed by abrasive particles in the polishing liquid, no mechanical damage is generated on a workpiece body material, and therefore the polishing efficiency and quality of the workpiece material are improved. The force rheological polishing method with the chemical action released at the fixed point is efficient, low in cost and environment-friendly.

Owner:ZHEJIANG UNIV OF TECH

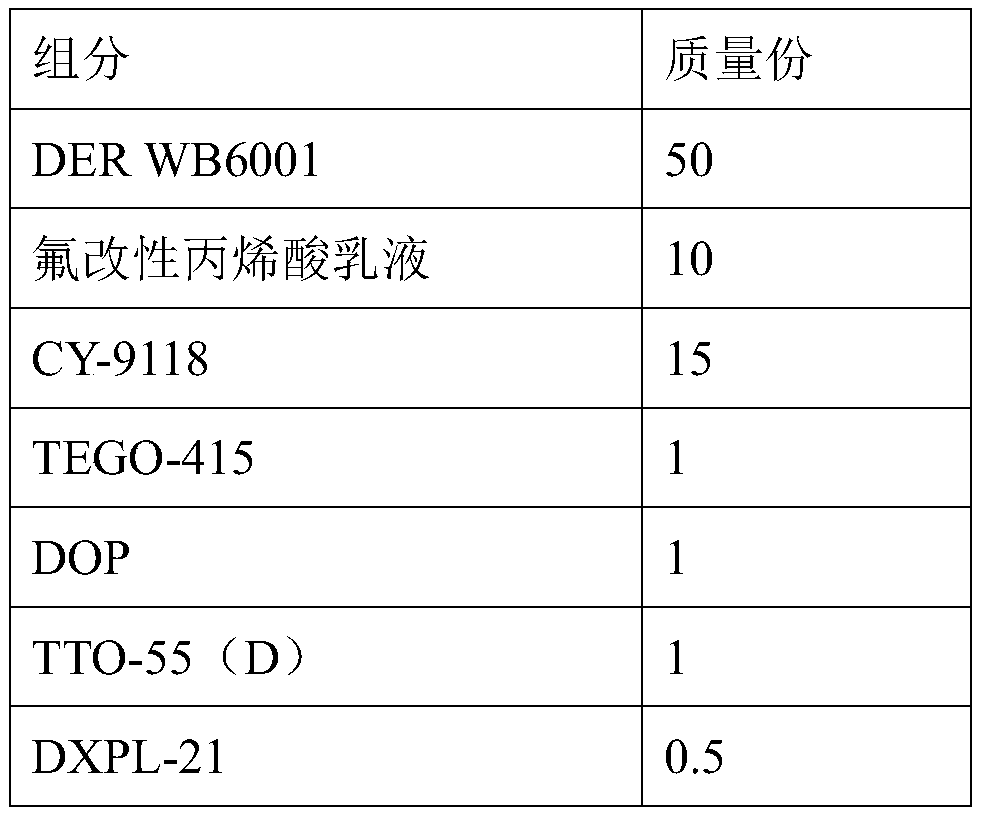

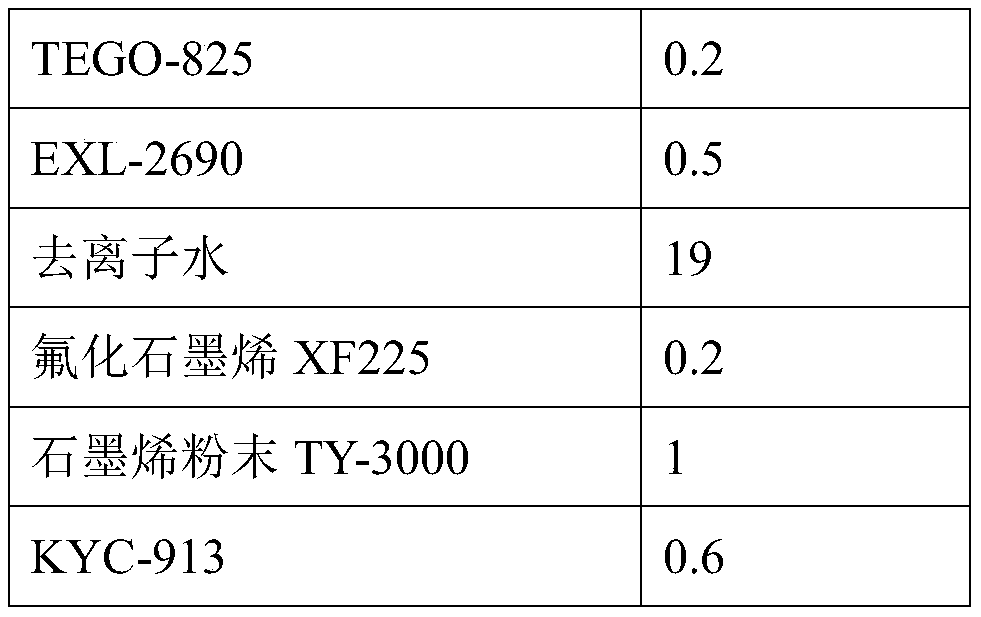

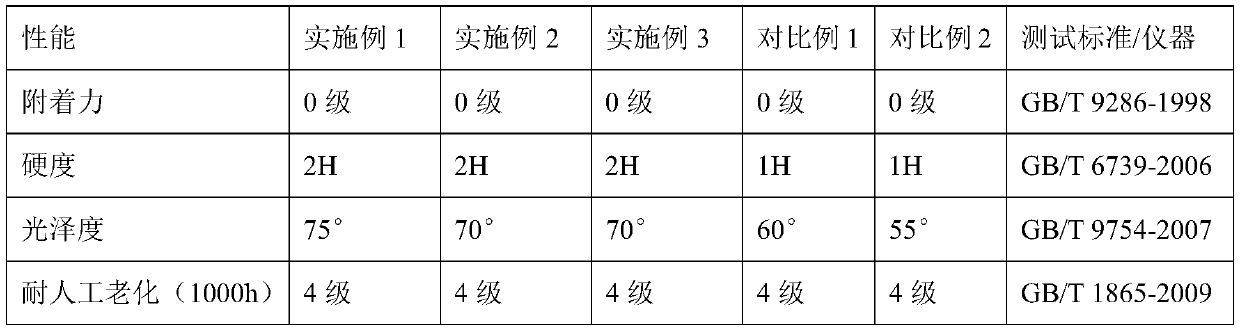

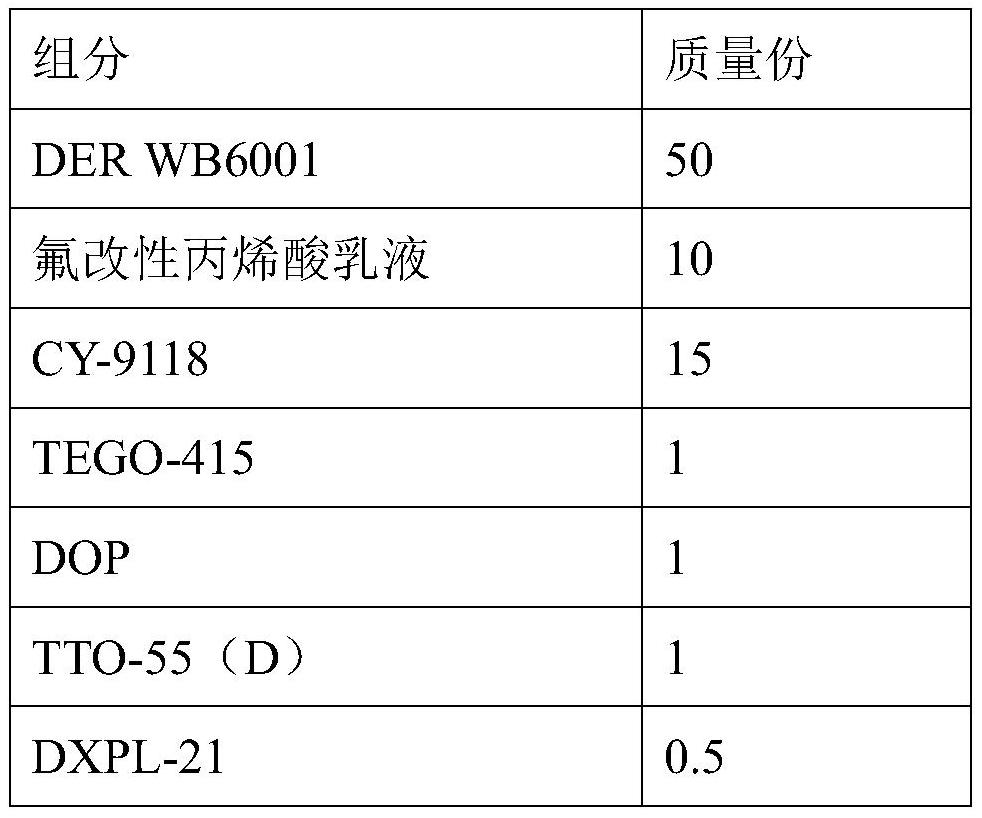

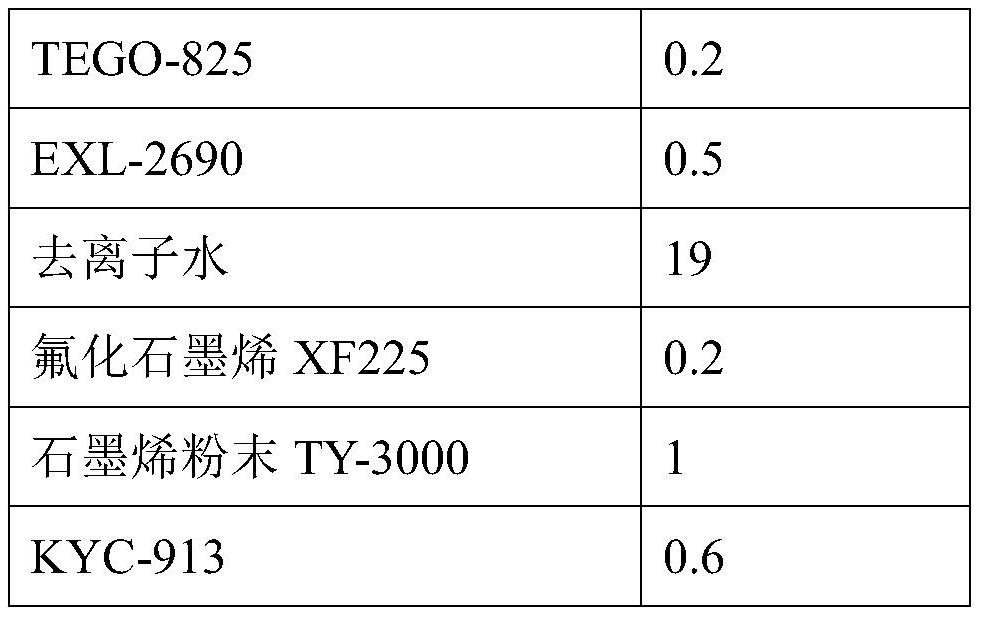

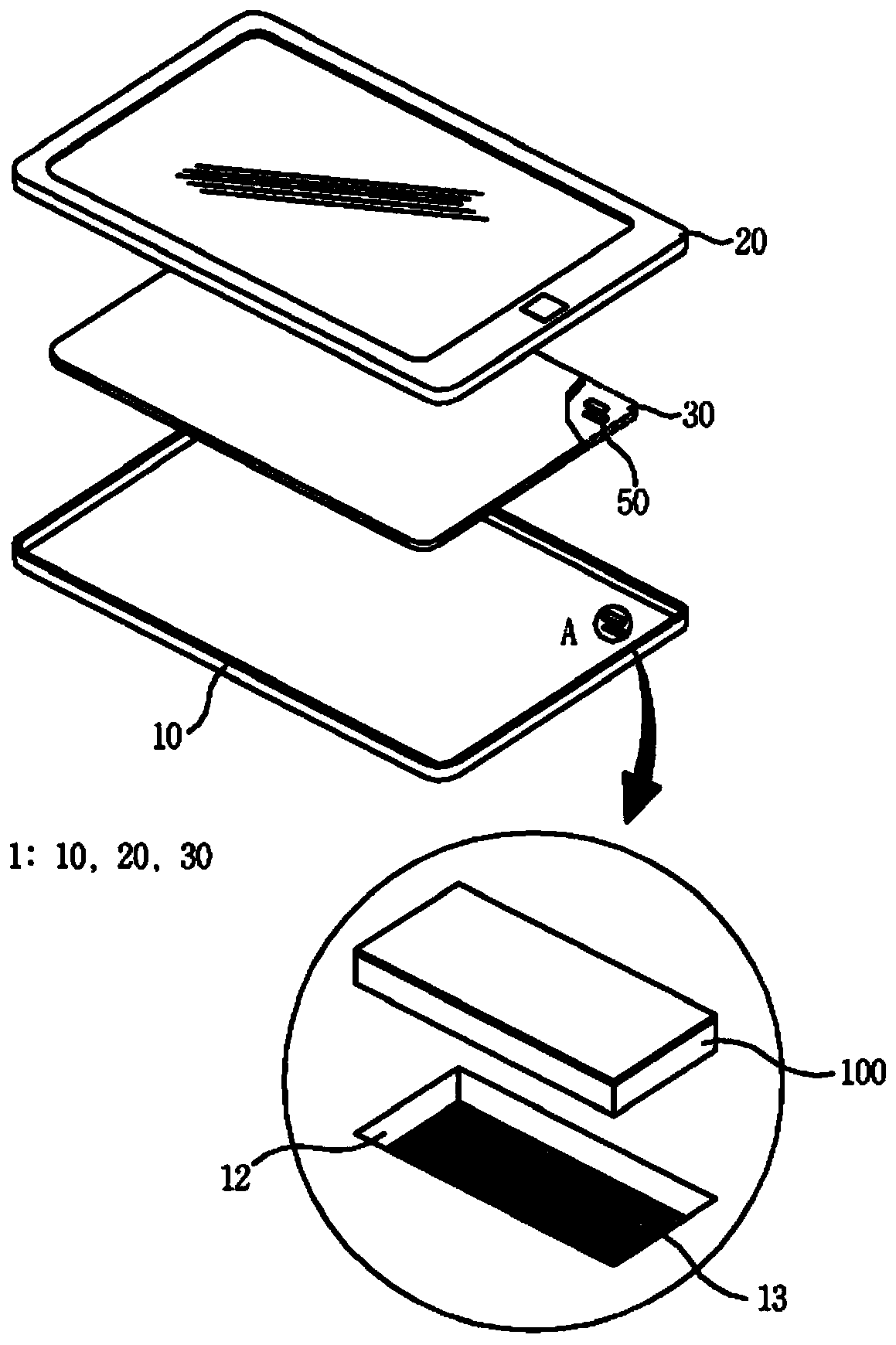

Waterborne fluorinated graphene coating and preparation method and application thereof

ActiveCN110776805AGood weather resistanceGood physical propertiesAntifouling/underwater paintsPaints with biocidesSilver pastePolymer science

The invention discloses a waterborne fluorinated graphene coating and a preparation method and application thereof. The waterborne fluorinated graphene coating comprises a component A and a componentB, wherein the component A is composed of the following components: a waterborne epoxy resin emulsion, a fluorine-modified acrylic emulsion, waterborne aluminum-silver paste, fluorinated graphene, graphene, a leveling agent, a plasticizer, a photo-catalyst, an alignment agent, a defoaming agent, a toughener, a dispersant, and water; the component B is a waterborne epoxy curing agent; and a mass ratio of the component A to the component B is (3-6):1. The invention also discloses the preparation method of the waterborne fluorinated graphene coating, and the application of the waterborne fluorinated graphene coating in the surface treatment of highway guardrails. The waterborne fluorinated graphene coating has good weather resistance and physical properties, at the same time has the antifouling and self-cleaning ability, and has excellent anticorrosive and rustproof performance, and thereby the coating is suitable for the surface treatment of highway guardrails.

Owner:广州盛门新材料科技有限公司

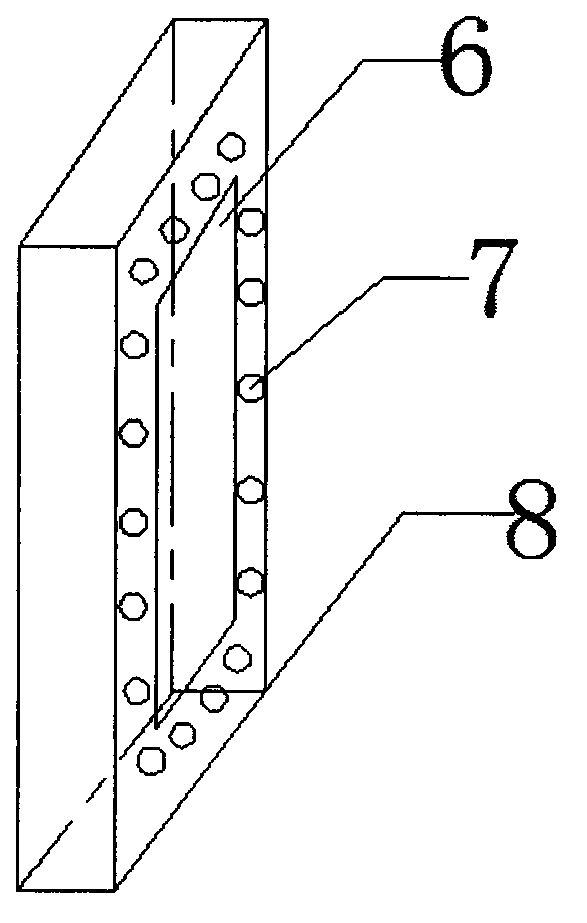

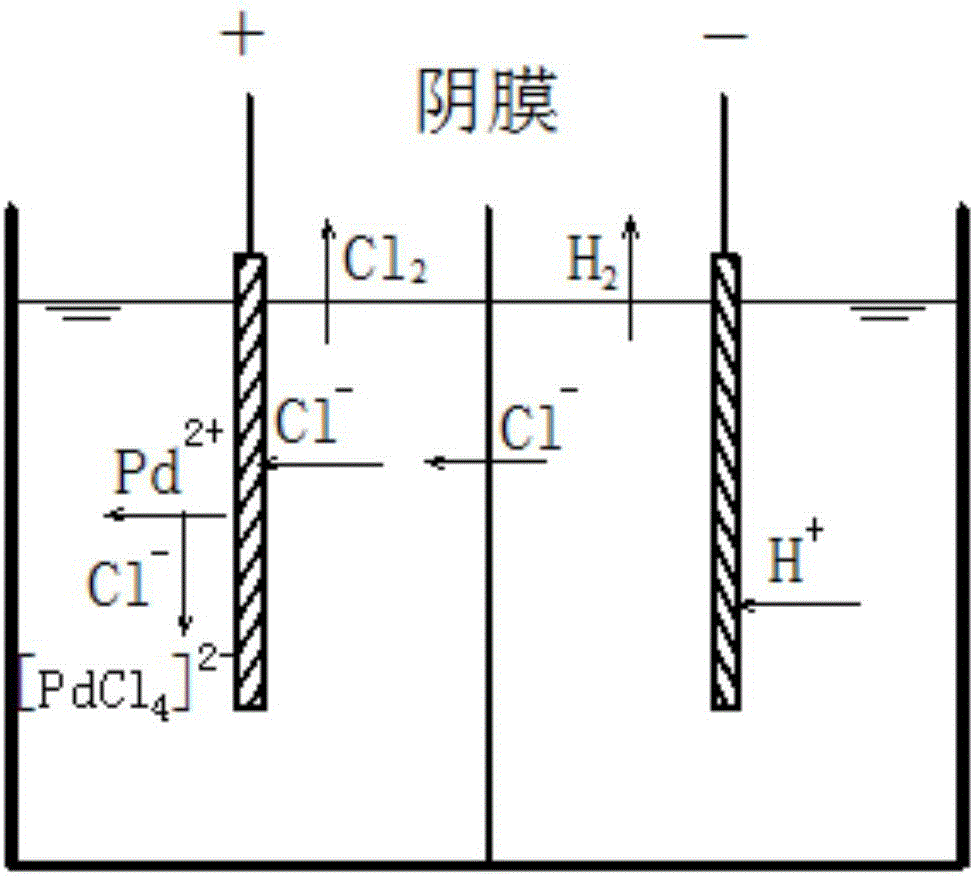

Method for preparing PdCl2

The invention relates to a method for preparing PdCl2. A diaphragm electrolytic cell is adopted for electrolysis, an anionic membrane is used for dividing the electrolytic cell into a dual-chamber electrolytic cell, a palladium strip is adopted as an anode, an inert electrode is adopted as a cathode, a hydrochloric acid solution of 1 mol / L to 6 mol / L is adopted as anode liquor, a sodium chloride solution of 0.1 mol / L is adopted as cathode liquor, electrolysis is carried out for 30 min to 60 min, the anode liquor obtained after electrolysis is concentrated and crystallized, and PdCl2 is obtained. The method has the beneficial effects that an ion exchange membrane electrolysis method is adopted as the core technology, an electrochemical method is adopted, the palladium strip is adopted as the anode, the inert electrode is adopted as the cathode, the hydrochloric acid solution and the sodium chloride solution are adopted as electrolysis liquor, no aqua regia is utilized, the process of removing nitre is omitted, the technological process is greatly simplified, equipment chemical corrosion is reduced, and environment pollution is reduced; and an ion exchange membrane is adopted, the situation that palladium dissolved out of the anode enters a cathode area and is separated out of the cathode again can be avoided, production efficiency is improved, energy saving and emission reduction of production are achieved, and great economic benefits and social benefits can be generated.

Owner:CHANGZHOU YIJIN ENVIRONMENTAL PROTECTION TECH

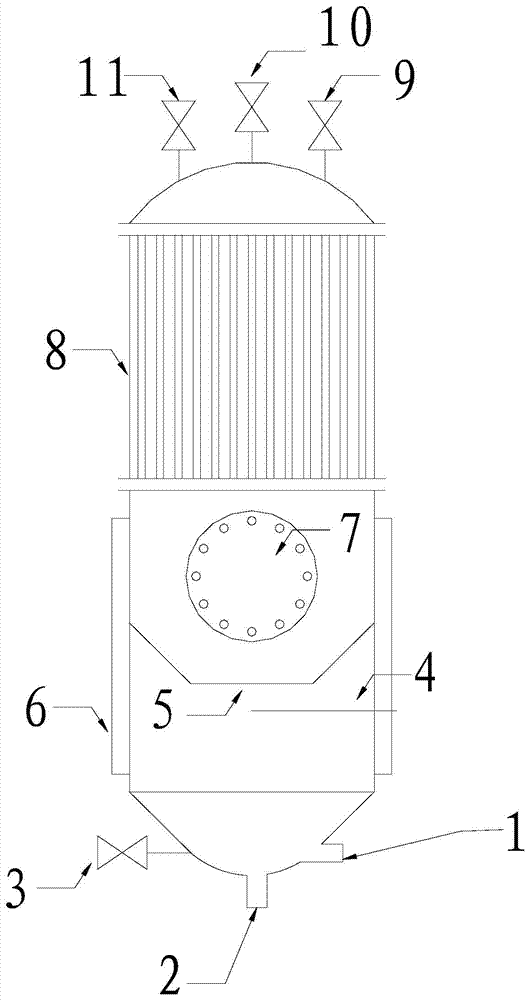

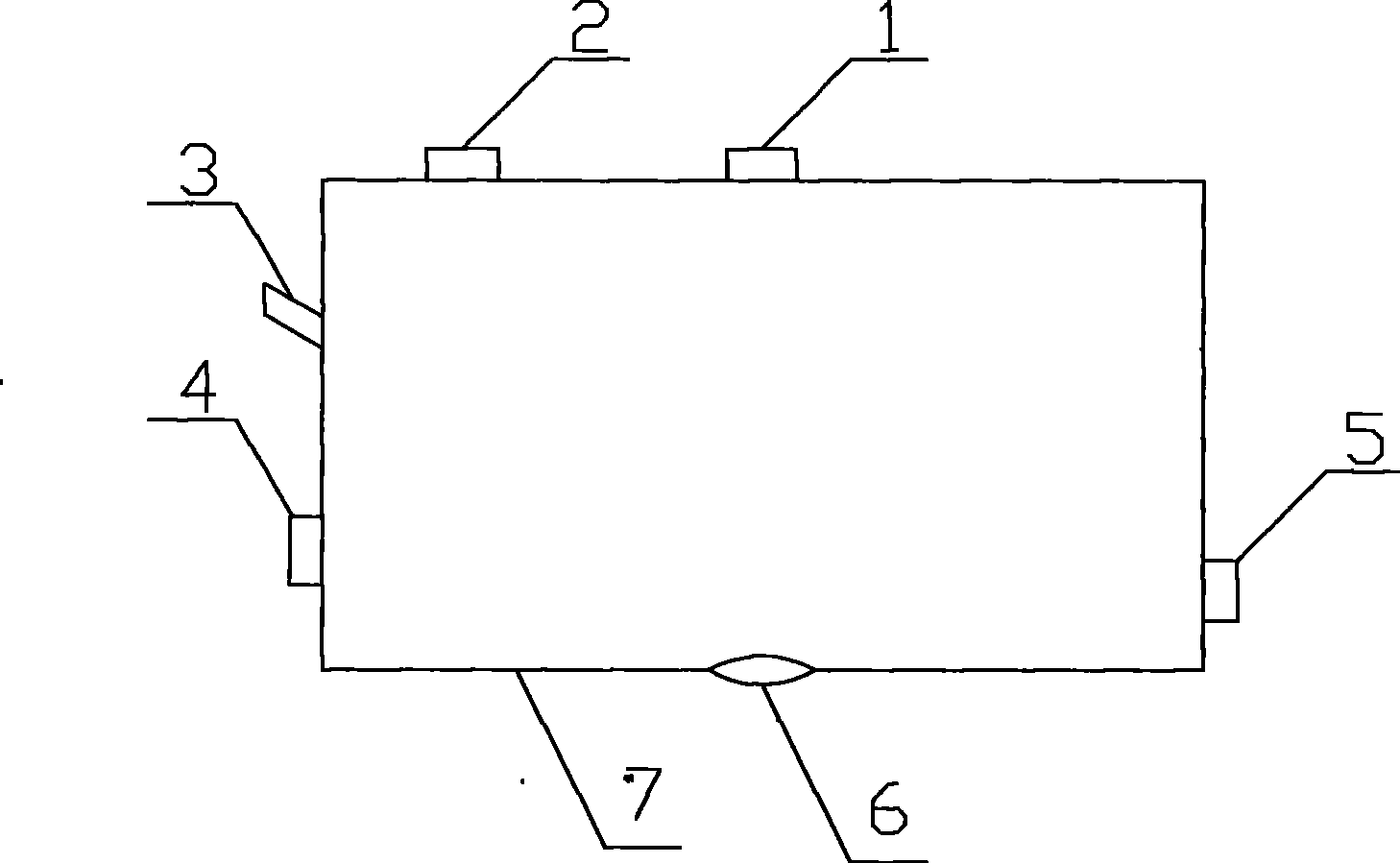

Method and reactor for preparing antimony pentafluoride

ActiveCN103613131ATemperature controlReduce chemical corrosionAntimony compoundsPressure vessels for chemical processAntimony pentafluorideNitrogen gas

The invention discloses a preparation method of antimony pentafluoride. The method comprises the following steps: 1) crushing a metallic antimony block, and adding to a reactor; 2) vacuumizing the reactor to form negative pressure, and heating to 120 DEG C to remove moisture in the reactor and a material; 3) introducing nitrogen to the reactor, so as to pressurize to constant pressure; 4) slowly introducing fluorine, reacting to generate antimony pentafluoride vapor, beginning to warm in the reaction, and emptying for a plurality of times until the pressure of a buffer tank does not ascend again; 5) preparing an antimony pentafluoride product from the antimony pentafluoride vapor in a condensation reflux mode. The invention simultaneously discloses the reactor for preparing antimony pentafluoride. In the reactor, metallic antimony directly reacts with fluorine, so as to generate antimony pentafluoride, so that the product quality is improved and the process is simplified, and the reactor is convenient to operate. Condensation reflux liquid takes away a part of reaction heat, so as to well control the internal temperature of the reactor; meanwhile, continuous reaction is also ensured; chemical corrosion inside the reactor is reduced. Thus, the service life of the reactor is prolonged.

Owner:FUJIAN YONGJING TECH CO LTD

A kind of anti-mold and antibacterial liquid crystal electronic glass spacer paper and its production process

Owner:YINGGE PULPING & PAPER MAKING LUOHE CITY

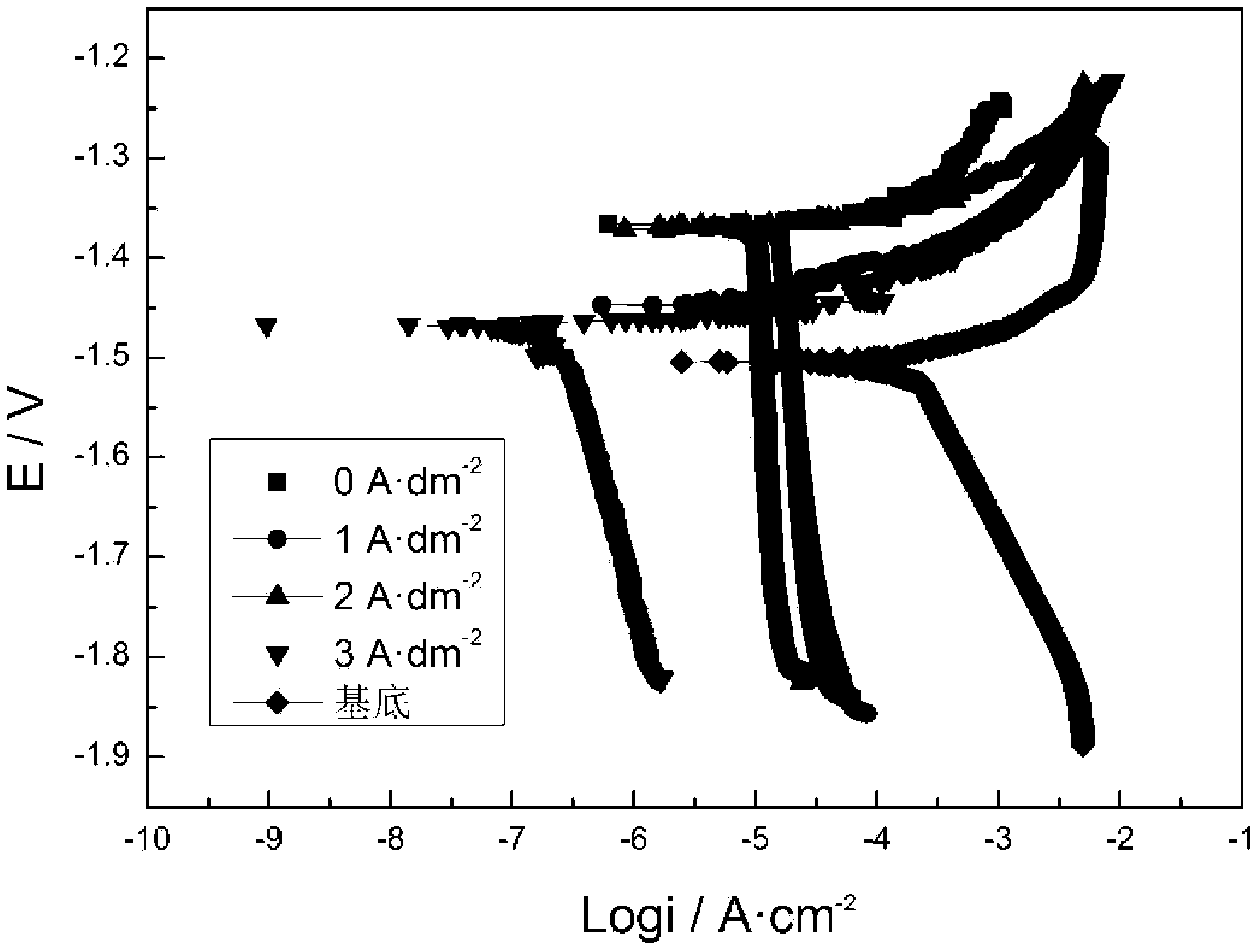

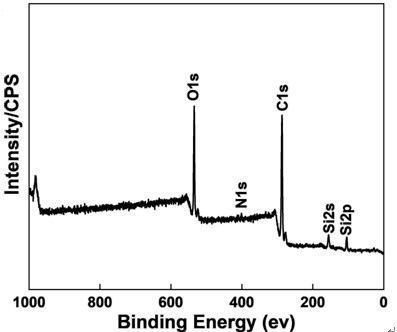

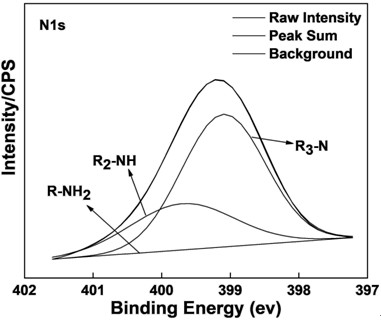

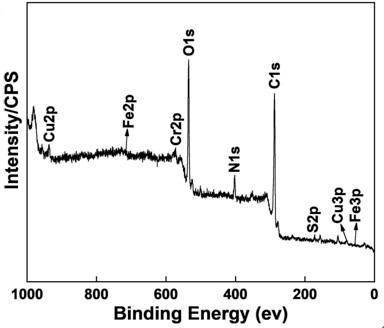

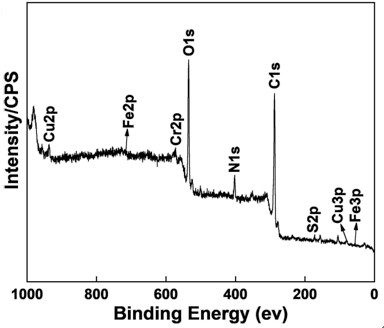

Preparation method and application of conductive polysiloxane-polyaniline anticorrosive coating

ActiveCN112625484AReduce galvanic corrosionReduce chemical corrosionAnti-corrosive paintsElectrically-conductive paintsSurface corrosionElectrically conductive

The invention belongs to the field of corrosion prevention of metal in saline solutions, and particularly relates to a preparation method and application of a stable super-hydrophobic conductive polysiloxane-polyaniline (PANIC-RA-POS) anticorrosive coating. According to the method, a compact and stable conductive polyaniline film is constructed on a metal surface through an electrochemical method, an external hydrophobic polysiloxane coating is constructed through a spraying method, meanwhile, an adhesive sticker (RA) is sprayed between polyaniline and polysiloxane to form a polysiloxane-polyaniline (PANIC-RA-POS) anti-corrosion coating, which is applied to the field of metal surface corrosion prevention. The coating is divided into an internal conductive polyaniline film PANIC and an external super-hydrophobic coating POS, the PANIC has the unique advantages of spontaneously passivating the metal surface and slowing down pitting corrosion, electrochemical corrosion is effectively reduced, the POS has the characteristic of spontaneously forming an air layer in a corrosive medium, transmission of a corrosive medium and electrons can be efficiently blocked, chemical corrosion is effectively reduced, the adhesive sticker glue spray SA enhances the binding force between the PANIC and the POS, and the metal corrosion resistance is effectively improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

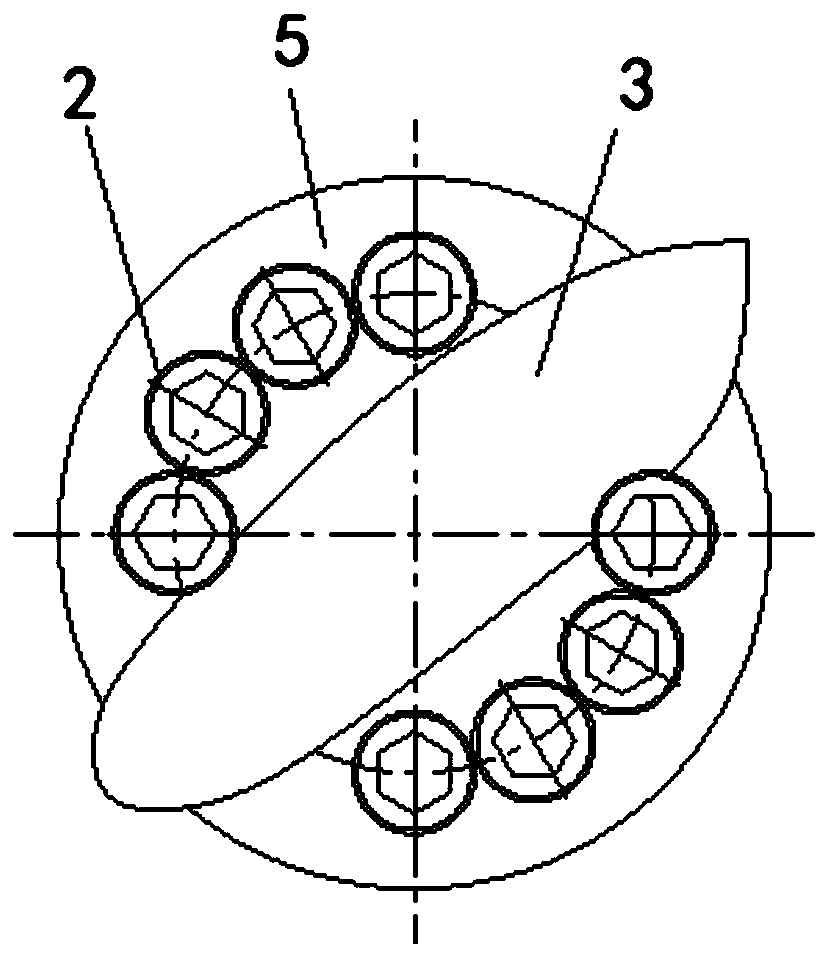

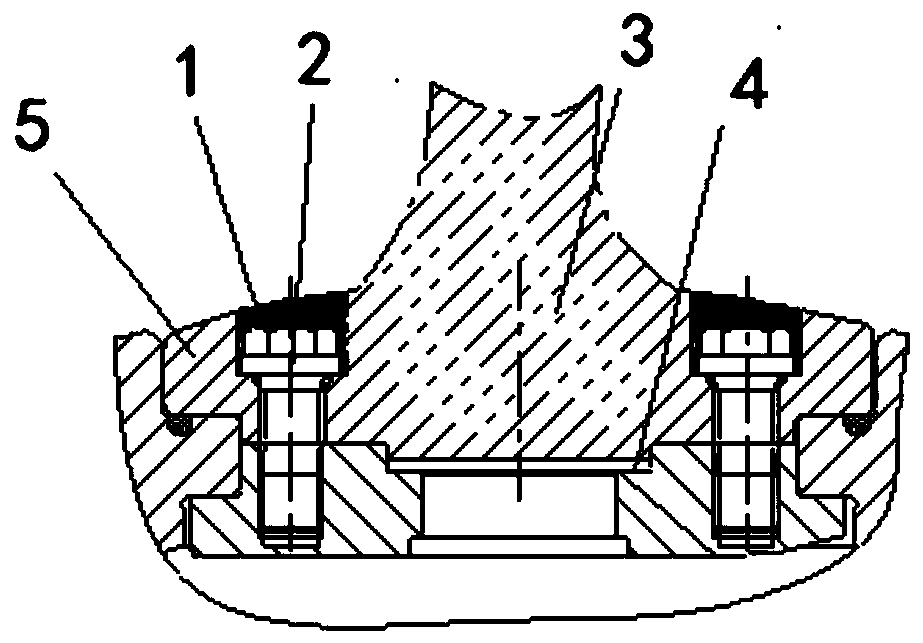

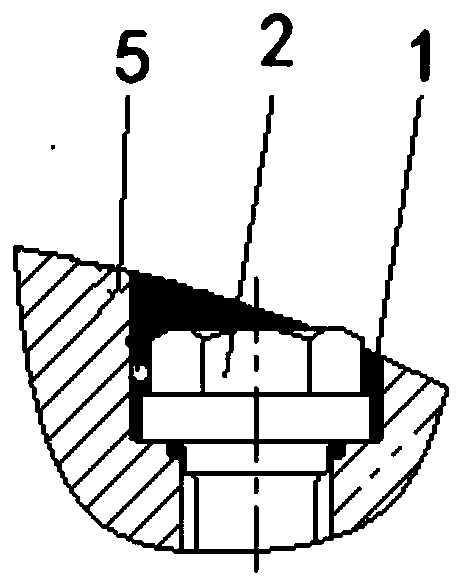

Protection device and method for controllable-pitch propeller blade root bolt

PendingCN111252224AGood insulation and corrosion resistanceReduce chemical corrosionRotary propellersPropellerCorrosive substance

The invention relates to a protection device and method for a controllable-pitch propeller blade root bolt. An annular space formed between the head of a blade root bolt and a mounting hole of a bladeflange is filled with a blade root bolt protective agent for guaranteeing the external line type of a blade, external foreign matters can be prevented from entering the annular space area, and a protective layer is formed outside the blade root bolt. The annular space formed by the blade root bolt and the blade flange mounting hole is filled with the blade root bolt protective agent, the externalline type of the blade is guaranteed, external foreign matters are prevented from entering the area, and the protective layer is formed outside the blade root bolt. The protective layer has good insulativity and corrosion resistance, and can effectively reduce the risks of chemical corrosion, electrochemical corrosion and hydrogen embrittlement fracture of the blade root bolt to a certain extent.And meanwhile, while isolating a circular truncated cone at the head of the blade root bolt from seawater, the protection device can be dismounted in a manual knocking mode, and repeated disassemblyand assembly of the blade root bolt are facilitated.

Owner:中国船舶重工集团公司第七0四研究所

A kind of water-based fluorinated graphene coating and preparation method and application thereof

ActiveCN110776805BGood weather resistanceGood physical propertiesAntifouling/underwater paintsPaints with biocidesSilver pasteGraphene coating

The invention discloses a water-based fluorinated graphene coating, a preparation method and application thereof. This water-based fluorinated graphene coating includes A component and B component; wherein, A component is composed of the following components: water-based epoxy resin emulsion, fluorine-modified acrylic emulsion, water-based aluminum silver paste, fluorinated graphite ene, graphene, leveling agent, plasticizer, photocatalyst, alignment agent, defoamer, toughening agent, dispersant, water; B component is water-based epoxy curing agent; A component and B component The mass ratio is (3-6):1. At the same time, the preparation method of the water-based fluorinated graphene coating and its application in the surface treatment of highway guardrails are also disclosed. The water-based fluorinated graphene paint of the present invention has good weather resistance and physical properties, and simultaneously has anti-fouling and self-cleaning capabilities, excellent anti-corrosion and anti-rust performance, and is suitable for surface treatment of expressway guardrails.

Owner:广州盛门新材料科技有限公司

Preparation method of polymeric material for neutral paper-making

InactiveCN108951285AReduce chemical corrosionReduce downtimeWater-repelling agents additionPaper coatingPapermakingMechanical equipment

The invention relates to the field of paper-making auxiliaries, in particular to a preparation method of a polymeric material for neutral paper-making. The preparation method of the polymeric materialfor neutral paper-making is characterized in that alkyl ketene dimer is prepared, modified polyether glycol is prepared, and the modified polyether glycol is uniformly melted with diphenylmethane diisocyanate, and then an acetone solution of a catalyst is dropwise added, a chain extender is added after reaction is carried out, and then purified water is added and is stirred at high speed to prepare aqueous polyurethane neutral sizing agent emulsions. By adopting the neutral sizing agent, chemical corrosion of mechanical equipment can be greatly reduced, paper breaking phenomenon is reduced, the downtime of a paper machine is shortened, the dryness of paper sheets is improved, the papermaking speed is accelerated, and thus, the production ability of the paper sheets can be improved.

Owner:宁波高新区诠宝绶新材料科技有限公司

Mounting structure for electric contact terminal

InactiveCN110021826AReduce chemical corrosionLess galvanic phenomenonSoldered/welded conductive connectionsElectrically conductive adhesive connectionsElectricityEngineering

The present invention discloses a mounting structure for an electrical contact terminal, and more particularly discloses a technique that enables reliable mounting of an electrical contact terminal atan electrical contact portion provided to a metal casing. An accommodation groove is integrally formed in the electrical contact portion of the surface of the metal casing, and the electrical contactterminal is forcibly inserted into the accommodation groove to be physically coupled to the accommodation groove, and gap portions between a main body and the casing are fused and joined to each other by welding at the entrance of the accommodating groove, so that the gap portions between the main body and the casing is mechanically coupled and electrically coupled.

Owner:JOINSET

Double-gate-disc casting for petroleum machinery

InactiveCN108707814AHigh strengthImprove toughnessFoundry mouldsSlide valveChemical compositionSulfur

The invention relates to a double-gate-disc casting for petroleum machinery. The double-gate-disc casting for petroleum machinery is prepared from the following chemical components in percentage by mass: less than or equal to 0.08 percent of C, 0.06 to 0.10 percent of Si, 0.05 to 0.2 percent of Zn, 1 to 5 percent of Ti, 0.05 to 0.10 percent of Al, 0.25 to 0.30 percent of Mn, less than or equal to0.025 percent of P, less than or equal to 0.15 percent of Mg, and the balance Fe and inevitable impurities. The possibility of producing a local primary battery during the use process of the double-gate-disc casting can be reduced, so that the electrochemical corrosion is reduced; and in addition, the chemical corrosion of sulfur elements in petroleum on the double-gate-disc casting can be reduced, and the double-gate-disc casting is ensured to have higher strength and toughness, so that the service life of the double-gate-disc casting is effectively prolonged.

Owner:CHANGSHU HONGQIAO CAST STEEL CO LTD

A kind of preparation method and application of conductive polysiloxane-polyaniline anticorrosion coating

ActiveCN112625484BImprove anti-corrosion performanceImprove practicalityAnti-corrosive paintsElectrolytic organic material coatingElectrochemical corrosionChemical corrosion

The invention belongs to the field of anti-corrosion of metals in saline solution, and specifically relates to a preparation method and application of a stable superhydrophobic conductive polysiloxane-polyaniline (PANIC-RA-POS) anti-corrosion coating. The method of the present invention utilizes the electrochemical method to construct a dense and stable conductive polyaniline film on the metal surface, adopts a spraying method to construct an external hydrophobic polysiloxane coating, and sprays self-adhesive (RA) between polyaniline and polysiloxane at the same time. ) to form a polysiloxane-polyaniline (PANIC-RA-POS) anti-corrosion coating and apply it to the field of metal surface anti-corrosion. The coating involved in the present invention is divided into internal conductive polyaniline film PANIC and external super-hydrophobic coating POS. PANIC has the unique advantages of spontaneous passivation of metal surfaces and slowing down pitting corrosion, effectively reducing electrochemical corrosion. The characteristic of spontaneously forming an air layer can effectively block the transmission of corrosive media and electrons, and effectively reduce chemical corrosion. The self-adhesive spray SA strengthens the bonding force between PANIC and POS, and effectively improves the metal anti-corrosion performance.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

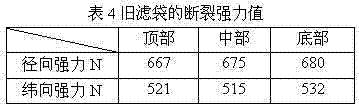

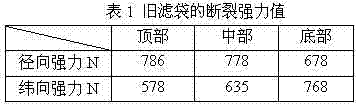

Method for cleaning filter bag for cloth-bag or electric-bag dust collector

ActiveCN102389880BRestore breathabilityExtended service lifeCleaning using liquidsBreaking strengthSmall sample

The invention relates to a method for cleaning a filter bag for a cloth-bag or electric-bag dust collector, which comprises the following steps: (1) clearing surface dust of the filter bag of which the breaking strength is not less than 400N, then, soaking an intercepted small sample into water, measuring the pH value and the ion concentration of soak solution, and if the pH value of the soak solution is less than 5 or in gteater than 9, or F<-> is greater than 2.0mg / l, Cl<-> is greater than 250mg / l, NO3<-> is greater than 30mg / l, SO42<-> is greater than 350mg / l and PO43<-> is greater than 3mg / l in the soak solution, judging that the filter bag needs to the cleaned; (2) firstly, clearing a surface pressed powder layer of the complete filter bag by using compressed air, then, clearing the surface dust by using the dust collector, then, shifting the filter bag into an ultrasonic instrument holding detergent solution for cleaning, washing with the water after the cleaning is completed, and drying in a drying oven. After being cleaned by adopting the method, the filter bag can be recovered in air permeability, the dust clearing period is shortened, corrosive ions remaining in the filter bag are removed, and the service life of the filter bag is prolonged.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

High lead-antimony slag type for anode slime smelting process and its use method

The invention relates to a high lead-antimony slag type which is used for smelting technique of anode mud and is used by the anode mud in the process of reduction smelting of an oxygen bottom blowing bullion lead furnace in the technique that an oxygen bottom blowing furnace smelts the anode mud and a using method, belonging to the scope of separation and extraction of precious metal and base metal; a formula thereof is the high lead-antimony slag type with low silicon, low calcium and low sodium; all the materials comprises the following ingredients according to mass ratio: 5 to 22 percent of SiO2, 1 to 8 percent of FeO, 0 to 6 percent of Na2O, 0 to 5 percent of CaO, 10 to 35 percent of PbO and 150 to 45 percent of Sb2O3, wherein, the control range of the mass ratio of the PbO and SiO2 is 1.50 to 6.0. The formula not only has good effect for prolonging the service life of a refractory material and improving the continuous operation rate and processing capacity of the bullion lead, but also leads the reduction and volatilization of arsenic and antimony and oxidation and slag formation of lead to be realized simultaneously, reduces the usage of flux and consumption of fuel and effectively separates the valuable metals.

Owner:HENAN YUGUANG GOLD & LEAD

A method for preparing superabrasive tools through ultrasonic-assisted active connection

ActiveCN106041768BFacilitate climbing abrasive grainsShorten exposure time to high temperature zoneTurning toolsGrinding devicesChemical LinkageUltrasonic assisted

The invention provides a method for preparing a superhard abrasive particle tool through ultrasonic-assisted active connection. The method comprises the following steps that A, a tool base body coated with active bonding agents and abrasive particles is fixed to an ultrasonic amplitude-change pole; B, the tool base body is subjected to braze heating and temperature rising technology operation, after the active bonding agents reach the melting temperature, first ultrasonic waves are applied to the tool base body, and chemical bonding and the wetting climbing effect of the active bonding agents and interfaces of the abrasive particles are facilitated through the ultrasonic effect; C, after the temperature rising technology is completed, the first ultrasonic waves are stopped applying, when the temperature of a connection zone is lowered to the liquid-solid converting temperature of the active bonding agents, second ultrasonic waves start to be applied to the tool base body, and heat stress releasing in the cooling process is conducted through high-frequency vibration of the second ultrasonic waves; and D, after the temperature of the connection zone is lowered to the tempering temperature of the active bonding agents, processing is stopped, and after temperature of the connection zone is further cooled to the room temperature, the abrasive particle tool is obtained.

Owner:HUAQIAO UNIVERSITY

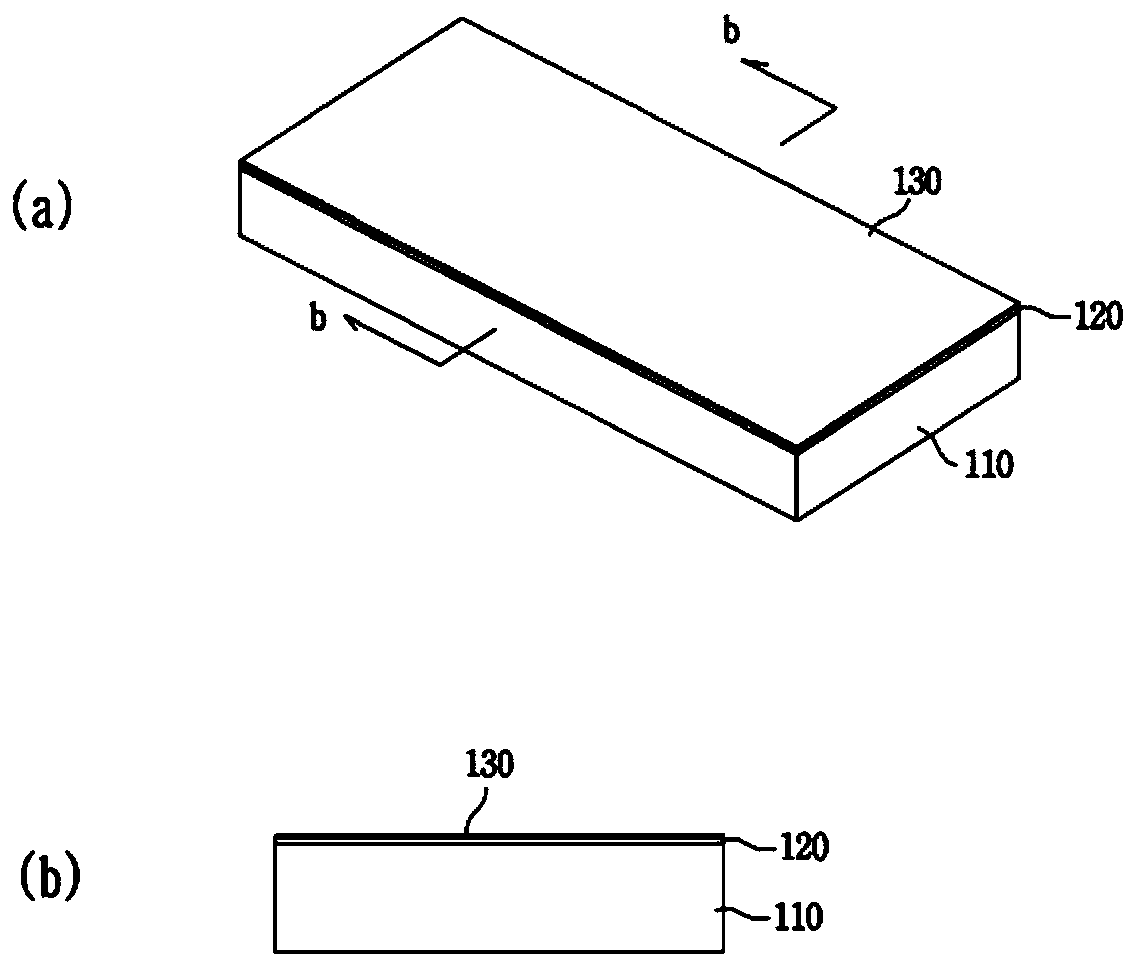

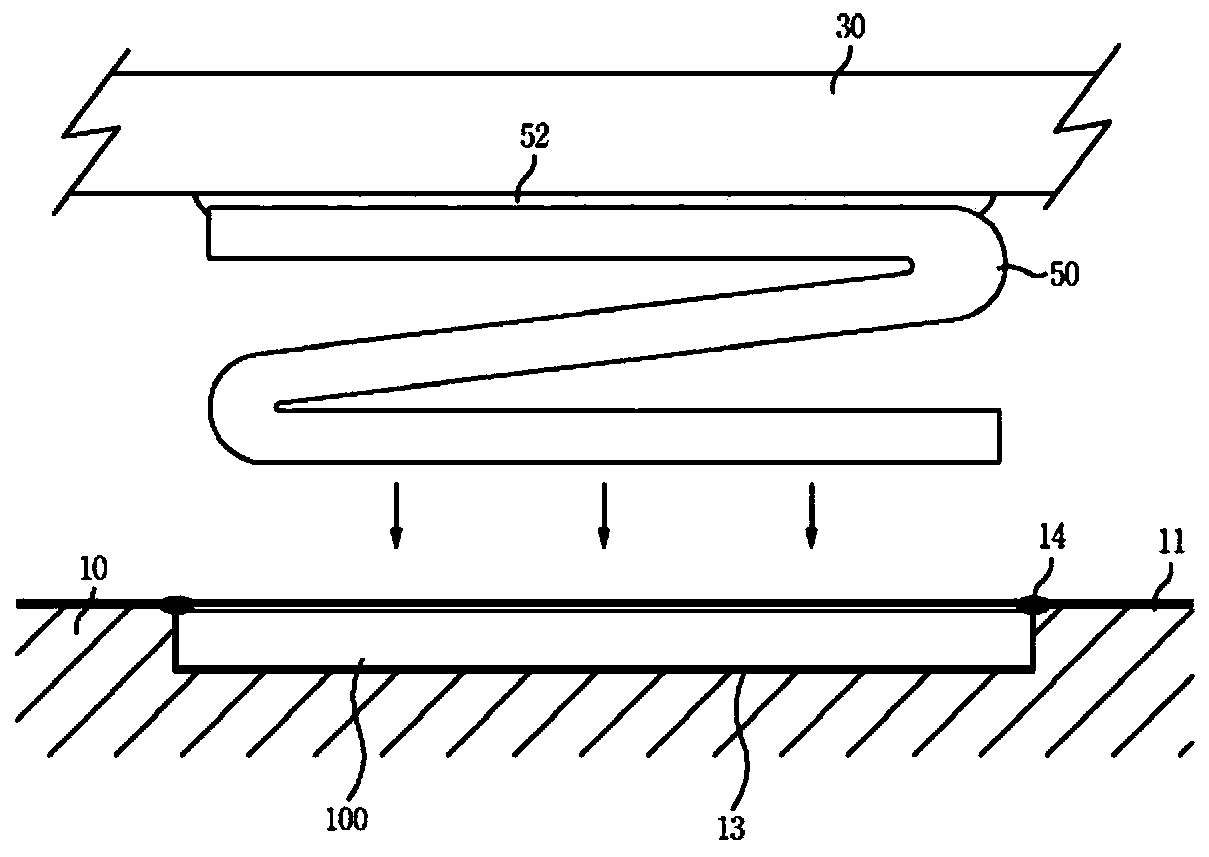

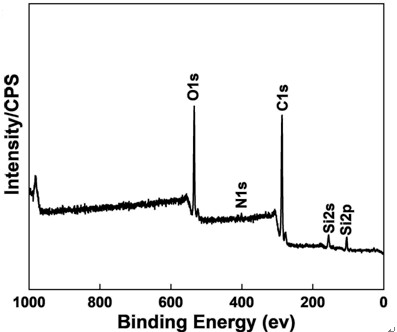

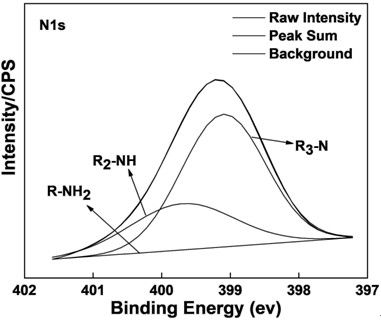

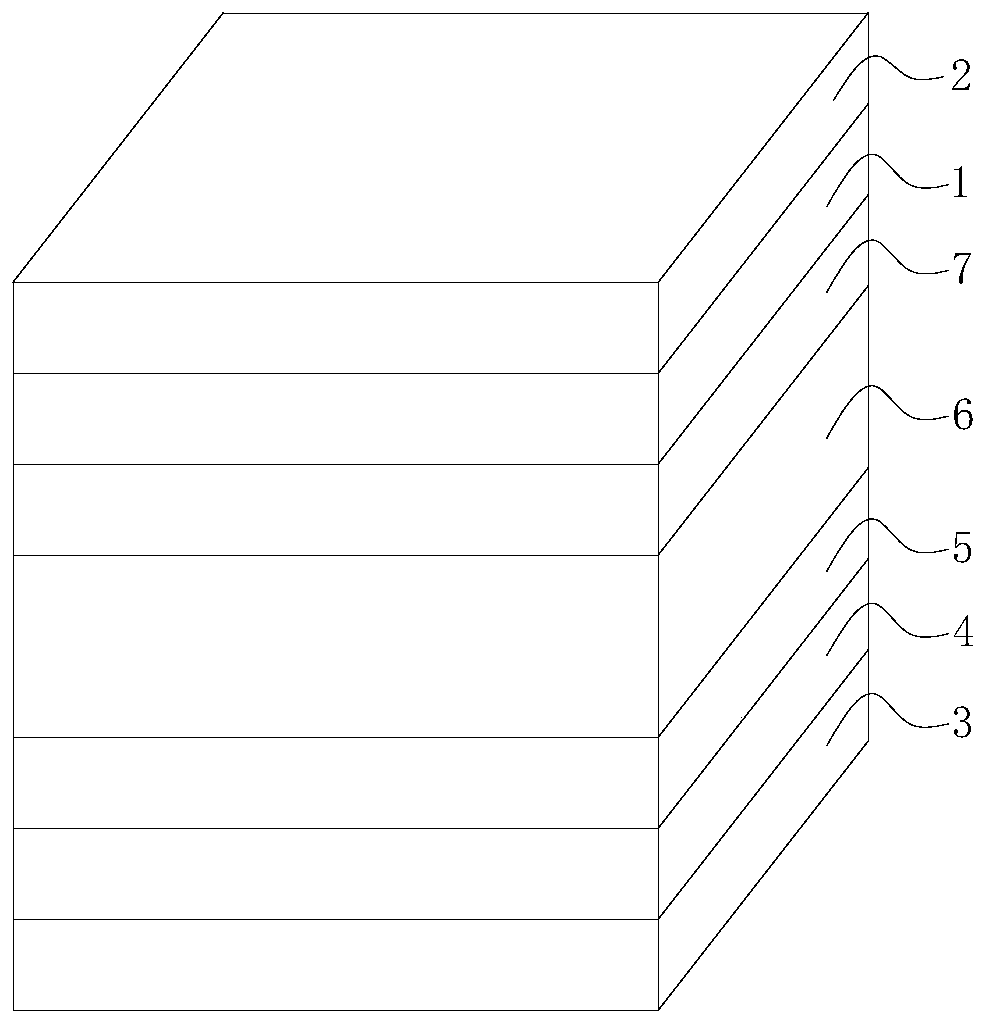

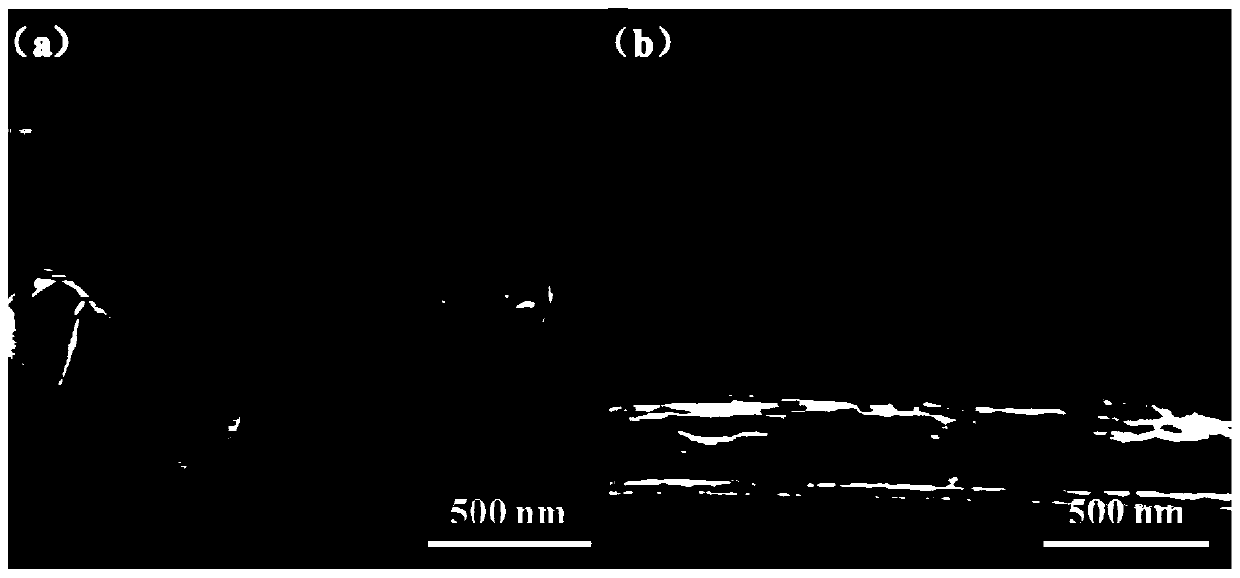

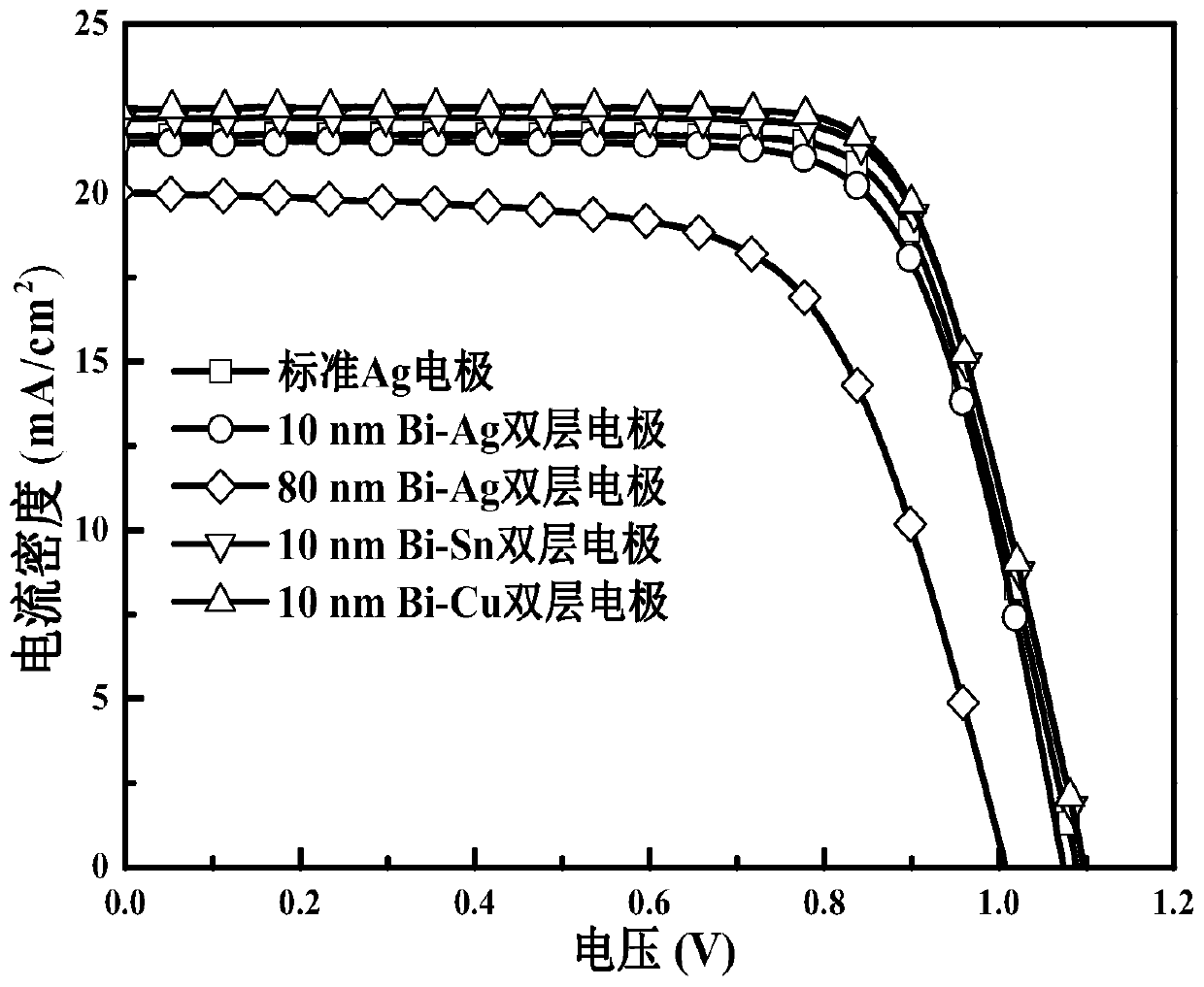

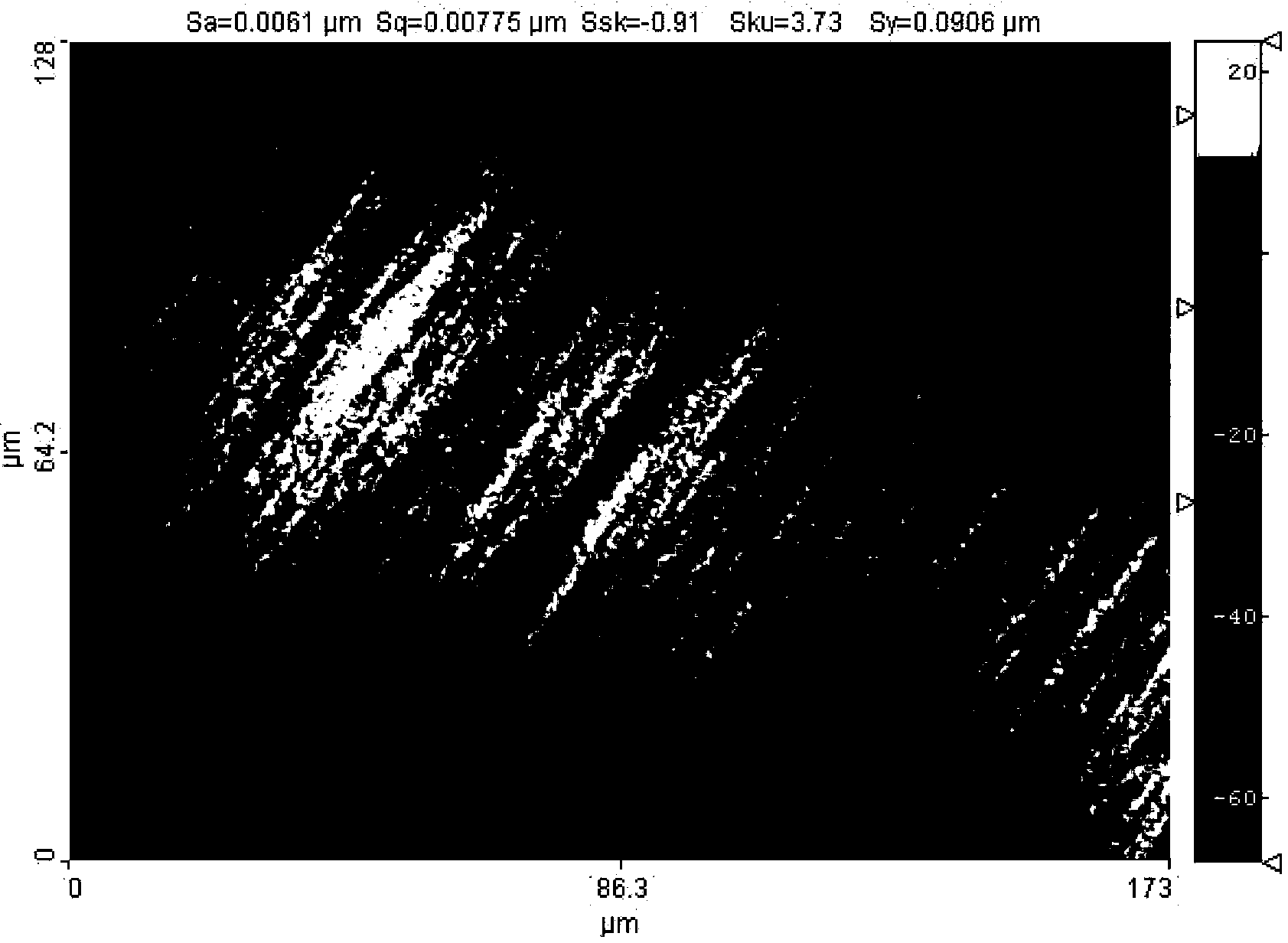

Perovskite solar cell, double-layer metal electrode and preparation method thereof

ActiveCN107994118BReduce chemical corrosionIsolation penetrationSolid-state devicesSemiconductor/solid-state device manufacturingMetallic electrodeHole transport layer

The invention discloses a perovskite solar cell, a double-layer metal electrode for the perovskite solar cell and a preparation method thereof. The perovskite solar cell comprises a glass substrate, a transparent conductive electrode, a hole transport layer, a perovskite thin film, electron transport layer and double-layer metal electrode; the double-layer metal electrode includes a first metal thin film layer and a second metal thin film layer, and its preparation method includes: depositing a layer of the first metal thin film layer on one side of the electron transport layer, A second metal thin film layer is deposited on the first metal thin film layer. In the present invention, a layer of chemically inert first metal thin film layer is deposited in low-temperature vacuum on the electron transport layer, and a second metal thin film layer with high conductivity is arranged on the first metal thin film layer, which can reduce photoelectric conversion On the basis of efficiency, it can effectively isolate the penetration of moisture and reduce the chemical corrosion of the second metal thin film layer, which is beneficial to improve the stability of the perovskite solar cell.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

Barium titanate chemico-mechanical polishing aqueous composition and its application

ActiveCN102786879BControl thicknessStabilize chemical interaction strengthPolishing machinesPolishing compositions with abrasivesBarium titanateSorbent

The invention relates to a barium titanate chemico-mechanical polishing aqueous composition and its application. Specifically, the barium titanate chemico-mechanical polishing aqueous composition comprises: 1-20 wt%, preferably 8-15 wt% of an abrasive; 0.5-10 wt%, preferably 1-3 wt% of a complexing agent; and 0.01-5 wt%, preferably 0.1-1 wt% of a surface adsorbent, wherein the barium titanate chemico-mechanical polishing aqueous composition has a pH value of 8.0-12.0, preferably 10.0-11.5. The barium titanate chemico-mechanical polishing aqueous composition provided in the invention can be effectively applied to a barium titanate substrate chemico-mechanical polishing process, thereby being able to effectively obtain a polished barium titanate layer with a high polishing rate and high surface quality.

Owner:TSINGHUA UNIV

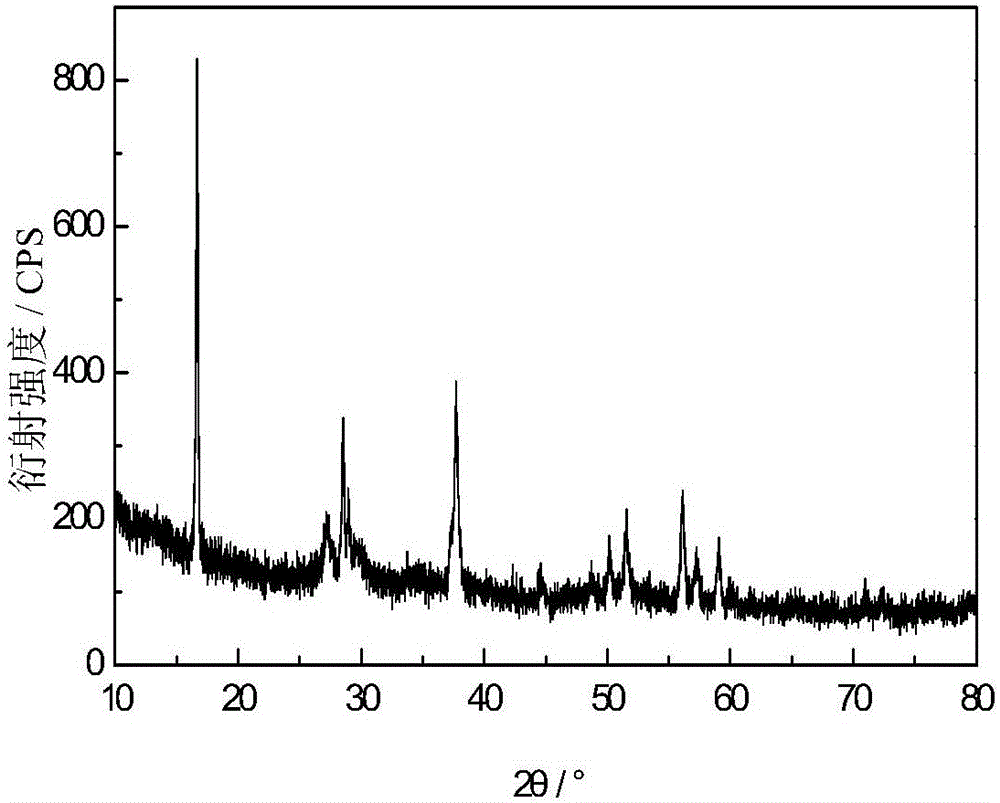

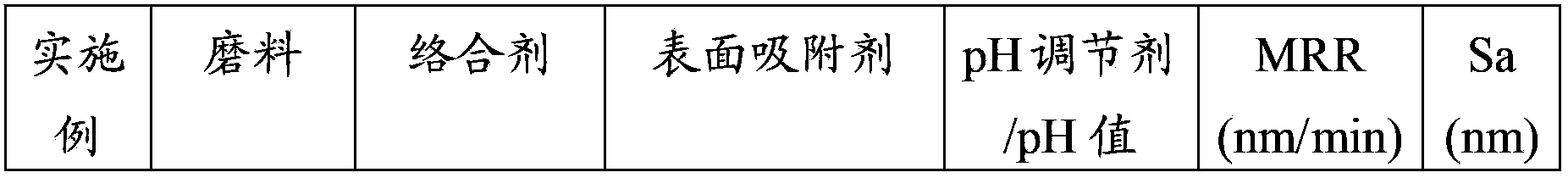

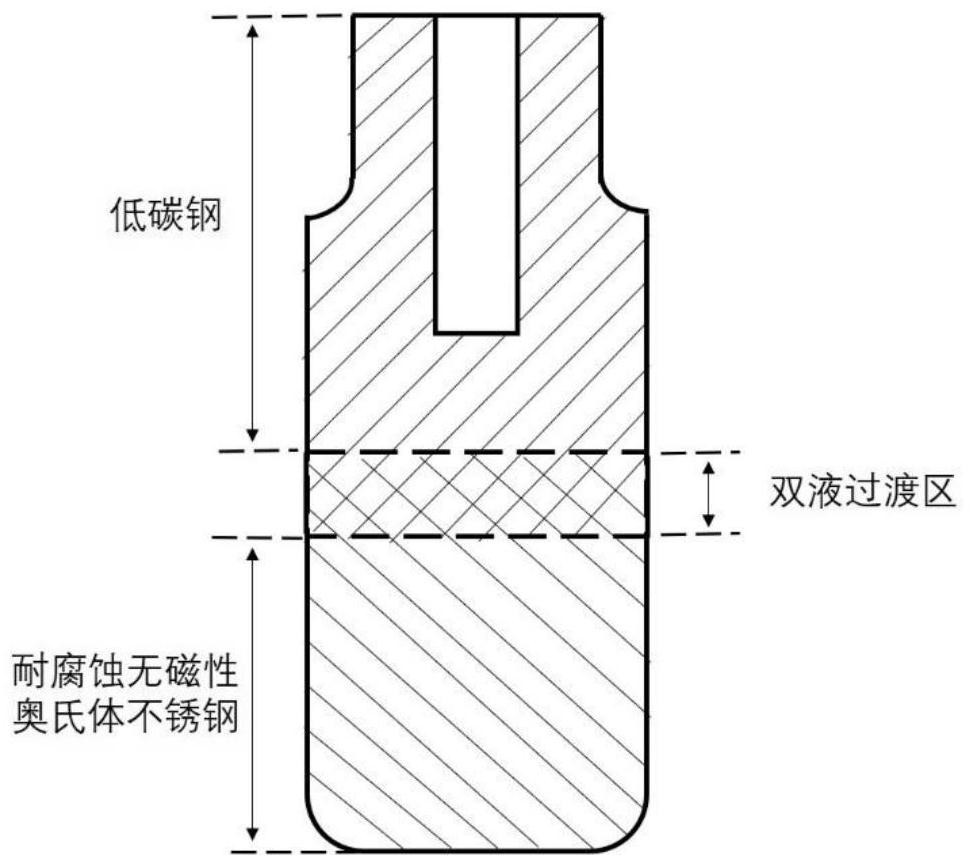

Preparation method of single-phase non-magnetic corrosion-resistant electrolytic aluminum crust breaking hammer and product thereof

PendingCN114378280AAvoid cost disadvantagesSimple production processProcess efficiency improvementSS - Stainless steelCastner process

The invention discloses a preparation method of a single-phase non-magnetic corrosion-resistant electrolytic aluminum crust breaking hammer and a product of the single-phase non-magnetic corrosion-resistant electrolytic aluminum crust breaking hammer, and belongs to the technical field of material forming. The method for preparing the electrolytic aluminum crust breaking hammer head by adopting a double-liquid casting method specifically comprises the following steps: manufacturing a lost foam cavity, carrying out carbonization treatment, and measuring the residual carbon amount; austenitic stainless steel components are molten and mixed, and Q235 steel is molten; and the molten austenitic stainless steel liquid and the molten Q235 steel liquid are guided into a lost foam cavity, and the single-phase non-magnetic corrosion-resistant electrolytic aluminum crust breaking hammer is obtained after cooling. The production process is simple, the double-liquid interface bonding property is good, the molten aluminum corrosion resistance is high, the production cost is low, heat generated by electromagnetic induction is little, heat generated by resistance is small, and the purity of primary aluminum is guaranteed through small hammer head loss. The service life of the electrolytic aluminum crust breaking hammer head prepared by the method is 24-26 months, the production efficiency is improved, and the electrolytic aluminum cost is reduced.

Owner:阜新祥远铸造有限公司

A kind of magnesium alloy anodic oxidation method

ActiveCN103911645BReduce chemical corrosionReduce alkalinityAnodisationSquare waveformPulse power supply

The invention relates to a magnesium alloy anode oxidation method sequentially comprising degreasing, pickling, alkali corrosion, anodic oxidation and drying steps, and a pulse power supply used in the anodic oxidation step outputs AC square wave pulses. An anodic oxidation film generated in the anodic oxidation process is not burnt and the surface of the oxidation film is smooth.

Owner:JIANGSU ZHONGKE YAMEI NEW MATERIAL CO LTD

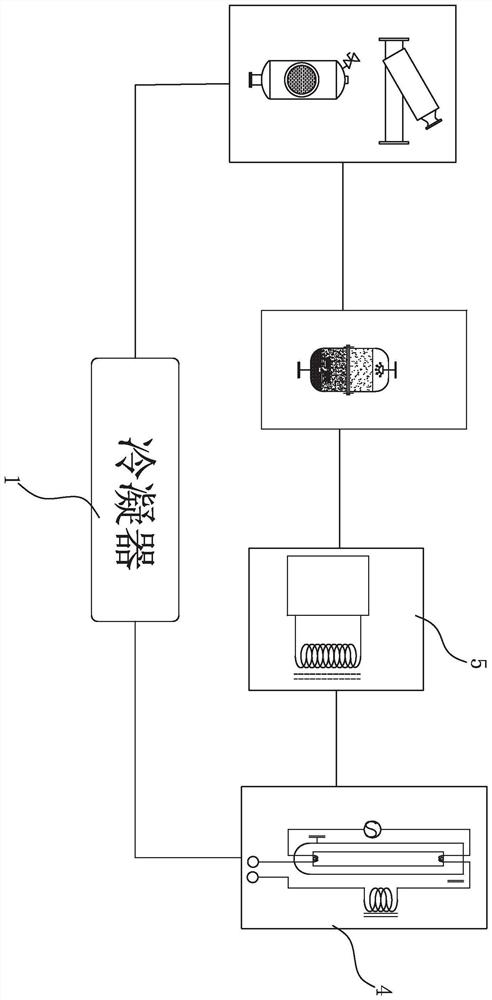

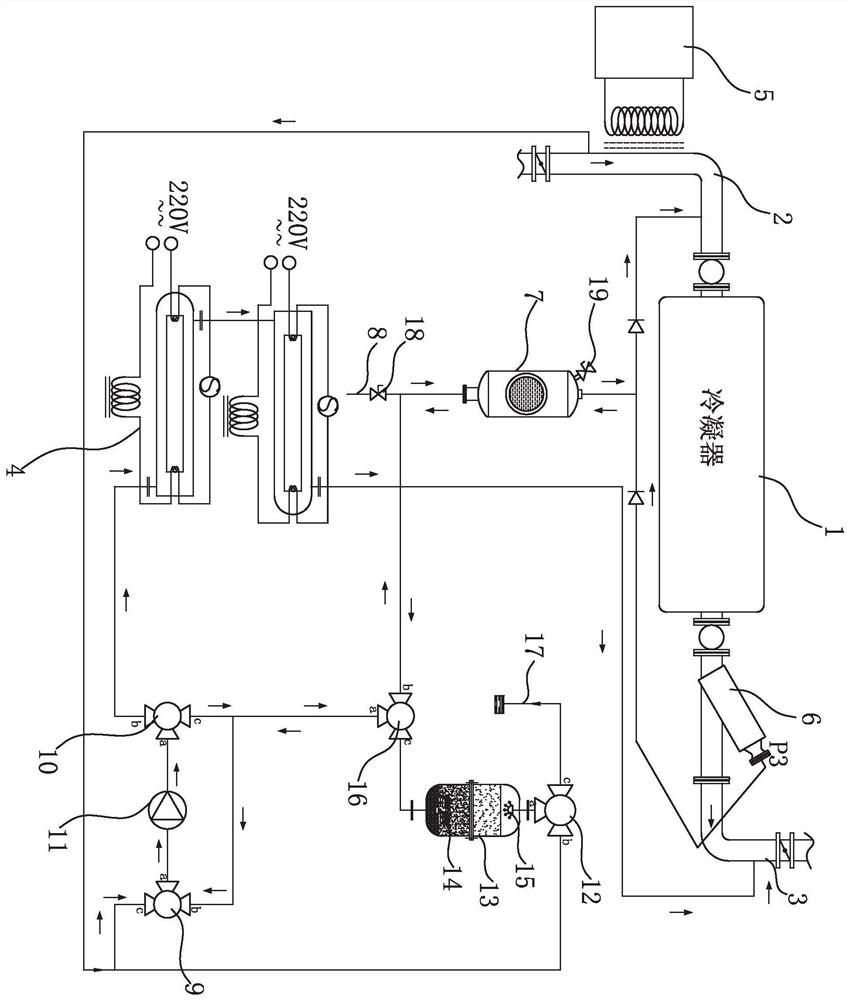

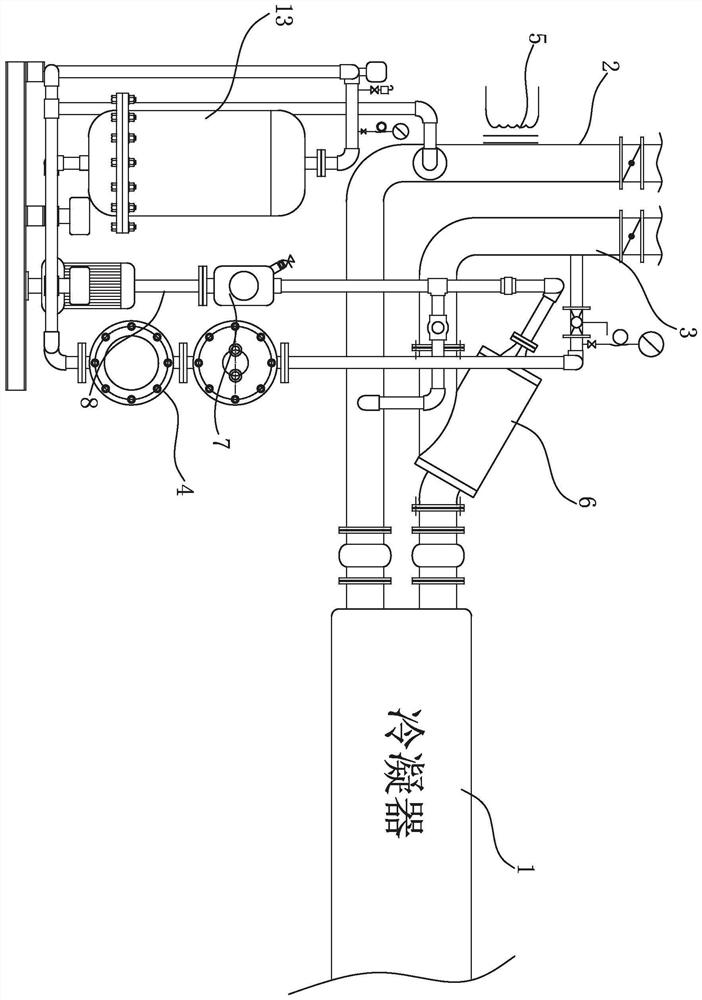

Energy-saving and emission-reducing machine for air-conditioning water-cooling water chilling unit

PendingCN114110840AImplement filteringRealization of filter recoil blowdownSpace heating and ventilation detailsFlush cleaningChemical corrosionEnergy conservation

The invention provides an energy-saving and emission-reducing machine for a water-cooling water chilling unit of an air conditioner, which comprises a condenser, a cooling water inlet pipe, a condenser water outlet pipe, an automatic condenser pipeline cleaning device, a sand cylinder filtering, backflushing and blowdown device connected and communicated with the automatic condenser pipeline cleaning device, and an ultraviolet sterilization cavity device communicated with the condenser water outlet pipe, the electromagnetic wave soft water descaling device is arranged on the cooling water inlet pipe; and the electromagnetic wave soft water descaling device is respectively connected with the sand cylinder filtering back-flushing blowdown device and the ultraviolet sterilization cavity device. Compared with the prior art, power consumption and water consumption are reduced, and meanwhile, the dual effects of no pollution, no corrosion, no emission, energy conservation and environmental protection in air conditioner water treatment are achieved; chemical pollution, chemical emission and chemical corrosion are reduced, energy conservation and emission reduction of a central air-conditioning system are completely achieved, and the service life of equipment, pipelines and valves of an air-conditioning water-cooling unit system can be prolonged; the installation site and space are saved, and the system can be suitable for more water-cooling air conditioner machine room environments.

Owner:深圳市新怡节能科技有限公司

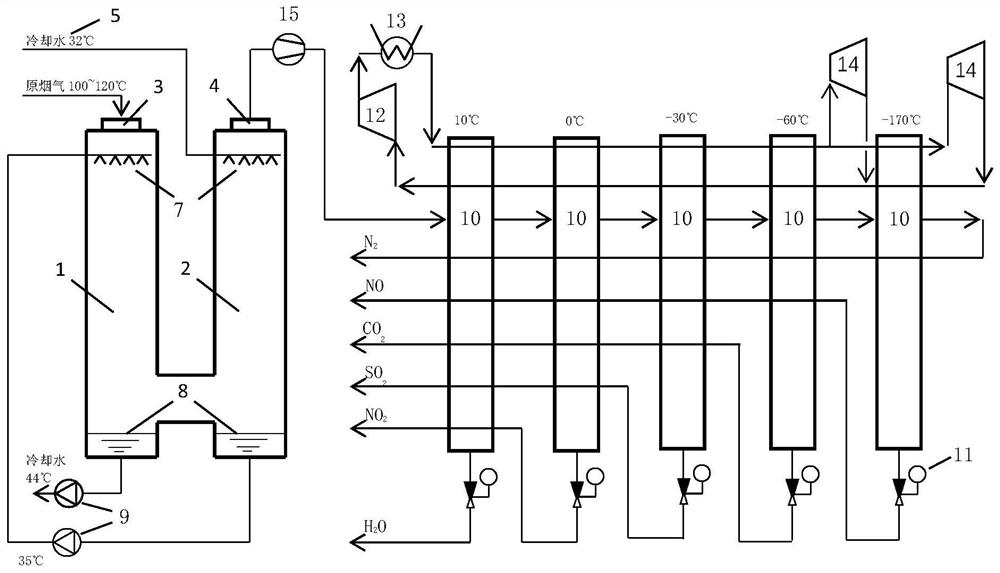

A flue gas treatment device based on low temperature gas separation

ActiveCN112058013BImprove economyLow running costGas treatmentUsing liquid separation agentParticulatesCooling tower

The invention discloses a flue gas treatment device based on low temperature gas separation. The process includes a spray cooling tower for pre-cooling the flue gas and washing the solid particles in the flue gas. The flue gas treated by the cooling tower then enters the partial condenser, and the different gas components in the flue gas are decomposed according to the gas condensation temperature. For phase change separation, the cooling capacity required by the partial condenser comes from the Brayton refrigeration cycle with nitrogen as the working medium. The device separates different gas components in the flue gas by low-temperature condensation, and is characterized by: no chemical reaction in the flue gas separation process, and little corrosion to the equipment; the separated gas can be recycled as a resource, which can generate economic benefits while meeting environmental protection requirements. ; Overcome the problems of high energy consumption, low value of by-products, easy corrosion of equipment and low-altitude white smoke emission of traditional wet desulfurization and selective catalytic reduction (SCR) denitration processes.

Owner:SHANGHAI MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com