Method for preparing PdCl2

An anolyte and inert electrode technology, applied in the field of membrane electrolysis, can solve the problems of low acid utilization rate, high final acid concentration, large acid mist, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

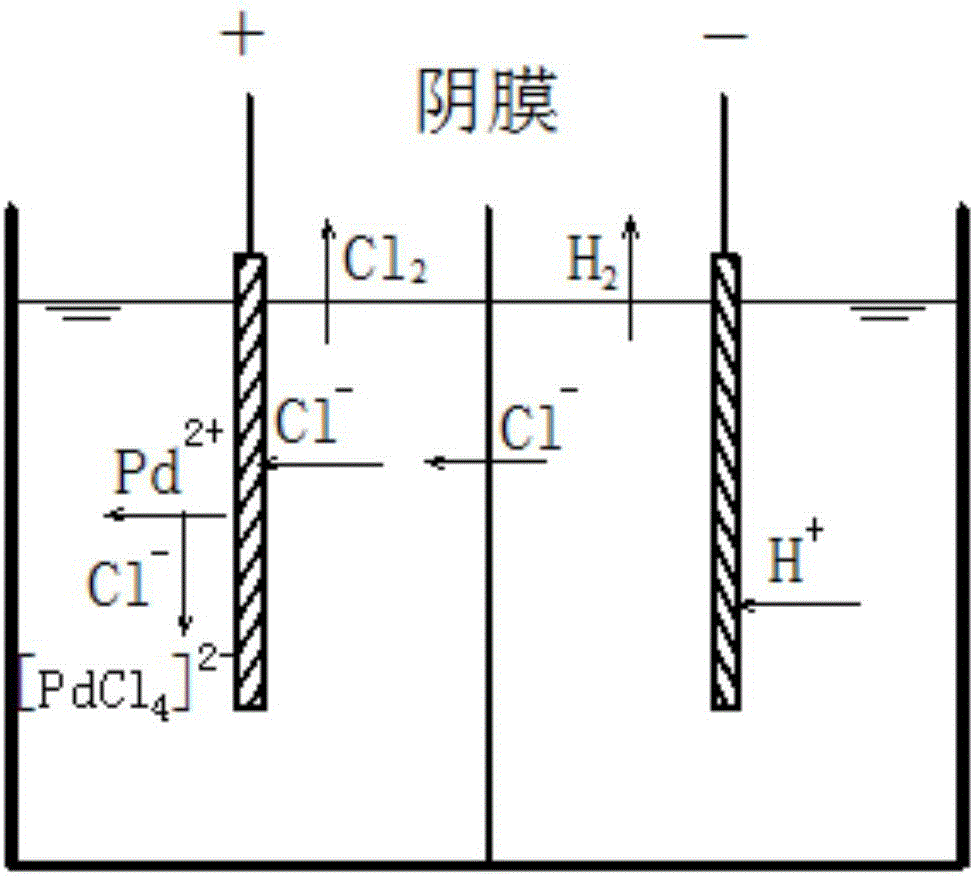

[0016] Preparation of PdCl by Membrane Electrolysis 2 The steps are:

[0017] (1) After metal palladium is pressed into sheets, the strip-shaped palladium bar obtained is placed in the anode chamber, and the platinum-plated titanium mesh is placed in the cathode chamber, all connected to the power supply;

[0018] (2) Electrolyte solution is poured into each electrode chamber, the anolyte is a hydrochloric acid solution of 6mol / L, and the catholyte is a sodium chloride solution of 0.1mol / L;

[0019] (3) Turn on the power, the condition of electrolysis is under normal temperature, the current density is 350A / m 2 , pole distance 3cm, anode reaction: Pd-2e=Pd 2+ , 30~60min;

[0020] (4) Treat that the palladium bar in the anode chamber dissolves completel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com