A method for preparing superabrasive tools through ultrasonic-assisted active connection

A technology of active connection and superhard abrasive grains, applied in manufacturing tools, turning equipment, grinding devices, etc., can solve the problems of restricting the promotion of brazing abrasive grain tools, short tool life, unstable processing process, etc. The effect of liquid surface tension, promoting flow, and shortening chemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] In order to solve the problems of thermal damage and excessive residual stress in the existing technology of brazed abrasive tools, the present invention provides a method for preparing superhard abrasive tools through ultrasonic-assisted active connection. Solving prior art problems with ultrasonic correlation effects.

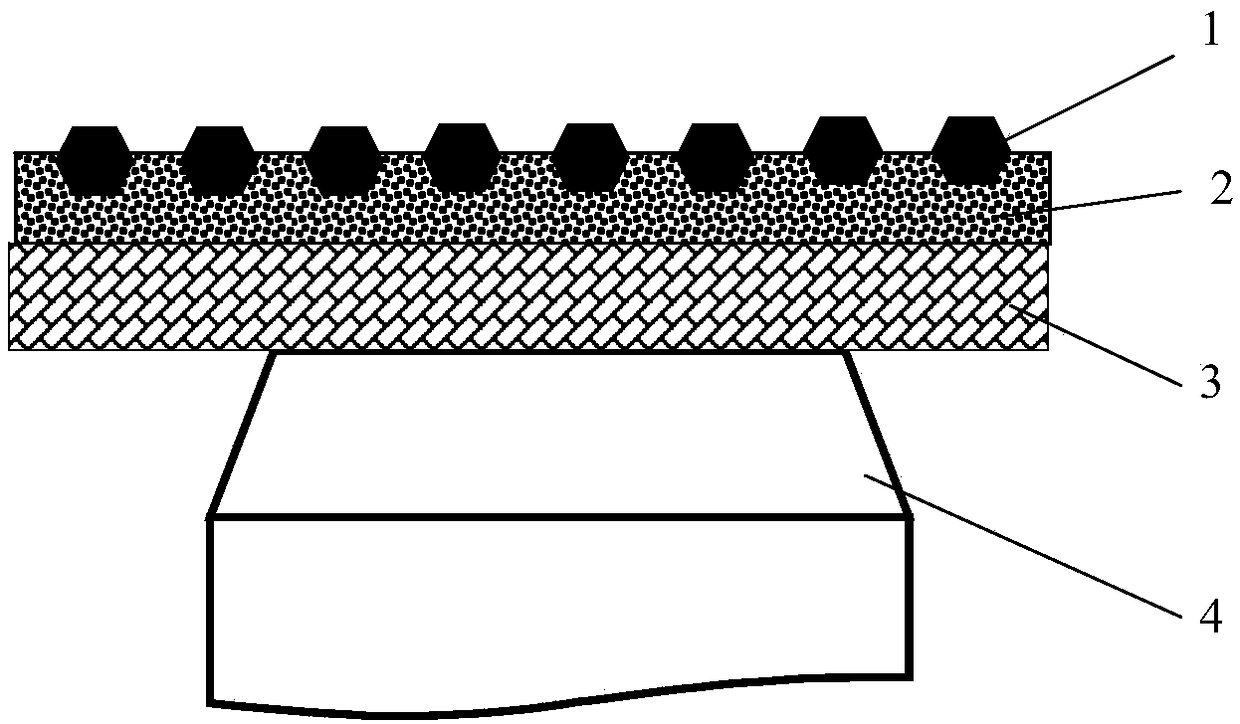

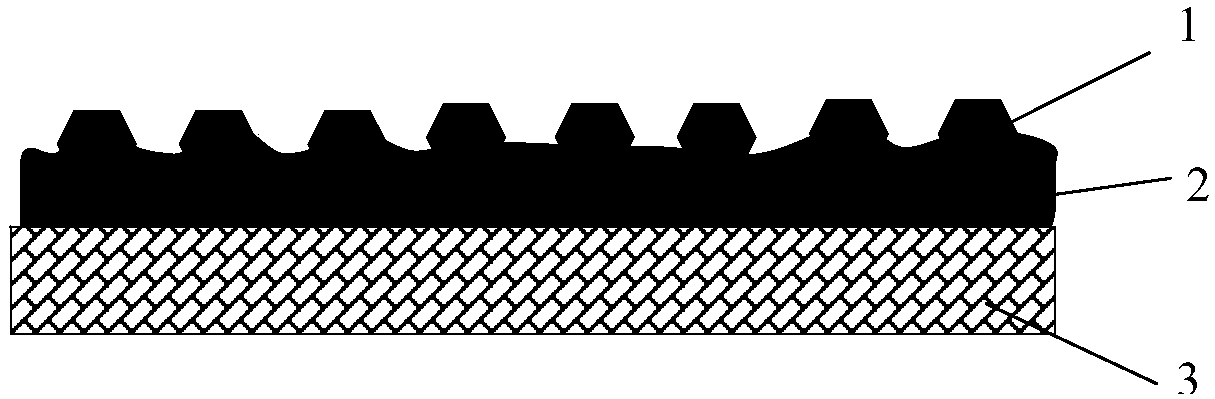

[0030] The method for preparing superabrasive grain tool by described ultrasonic-assisted active connection, at first, such as figure 1 As shown, the diamond abrasive grain 1 and the NiCrBSi active bond 2 are coated on the tool substrate (No. 45 steel) 3, and the thickness of the active bond 2 is 0.3 times the diameter of the abrasive grain. After drying, the coated abrasive The grain 1 and the abrasive grain matrix 3 of the bond 2 are fixed on the ultrasonic horn 4 through screw connection.

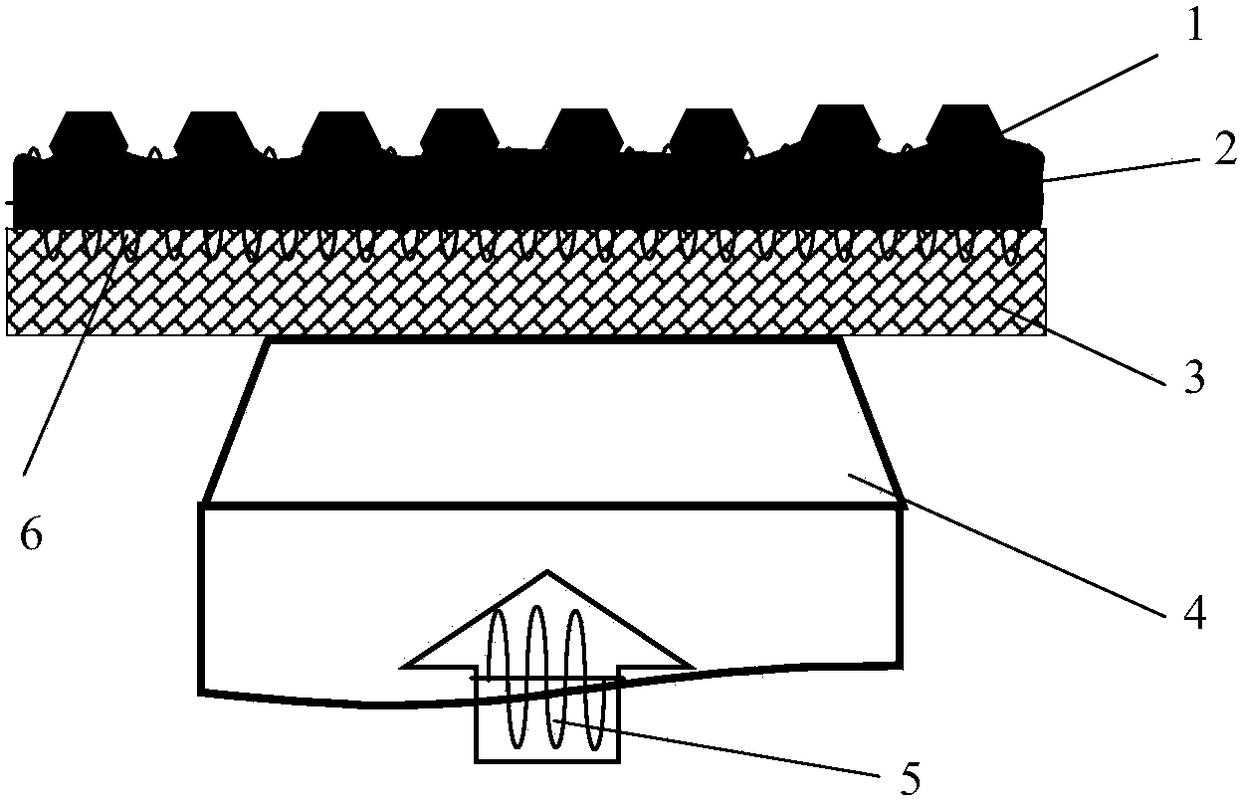

[0031] Then, if figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com