Ultrasonic-assisted induction preheating laser soldering method and device for preparing abrasive particle grinding wheel

An induction preheating and ultrasonic technology, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve the problems of large welding residual stress and excessive temperature difference caused by abrasive particles, and can promote the formation of interfacial chemical connections, promote melting and Bonding, shortening the effect of chemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following combination Attached picture And embodiment the present invention is described in further detail.

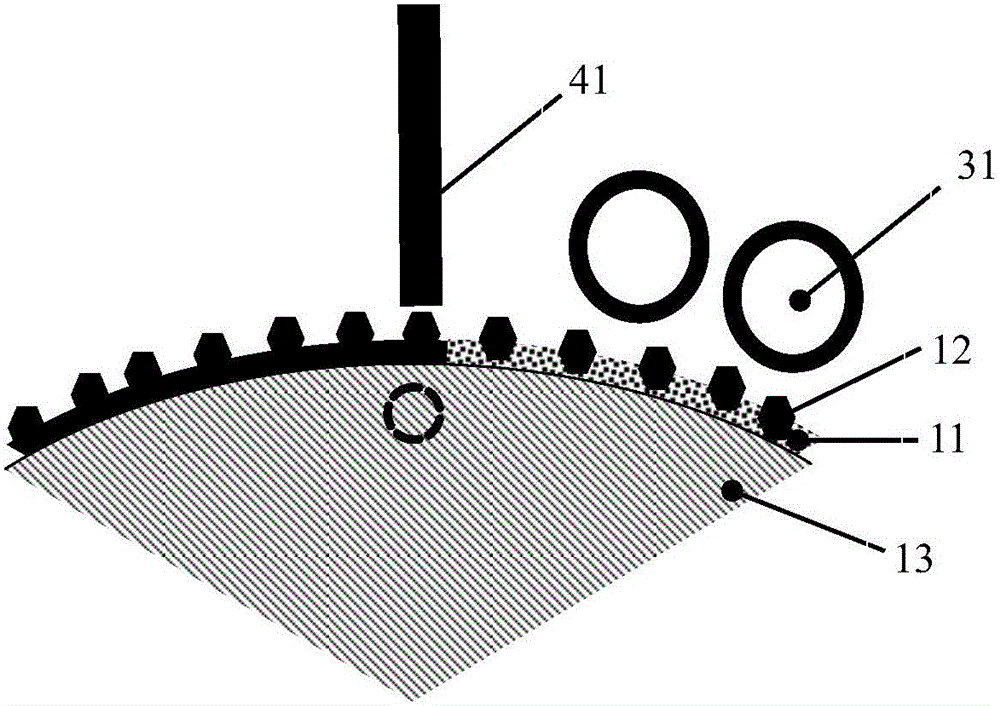

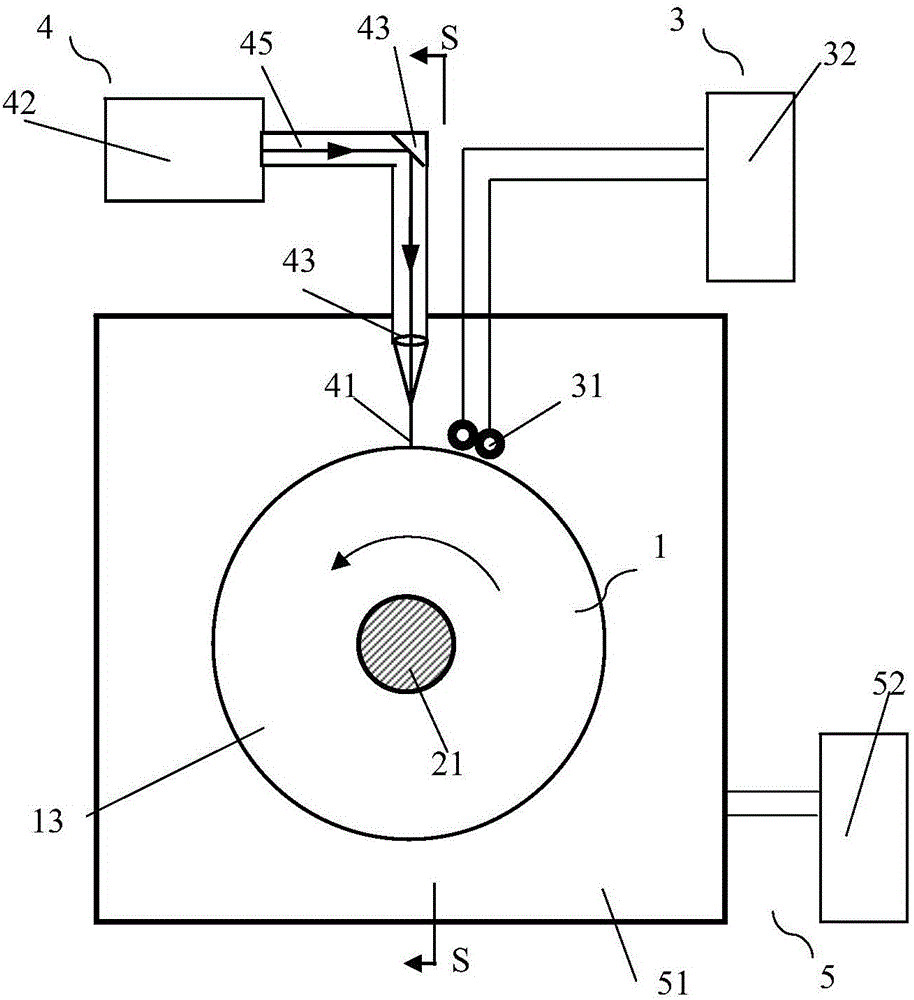

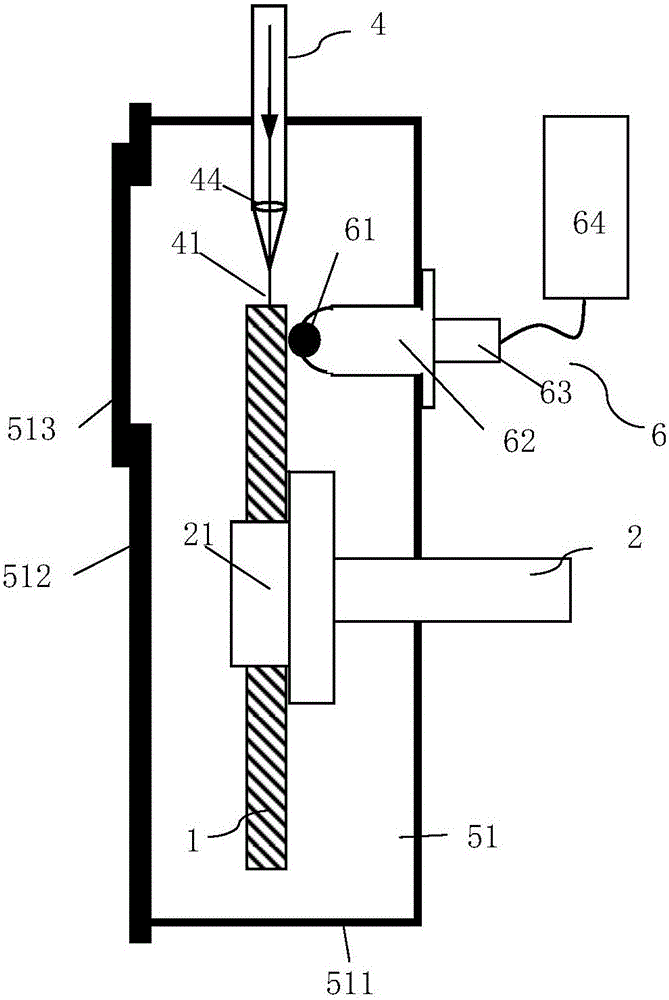

[0041] refer to picture 1-3 In order to solve the problems of excessive temperature field inside and outside the molten pool and excessive laser beam power when preparing brazing abrasive grains by laser heating, the present invention provides a method and method for preparing abrasive grain grinding wheels by ultrasonic-assisted induction preheating laser brazing The device preheats the heating area of the workpiece to be welded by induction heating, so that the disadvantages of the laser heating method can be effectively controlled.

[0042] A device for preparing abrasive grinding wheels by ultrasonic-assisted induction preheating laser brazing, comprising a grinding wheel to be welded 1, a rotating shaft 2, an induction heating system 3, a laser heating system 4, an atmosphere protection system 5 and an ultrasonic loading system.

[0043] The grind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com