Patents

Literature

222results about How to "Raise the temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

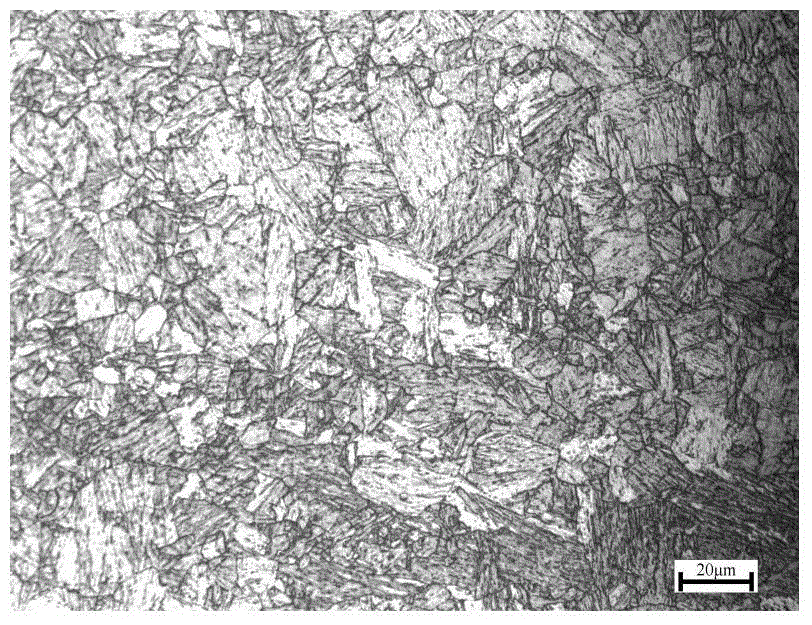

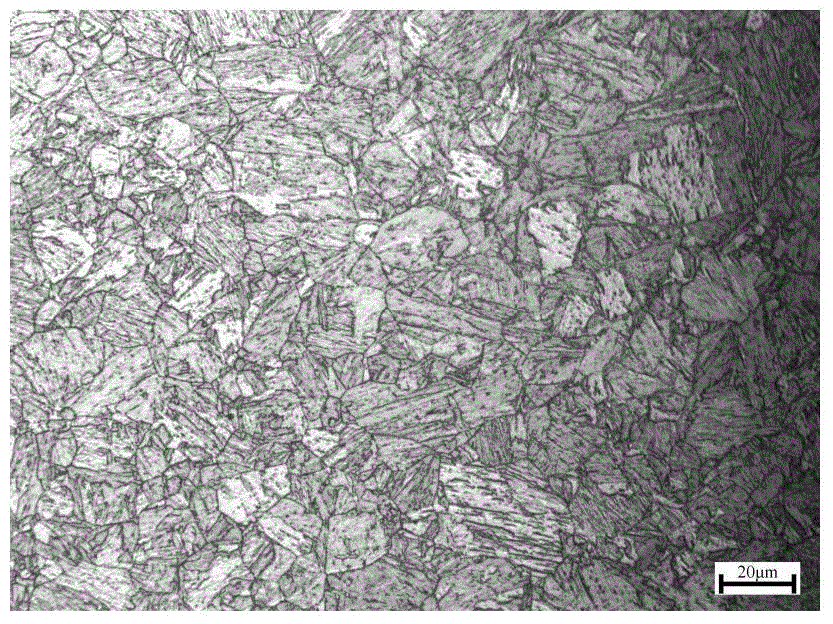

Low compression ratio 690MPa grade extra thick steel plate and production method thereof

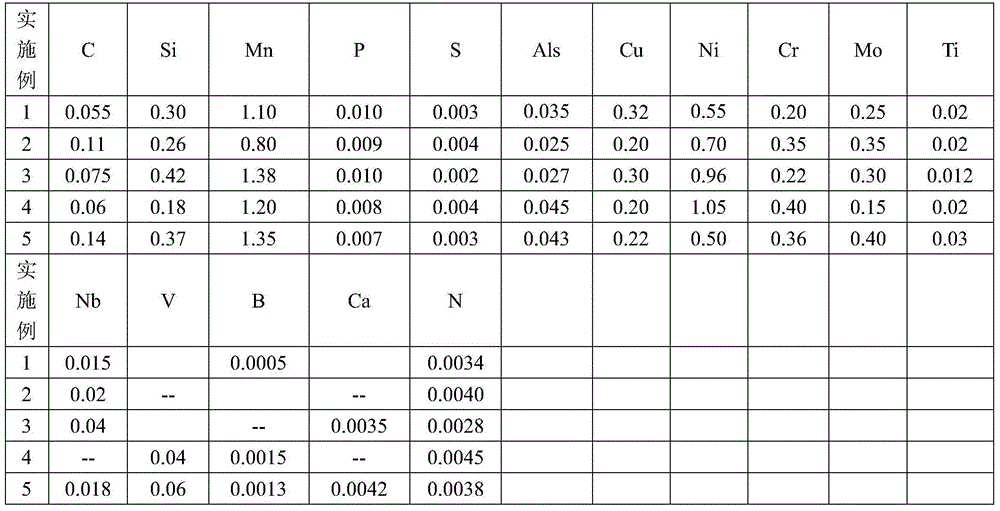

The invention discloses a low compression ratio 690MPa grade extra thick steel plate and a production method thereof, and the low compression ratio 690MPa grade extra thick steel plate comprises the following components by weight: 0.05%-0.14% of C, 0.12%-0.45% of Si, 0.70%-1.40% of Mn, < = 0.010% of P, < = 0.005% of S, 0.025%-0.065% of Als, < = 0.005% of N, 0.10%-0.50% of Cu, 0.50%-1.00% of Ni, 0.10%-0.40% of Cr, 0.10%-0.45% of Mo, also comprises one or more than two components selected from the following chemical components: 0.03%-0.08% of V, 0.005%-0.04% of Nb, 0.005%-0.03% of Ti, 0.0008-0.004% of B and 0.002%-0.006% of Ca, and also comprises balance of Fe and inevitable impurities, wherein the total ratio of precious and strengthening elements of Cr, Mo, Ni and Cu is less than or equal to 1.5%.

Owner:ANGANG STEEL CO LTD

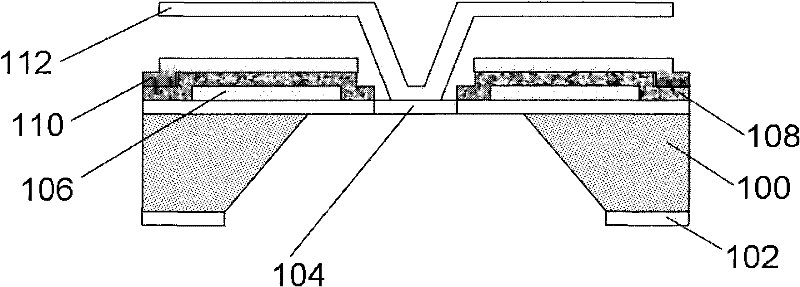

Micromachined thermopile infrared detector

ActiveCN101575083AReduce stressNo high temperature annealing requiredTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesThermopileReflective layer

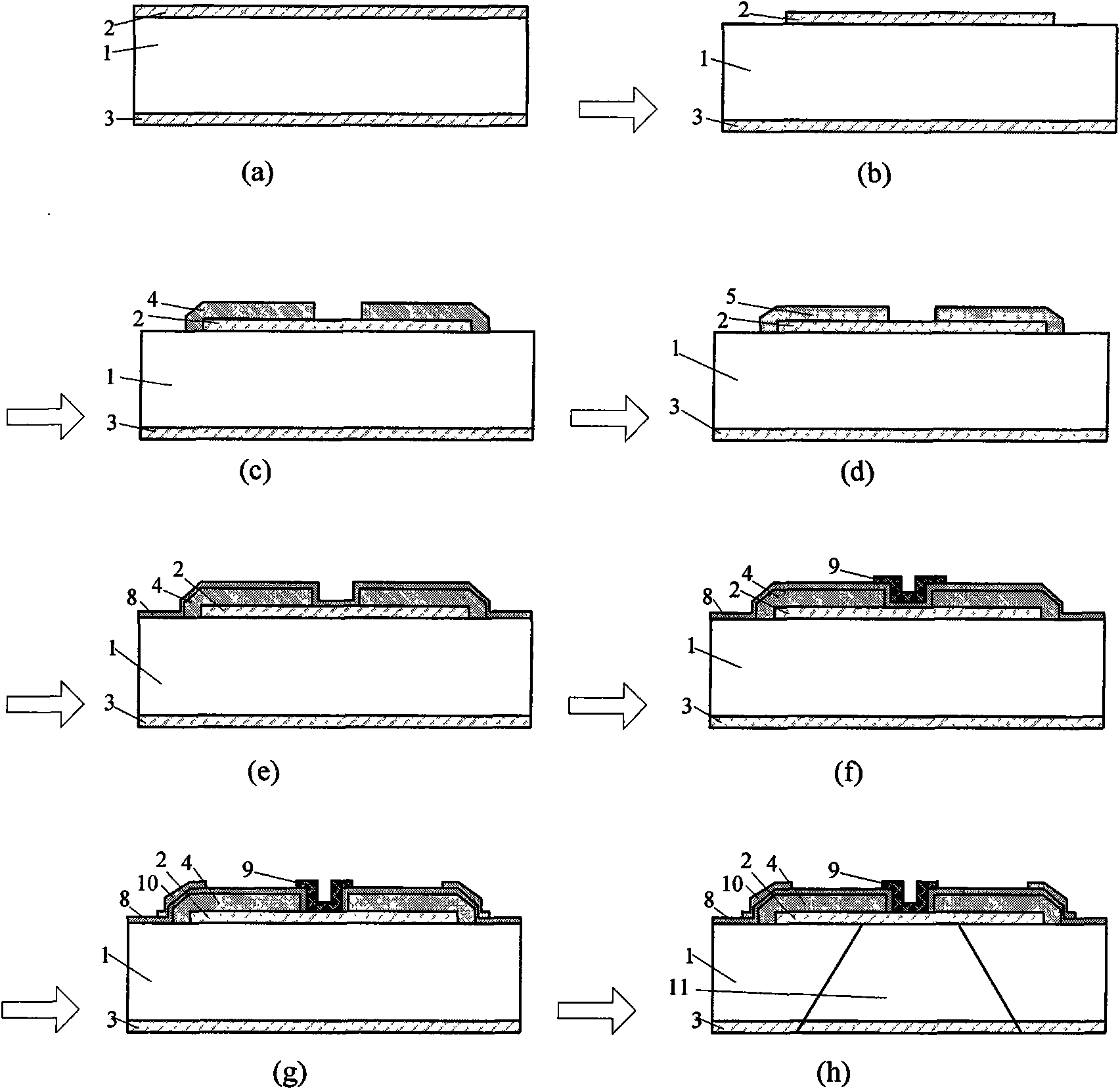

The invention relates to the field of an infrared detector, in particular to a micromachined thermopile infrared detector. The manufacturing technique is simplified and the performance and finished product rate are improved. The manufacture of the micromachined thermopile infrared detector comprises the following steps of: (1) depositing silicon nitride film on the both sides of a silicon substrate by an LPCVD method; (2) etching to remove peripheral silicon nitride film on the frontal side of the silicon substrate by lithography; (3) manufacturing a plurality of Poly-Si strips both ends of which are respectively arranged on the silicon nitride film and the silicon substrate by LPCVD method and photolithographic process; (4) manufacturing a plurality of aluminum strips which form a thermocouple with the plurality of Poly-Si strips by sputtering and photolithographic processes; (5) depositing the silicon nitride film on the frontal side of the silicon substrate by PECVD method; (6) manufacturing an infrared absorption layer (a carbonized photoresist layer) covering the hot junction area of the thermopile with photolithographic process; (7) manufacturing a metal reflective layer (a metal layer) covering the cold junction area of the thermopile with lift-off process; and (8) eroding the back side of the silicon substrate to form a square frustum pyramid shaped groove. The micromachined thermopile infrared detector has reasonable structure design, simple manufacturing process, high detector performance, high finished product rate, good development prospect and is easy to realize.

Owner:ZHONGBEI UNIV

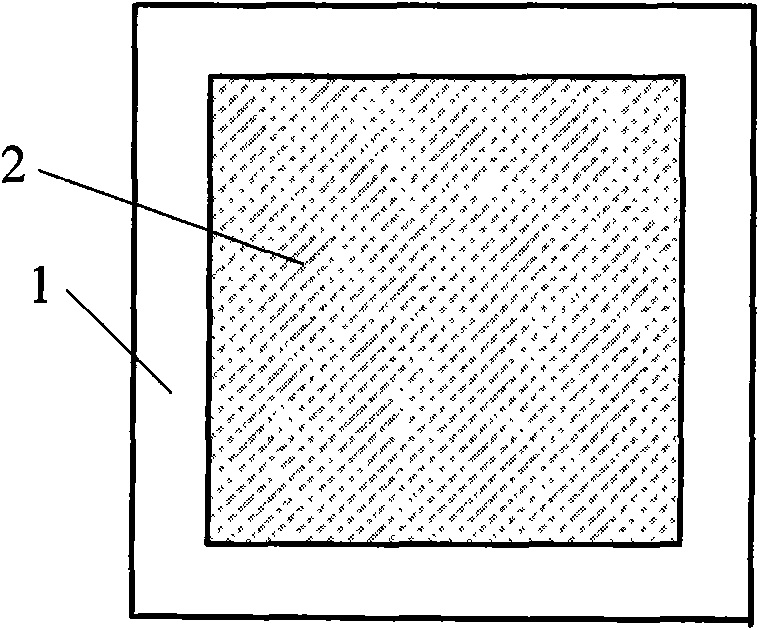

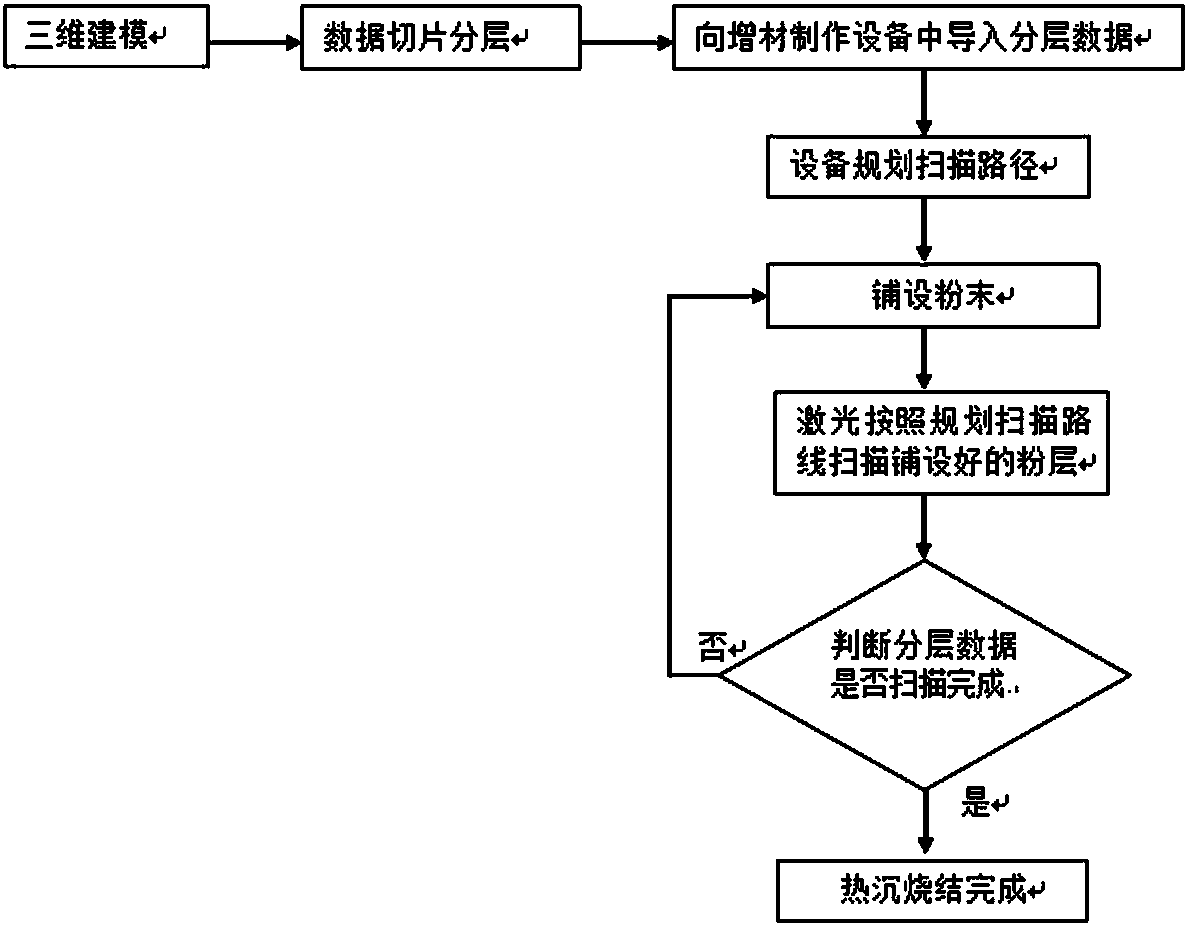

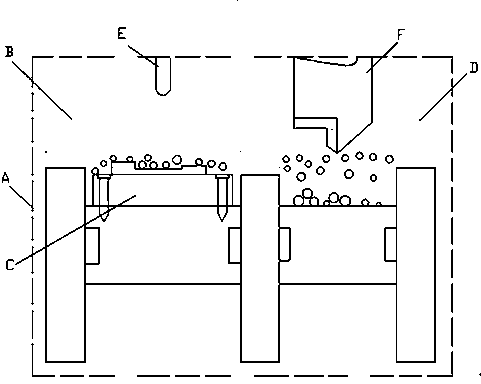

Method for manufacturing heat sink body

ActiveCN104028758AReduced time for structural optimization and product manufacturingImprove thermal performanceIncreasing energy efficiencyThree dimensional modelHeat sink

The invention discloses a method for manufacturing a heat sink body. The method aims at solving the problems that in the traditional heat sink manufacturing process, heat resistance is increased due to multilayer welding, and a heat sink body needs to be manufactured through multiple processes and is short in service life. The method includes the steps that three-dimensional modeling is conducted on the whole structure of the heat sink body; a three-dimensional model is guided to a workbench computer, and the printing angle and positions are set according to the structure of a three-dimensional pattern; a powder layer laid on a base plate of a workbench in advance is sintered into two-dimensional shapes corresponding to the powder layer through high-energy laser beams according to the scanning path; powder as thick as the powder layer is laid on the workbench on which one layer of pattern is sintered, and lasers scan the powder according to the scanning path of the layer until the whole three-dimensional pattern is finished. Through the structure, the heat sink body has the advantages that pressure distribution is uniform and the service life of the heat sink body is prolonged.

Owner:CHENGDU 3D CHANGE TECH

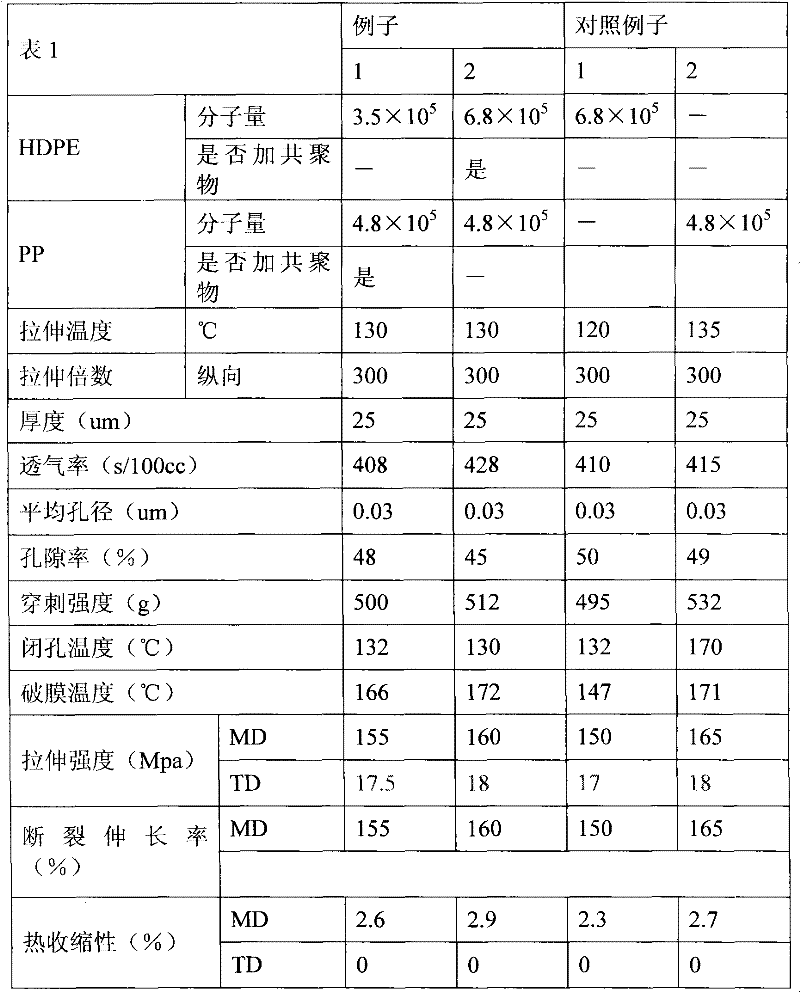

Polyene microporous multilayer diaphragm and manufacturing method thereof

ActiveCN102248713AImprove securityRaise the temperature differenceSynthetic resin layered productsPolyeneEthylene propylene copolymer

The invention provides a polyene microporous multilayer diaphragm and a manufacturing method thereof. The diaphragm is formed by combing three or more than three polyene layers, wherein in a plurality of polyene layers, at least one polyene layer is a polyethylene layer, and at least one polyene layer is a polypropylene layer; the polyethylene layer and the polypropylene layer are tightly attached to each other; and in adjacent polyethylene and polypropylene layers, at least one layer is a polymer blend layer which contains a certain amount of ethylene-propylene copolymer. The invention has the advantages that: in the integrated structure of the polyene microporous multilayer diaphragm, the properties of porosity, puncture strength, pore size, ventilation ratio, tensile strength, breaking elongation and the like are also identical to the high properties of a single-layer diaphragm; simultaneously, the defects of the single-layer diaphragm is overcome, namely the safety of the diaphragm is improved.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

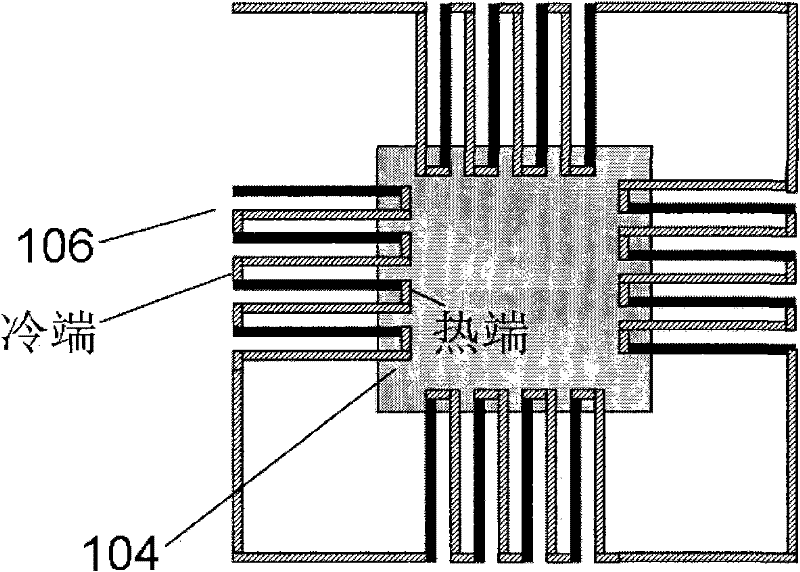

Thermo-electric pile infrared detector

ActiveCN102244190AHigh sensitivityIncrease the areaThermoelectric device with peltier/seeback effectThermoelectric device detailsResponsivityTemperature difference

The invention relates to a thermo-electric pile infrared detector, which comprises a substrate with a full-hollow structure, a thermo-electric pile, a first infrared absorption layer, a passivation layer, a reflective layer and a second infrared absorption layer formed by the release technology of a sacrifice layer, wherein the thermo-electric pile, the first infrared absorption layer and the passivation layer are formed on the substrate; and the reflective layer is formed on the passivation layer. By the detector, the infrared absorptivity is improved, and temperature difference of a thermoelectric couple at a cold end and a hot end is increased, so the response rate and sensitivity of the detector are improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

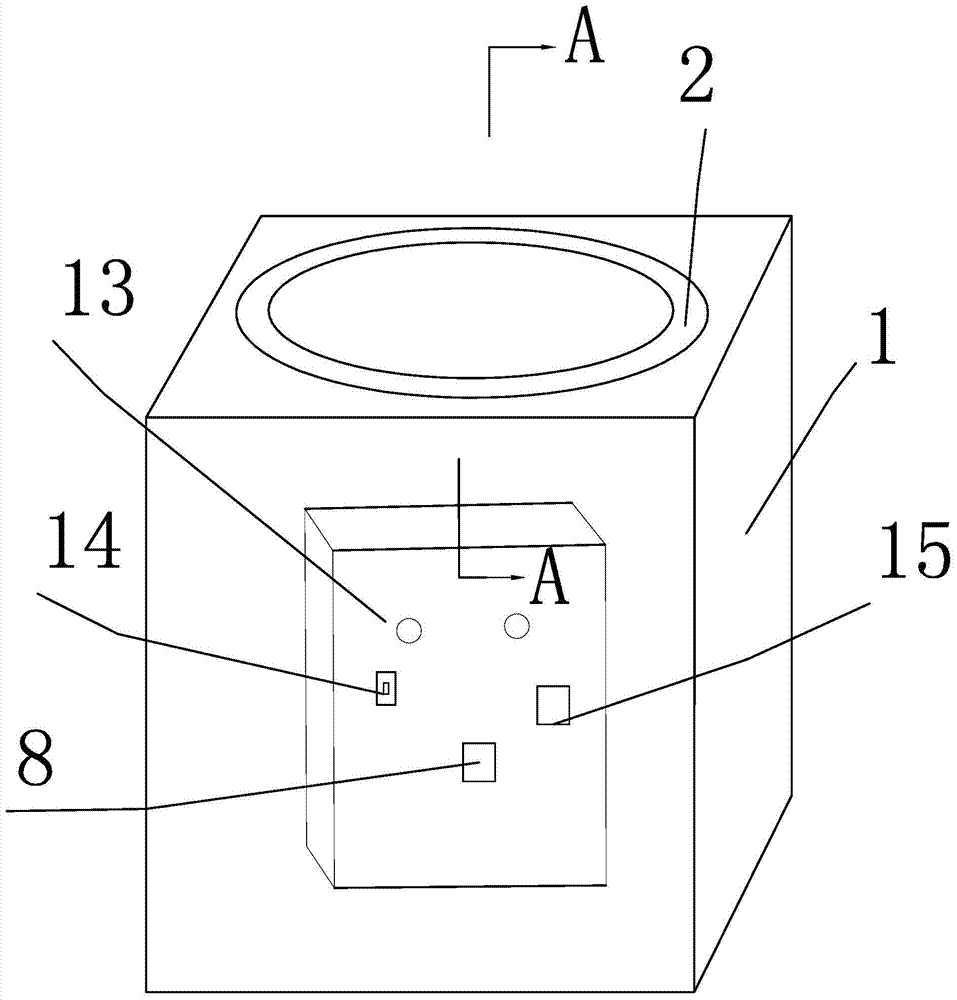

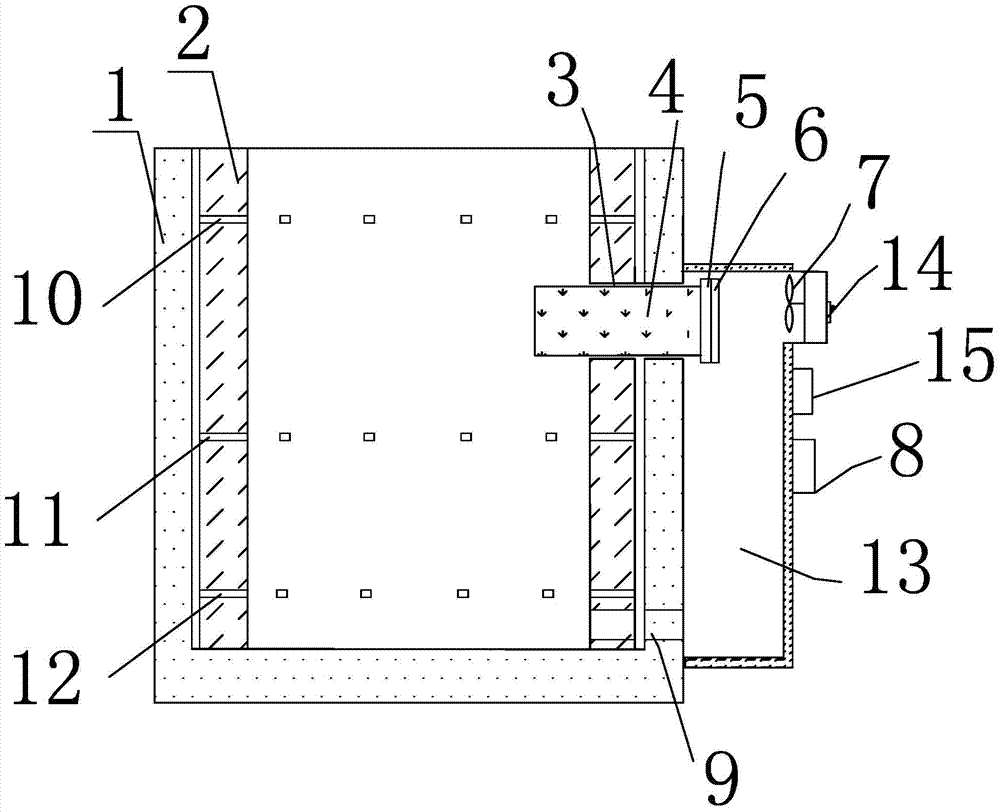

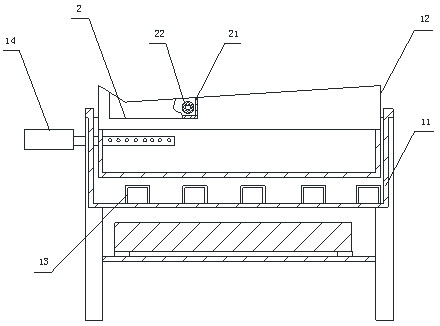

Outdoor wood stove capable of generating electricity

InactiveCN103615745ARaise the temperature differencePlay a supporting roleDomestic stoves or rangesLighting and heating apparatusElectricityTemperature difference

The invention discloses an outdoor wood stove capable of generating electricity. The outdoor wood stove comprises a stove body and a temperature difference power generation device fixed to the outer side wall of the stove body, at least one primary air inlet, a secondary air inlet and a tertiary air inlet are formed in the lower portion, the middle and the upper portion of an inner container respectively, an air guiding opening is formed below the primary air inlet, and a heat conduction hole is formed between the secondary air inlet and the tertiary air inlet; the temperature difference power generation device comprises a heat conduction metal rod, at least one temperature different power generation piece, a radiating aluminum plate, an air blower, a storage battery module and a radiating air duct, the radiating air duct is communicated with the air guiding opening, the heat conduction metal rod is fixed in the heat conduction hole, one end of the heat conduction metal rod is attached to the heat collection surface of the temperature different power generation piece, and the radiating surface of the temperature difference power generation piece is attached to the radiating aluminum plate. The outdoor wood stove has the advantages of being simple in structure, convenient to carry, low in cost and capable of forcing air feeding and effectively carrying out power generation and power supply outdoors.

Owner:孟波

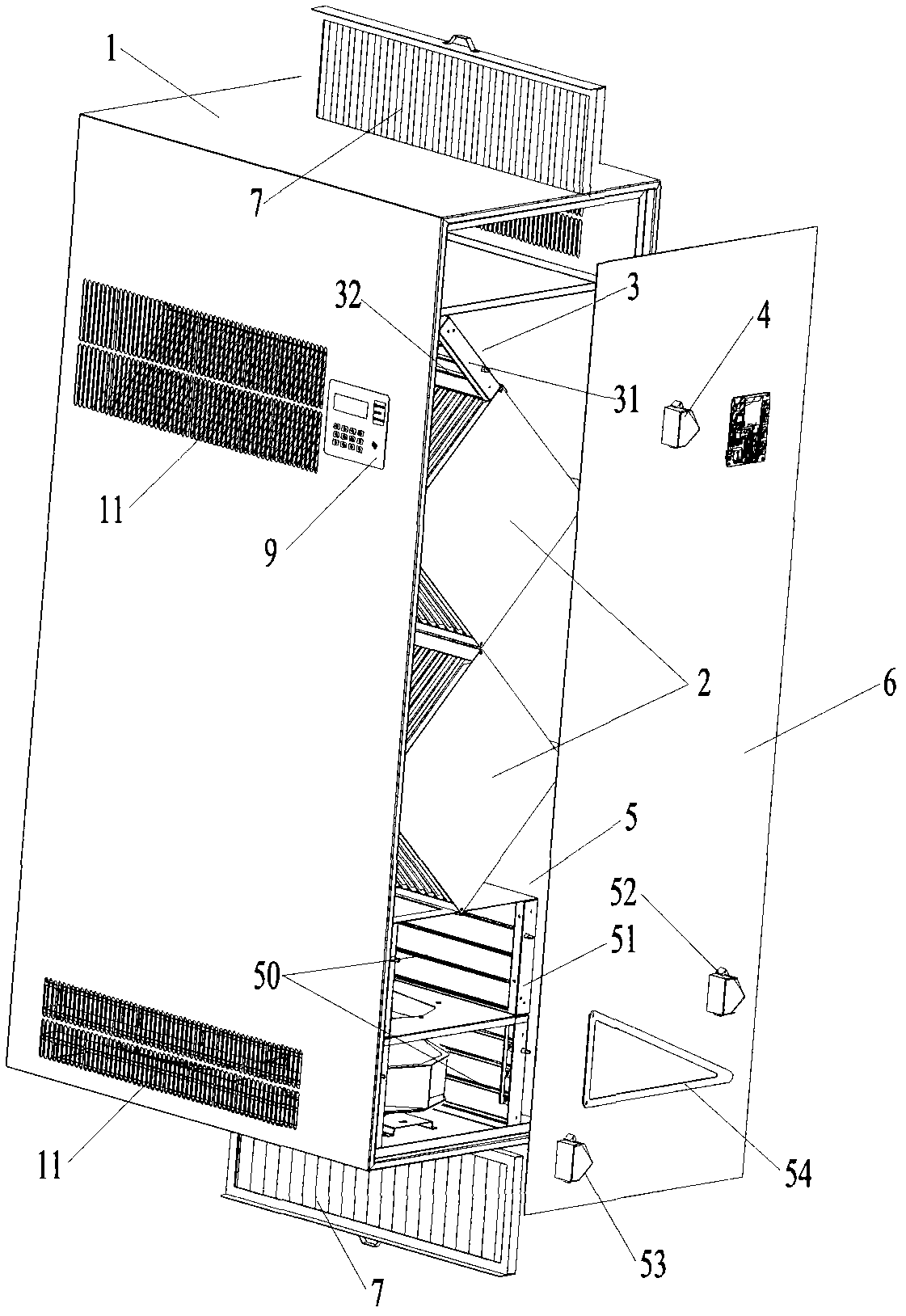

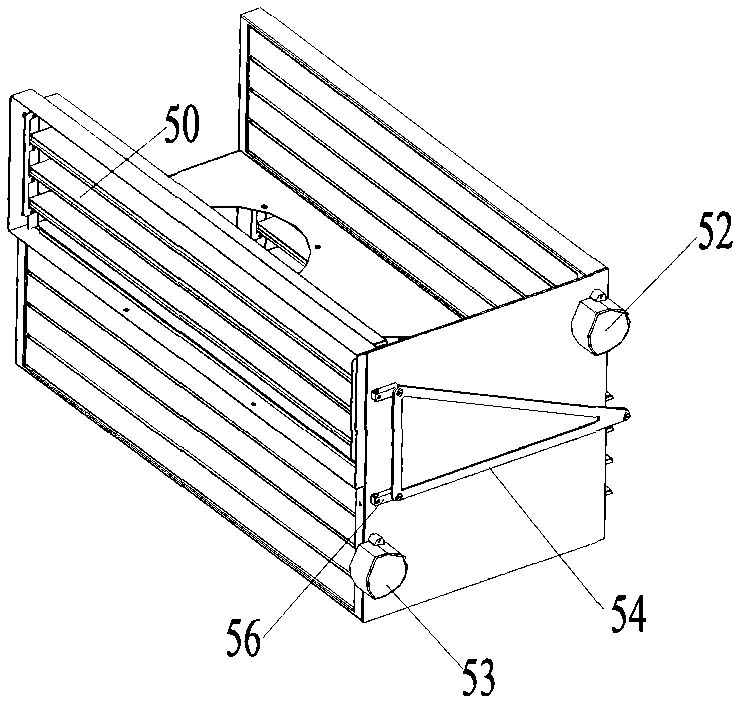

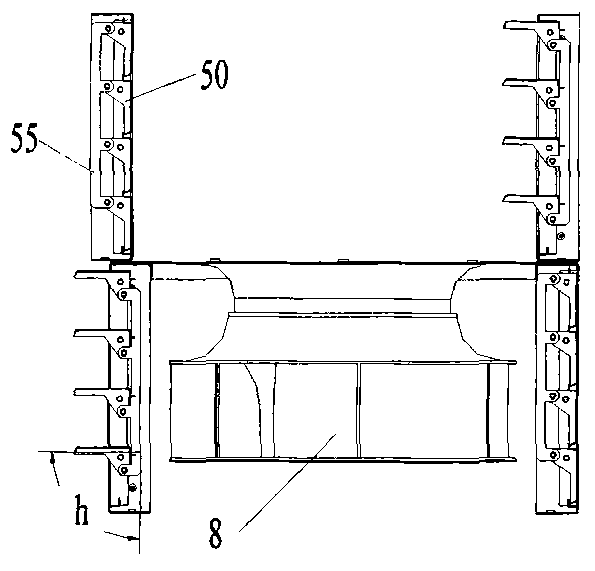

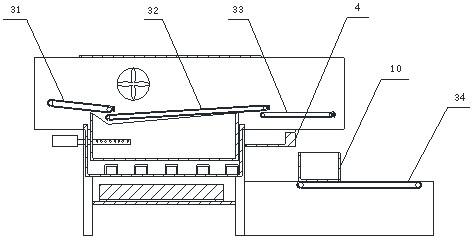

Integrated automatic dedusting energy-saving system and conversion method thereof

InactiveCN102829512AImprove cooling efficiencyWith the function of direct ventilation and heat dissipationEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsDrive motorEngineering

The invention discloses an integrated automatic dedusting energy-saving system. The integrated automatic dedusting energy-saving system comprises a controller, a first air door device and a second air door device, wherein the first air door device is controlled by the controller, and is positioned between a first fan and a heat exchange movement at the upper part; the second air door device is arranged between a heat exchange movement at the lower part and a second fan; and the first air door device and the second air door device are controlled and linked by the controller through a first drive motor, a second drive motor and a third drive motor, and the three functions including heat exchange dissipation, forward air-feed dissipation and backward air exhaust dissipation and dust removal are achieved by not changing rotation direction inside the two fans. When the integrated automatic dedusting energy-saving system is at the backward air exhaust dissipation state, dust, fine sands and the like accumulated at a filtering net can be blown out reversely, so that the heat dissipation efficiency for long-term use of the system at the heat exchange heat dissipation state and the forward air-feed heat dissipation state can be improved. The integrated automatic dedusting energy-saving system ingeniously combines the advantages of a heat exchange system and a fresh air energy-saving system, so that the system has straight ventilation and dissipation functions and also has an automatic dedusting function, meanwhile, the integrated automatic dedusting energy-saving system is compact in structure.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

Deep-sea hydrothermal liquid temperature difference energy generating set

InactiveCN103944452ASimple structureCompact structureGenerators/motorsThermal energyLiquid temperature

The invention discloses a deep-sea hydrothermal liquid temperature difference energy generating set which comprises a heat pipe, a vacuum thermal insulation cavity, a radiating cavity, a temperature difference energy generating sheet, a generating sheet fixing block, a radiating block, a voltage conversion circuit and a charging circuit, wherein the vacuum thermal insulation cavity and the radiating cavity are fastened as a whole. The heat pipe is provided with an evaporation section, a thermal insulation section and a condensation section, wherein the evaporation section is exposed out of the vacuum thermal insulation cavity, the thermal insulation section is located in the vacuum thermal insulation cavity, and the condensation section is arranged in the radiating cavity. According to the deep-sea hydrothermal liquid temperature difference energy generating set, the heat pipe is used for capturing the thermal energy of deep-sea hydrothermal liquid, the structure is simple, reliability is good, and the energy conversion rate is high. The temperature difference energy generating sheet is used for converting the temperature difference energy of the deep-sea hydrothermal liquid and peripheral sea water into electric energy, and the electric energy passes through the voltage conversion circuit and the charging circuit and then is output and provided for deep-sea detection equipment. In addition, the deep-sea hydrothermal liquid temperature difference energy generating set is compact in overall structure, small in boundary dimension and suitable for the operation of a mechanical arm of a bathyscaph.

Owner:ZHEJIANG UNIV

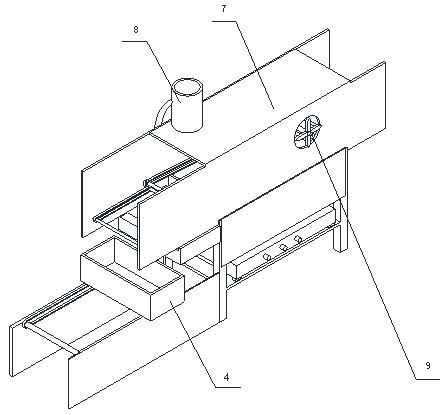

Bean gluten machine

InactiveCN102204592AHeating evenlyGuaranteed to boilCheese manufactureFood scienceHeat conductingTransmission belt

The invention discloses a bean gluten machine comprising a heating container, a shaping roller and a cover body, wherein the heating container has a double-layer structure, the outer layer is a heat-conducting layer, the inner layer is a material layer with an opening, the heat-conducting layer is internally provided with a secondary heater, two opposite side surfaces of the material layer are V-shaped, an anti-overflowing device is arranged at the edge of the material layer, a water pump facilitating circulation and heating of materials is arranged on the material layer, a gas pipe of the water pump is communicated with the material layer and provided with a group of through holes; first, second and third transmission belts are arranged above the material layer in the direction from feeding to discharging, a guiding device is respectively arranged on the discharging ends of the first, second and third transmission belts; the surface of the shaping roller contacts the bean milk surface at the lowest point of the material layer; and the cover body is positioned above the material layer and provided with a feeding device and a fan facing the bean milk in the material layer.

Owner:蒲宁

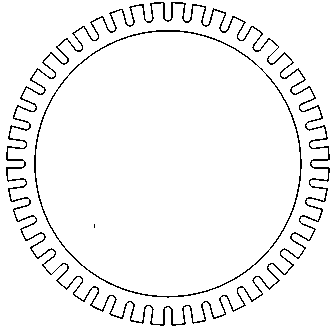

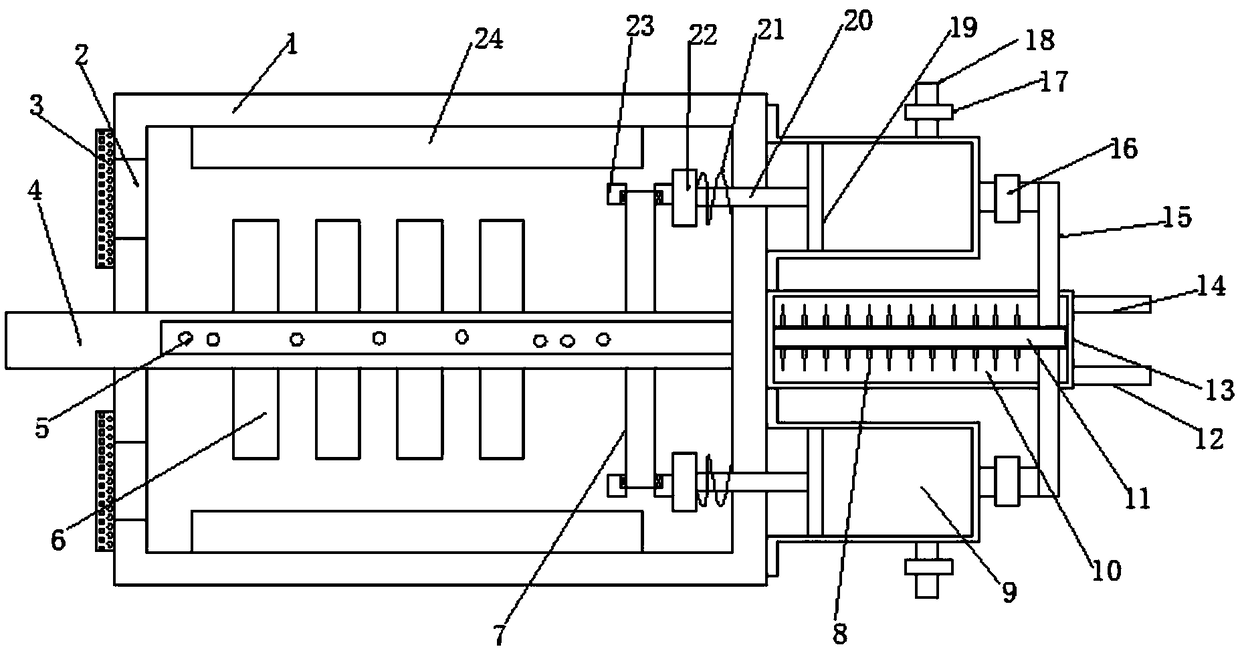

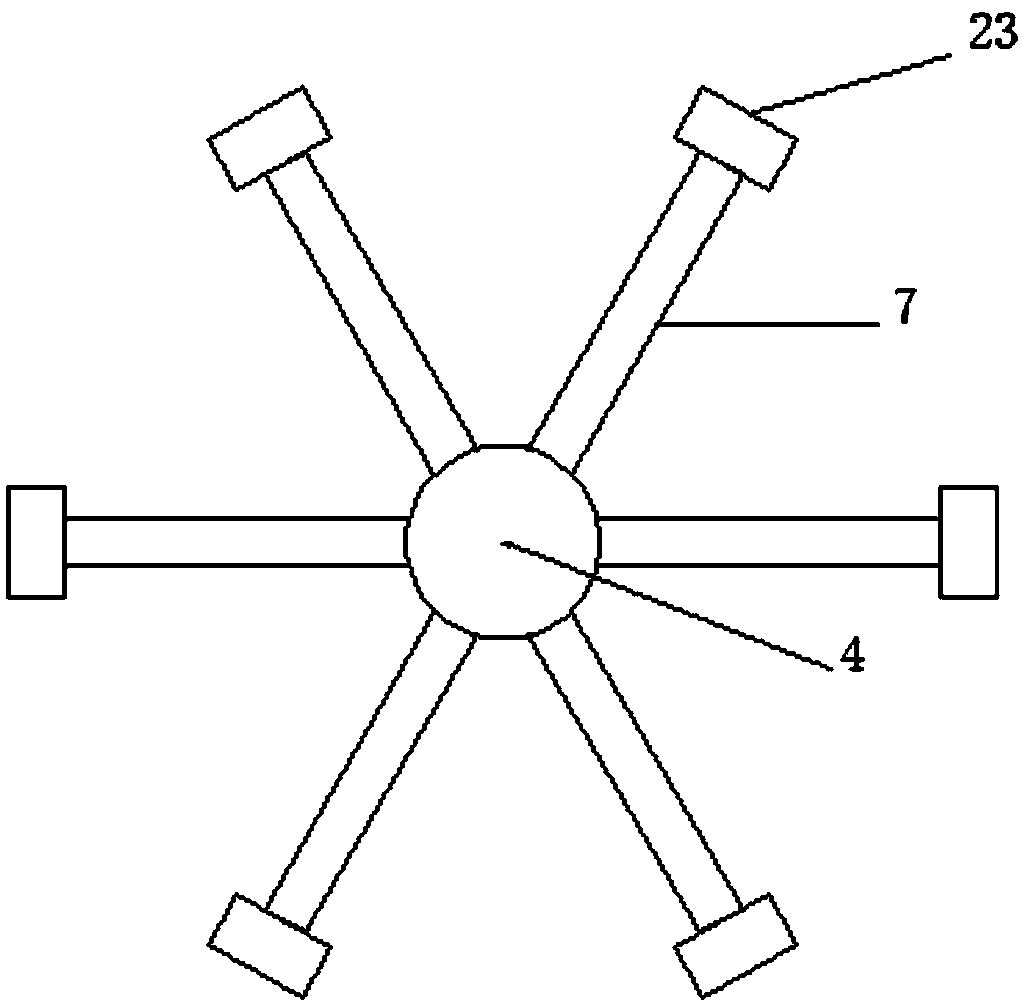

Polarization radiating unit permanent magnet motor

PendingCN108768075AIncrease temperatureReduce the temperaturePiston pumpsCooling/ventillation arrangementAir compressionTemperature difference

The invention discloses a polarization radiating unit permanent magnet motor which comprises a case, wherein a rotating shaft is arranged at a middle position of the case; an air guide chamber is formed inside the rotating shaft; a gas orifice is formed in the surface of the rotating shaft on which the air guide chamber is positioned; a rotor is arranged on the surface of the rotating shaft; a stator corresponding to the rotor is fixed on the inner wall of the case; an air compression heat exchange mechanism for continuously replacing, compressing and cooling air inside the case is arranged atthe right end of the rotating shaft. The polarization radiating unit permanent magnet motor disclosed by the invention is simple and reasonable in structure, and the operation of the air compressionmechanism is driven by taking the rotating shaft as driving force, so that the air is compressed, the temperature of the air is increased, the temperature difference with heat exchange liquid is increased, and the heat exchange effect. Then, the compressed air is ejected out via the gas orifice, and the compressed air outwards expands to reduce the temperature, so that the heat dissipation effectof the case is improved. Moreover, due to the rotary gas orifice, heat dissipation on the inner wall of the case is uniform, and the practicality is high.

Owner:包头长安永磁电机有限公司

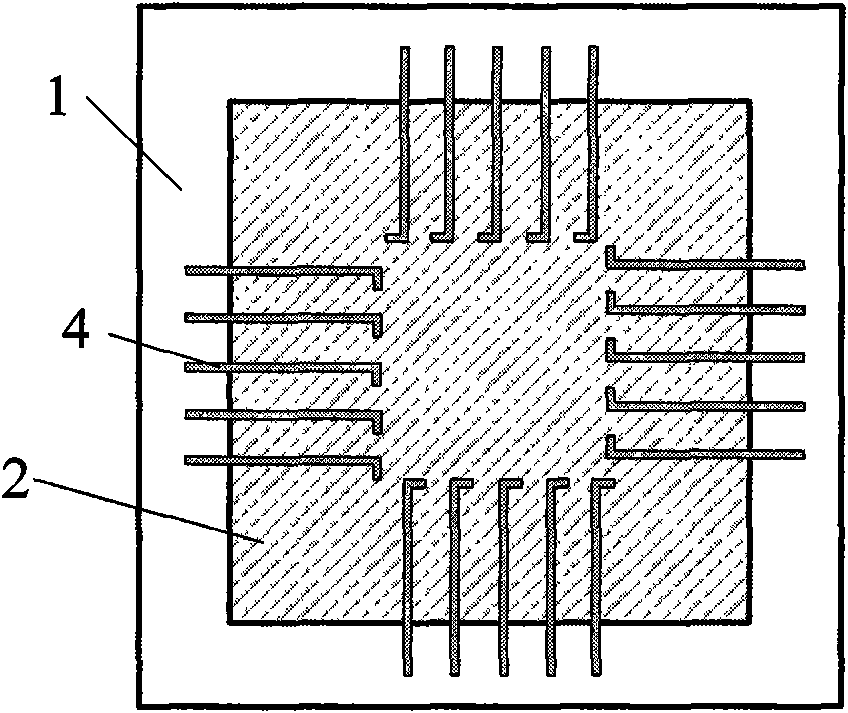

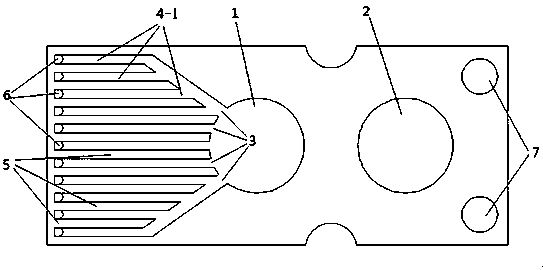

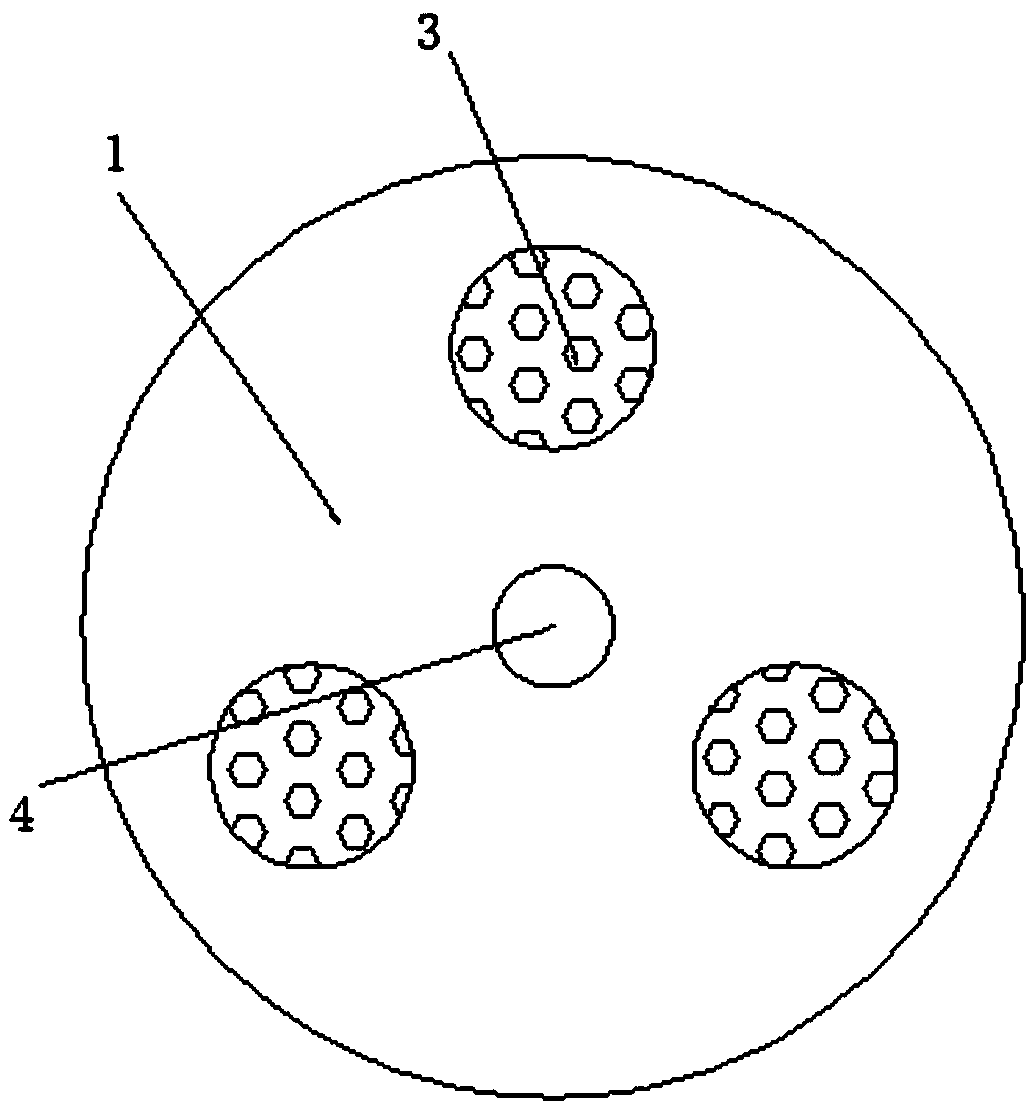

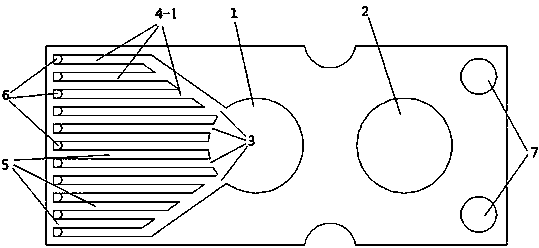

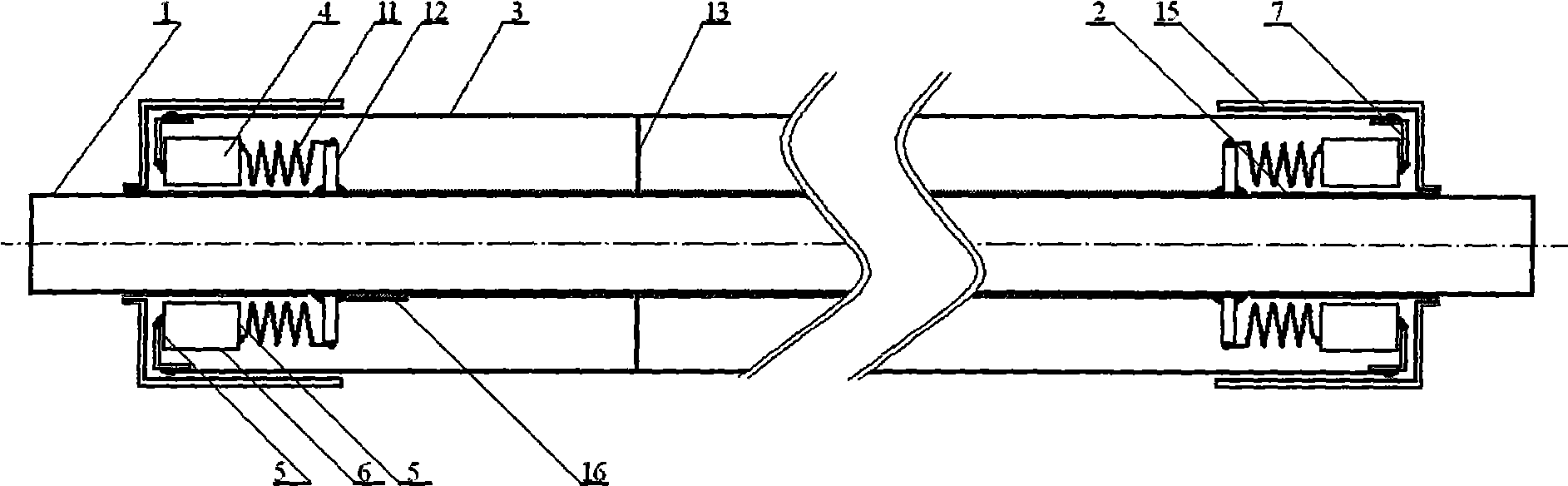

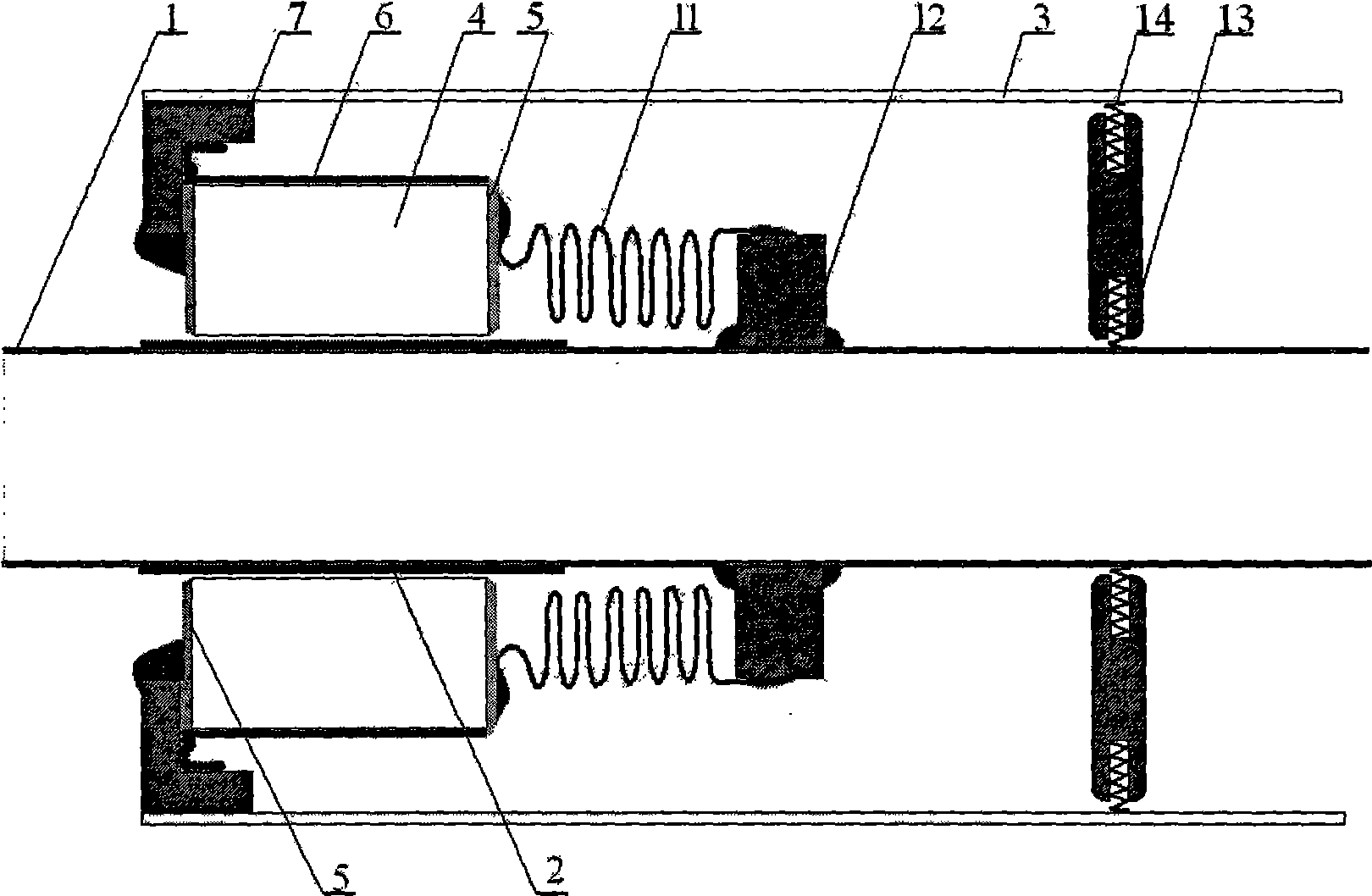

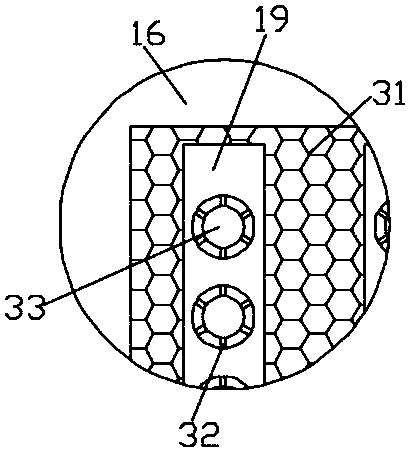

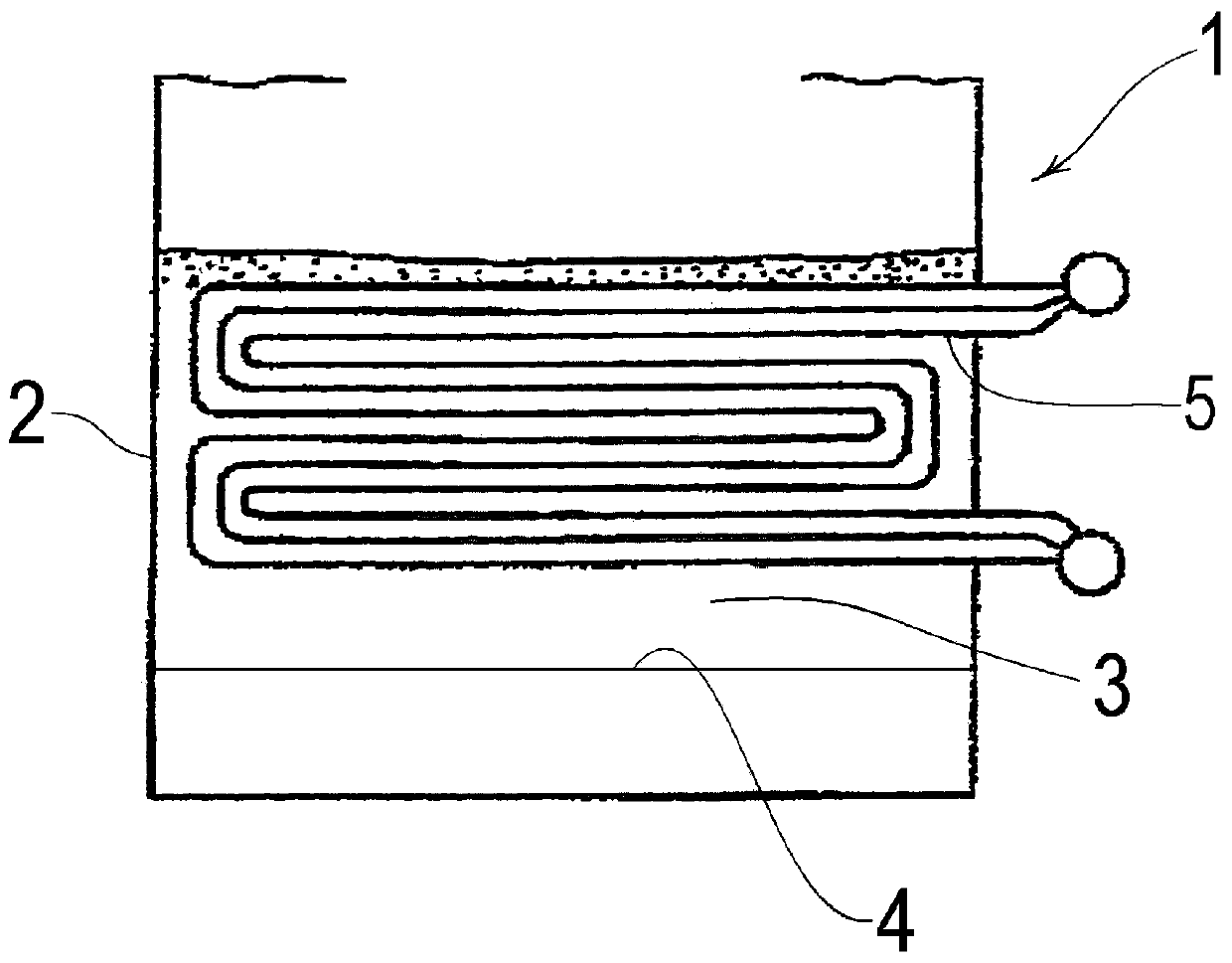

Internal micro-channel heat sink

ActiveCN104051952AHigh speedRaise the temperature differenceLaser detailsSemiconductor lasersInlet channelHeat resistance

The invention provides an internal micro-channel heat sink and relates to the field of heat dissipation structures of a semiconductor laser, an array device and a large-scale integrated circuit. The internal micro-channel heat sink mainly overcomes the defects that an existing heat sink is low in heat exchange efficiency and reduces heat resistance and pressure drop. The internal micro-channel heat sink comprises a water outlet layer, a water distribution layer and a water inlet layer which are arranged in sequence from top to bottom. A water inlet hole is formed in the water inlet layer and connected with water inlet channels. Return water holes are formed in the water distribution layer. A water outlet hole is formed in the water outlet layer and connected with water outlet channels. The water inlet channels are connected with the water outlet channels through the return water holes. The internal micro-channel heat sink is characterized in that the apertures of the water inlet channels decrease in the direction from the water inlet hole to the return water holes; the apertures of the water outlet channels decrease in the direction from the return water holes to the water outlet hole.

Owner:CHENGDU 3D CHANGE TECH

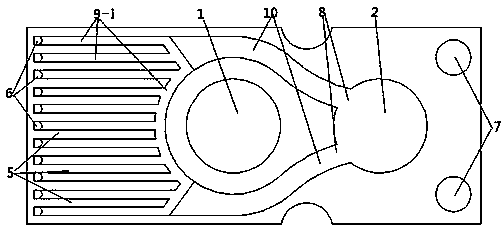

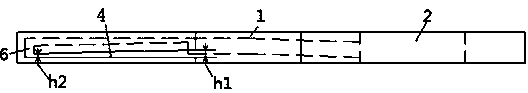

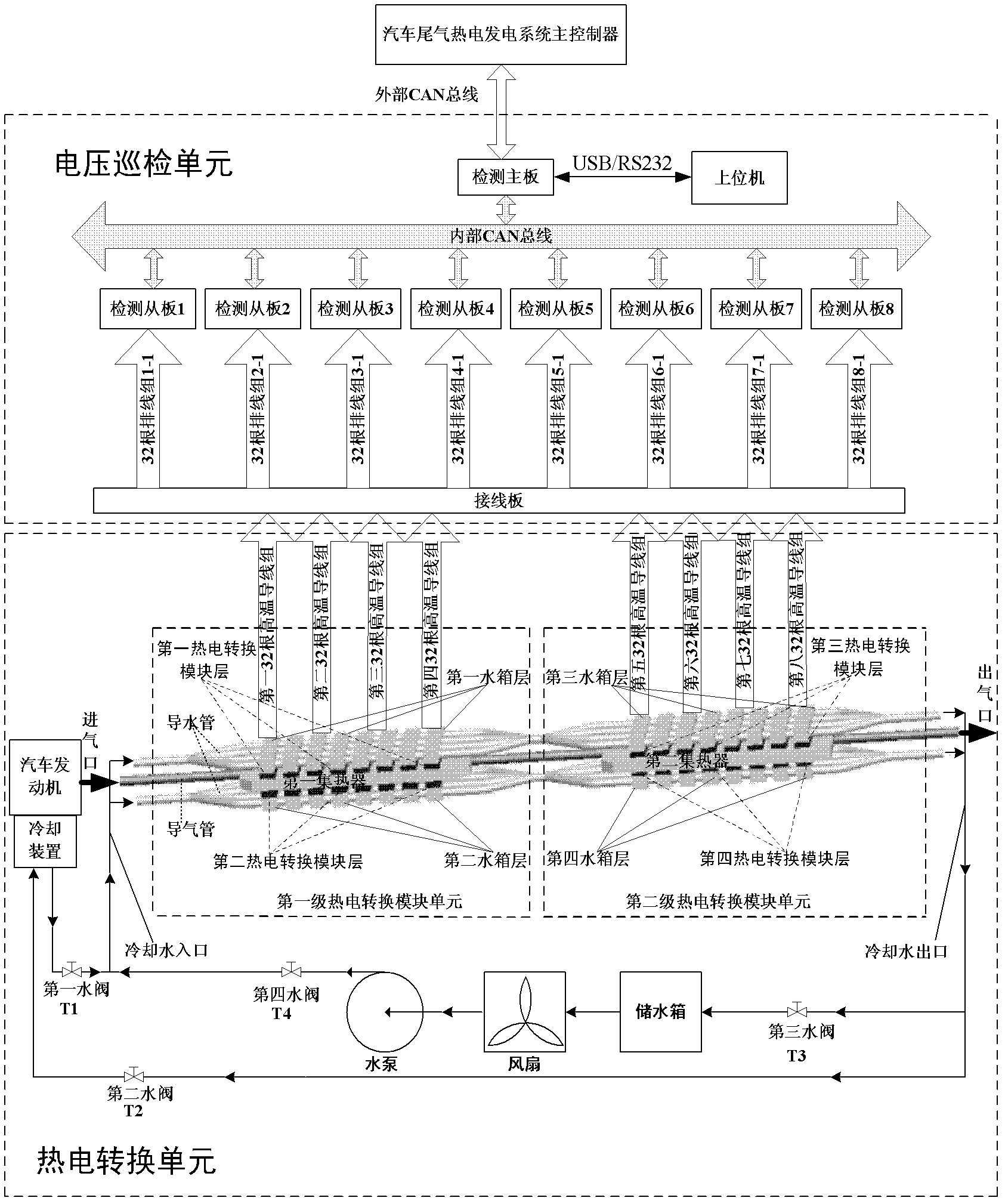

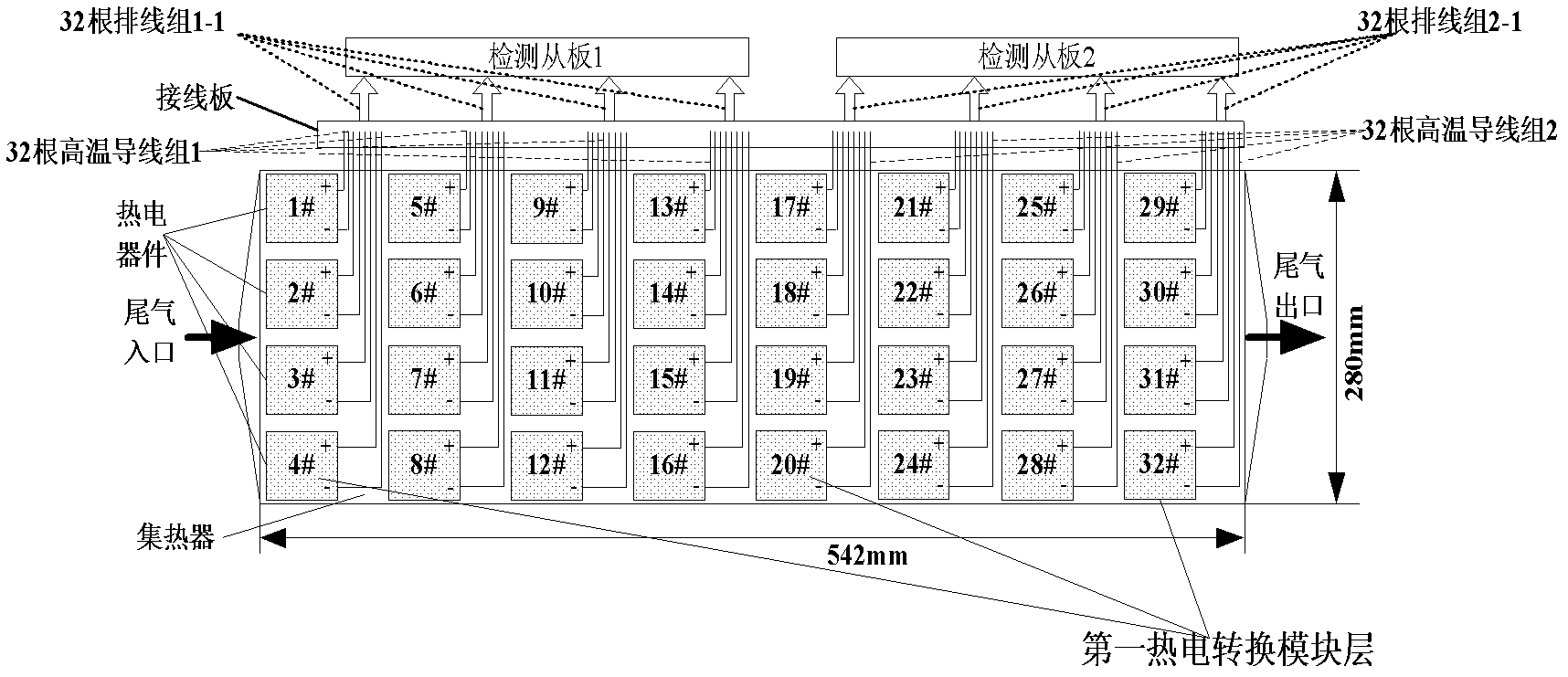

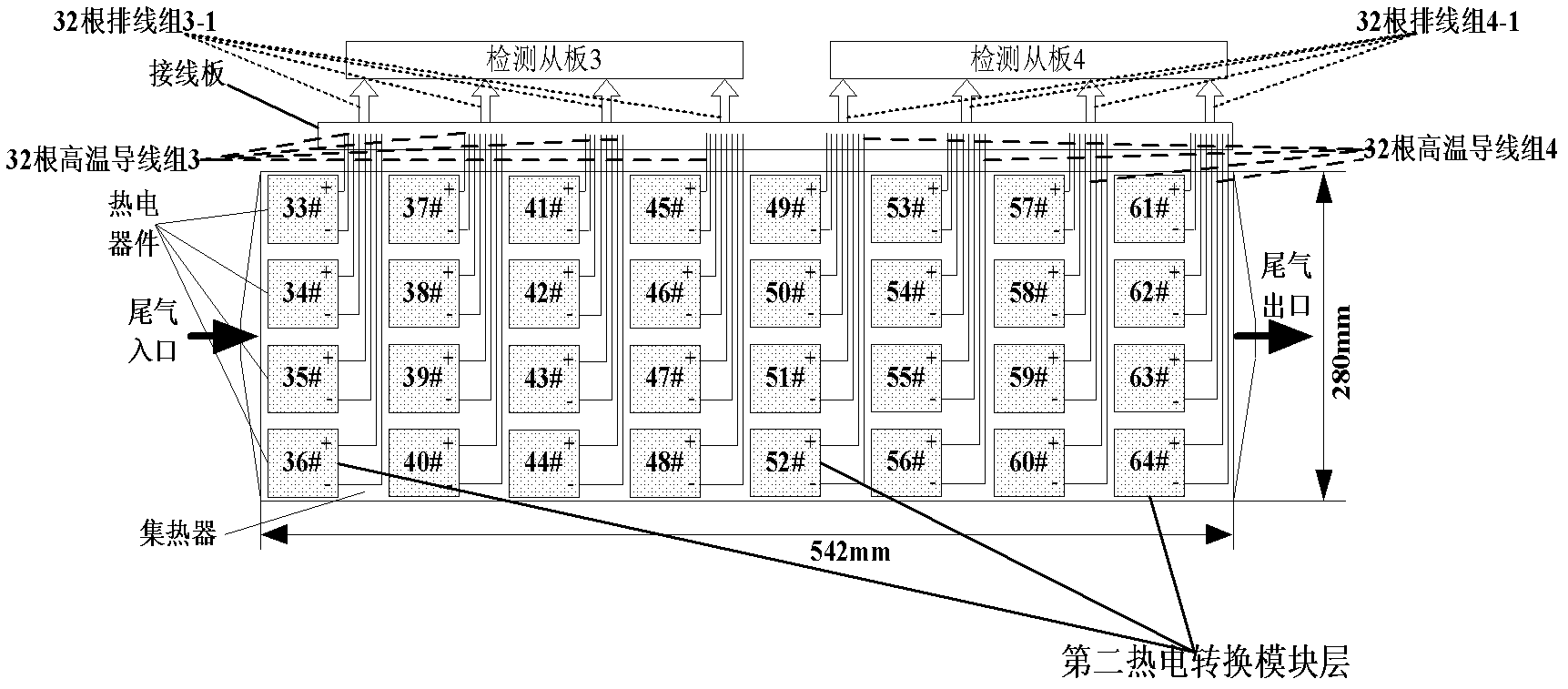

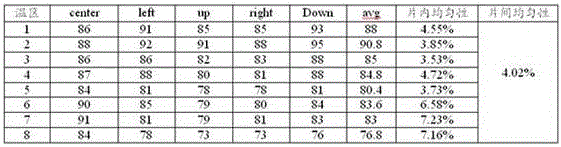

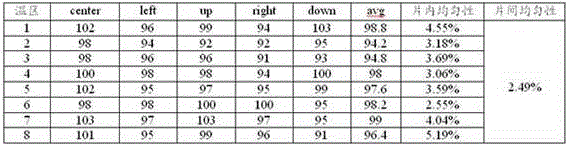

Single-module independent water-cooled type automobile tail gas thermoelectric conversion device and method

InactiveCN102427319AIncrease output powerRaise the temperature differenceInternal combustion piston enginesExhaust apparatusLoop designTemperature difference

The invention relates to a single-module independent water-cooled type automobile tail gas thermoelectric conversion device and method. The device consists of a thermoelectric conversion unit and a voltage polling unit and is characterized in that: an engine exhausts high-temperature tail gas; in a plurality of thermoelectric conversion modules of the thermoelectric conversion unit, the hot ends absorb the heat of the high-temperature tail gas and the cold ends cling to an independent small water tank; the temperature difference between the hot ends and the cold ends is increased by cooling water of a cooling device of the engine or a cooling water loop designed externally and independently, so that direct-current electric energy is generated; the voltage polling unit detects the direct-current voltage generated by each thermoelectric conversion module; and optimal series and parallel combination is performed according to the output characteristic of each thermoelectric conversion module, so that output power and conversion efficiency of the automobile tail gas thermoelectric conversion device can be improved to the maximum degree. The temperature difference between the hot ends and the cold ends is increased by the single-module independent water-cooled mode; the heat of the waste gas exhausted by the automobile is effectively utilized; and the generated electric energy is applied to vehicle-mounted equipment, so energy conservation and emission reduction of the automobile are facilitated.

Owner:WUHAN UNIV OF TECH

Phosphorus diffusion method of crystalline silicon solar cell

ActiveCN106057980AControl concentrationConcentration Control Concurrent Reduction of Phosphorus Doping Concentration Gradients in the BodyFinal product manufactureSemiconductor/solid-state device manufacturingConcentration gradientOxygen

The present invention discloses a phosphorus diffusion method of a crystalline silicon solar cell. The method comprises the steps of (1) entering into a boat, (2) adjusting temperature to be below 800 DEG C, introducing nitrogen carrying phosphorus source and dry oxygen, and forming a silicon dioxide layer containing phosphorus, (3) carrying out low temperature diffusion, (4) raising the temperature in a furnace and pushing with the rise of the temperature, (5) carrying out first time of high temperature diffusion, (6) raising the temperature in the furnace and pushing with the rise of the temperature, (7) carrying out second time of high temperature diffusion, (8) reducing the temperature in the furnace and pushing with the decrease of the temperature, and (9) reducing the temperature and going out of the boat, and completing a diffusion process. According to the method, an oxidation gettering effect is enhanced and the concentration gradient of the phosphorus doping is controlled, the separation and collection of carriers are facilitated, the open circuit voltage is raised, the temperature difference in a cooling process is controlled, and a crystal boundary gettering effect is enhanced.

Owner:CSI CELLS CO LTD +1

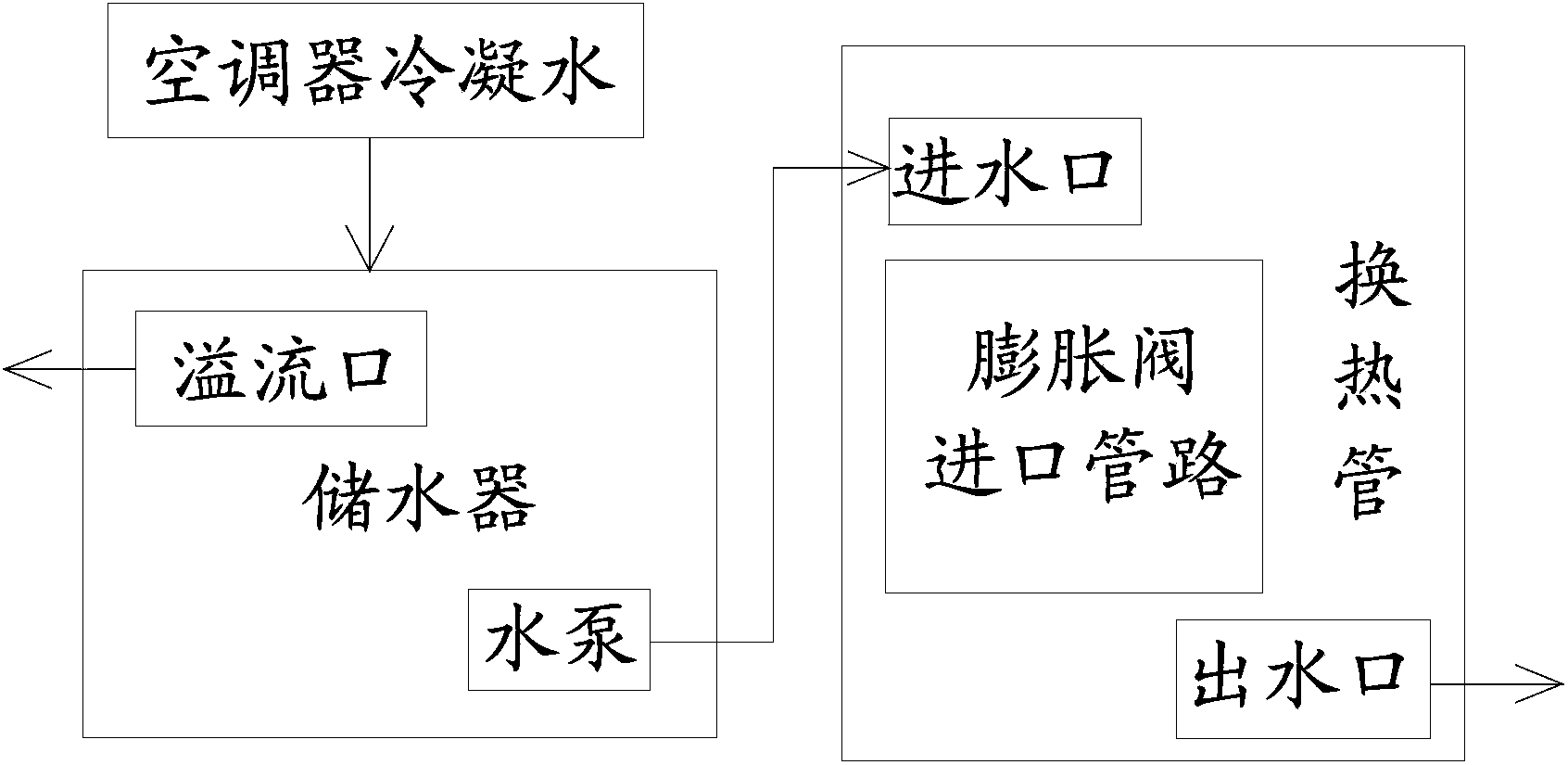

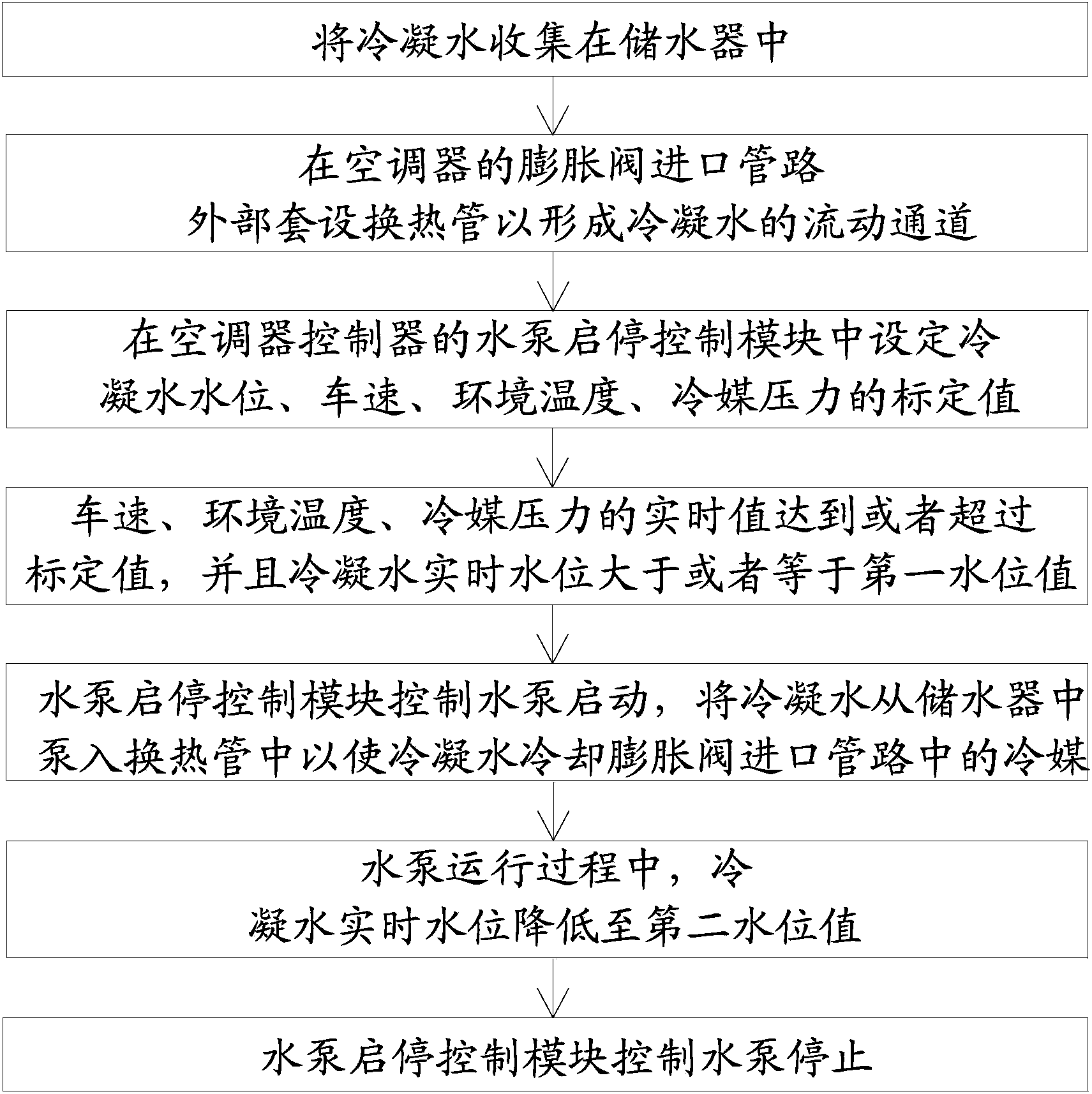

Cooling device and cooling method for cooling refrigerant of vehicle air conditioner

InactiveCN103423925AImprove heat transfer effectImprove heat transfer efficiencyMechanical apparatusCondensate preventionCondensate pumpRefrigerant

The invention provides a cooling device for cooling refrigerant of a vehicle air conditioner. The cooling device comprises a water storing device, a heat exchanging tube and a pump. The water storing device is used for collecting condensate of the vehicle air conditioner; the heat exchanging tube is sleeved on the exterior of an inlet tube of an expansion valve of the vehicle air conditioner to form a flowing channel of condensate; and the pump is used for pumping the condensate in the water storing device into the heat exchanging tube. The invention further provides a cooling method for cooling the refrigerant of the vehicle air conditioner. The cooling method includes firstly collecting the condensate of the air conditioner into the water storing device, and secondly cooling the condensate in the inlet tube of the expansion valve of the vehicle air conditioner by utilizing the condensate. According to the cooling device, the condensate produced during the operation of the vehicle air conditioner is collected and serves as cooling medium for the inlet tube of the expansion valve of the air conditioner. Thus, the heat exchanging efficiency of the air conditioner is improved.

Owner:BEIQI FOTON MOTOR CO LTD

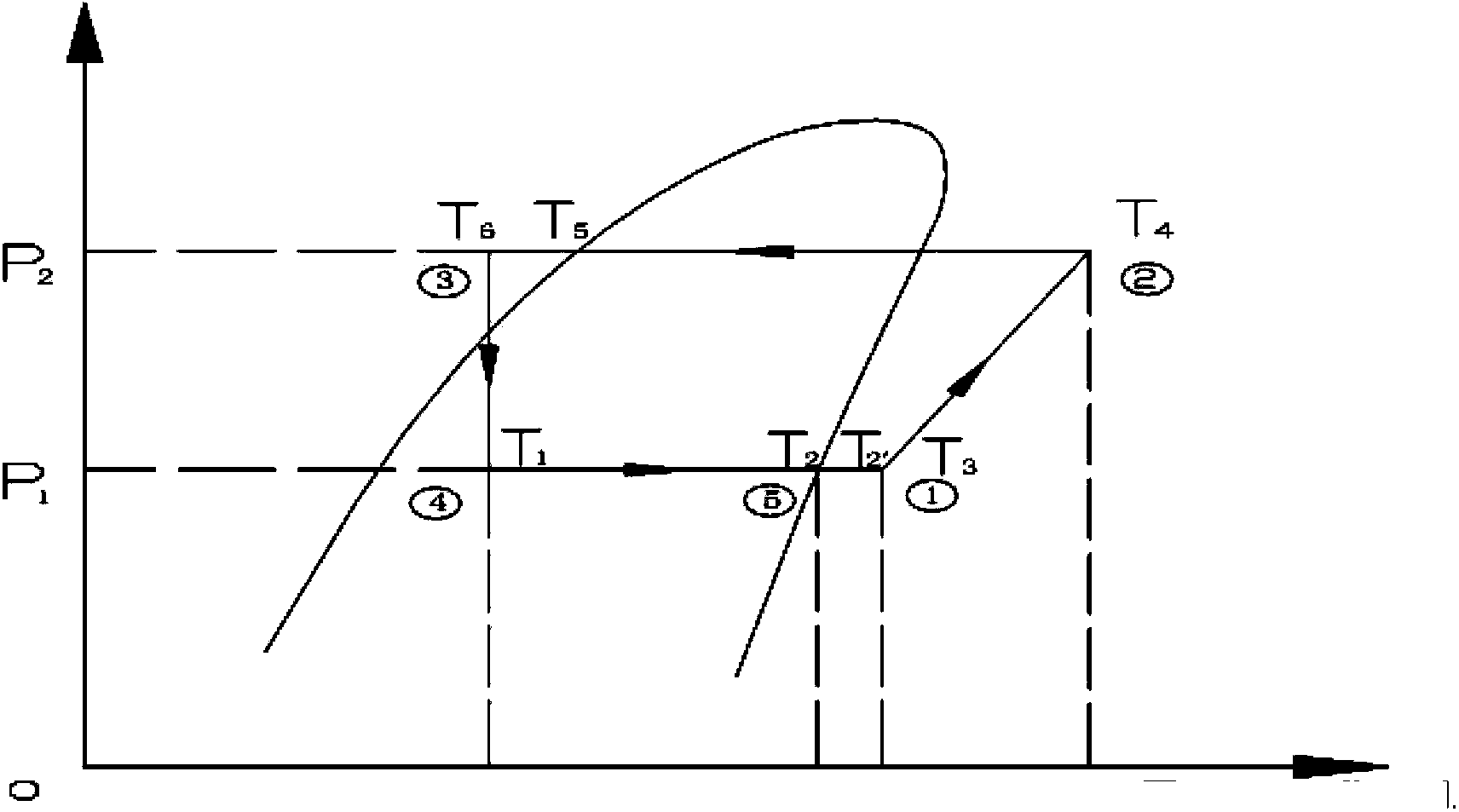

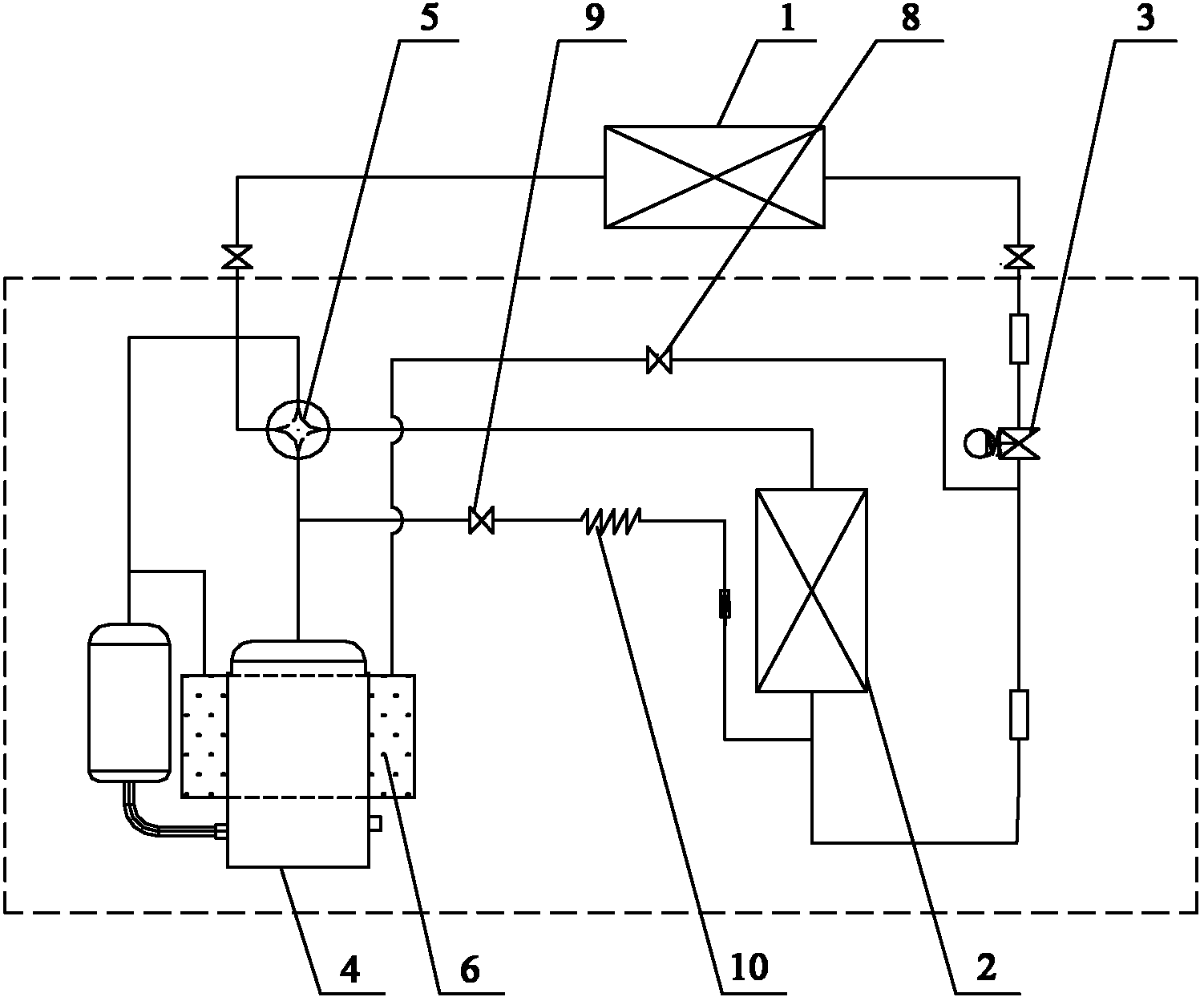

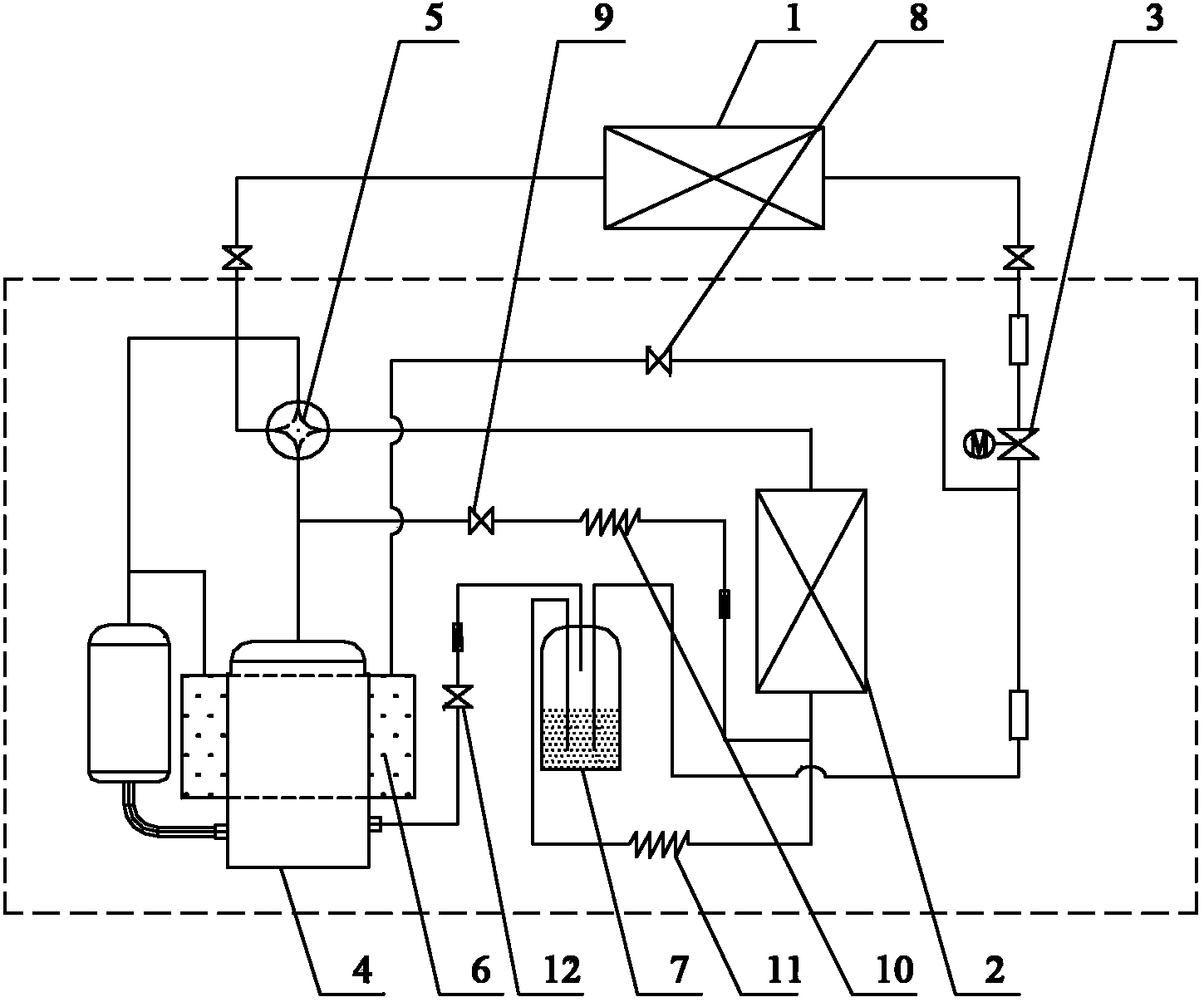

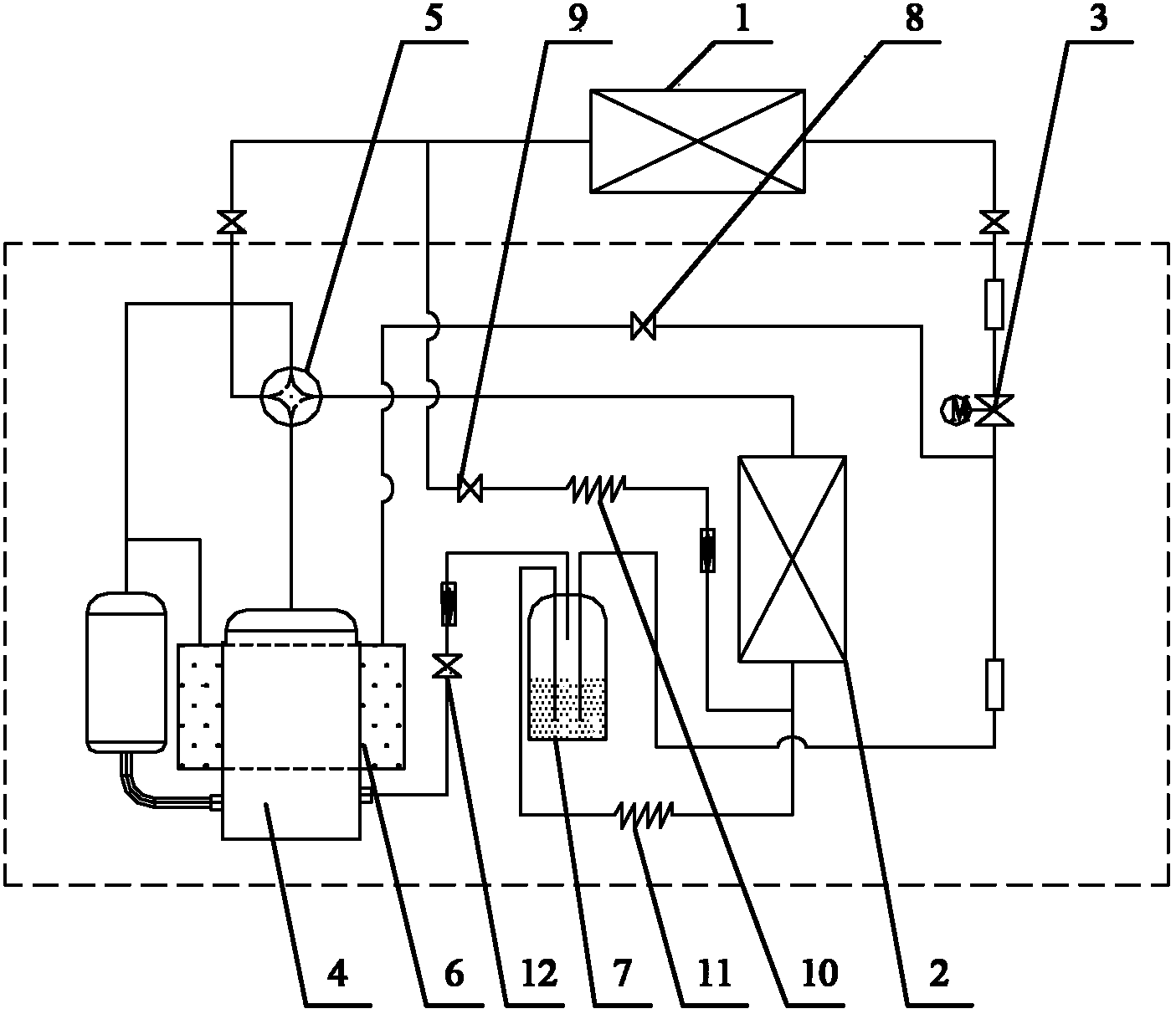

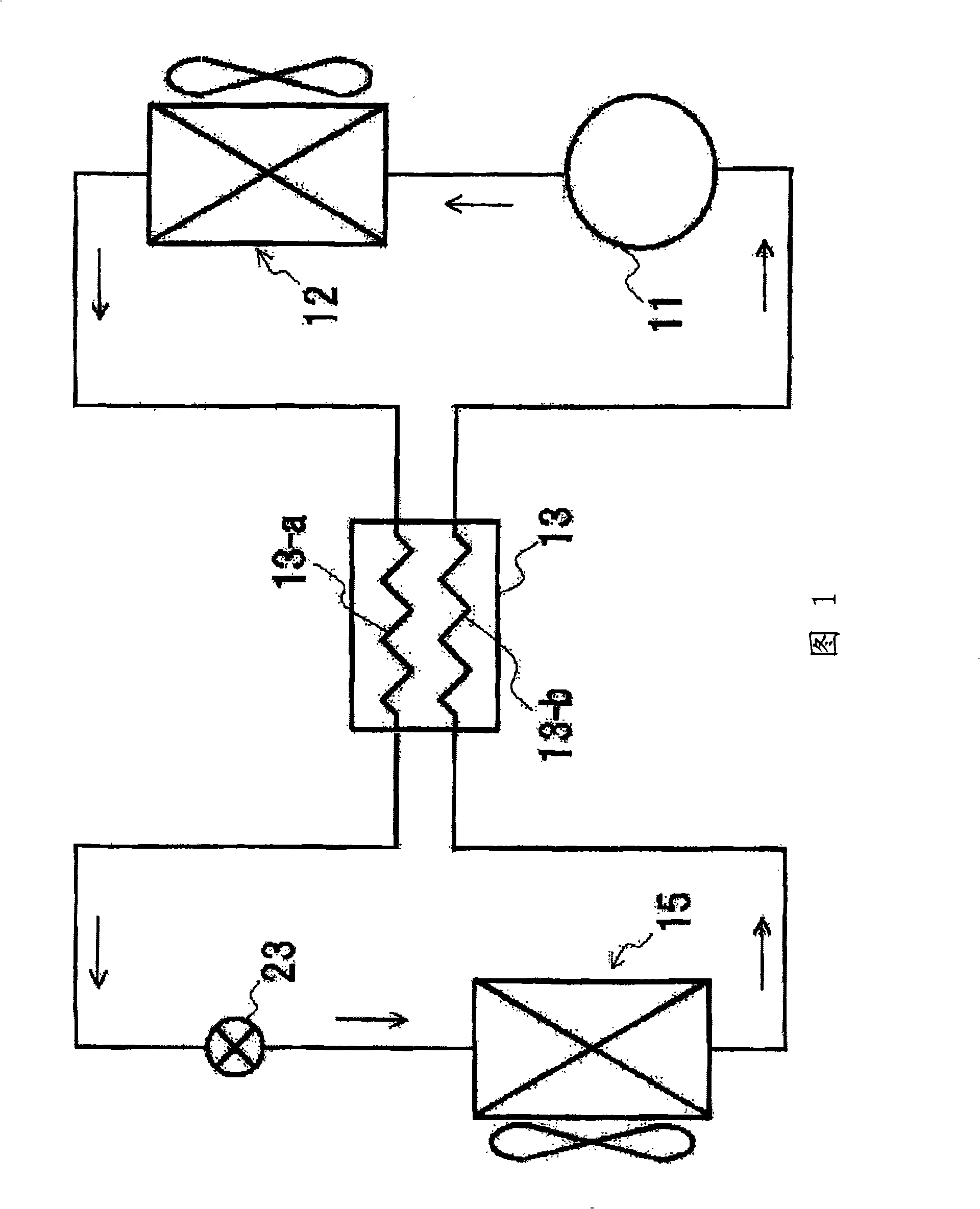

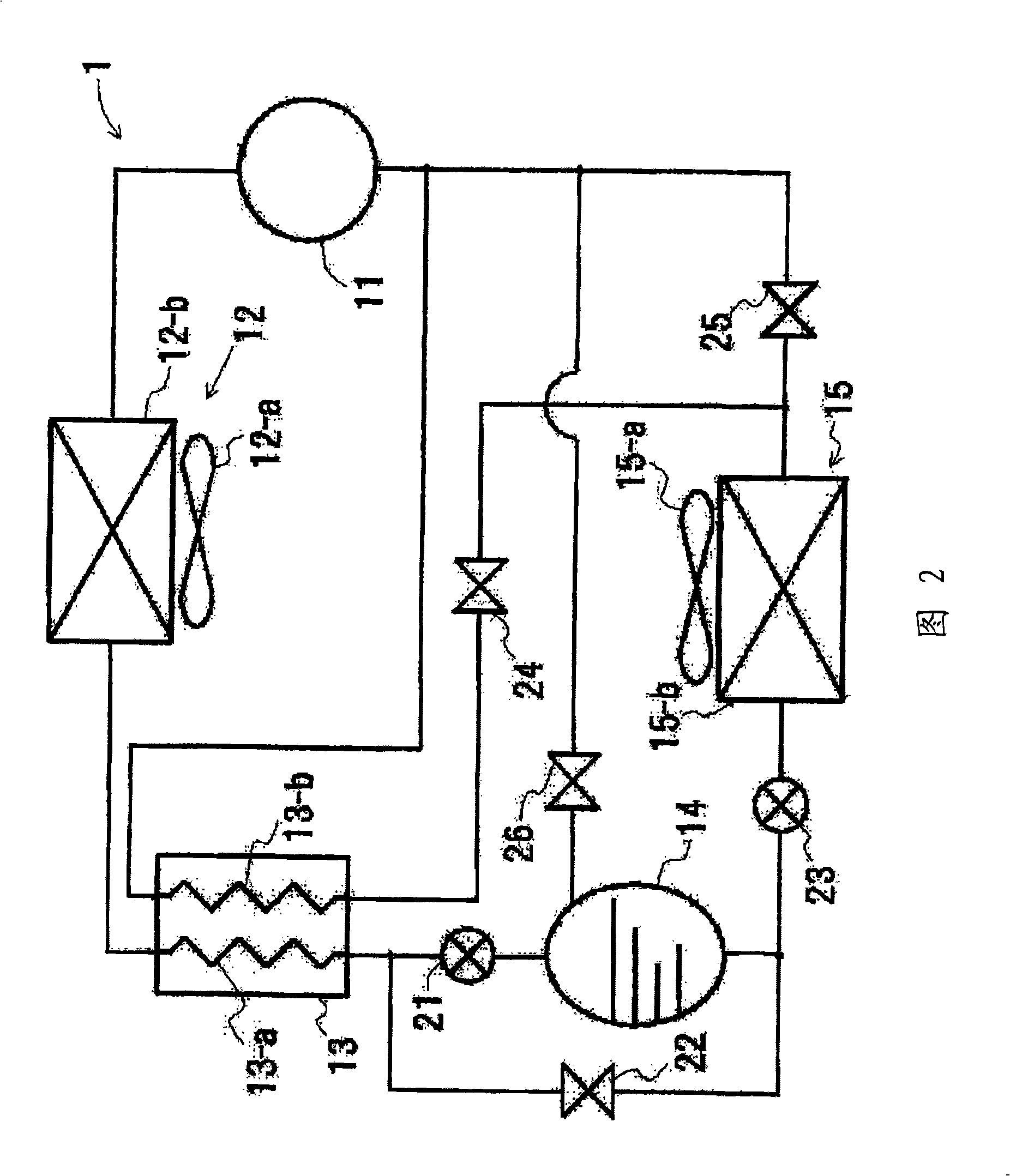

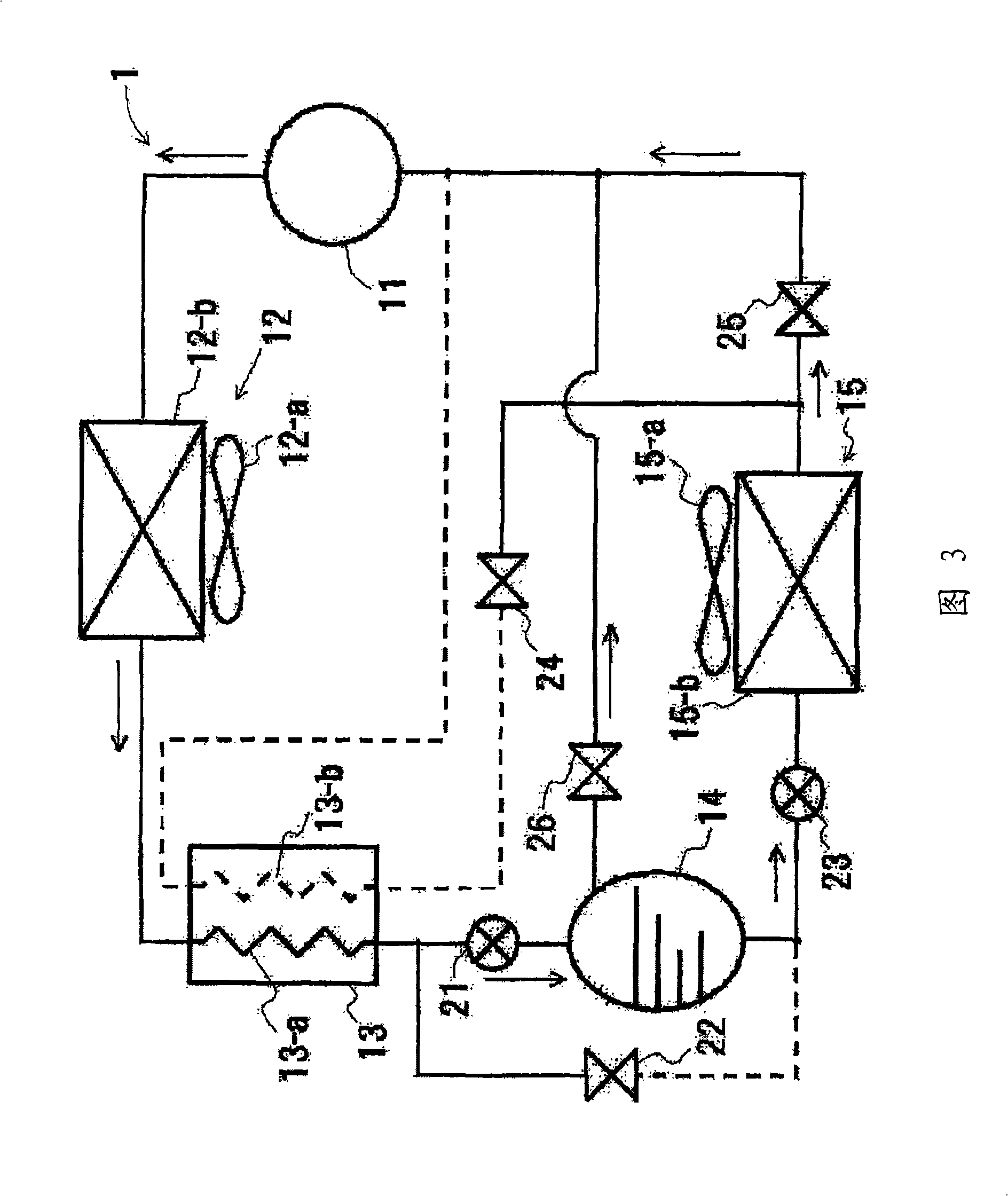

Heat-pump-type air conditioning system, sensible-heat defrosting method, heat-storage defrosting method

ActiveCN103574798AReduce the temperatureRaise the temperature differenceCorrosion preventionRefrigeration componentsFour-way valveEngineering

The invention discloses a heat-pump-type air conditioning system which comprises an indoor heat exchanger, an outdoor heat exchanger, a first pipeline, an expansion valve, a compressor, a four-way valve, a heat storage loop and a hot-gas bypass loop. The first pipeline connects the indoor heat exchanger with the outdoor heat exchanger, the expansion valve is serially connected on the first pipeline, the compressor is used for compressing refrigerant steam, the four-way valve is connected with an input end and an output end of the compressor and connected with the indoor heat exchanger and the outdoor heat exchanger, one end of the heat storage loop is connected between the expansion valve on the first pipeline and the outdoor heat exchanger, a first two-way valve and a heat accumulator wrapped on the outer wall of the compressor are serially connected on the heat storage loop, the other end of the heat storage loop is connected with an input end of the compressor, one end of the hot-gas bypass loop is connected between the output end of the compressor and the indoor heat exchanger while the other end of the same is connected with the outdoor heat exchanger, and a second two-way valve and a throttling device are serially connected on the hot-gas bypass loop. By the heat-pump-type air conditioning system, temperature difference between a refrigerant flowing into the heat accumulator and the heat accumulator is increased, and defrosting effect is effectively improved. The invention further provides a sensible-heat defrosting method and a heat-storage defrosting method.

Owner:GREE ELECTRIC APPLIANCES INC

Solar high-temperature vacuum heat-collecting tube

InactiveCN101498517AImprove insulation effectGood insulation performanceSolar heating energySolar heat devicesAlloyMetal

The invention relates to a high-temperature vacuum heat collection pipe for a trough type solar thermoelectric system, comprising a glass outside pipe and a metal inside pipe installed in the glass outside pipe. The glass outside pipe is connected with the metal inside pipe in a sealing way, and the interlayer of the glass outside pipe and the metal inside pipe is in a vacuum state. The high-temperature vacuum heat collection pipe is characterized in that a ceramic insulation ring is arranged between the end of the glass outside pipe and the end of the metal inside pipe. Both end surfaces of the ceramic insulation ring are covered by metallization layers or are respectively provided with an annular groove, the ceramic insulation ring is connected with the glass outside pipe in the sealing way through an alloy component which is connected on or fixedly inlaid in the metallization layer at one end, the other end of the ceramic insulation ring is connected with the metal inside pipe in the sealing way through a transition connecting disk or through the alloy component connected on or fixedly inlaid in the metallization layer and the transition connecting disk. Not only the ceramic insulation ring can eliminate a heat bridge between the glass outside pipe and the metal inside pipe to block heat exchange between the two pipes, and efficiently enhances the working efficiency of the heat collection pipe, but also the invention has simple structure and low manufacture cost, can overcome the manufacture bottleneck of the high-temperature vacuum heat collection pipe for the trough type solar thermoelectric system, and efficiently promotes the development of the solar thermoelectric technology and application thereof.

Owner:SICHUAN UNIV

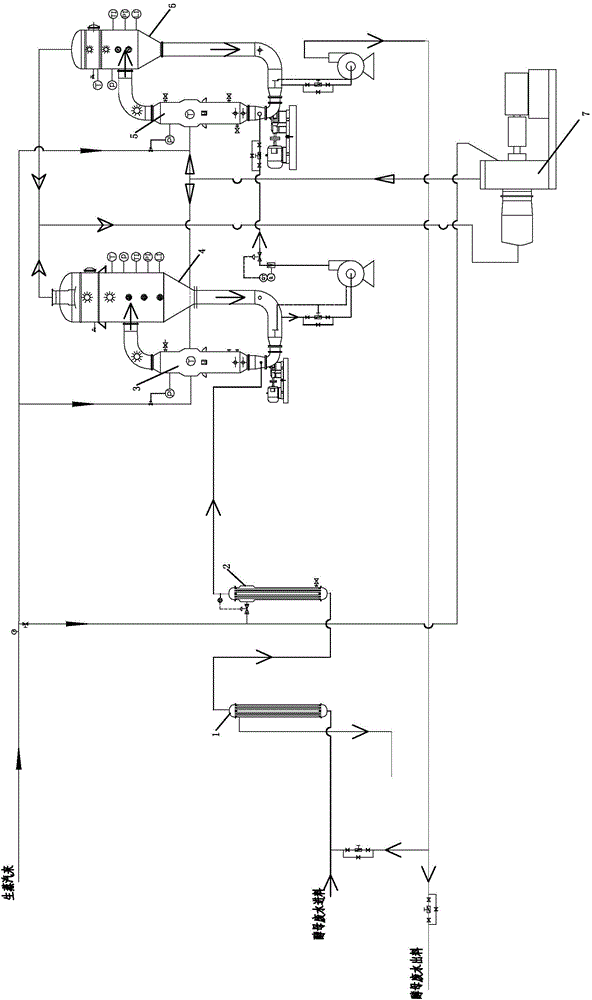

Yeast wastewater zero discharge treatment method

ActiveCN104787823AAvoid entrainmentSolve the phenomenon of reducing separation efficiencyWater/sewage treatment by heatingWater treatment multistage treatmentsYeastGas phase

The invention discloses a yeast wastewater zero discharge treatment method, and belongs to the field of yeast wastewater treatment. The method solves the technical problems of high operating cost and drywall phenomenon in the existing multi-stage film fall evaporator yeast wastewater concentration. The method comprises the following steps: firstly, preheating yeast wastewater for two times to 90 DEG C; secondly, performing circulation of heating and separation by evaporating till the concentration of solid content in the yeast wastewater is 30 percent; thirdly, performing circulation of heating and separation by evaporating till the concentration of solid content in the yeast wastewater is 50 percent, and ensuring that a discharged material part returns a material inlet part; then adopting conventional centrifugation and spray drying methods to obtain organic fertilizer and feed additives; discharging condensate water after the condensate water is subjected to biochemical treatment and meet wastewater standard. The method effectively controls the concentration of materials in all links, and avoids the drywall phenomenon of heating tubes. According to the method, evaporated and separated gas phase is reused, so that the production cost is reduced.

Owner:ZHEJIANG QIANCAOSU BIOTECH CO LTD

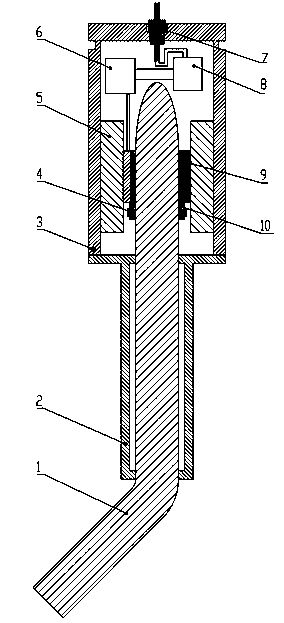

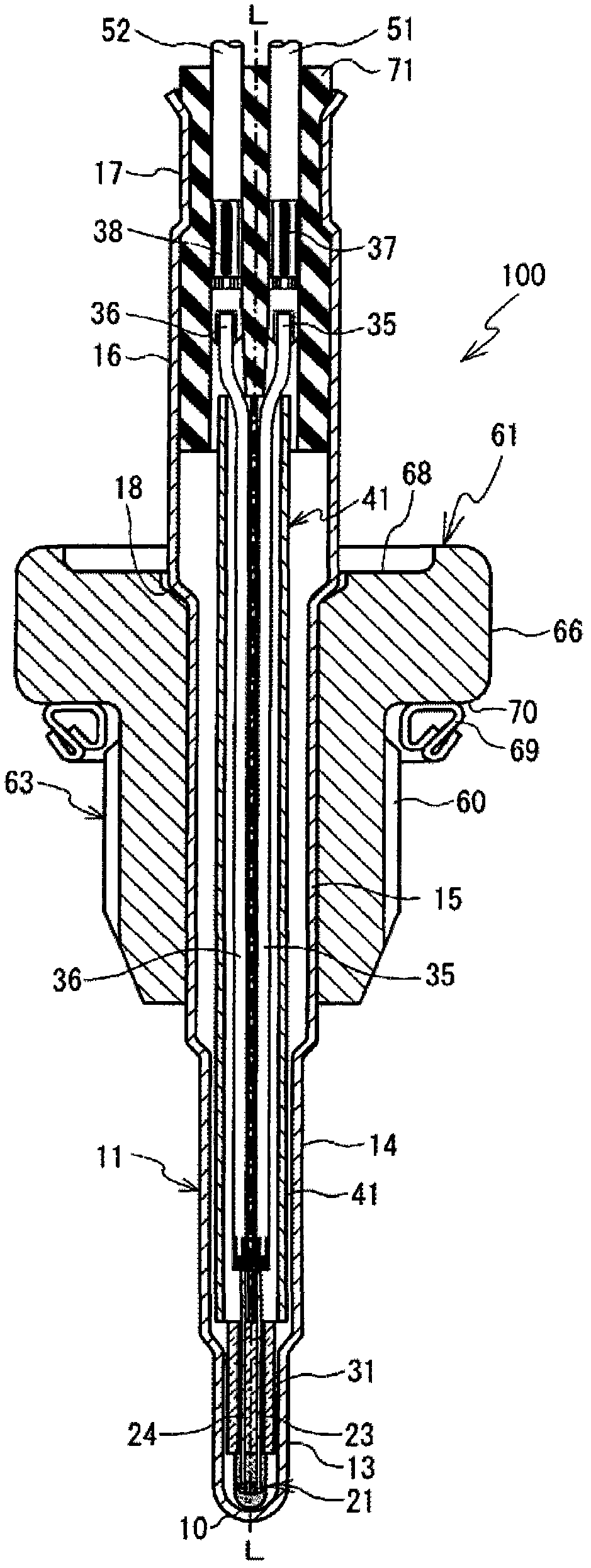

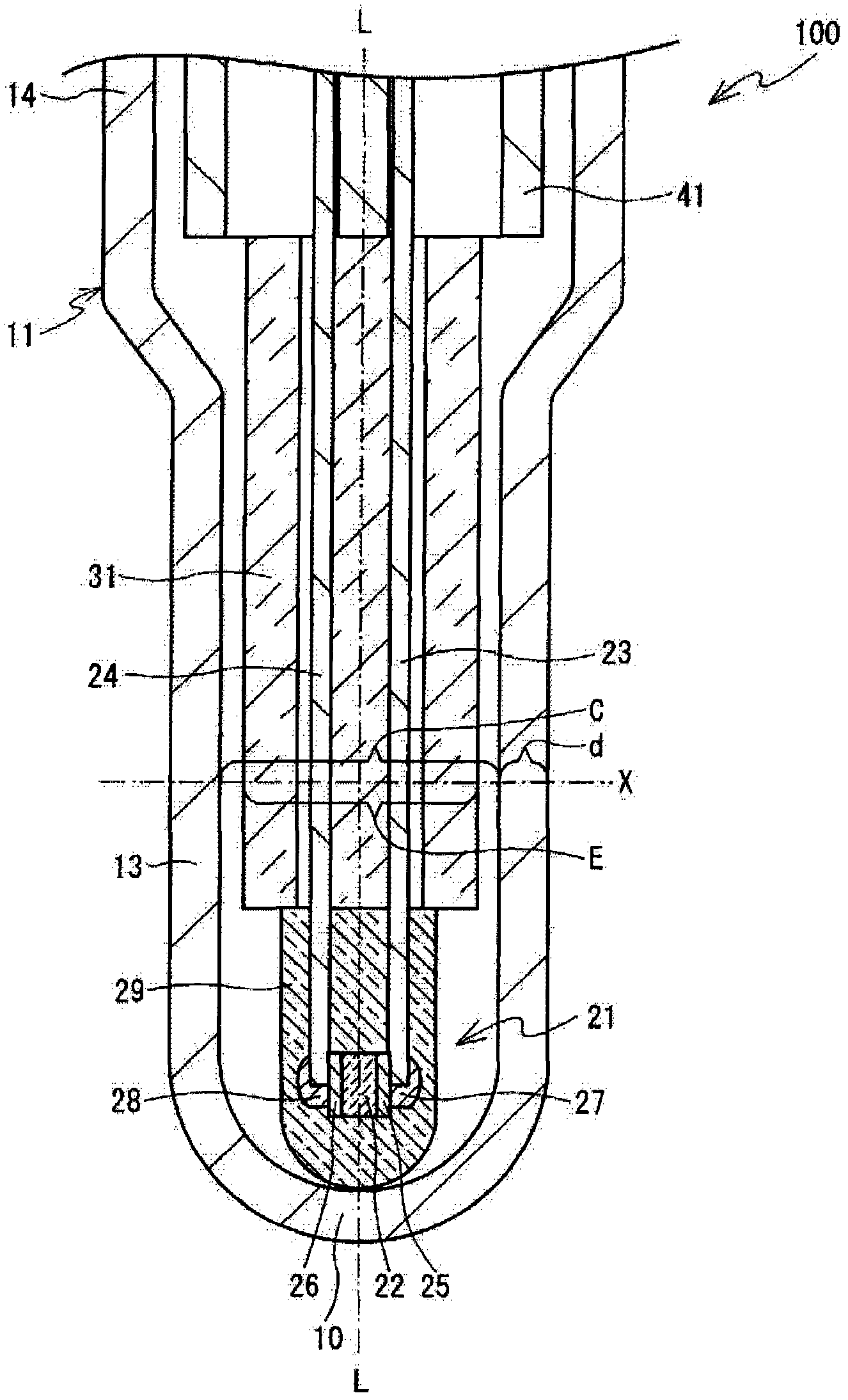

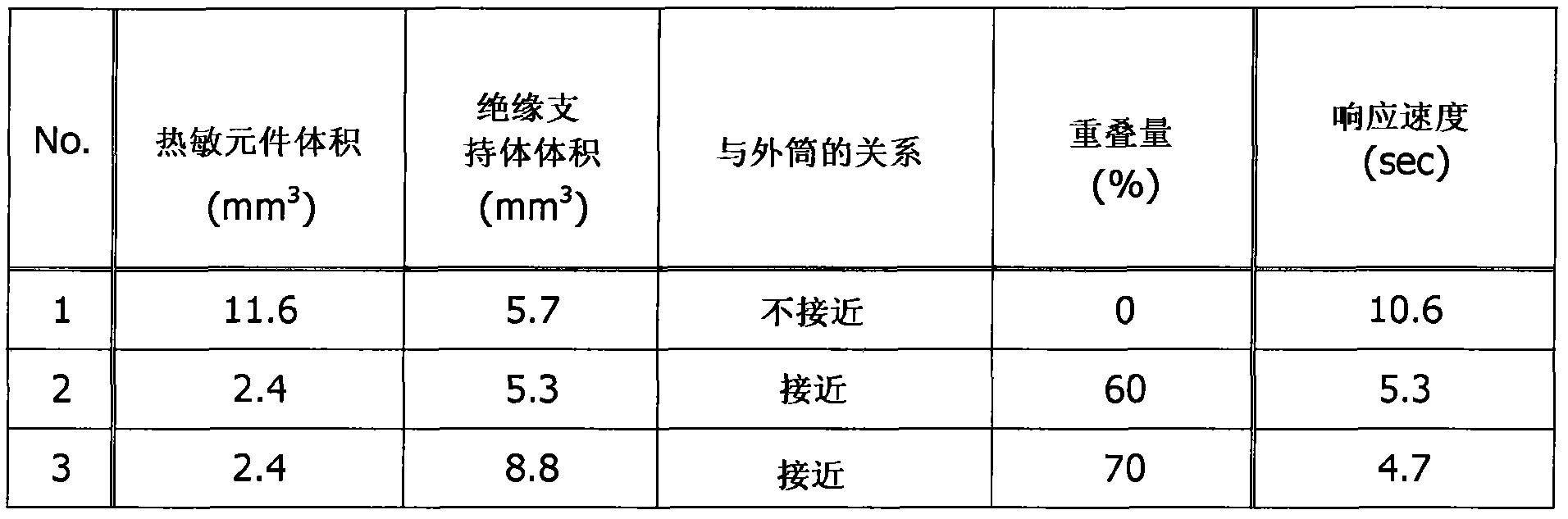

Temperature sensor

InactiveCN102419219AImprove responsivenessRaise the temperature differenceThermometer detailsTemperature measurement in motorsHeat sensitiveThermistor

A temperature sensor (100) includes a heat-sensitive element (21) having a thermistor sintered-body (22), an insulating support (31), an insulation sheath (41) and a housing tube (11). The insulating support (31) is in contact with the rear end of the heat-sensitive element (21) and the insulation sheath (41) is in contact with the rear end of the insulating support (31). The housing tube (11) accommodates the heat-sensitive element (21), the insulating support (31) and the insulation sheath (41). The housing tube (11) includes a sheath accommodation portion (14) which accommodates the insulation sheath (41) and a distal accommodation portion (13). The distal accommodation portion (13) is located toward the distal end of the housing tube (11) with respect to the sheath accommodation portion (14), is smaller in outside diameter than the sheath accommodation portion (14), and accommodates at least half of the insulating support (31) as measured from the axially distal end of the insulating support (31).

Owner:NGK SPARK PLUG CO LTD

Refrigerating device

ActiveCN101410678AImprove stress reliefImprove freezing effectCompression machines with non-reversible cycleRefrigeration componentsGas coolerEngineering

A freezing apparatus using such a coolant as will take a supercritical state when discharged from a compressor is troubled by a problem that the charge of the coolant has to be increased to quicken the cooling operation, because of shortage of the freezing power. Another problem is that an excess coolant is much produced in a coolant circuit when the freezing apparatus is sufficiently cooled. Provided is a coolant circuit, in which a compressor, a gas cooler, a first pressure reducing device and an evaporator are sequentially piped and connected in an annular shape. The coolant circuit comprises a second pressure reducing device and a liquid receiver between the gas cooler and the first pressure reducing device, and the liquid receiver and the suction port of the compressor are piped and connected. The opening degree of the second pressure reducing device is controlled according to the pressure difference between the discharge side pressure and the suction side pressure of the compressor, so that the circulation rate of the coolant can be adjusted by increasing the coolant circulation rate in case the freezing ability is short and by reserving the excess coolant in the liquid receiver in case the freezing ability is excessive.

Owner:SANYO ELECTRIC CO LTD

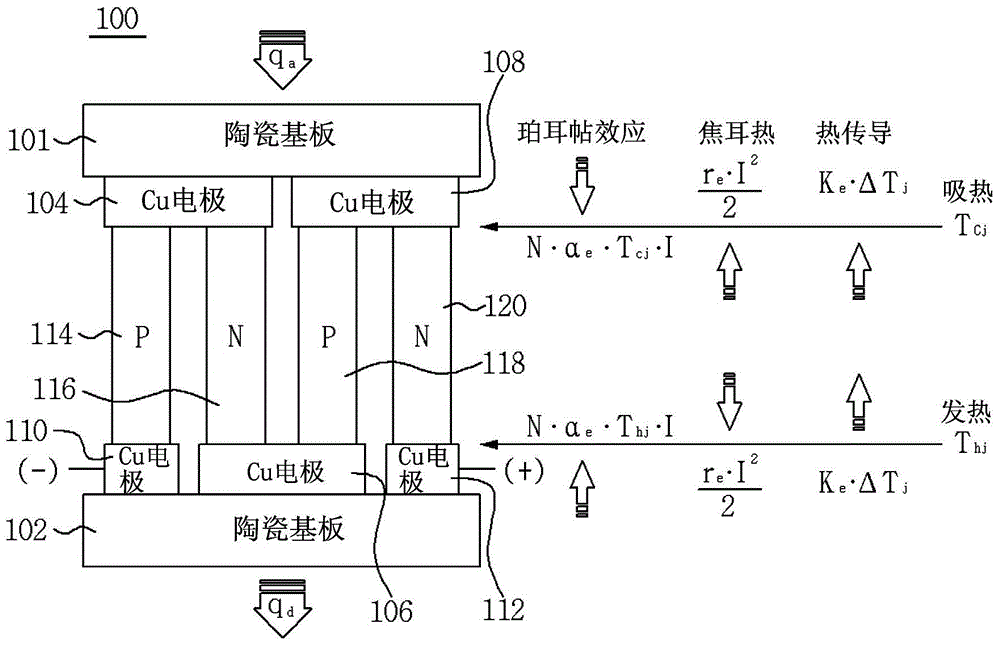

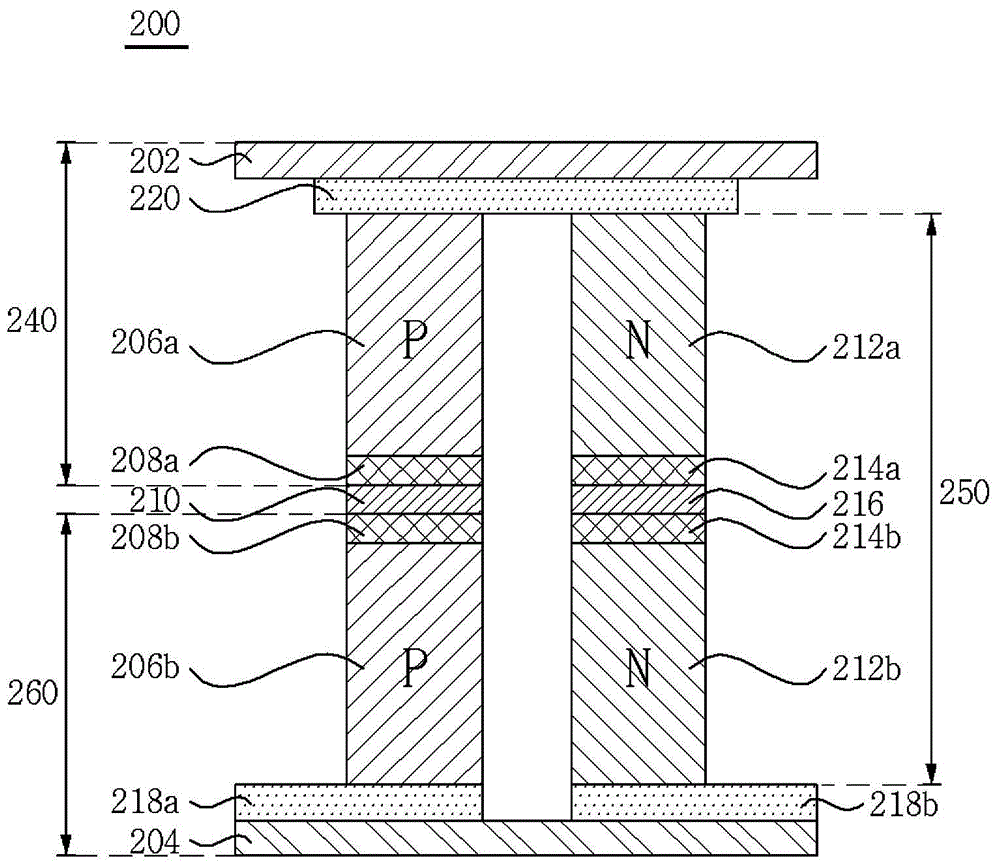

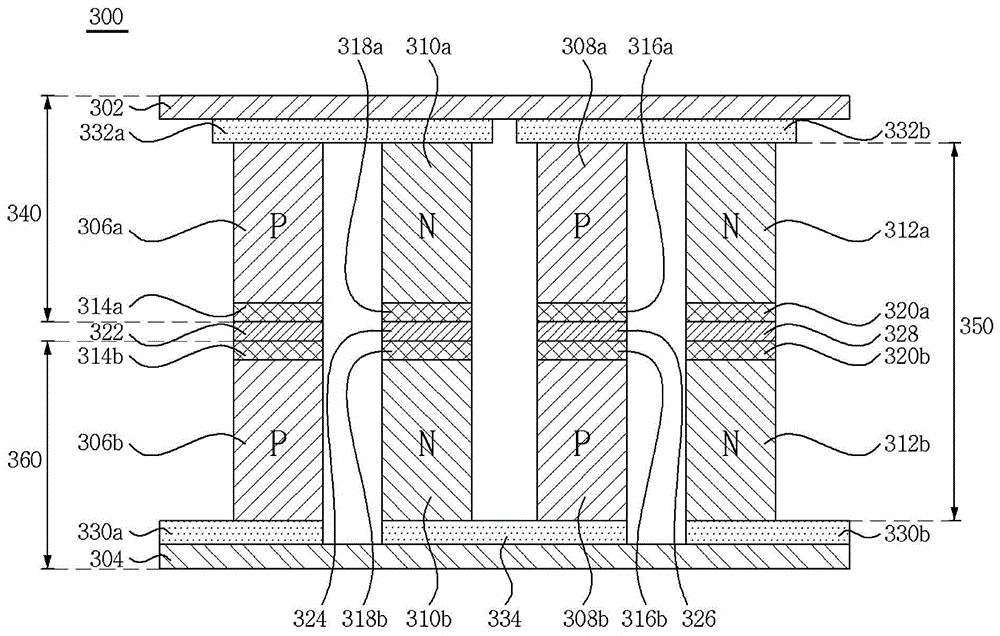

Thermoelectric module and manufacturing method thereof

InactiveCN105374927ARaise the temperature differenceIncrease thermal electromotive forceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEngineeringTemperature difference

The invention discloses a thermoelectric module and a manufacturing method thereof. The thermoelectric module comprises a lower thermoelectric module, wherein p type and n type semiconductor elements are arranged on the upper part of the lower insulation substrate along the horizontal direction; an upper thermoelectric module, wherein p type and n type semiconductor elements, which are electrically connected, are arranged on the lower part of the upper insulation substrate along the horizontal direction; and a joint part, which joins the p type semiconductor element in the upper thermoelectric module and the p type semiconductor element in the lower thermoelectric module and also joins the n type semiconductor element in the upper thermoelectric module and the n type semiconductor element in the lower thermoelectric module. Through the joint part, the upper part thermoelectric module comprising a thermoelectric semiconductor element and the lower part thermoelectric module comprising a thermoelectric semiconductor element are joined together, thus the thickness of thermoelectric semiconductor element part is multiplied by two; so the temperature difference between two ends of the thermoelectric semiconductor element part is increased, the electro-dynamic potential of the thermoelectric module is increased, and when the thermoelectric module is used as a temperature sensor, the sensitivity of the sensor is improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

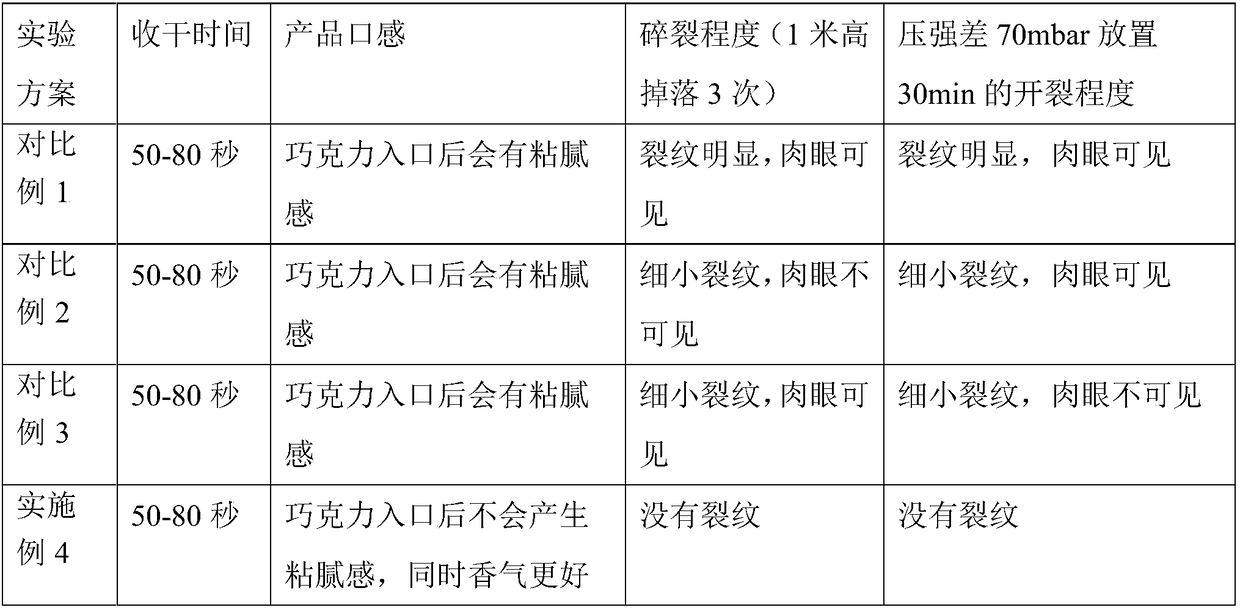

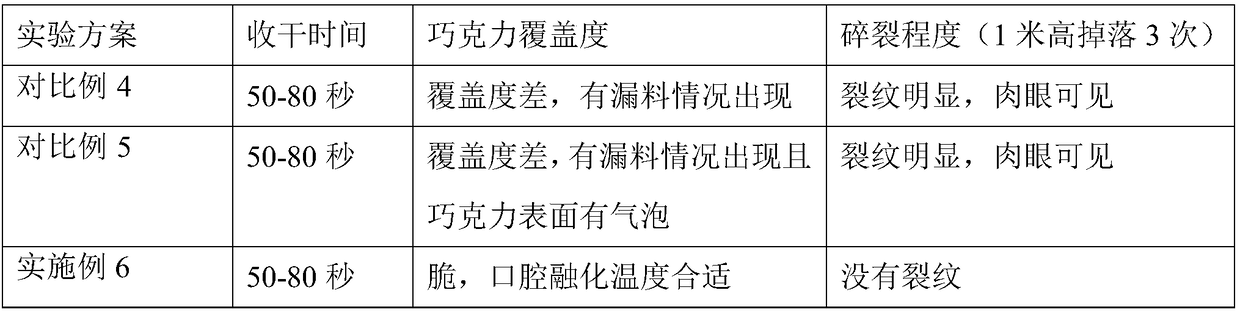

Brittle-failure-resistant chocolate coating and method for coating frozen beverage with brittle-failure-resistant chocolate coating

The invention discloses a brittle-failure-resistant chocolate coating, which comprises the following raw materials by weight: 330-400 parts of white granulated sugar, 130-170 parts of milk powder, 120-160 parts of cocoa liquid block, 40-60 parts of natural anhydrous cream, 260-300 parts of cocoa butter, 1-3 parts of lecithin, and 1-3 parts of polyglyceryl-3 polyricinoleate. The invention further discloses a method for coating a frozen beverage with the brittle-failure-resistant chocolate coating. According to the present invention, by adjusting the ratio of various raw materials of the chocolate coating and optimizing the method for coating the frozen beverage with the chocolate coating, the brittleness of the chocolate coating is ensured, and no cracking is generated within pressure difference of 70 mbar, such that the quality of the product is enhanced, and the market is easily broadened.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

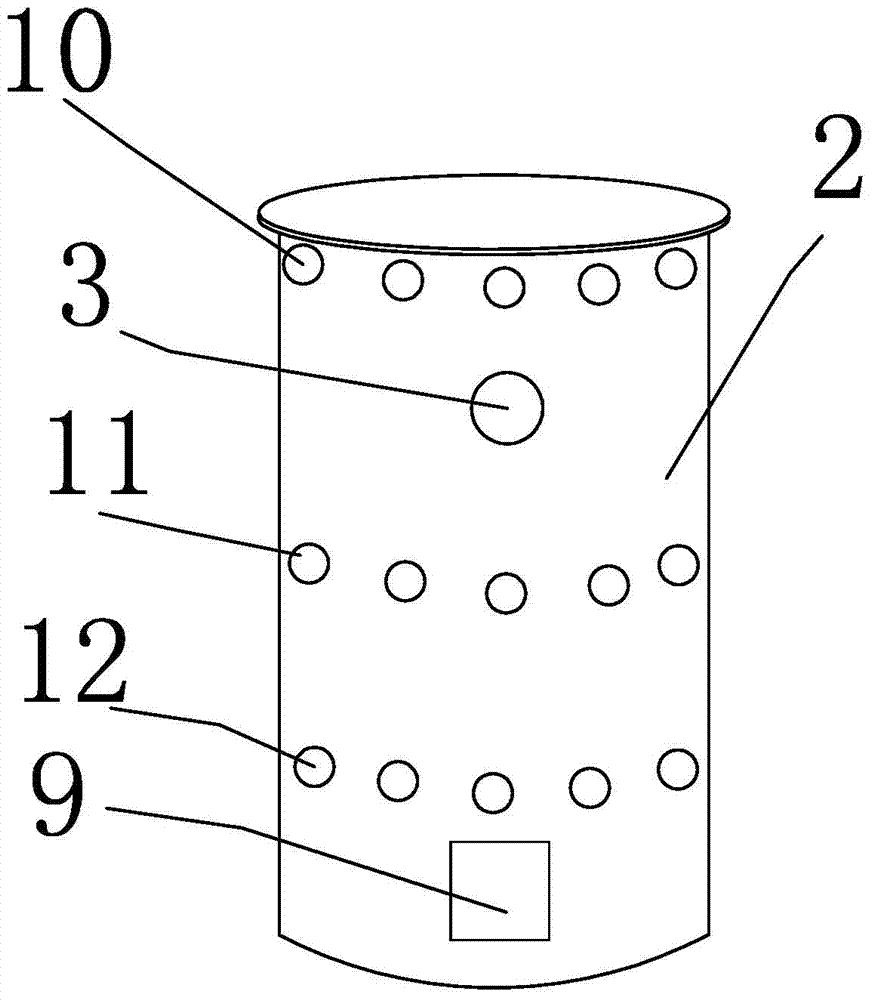

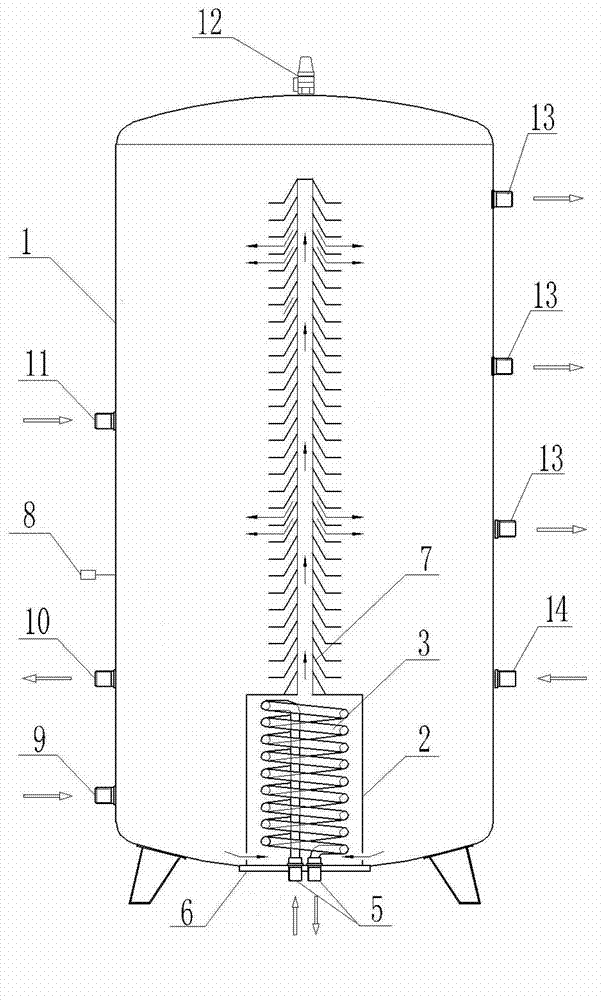

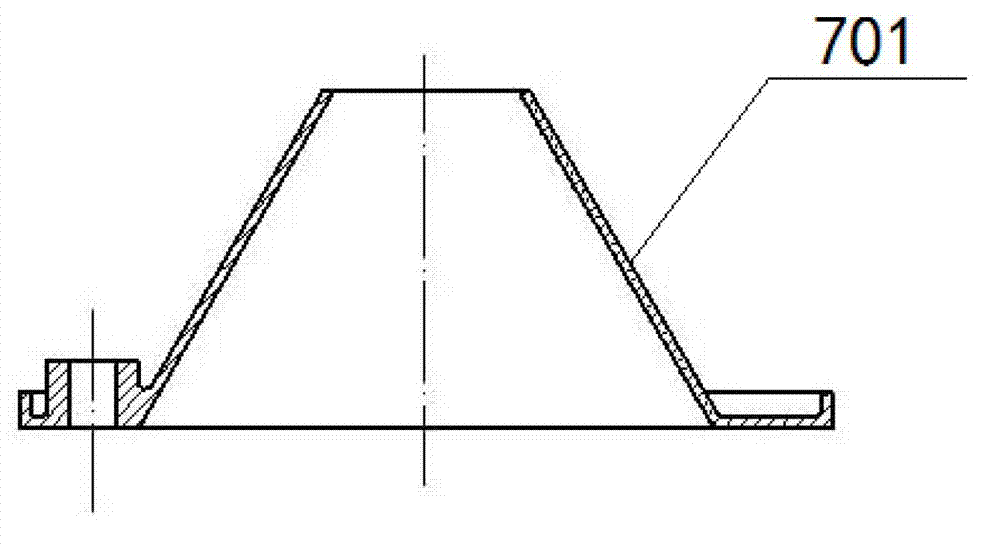

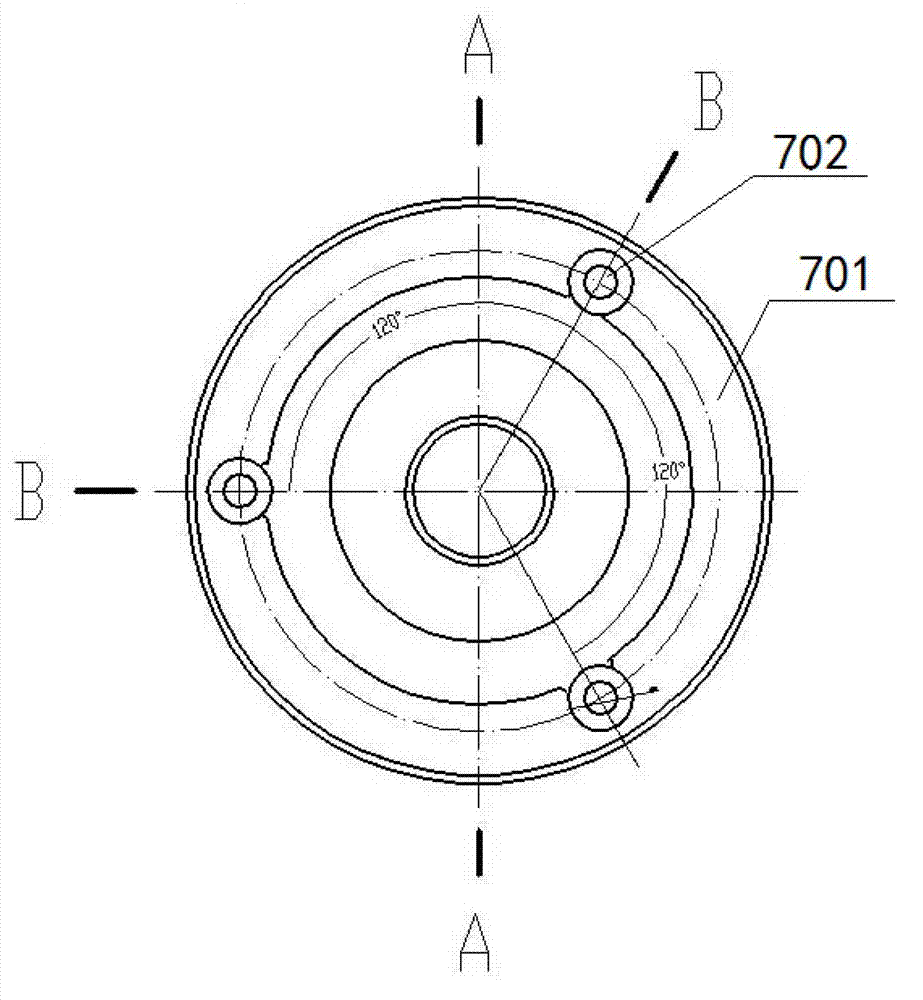

Stepless stratified hot water storage tank

ActiveCN103047785ARaise the temperature differencePromote absorptionSolar heat devicesSolar thermal energy generationCollector deviceTemperature difference

The invention discloses a stepless stratified hot water storage tank. The stepless stratified hot water storage tank comprises a water tank, a heat exchange tube, an isolation cover and a guide element combined tube, wherein the heat exchange tube is arranged at the bottom of the water tank; a gap is reserved between the bottom of the water bank and the isolation cover which is arranged outside the heat exchange tube; the guide element combined tube which is of fin-shaped outer wall and extends vertically and upwardly is communicated with the top portion of the isolation cover, and the wall between each two layer of fins is communicated with the water tank. The stepless stratified hot water storage tank is capable of quickly enabling the water temperature to reach a moderated value while keeping the water in the lower layer of the hot water storage tank cool, and the cooled lower layer of the hot water storage tank is capable of cooling the heat exchanger reflux and quickly, thereby improving the temperature difference between the heat exchanger and the hot water storage tank so as to increase the absorption of solar heat radiation.

Owner:WUHU BEST NEW ENERGY DEV

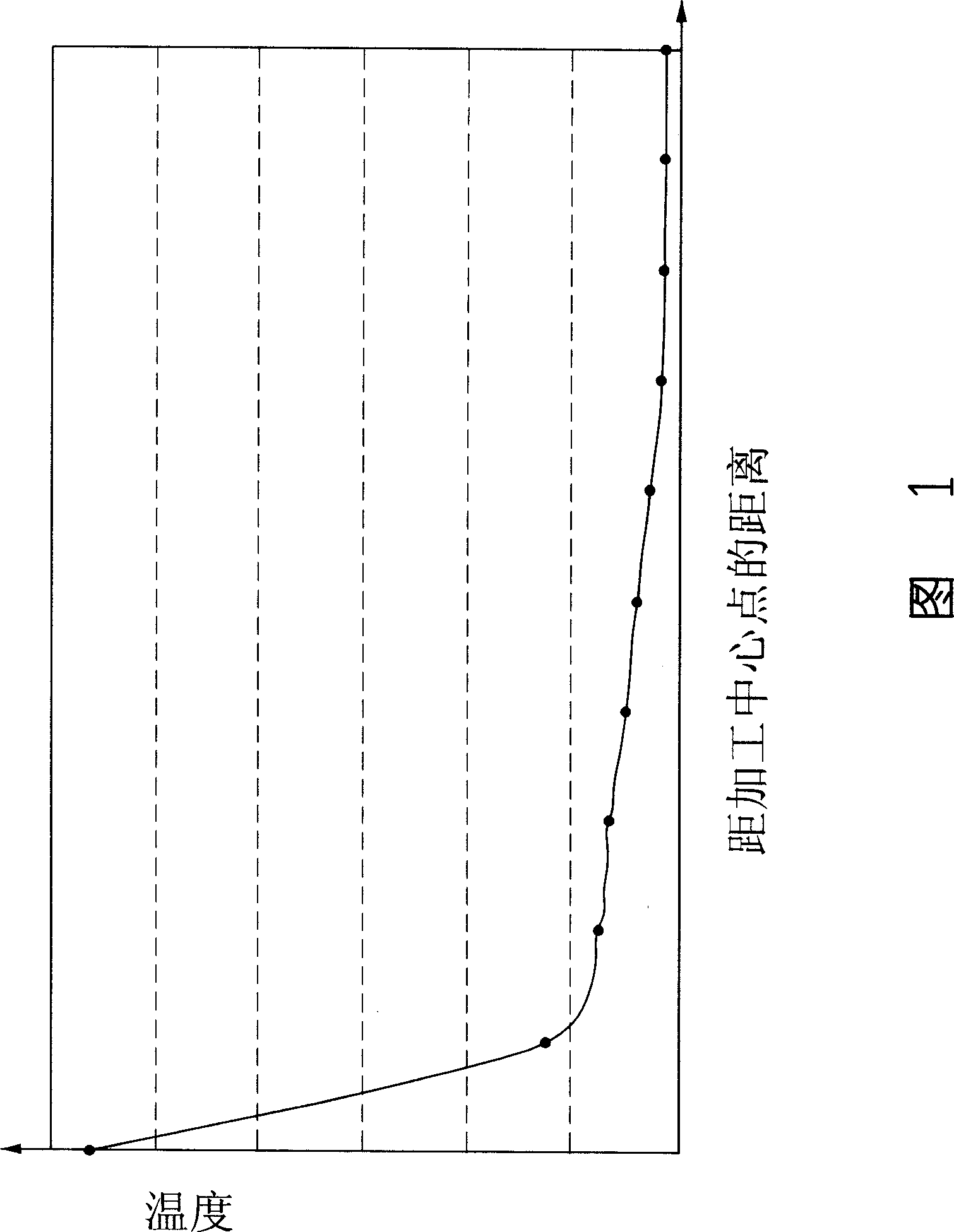

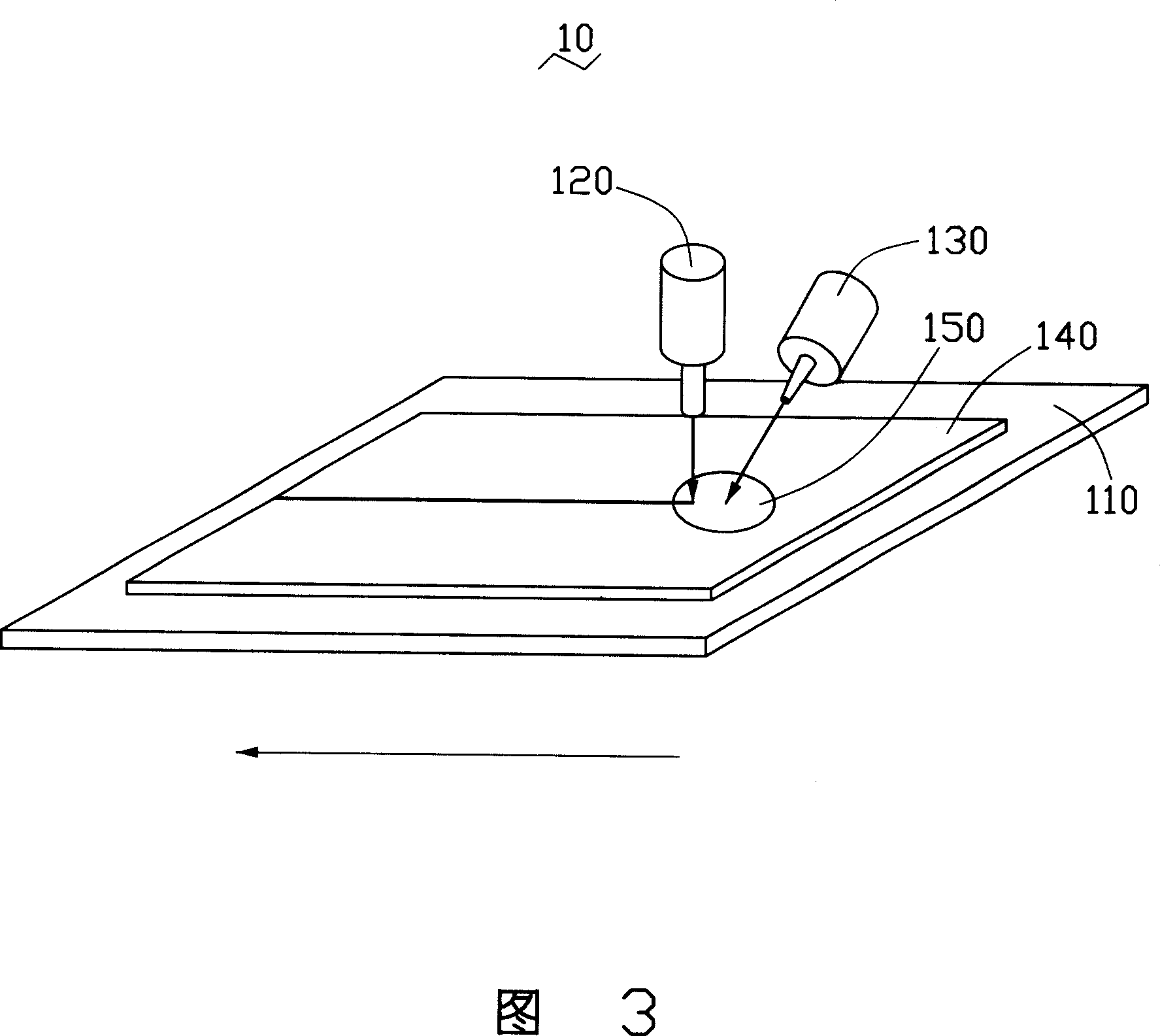

Laser processing method and corresponding laser machining apparatus

InactiveCN101134263AMinimize thermal expansion differencesRaise the temperature differenceGlass severing apparatusWelding/soldering/cutting articlesLaser processingLaser beam machining

The present invention relates to laser machining process and equipment. The laser machining process includes the following steps; setting the workpiece onto the working bench, heating the machined area of the workpiece to preset temperature, and machining the heated machined area with laser beam. The laser machining equipment includes one working bench for bearing the workpiece, one laser source to emit laser beam, and one heating source to preheat the machined area of the workpiece to preset temperature and reduce the temperature difference between the temperature of the machined area and the high temperature the laser beam generates.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

Inside heated FBG sensor and packaging method thereof

ActiveCN106979791AImprove thermal stabilityImprove thermal conductivityConverting sensor output opticallyMaterial analysisElectrical resistance and conductanceFiber Bragg grating

The invention provides an inside heated FBG sensor and a packaging method thereof. The inside heated FBG sensor comprises an alundum tube body, optical fiber leads, a heating resistance wire and an FBG sensor, and is characterized in that the alundum tube body is provided with a plurality of ducts, both ends of the FBG sensor are provided with the optical fiber leads, the FBG sensor is arranged in one of the ducts, and the heating resistance wire is arranged in the other ducts. According to the invention, moisture field data measured by the sensor is enabled to be all based on a temperature field to the maximum extent, so that the interference imposed on a measurement result by strain factors is reduced to the lowest; and the porous alundum tube is internally provided with the heating resistance wire, so that an inside heating function of an alundum tube FBG rock and soil mass moisture field monitoring sensor is realized.

Owner:SUZHOU NANZEE SENSING TECH +1

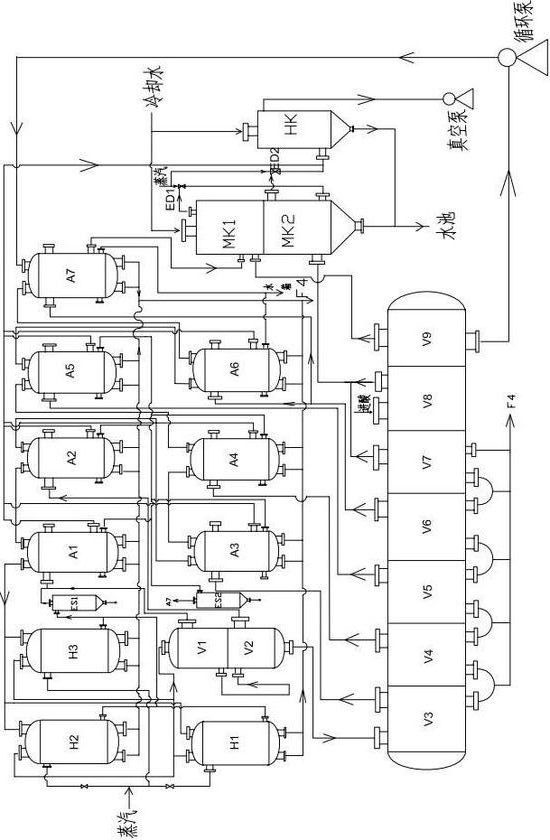

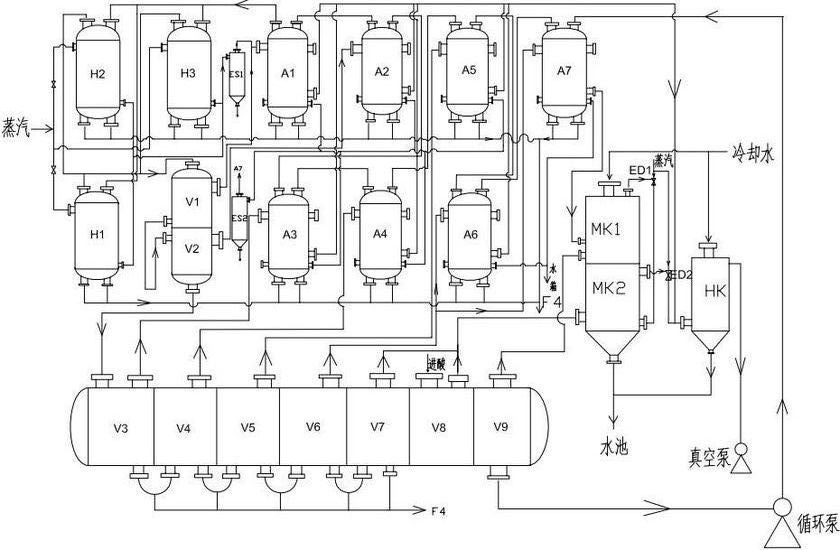

Multistage evaporating process in viscose production

ActiveCN102100973ATake advantage ofImprove evaporation efficiencyEvaporationWater useProcess engineering

The invention relates to a multistage evaporating process in viscose production, which comprises the steps of acid bath heating, acid bath evaporating, secondary steam recycling and exhausting, condensed water discharging, incoagulable gas exhausting and the like. Aiming at the prior art, equipment and a process route are re-designed, secondary steam is recycled, the heat which is not utilized inthe prior art is fully utilized, so that the purpose of improving the yield is achieved, the zero emission of evaporating water is realized, and a large quantity of sewage treatment cost and clear water supply and discharge costs are saved.

Owner:CHENGDU GRACE FIBER +1

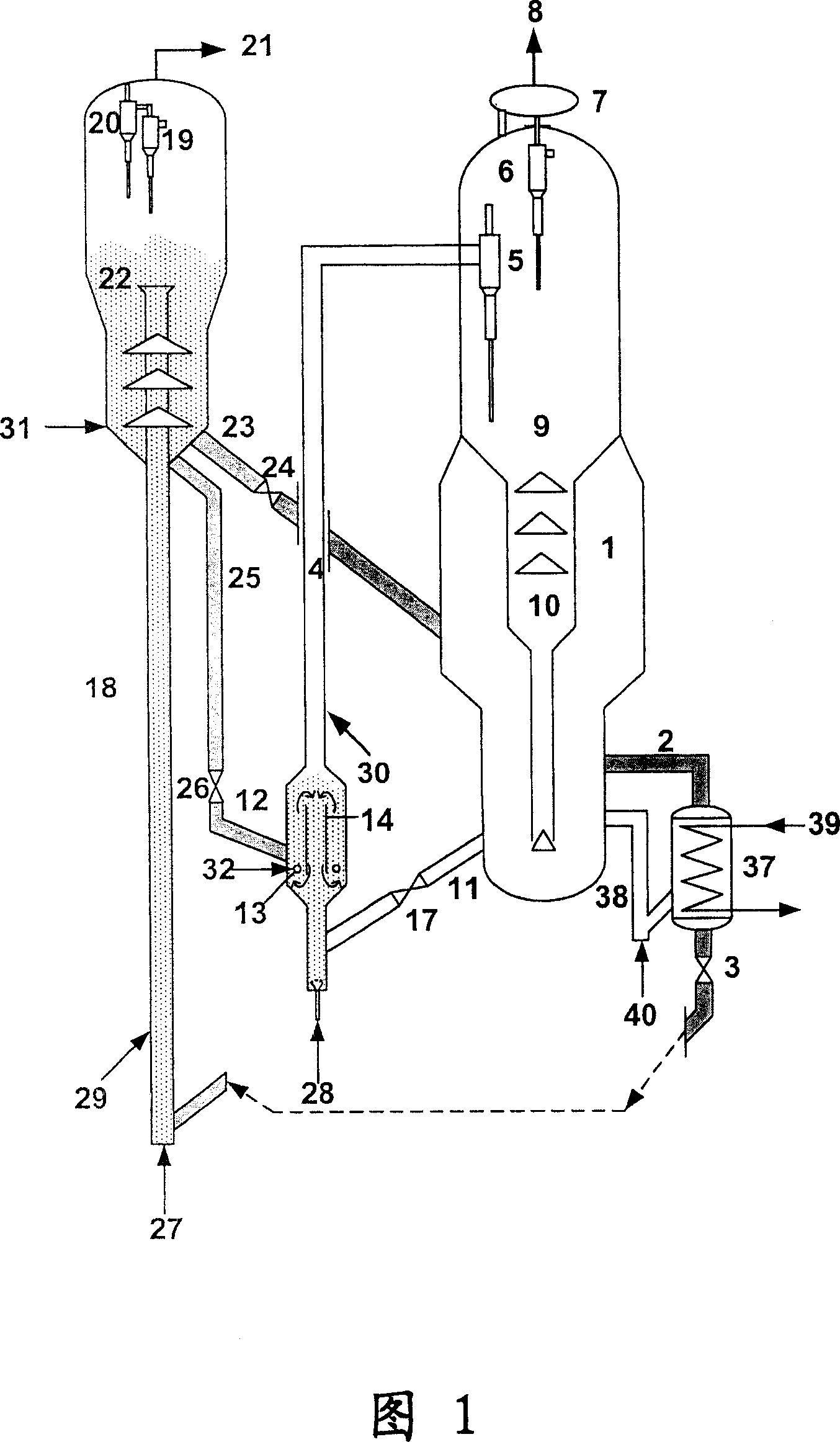

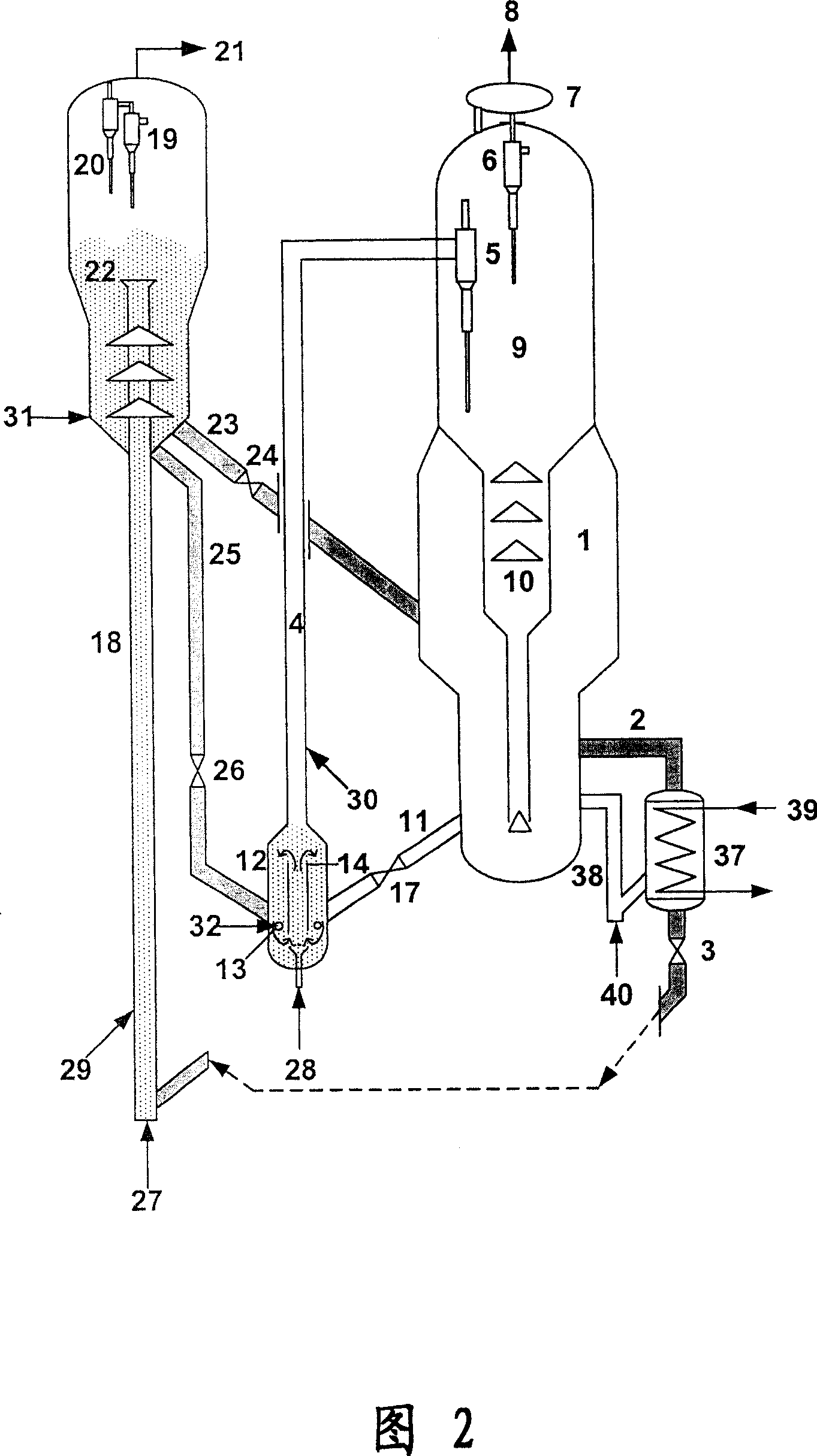

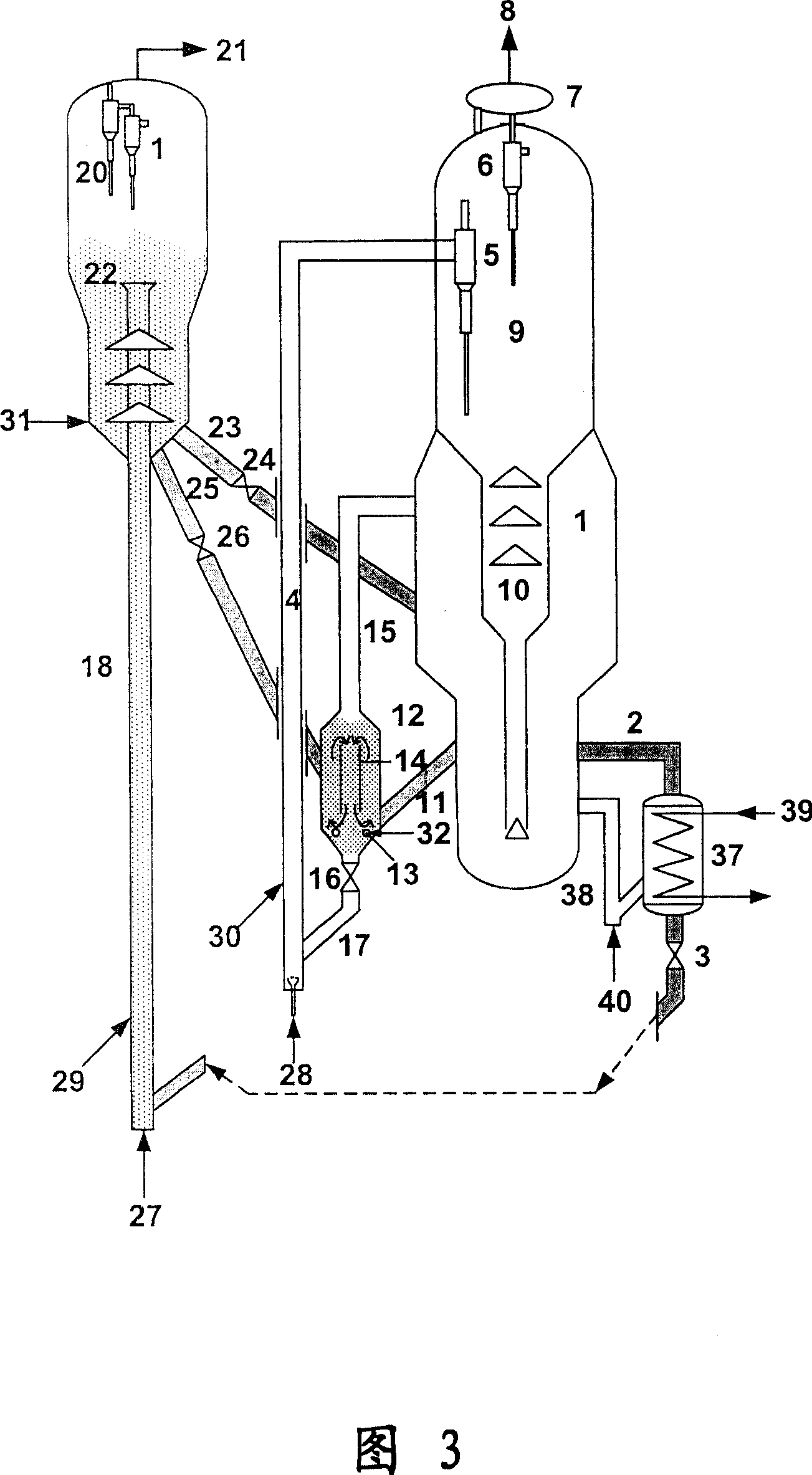

Heavyoil catalytic cracking and gasoline modifying mutual control method and apparatus

ActiveCN1978596ARealize mutual controlRaise the temperature differenceCatalytic crackingHydrocarbon distillationGasolineFuel oil

The invention relates to the method and the device to adjust and control in heavy oil catalytic cracking and gasoline modified process. It adds the catalyst circular mixer and the regenerative catalyst cooler into the heavy oil catalytic cracking system with the gasoline modified assistant fluidized reactor. So it can lead the future and regenerative catalyst from the gasoline modified assistant fluidized reactor to the mixer and mix uniformly in the water vapour, then the mixture go into the heavy oil reactor riser to crack with the raw oil; the regenerative catalyst used for the gasoline modified is cooled in cooler before going into the assistant fluidized reactor and reacts with the vapour gasoline material. The invention can decrease the gasoline alkene content to 18%(V) and it is proper for the country environment protecting rule but improve the yield of the light oil.

Owner:BEIJING YANSHAN YULONG PEC

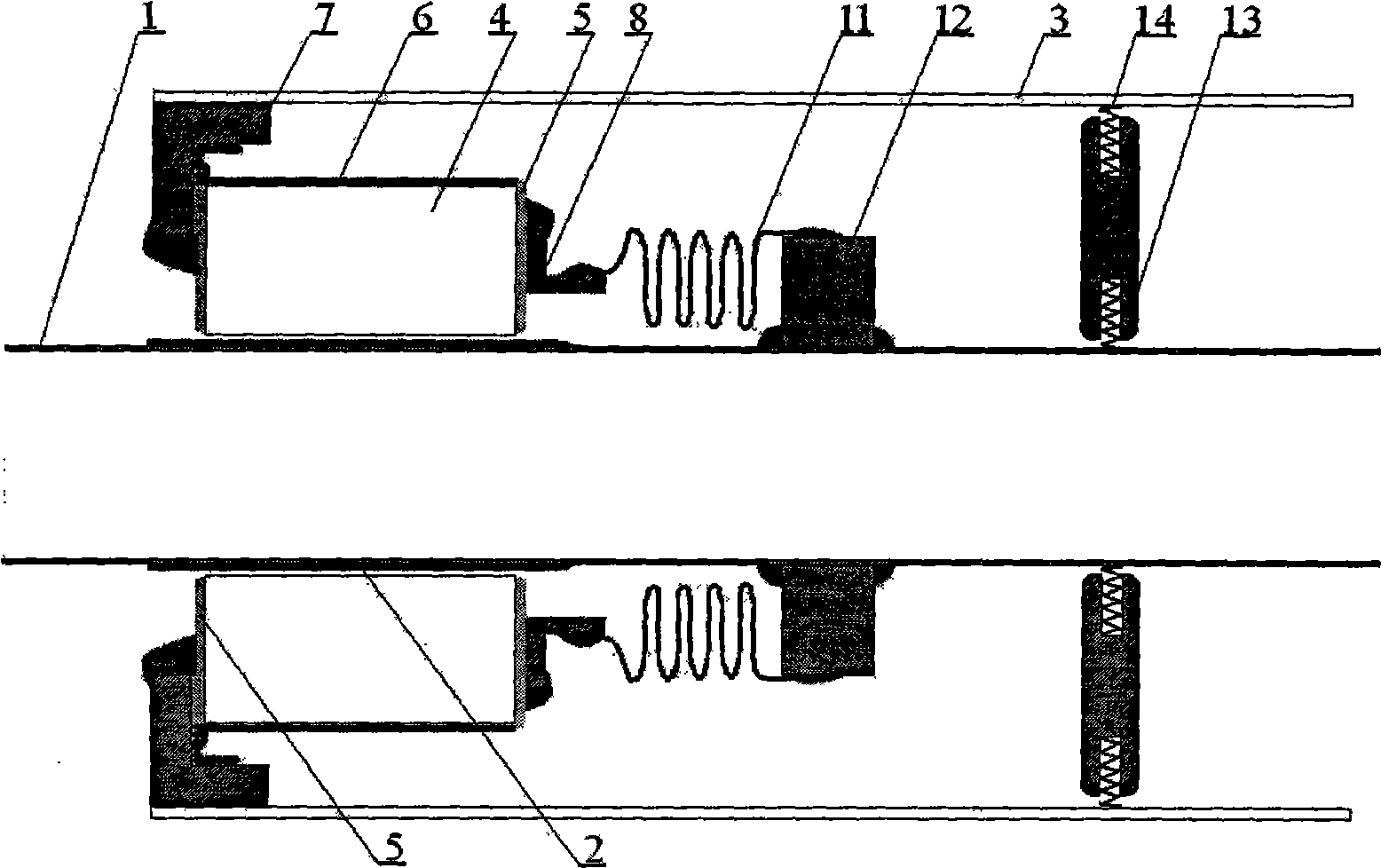

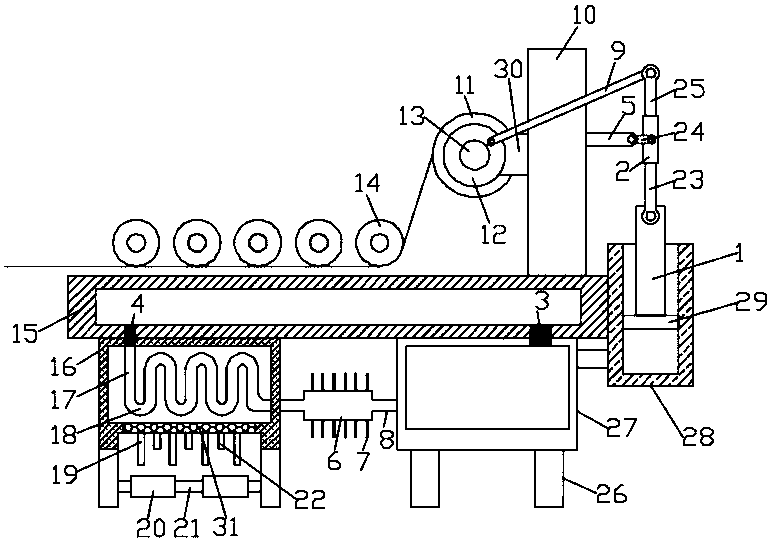

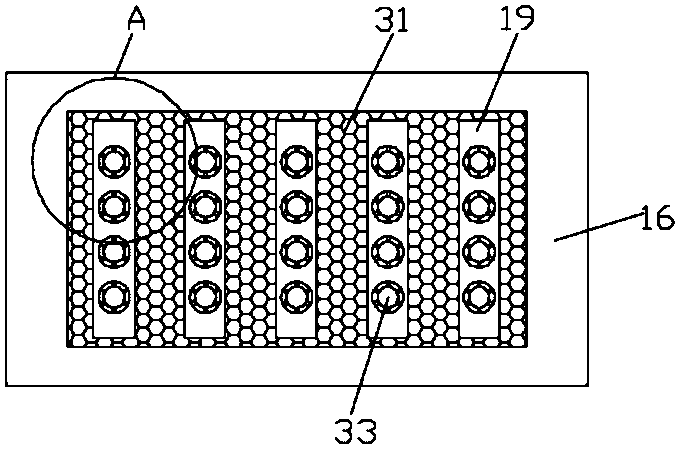

Heat-dissipating and rolling device for composite cloth material

InactiveCN108726228AImprove cooling effectFast heat absorptionWebs handlingHeat conductingReciprocating motion

The invention discloses a heat-dissipating and rolling device for a composite cloth material. The heat-dissipating and rolling device for the composite cloth material comprises a worktable. A supporting pole is fixedly connected to the upper end of the worktable. A cloth rolling device is fixedly connected to the right side wall of the supporting pole. A reciprocating device is fixedly connected to the left side of the supporting pole. According to the heat-dissipating and rolling device for the composite cloth material, the rotation of a winding roller drives a piston and a cylinder barrel totransit, with pressure, cooling liquid into a heat-dissipating cavity to perform preliminary heat dissipation. Cooling fins arranged on the outer surface of the heat-dissipating cavity can accelerateheat dissipation of the cooling liquid. A heat-dissipating tube, a heat-conducting plate, first heat-dissipating plates, second heat-dissipating plates and heat-dissipating fans are arranged to carryout further heat dissipation on the cooling liquid. Phase transformation occurs when heat-conducting parts in the first heat-dissipating plates and the second heat-dissipating plates and phase changematerials arranged in the heat-conducting parts are heated, and heat dissipation on the heat-conducting plate is accelerated. Temperature difference between the heat-conducting plate and the coolingliquid is increased. Thus, heat absorption of the heat-conducting plate is further accelerated. A coil disc do reciprocating motion, and thus the cooling liquid in the heat-dissipating and rolling device for the composite cloth material is kept flowing without external power supply. The heat-dissipating and rolling device for the composite cloth material saves energy and protects environment.

Owner:颜培吉 +2

Evaporation source and vacuum evaporation system

InactiveCN107400858AAvoid heat conductionRaise the temperature differenceVacuum evaporation coatingSputtering coatingSpray nozzleEngineering

The invention relates to an evaporation source. The evaporation source comprises a crucible body and a spray nozzle cover plate, wherein the crucible body is provided with an evaporation chamber used for accommodating a vacuum evaporation material, and one end of the evaporation chamber is open; the spray nozzle cover plate covers the opening of the evaporation chamber of the crucible body, and a spray nozzle is arranged on the spray nozzle cover; the crucible body comprises a first butt-joint part which is in butt joint with the spray nozzle cover plate; the spray nozzle cover plate comprises a second butt-joint part which is in butt joint with the crucible body; and a heat insulation layer is arranged between the first butt-joint part and the second butt-joint part. The invention further relates to a vacuum evaporation system. The evaporation source has the beneficial effects that: the heat insulation layer is arranged for avoiding heat conduction between the crucible body and the spray nozzle cover plate, so that temperature difference between the crucible body and the spray nozzle cover plate is increased, and the problem of blocking holes by materials is improved.

Owner:BOE TECH GRP CO LTD +1

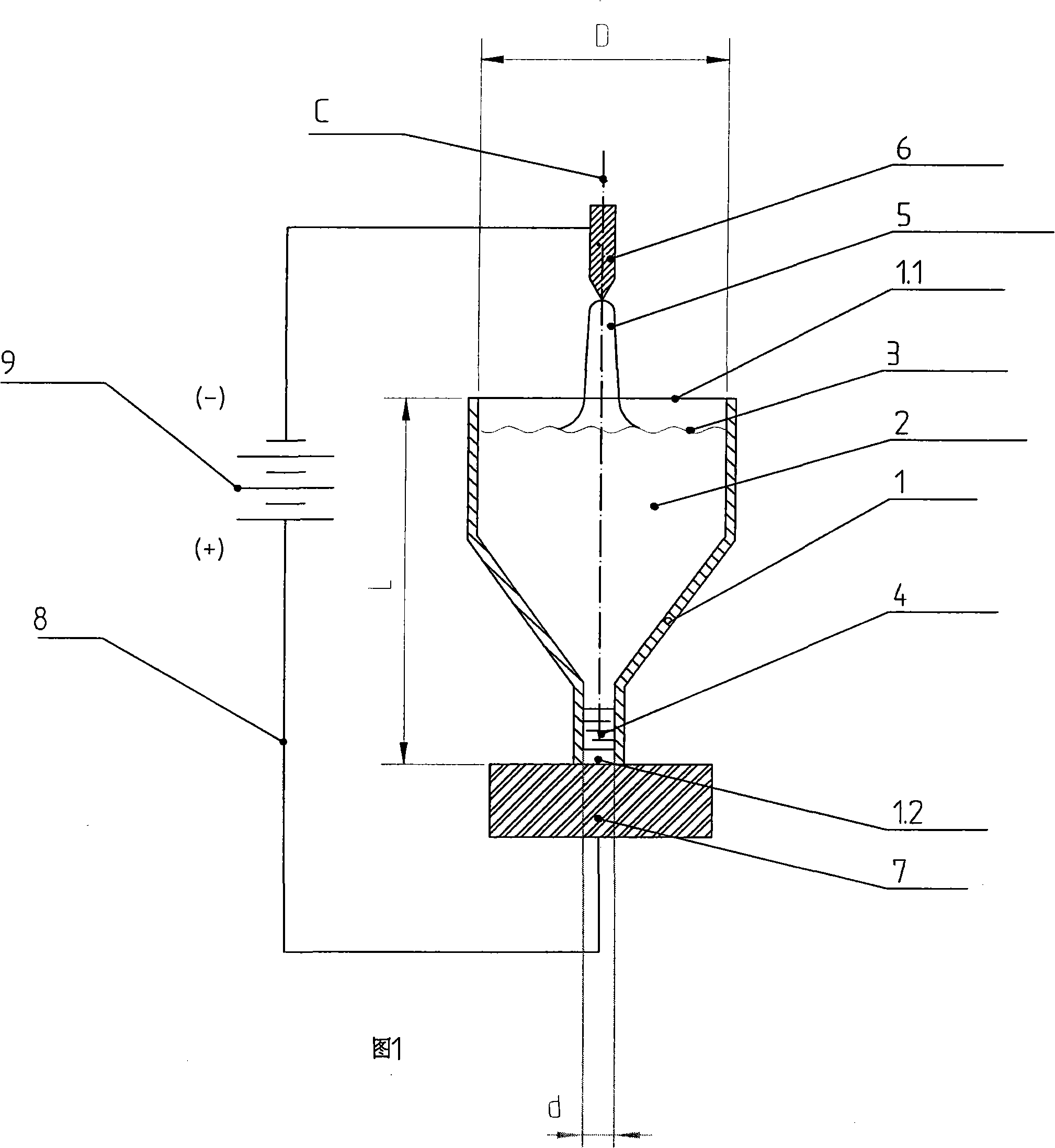

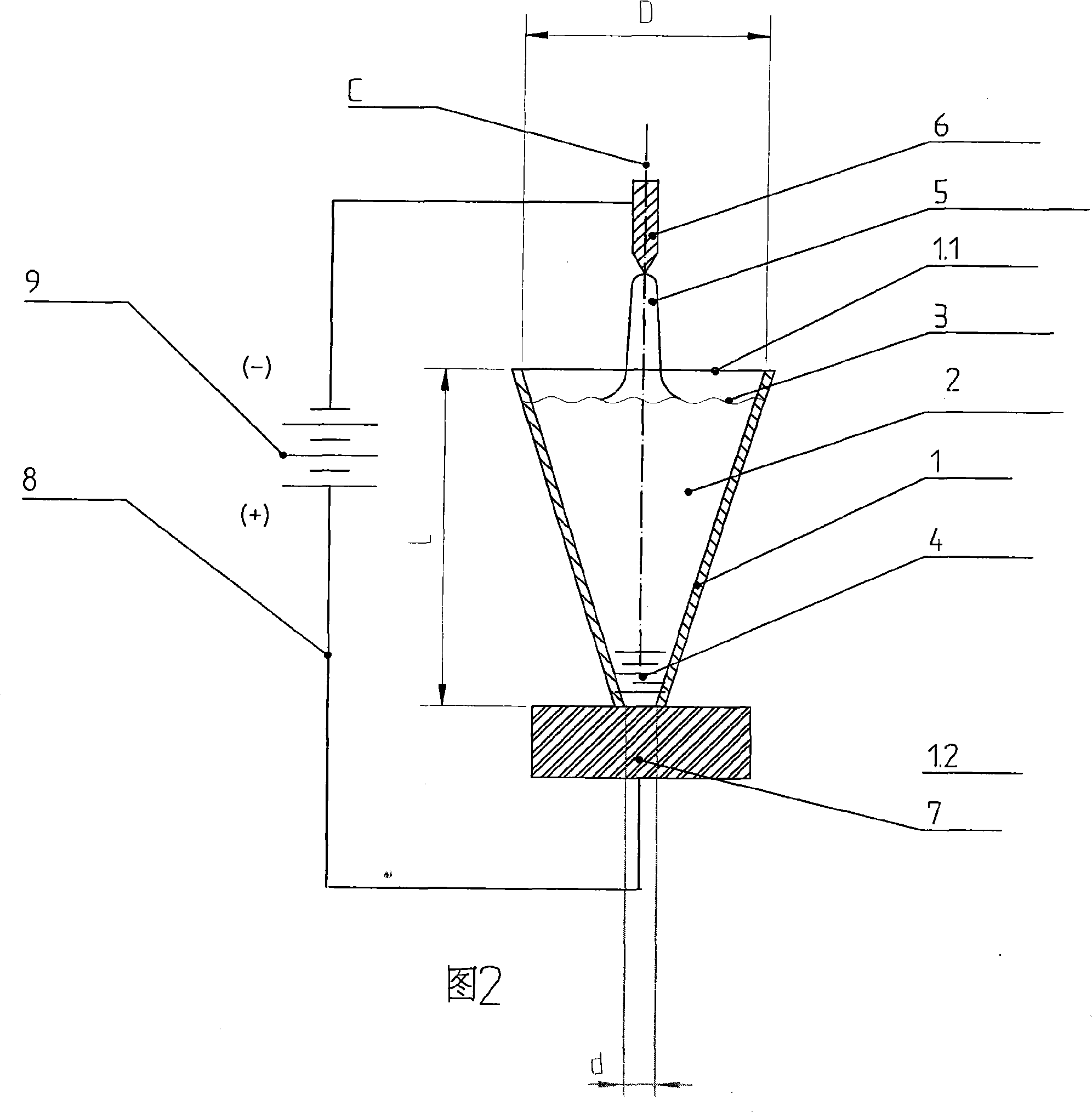

Ceramic crucible

The invention discloses a ceramic crucible, the top view of the crucible body (1) is round, the top part is equipped with upper mouth (1. 1), the crucible body (1) is made from ceramic materials containing oxides such as Alumina, Magnesia or Zirconia, the bottom part of the crucible body (1) is equipped with a bottom mouth (1. 2), the proportion between the diameter (d) of the bottom mouth (1. 2) of the crucible body (1) and the diameter (d) of the upper mouth (1. 1) of the crucible (1) is 1:5-15; the proportion between the height (L) from the bottom surface of the crucible body (1) to the top surface of the crucible body (1) and the diameter (D) of the upper mouth (1. 1) of the crucible body (1) is 5:1-5. The ceramic crucible not only fuses into the metal contained or forms alloy with the metal contained to influence the production quality of the nano metal powder, but also has good conductive character.

Owner:JIANGSU BOQIAN NEW MATERIALS

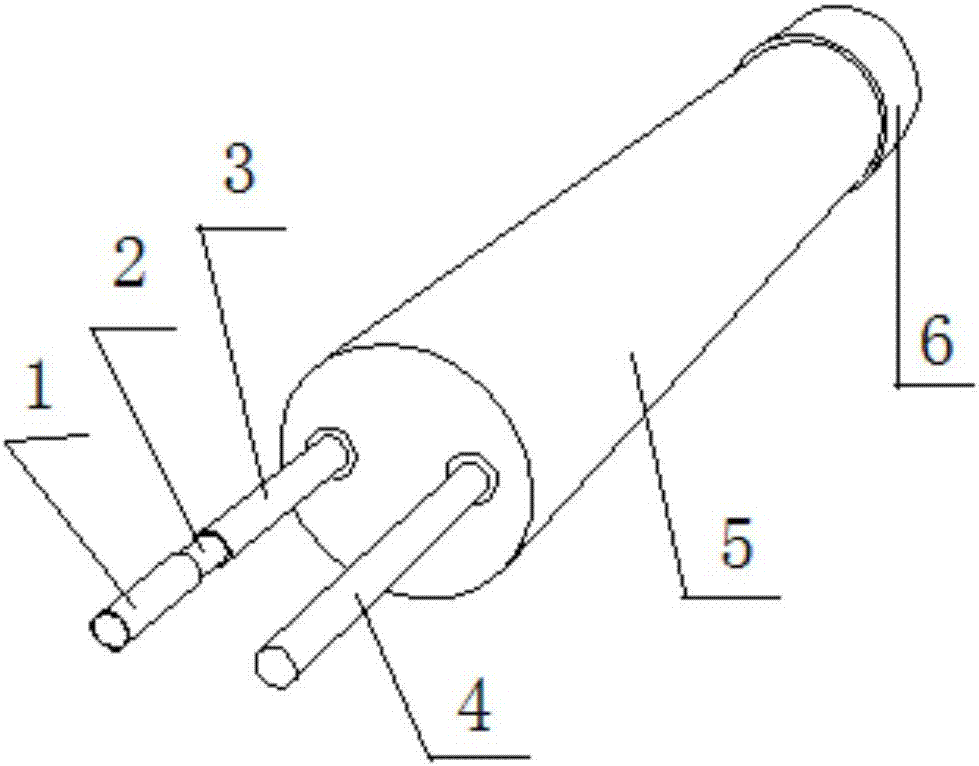

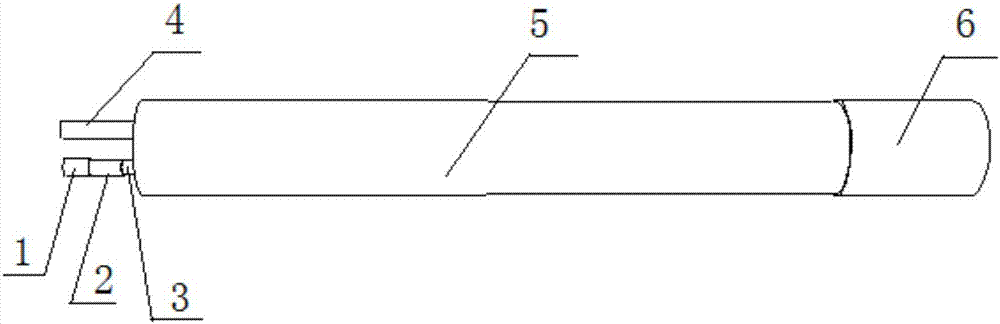

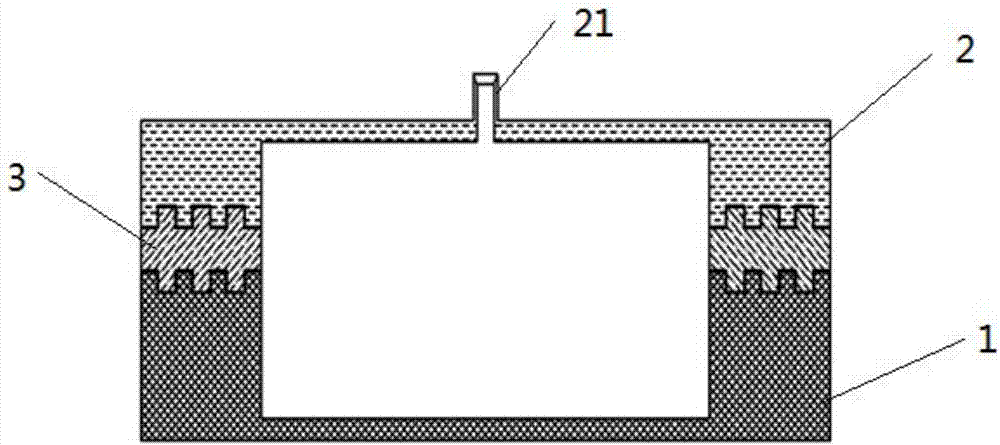

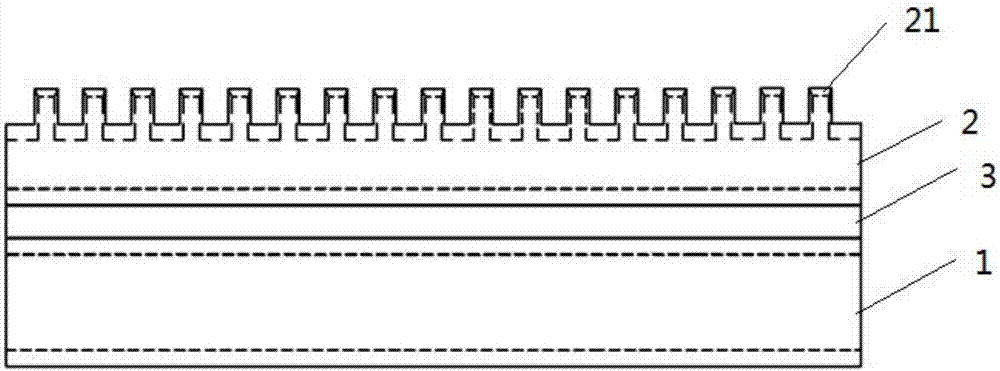

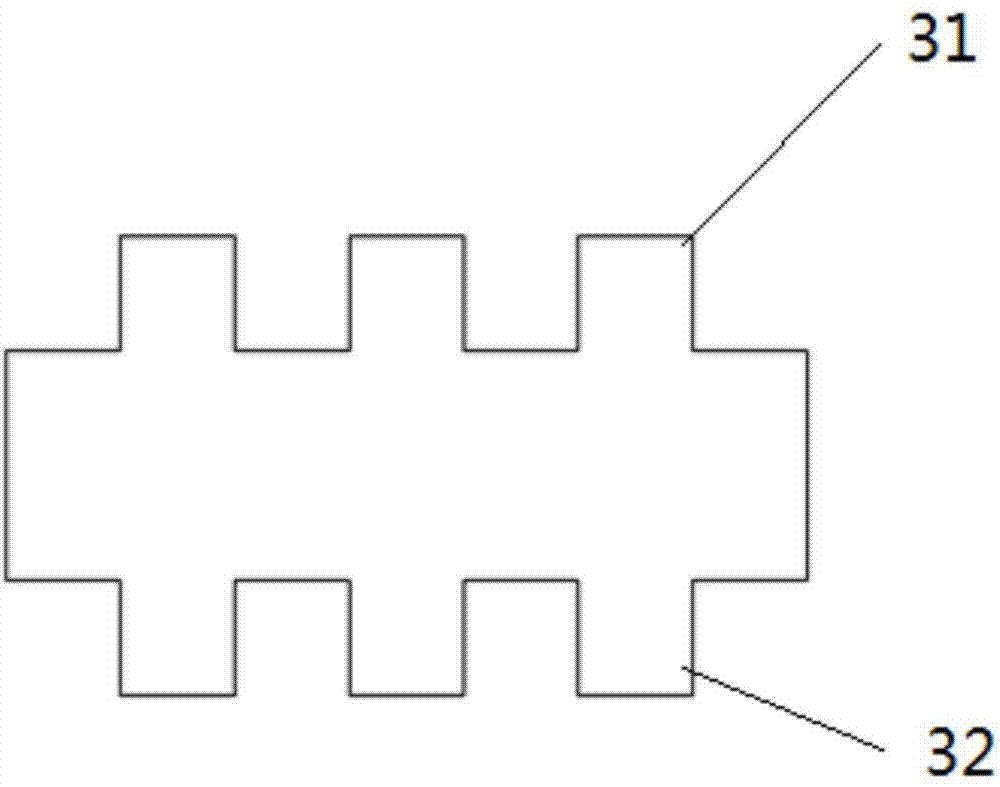

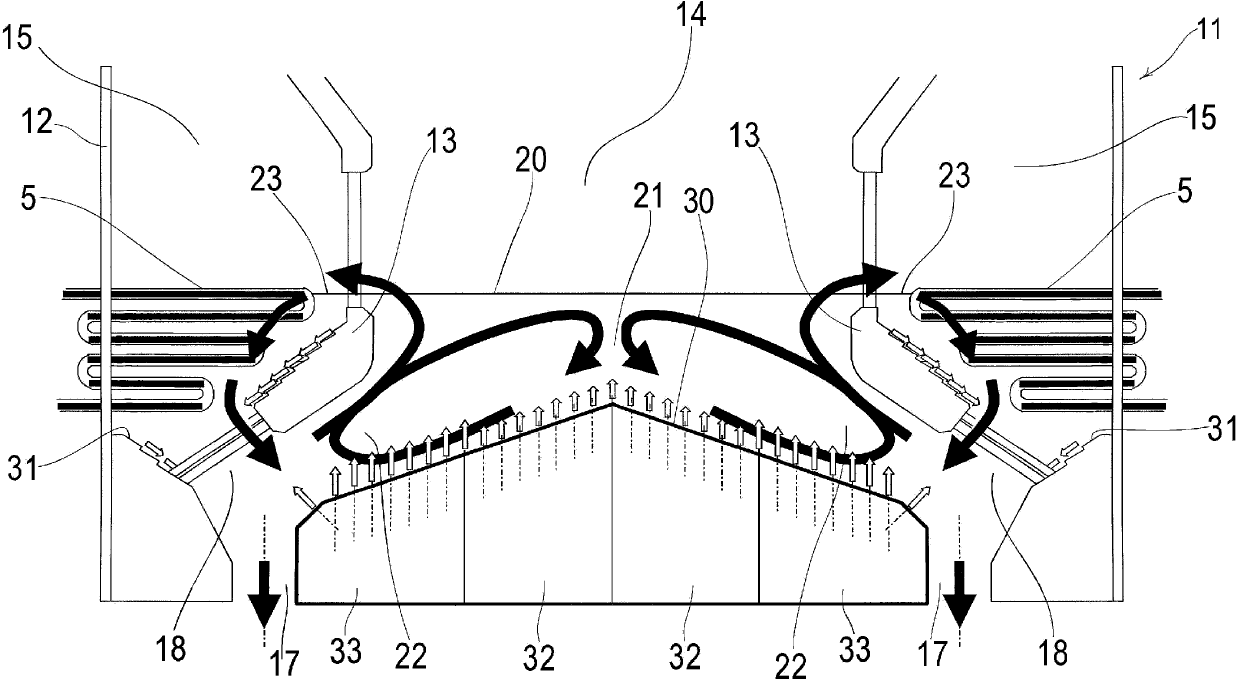

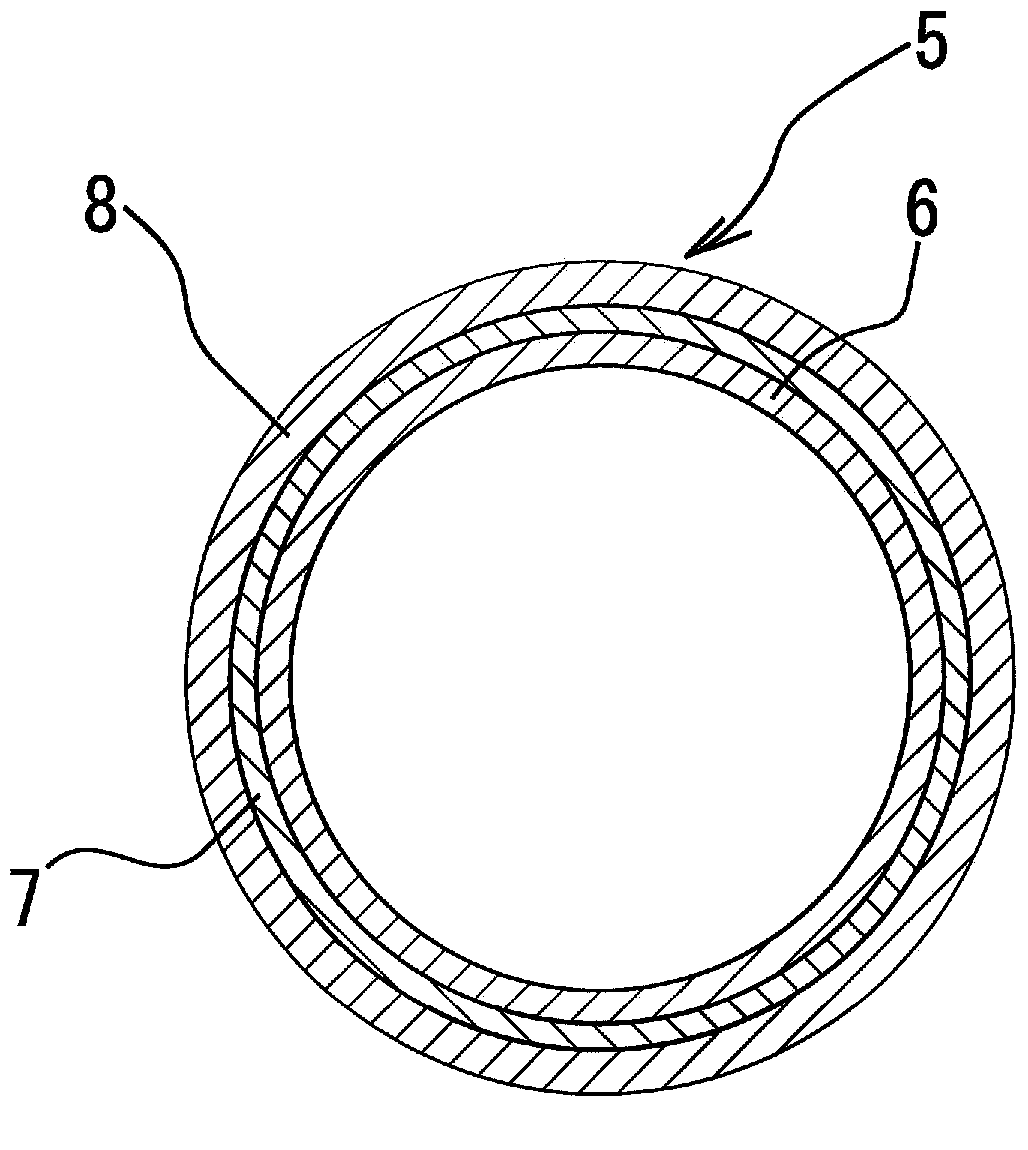

In-bed heat transfer tube for fluidized bed boiler

ActiveCN104136842AIncreased durabilityMolten Salt Corrosion InhibitionFluidized bed combustionBoiler water tubesFluidized bedHeat of combustion

The present invention pertains to an in-bed heat transfer tube installed in the fluidized bed of a fluidized bed boiler that burns fuels such as refuse-derived fuel (RDF) and waste with a high calorific value, including biomass and plastic, and recovers combustion heat. This in-bed heat transfer tube (5) for a fluidized bed boiler is installed in the fluidized bed (3) of the fluidized bed boiler (1), and the in-bed heat transfer tube (5) consists of: a water tube (6) through which a fluid flows; a protector (8) for protecting the water tube (6), said protector (8) being disposed on the outer circumferential side of the water tube (6); and a filler layer (7) disposed between the water tube (6) and the protector (8).

Owner:EBARA ENVIRONMENTAL PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com