Polarization radiating unit permanent magnet motor

A permanent magnet motor, heat dissipation technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of irreversible demagnetization of permanent magnets, limit motor output, increase safety hazards, etc., to eliminate poor heat dissipation effect, increase Temperature difference, the effect of improving the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

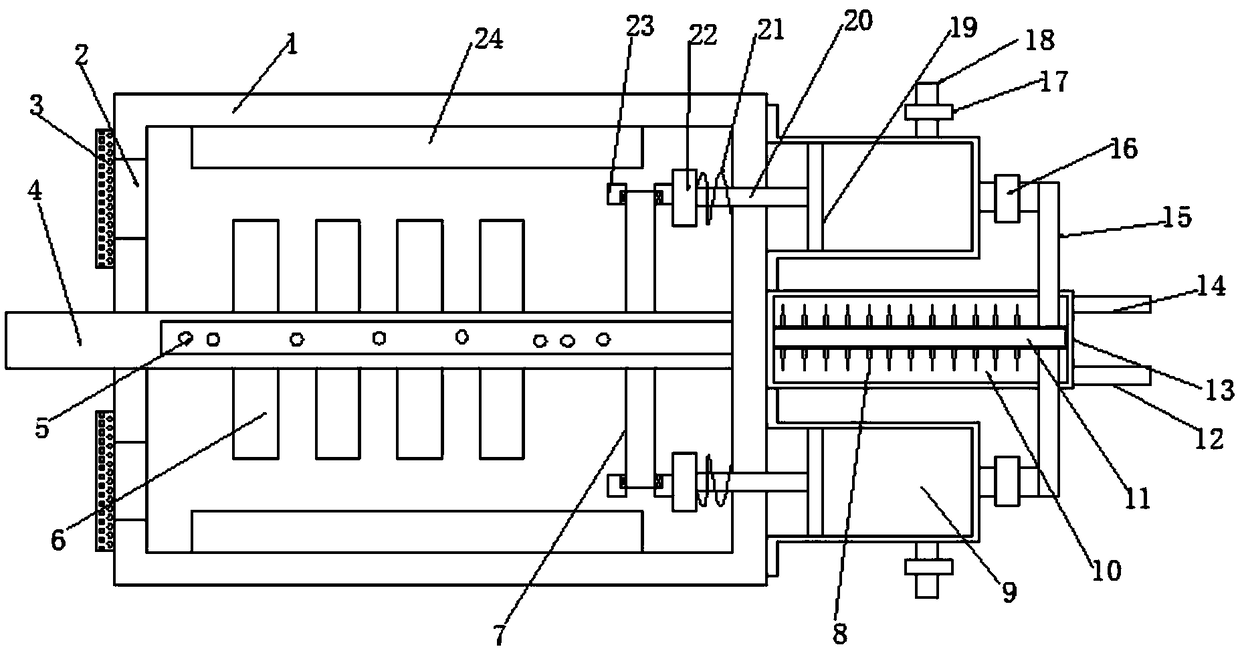

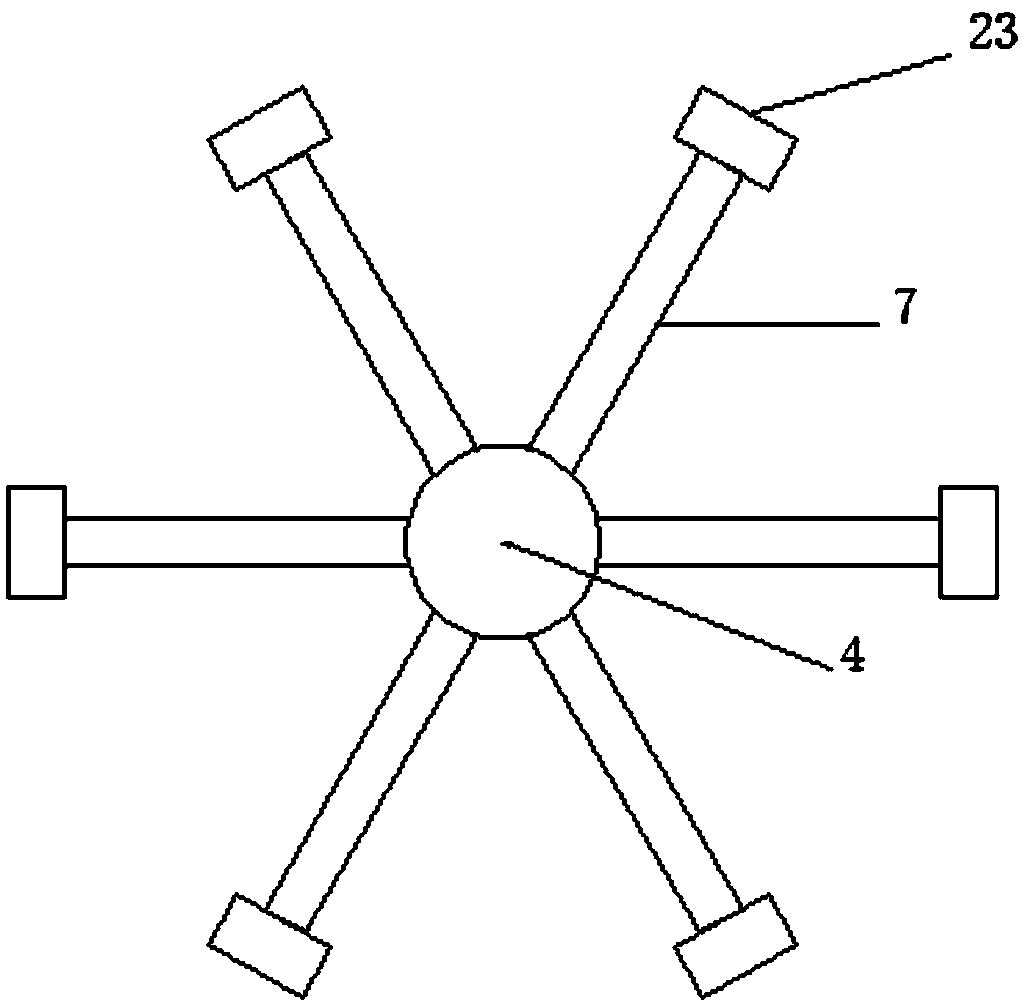

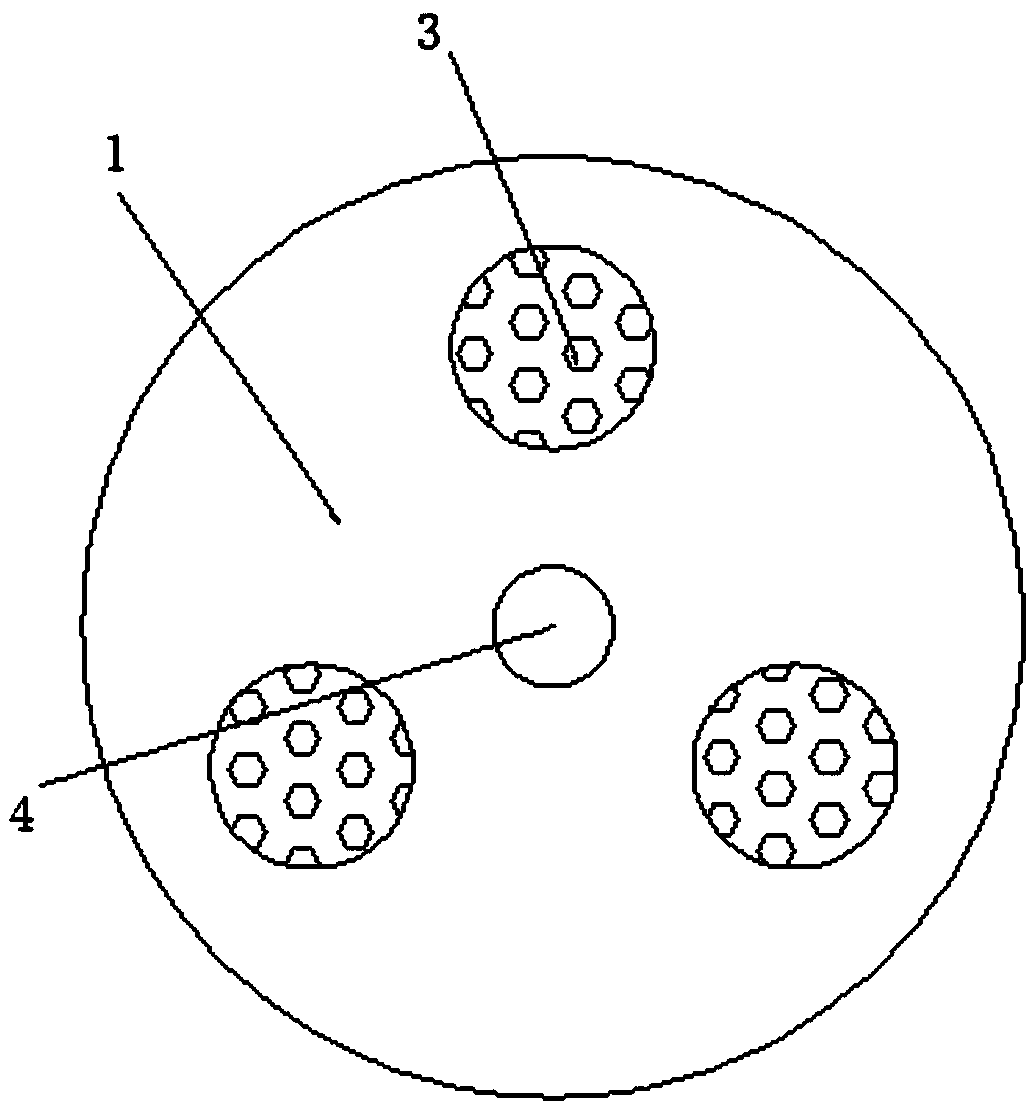

[0019] see Figure 1~3 , in the embodiment of the present invention, a polarized heat dissipation unit permanent magnet motor includes a casing 1, a rotating shaft 4 is provided in the middle of the casing 1, and an air guiding cavity is arranged inside the rotating shaft 4, where the air guiding cavity is located. The surface of the rotating shaft 4 is provided with an air injection hole 5, the surface of the rotating shaft 4 is provided with a rotor 6, the inner wall of the casing 1 is fixed with a stator 24 corresponding to the rotor 6, and the right end of the rotating shaft 4 is distributed with a number of polarization Rod 7, the polarizing wheel 23 is arranged at the end of the polarizing rod 7, and a rotating bearing is arranged between the polarizing wheel 23 and the polarizing rod 7, and a plurality of exhaust ports 2 are distributed on the left end of the casing 1, and the exhaust ports 2 The number is three, the outer surface of the exhaust port 2 is provided with ...

Embodiment 2

[0021] The difference from Embodiment 1 is that several heat dissipation fins 8 are provided outside the heat exchange air duct 11, thereby increasing the heat dissipation area and improving the heat dissipation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com