Evaporation source and vacuum evaporation system

An evaporation source and evaporation technology, applied in the field of evaporation sources and evaporation systems, can solve the problems of inconspicuous plugging, long cooling time, material blocking of the hole wall, etc., to improve the material plugging problem, avoid heat conduction, increase The effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

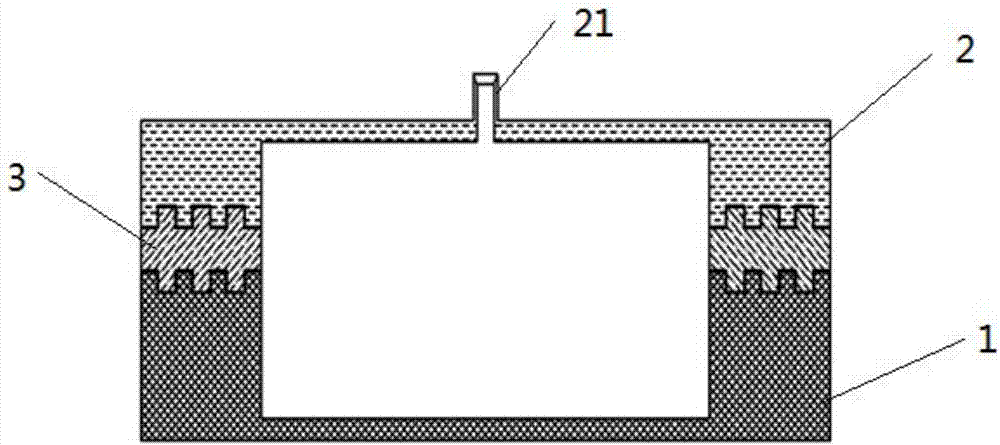

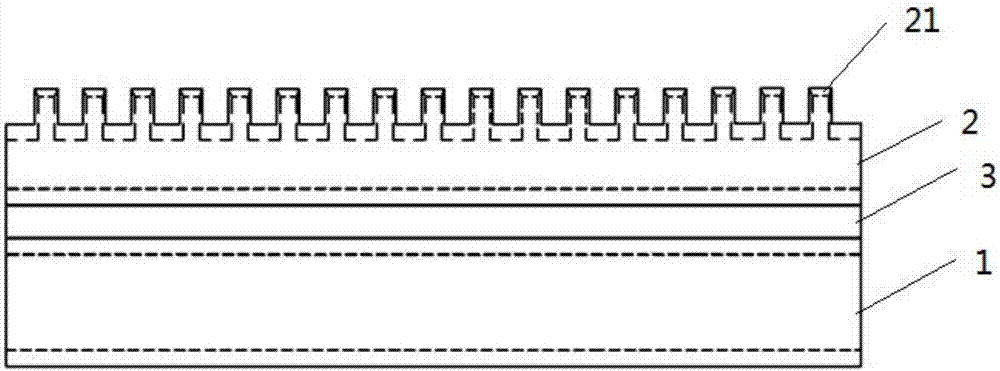

[0023] like Figure 1-Figure 3 As shown, the present embodiment provides a kind of evaporation source, comprising:

[0024] A crucible body 1, the crucible body 1 has an evaporation chamber for accommodating evaporation materials, and one end of the evaporation chamber is open;

[0025] And, buckle the nozzle cover plate 2 on the opening of the evaporation chamber of the crucible body 1, and the nozzle 21 cover is provided with a nozzle 21;

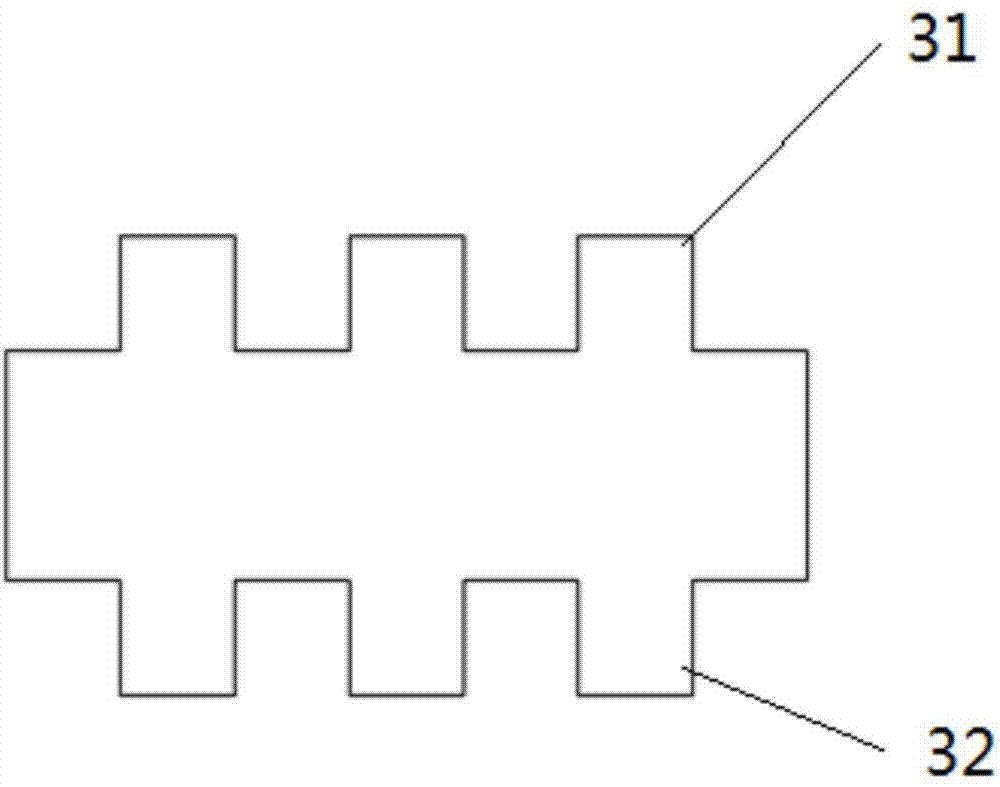

[0026] The crucible body 1 includes a first docking portion for docking with the nozzle cover plate 2; the nozzle cover plate 2 includes a second docking portion for docking with the crucible body 1; the first docking portion A heat insulating layer 3 is provided betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com