Integrated automatic dedusting energy-saving system and conversion method thereof

A technology for automatic dust removal and energy-saving systems, which is applied to energy recovery systems for ventilation and heating, air-conditioning systems, and ventilation systems, and can solve problems such as high energy consumption, high air-conditioning failure rates, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

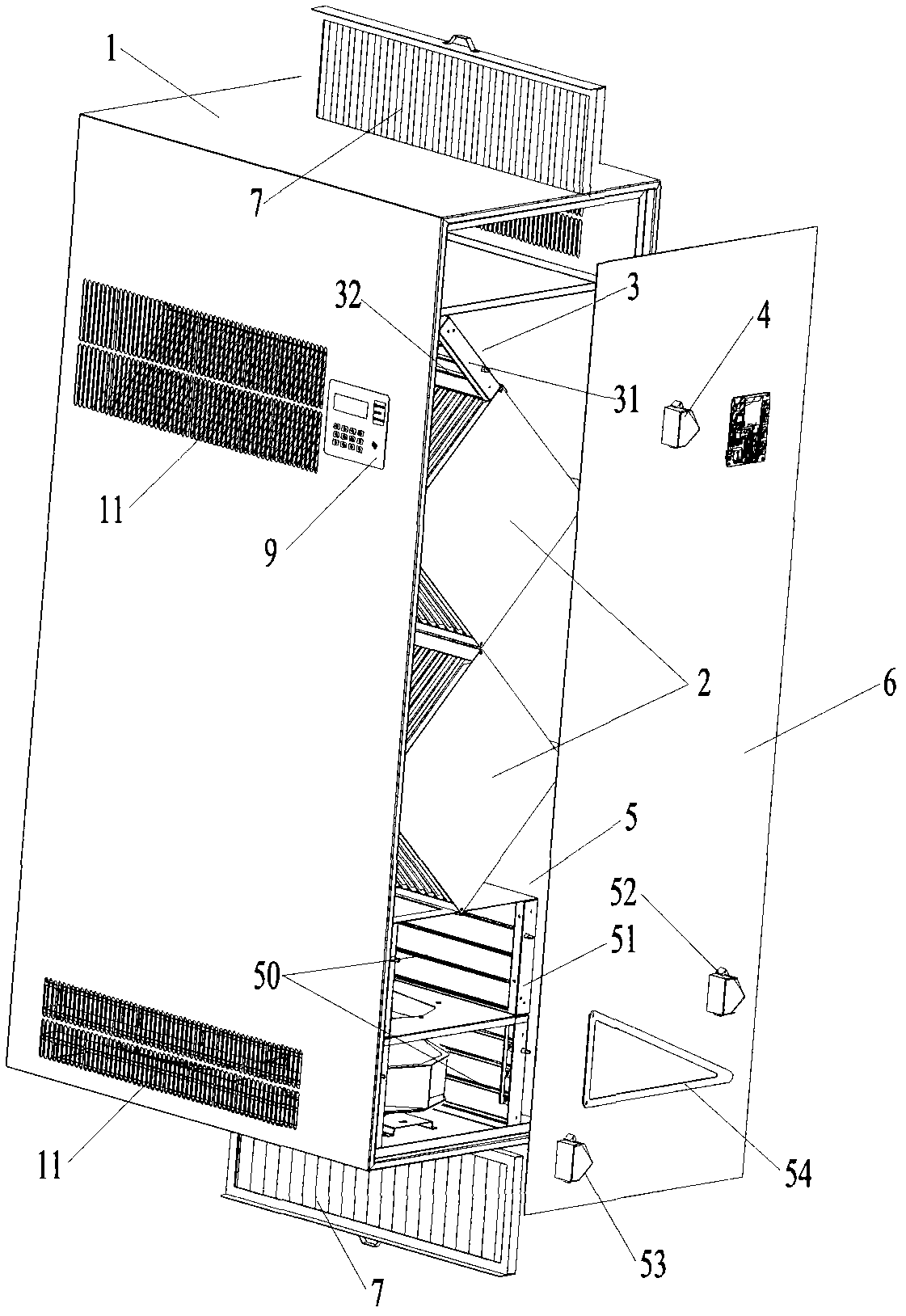

[0027] Such as figure 1 , figure 2 and image 3 As shown, the present invention proposes an embodiment of an integrated automatic dust removal and energy saving system.

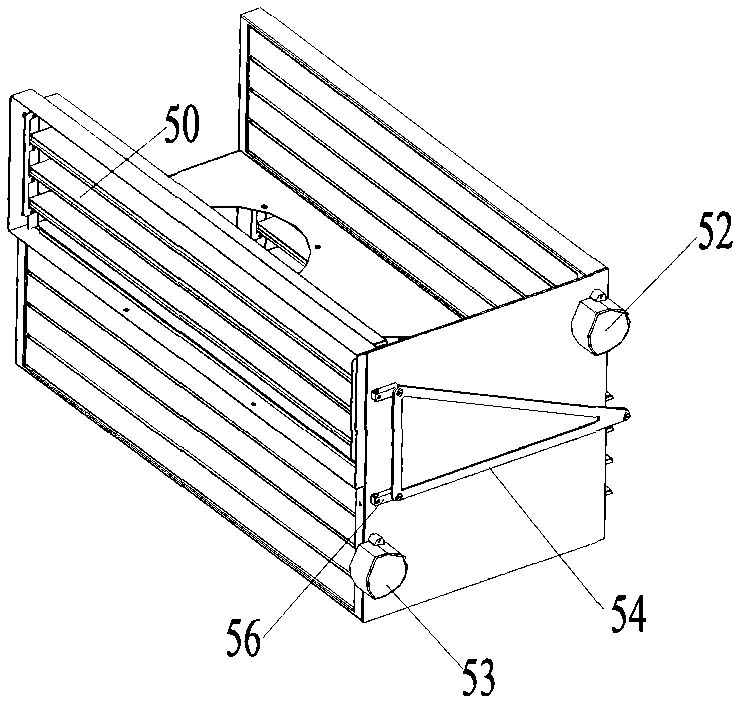

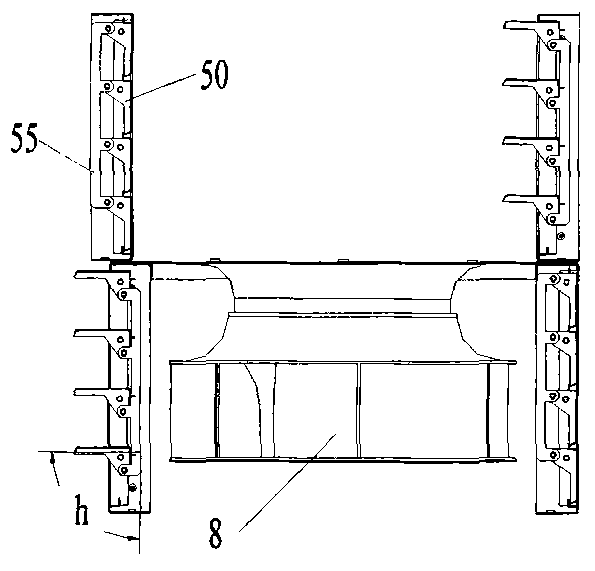

[0028] The integrated automatic dust removal and energy-saving system includes a chassis 1 with vents 11 on the upper and lower parts respectively, two heat exchange cores 2 arranged up and down inside the chassis 1, and a first heat exchange core 2 which is controlled by the controller 9 and arranged on the top of the chassis 1. The fan 10 and the second fan 8 arranged at the bottom of the chassis 1, the system also includes a first damper 3 and a second damper 5 which are opened or closed by the controller 9 respectively, the first damper 3 is located at the first fan 10 and the upper heat exchange core 2, and isolating and forming an inner circulation air passage B-B and an outer circulation air passage A-A cooperating with the upper heat exchange core 2 on the upper part of the chassis 1, the second da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com