Heavyoil catalytic cracking and gasoline modifying mutual control method and apparatus

A heavy oil catalysis and upgrading technology, applied in the catalytic conversion process, the device for realizing the process, and the field of the catalytic conversion process of petroleum hydrocarbons, which can solve the problem of the decrease of the yield of light oil, the increase of the yield of cracked gas, the over-cracking reaction of oil and gas, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

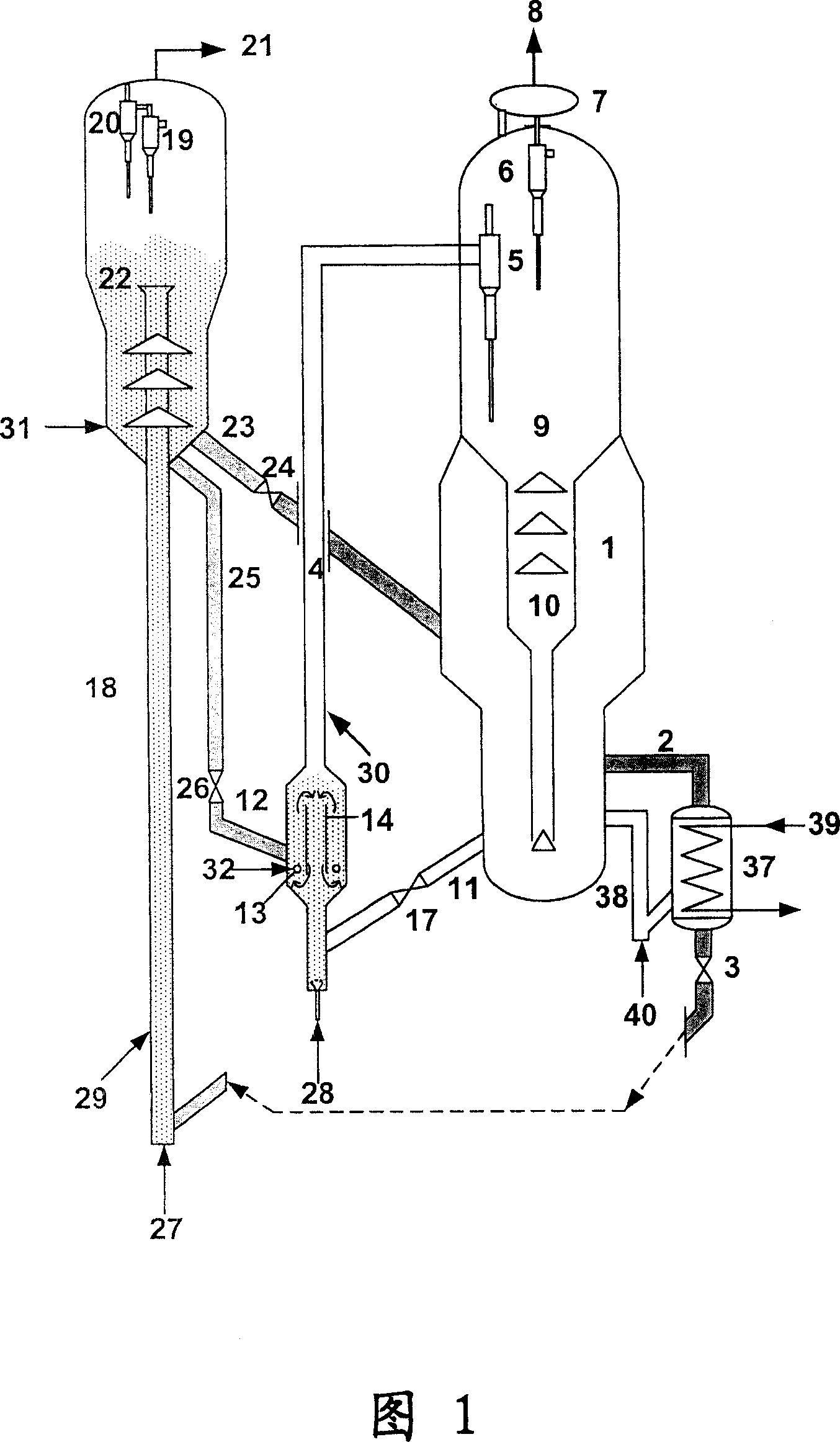

[0065] The process flow is shown in Figure 1: a catalyst circulation mixer 12 is set up at the bottom of the industrial catalytic cracking unit heavy oil riser reactor 4 with catalytic gasoline upgrading auxiliary fluidization reactor, and the top and bottom of the catalyst circulation mixer 12 are connected with The heavy oil riser reactors are connected to each other. Catalyst circulation mixer 12 is a cylindrical cylinder, inside coaxially arranges an inner cylinder 14, forms outer annular space between inner and outer cylinders, and a gas outer ring distribution pipe 13 is arranged at the bottom of this annular space, and water vapor 32 enters the annular space in the catalyst circulation mixer 12 through the gas outer ring distribution pipe 13 as a fluidization medium, and adjusts the flow rate of the water vapor 32 entering the catalyst circulation mixer 12 so that the gas velocity in the outer ring space of the catalyst circulation mixer 12 is low Due to the gas velocit...

Embodiment 2

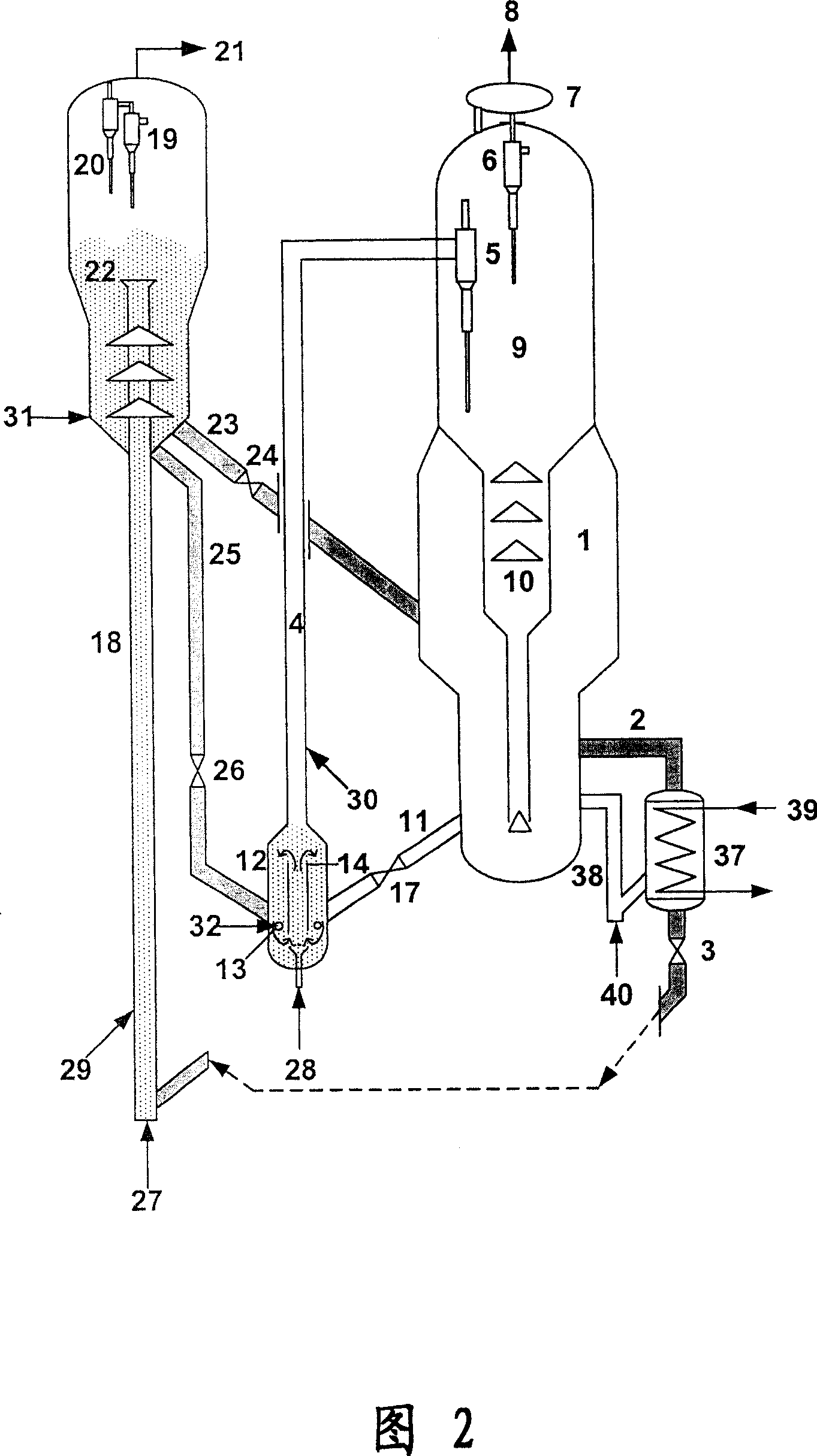

[0070] Referring to the flow process shown in Figure 2, it is briefly described as follows: a catalyst loop mixer 12 is set up at the bottom of the heavy oil riser reactor 4 of the industrial catalytic cracking unit with catalytic gasoline upgrading auxiliary fluidization reactor, and the catalyst loop mixer 12 The top of the reactor is connected with the heavy oil riser reactor 4, and the bottom of the catalyst circulation mixer 12 is a closed head. The catalyst circulation mixer 12 is a cylindrical cylinder, and an inner cylinder 14 is arranged inside. An outer ring space is formed between the inner cylinder 14 and the outer wall of the catalyst circulation mixer 12, and a gas outer ring distribution pipe is arranged at the bottom of the ring space. 13. The water vapor 32 enters the outer ring space of the catalyst circulation mixer 12 through the gas outer ring distribution pipe 13, and the pre-lift steam 28 at the bottom of the original heavy oil riser reactor 4 enters the ...

Embodiment 3

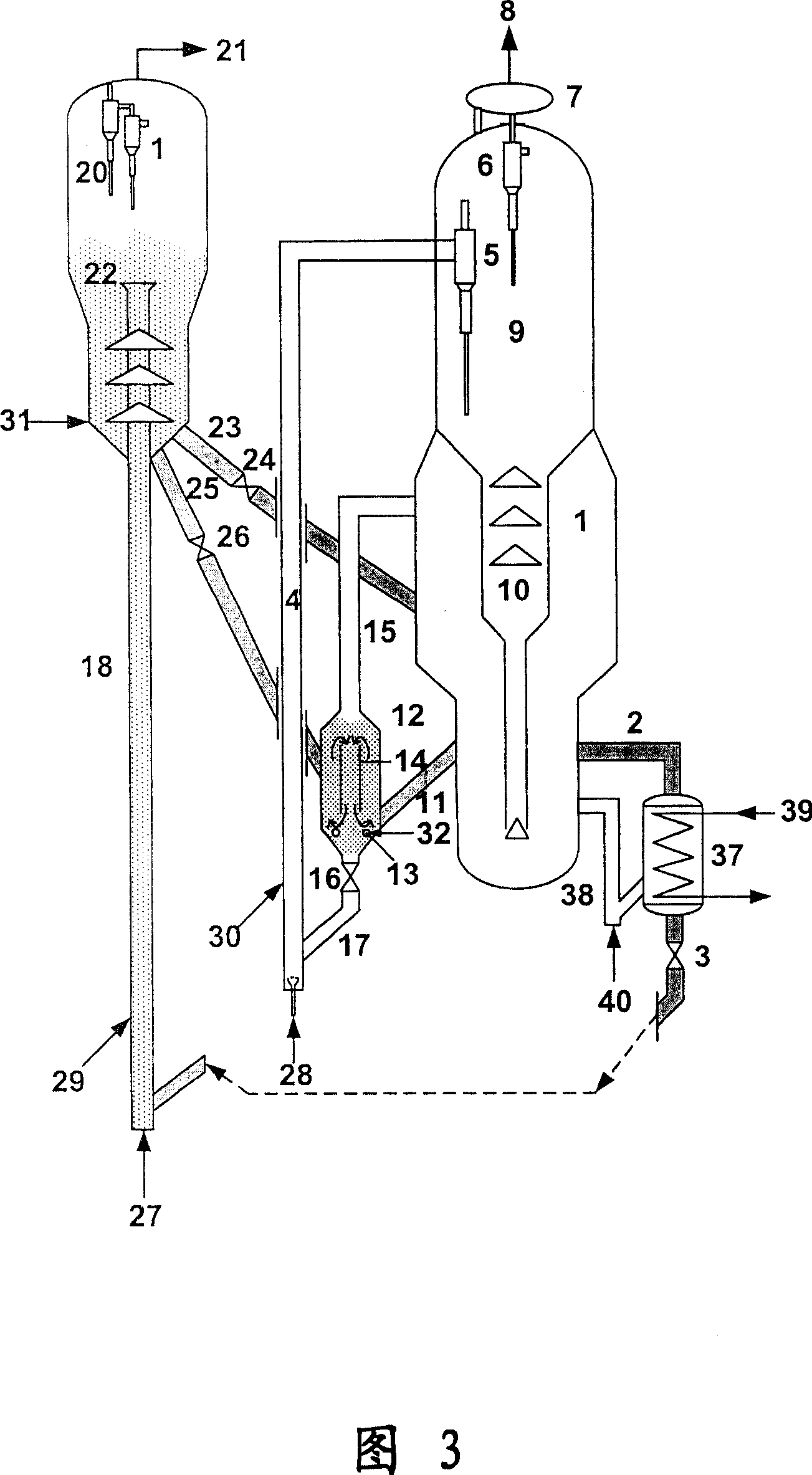

[0075]Referring to the flow process shown in Figure 3, it is briefly described as follows: a catalyst circulation mixer 12 is set up next to the industrial catalytic cracking unit heavy oil riser reactor 4 with catalytic gasoline upgrading auxiliary fluidization reactor, and the catalyst circulation mixer 12 The top of the catalyst loop mixer 12 is connected with the fourth regenerated catalyst delivery pipe 15, and the bottom of the catalyst circulation mixer 12 is connected with the mixed catalyst delivery pipe 16. The catalyst circulation mixer 12 is a cylindrical cylinder, and an inner cylinder 14 is arranged inside. An outer ring space is formed between the inner cylinder 14 and the outer wall of the catalyst circulation mixer 12, and a gas outer ring distribution pipe is arranged at the bottom of the ring space. 13. Water vapor 32 enters the outer ring space in the catalyst circulation mixer 12 through the gas outer ring distribution pipe 13, so that the gas velocity in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com