Patents

Literature

46results about How to "Absorbs odor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon heating clothes and preparation method thereof

ActiveCN101396176AHeating up fastTastelessOhmic-resistance heatingGarment beltsSmart polymerEngineering

The invention relates to a garment and a preparation method thereof, in particular to a carbon heating garment taking carbon conductive yarns as a heating element and a preparation method thereof. The outside of the rear piece of the carbon heating garment is provided with a pocket which is positioned near the lumbar vertebrae of a human body; and the pocket is provided with a carbon heating sheet sewn and packed by nano bamboo charcoal knitted fabric, connecting wires and intelligent polymer lithium battery pack; the carbon heating sheet is connected with the anode and the cathode of the lithium battery pack by the connecting wires; and the carbon heating sheet is compounded by pressing and rolling carbon conductive fabric with an environment friendly polyurethane thin film or vinyl acetate thin film. The garment has the advantages of fast heating and temperature rise, no odor, no pollution and good effect, and the garment is an ideal warm garment with heat supply function.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

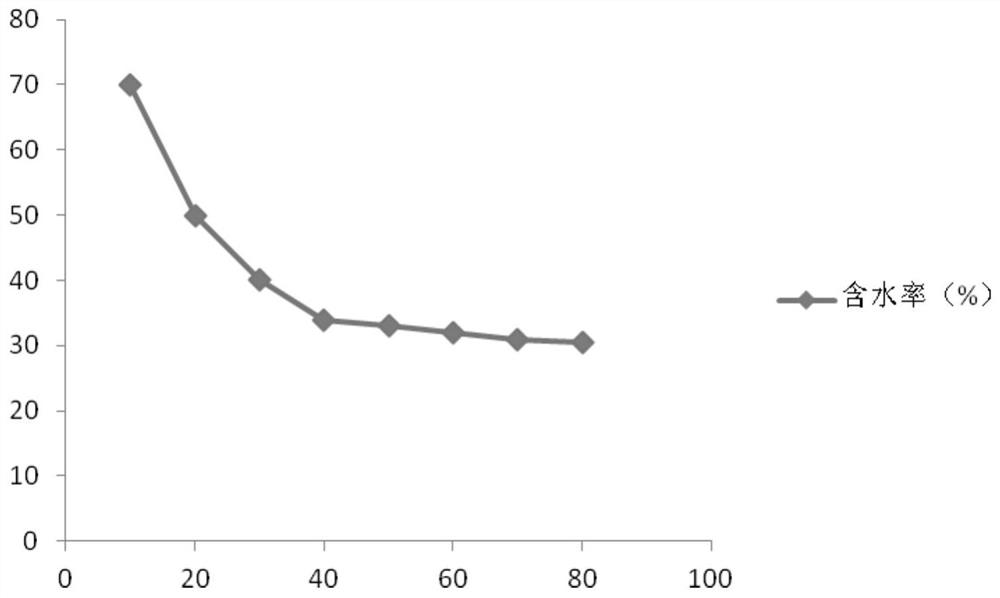

Biological desiccant and preparing method of biological desiccant

InactiveCN105032135ALow cost situationIncrease diversityOther chemical processesDispersed particle separationAdditive ingredientSorbent

The invention relates to a biological desiccant, which is characterized by comprising the following ingredients including a water retention agent, a water absorbent, an anti-sticking agent and an adsorbent, wherein the water retention agent is konjak flying powder or konjak full powder; the water absorbent is one or a mixture of several materials from anhydrous calcium chloride, magnesium chloride and L-carnitine-L-tartrate; the anti-sticking agent is one or a mixture of several materials from silicon dioxide, white carbon black and talcum powder; the adsorbent is bamboo charcoal or active carbon. The biological desiccant and a preparing method of the biological desiccant have the advantages that the effects of safety, no toxicity and no pollution are achieved; the water absorbing capacity is high; the biological desiccant is suitable for being applied to environments with any humidity; in the environment with T being 25 DEG C and RH being 90 percent, the moisture absorption rate can reach 70 to 200 percent; the prepared desiccant finished product also has the function of odor adsorption; the preparing process is simple; the one-step forming rate of the product is high; the problem of low profits since the konjak flying powder is only used as feed for a long time is solved; the application value of konjak by-products and the diversity of drying agent products are improved.

Owner:WUHAN POLYTECHNIC UNIVERSITY +1

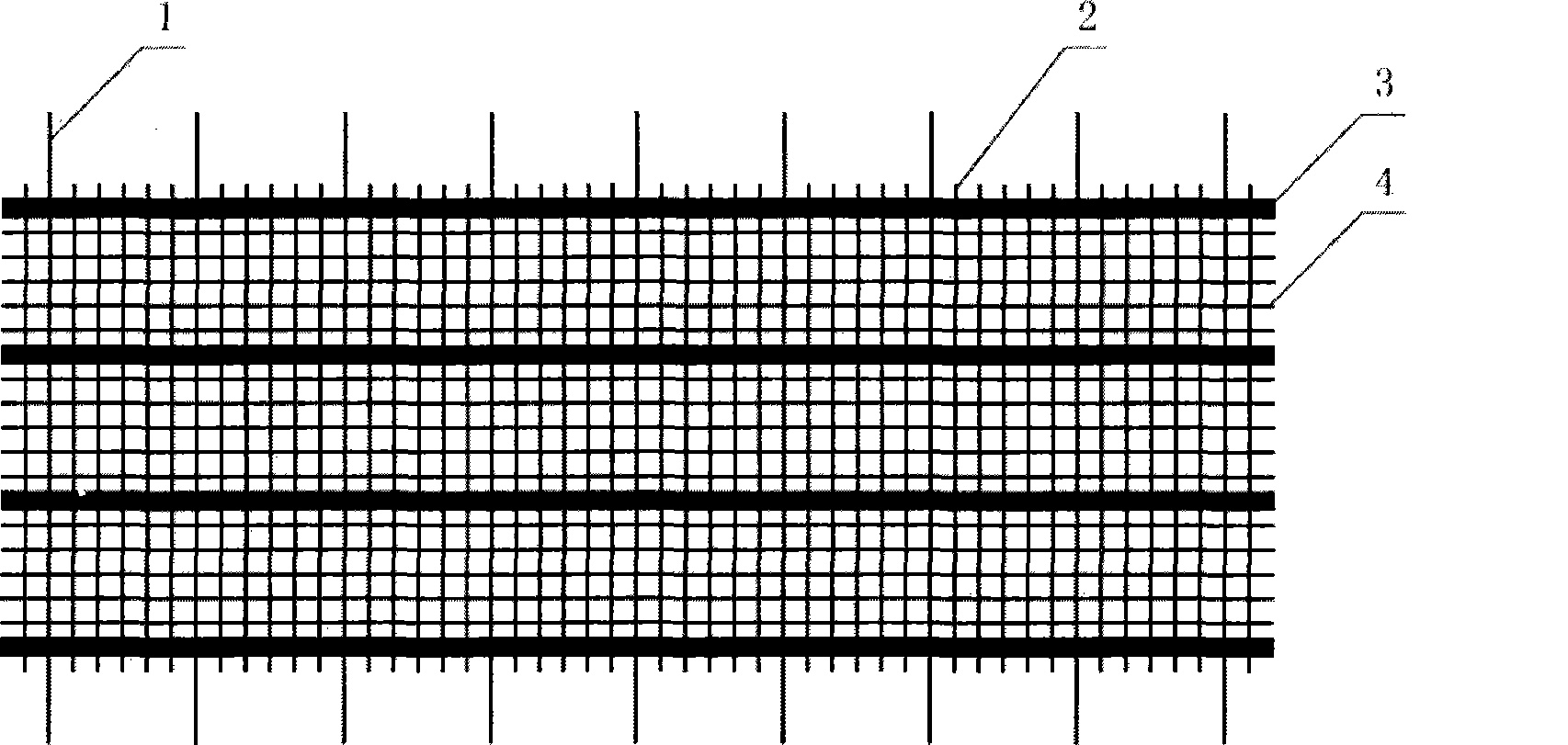

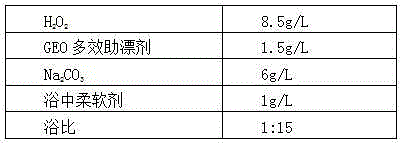

Preparation method of knitted wool-like warm fabric

InactiveCN105332155AGood dissipationHigh pectinWeft knittingBiochemical fibre treatmentYarnPolymer science

The invention relates to a preparation method of a knitted wool-like warm fabric. The preparation method comprises the following steps: (1) raw material selection; (2) spinning technology implementation; (3) weaving technology implementation; (4) printing, dyeing and after-finishing. The knitted wool-like warm fabric is formed by performing the after-finishing, such as knitting, dyeing, carbon grinding and softening, on hemp / cotton / polypropylene fiber blended yarns and polyolefin elastic fibers, namely confirmable elastic fibers, which serve as raw materials. By the adoption of hemp, a product can realize antibacterial, health care and anti-ultraviolet functions; cotton fibers are high in hygroscopicity and spinnability; the polypropylene fibers are poor in heat conductance and high in heat insulation property; by the blending of the three types of fibers, a product has the functions of heat insulation, moisture absorption, breathing, bacteria prevention and ultraviolet resistance; by the weaving of the polyolefin elastic fibers, the product is extremely high in elasticity and conformality. The product is soft, fine, breathable, relaxing, high in heat retention property and suitable for making high-end warm coats or skirts, is a high-quality antibacterial, health care and warm fabric which has a wide market development prospect.

Owner:JIANGSU YDTEX GRP LTD

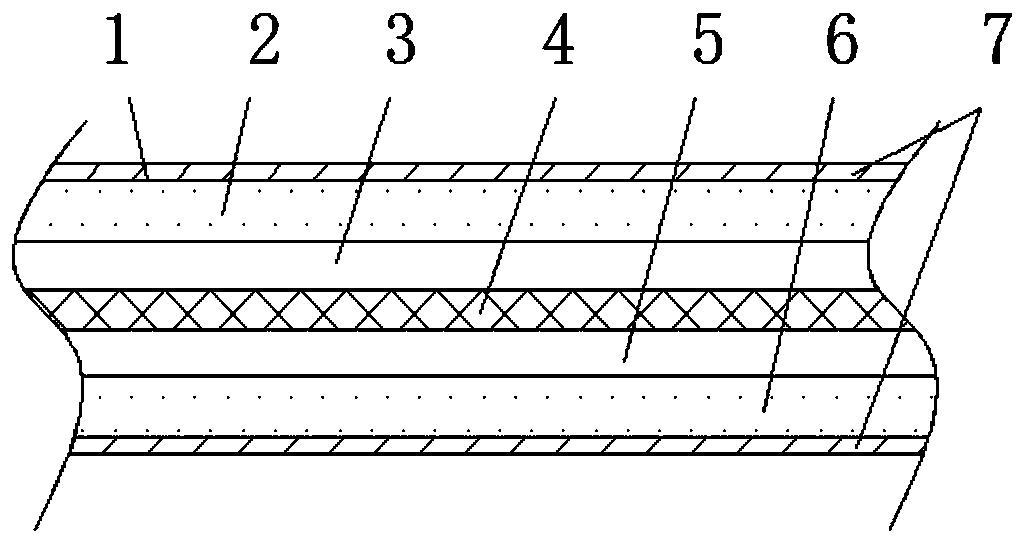

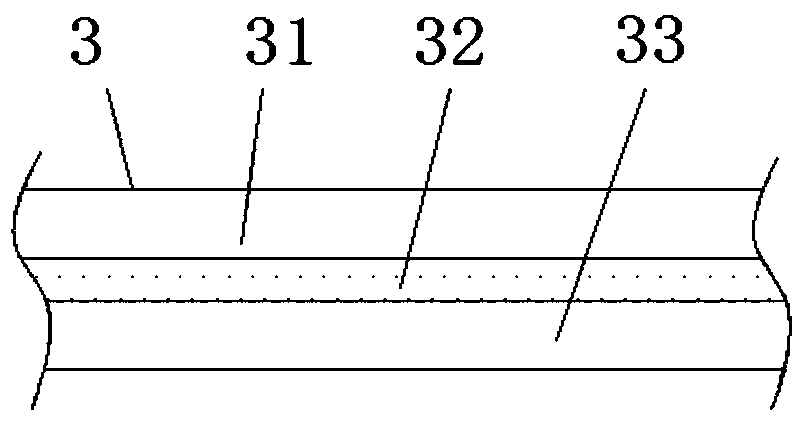

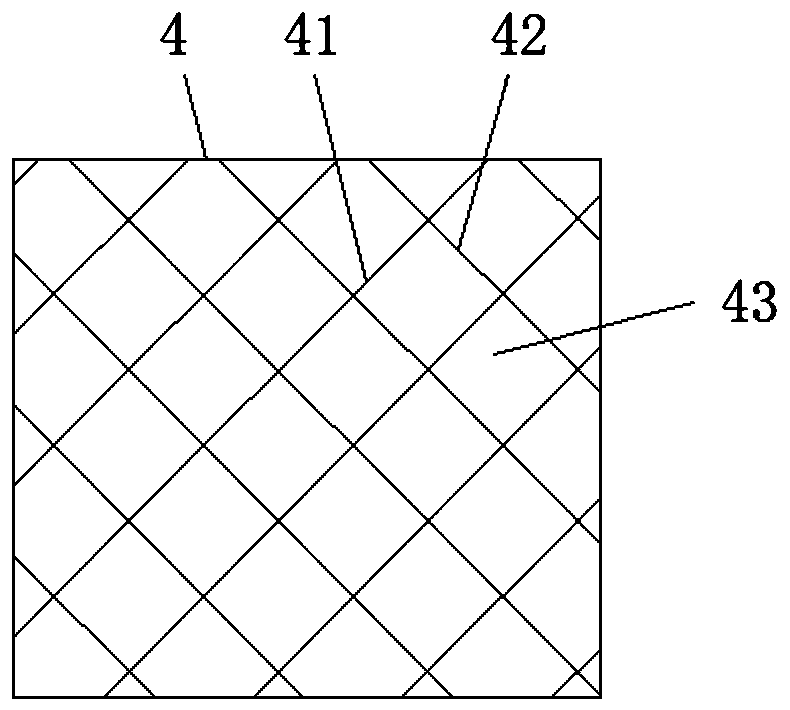

Mutli-layer protective type diaper and method for making diaper

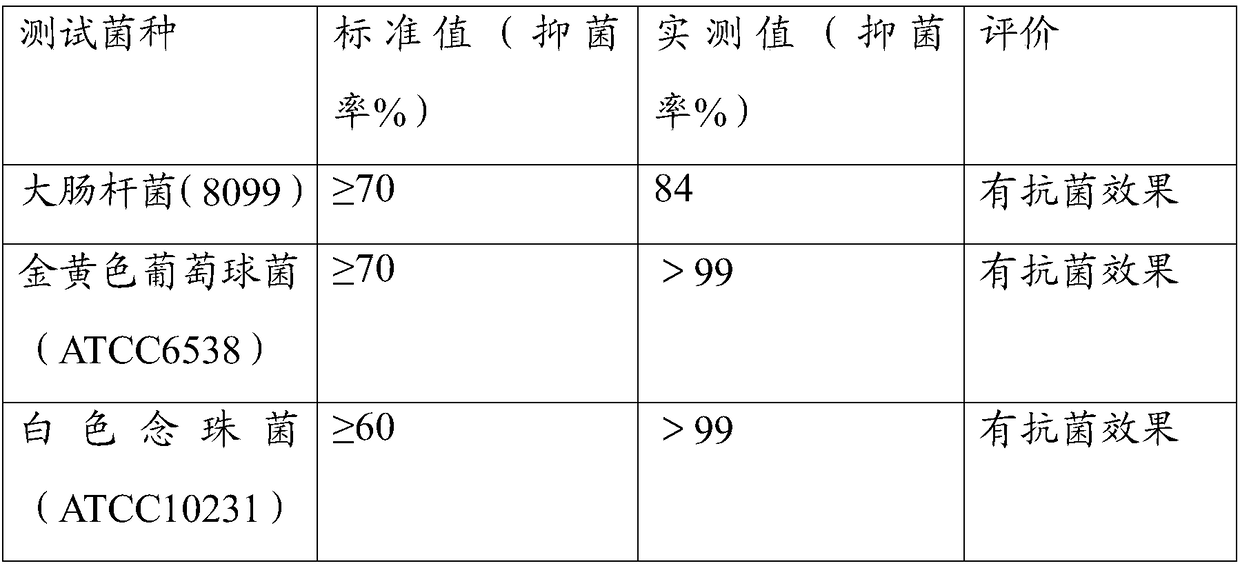

ActiveCN108143542APreserves antimicrobial propertiesAvoid brittlenessAbsorbent padsBandagesSurface layerDeodorant

The invention discloses a multi-layer protective type diaper. The diaper comprises an antibacterial and deodorant fabric layer, a sweat-absorbent and moisture transfer fabric layer, a water-absorptiontype non-woven fabric layer and a surface layer from inside to ouTSide in sequence. The invention further discloses a method for making the multi-layer protective type diaper. The diaper has the advantages of being good in antibacterial effect, high in deodorant capacity and capable of absorbing moisture and releasing sweat.

Owner:DADDY BABY

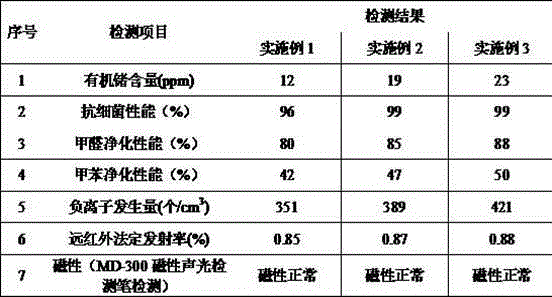

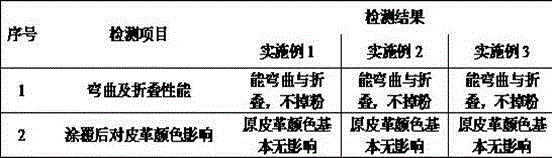

Coating material having health functions and specially used for leather

InactiveCN105038550ADoes not change appearanceBacteriostaticAntifouling/underwater paintsPaints with biocidesFar infraredIon

The invention provides a coating material having health functions and specially used for leather. The coating layer is composed of a leather front side coating material and a leather back side coating material, and the front side and the back side of leather are respectively coated with the leather front side coating material and the leather back side coating material in a roll coating, knife coating or spraying mode. Test verifies that the leather is coated with the coating material to have a health element germanium and also have functions of bacteriostasis, peculiar smell adsorption, negative ion generation caused by induction and release, far infrared ray emission and magnetism.

Owner:深圳市宜丽环保科技有限公司

Carbon heating headscarf and preparation method thereof

The invention relates to a carbon heating scarf and a preparation method thereof. The carbon heating scarf is characterized by comprising a base cloth, a carbon heating sheet, agraffes, connecting wires and intelligent polymer lithium battery pack; the carbon heating sheet is compounded by pressing and rolling carbon conductive fabric with a environment friendly polyurethane thin film or vinyl acetate thin film, and sewn and packed by nano bamboo charcoal knitted fabric; the carbon heating sheet is connected with the intelligent polymer lithium battery pack and a thin film regulating switch in series by the connecting wires to form a circuit; the agraffes are respectively sewn in the middle part of the base cloth of the scarf and on one side of the nano bamboo charcoal fabric of the carbon heating sheet so as to bond each other. The scarf has the advantages of fast heating and temperature rise, no odor, no pollution and good heat preservation effect, and the scarf is an ideal warm scarf with heat supply function.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

Graphene island fiber and manufacturing method thereof

ActiveCN109706546AStimulate vitalityTo promote metabolismElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsCvd grapheneSurface resistivity

The invention relates to a graphene island fiber and a manufacturing method thereof. The manufacturing method comprises the following steps of preparing graphene master batch from a functional graphene material through esterification polymerization, and then blending and melting the graphene master batch and PET to obtain a graphene island composition; melting and blending the graphene island composition and a soluble polyester marine composition to obtain graphene island protofilaments, and conducting working processes of bundling, drafting, tension heat setting, curling, oiling, relaxation heat setting, cutting and the like to obtain the graphene island fiber. The graphene island fiber can reduce the surface resistivity of a material, quickly release generated electrostatic charge, endowthe surface of the material with certain lubricity at the same time and further reduce the friction coefficient so as to inhibit and reduce the generation of electrostatic charge. The biocompatibility is high, and the graphene island fiber is a non-toxic, environment-friendly and efficient functional textile and has the far infrared function, antibacterial function, bacteriostatic function and antistatic function of graphene fibers.

Owner:SHANGHAI DEFULUN CHEM FIBER

Environmental protection building material and preparation method thereof

InactiveCN107098651ATo achieve the purpose of energy saving and environmental protectionImprove insulation effectChipsealCompressive strength

The invention provides an environmental protection building material and a preparation method thereof, which belong to the field of a building material. The environmental protection building material comprises the following raw materials: 10-30 parts of granite powder, 17-25 parts of alumina silicate powder, 7-13 parts of glass wool, 4-9 parts of polypropylene fiber, 21-35 parts of fine sand, 22-38 parts of broken stone, 15-21 parts of cement, 15-27 parts of waste rock wool plate, 13-21 parts of waste glass, 15-33 parts of meerschaum, 21-27 parts of bamboo charcoal, 0.3-0.7 parts of an air-entrainer, 0.4-0.6 parts of a hardener, 0.3-0.9 parts of a water reducer, and 3-11 parts of water. The preparation method comprises the following steps: 1) weighing the raw materials; 2) crushing the raw materials; 3) stirring the raw materials; and 4) performing compacting moulding, drying the material, and cooling and preserving the product. The method solves the problem that the current environmental protection building materials used for the buildings having high compressive strength, heat insulation, and environmental protection and energy saving requirements are insufficient.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

Yoga mattress formula

InactiveCN106479160AImprove adsorption capacityDoes not affect the mood of exerciseElastomerPolyvinyl alcohol

The present invention relates to a yoga mattress formula, wherein the components comprise, by weight, 25-30 parts of an elastomer, 30-45 parts of nylon, 25-60 parts of a polyvinyl alcohol resin, 5-15 parts of an elastomer processing oil, 0.2-1.0 part of an antioxidant, 5-10 parts of a softening agent, and 1-1.8 parts of active carbon. According to the present invention, the active carbon is added based on the original yoga mattress formula, such that the yoga mattress has the effects of odor adsorption and odor removing, and people can move for a long time.

Owner:JIANGSU YAOZHANG SPORTING GOODS

Air filtering material

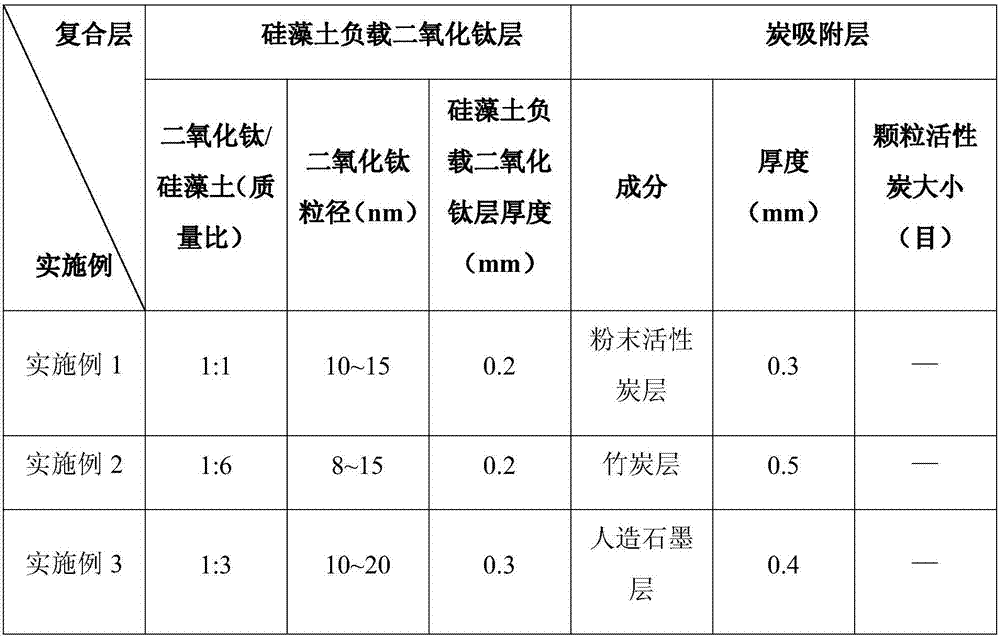

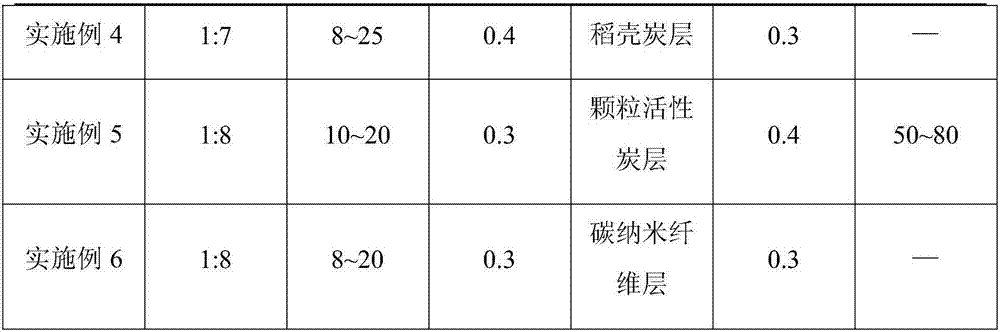

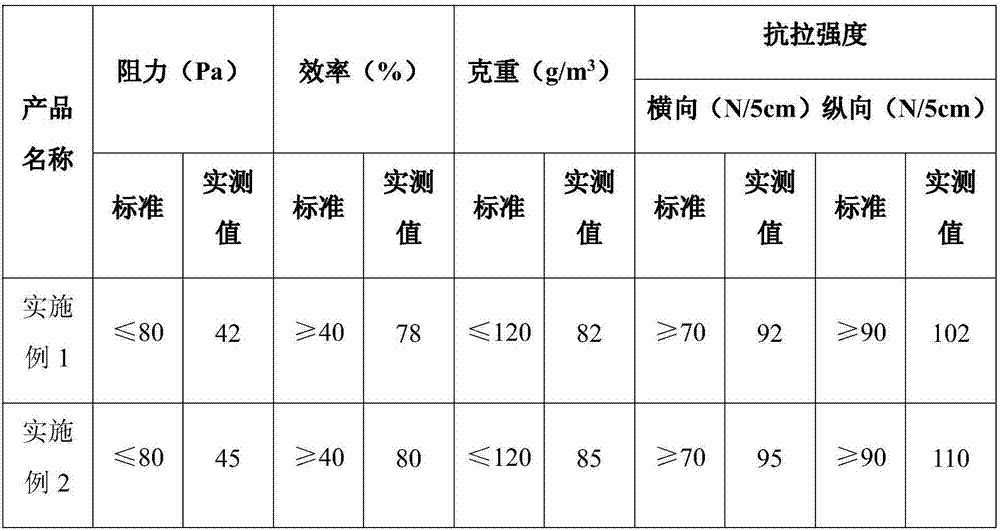

InactiveCN107198906AEffective combinationImprove adsorption capacityBiocideDispersed particle filtrationFiberAir filtration

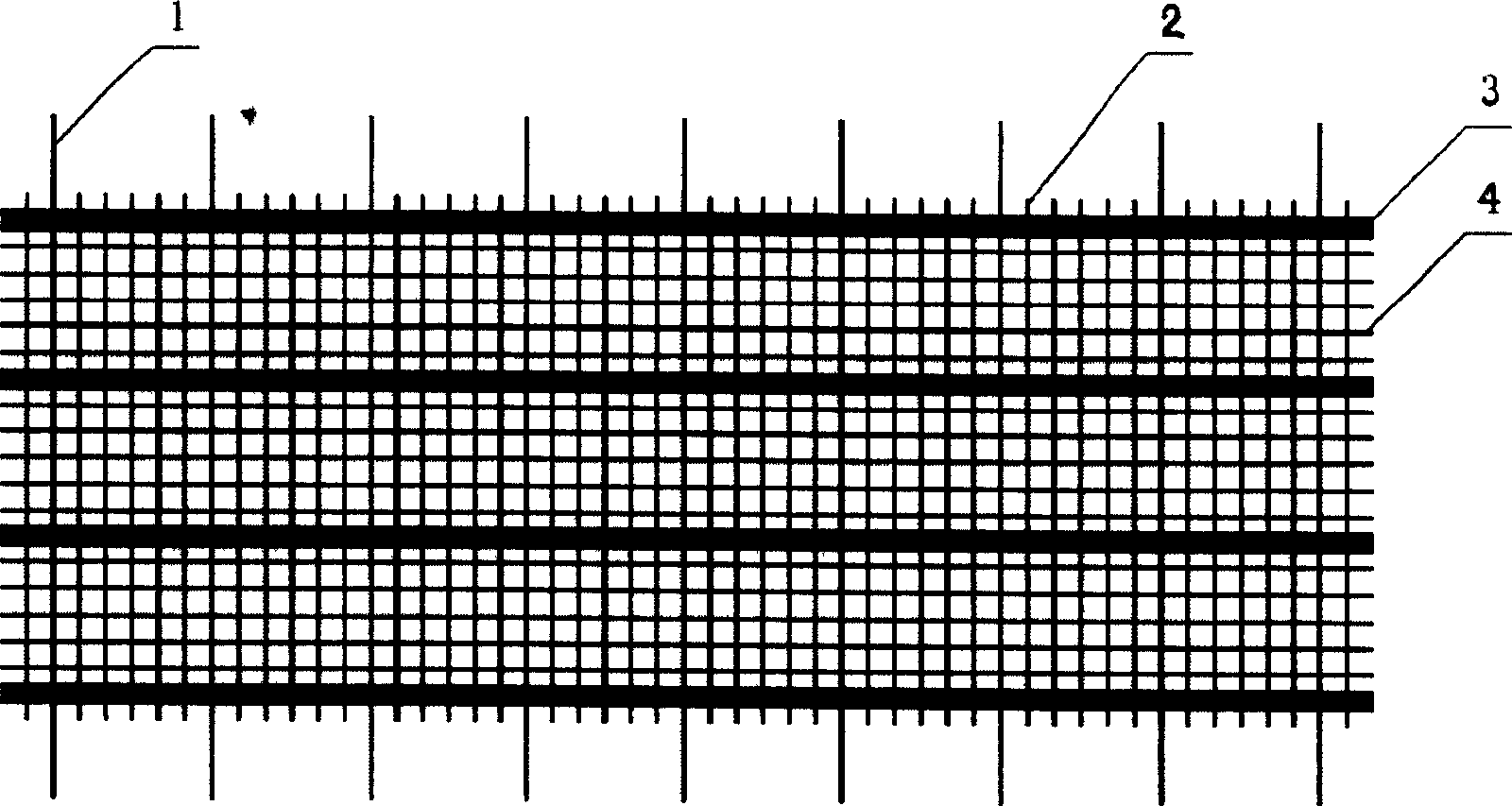

The invention provides an air filtering material, which comprises a base material and a compound layer, wherein the base material consists of an upper layer of carbon fiber reticular filtering cloth and a lower layer of carbon fiber reticular filtering cloth; the compound layer is positioned between the upper layer of carbon fiber reticular filtering cloth and the lower layer of carbon fiber reticular filtering cloth and comprises a kieselguhr loaded titanium dioxide layer and a carbon material adsorption layer from top to bottom in sequence. In the air filtering material, the kieselguhr loaded titanium dioxide layer and the carbon material adsorption layer are taken as main adsorption layers so as to effectively combine physical adsorption with chemical adsorption. While small particles are filtered, volatile organic compounds can be degraded into poisonless and harmless CO2 and H2O as well as corresponding inorganic ions, and therefore, the air filtering material has the advantages of no secondary pollution, high adsorption function, obvious filtering effect and wide popularization function.

Owner:长沙善道新材料科技有限公司

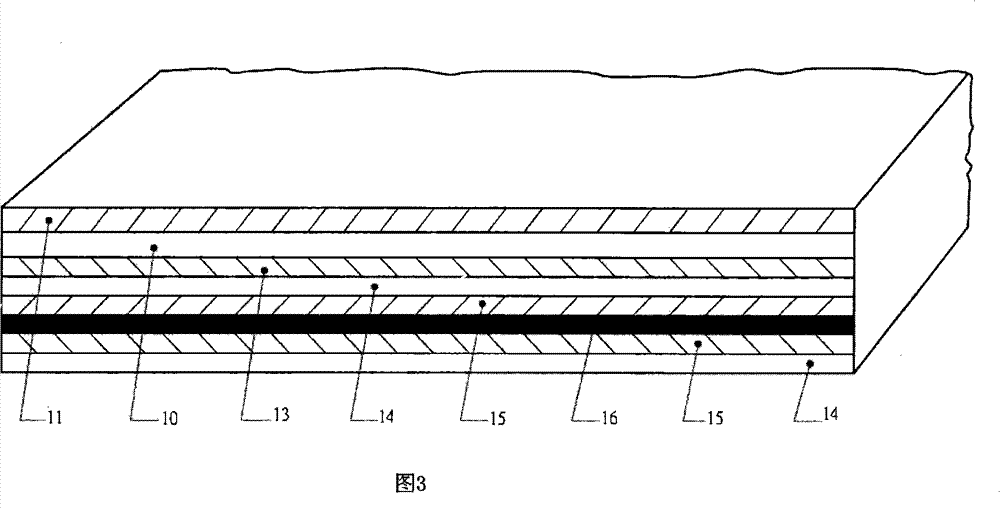

Novel wood-plastic composite board and preparation method thereof

InactiveCN108129776AImprove performanceAdsorption hasSynthetic resin layered productsActivated carbonWear resistant

The invention discloses a novel wood-plastic composite board, which is sequentially provided with a decoration layer, an activated carbon adsorption layer, a mute layer, a wear-resistant layer, a wood-plastic base plate and a waterproof layer from top to bottom. The thickness of the decoration layer is 0.2 to 0.4cm, the thickness of the activated carbon adsorption layer is 0.1 to 0.3cm, the thickness of the mute layer is 0.3 to 0.6cm, the thickness of the wear-resistant layer is 0.5 to 1cm, the thickness of the wood-plastic base plate is 2.5 to 3.2cm, and the thickness of the waterproof layeris 0.2 to 0.3cm. The novel wood-plastic composite board is excellent in performance; through arranging the decoration layer, the activated carbon adsorption layer, the mute layer and the waterproof layer, functions of the board is enriched, the appearance of the board is attractive, and the board has the functions of abnormal taste adsorption, sterilization, waterproofness, silence and the like; through arranging the wear-resistant layer and the wood-plastic base plate, the performance of the board is optimized.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

Silk composite fibers applicable to allergic constitution and manufacturing method thereof

InactiveCN104233506AAbsorbs odorMoisture-proofConjugated cellulose/protein artificial filamentsArtifical filament manufactureDiethyl phosphateFiber

The invention discloses silk composite fibers applicable to allergic constitution. The silk composite fibers are characterized by comprising the following materials in parts by weight: 15-20 parts of mulberry silk, 12-14 parts of down feather, 9-11 parts of camel wool, 5-8 parts of aloe fiber, 7-9 parts of banana stem fiber, 6-8 parts of Lycra fibers, 5.6-7.8 parts of coconut-carbon fibers, 1.2-3.1 parts of fatty acid methyl ester ethoxylate, 0.6-1.2 parts of cinnamomum camphora essential oil, 0.8-1.4 parts of calcium alginate, 100-110 parts of 1-butyl-3-methylimidazole dibutyl phosphate, 110-120 parts of 1-ethyl-3-methylimidazole diethyl phosphate, 2-4 parts of liquorice, 1-3 parts of bitter almond kernel, 0.5-0.8 part of sophora alopecuroides, 2-3 parts of folium artemisiae argyi, 3-5 parts of additives and a proper amount of water. Due to addition of the coconut-carbon fibers, the silk composite fibers contain coconut-carbon particles and achieve health effects of activating cells, purifying blood, eliminating fatigue, changing allergic constitution and the like to a human body, and simultaneously, due to addition of other plant fibers, Chinese herbal medicines and other animal protein fibers, the prepared silk composite fibers have health functions of adsorbing odor, resisting moisture, removing odor, resisting ultraviolet rays and the like.

Owner:TONGCHENG SHUANGLONG SILK

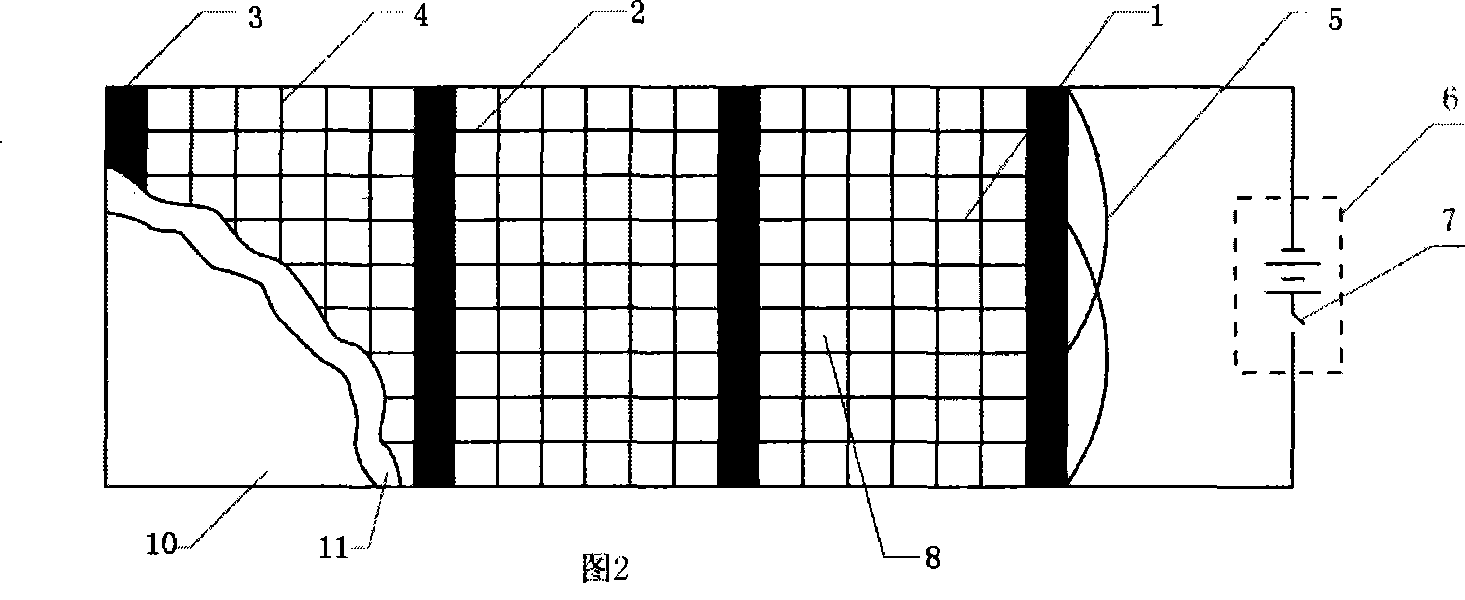

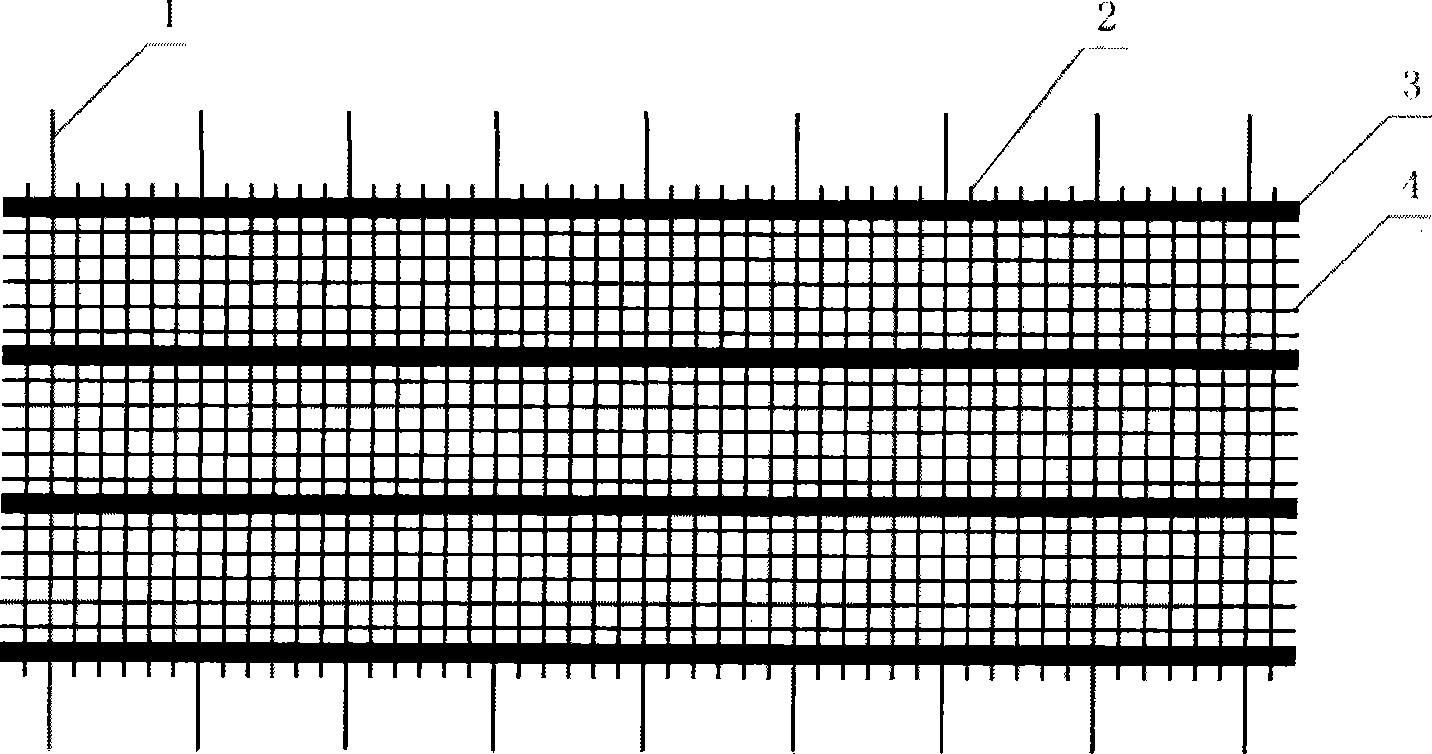

Multi-purpose carbon heating soft cushion and preparation thereof

ActiveCN101400193AWide range of usesHeating up fastStuffed mattressesFibre treatmentSmart polymerCarvacryl acetate

The invention relates to a multi-purpose carbon cushion and method for producing the same. The cushion is divided into an inner mat and an outer packaging, wherein, the inner mat includes carbon heating pieces, connecting wires, and intelligent polymer lithium batteries. The carbon heating pieces are formed by pressing an environmental-protecting type polyurethane or vinyl acetate film on the carbon conductive fabrics, and a nano-bamboo carbon knitting fabric is adopted to tailor and package; radial direction conductive filaments in the carbon heating piece adopt a paralleled connection mode,and then are connected to the anode and cathode of the polymer lithium batteries; and the outer layer packages of the carbon heating cushion is made of textiles into a bag shape. The present invention is an ideal heat supply and thermal protection cushion, which has advantages of fast heating up, tasteless, pollution-free, and widely application to legs, shoulders, stomach, waist, abdomen, etc.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

Nano bamboo brush wires and preparation method thereof

InactiveCN102392315AImprove wear resistanceAntibacterial and antibacterialFibre typesBristlePolyamideNanometre

The invention relates to nano bamboo brush wires and a preparation method thereof. The nano bamboo brush wires comprise polyamide wire cores and nano bamboo powder layers coated on the surfaces of the wire cores. By adopting the nano bamboo brush wires and the preparation method, the technical problems that the existing toothbrushes have high manufacturing cost, waste resources, can not be recycled and harm human bodies are solved. The nano bamboo brush wires have the functions of inhibiting and resisting bacteria and adsorbing peculiar smell and have biodegradability and environment compatibility.

Owner:奉化市竹匠日用品制造有限公司

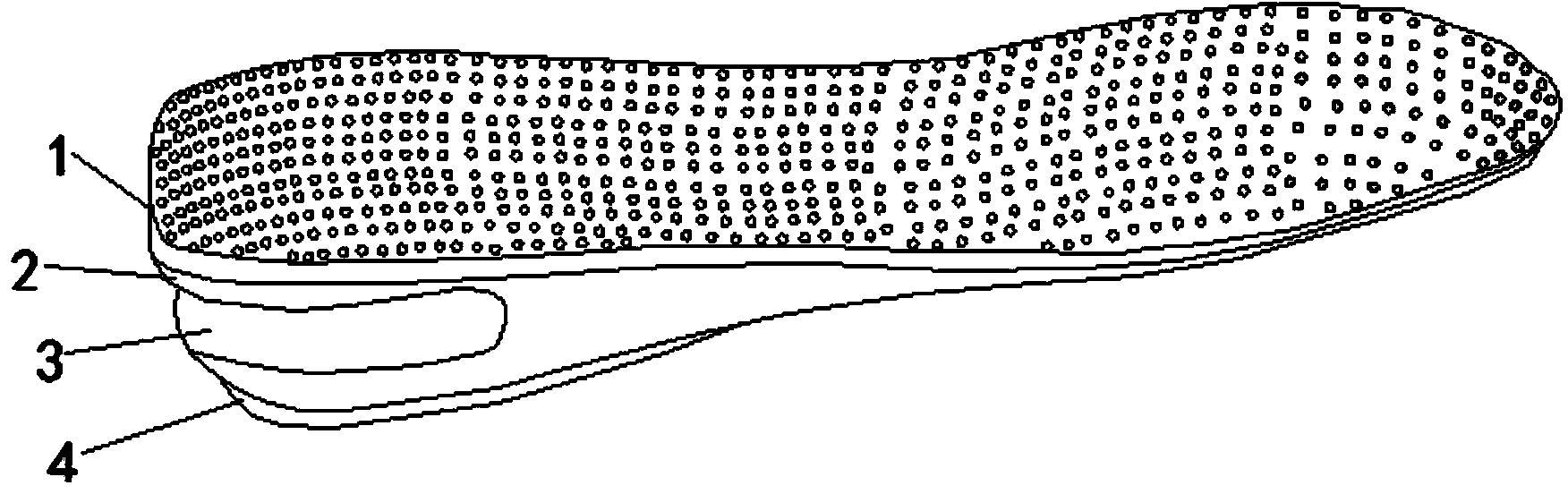

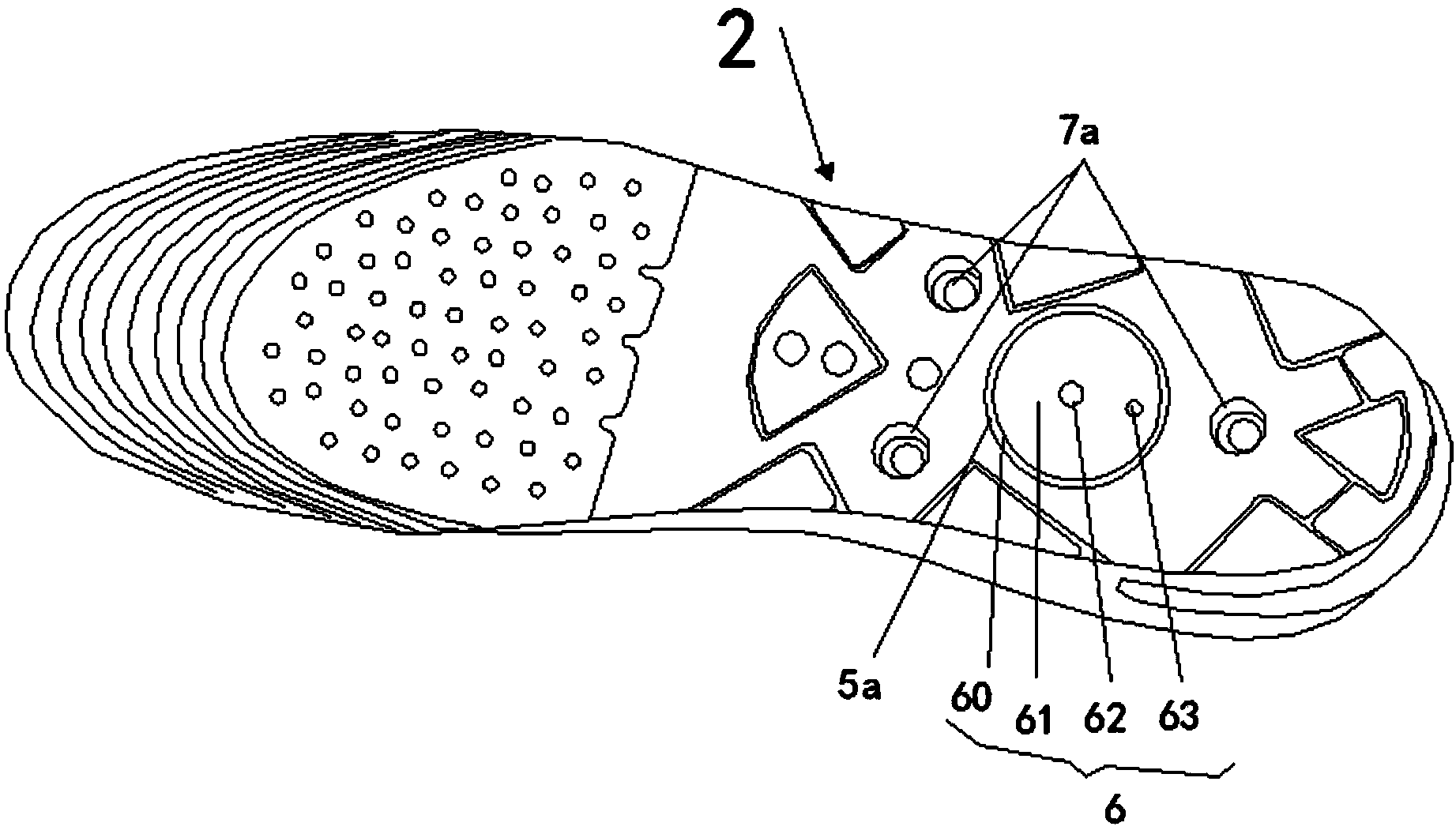

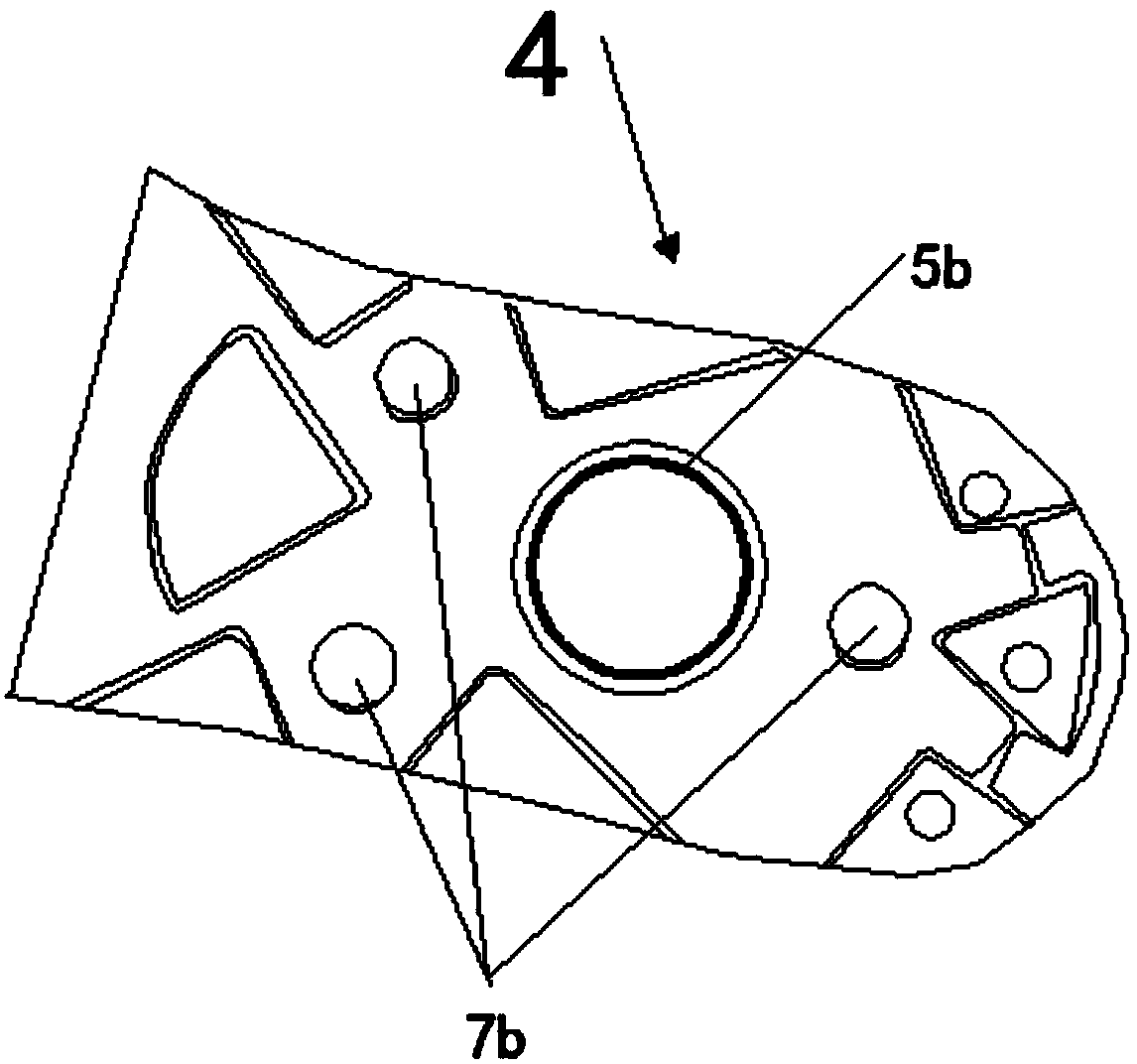

Intelligent sports insole

The invention discloses an intelligent sports insole. The intelligent sports insole comprises a surface layer, a buffer layer, a buffer air cushion, a reinforcing bottom and a recorder. The surface layer is pasted on the upper side face of the buffer layer, the buffer layer is made of silicone materials, the reinforcing bottom is detachably installed on the lower side face of the buffer layer, a buffer air cushion installation groove is formed in the heel of the buffer layer, the buffer air cushion is installed in the buffer air cushion installation groove, the buffer air cushion is of a hollow air bag structure, a recorder installation groove is formed in the bottom side face of the heel of the buffer air cushion, the recorder is installed in the recorder installation groove, and a recorder clamping groove is formed in the upper side face of the reinforcing bottom and is clamped in the recorder installation groove to fix the recorder. The intelligent sports insole is good in buffer effect, can solve the problems that peculiar smell can be generated by insoles and feet are prone to sweating and can play a role of treating diseases on the feet; the recorder can record and analyze sports data of a user and help the user to do sports better.

Owner:EAST CHINA NORMAL UNIV

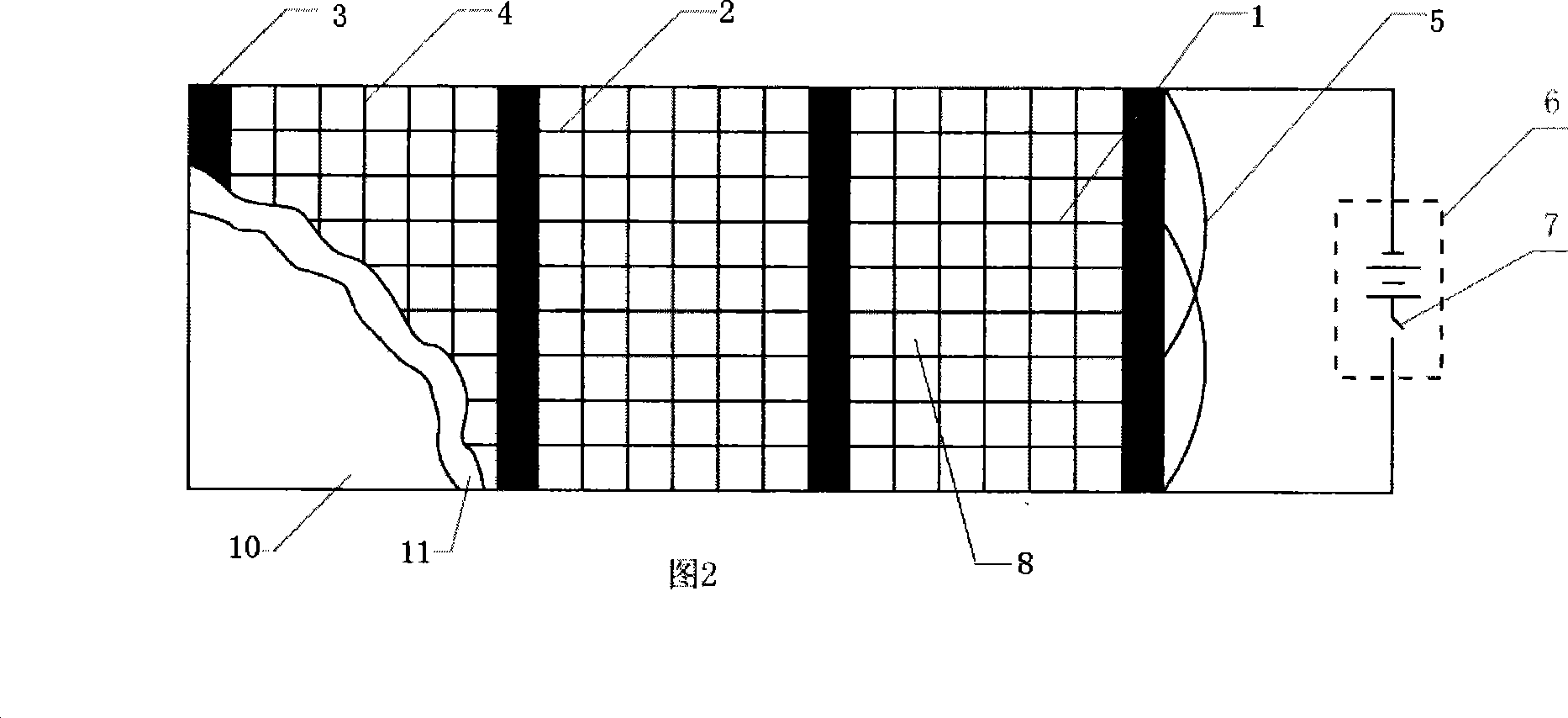

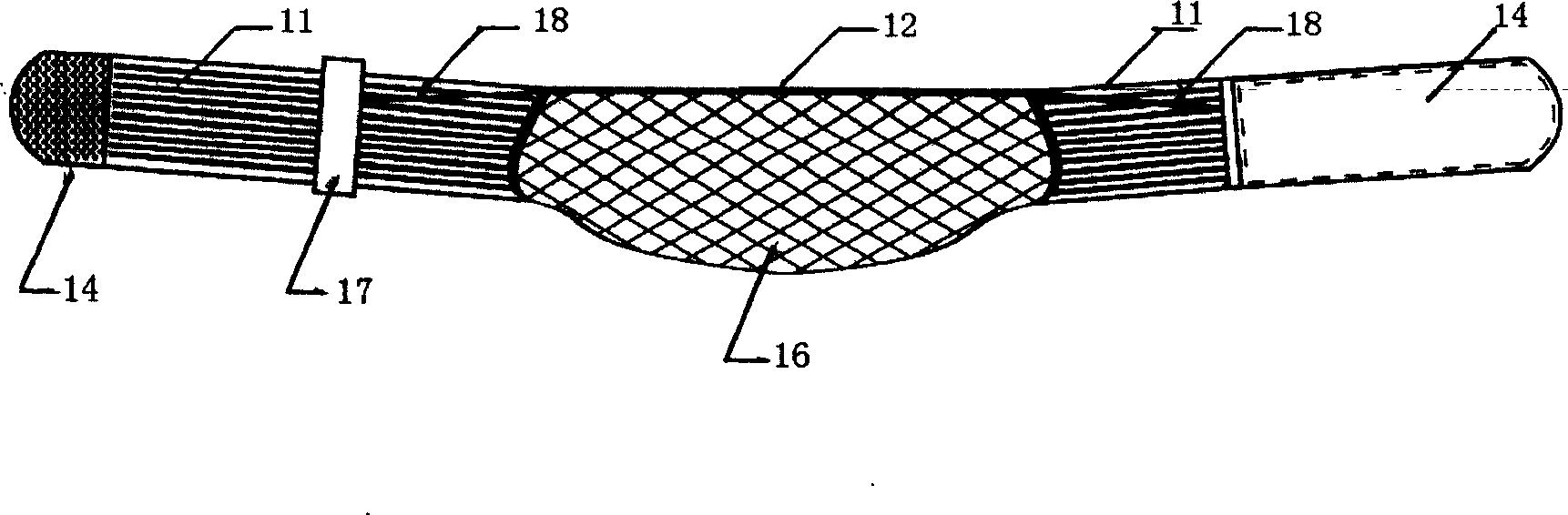

Carbon heating waistband and preparation method thereof

InactiveCN101396310AHeating up fastTastelessOhmic-resistance heatingTherapeutic coolingSmart polymerEngineering

The invention relates to a carbon heating waistband and a preparation method thereof. The waistband comprises a lumbar support, a patch pocket, an elastic band, a fibula, a battery bag, a carbon heating piece, a connecting lead, and an intelligent polymer lithium battery; a warp direction static wire in the carbon heating piece adopts the parallel connection mode, and then is connected with the positive set and the negative set of the lithium battery; the elastic band is connected with the two ends of the waistband; the fibula is respectively connected with the two ends of the elastic band; the lumbar support are weaved by three layers of textile fabrics and forms two patch pockets; the internal layer patch pocket is close to the waist of human body, made of knitting fishnet and used for putting the heating element; the outer layer is made of woven fabric and used for putting flexible synthetic glass thin material according to the requirements; the battery bag is arranged at one end of the elastic band and can be adjusted according to the requirements. The waistband has the advantages of quick heating and warming, being odourless and pollution-free, good effect, and is an ideal heat supplying and insulation waistband.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

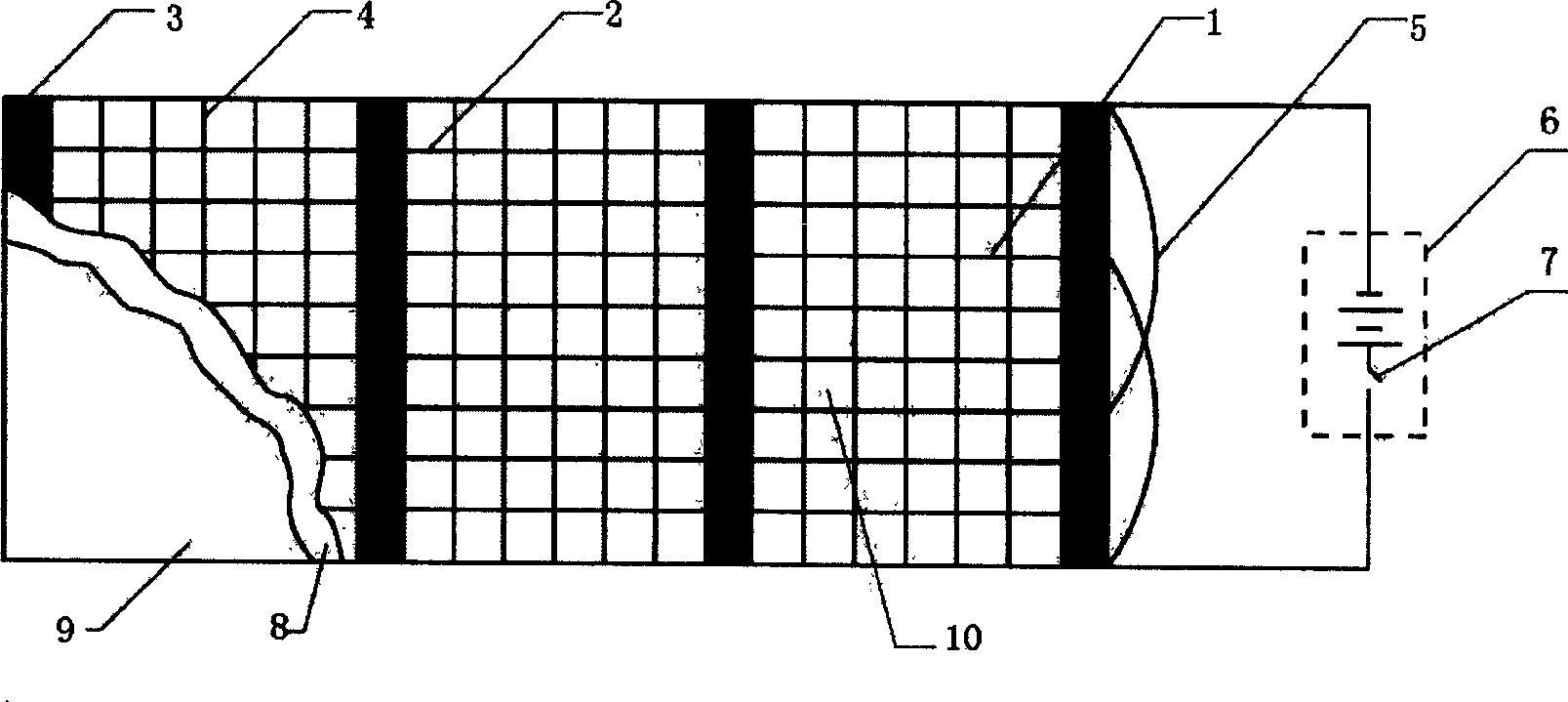

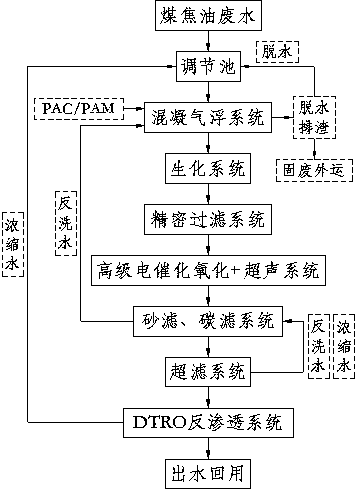

New technology for treating production wastewater generated from effective component extraction of coal tar

InactiveCN110117114AUniform water qualitySmall fluctuationWater treatment parameter controlSpecific water treatment objectivesFlocculationUltrafiltration

The invention relates to a new technology for treating production wastewater generated from effective component extraction of coal tar. The technology comprises the following steps that (1) the coal tar wastewater is pumped into an adjusting pond; (2) the wastewater in the step (1) is conveyed into a coagulation air floatation system for flocculation; (3), dross obtained in the step (2) after theflocculation is dehydrated; (4) the wastewater in the step (2) after the flocculation flows through a biochemical system, a precision filtering system, an advanced electrocatalytic oxidation system and an ultrasound system in sequence and flows into a sand filtration and carbon filtration system; (5) a filtrate treated by the sand filtration and carbon filtration system in the step (4) is conveyedto an ultrafiltration system; (6) concentrated water treated by the ultrafiltration system in the step (5) is returned to the sand filtration and carbon filtration system, and the filtrate directly flows into a DTRO reverse osmosis system; (7) the concentrated water treated by the DTRO reverse osmosis system in the step (6) is returned to the adjusting pond, and clear water can be directly recycled; the technology is low in treatment cost, and the treated wastewater can stably come up to the standard for being discharged or recycled.

Owner:ZHENGZHOU UNIV MULTI-FUNTIONAL DESIGN & RES ACAD CO LTD

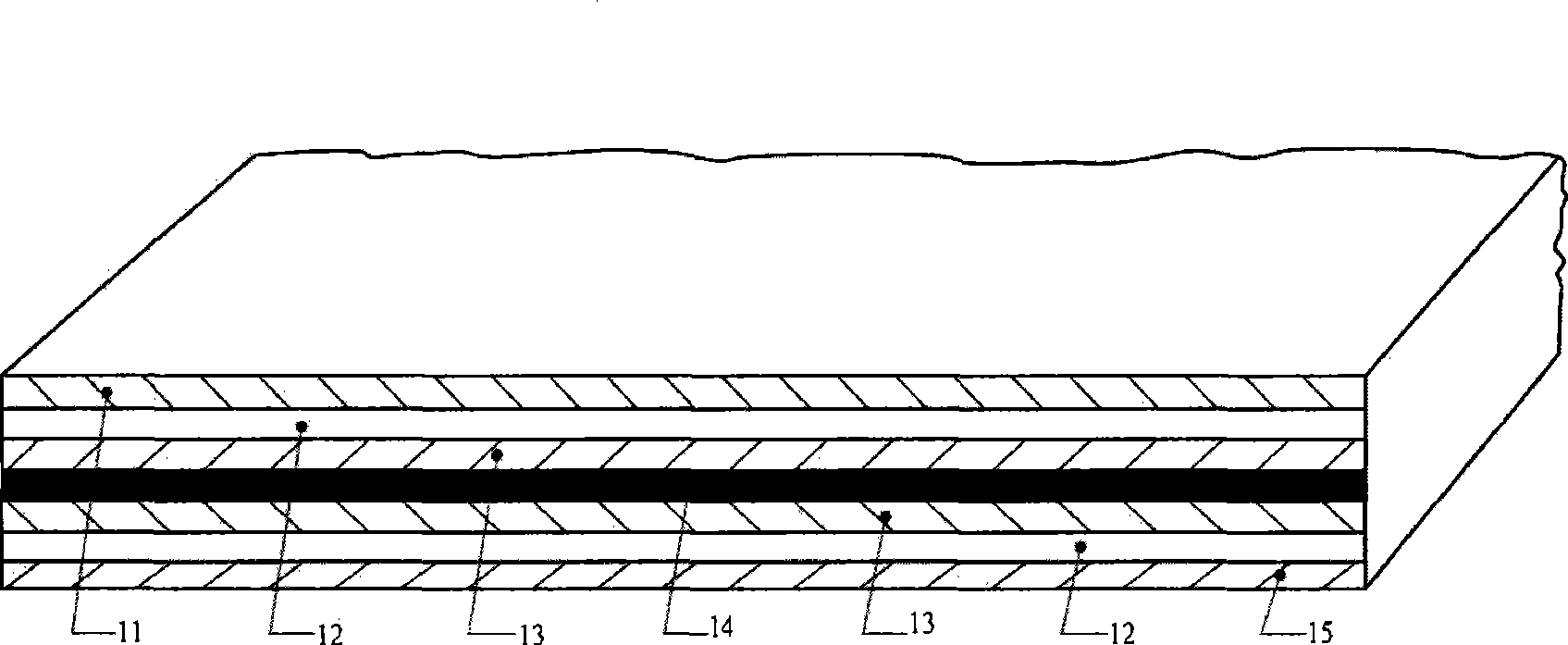

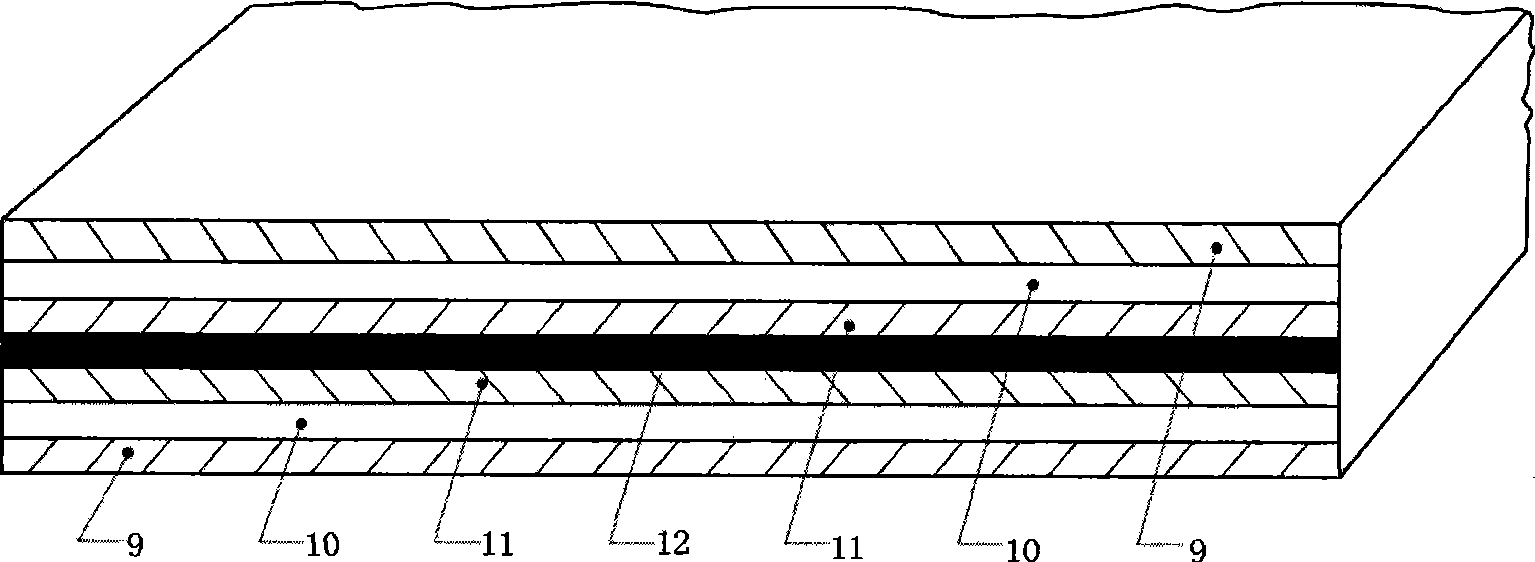

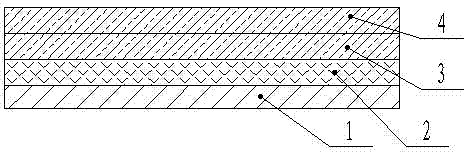

Composite non-woven fabric

InactiveCN104494218AAntibacterialAbsorbs odorSynthetic resin layered productsClothingsActivated carbonThermal energy

The invention discloses a composite non-woven fabric which comprises a first non-woven fabric layer, a support layer, a second non-woven fabric layer and a third non-woven fabric layer, wherein the support layer is adhered between the first non-woven fabric layer and the second non-woven fabric layer; the third non-woven fabric layer is sewn on the second non-woven fabric layer; the first non-woven fabric layer is a polyester fiber spunbond non-woven fabric; the second non-woven fabric layer and the third non-woven fabric layer are both polyester fiber thermal synthesis non-woven fabrics; the support layer is a bamboo fiber gauze; a plurality of activated carbon granules are adhered to the bamboo fiber gauze. By adopting the mode, the composite non-woven fabric is of a multi-layer composite structure, has the function of releasing heat for a long time, also has the functions of bacterium resistance and prevention and odor adsorption, and moreover is non-toxic, irritation-free, safe and environmentally friendly.

Owner:CHANGSHU YIXIN NONWOVEN PROD

Air spray containing negative oxygen ions and preparation method thereof

InactiveCN109945338ARelieve fatigueGood qualityLighting and heating apparatusDeodrantsLithium oxideElectrolysis

The invention relates to air spray, in particular to air spray containing negative oxygen ions and a preparation method thereof. Verdelite, silicon oxide, titanium oxide, lithium oxide, sodium oxide,iron ions, resin and tea extractives are used as main materials, and are matched with thermal spring water for electrolysis to form small-particle hydroxyl negative oxygen ions; and through a spray mode, the hydroxyl negative oxygen ions can be quickly chelated or neutralized with harmful substances in air, so that the harmful substances are precipitated or decomposed to achieve the effects of purifying the air and increasing negative ions in the air. The air spray can increase the content of the negative ions in the air to achieve the breathing smoothness, the odor removal and the pressure reduction; such indoor flying allergens as PM2.5 are precipitated to purify the air; various air pollutants such as formaldehyde are decomposed to achieve refreshing, activation and fatigue relief; thephysical fitness can be effectively improved after long-time living in the air environment with high negative ion concentration; and the raw materials are quantized, so that the energy of generating the negative ions is greatly improved, and the conversion efficiency is improved.

Owner:广东圣蜜生物科技有限公司

Carbon heating headscarf and preparation method thereof

The invention relates to a carbon heating scarf and a preparation method thereof. The carbon heating scarf is characterized by comprising a base cloth, a carbon heating sheet, agraffes, connecting wires and intelligent polymer lithium battery pack; the carbon heating sheet is compounded by pressing and rolling carbon conductive fabric with a environment friendly polyurethane thin film or vinyl acetate thin film, and sewn and packed by nano bamboo charcoal knitted fabric; the carbon heating sheet is connected with the intelligent polymer lithium battery pack and a thin film regulating switch in series by the connecting wires to form a circuit; the agraffes are respectively sewn in the middle part of the base cloth of the scarf and on one side of the nano bamboo charcoal fabric of the carbon heating sheet so as to bond each other. The scarf has the advantages of fast heating and temperature rise, no odor, no pollution and good heat preservation effect, and the scarf is an ideal warm scarf with heat supply function.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

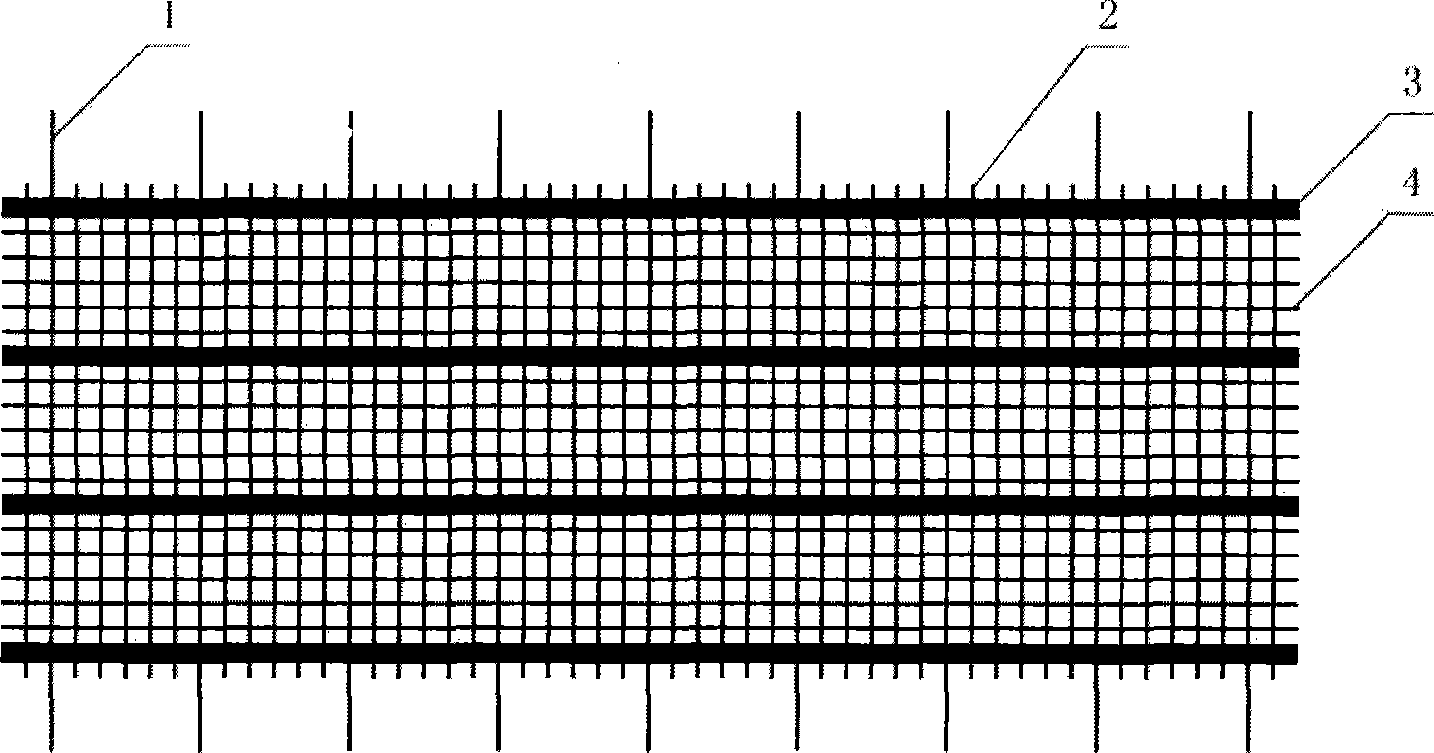

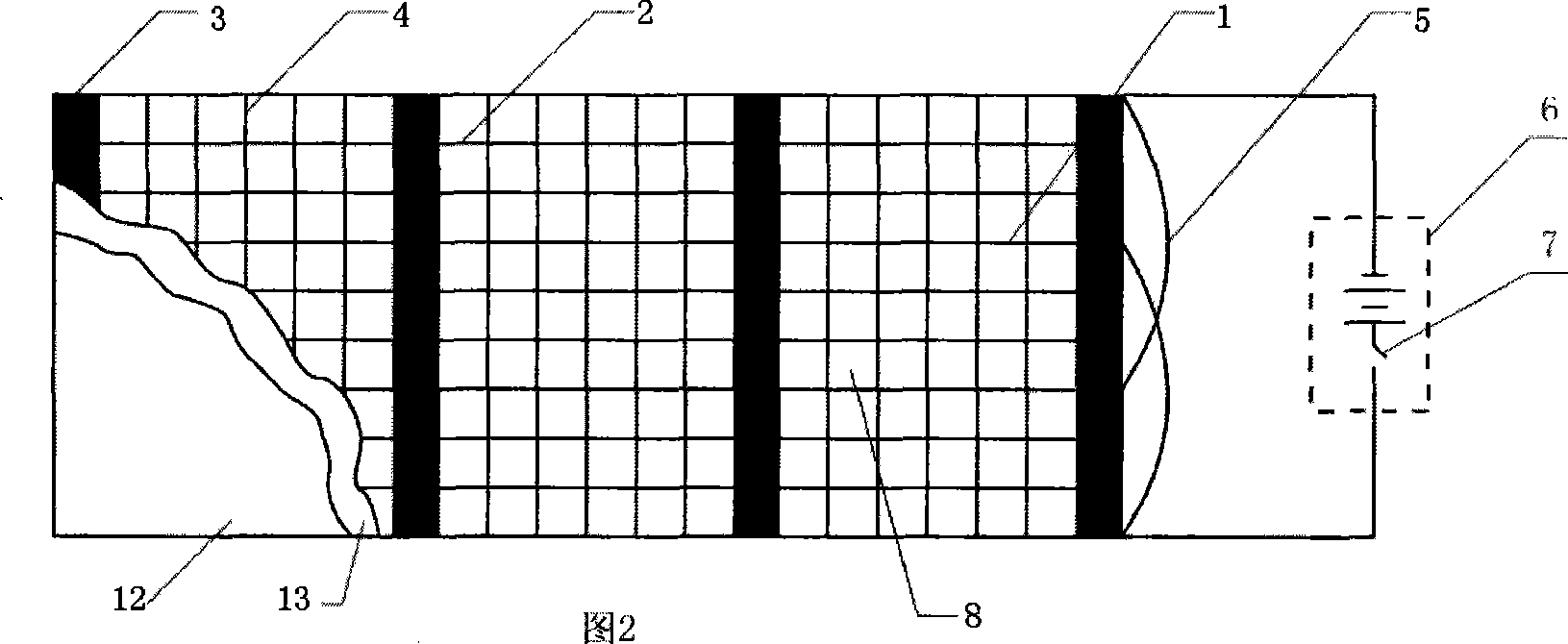

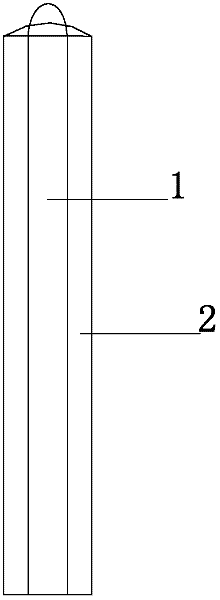

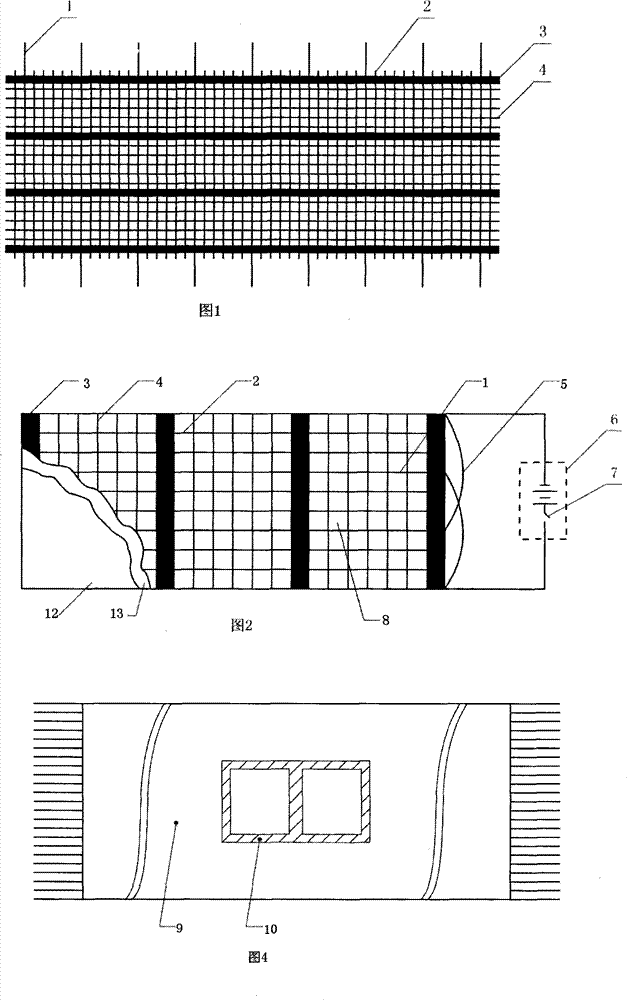

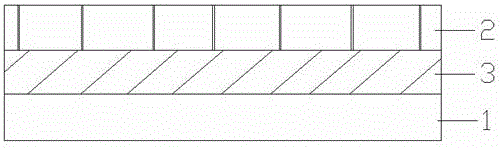

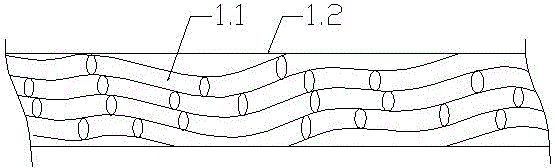

Fragrant deodorized artificial leather

InactiveCN104963207AGuaranteed persistenceGood effectLayered productsTextiles and paperActive carbonFiber

The invention relates to fragrant deodorized artificial leather which comprises a base layer (1) and a surface layer (2). A deodorized interlayer (3) is arranged between the base layer (1) and the surface layer (2). A plurality of groups of fragrance cells (1.1) which are fixed by means of binders are arranged in gaps of the base layer (1), the outer side of each group of fragrance cells is provided with a waterproof layer, and a fragrance control layer (1.2) for controlling vitalization of fragrance in the fragrance cells (1.1) is coated on the outer surface of the base layer (1). As the deodorized interlayer arranged between the base layer and the surface layer is made of active carbon fibers which are specifically bonded between the base layer and the surface layer, the artificial leather has an odor adsorbing and removing function and achieves deodorization. Since the fragrance cells are fixed into the gaps of the base layer by the binders and vitalization of fragrance in the fragrance cells is controlled by the fragrance control layer, persistence of fragrance of the fragrance cells is guaranteed.

Owner:JIANGSU HUAHONG RUBBER & PLASTIC

Preparation method of aged-aroma flavoring liquor

The invention discloses a preparation method of aged-aroma flavoring liquor, relates to the technical field of the liquor brewing industry and aims to solve the problems that aged aroma of basic liquor is insufficient and traditional flavoring liquor preparation processes are complex. The preparation method comprises the preparation steps as follows: superior corn alcohol is blended through activated carbon, flos magnoliae, fructus amomi, edible aluminum-damage-free double-effect baking powder, ethyl valerate and valeric acid. The preparation method has the benefits as follows: the preparationprocess is simple, the effect is significant, the production cycle is short, the investment is low, and the defects that the aged aroma of baijiu is insufficient and the tail aroma is not clean can be overcome effectively.

Owner:冯硕

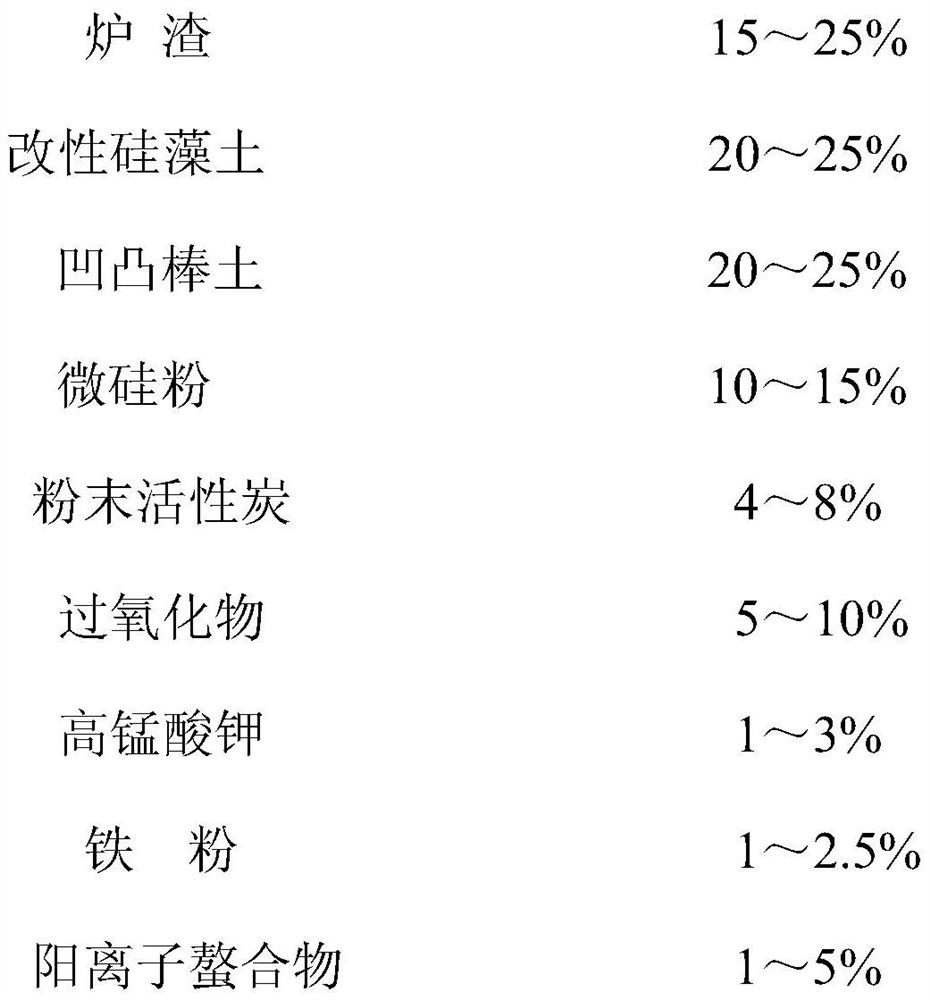

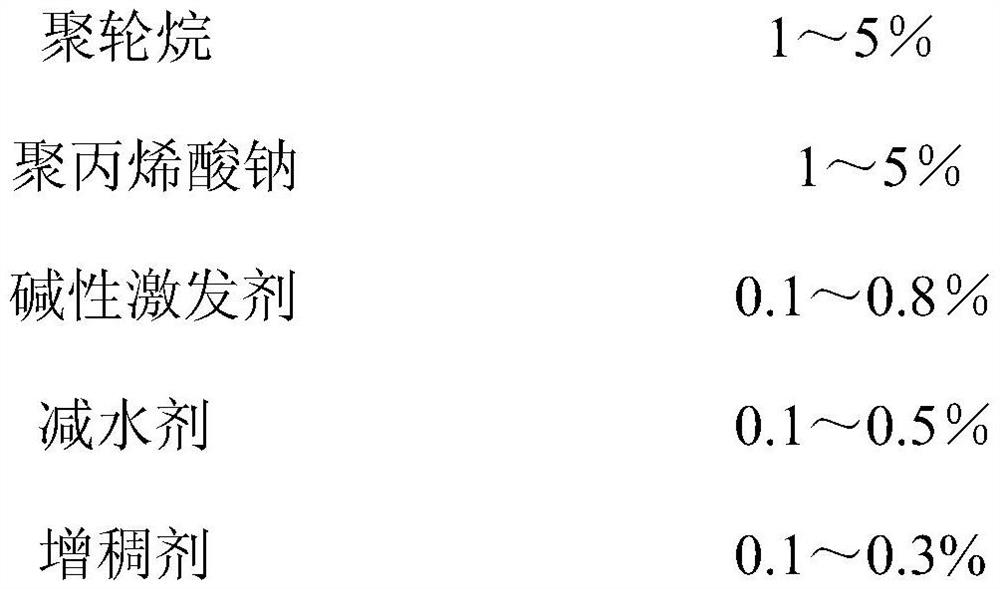

Sludge solidifying agent prepared from slag and its preparation method and application

ActiveCN109133820BTo achieve the effect of solidificationImprove curing effectFixation/solidifcation sludge treatmentSlagSludge

Owner:湖北恒沁环保科技有限责任公司

Dye-absorption odor-absorption antibacterial activated carbon spunlace cloth

InactiveCN107938170ASoft touchNot easy to fadeSucessive textile treatmentsLiquid/gas/vapor removalDye absorptionActivated carbon

Dye-absorption odor-absorption antibacterial activated carbon spunlace cloth is prepared from 70%-90% of 1.67D*38 activated carbon viscose fibers and 10%-30% of 1.5D*38 antibacterial fibers. The 1.67D*38 activated carbon viscose fibers and the 1.5D*38 antibacterial fibers are subjected to opening, mixing, carding, lapping, laminating, drafting and spunlace reinforcing to form the spunlace cloth. By cationization of the spunlace cloth, the dye-absorption odor-absorption antibacterial activated carbon spunlace cloth has advantages of soft hand feel, less proneness to fading, crease resistance, wear resistance and the like. Aiming at functional defects, by combination of the 1.67D*38 activated carbon viscose fibers and the 1.5D*38 antibacterial fibers, the spunlace cloth have excellent antibacterial, dye absorption and odor absorption performances.

Owner:上海瑞洋思生活用品有限公司

Exercise mat

The present invention relates to a sports mat, the production method of which is the same as the common production method, and consists of the following components in parts by weight: the sports mat is composed of the following components in parts by weight: 50 parts of matrix resin; 0.5 parts of stearic acid; N— 30 parts of 220 black smoke powder; 30 parts of EPDM rubber powder; 5 parts of naphthenic oil; 1 part of phenolic resin; 0.6 parts of M accelerator; 0.1 part of TMTD accelerator; 6 parts of activated carbon. The invention has the advantages that: the sports mat made of the above formula is not easy to be polluted, deformed, worn, easy to dehumidify, and has good heat insulation; it is suitable for stepping on dense crowds, has good elasticity, and can meet the sports requirements.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

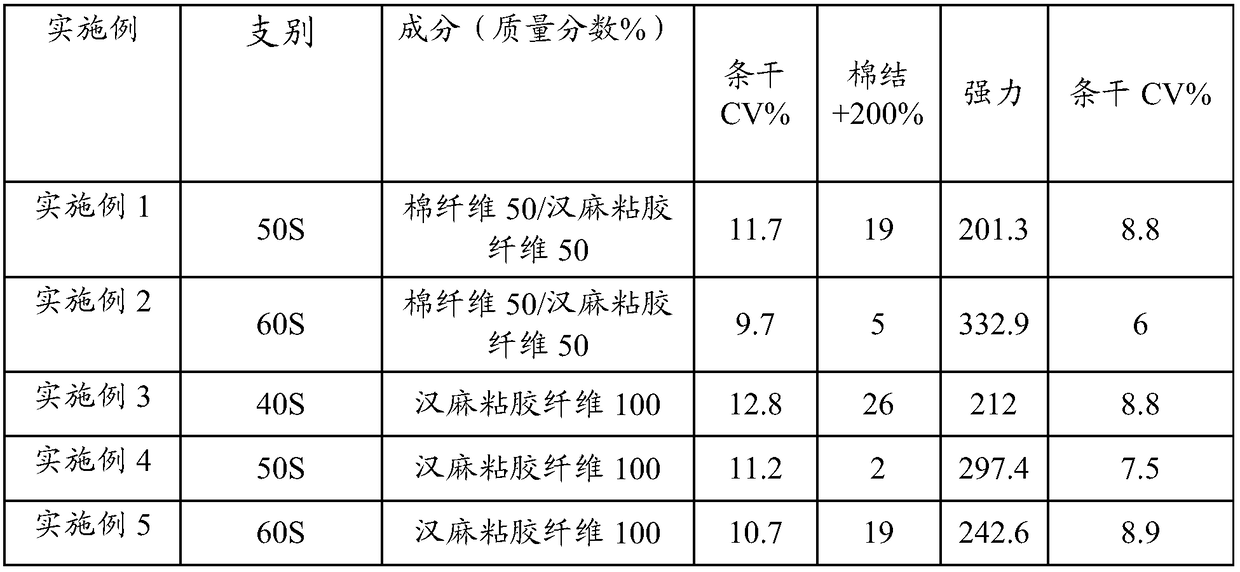

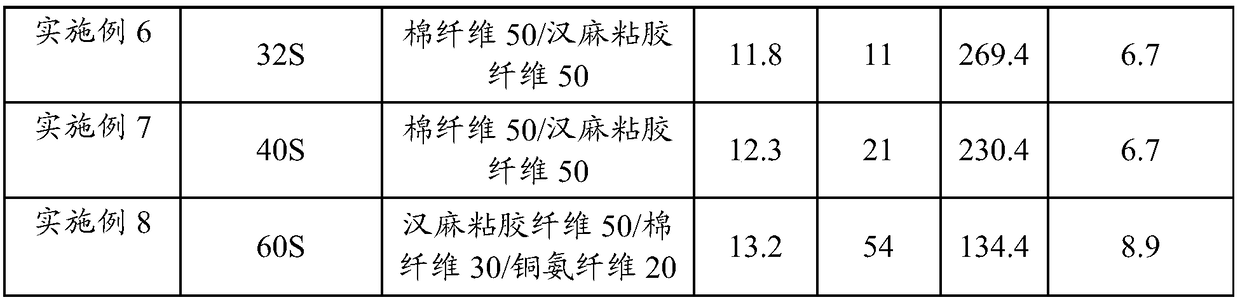

Yarn containing China hemp viscose

The invention belongs to the technical field of textile, and particularly provides a yarn containing China hemp viscose. Textile fabric woven from the yarn, clothing and bags prepared from the textilefabric and the like all have the functional advantages of being soft, dry and comfortable, breathable, comfortable, antibacterial, antistatic, green and natural, absorbing sweat, resisting ultraviolet radiation and the like.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

High-density and high-barrier polyethylene plastic thin film and making method thereof

The invention discloses a high-density and high-barrier polyethylene plastic thin film and a making method thereof. The high-density and high-barrier polyethylene plastic thin film comprises a thin film body and waterproof layers; an upper thin film layer is arranged above the thin film body, a first thickening layer is connected under the upper thin film layer, a reinforcing layer is fixed on thefirst thickening layer, a second thickening layer is connected under the reinforcing layer, a lower thin film layer is arranged under the second thickening layer, the waterproof layers are arranged on the surfaces of the upper thin film layer and the lower thin film layer, the first thickening layer and the second thickening layer are symmetrically distributed about the reinforcing layer, the first thickening layer comprises a first layer body, an absorbing layer and a second layer body, and the absorbing layer is arranged between the first layer body and the second layer. The high-density and high-barrier polyethylene plastic thin film and the making method thereof disclosed by the invention have the benefit that the high-density and high-barrier polyethylene plastic thin film is improved aiming at the defects of the conventional polyethylene plastic thin film technology so as to be high in density and strong in barrier effect and have the function of absorbing odor, thereby being more convenient to use.

Owner:河南联和聚邦新材料股份有限公司

Health care scarf used for clearing and activating the channels and collaterals and relieving fatigue of neck muscle strains

Provided is a health care scarf used for clearing and activating the channels and collaterals and relieving fatigue of neck muscle strains. The scarf is characterized in that fabric of the scarf is formed by interweaving of warps and wefts composed of far infrared ceramic fibers, bamboo fibers, conducting heating fibers and nano silver fibers; the multi-functional health care fabric comprises following components, including 16%-23% parts by weight of far infrared ceramic fibers, 38-53% parts by weight of bamboo fibers, 24-28% parts by weight of conducting heating fibers, and 7-11% parts by weight of nano silver fibers. The warps comprise first warps and second warps. The first warps utilize far infrared ceramic fibers and the second warps utilize bamboo fibers. First wefts utilize conducting heating fibers and second wefts utilize nano silver fibers.

Owner:浙江希泽服饰有限公司

Sports mat

The invention relates to a sports mat. A preparation method of the sports mat is the same with that of the common preparation method. The sports mat is prepared from the following components in parts by weight: 50 to 80 parts of matrix resin, 0.5 to 0.8 part of stearic acid, 30 to 50 parts of N-220 anthracite fine, 30 to 50 parts of EPDM (ethylene-propylene-diene monomer) rubber powder, 5 to 10 parts of naphthenic oil, 1 to 3 parts of phenolic resin, 0.6 to 0.7 part of M accelerant, 0.1 to 0.3 part of TMTD (tetramethyl thiuram disulfide) accelerant, and 6 to 10 parts of activated carbon. The sports mat has the advantages that by adopting the formula, the easiness in pollution, deformation and abrasion is avoided, the dehumidifying is easy, and the heat isolation property is good; the sports mat is suitable for dense populations to tread, the elasticity is good, and the sports requirement is met.

Owner:南通绿美佳塑胶有限公司

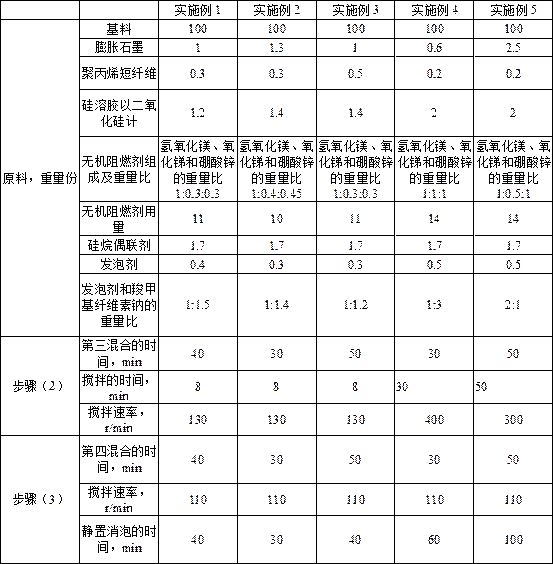

A kind of lightweight flexible soft porcelain and preparation method thereof

The invention relates to the technical field of soft porcelain, in particular to a lightweight flexible soft porcelain and a preparation method thereof, comprising the following components in parts by weight: 100 parts of base material, 0.6-3 parts of expanded graphite, and 0.2-0.5 parts of polypropylene short fibers , 0.6-3 parts of silica sol, 8-15 parts of inorganic flame retardant, 1-2.4 parts of silane coupling agent, 0.2-0.5 parts of foaming agent, and 0.5-1.5 parts of sodium carboxymethyl cellulose. The light and flexible soft porcelain has high strength, good flexibility, light weight, good tear resistance and high elongation at break, has a porous structure, and has the functions of absorbing odor and flame retardant, and does not need to add a large amount of inorganic fillers, making full use of scrap.

Owner:HENAN B R D NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com