Air filtering material

An air filter material and carbon material technology, applied in the field of materials, can solve the problems of limited registration of air filter materials, etc., and achieve the effects of low production cost, simple preparation process and strong adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] An air filter material, the air filter material includes a base material and a composite layer, the base material is an upper and lower layer of carbon fiber mesh filter cloth, the composite layer is between the upper and lower layers of carbon fiber mesh filter cloth, from From top to bottom are diatomaceous earth supported titanium dioxide layer and carbon material adsorption layer.

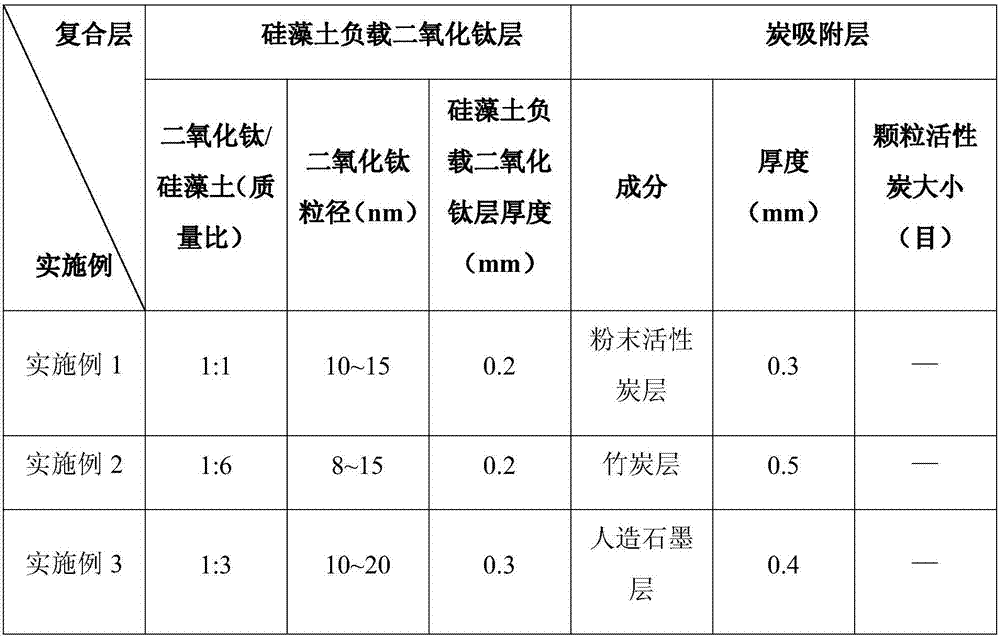

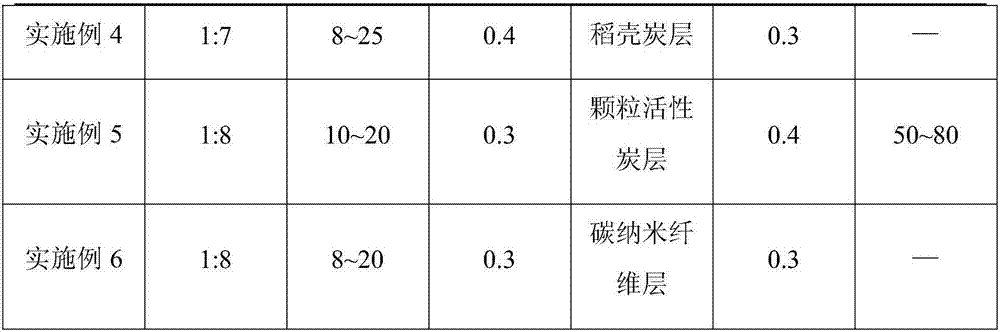

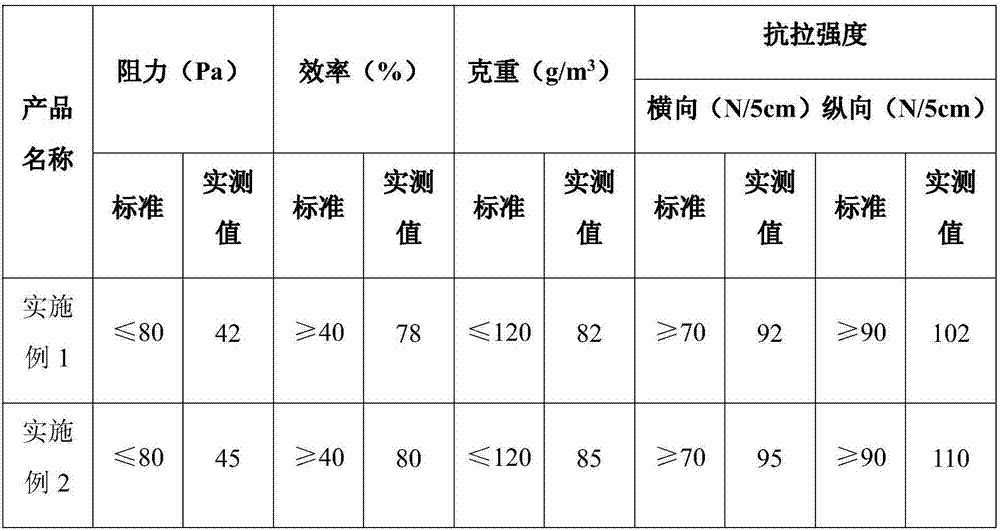

[0023] The specific parameters of the air filter material of embodiments 1 to 6 are listed in the form of a table, specifically in Table 1:

[0024] The concrete parameter of the air filter material of table 1 embodiment 1~6

[0025]

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com