Patents

Literature

103results about How to "Guarantee a clean environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

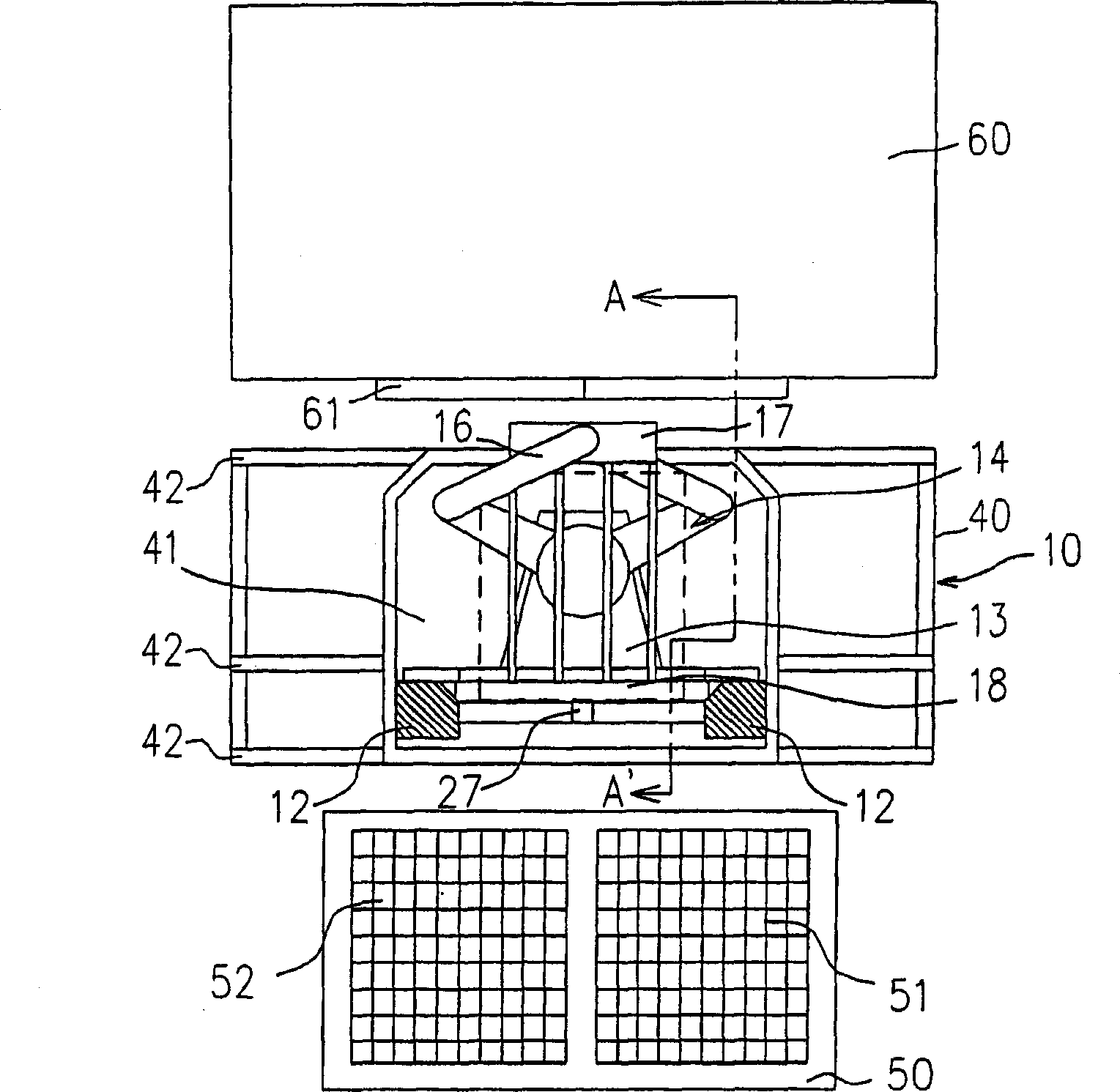

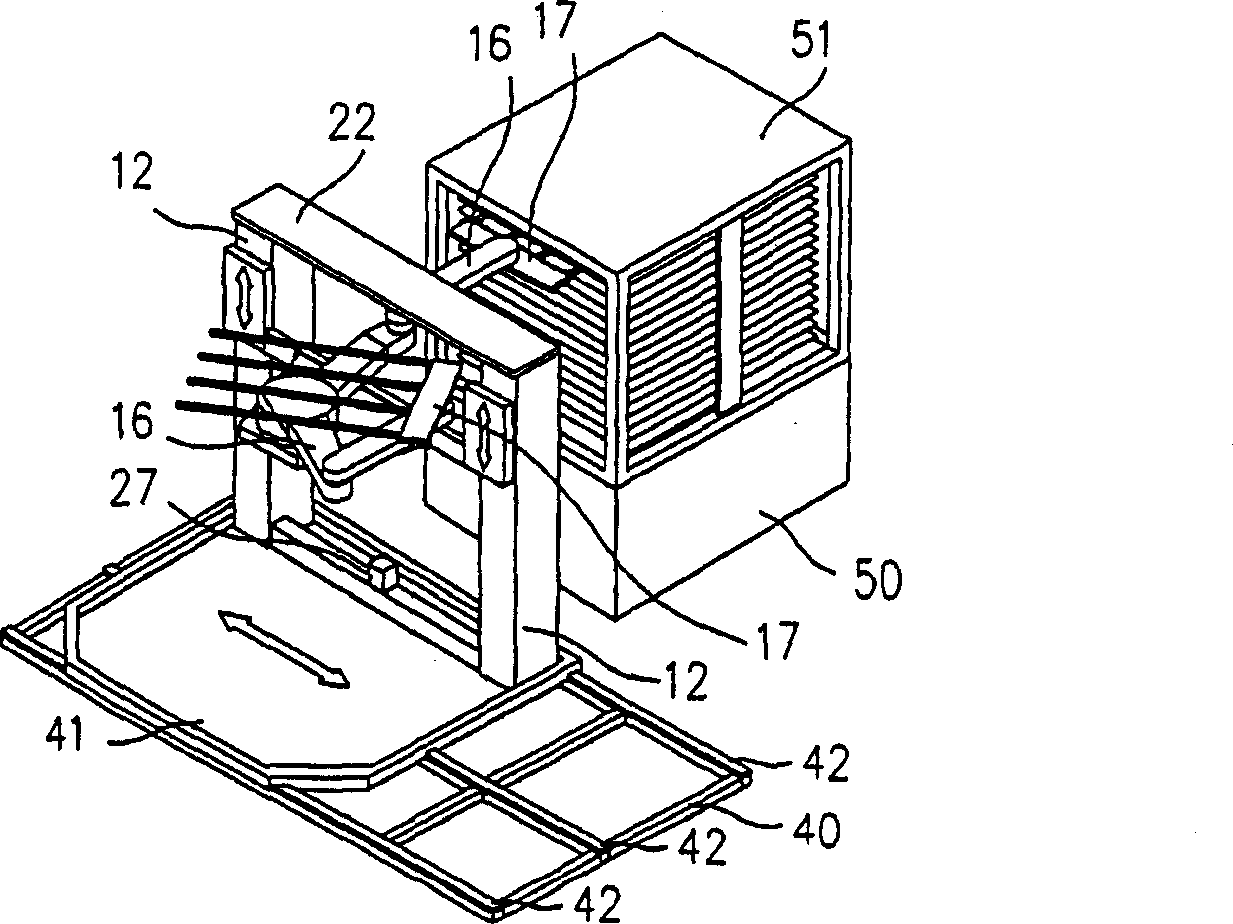

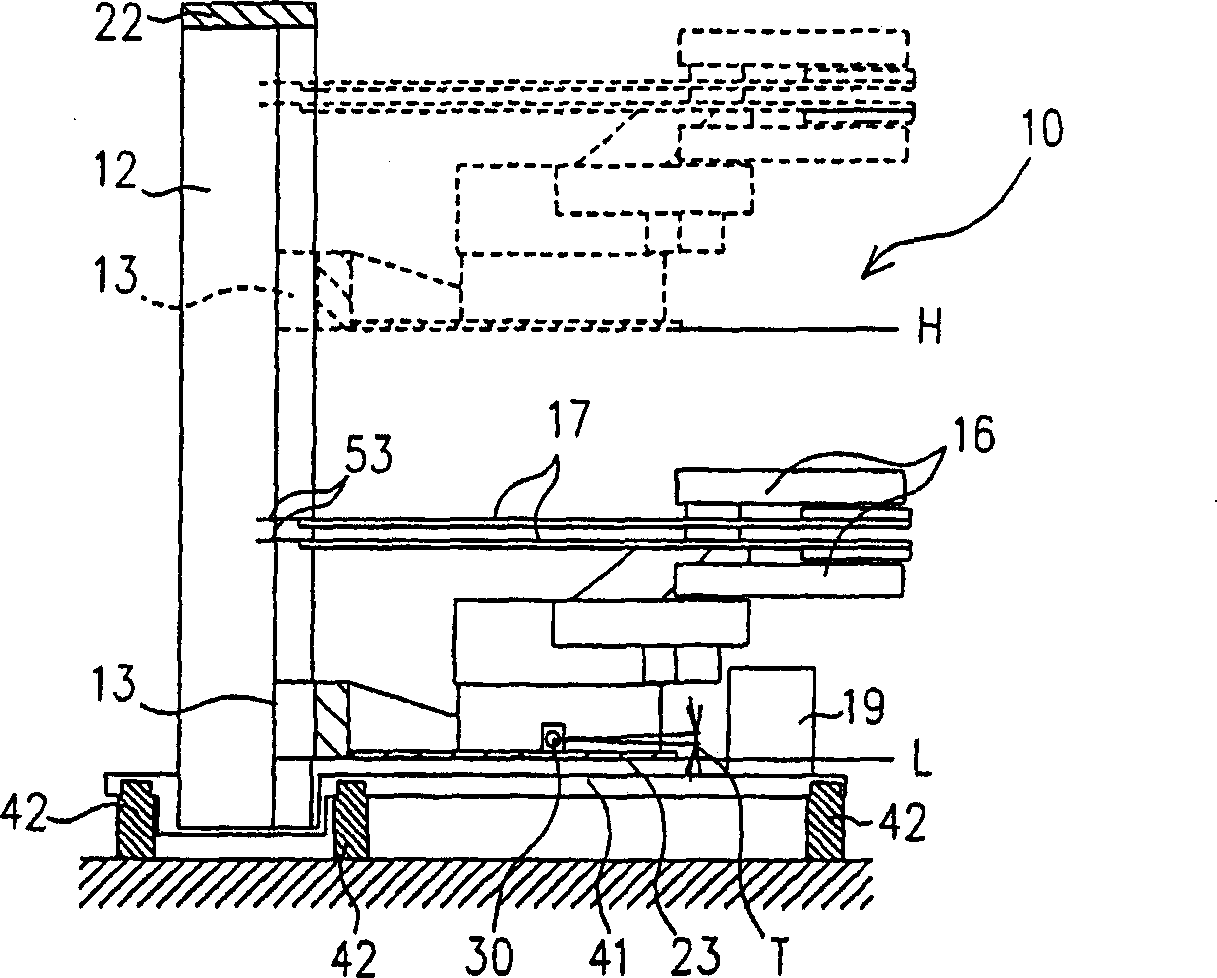

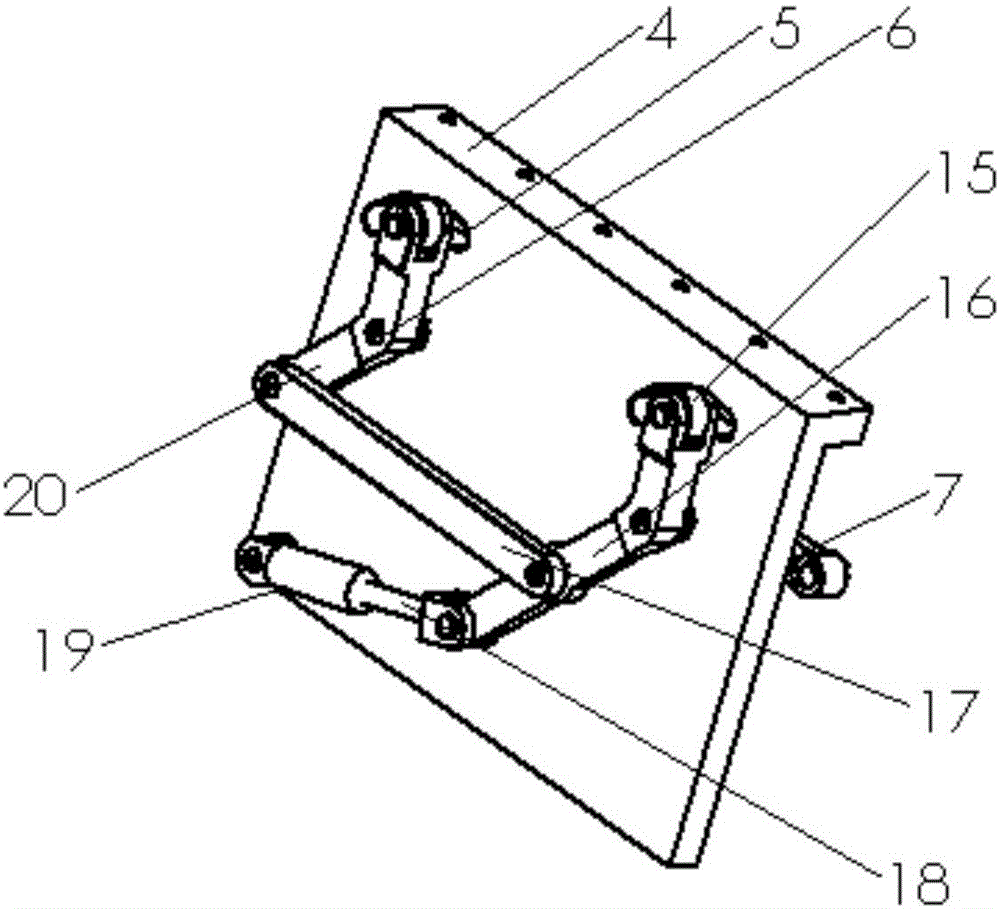

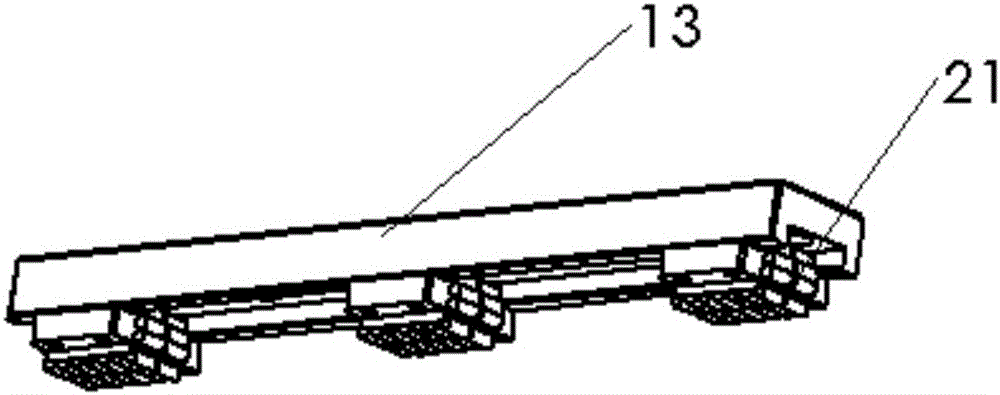

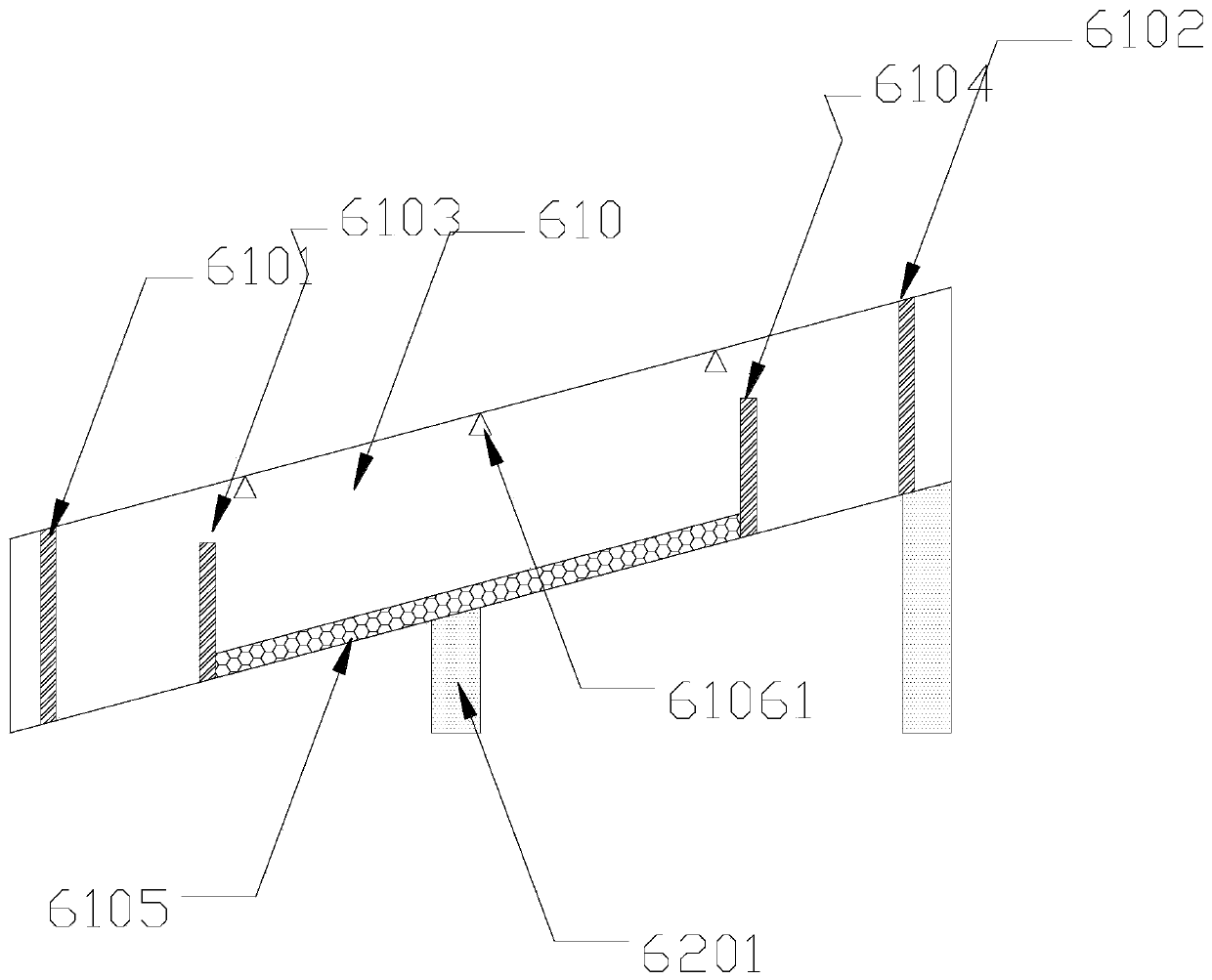

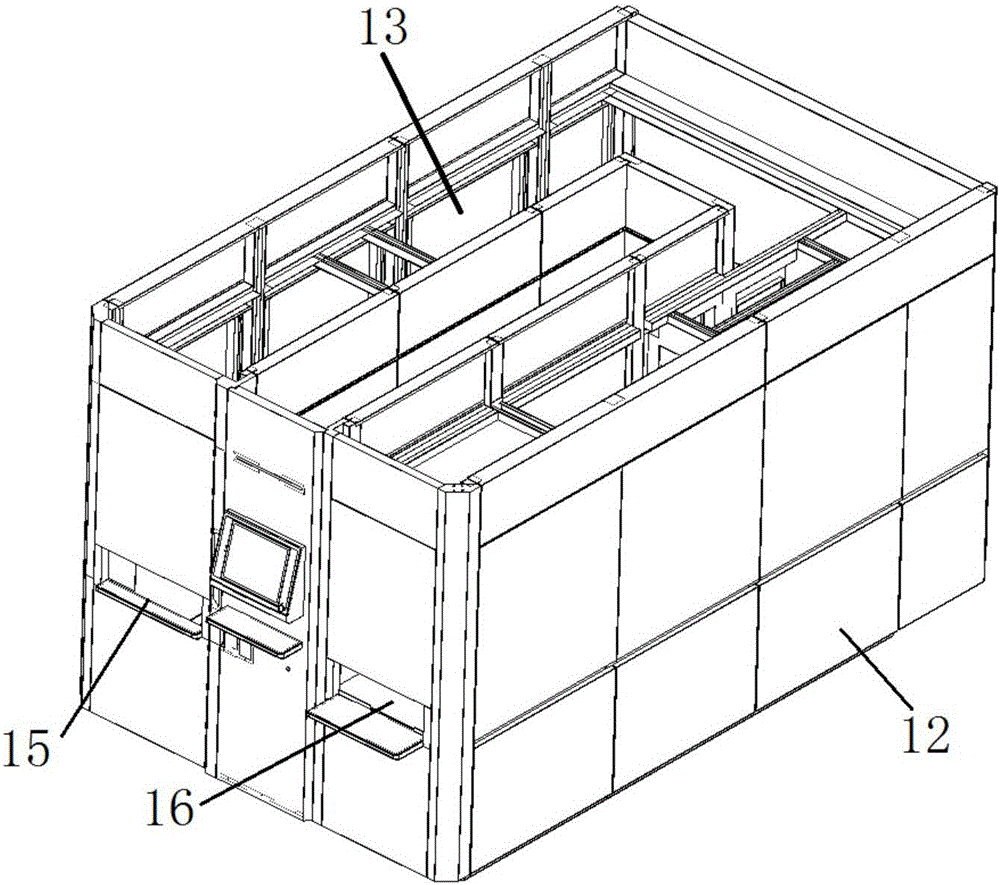

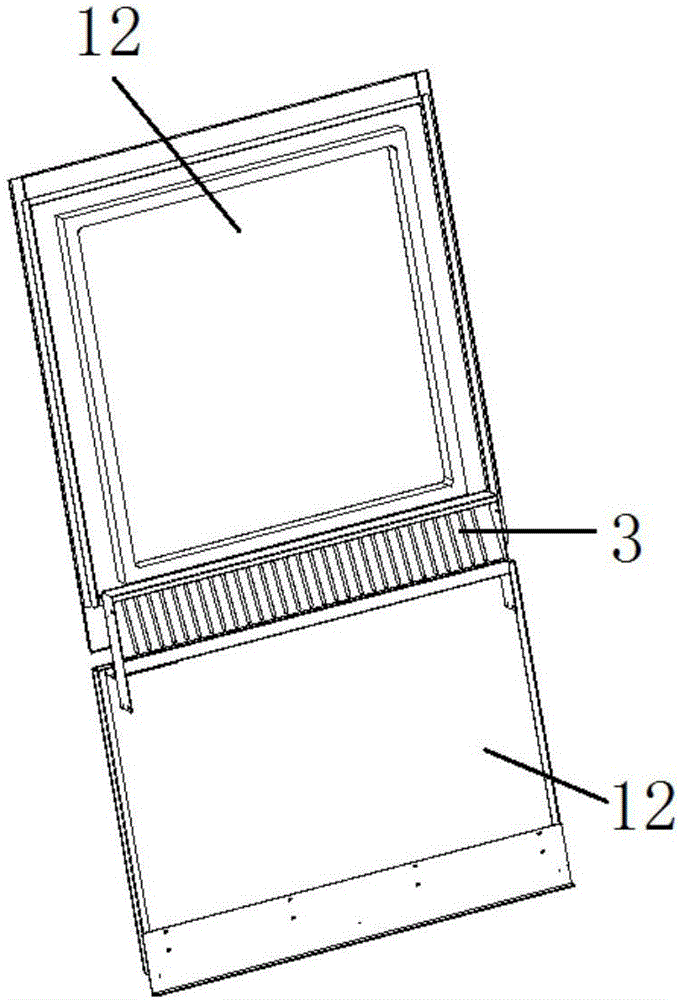

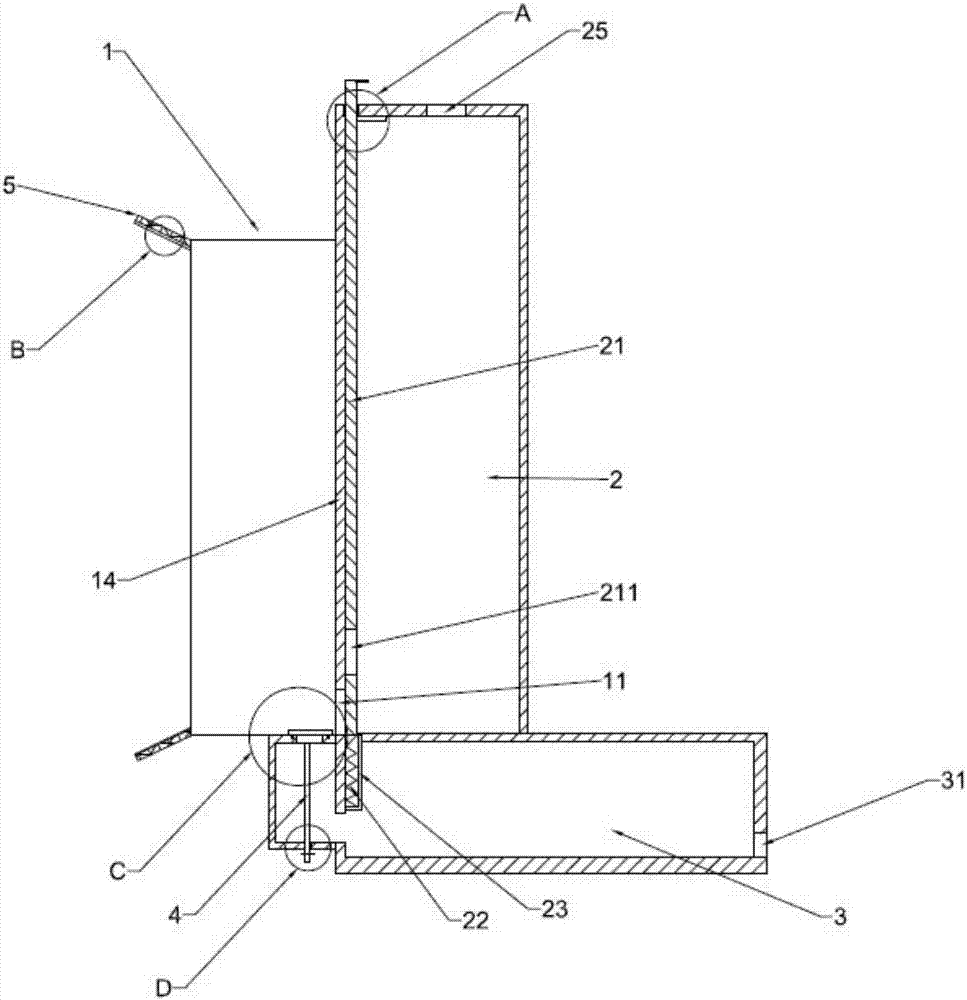

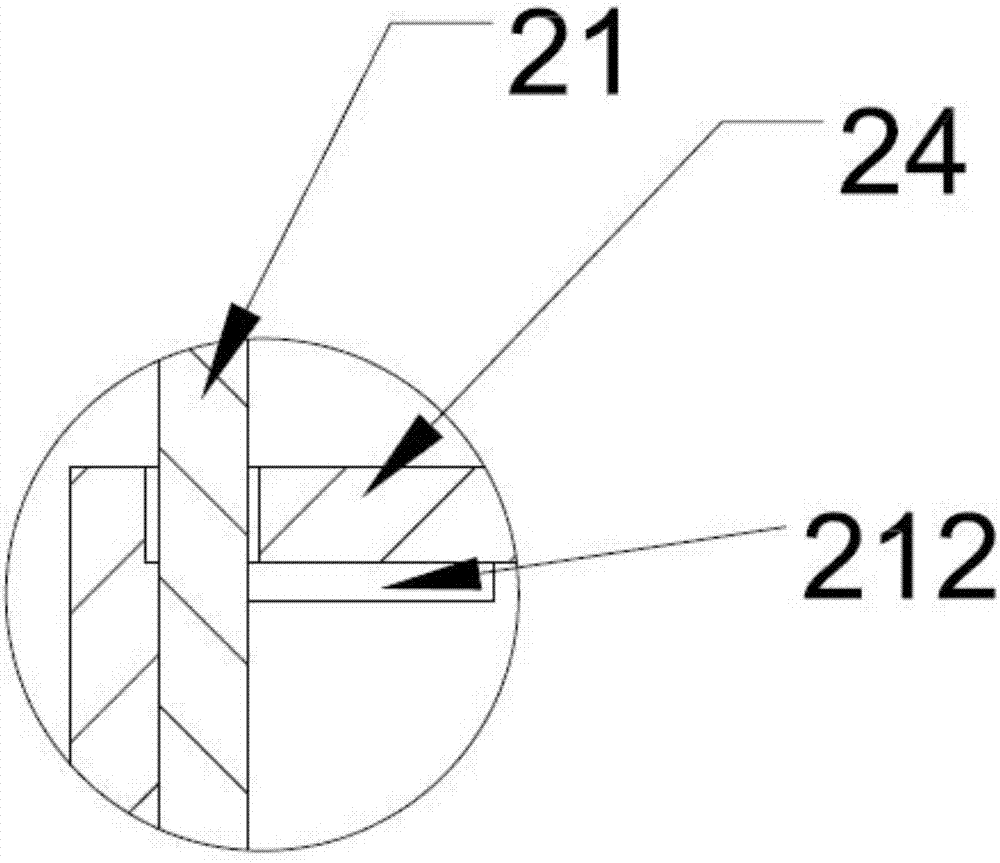

Carrying apparatus and carrying control method for sheet-like substrate

ActiveCN1816907ASmooth movementStable and fast shippingProgramme-controlled manipulatorConveyorsLiquid-crystal displayTransfer system

The invention relates to a transfer device for transferring thin plate-like articles, such as liquid crystal display panels and glass substrates, into a processing device. The invention provides, in a transfer device provided with a relatively large robot (14) having a turning arm (16) for transferring large-sized thin plate-like articles, a transfer device capable of stabilized lifting even if the height is 2 m or so and capable of transfer in which the amount of deflection with the turning arm (16) extended can be corrected; and a thin plate-like article transferring system. A transfer robot (14) having the turning arm (16) is mounted on a horizontal support block (13) cantilevered for lifting and lowering motion on two upright support bodies (12). Further, the amount of deflection with the arm extended is corrected by raising the level of the horizontal support block (13) according to the amount of deflection. The amount of deflection can also be corrected by changing the angle of installation at which the robot (14) is mounted on the horizontal support block (13).

Owner:RORZE CORP

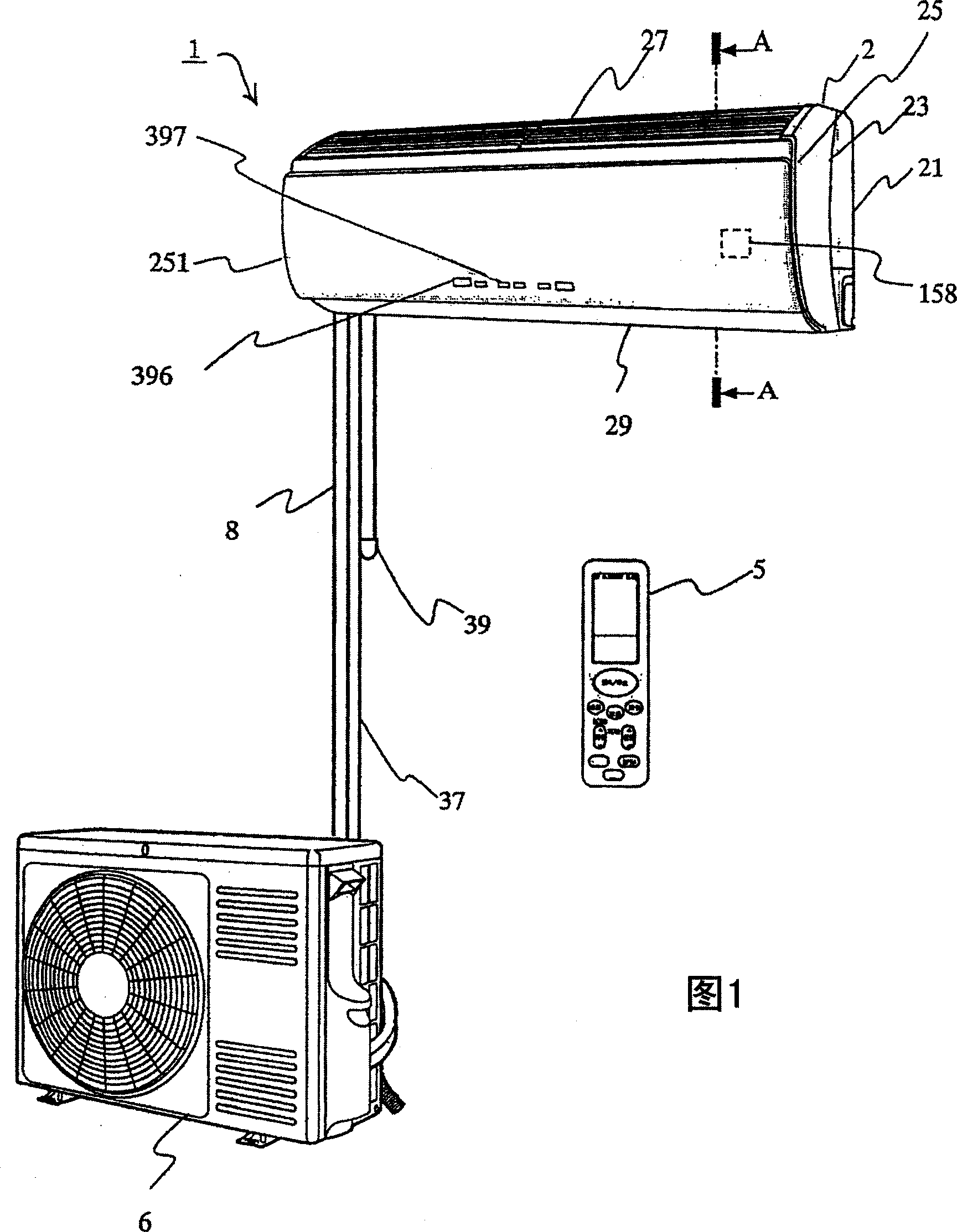

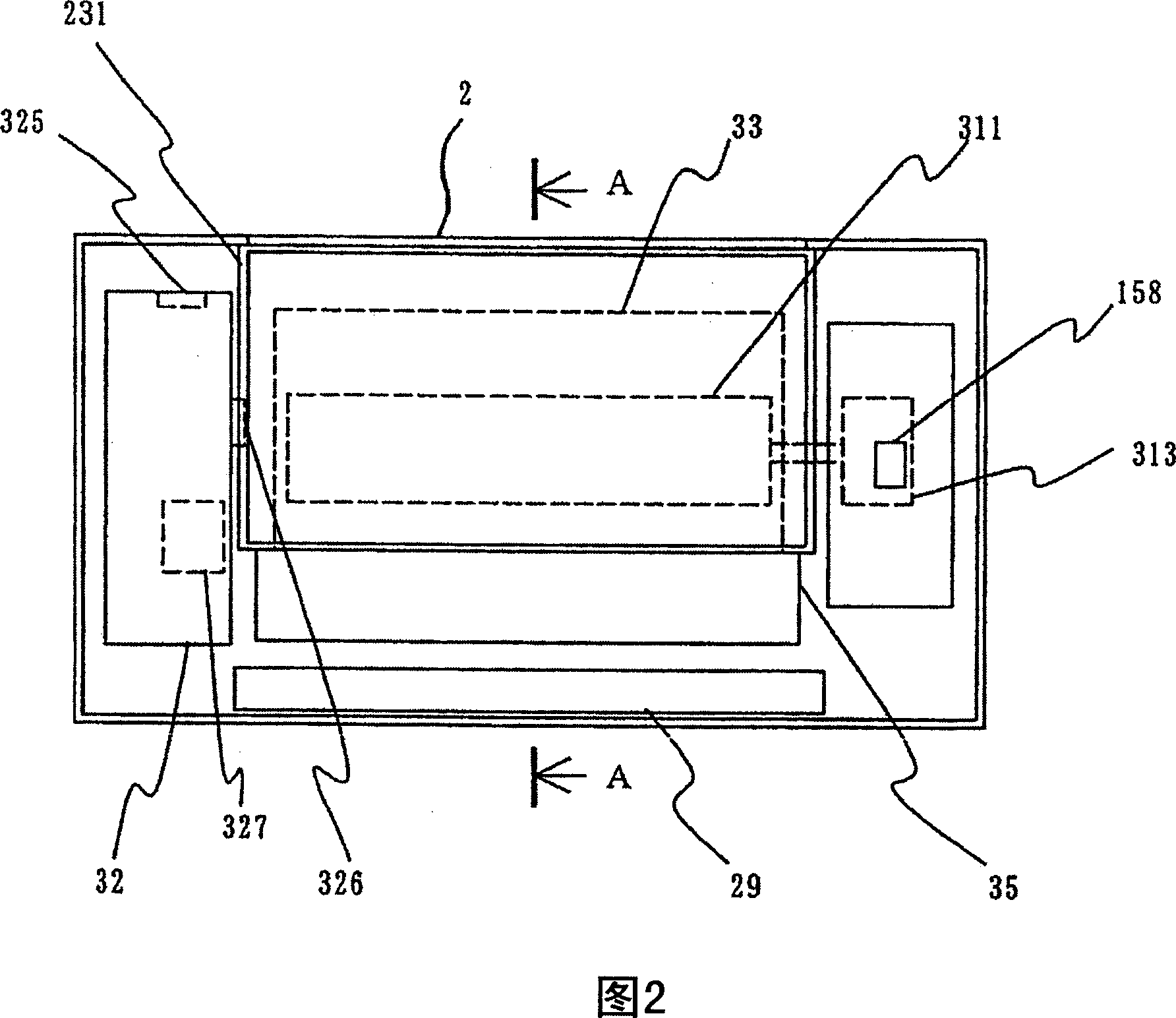

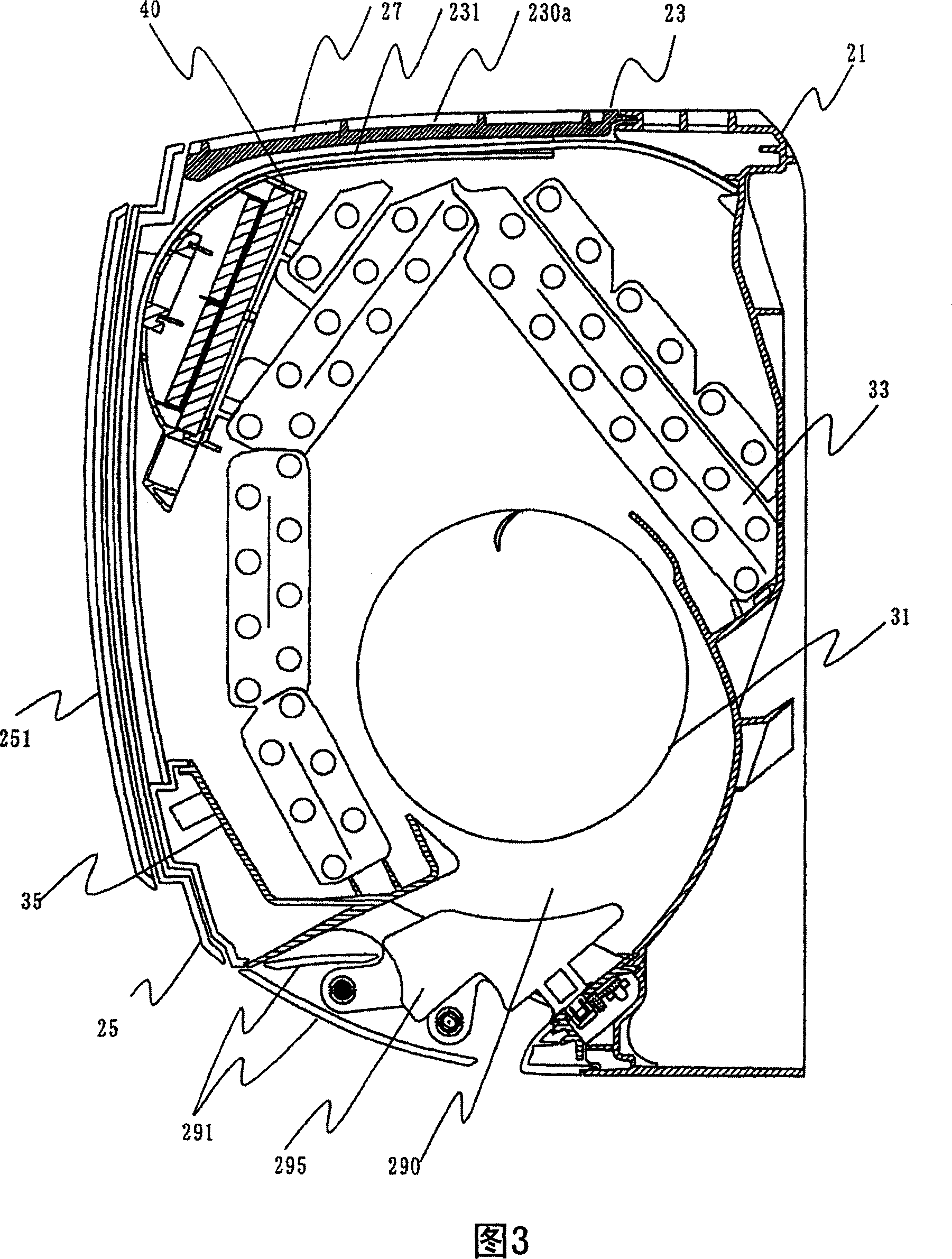

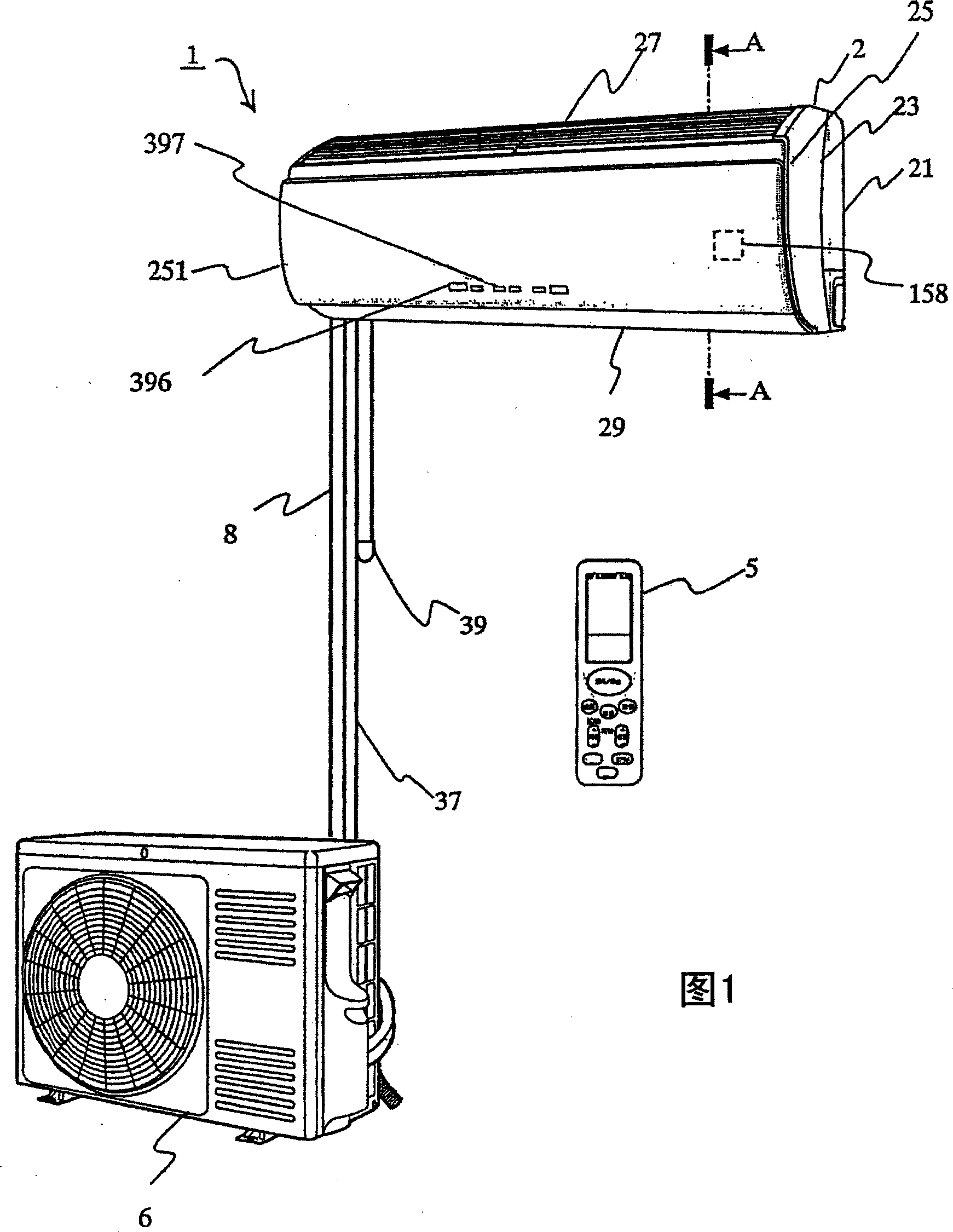

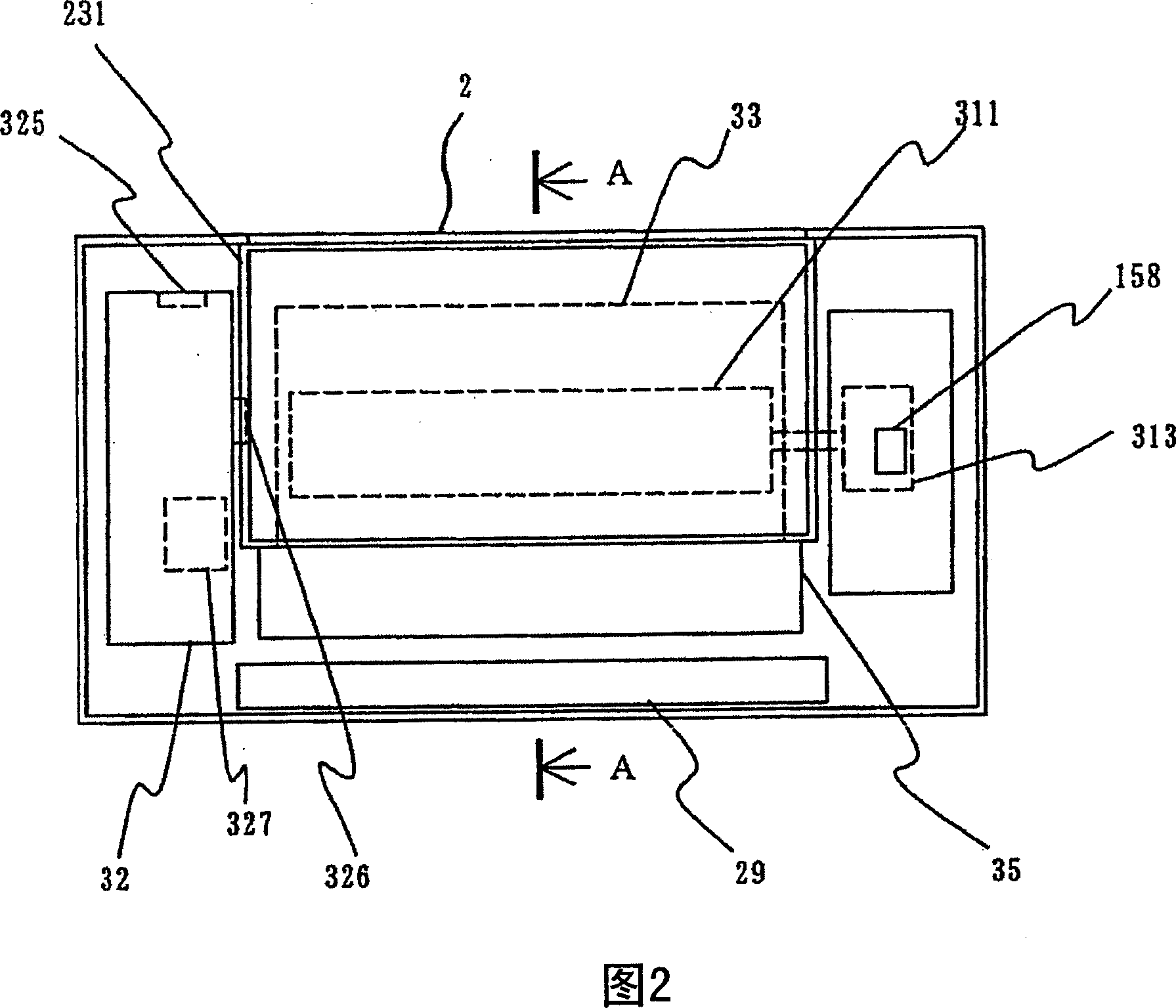

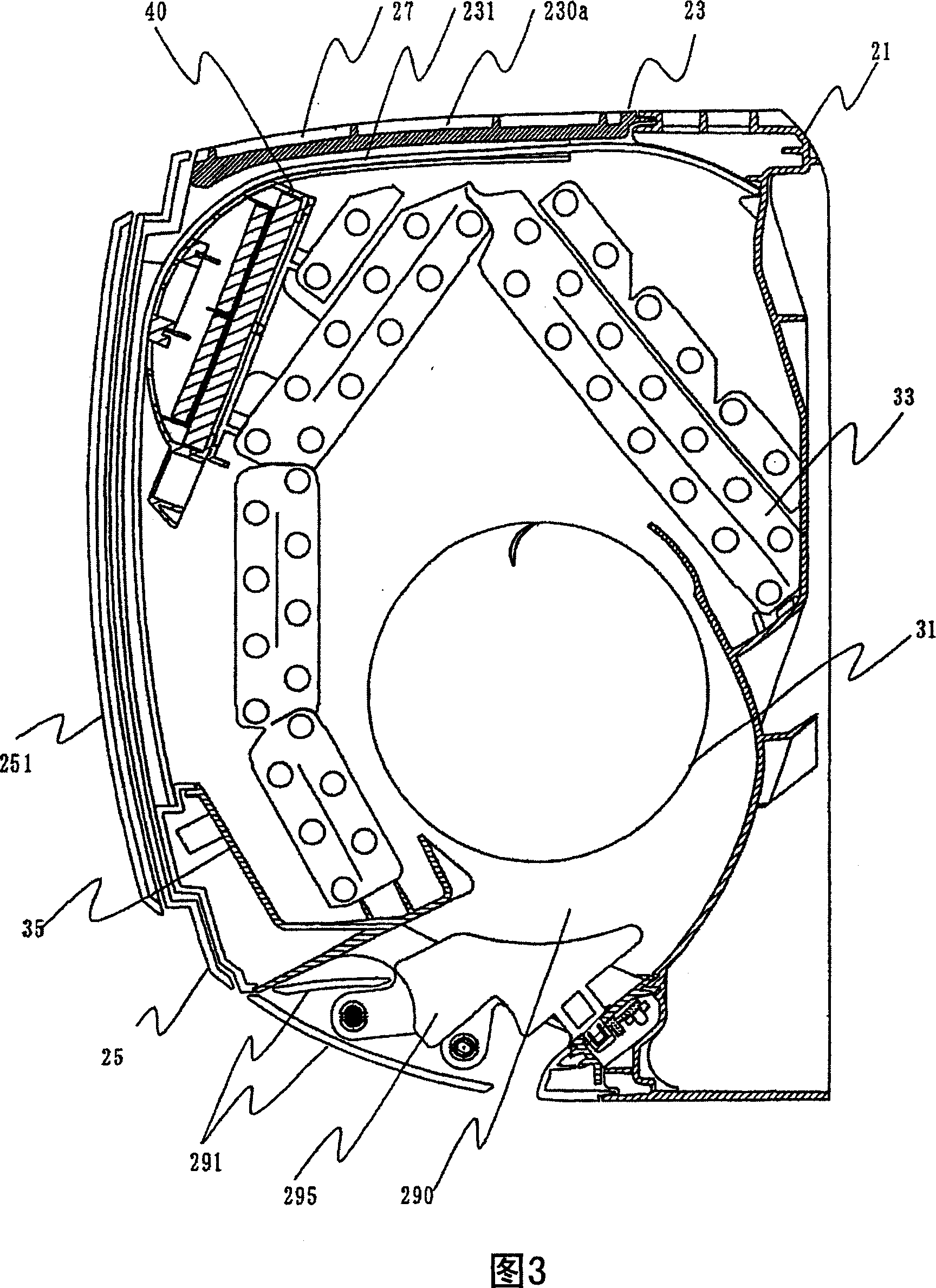

Air conditioner

InactiveCN1948840ARelaxReduce dustHuman health protectionMechanical apparatusAllergic reactionElectric power

Provided is an air conditioner, capable of maintaining the inside of a room with a dust-minimized state by detecting specific dust containing pollen that is a substance generated outdoors and causing seizures by allergic reaction or promoting the seizures, and performing dust removing operation. This air conditioner (1) comprises an indoor unit (2) including an electric dust collecting and cleaning unit provided with a dielectric filter, a ventilating device capable of performing air supply operation for taking outside air into the room, a cleaning filter provided in an suction passage of the outside air by the ventilating device, a dust sensor (158) capable of discriminating dust floating in the air. A control device of the air conditioner (1) controls, when the dust sensor detects dust of a specific group including pollen, so as to perform operation of the electric dust collecting and cleaning unit and the air supply operation of the ventilating device.

Owner:HITACHI HOME & LIFE SOLUTIONS INC

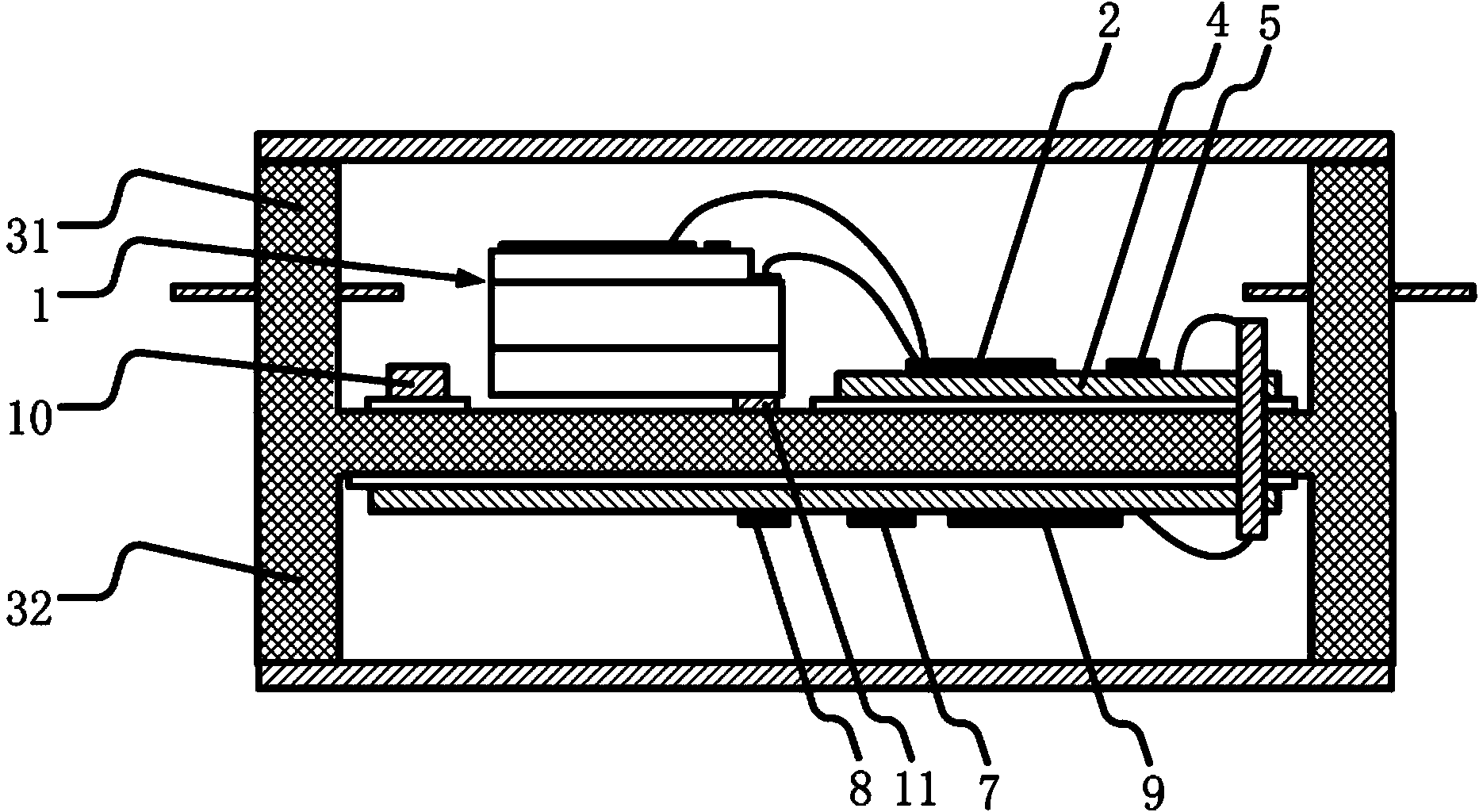

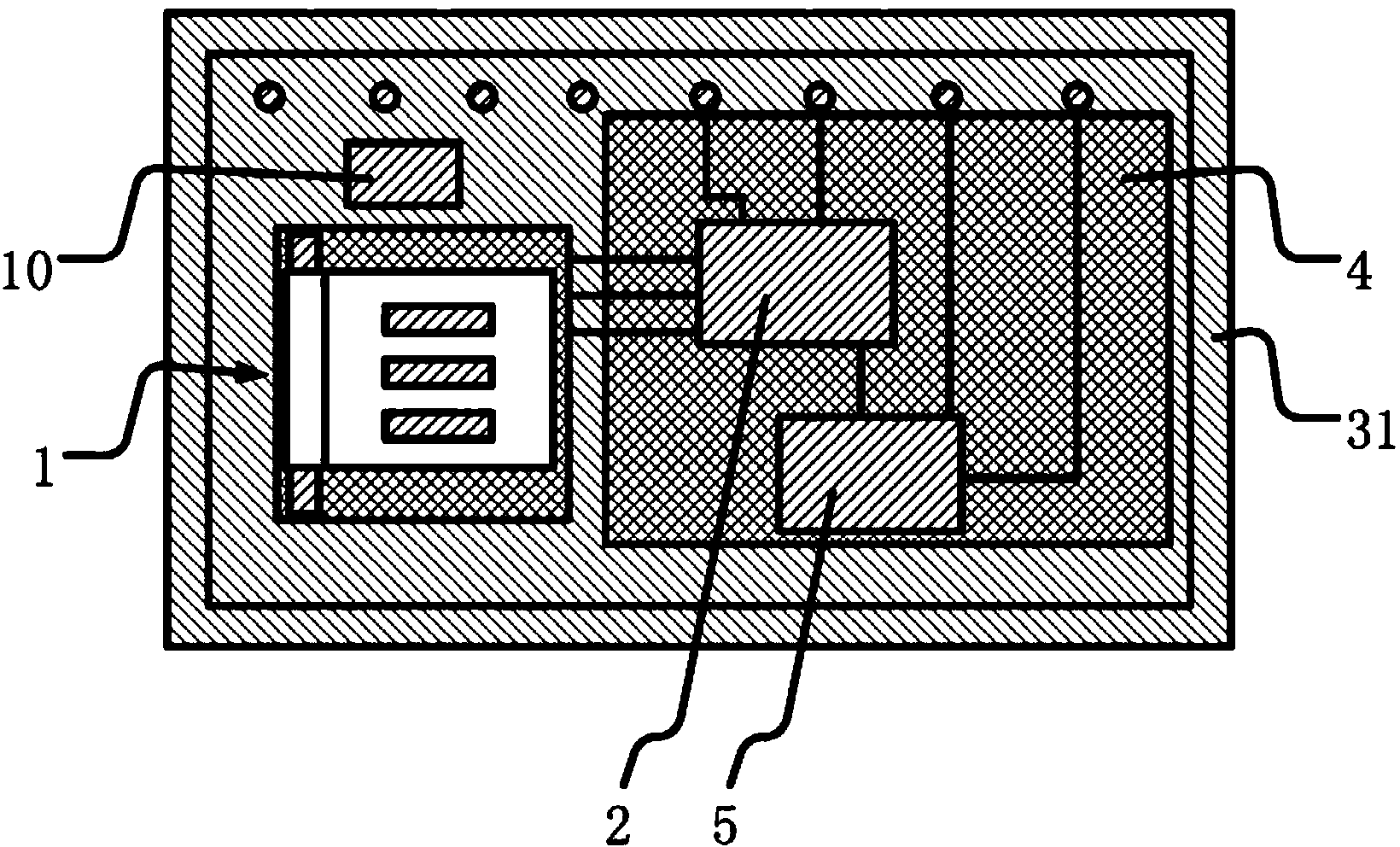

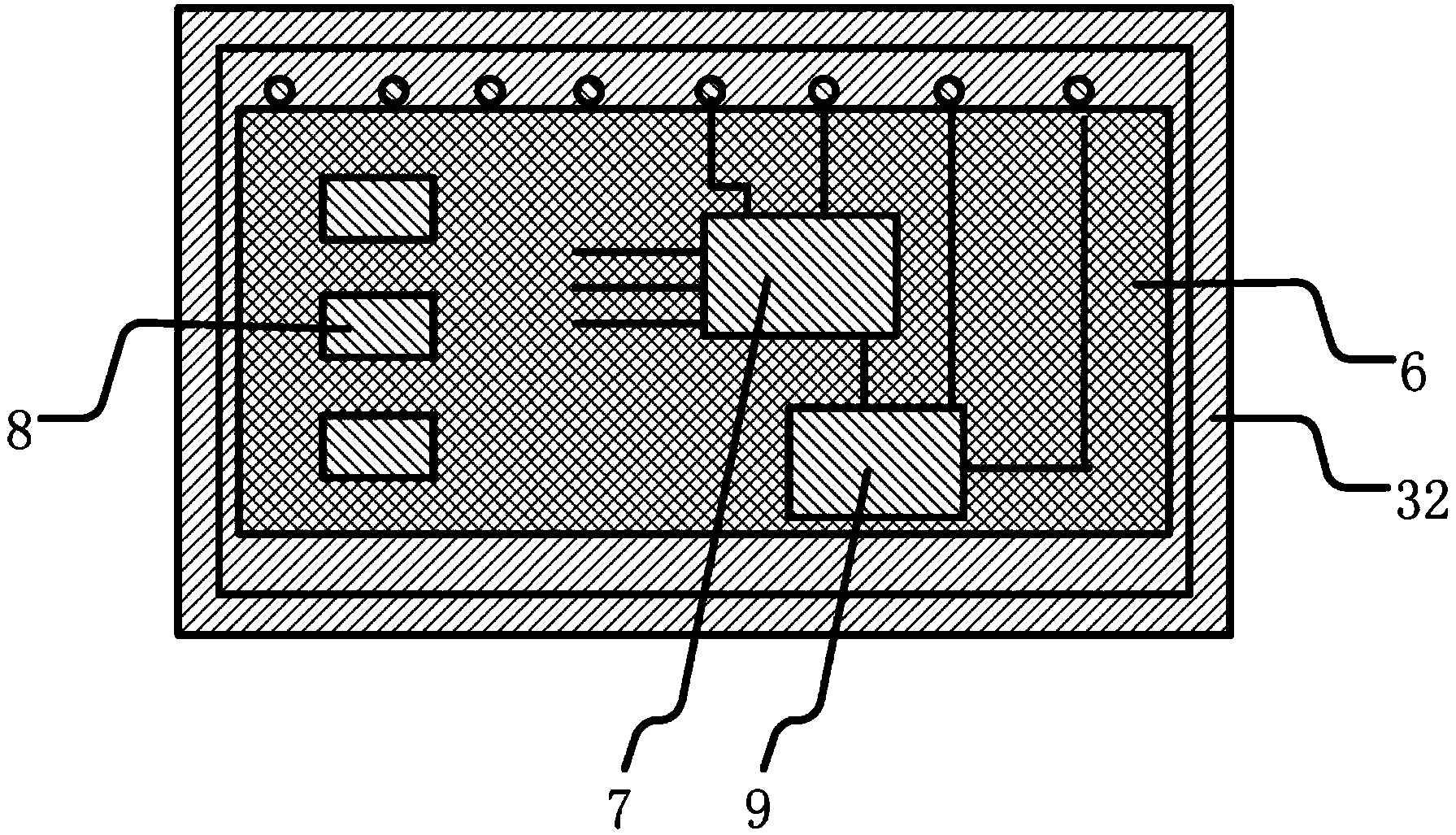

MEMS accelerometer capable of being engineered

ActiveCN103954795AGuarantee a clean environmentQuality assuranceAcceleration measurementAccelerometerEngineering

An MEMS accelerometer capable of being engineered comprises an acceleration sensitive chip, a signal conversion circuit, a first metal pipe shell, a second metal pipe shell, a first substrate, a second substrate and a signal regulating circuit. The accelerometer further comprises a temperature sensor adjacent to the acceleration sensitive chip; the acceleration sensitive chip, the signal conversion circuit and the temperature sensor are packaged into a first independent module, the signal regulating circuit is packaged into a second independent module after being debugged, and package of the second module is posterior to that of the first module. The signal conversion circuit comprises a C-V conversion circuit and a voltage reference unpacked chip; the signal regulating circuit comprises a correction and feedback circuit, a zero adjusting circuit and a filter circuit. The MEMS accelerometer solves a plurality of problems of engineering of the MEMS accelerometer and particularly the problems of temperature characteristics and environmental adaptation of impact and overload, can be used for manufacturing an acceleration sensitive element for inertia measurement and inertia navigation, and can also serve as an acceleration measurement element in the fields of bridge health monitoring and the like.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

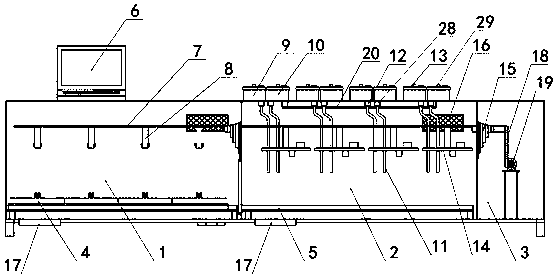

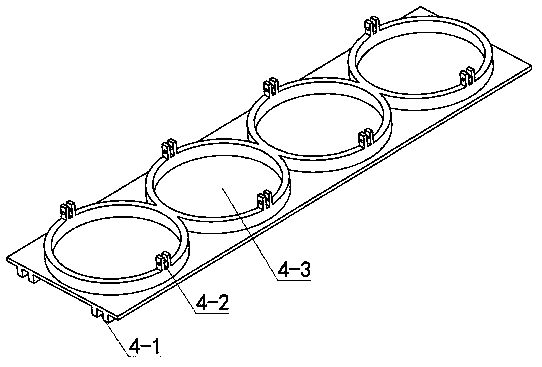

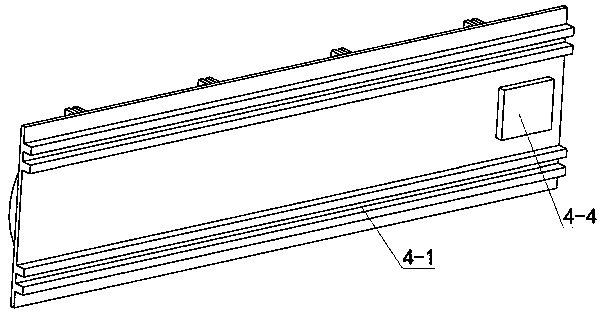

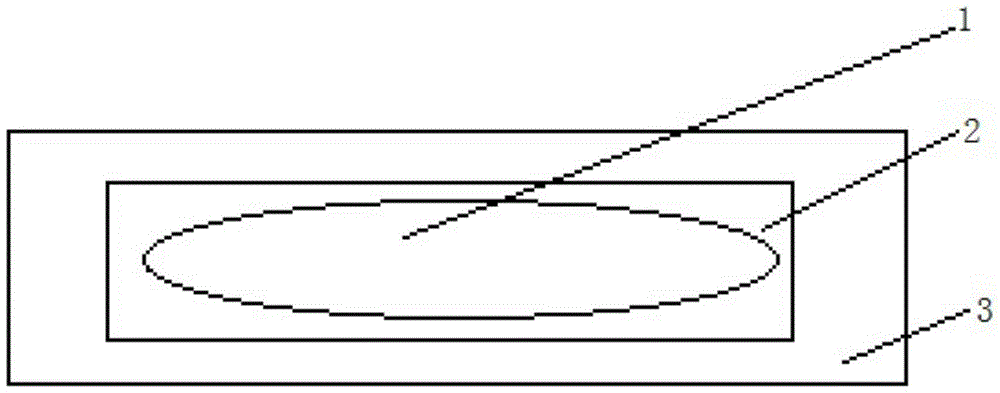

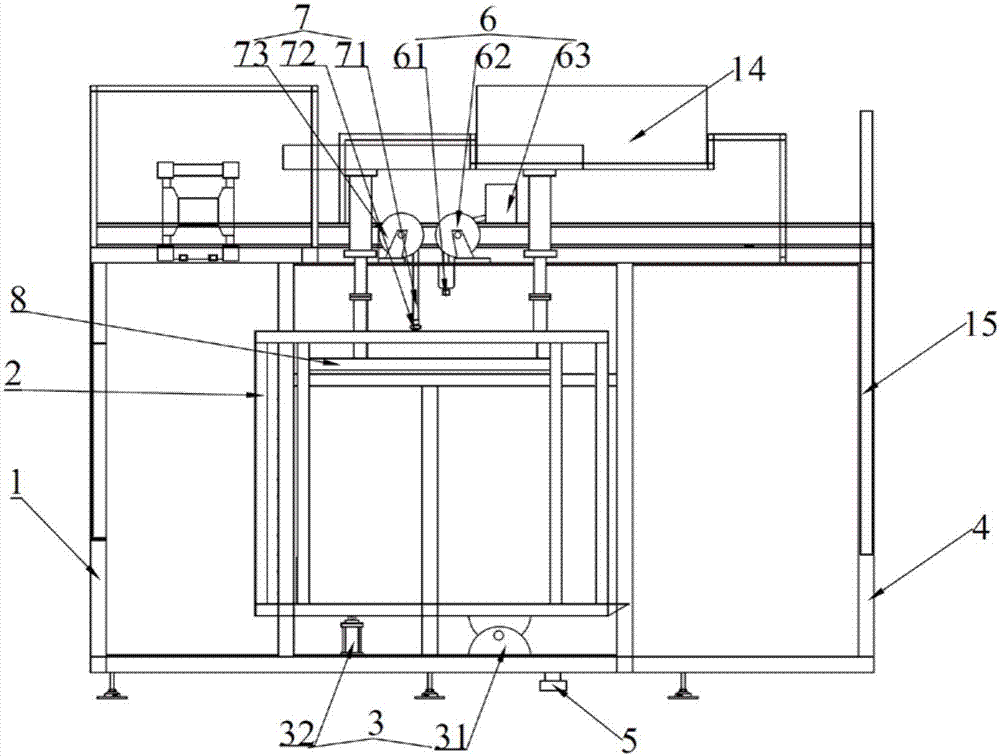

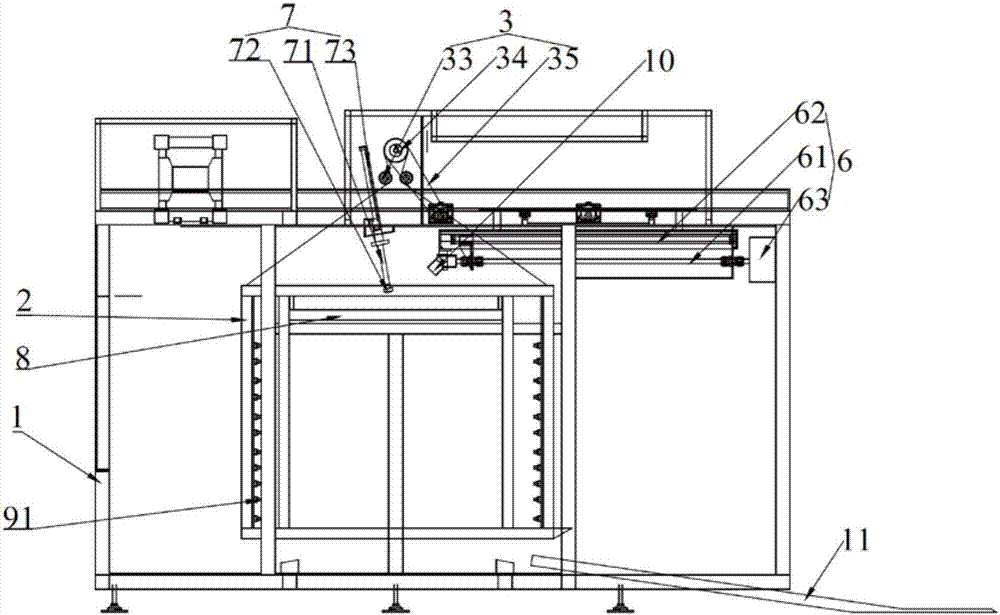

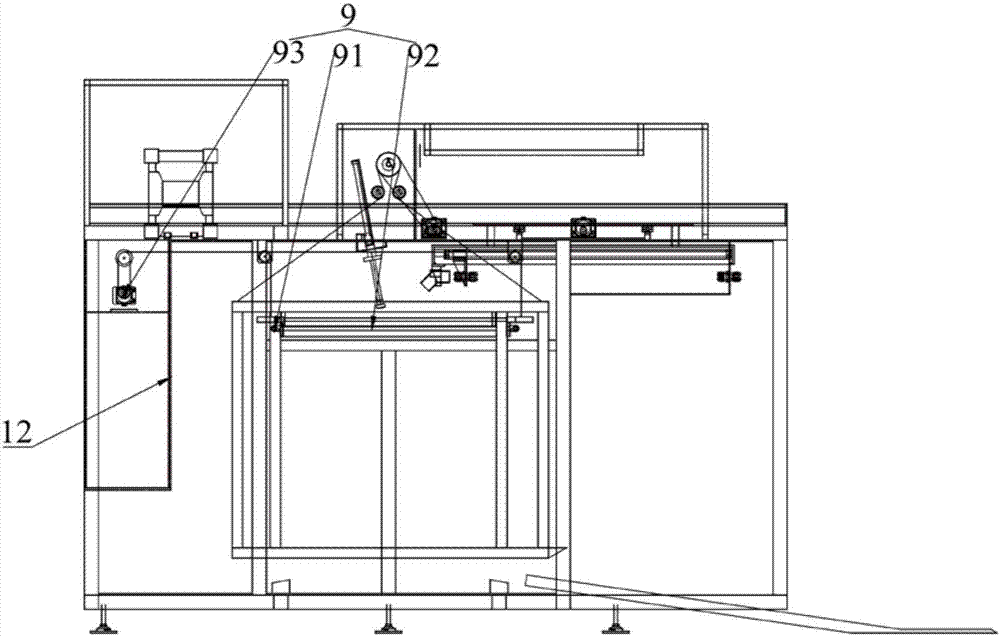

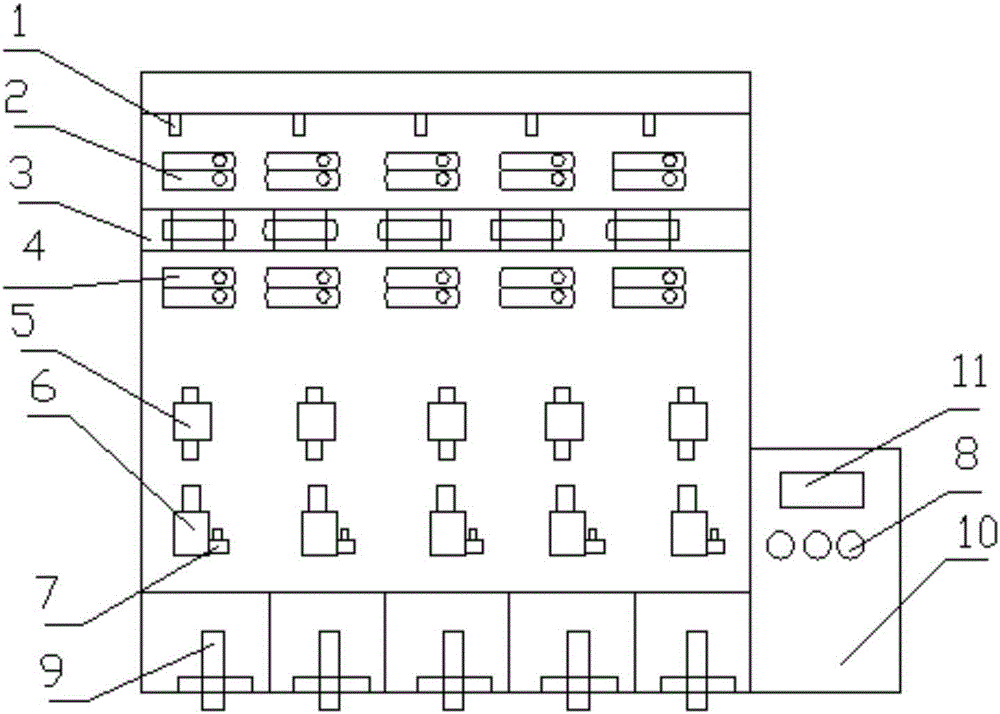

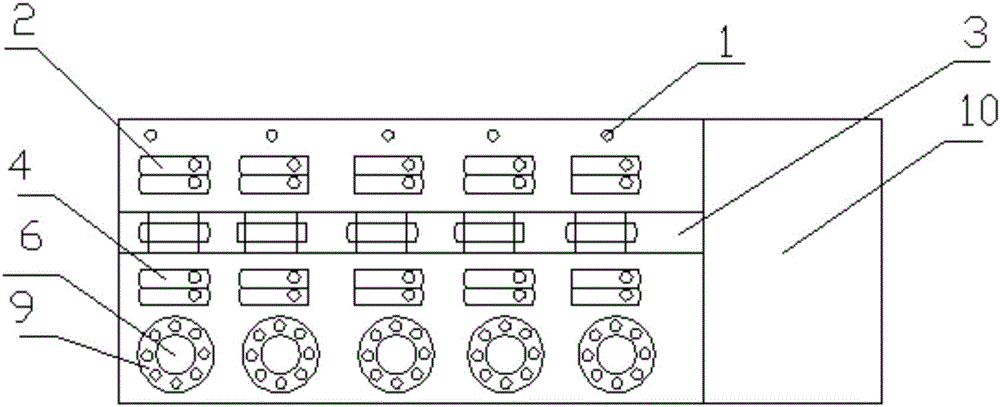

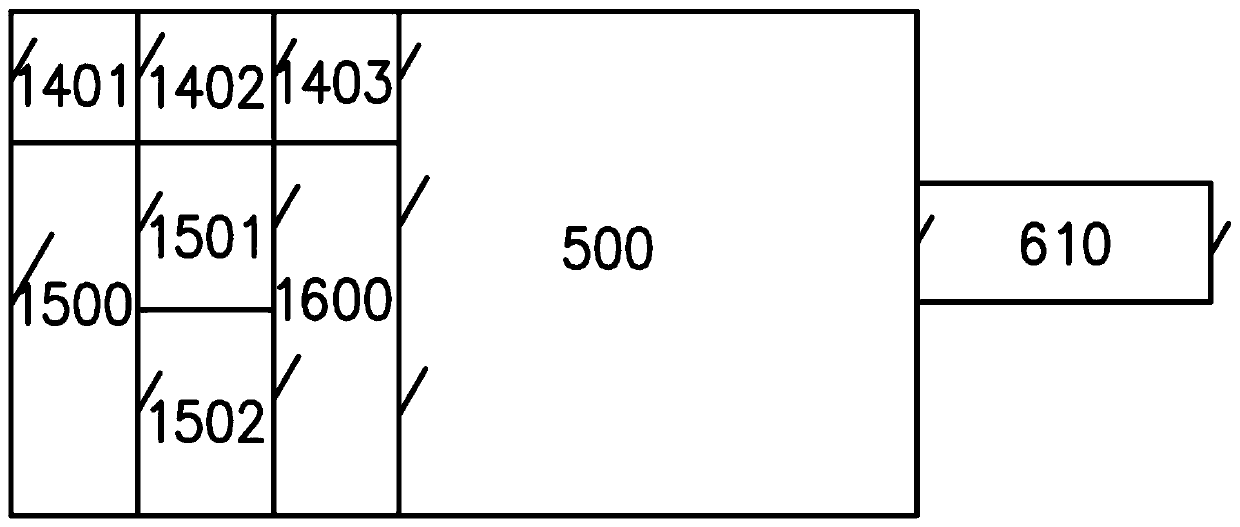

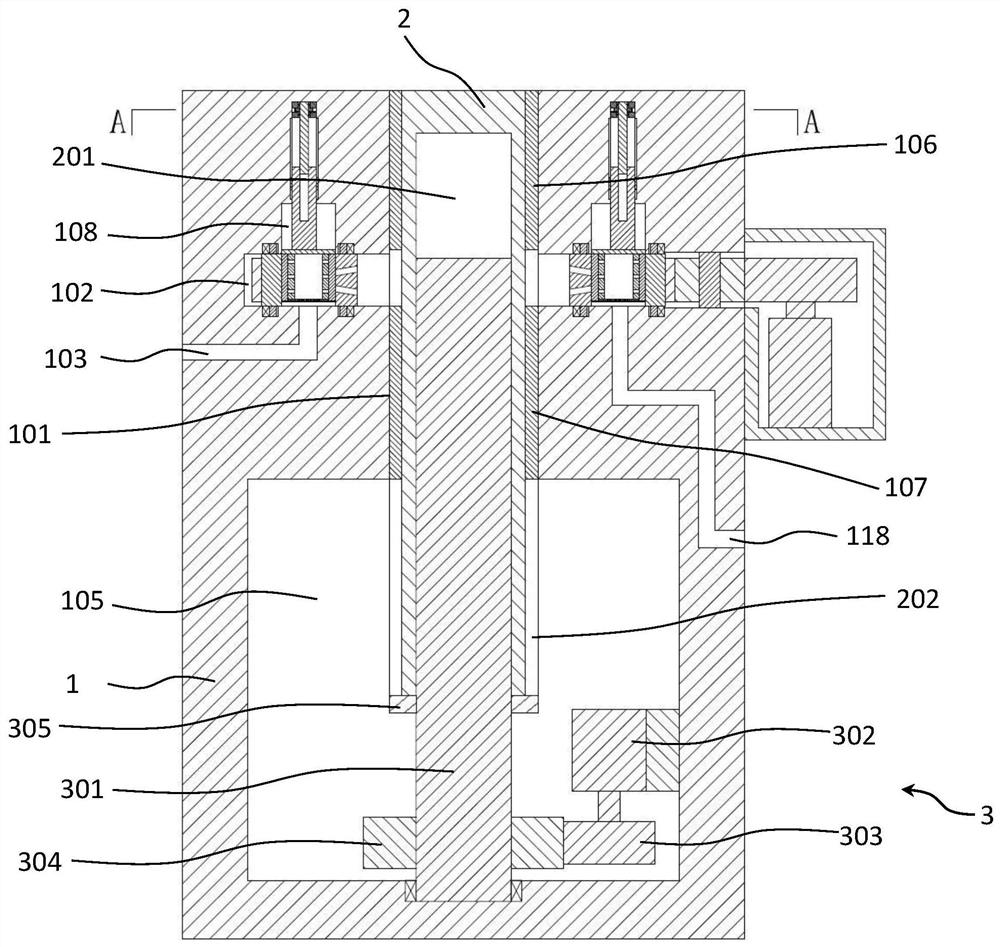

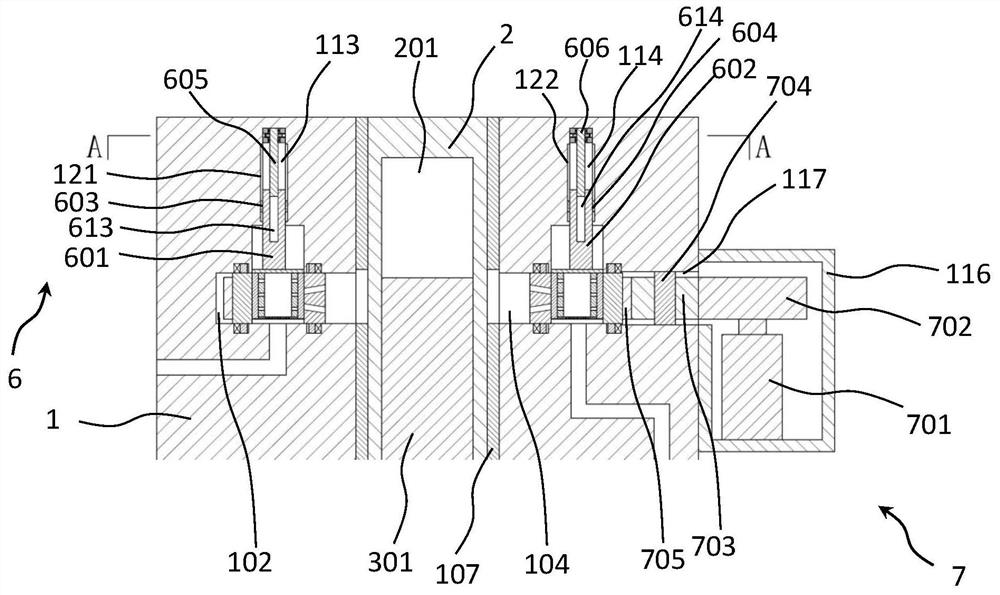

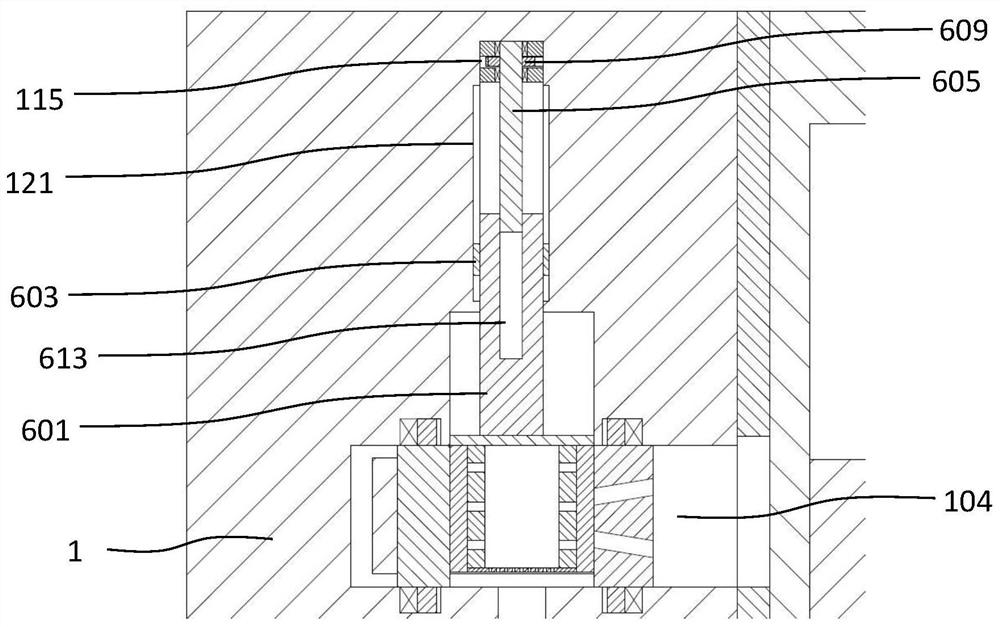

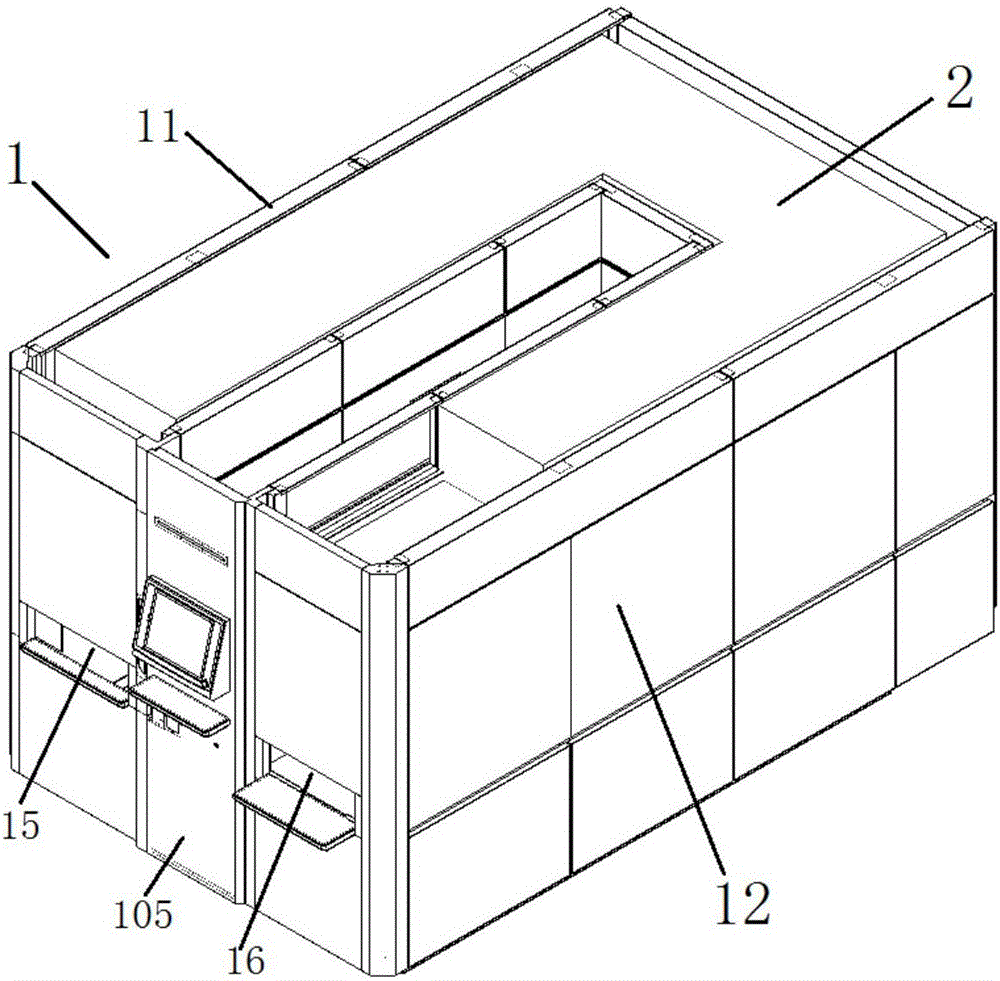

Cell culture equipment

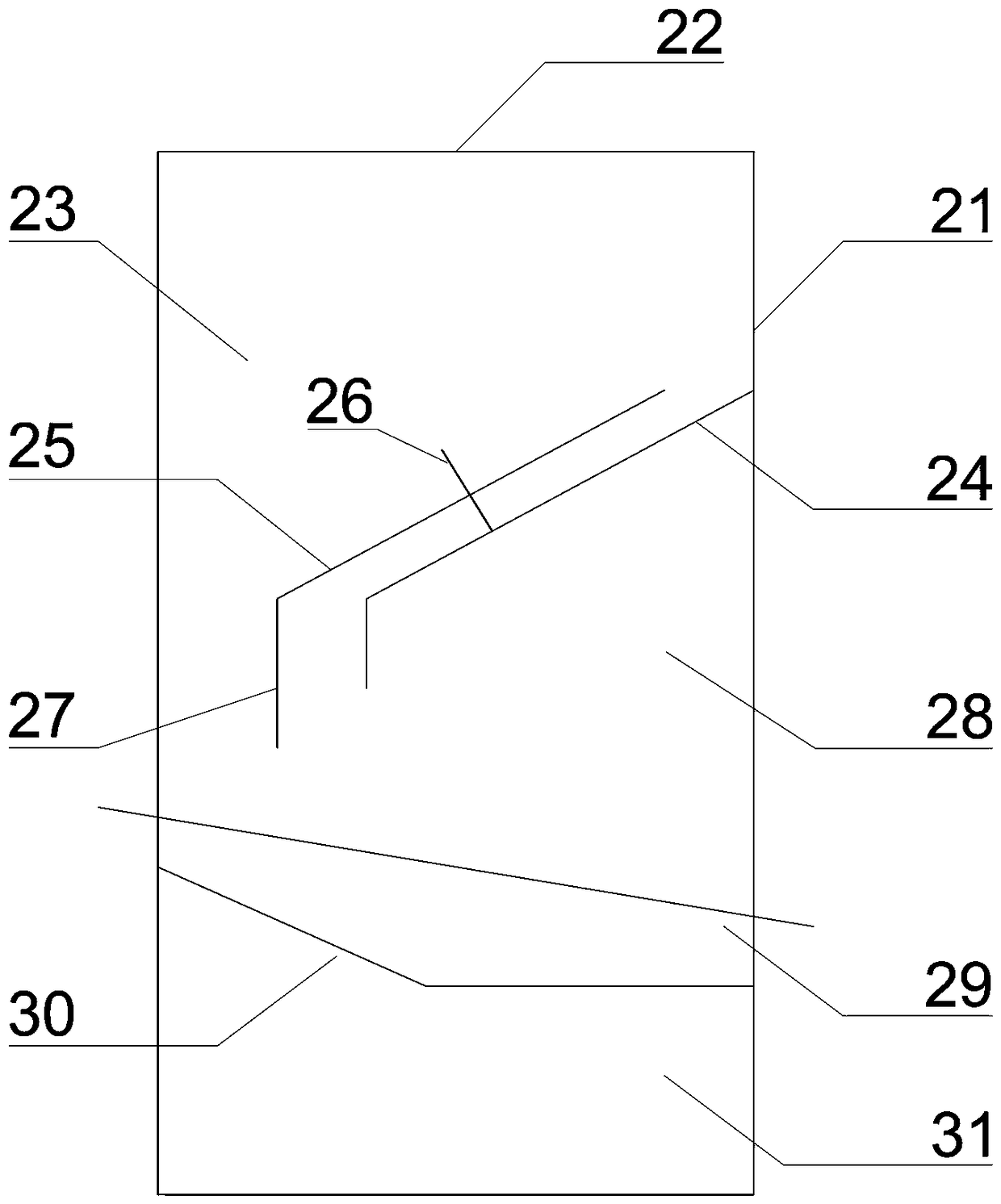

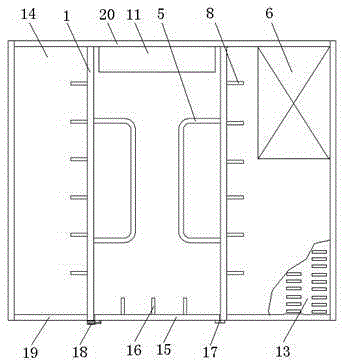

PendingCN108913602AAchieve isolationGuaranteed sterilityBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid ChangeAir filtration

The invention discloses cell culture equipment, and belongs to the technical field of biomedical cell culture. The cell culture equipment mainly comprises a sample injection chamber, a culture chamberand a motor chamber, and specifically comprises a culture dish conveying device, a culture dish-cover separation and closing device, a liquid changing device, an air filtering system, a disinfectingheating device, an automatic control system and a culture dish. According to the present invention, with the cell culture equipment, the isolation between the culture chamber and the outside world isachieved, the culture condition of the cells in the culture dish can be real-timely observed or shot and recorded, the automatic replacement of the culture liquid is achieved, and the gas in the culture dish and the gas in the culture chamber can be freely and smoothly exchanged while the water in the culture dish cannot be removed from the culture dish by evaporation. In the prior art, the pollution in the incubator is easily caused during the taking and placing of the culture dish, the manual adding or replacing of the culture liquid is cumbersome in the operation and easily causes the liquid changing error or the culture liquid pollution, and the growth condition of the cells in the culture dish is inconveniently observed. With the cell culture equipment of the present invention, the problems in the prior art can be solved.

Owner:山西正一康生物科技有限公司

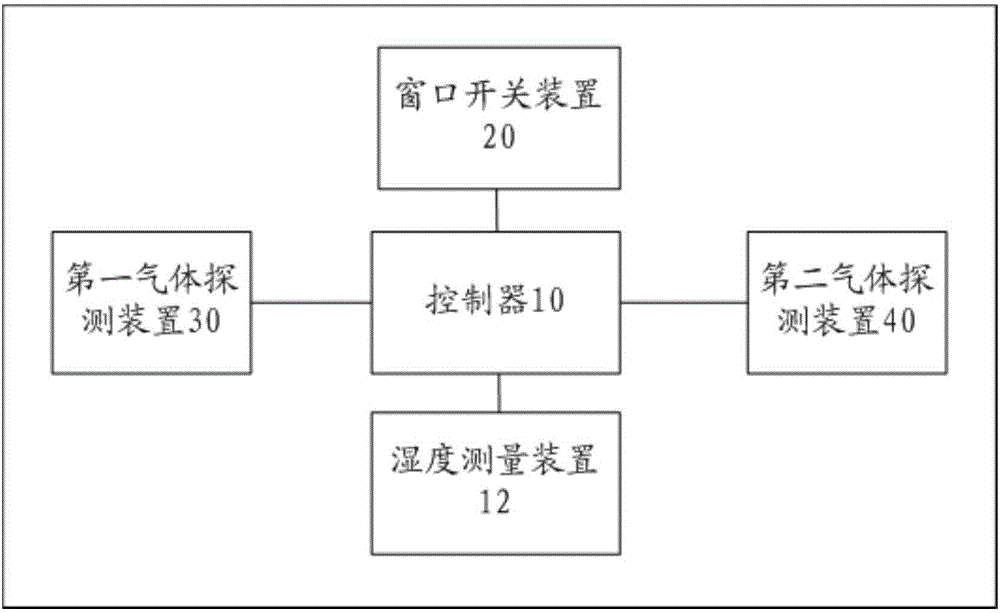

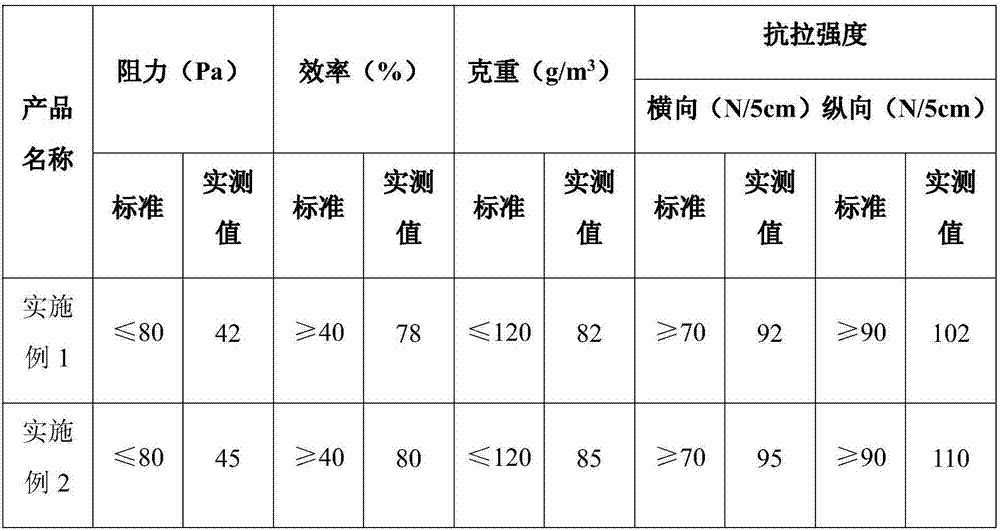

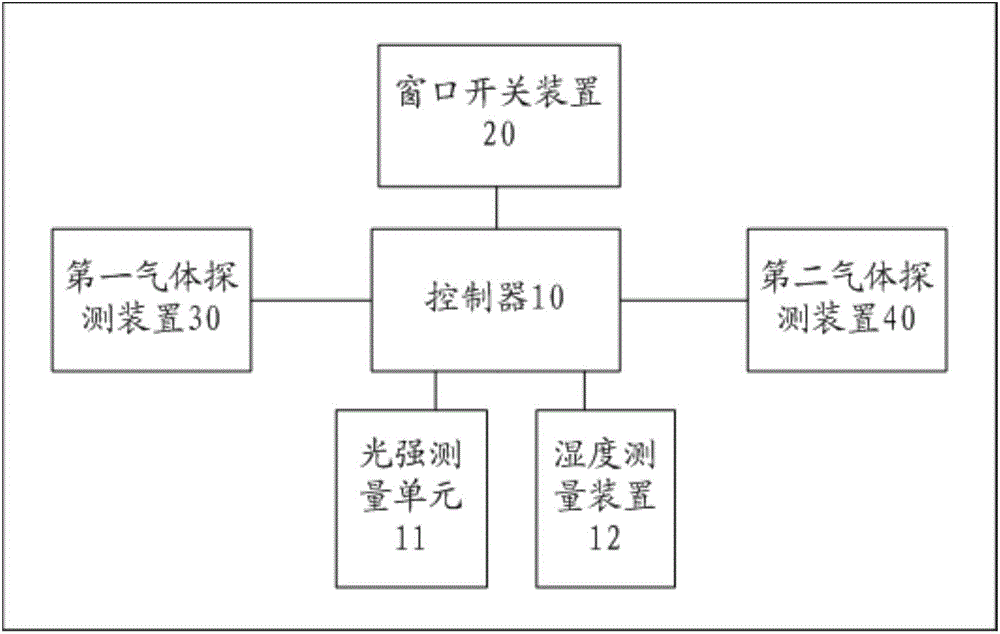

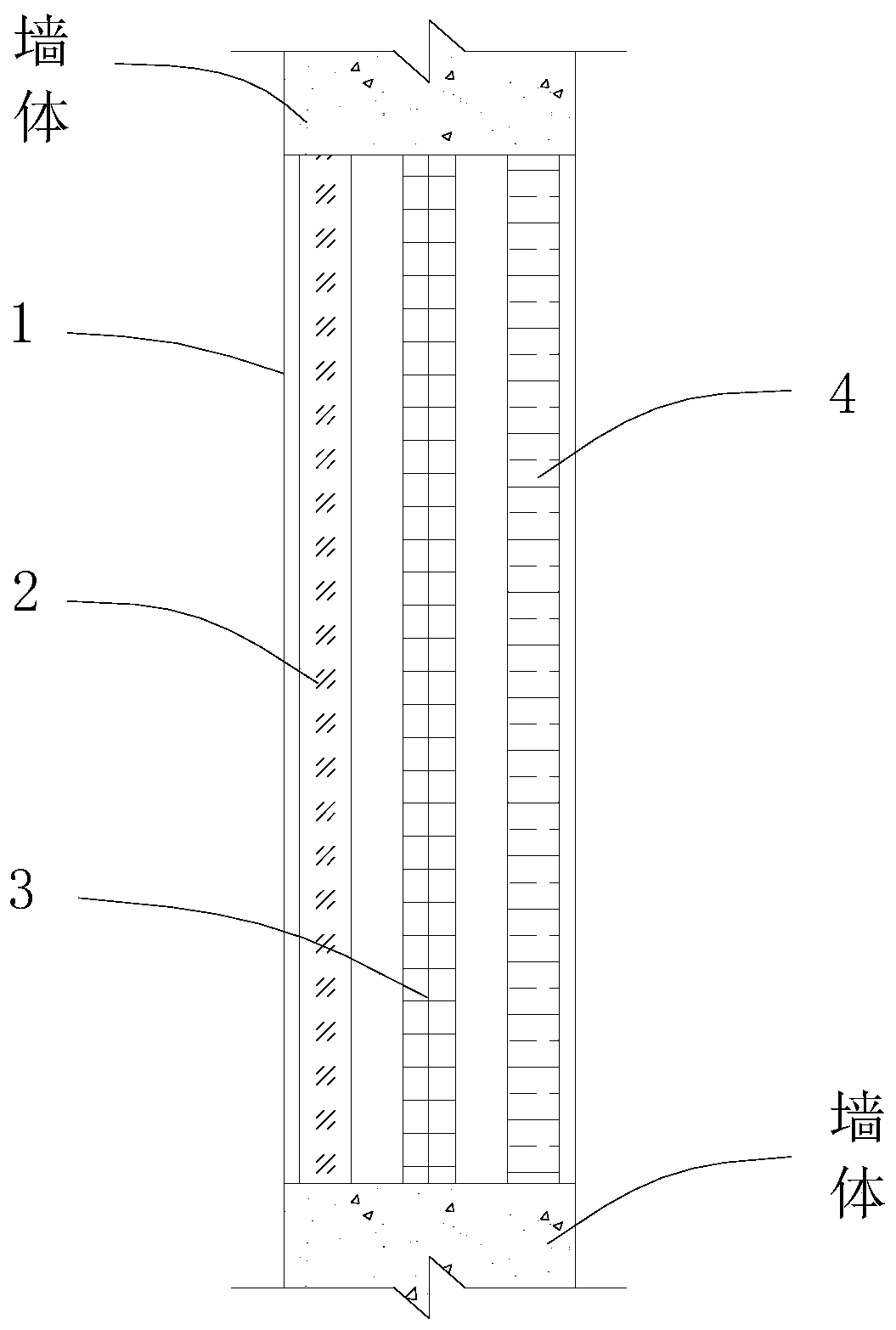

Full-automatic opening and closing type window

ActiveCN104316652AWon't get wetGuarantee a clean environmentTotal factory controlProgramme total factory controlMeasurement deviceWindow opening

The invention provides a full-automatic opening and closing type window. The Full-automatic opening and closing type window comprises a first gas detection device, a second gas detection device and a humidity measurement device, wherein the first gas detection device is used for analyzing indoor particles and detecting first concentration of indoor PM2.5; the second gas detection device is used for analyzing outdoor particles and detecting second concentration of the indoor PM2.5; and a control unit is used for comparing the first concentration and the second concentration when receiving the first concentration from the first gas detection device and the second concentration from the second gas detection device, and sending out a window opening signal to a window opening and closing device when a difference value obtained by subtracting the second concentration from the first concentration is greater than a preset concentration threshold value, so as to open the window by the window opening and closing device.

Owner:邵阳县家和门窗有限公司

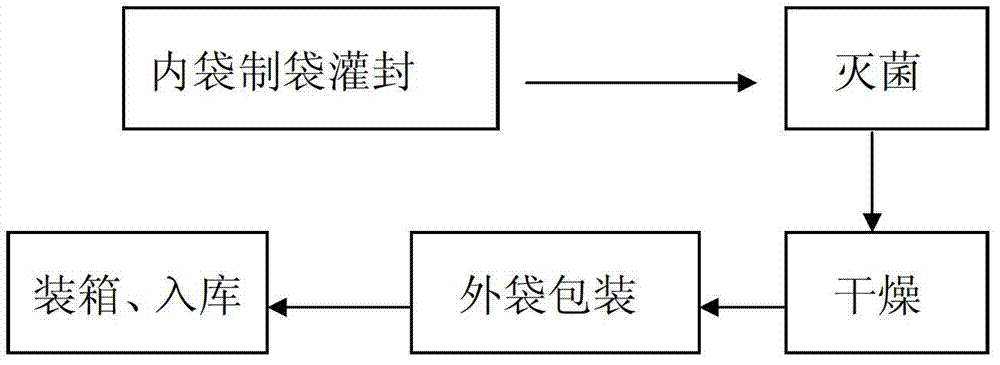

Production process for double-layer sterile flexibly-packaged infusion bag

InactiveCN102730207ANo requirements for high temperature resistance to sterilizationUniform penetrationFlexible coversWrappersGuide tubeBiomedical engineering

The invention relates to a production process for an infusion bag, and particularly to a production process for a double-layer sterile flexibly-packaged infusion bag. The production process comprises the following steps of: (1) producing an infusion film into a bag, filling a medicine liquid, and then sealing; (2) placing the filled-sealed inner packaging bag in a sterilization device to sterilize; (3) blowing clean air into the sterilized inner packaging bag to dry the sterilized inner packaging bag; (4) in a clean room, performing a lamp inspection on the dried inner packaging bag, and conveying the dried inner packaging bag to a packaging machine to package an outer packaging bag, so as to obtain the double-layer sterile flexibly-packaged infusion bag, wherein ozone is directly conveyed to be in front of a transversal seal from a vertical seal of the packaging machine via a gas guide tube, so as to be filled between the inner packaging bag and the outer packaging bag; and (5) boxing and warehousing. According to the invention, the production process of sterilizing at first and then packaging is adopted, thus decreasing cost and simplifying the process flow; and moreover, the sterilization effect is good.

Owner:SHANDONG QIDU PHARMA

Preparation For Wound Healing And Prevention Of Bandage Adhesion To The Wound, Containing Chitosan-Glucan

The invention relates to a preparation containing a pharmacologically suitable chitosan-glucan complex or a salt thereof, either alone or in combination with one or more polysaccharides or suitable salts thereof and an antiseptic agent, that is intended for wound healing and that, besides accelerating wound healing, is at the same time able to prevent a bandage adhesion to the wound. The preparation according to the invention, having been applied, indirectly supports the healing processes in the wound and drains the redundant secretion together with the tissue mediators and enzymes that support the healing. By doing this, it provides for the necessary hydration of the wound and its surroundings, without any maceration of the surrounding skin or drying and sticking to the wound. An addition of antiseptic agents prevents a further infection. The preparation contains 0.01 to 100% by weight of chitosan-glucan complex, 0 to 99.99% by weight of another polysaccharide and 0 to 50% by weight of an antiseptic agent.

Owner:CONTIPRO BIOTECH

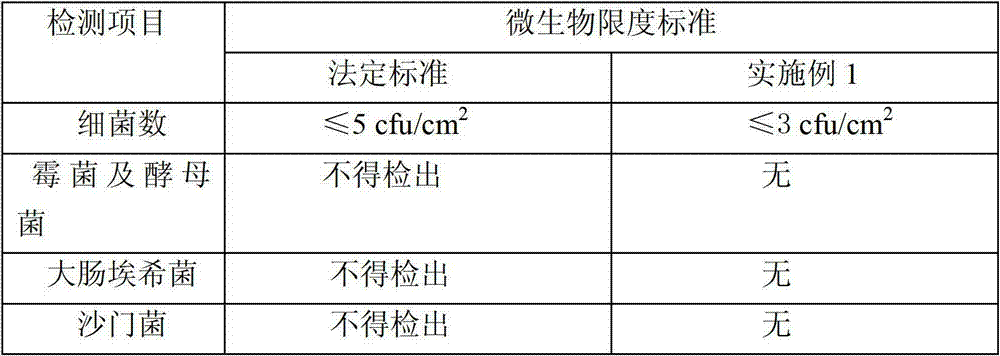

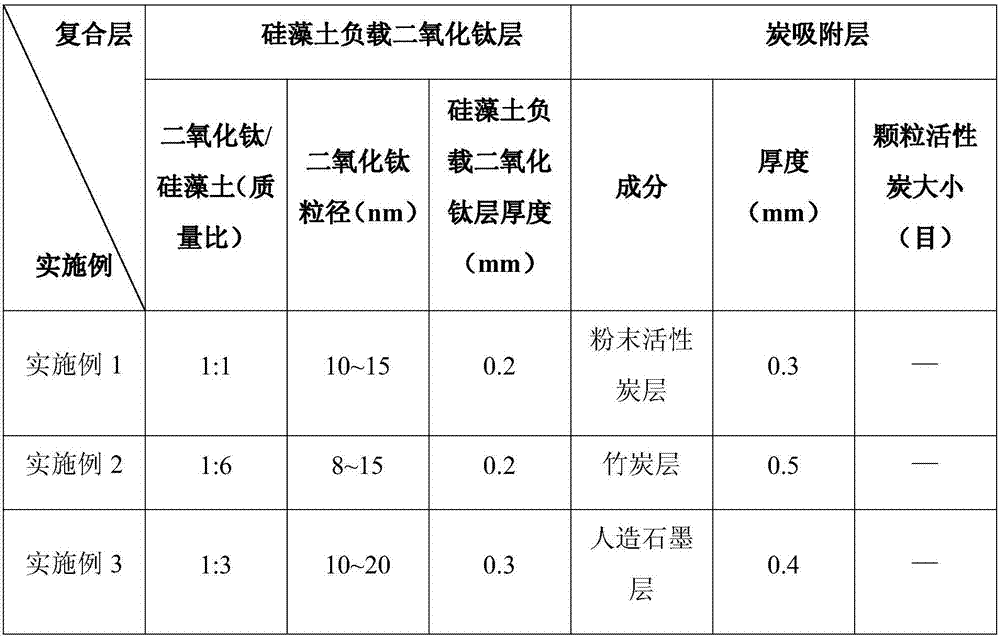

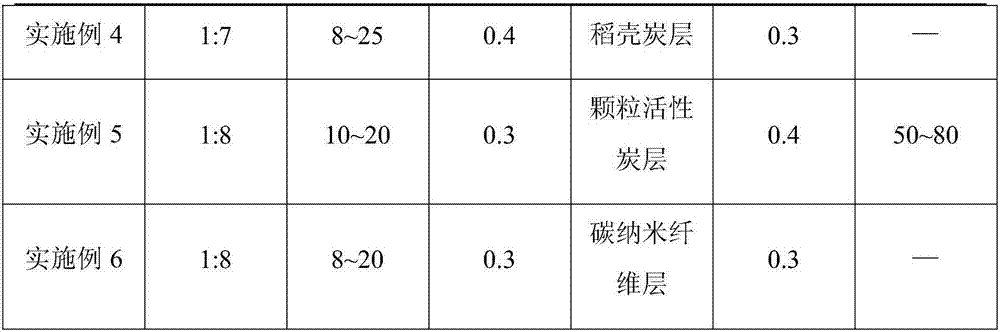

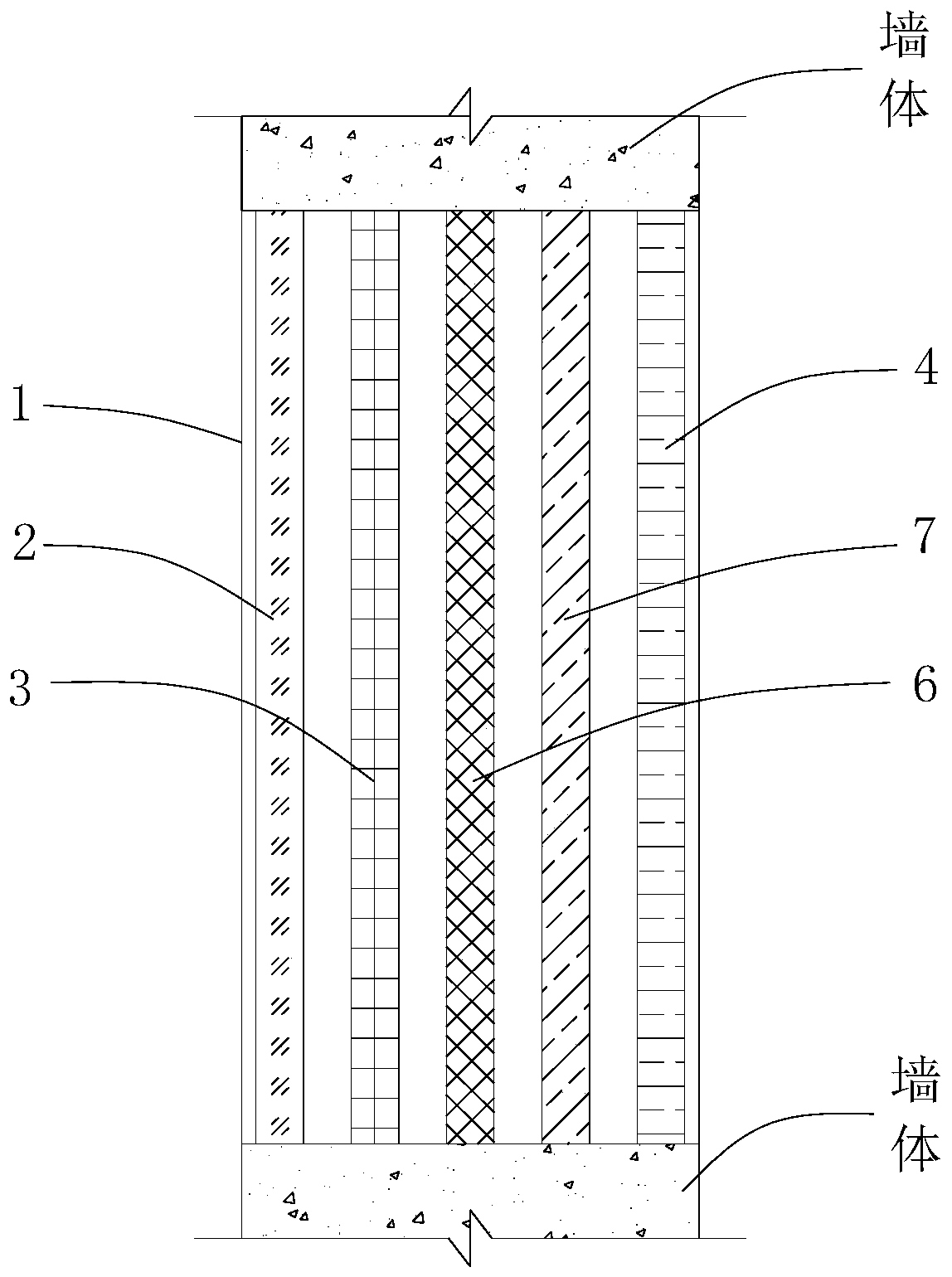

Air filtering material

InactiveCN107198906AEffective combinationImprove adsorption capacityBiocideDispersed particle filtrationFiberAir filtration

The invention provides an air filtering material, which comprises a base material and a compound layer, wherein the base material consists of an upper layer of carbon fiber reticular filtering cloth and a lower layer of carbon fiber reticular filtering cloth; the compound layer is positioned between the upper layer of carbon fiber reticular filtering cloth and the lower layer of carbon fiber reticular filtering cloth and comprises a kieselguhr loaded titanium dioxide layer and a carbon material adsorption layer from top to bottom in sequence. In the air filtering material, the kieselguhr loaded titanium dioxide layer and the carbon material adsorption layer are taken as main adsorption layers so as to effectively combine physical adsorption with chemical adsorption. While small particles are filtered, volatile organic compounds can be degraded into poisonless and harmless CO2 and H2O as well as corresponding inorganic ions, and therefore, the air filtering material has the advantages of no secondary pollution, high adsorption function, obvious filtering effect and wide popularization function.

Owner:长沙善道新材料科技有限公司

Remote-control intelligent fully-automatically opening and closing window

InactiveCN104343312AQuality improvementEnsure safetyPower-operated mechanismMeasurement deviceRemote control

The invention provides a remote-control intelligent fully-automatically opening and closing window. The window comprises a first gas detector, a second gas detector and a humidity measurement device, wherein the first gas detector is used for analyzing indoor particles and detecting the first concentration of indoor PM2.5; the second gas detector is used for analyzing outdoor particles and detecting the second concentration of the indoor PM2.5; when the first concentration from the first gas detector and the second concentration from the second gas detector are received by a control unit, the first concentration is compared with the second concentration, a window opening signal is sent to a window opening and closing device when a difference value obtained by subtracting the second concentration from the first concentration is greater than a preset concentration threshold, and the window is opened by the window opening and closing device.

Owner:YUYAO DAQI PLASTIC & RUBBER PROD

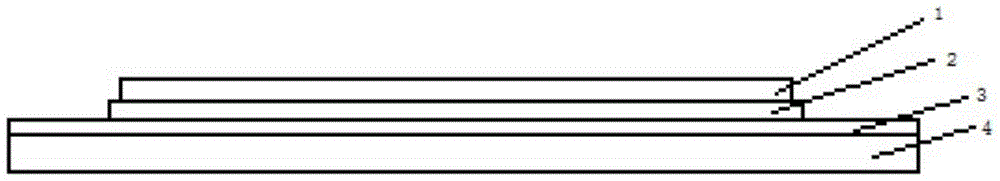

Medical dressing for treating large area wound and manufacturing method thereof

InactiveCN105662713APromote healingAnti-water intrusionPlastersAdhesive dressingsWound healingBurning Pain

The invention discloses a medical dressing for treating a large area wound and a manufacturing method thereof. The medical dressing is composed of from top to bottom: an isolation paper, a sodium alginate hydrogel, a non-woven fabric, a medical glue layer and a base cloth; or from top to bottom, an isolation paper, an alginate hydrogel, a medical glue layer and a base cloth. The sodium alginate hydrogel is a hydrogel mixed by 100 percent pure sodium alginate crystals and water. The alginate hydrogel is a hydrogel, which assumes a transparent gel shape formed by immersing a 100 percent pure calcium alginate non-woven fabric to a sodium alginate solution, automatically converts between a solid state and a liquid state based on changes of using state. The novelty of the invention lies in combining a material which promotes curing of the wound and a material which is secured to body surface. The medical dressing of the invention has the advantages of outside water resistance, extra-long adhering time, and simple operation and usage. The medical dressing of the invention faces towards the wound in humid environment, which promotes healing. The medical dressing can also reduce burning pain caused by the large area wound, prevent infection and wound adhesion, block bacteria from entering, and reduce times for changing medicine.

Owner:WUXI HENGCHENG MEDICAL TECH CO LTD

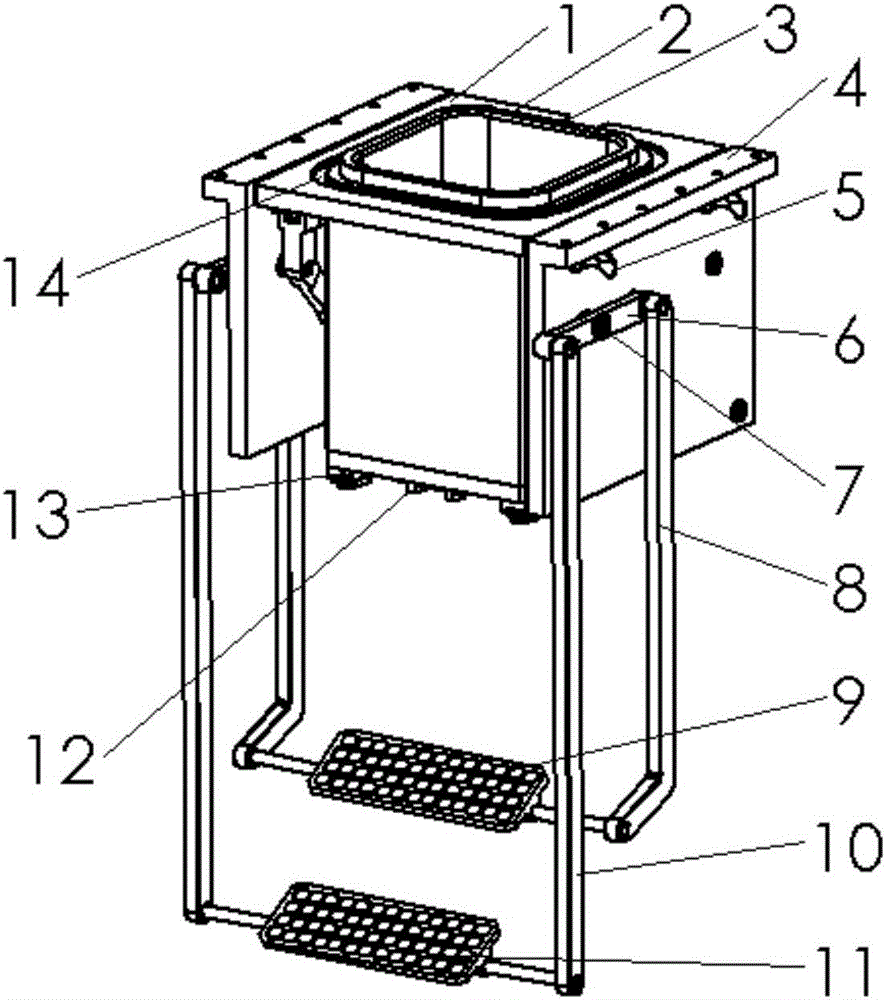

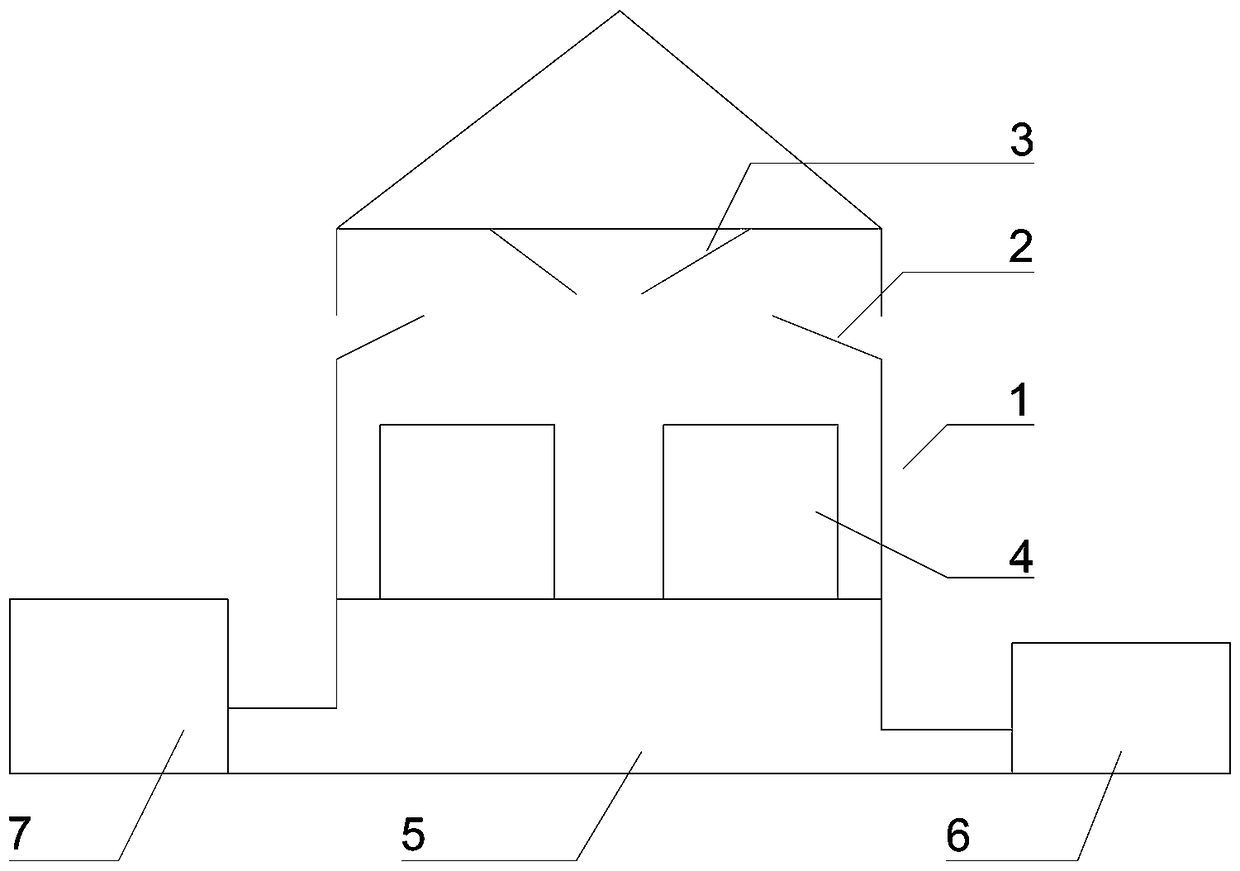

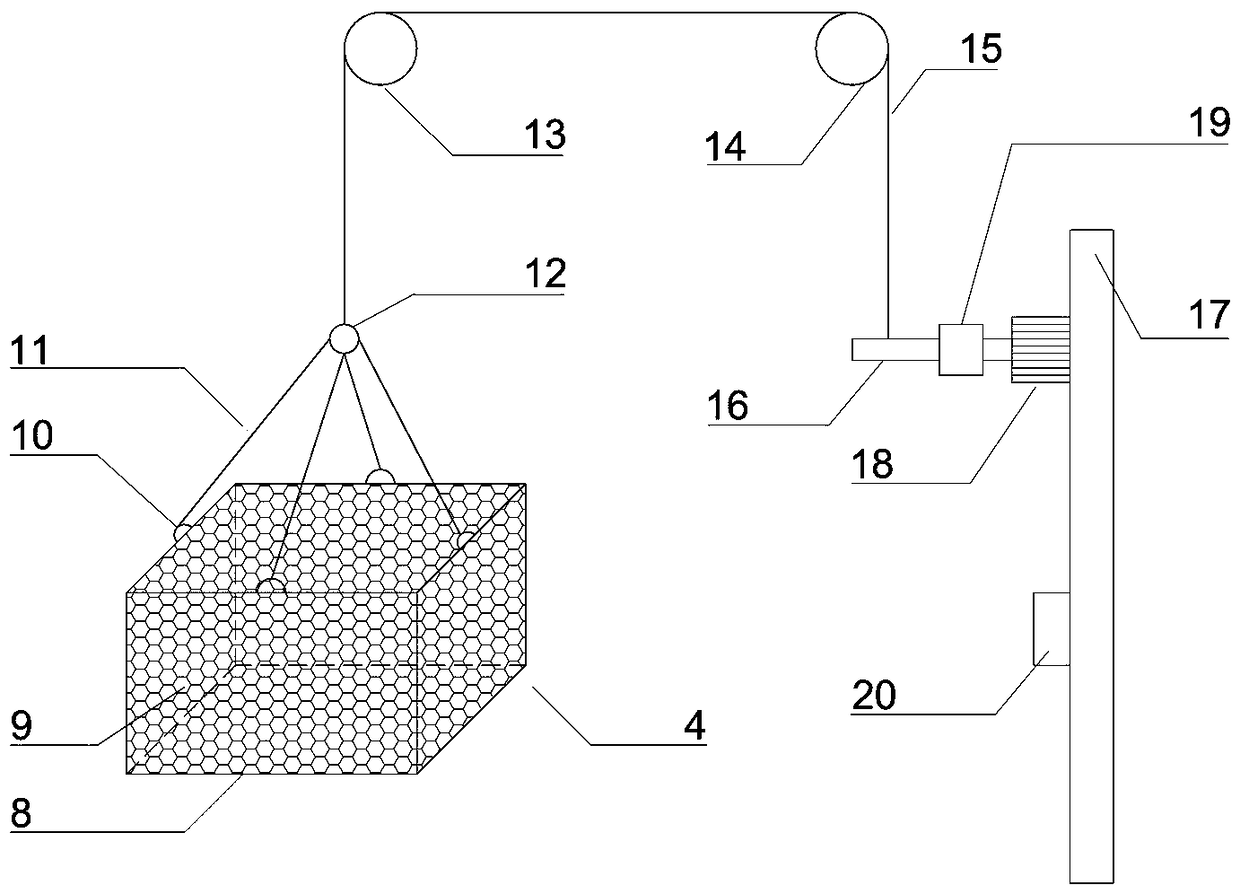

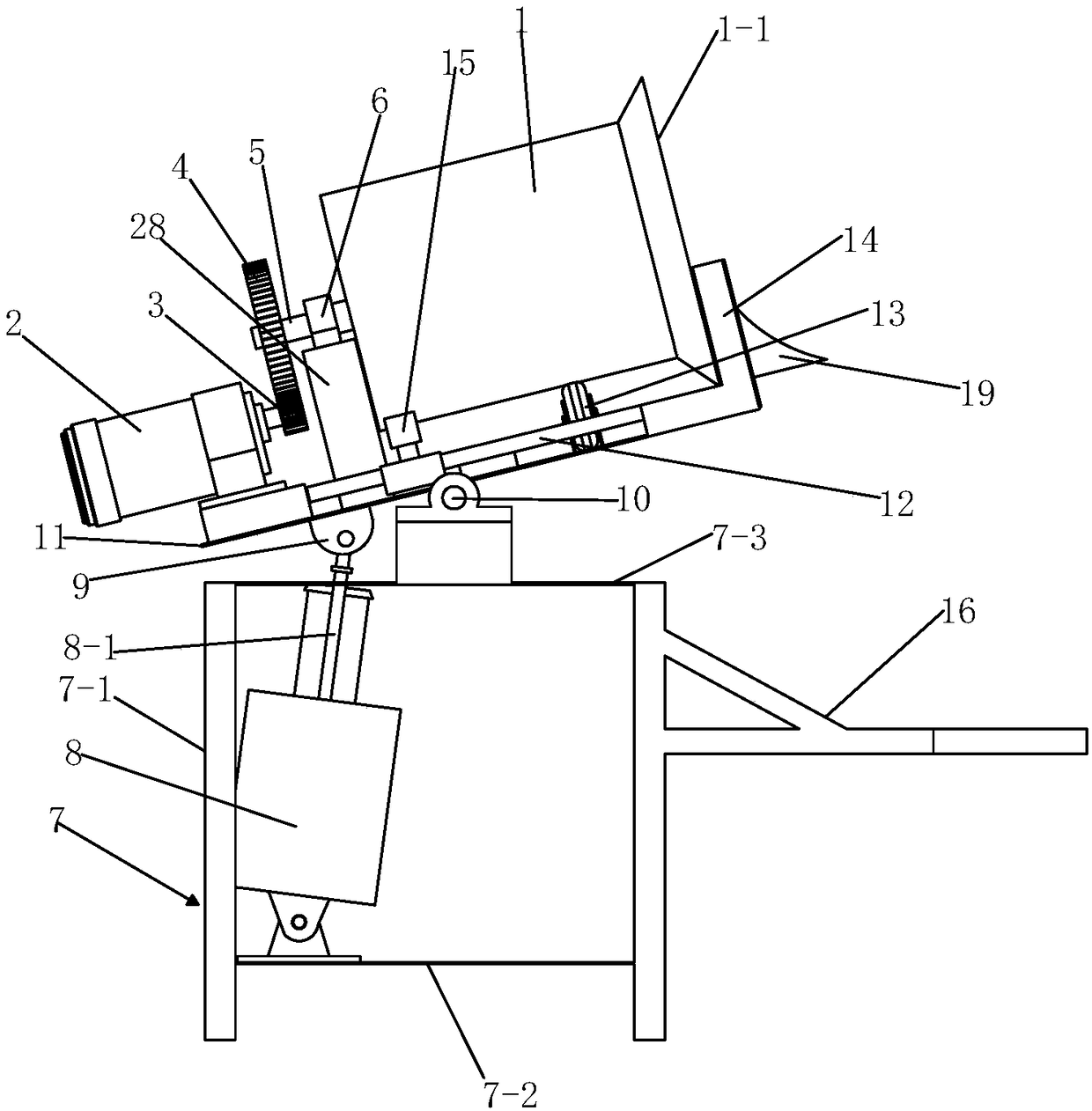

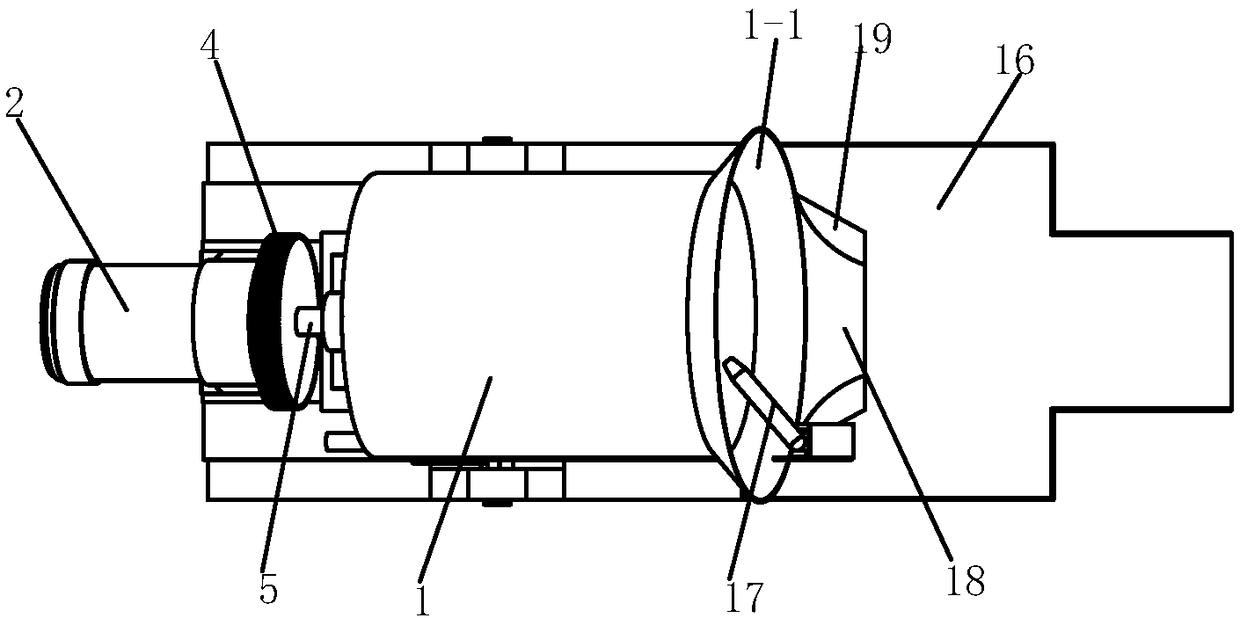

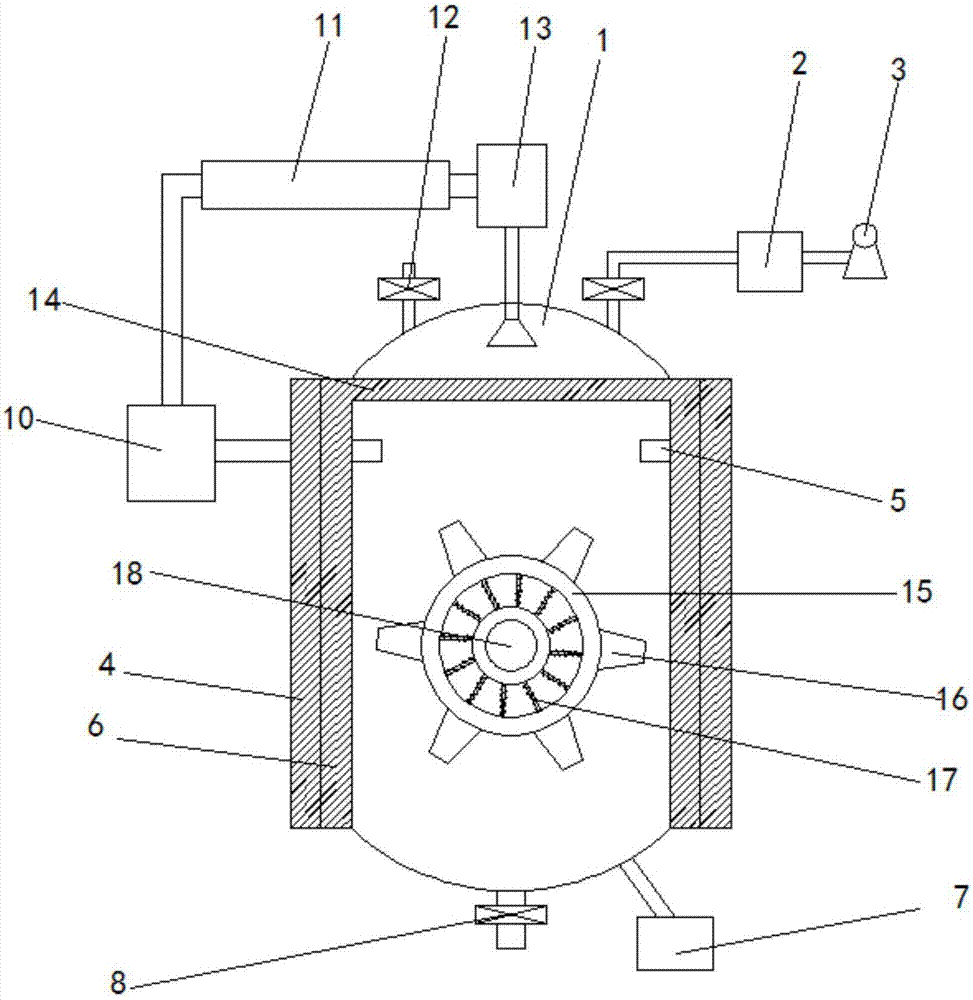

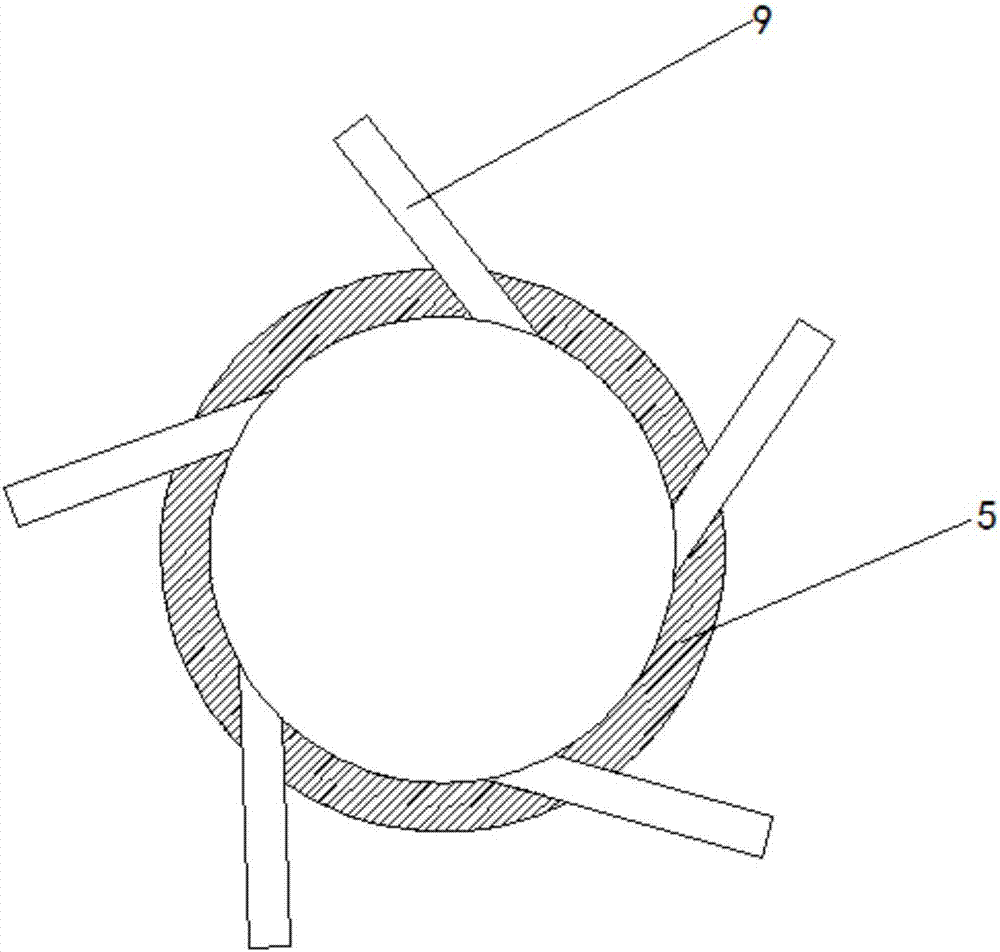

Cleaning device for intermediate bulk container for liquid chemicals

ActiveCN107088568ASimple structureExtract completelyHollow article cleaningIntermediate bulk containerCompound (substance)

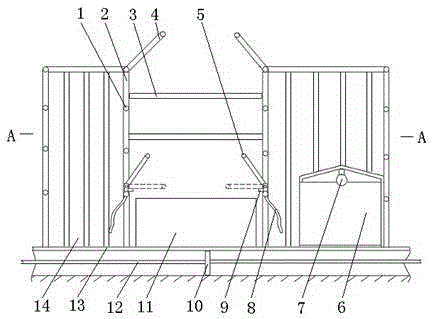

The invention discloses a cleaning device for an intermediate bulk container for liquid chemicals. The cleaning device for the intermediate bulk container for the liquid chemicals comprises a cleaning chamber, an intermediate bulk container carrying frame and an overturning mechanism, wherein an intermediate bulk container inlet-outlet is formed in one side of the cleaning chamber; a cleaning waste liquid outlet is formed in the bottom end of the cleaning chamber; the overturning mechanism is used for driving the intermediate bulk container carrying frame to overturn in the inner cavity of the cleaning chamber; a limit element matched with the intermediate bulk container is arranged on the intermediate bulk container carrying frame; and an inner liquid pumping assembly for the intermediate bulk container and an inner wall cleaning assembly for the intermediate bulk container are arranged at the top end of the intermediate bulk container carrying frame. The cleaning device for the intermediate bulk container for the liquid chemicals is simple in structure; the structure is capable of ensuring a clean environment for cleaning operation through the arrangement of the cleaning chamber and the intermediate bulk container carrying frame capable of overturning; and the intermediate bulk container carrying frame drives the intermediate bulk container to overturn, so that a residual liquid and a cleaning liquid in the intermediate bulk container can be thoroughly pumped away, and the usage amount of the cleaning liquid and the treatment amount of a cleaning waste liquid are reduced.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

Intelligent fully-automatic opening/closing window

InactiveCN104153675AWon't get wetGuarantee a clean environmentPower-operated mechanismWindow openingEngineering

The invention provides an intelligent fully-automatic opening / closing window which comprises a first gas detection device, a second gas detection device and a humidity measuring device. The first gas detection device analyzes indoor particles and detects the first concentration of the indoor PM 2.5. The second gas detection device analyzes outdoor particles and detects the second concentration of the indoor PM 2.5. A control unit compares the first concentration with the second concentration when receiving the first concentration from the first gas detection device and the second concentration from the second gas detection device and sends a window opening signal to a window switch device so that the window can be opened by the window switch device when the difference value generated by subtracting the second concentration from the first concentration is larger than the preset concentration threshold.

Owner:王波兰

Wool jetting machine

The invention relates to a wool jetting machine. The wool jetting machine comprises wool strip clamping positions, pressing wheels, bubble pressing wheels, fiber stretching wheels, negative pressure generators, work drums, motors, control switches, yarn winding bars, a variable frequency control box and a display panel, and the wool strip clamping positions, the pressing wheels, the bubble pressing wheels, the fiber stretching wheels, the negative pressure generators, the work drums and the yarn winding bars are arranged on a rack of the wool jetting machine from top to bottom; belts are arranged on the motors and connected with the work drums; the variable frequency control box is arranged on one side of the rack of the wool jetting machine; the control switches and the display panel are arranged on the variable frequency control box. According to the wool jetting machine, the belts are driven in a joint driving mode, the power of each motor is reduced from 31 KW to 25 KW, the cost is reduced to 5,000 yuan per spindle from 7,000 yuan per spindle, energy consumption is reduced by 20%, and the cost is reduced by 30%; the soft characteristic of jet wool yarn still exists, and the wool losing and ununiform wool jetting phenomena are not prone to occur.

Owner:嘉鱼柯特纺织股份有限公司

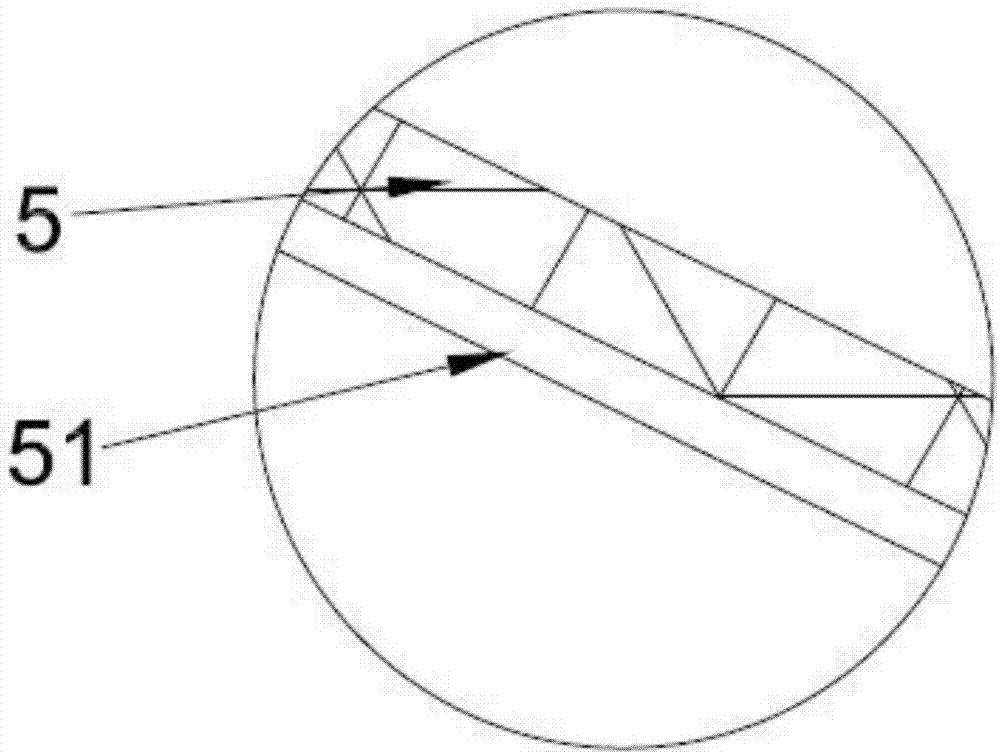

Push-pull type selective laser melting (SLM) device forming cylinder capable of rising and falling

ActiveCN105921882AEasy to replaceGuaranteed stabilityLaser beam welding apparatusPush pullEngineering

Owner:XI AN JIAOTONG UNIV +1

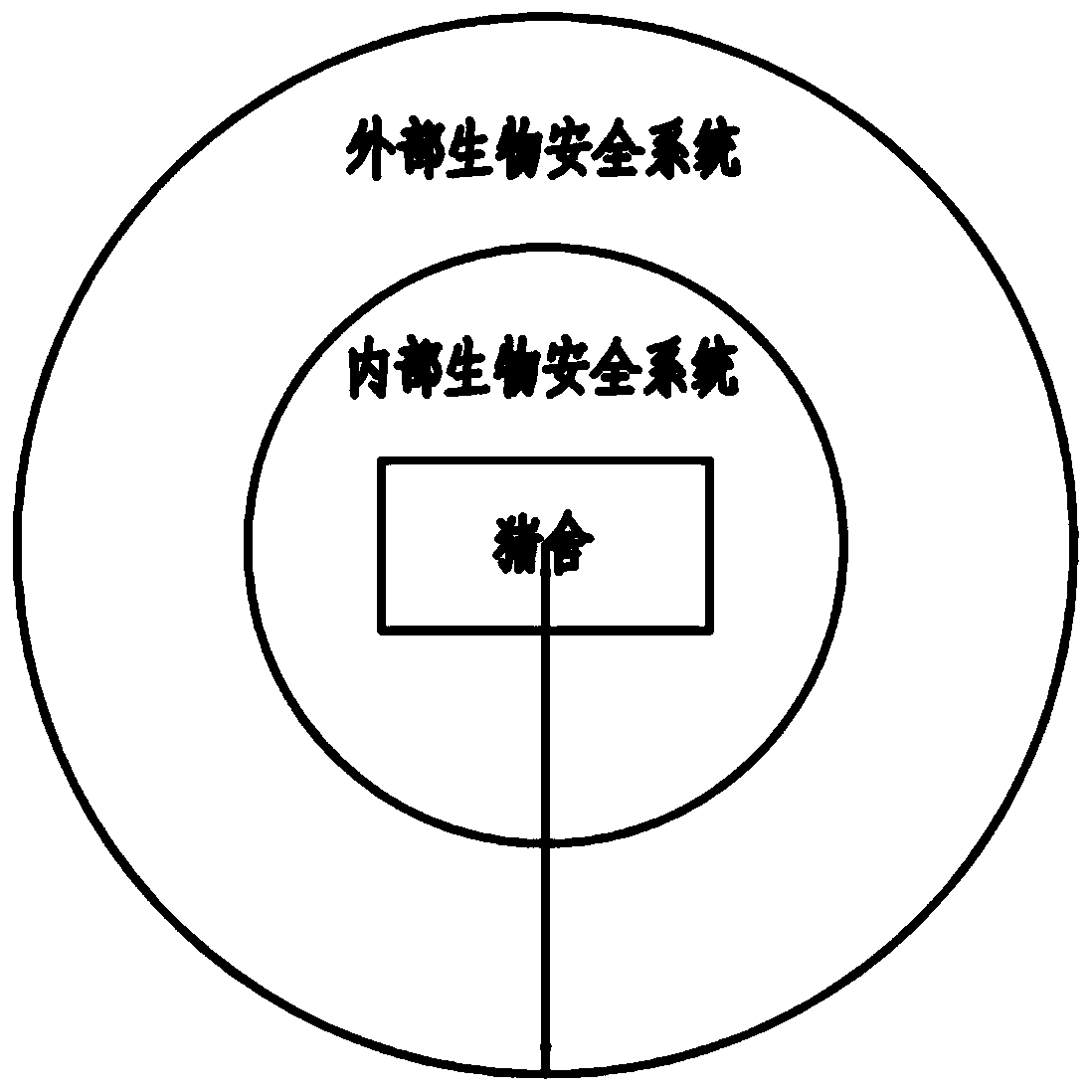

Biological safety system for pig farm

The invention discloses a biological safety system for a pig farm. The biological safety system comprises an inner biological safety system arranged in the pig farm, and an outer biological safety system arranged out of the pig farm, wherein the inner biological safety system comprises a production line personnel disinfection channel, a production line material disinfection channel, a road disinfection vehicle used for disinfecting the inner roads and facilities of the pig farm, a living area and production area fence, a front dressing room, a material library used for storing materials in thepig farm, and a pig discharging table used for sending pigs out of the pig farm or sending pigs into the pig farm; the outer biological safety system comprises a peripheral safety system arranged ina place which is far away from the pig farm for more than a preset distance, and an out-of-farm safety system arranged in the peripheral safety system out of a pig farm area; and the entering and leaving channel of each part of the inner biological safety system and the outer biological safety system only can carry out single-direction circulation.

Owner:黑龙江大北农食品科技集团有限公司 +2

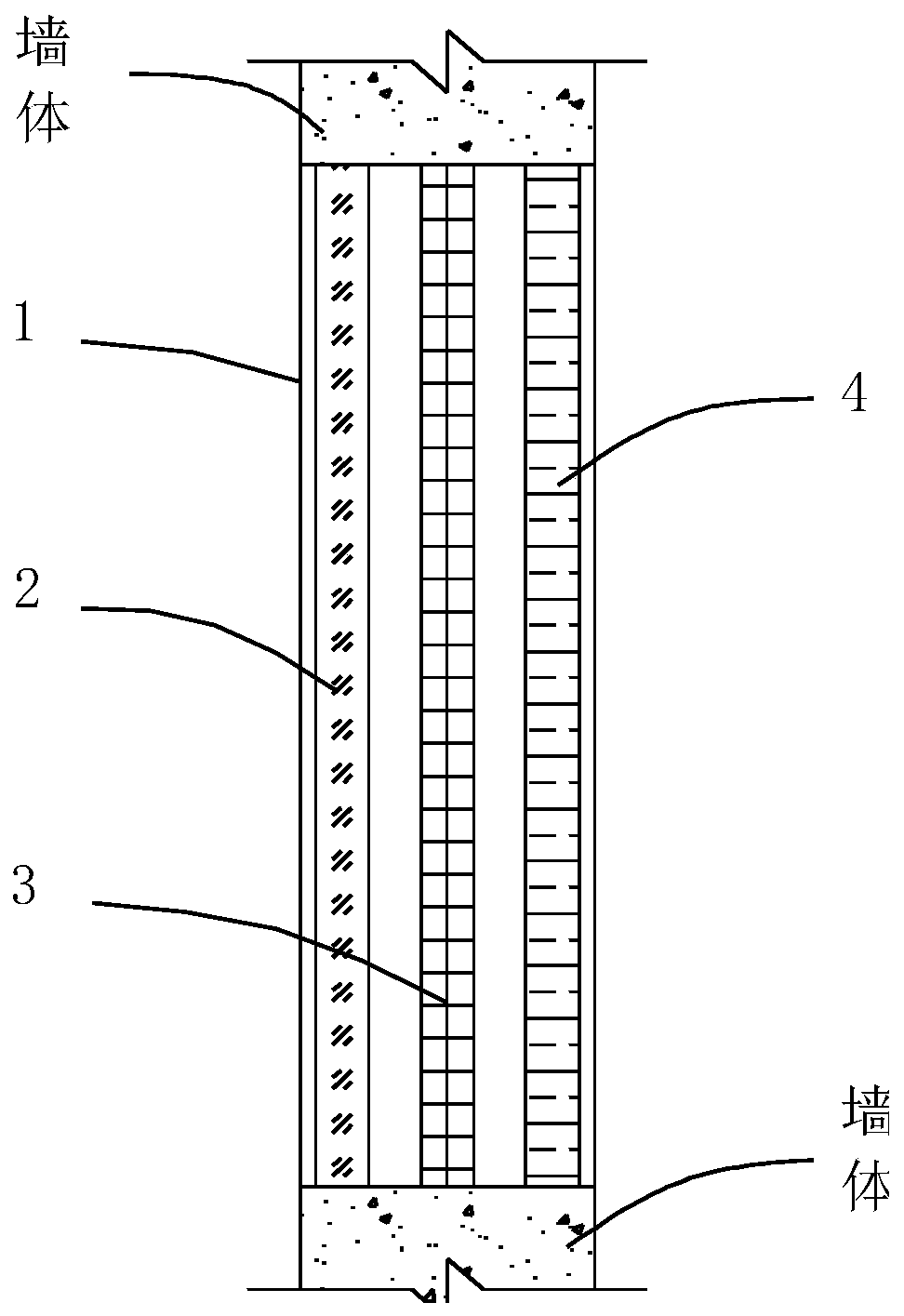

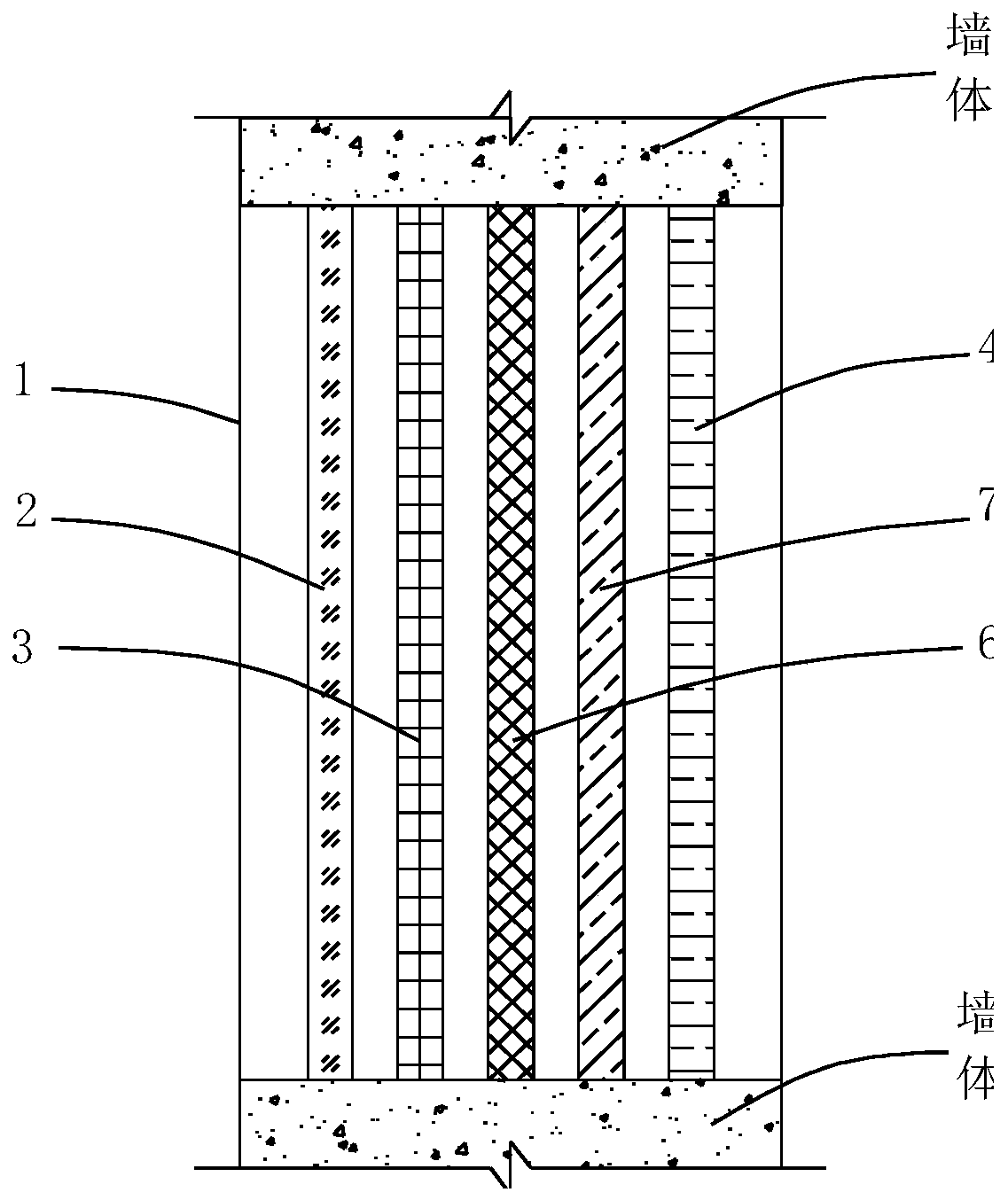

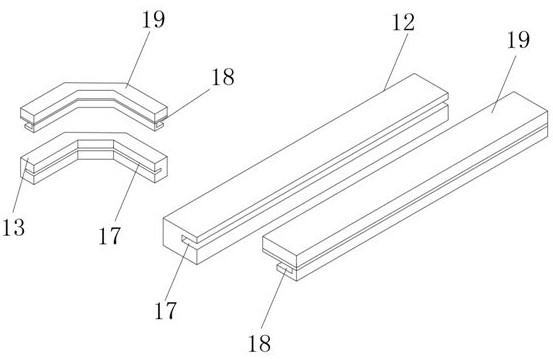

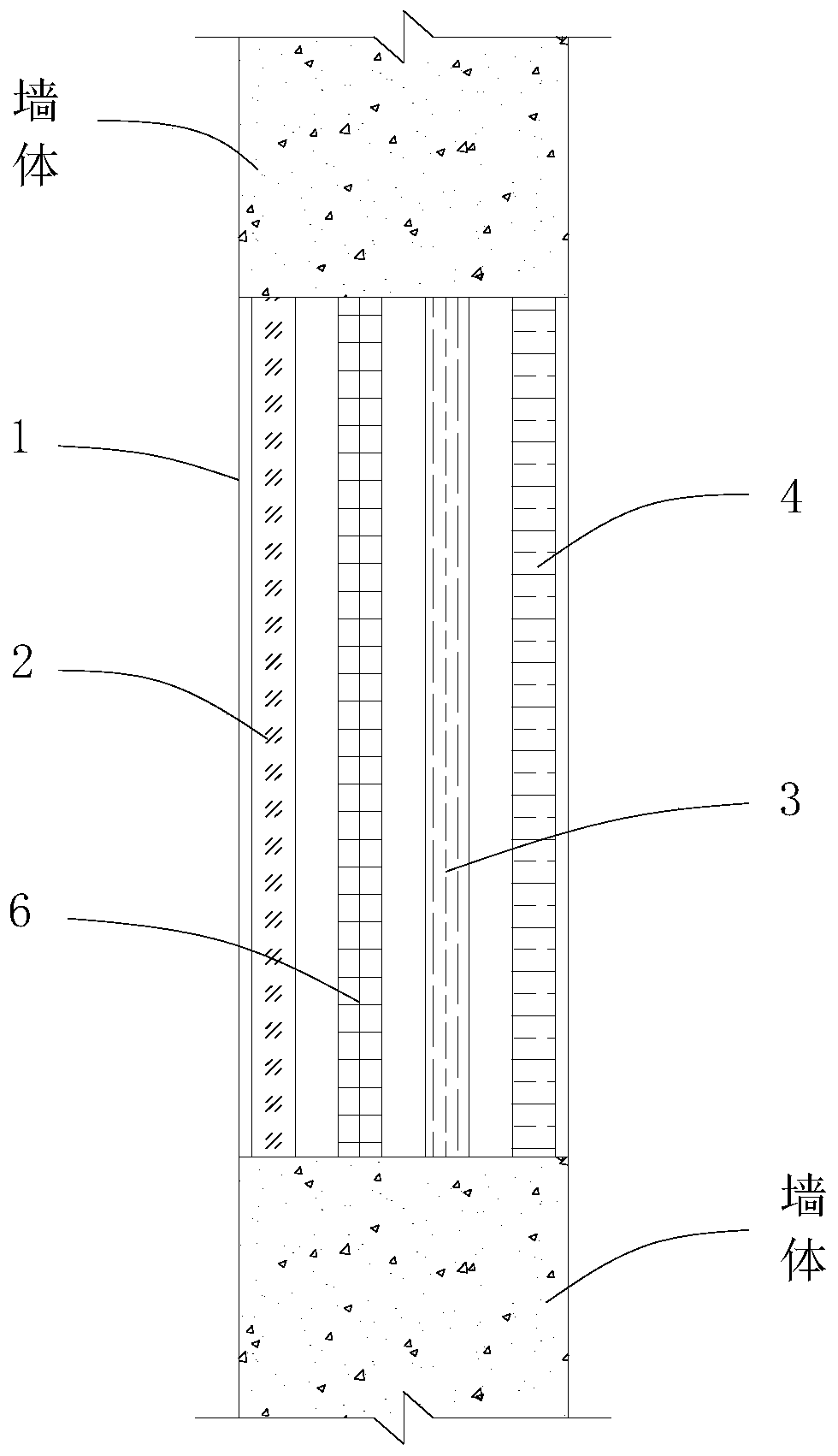

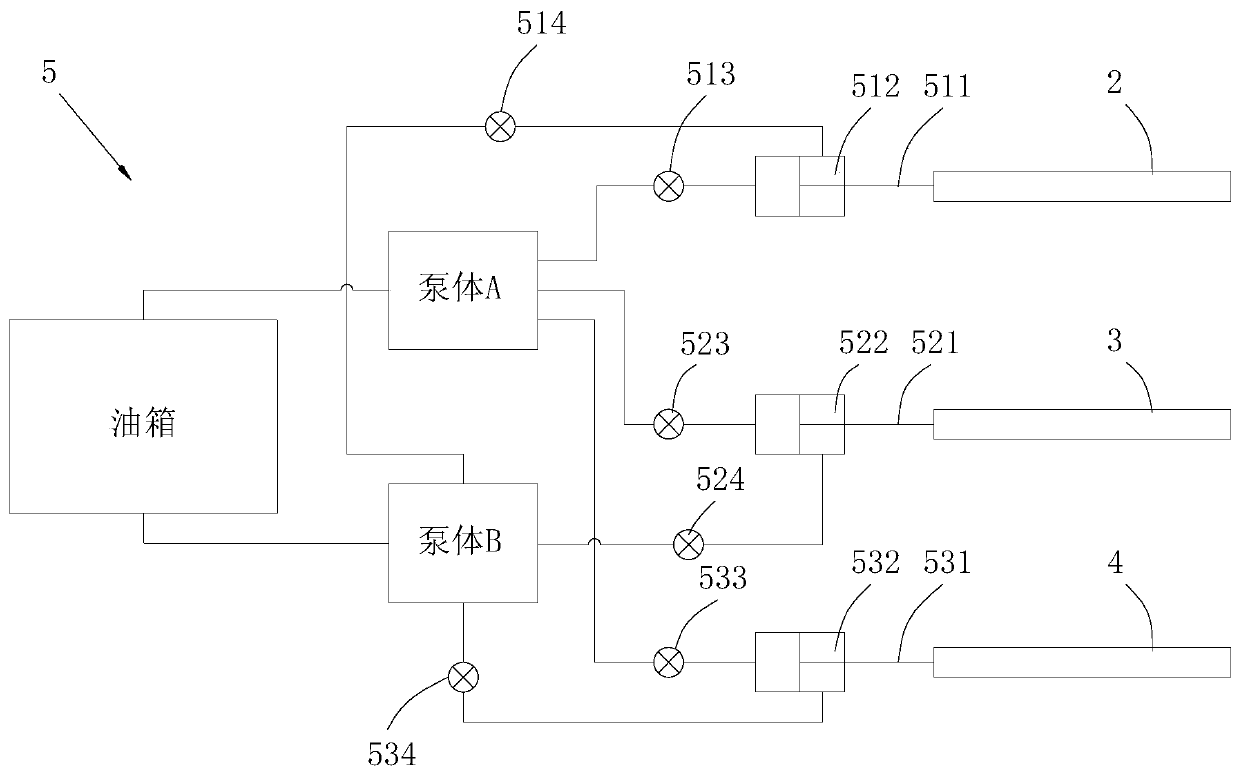

Smart window and control method for smart window

ActiveCN110118413ACO2 concentration improvementReduce carbon dioxide concentrationMechanical apparatusSpace heating and ventilation safety systemsFresh airEngineering

The invention belongs to the technical field of smart equipment, and in particular, provides a smart window and a control method for the smart window. The smart window comprises a main body, a windowbody module and driving mechanisms; the main body is provided with an opening; the window body module comprises a glass layer structure, a filter layer structure and a power layer structure; the driving mechanisms can independently drive the glass layer structure, the filter layer structure and the power layer structure; and the smart window can selectively enable the glass layer structure, the filter layer structure and the power layer structure to cover an opening according to the identity information of users, indoor carbon dioxide concentration and outdoor particle pollutant concentration.When the indoor carbon dioxide concentration is higher than the carbon dioxide concentration (determined according to the identity information of the users) suitable for users, outdoor fresh air is absorbed indoors through the power layer structure to reduce the indoor carbon dioxide concentration, and the indoor air is filtered through the filter layer structure to prevent outdoor particle pollutants from entering indoors.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Cleaning system for intelligent traffic obstacle pile

ActiveCN112775079AEasy to useReduce maintenance costsCleaning using toolsCleaning using liquidsStructural engineeringBrush

The invention discloses a cleaning system for an intelligent traffic obstacle pile. The cleaning system comprises an obstacle pile body, a cleaning mechanism, an auxiliary cleaning mechanism and an auxiliary lifting mechanism; the obstacle pile body is provided with an annular sliding cavity communicating with an annular cleaning cavity, the annular sliding cavity and the annular cleaning cavity are arranged up and down, and the auxiliary cleaning mechanism is used for cleaning the cleaning mechanism; an annular top plate is in sliding sealing connection with the annular sliding cavity, the upper end of an inner supporting ring and the upper end of an outer supporting ring are both in concentric shaft connection with the annular top plate, and the lower end of the inner supporting ring and the lower end of the outer supporting ring are both in concentric shaft connection with an annular bottom plate; brushes are evenly distributed on the inner side of the inner supporting ring in the circumferential direction, and brushes are evenly distributed on the outer side of the outer supporting ring in the circumferential direction; the auxiliary lifting mechanism is connected with the annular top plate and used for operating the annular top plate to ascend or descend. According to the cleaning system, full clamping of a bucket rod supporting assembly is guaranteed, and the phenomenon that the bucket rod supporting assembly is prone to falling off or shifting in the welding process is avoided.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

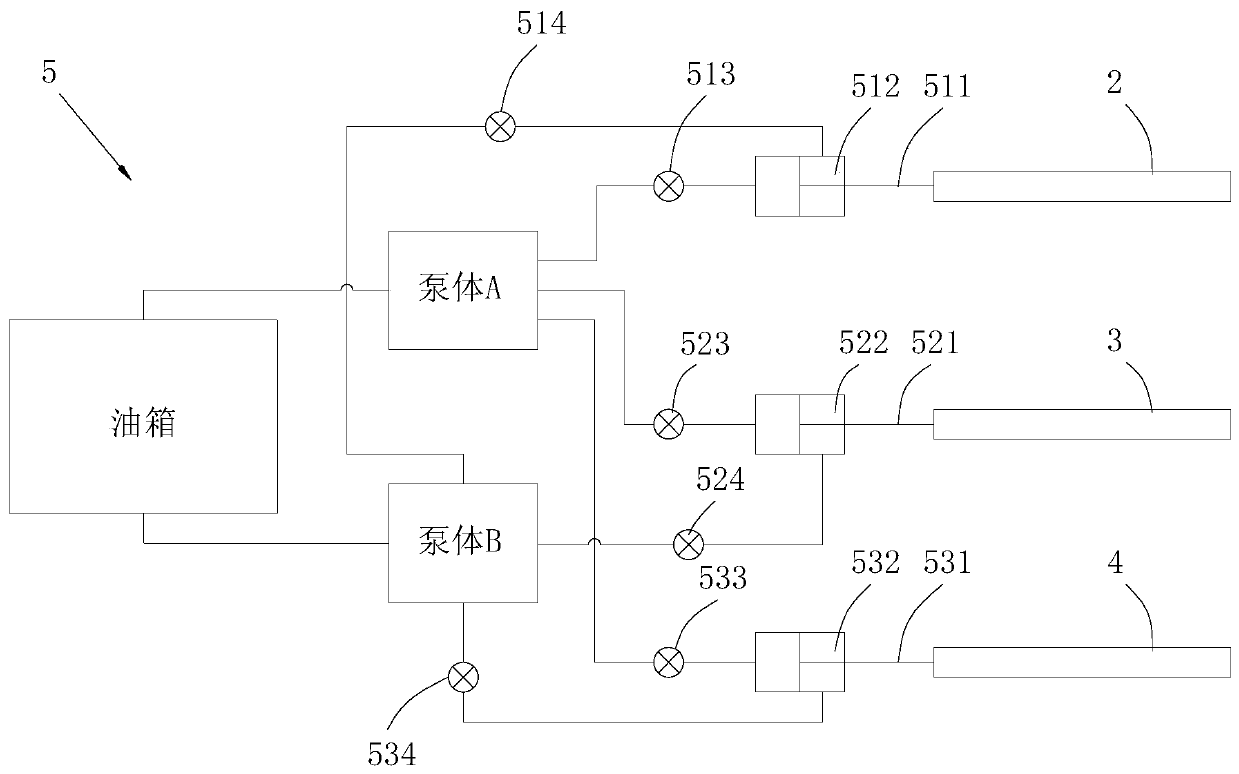

Packaging equipment and packaging process under clean environment

ActiveCN106829035AExtended shelf lifeFully automatedWrapper twisting/gatheringPackaging protectionPositive pressureEngineering

The invention provides packaging equipment and a packaging process under the clean environment. The packaging equipment comprises a rack assembly, a wind feeding device, an exhaust structure and a first heat sealing mechanism; the rack assembly is provided with a mounting cavity provided with an opening in the top; the wind feeding device is used for blowing in air with required cleanliness to the mounting cavity along the vertical direction via air inlets; the exhaust structure is arranged on the rack assembly and is used for exhausting the air in the mounting cavity out and combining with the wind feeding device to form positive pressure environment in the mounting cavity; the first heat sealing mechanism is used for heat-sealing a cover of an acquired material on the top opening of a box. The packaging process is performed by adopting the above packaging equipment. Wind feeding speed of an exhaust assembly is controlled so as to be greater than wind exhausting speed of the exhaust structure, the positive pressure environment is formed in the mounting cavity, the required clean environment is achieved, the cover of the required material is heat-sealed in the top opening of the box through the heat sealing mechanism, and packaging of biological tissue or oranges under the clean environment is realized.

Owner:苏州奥特科然医疗科技有限公司

Eye washing device

The invention discloses an eye washing device. The eye washing device comprises a housing. The housing comprises an eyewash containing chamber, an eyewash discharging chamber and an eye cleaning chamber. A chamber opening is formed in the eye cleaning chamber, a sealing ring is arranged at the chamber opening, a strip-shaped protrusion is arranged on the sealing ring, and a first communication hole communicated with the eyewash containing chamber and a second communication hole communicated with the eyewash discharging chamber are also formed in the eye cleaning chamber. The eyewash containingchamber is of a closed cavity structure with a liquid injection port. A first adjustment component is arranged in the eyewash containing chamber. The eyewash discharging chamber is a closed cavity with a liquid outlet. A second adjustment component is arranged in the eyewash discharging chamber. The eye washing device is provided with chambers with different functions to separate an eyewash to ensure the eye washing environment. At the same time, the eyewash is prevented from being dropped and wasted when the eye washing device is matched with the eyes, and meanwhile, the eye washing device is more convenient to use.

Owner:枣庄瑞衡建筑工程有限公司

Chicken raising cage with feeding device

The invention discloses a chicken raising cage with a feeding device. The chicken raising cage comprises a chicken raising cage body, a lifting device and the feeding device. The feeding device is divided into an upper feeding layer and a lower feeding layer and can control the amount of feed of the upper and lower feeding layers, the feed intake space is reasonably distributed and utilized to make the feed intake of home-kept chicken more convenient, and rapid growth of the home-kept chicken is promoted. The chicken raising cage body is connected with the lifting device, the chicken raising cage is arranged on a defecation ditch, the lifting and lowering of the chicken raising cage are controlled according to demands, the chicken raising cage is lifted when excrement cleaning and sterilizing need to be conducted, the chicken raising cage is lowered when normal raising needs to be conducted so that the cleaning and sanitation of a chicken house can be ensured, and healthy growth of chicken is ensured.

Owner:佛山市辉华生物科技有限公司

Sow safe piglet breeding pigsty

The invention provides a sow safe piglet breeding pigsty which comprises left, right and back side bars enclosed by longitudinal bars, horizontal bars and upright bars, and a sow pigsty formed by a front pigsty door arranged at the front ends of the left and right side bars, and is characterized in that: blocking pieces capable of being upwards turned and lifted are hinged to the lower parts of the inner sides of the left and right side bars through articulation pieces; outward convex shelf bars are arranged below the outer side of each blocking piece at intervals. According to the sow safe piglet breeding pigsty, when a sow lies on her side to feed piglets, under the blocking action of the blocking pieces, the sow can only lower the body to avoid the blocking pieces in a kneeling posture, so as to lie on her side along the outward convex shelf bars below the outer sides of the blocking pieces, so that the force and speed of lying of the sow can be limited, and too fierce lying action is prevented from pressing piglets to injury and even death; when the sow arises and stands, the blocking pieces are automatically turned and lifted upwards, so that sow standing is not influenced; a clean environment is maintained, so that the piglets can normally grow to the furthest, and the slaughter rate of hogs is increased.

Owner:YUNNAN SHUANGBAI COUNTY TIANPENG CULTURE CO LTD

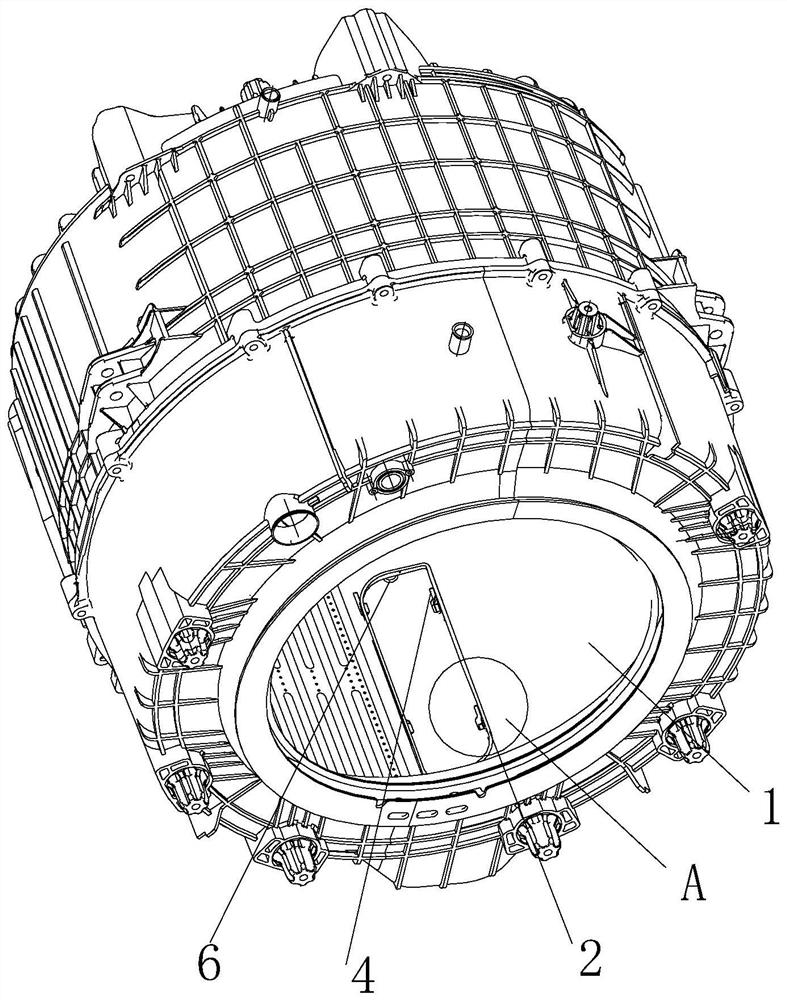

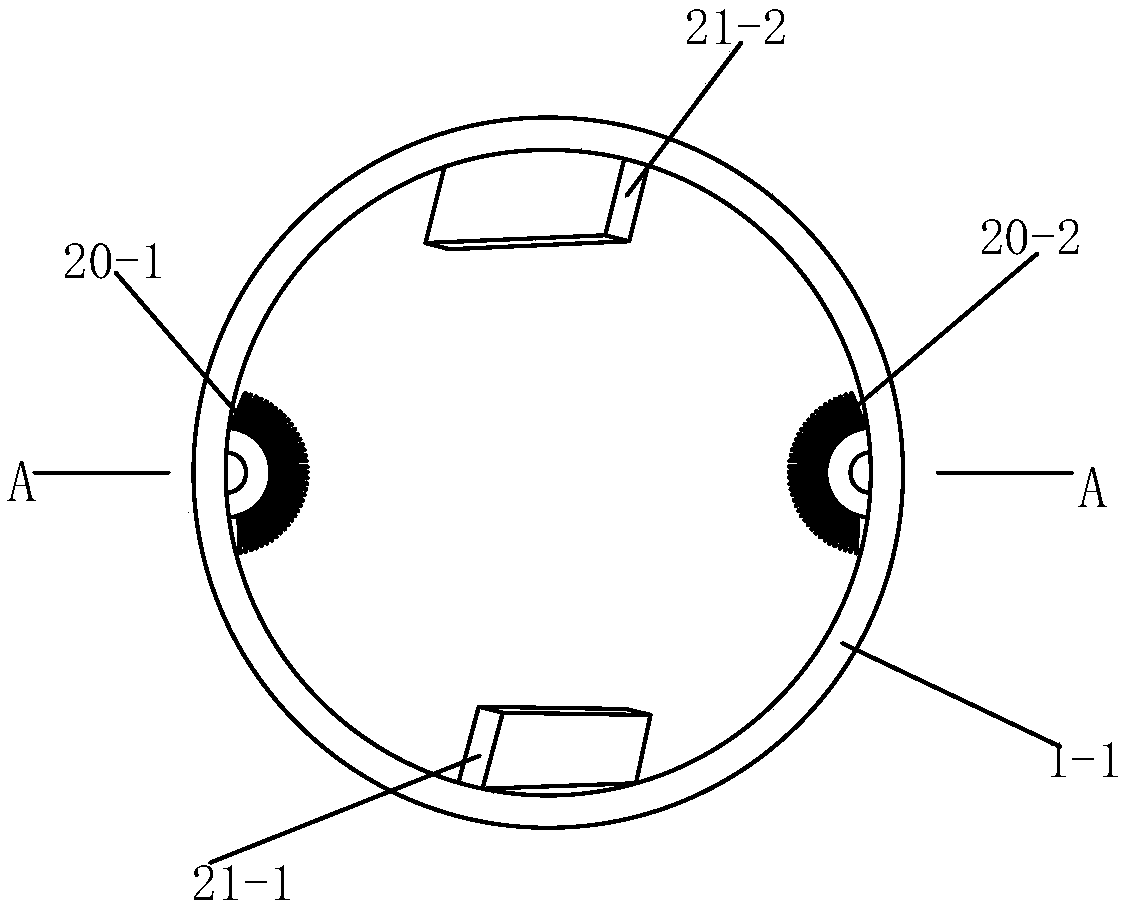

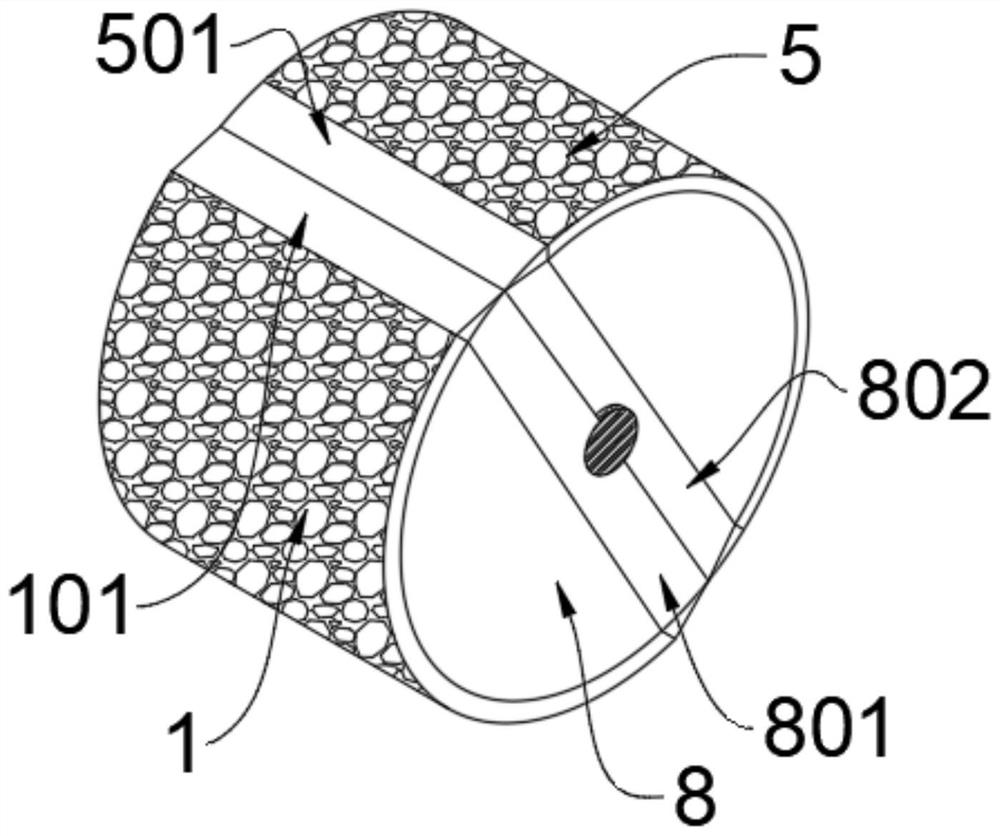

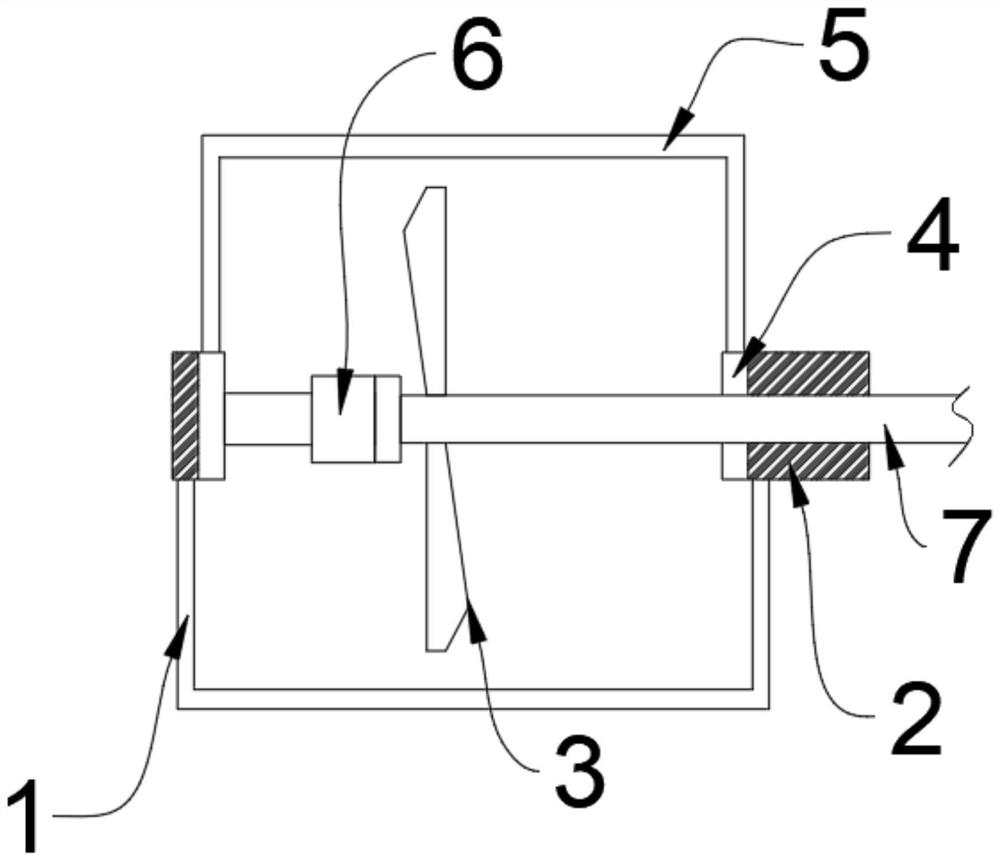

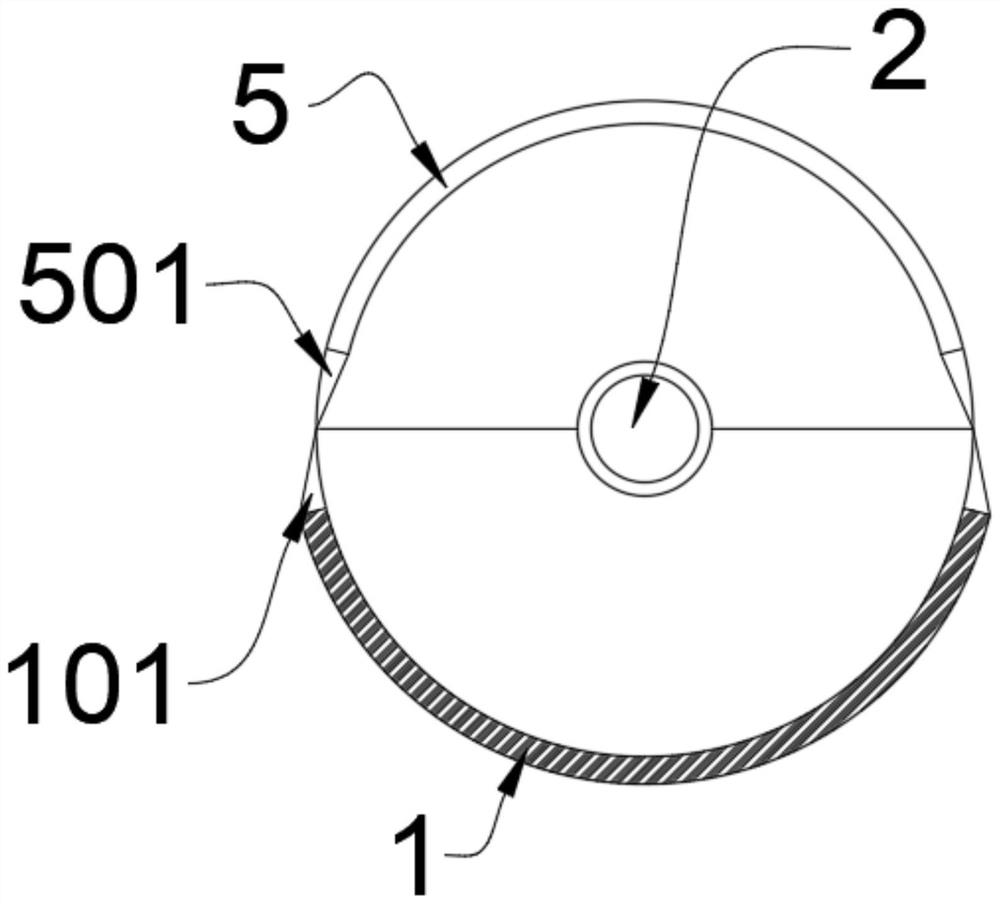

Lifting rib of clothes disposal facility and clothes disposal facility

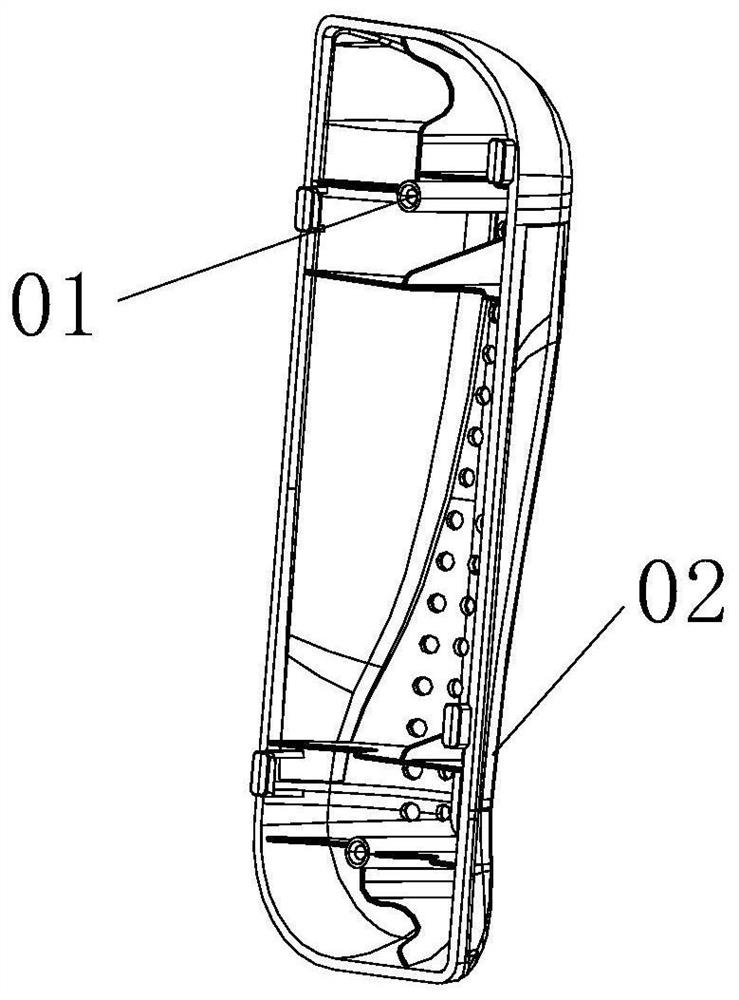

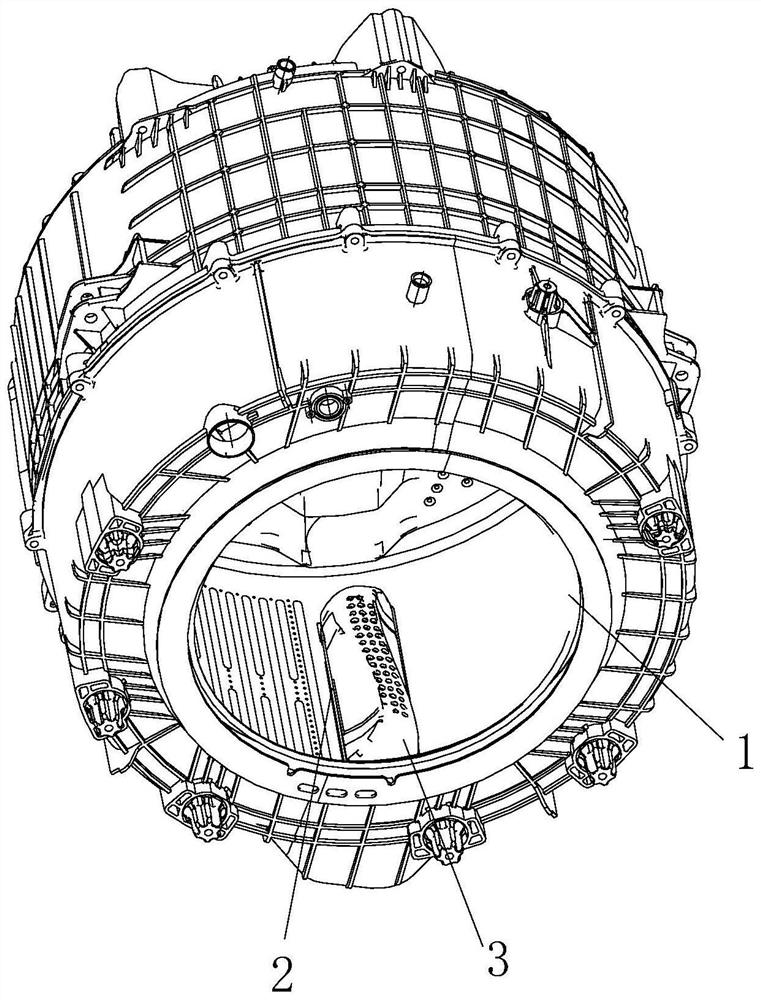

ActiveCN111826891AGuarantee a clean environmentEasy to cleanOther washing machinesTextiles and paperClean environmentStructural engineering

The invention discloses a lifting rib of a clothes disposal facility and the clothes disposal facility. The lifting rib of the clothes disposal facility comprises a mounting base and a lifting rib body. The mounting base and the lifting rib body are arranged in a split mode, the mounting base is fixed to the side wall of an inner barrel, and the lifting rib body is detachably fixed to the mountingbase. The lifting rib is arranged in a split mode, a user can conveniently take down the lifting rib body from the side wall of the washing inner barrel, the area between the lifting rib body and theinner barrel is cleaned, and the clean environment in the inner barrel is guaranteed. Besides, a cavity can be further formed inside the lifting rib and used for holding clothes disposal reagents, orthe lifting rib has the thread scrap filtering function at the same time, and therefore the functions of the split type lifting rib are diversified, and the clothes cleaning effect is further improved.

Owner:CHONGQING HAIER ROLLER WASHING MASCH CO LTD +1

Slurry stop clamp cleaning machine

ActiveCN108393285AGuaranteed cleanlinessImprove cleaning efficiencyCleaning using toolsCleaning using liquidsMotor driveCleaning methods

The invention discloses a slurry stop clamp cleaning machine. The slurry stop clamp cleaning machine comprises a support, a balance warped plate arranged on the support through a rotation shaft, a cleaning roller, a cleaning motor driving the cleaning roller to rotate and a control terminal, wherein the cleaning roller and the cleaning motor are arranged on the balance warped plate. A plurality ofcleaning brushes are arranged on the inner wall of the cleaning roller. A nozzle is arranged at the feeding port end of the cleaning roller, and the support is provided with an electric hydraulic thruster for pushing the feeding port end of the balance warped plate to be inclined downwards. The cleaning motor is used for driving the cleaning roller to rotate, meanwhile, the nozzle is used for spraying cleaning fluid into the cleaning roller, and accordingly slurry stop clamp cleaning is finished. The cleaned slurry stop clamp is poured out of the cleaning roller through pushing of the cleaning roller via the electric hydraulic thruster and reverse rotation of the cleaning roller, the control terminal can control cleaning and material pouring of the slurry stop clamp in good time, and automatic slurry stop clamp cleaning is achieved; and accordingly, compared with the prior art, the cleaning efficiency is effectively improved, the cleaning intensity is relieved, and the slurry stop clamp cleaning effect is improved.

Owner:CHINA RAILWAY FIRST GRP CO LTD

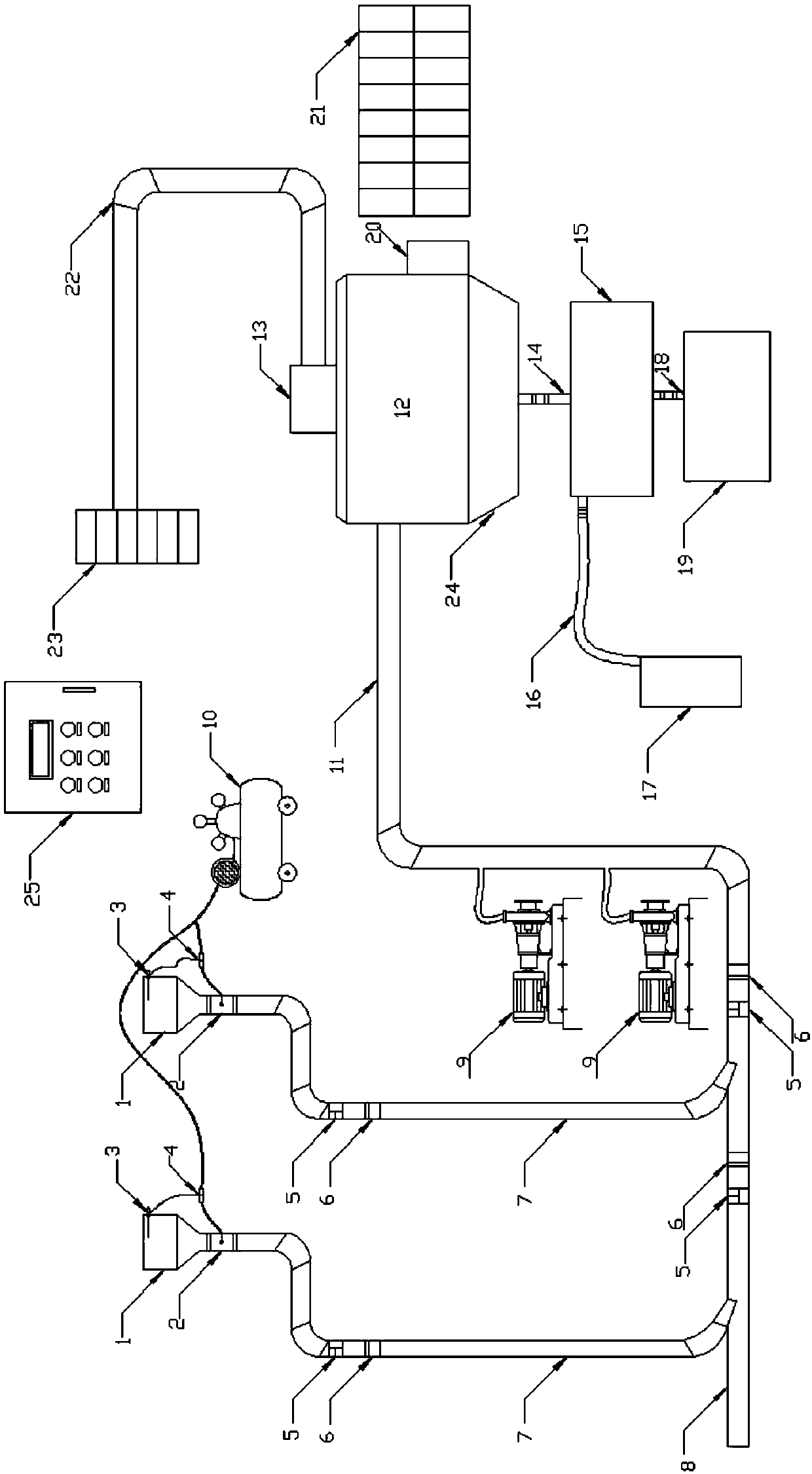

Kitchen waste vacuum collecting, crushing and classifying treatment system and method

PendingCN109570193AIncrease water pressureGuarantee a clean environmentSolid waste disposalAutomatic controlControl system

The invention discloses a kitchen waste vacuum collecting, crushing and classifying treatment system and method. The kitchen waste vacuum collecting, crushing and classifying treatment system comprises a kitchen garbage collecting tank, a flushing device, a vacuum transporting device, a kitchen waste crushing treatment device and a PLC automatic control system; power structures and movable parts of the flushing device, the vacuum transporting device and the kitchen waste crushing treatment device are all controlled by the PLC automatic control system; kitchen waste is sucked into the vacuum transporting device through a vacuum interface valve under the effects of water flow impulsion, gravity and vacuum negative pressure; and the vacuum transporting device transports the waste to the kitchen waste crushing treatment device through the negative pressure generated by the vacuum transporting device. The negative pressure is generated through the vacuum principle to suck the kitchen waste,and thus as for waste treating, the defects that waste residue is left, and the smell of the waste is not diffused for a long time can be avoided, so that a kitchen is always in a clean and fresh environment.

Owner:SHANDONG UNIV

Air conditioner

InactiveCN1952505ARelaxReduce dustHuman health protectionMechanical apparatusAllergic reactionElectric power

The present invention provides an air conditioner, capable of maintaining the inside of a room with a dust-minimized state by detecting specific dust containing pollen that is a substance generated outdoors and causes seizures by allergic reaction or promoting the seizures, and performs dust removing operation. This air conditioner 1 comprises an indoor unit 2 including an electric dust collecting and a cleaning unit provided with a dielectric filter, a ventilating device capable of performing air supply operation for taking outside air into the room, a cleaning filter provided in an suction passage of the outside air by the ventilating device, a dust sensor 158 capable of discriminating dust floating in the air. A control device of the air conditioner 1 controls, when the dust sensor detects dust of a specific group includes pollen, so as to perform operation of the electric dust collecting and cleaning unit and the air supply operation of the ventilating device.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Ship propeller protection component

The invention discloses a ship propeller protection component, and relates to the field of ships. The protection piece comprises a protection piece body and a mounting base, first cutting blades are fixed to the two sides of the protection piece body, the protection piece body is fixedly mounted on the mounting base, a rotating shaft is movably mounted at one end of the mounting base, and a cutting piece is fixed to the outer surface of the rotating shaft. The driving shaft drives the cutting piece fixedly connected with the rotating shaft at the same time, so that the cutting piece rotates, when second cutting blades on the two sides of the cutting piece are tangent to first cutting blades, old fishing nets and sundries wound on the protection piece body and the cutting piece are cut, and therefore chippings and sundries fall off and are prevented from being wound. The clean environment around the propeller can be kept for a long time, the protection piece body is kept clean, the purpose of automatically treating sundries is achieved, and manual cleaning is not needed.

Owner:中船广西船舶及海洋工程有限公司

Intelligent window and control method for intelligent window

ActiveCN110118410AReduce carbon dioxide concentrationGuarantee a clean environmentMechanical apparatusSpace heating and ventilation safety systemsParticulatesFresh air

The invention belongs to the technical field of intelligent equipment, and particularly provides an intelligent window and a control method for the intelligent window. The intelligent window comprisesa body, a window body assembly and a driving mechanism, an opening is formed in the body, the window body assembly comprises a glass layer structure, a filter layer structure and a power layer structure, the driving mechanism is arranged to be capable of driving the glass layer structure, the filter layer structure and the power layer structure separately, the intelligent window is arranged to becapable of selectively making the glass layer structure, the filter layer structure, and the power layer structure cover the opening according to the user behavior state, the indoor carbon dioxide concentration and the outdoor particulate pollutant concentration. When the indoor carbon dioxide concentration is greater than the carbon dioxide concentration (determined according to the user behavior state) suitable for the user, the outdoor fresh air is sucked into the room through the power layer structure so as to reduce the indoor carbon dioxide concentration, and filtering is conducted on the air entering the room through the filter layer structure so as to prevent the outdoor particulate pollutant from entering the room.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

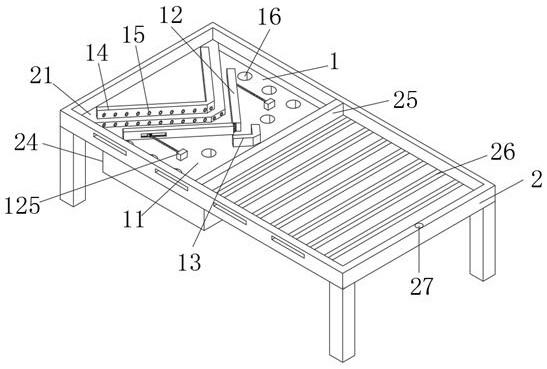

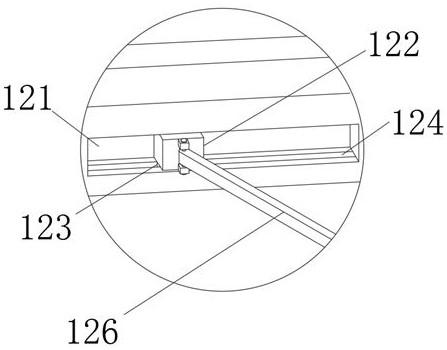

Multifunctional household dining table

InactiveCN112401486AGuarantee a clean environmentReduce workloadServing tablesFeetEngineeringMechanical engineering

The invention provides a multifunctional household dining table. The table comprises a cleaning mechanism, the cleaning mechanism is located in a cleaning cavity, the cleaning cavity is located on oneside in a table body, a table top is correspondingly arranged on the top face of the table body, the table top is detachably connected with the table body, a certain vertical distance is formed between the table top and the table body, turnover mechanisms are further included, the turnover mechanisms are symmetrically arranged on the two sides of the table body, the turnover mechanisms are sleeved with elastic auxiliary faces, the elastic auxiliary faces wrap the top face and the bottom face of the table top, transparent plastic table cloth is connected to the elastic auxiliary faces in a pasted mode, and the cleaning mechanism and the turnover mechanisms are matched together to complete cleaning of the table cloth.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

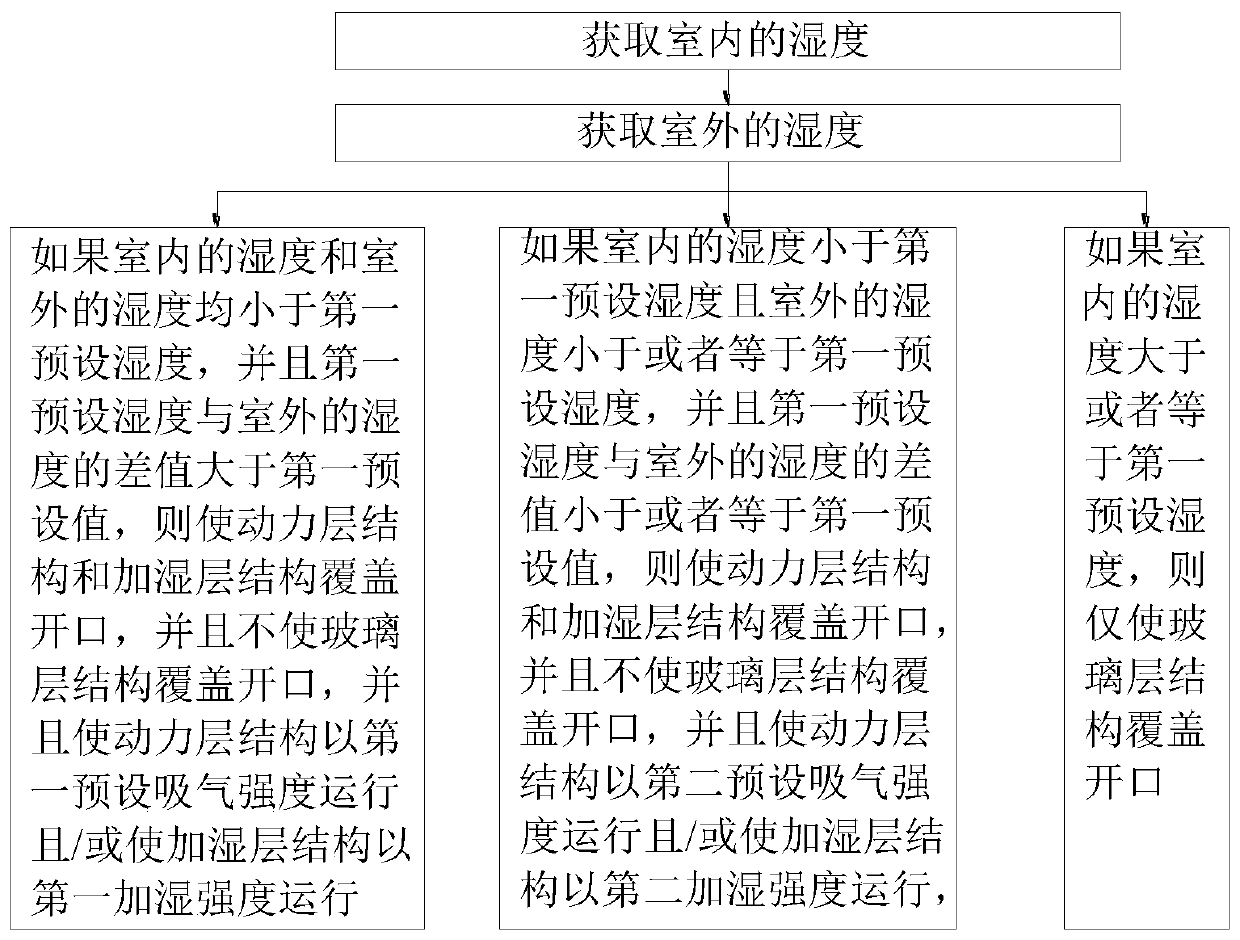

Smart window and control method for smart window

ActiveCN110260438AGuarantee a clean environmentImprove experienceMechanical apparatusSpace heating and ventilation safety systemsOutdoor temperatureIntelligent equipment

The invention belongs to the technical field of smart equipment, and particularly provides a smart window and a control method for the smart window. The smart window comprises a main body, and a window body assembly and a drive mechanism arranged on the main body, wherein an opening is formed in the main body; the window body assembly comprises a glass layer structure, a humidification layer structure and a power layer structure; the drive mechanism is connected with the glass layer structure, the humidification layer structure and the power layer structure, and is arranged to be used for independently driving the glass layer structure, the humidification layer structure and the power layer structure; and the smart window is arranged to be used for selectively enabling the glass layer structure, the humidification layer structure and the power layer structure to cover the opening according to the indoor temperature and the outdoor temperature. When the indoor temperature is low, the power layer structure can suck outdoor air into the room, and the humidification layer structure can humidify indoor air so as to improve the indoor humidity.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Traditional Chinese medicine concentrating device, and ginkgolide extraction method

InactiveCN107158727AImprove filtration efficiencyIncrease enrichment progressOrganic chemistryEvaporator accessoriesInsulation layerWater storage tank

The invention discloses a traditional Chinese medicine concentrating device. The device comprises a tank body, a liquid inlet positioned at the top of the tank body and a liquid outlet positioned at the bottom of the tank body, a layer of a heating plate is arranged at the outer side of the tank body, a heat insulation layer is arranged at the outer side of the heating plate, a ring of a cleaning pipeline is arranged on the inner wall of the tank body, the cleaning pipeline is equidistantly provided with a plurality of cleaning nozzles, the top of the tank body is connected with a vacuum pump through a vacuum tube, a buffering tank is arranged between the tank body and the vacuum pump, the top of the tank body is connected with an evaporator through a pipeline, the other end of the evaporator is connected with a condenser, the other end of the condenser is connected with a water storage tank, the water outlet of the water storage tank communicates with the cleaning pipeline, a filter screen is arranged below the liquid inlet and in the tank body, the tank body is provided with a negative pressure fan, and a stirring rod is arranged in the tank body. The device has the advantages of convenience in cleaning, high concentrating efficiency, realization of repeated use of water, resource saving, and reduction of the production cost.

Owner:NANJING JINGYUN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com