Push-pull type selective laser melting (SLM) device forming cylinder capable of rising and falling

A laser selective melting and forming cylinder technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the difficulty of powder cleaning in fixed forming cylinders, the low efficiency of parts disassembly and powder collection, and the efficiency of preparation and cleaning Low-level problems, to achieve the effect of easy replacement, guaranteed convenience, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The present invention will be further described below in conjunction with the drawings and embodiments.

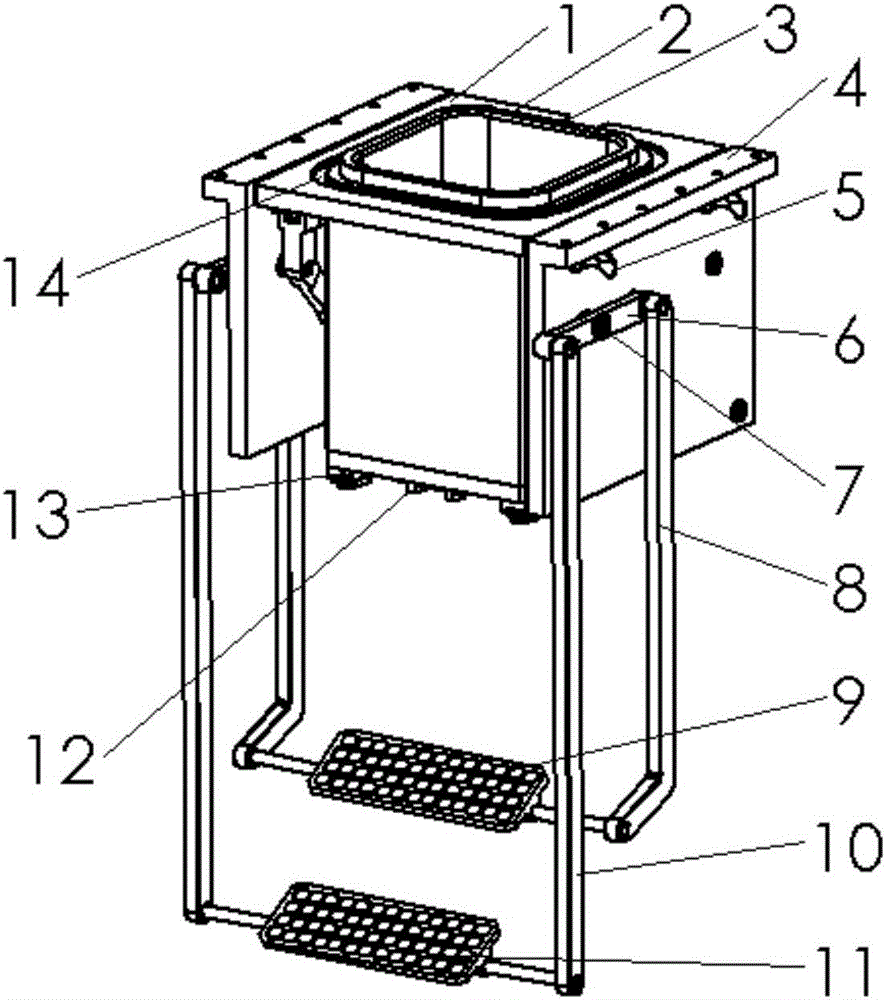

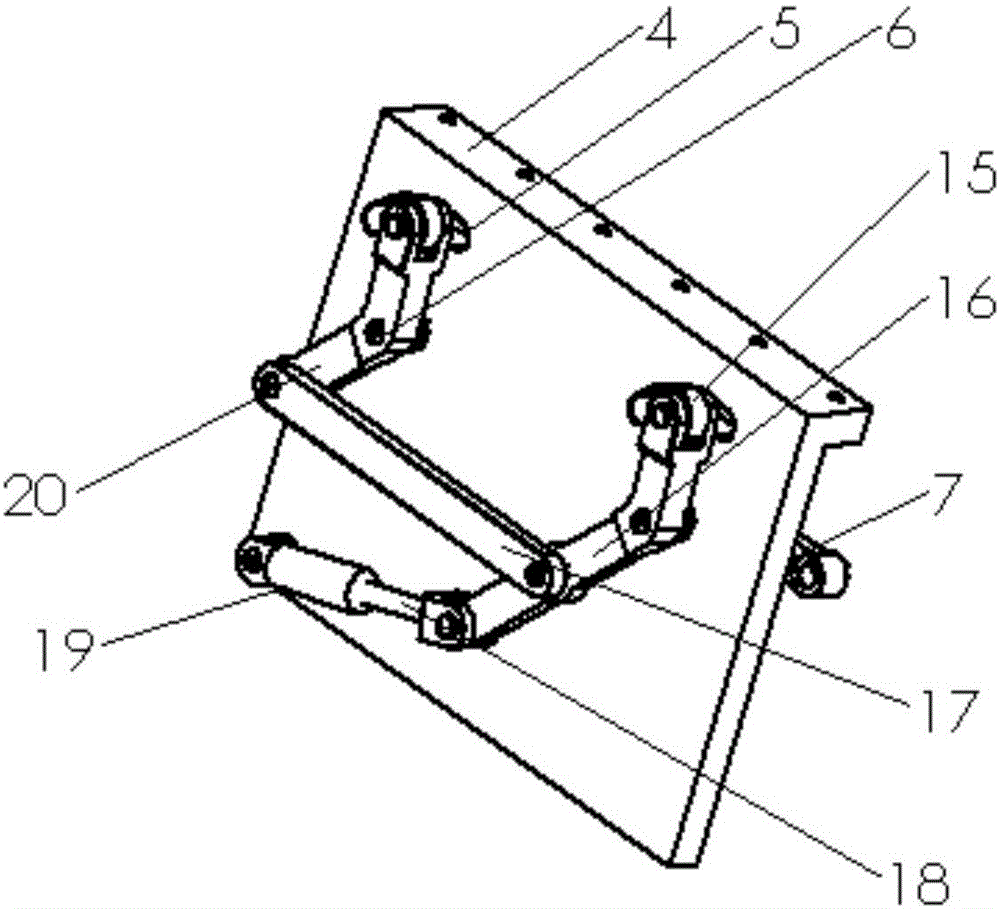

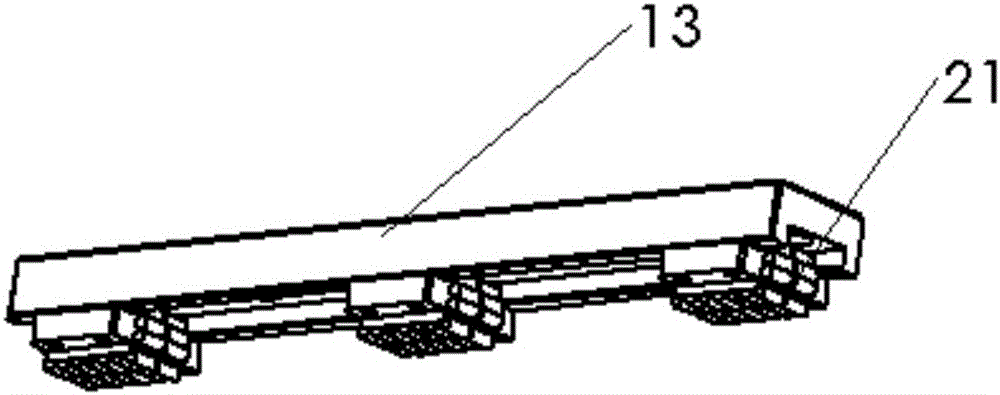

[0017] Reference figure 1 , figure 2 with image 3 , A lifting push-pull laser selective melting SLM equipment forming cylinder, including a forming cylinder body 1, the upper end of the forming cylinder body 1 is provided with a T-shaped boss 2, through the T-shaped boss 2 to realize the forming cylinder body 1 and the laser selective melting SLM For the guiding and docking of the molding chamber of the equipment, the lower end of the molding cylinder body 1 is provided with a tapered guide block 12 in the horizontal pull-out direction, and the outer extension part of the rear part of the molding cylinder body 1 is provided with a tapered guide positioning groove 3. A movable roller block 13 is provided, and three roller racks 21 are provided on the movable roller block 13. The guiding and movement of the forming cylinder body 1 is realized by the tapered guide block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com