Carrying apparatus and carrying control method for sheet-like substrate

A technology of transportation device and control method, which is applied in the direction of transportation and packaging, program control manipulator, conveyor, etc., which can solve the problems of thin plate substrate damage, heavy substrate weight, easy bending, etc., and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

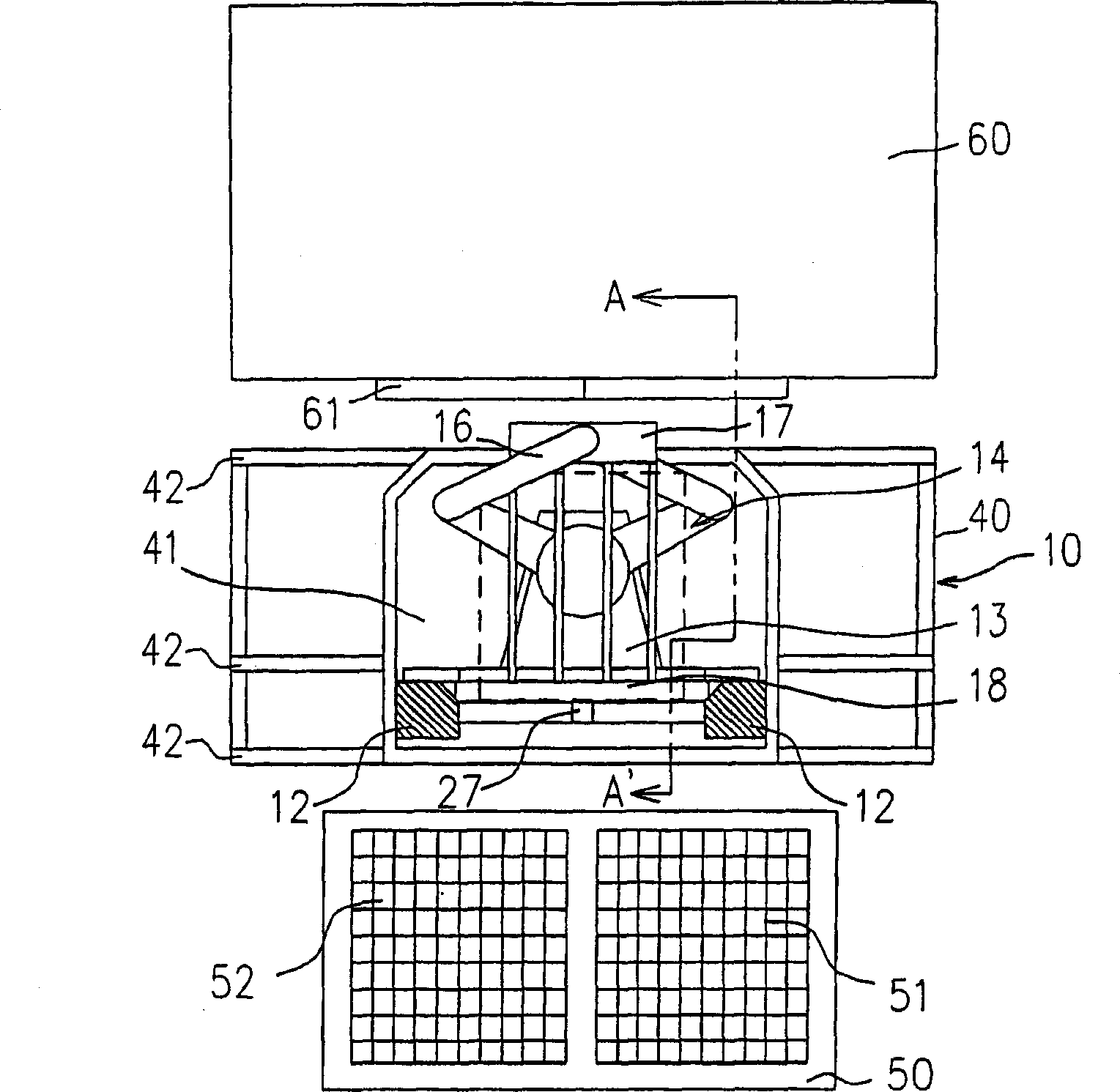

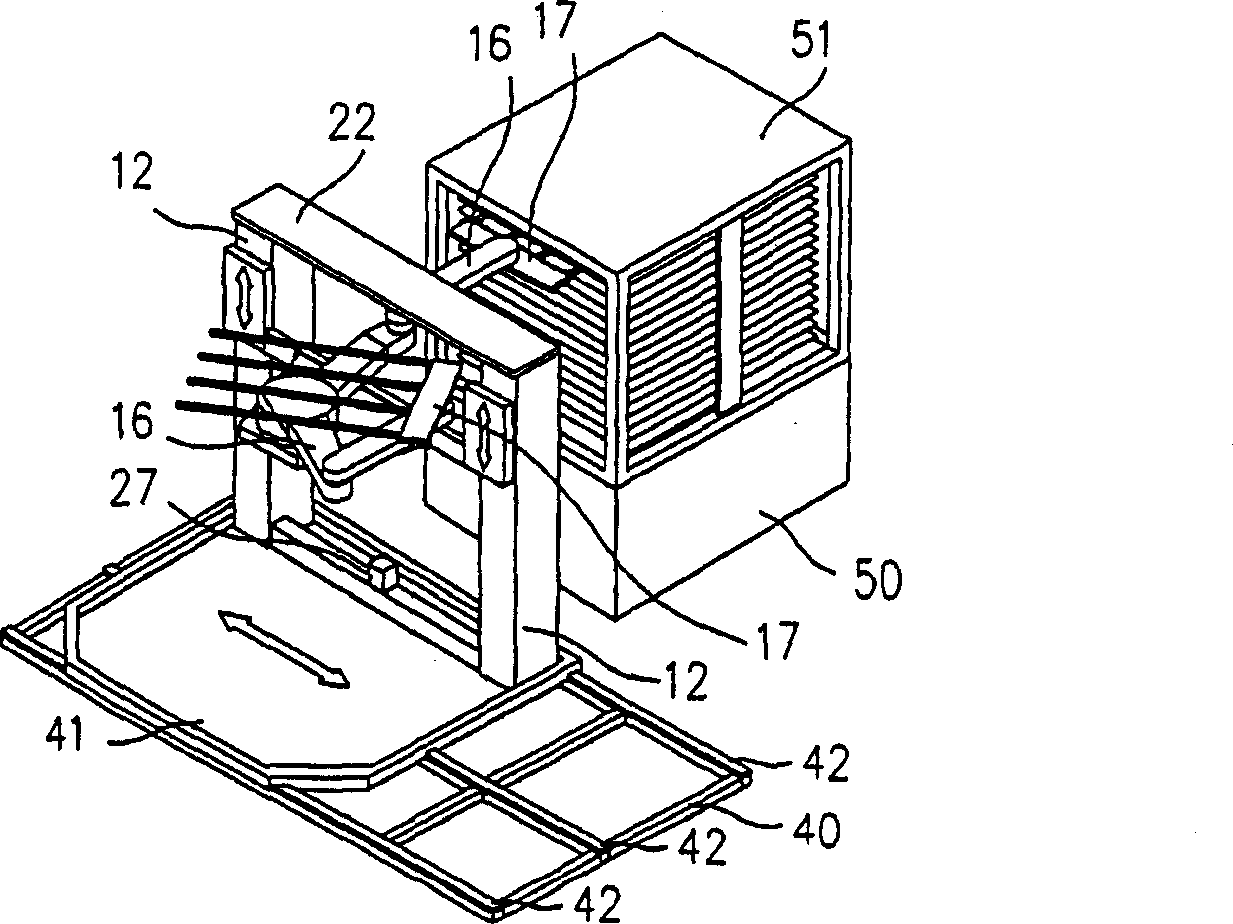

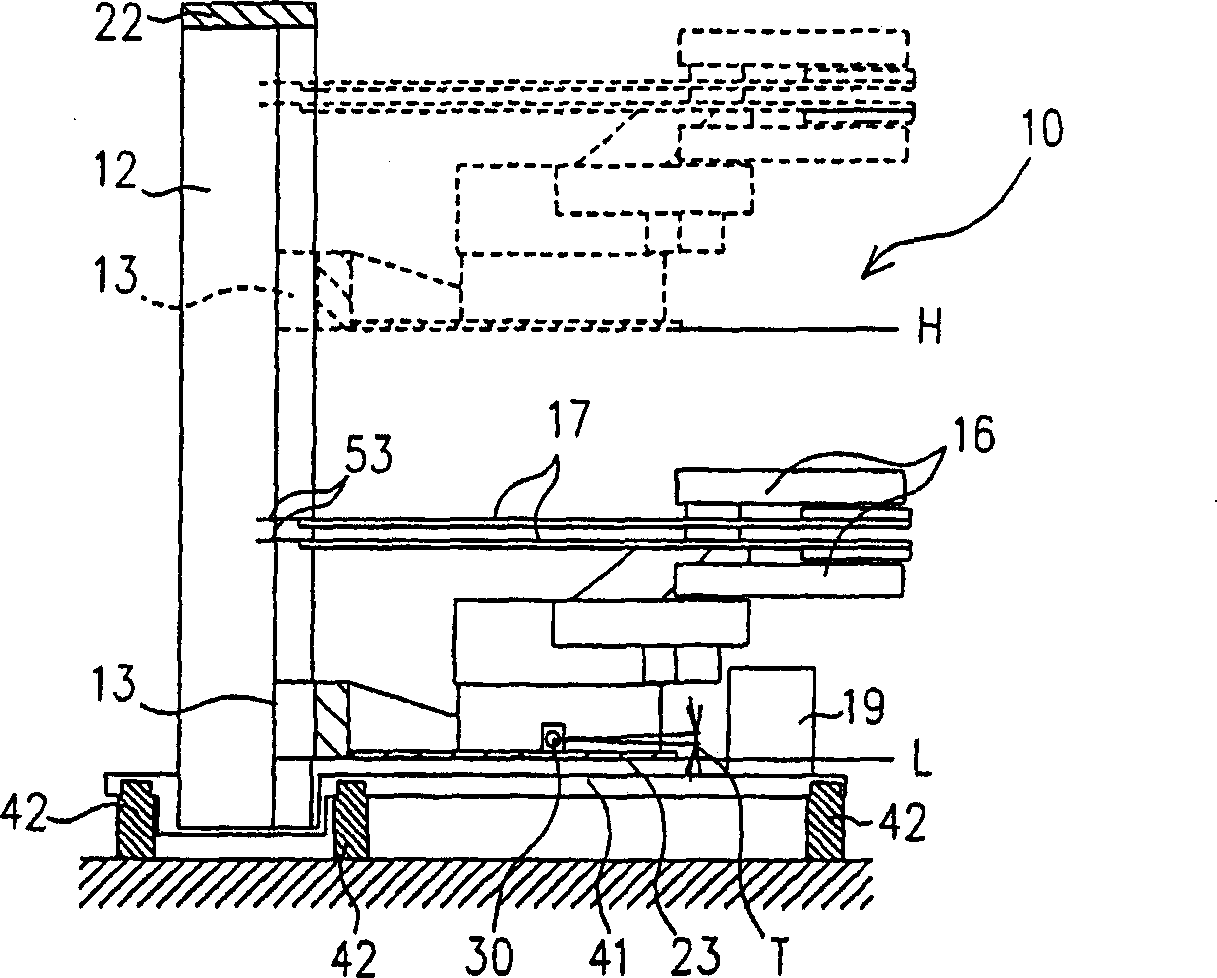

[0069] The best mode for carrying out the invention will be described in detail below with reference to the accompanying drawings. In the following description, it is assumed that a square glass plate with a side length of about 2 m is transported as a thin plate-shaped substrate. In addition, the conveying device of the present invention is a device for conveying thin plate-shaped members for forming semiconductor integrated circuits, so although the degree of cleanliness is lower than that of a so-called clean room, it can work in a certain clean environment. Therefore, the conveying device of the present invention is a conveying device equipped with predetermined requirements for working in a clean environment, such as suppressing dust generation, and its properties are completely different from conveying devices such as general lifting devices and elevators in warehouses and the like.

[0070] figure 1 It is a plan view showing a thin plate manufacturing system for semico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com