Patents

Literature

107results about How to "Shipped accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carrying apparatus and carrying control method for sheet-like substrate

ActiveCN1816907ASmooth movementStable and fast shippingProgramme-controlled manipulatorConveyorsLiquid-crystal displayTransfer system

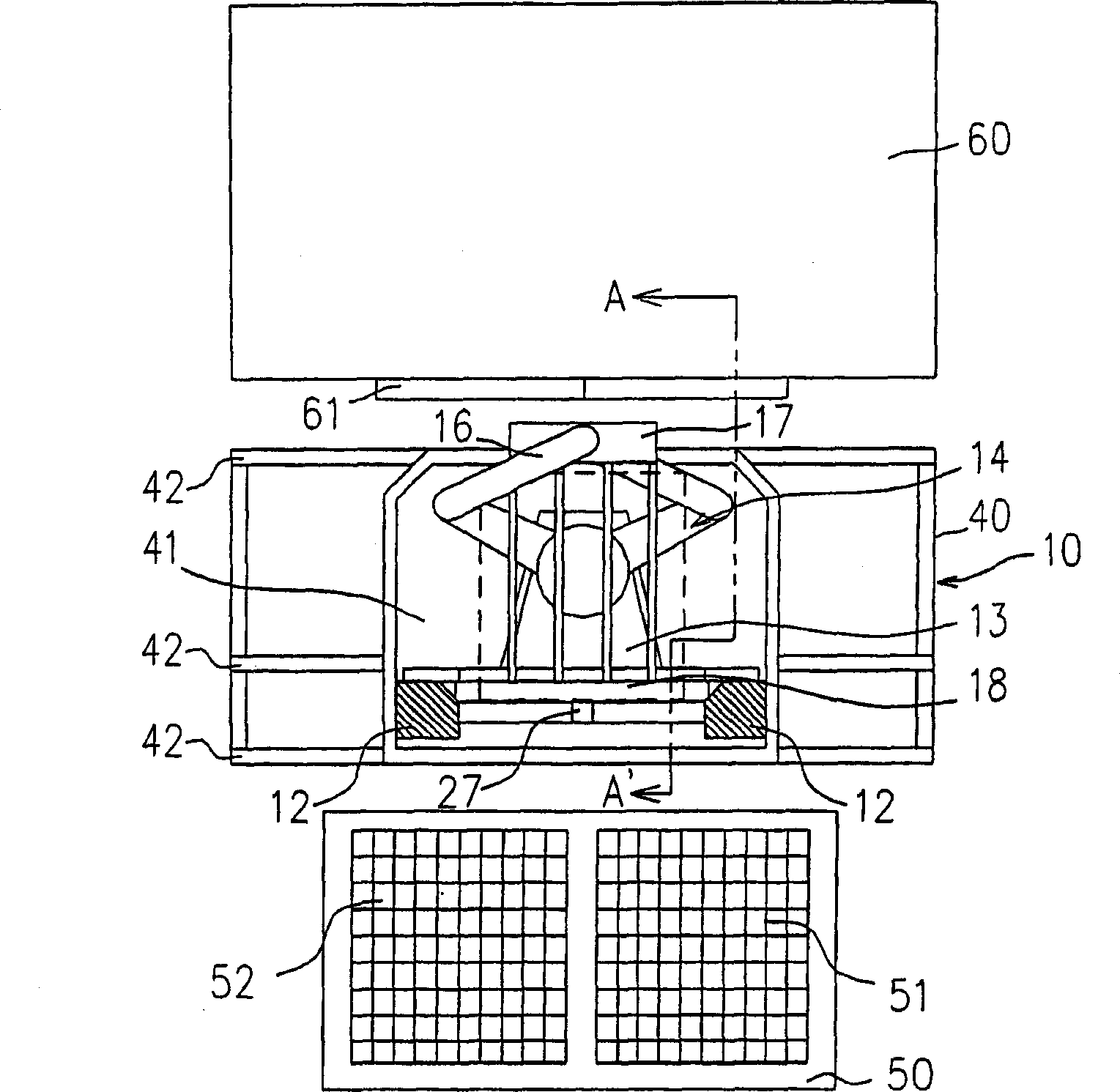

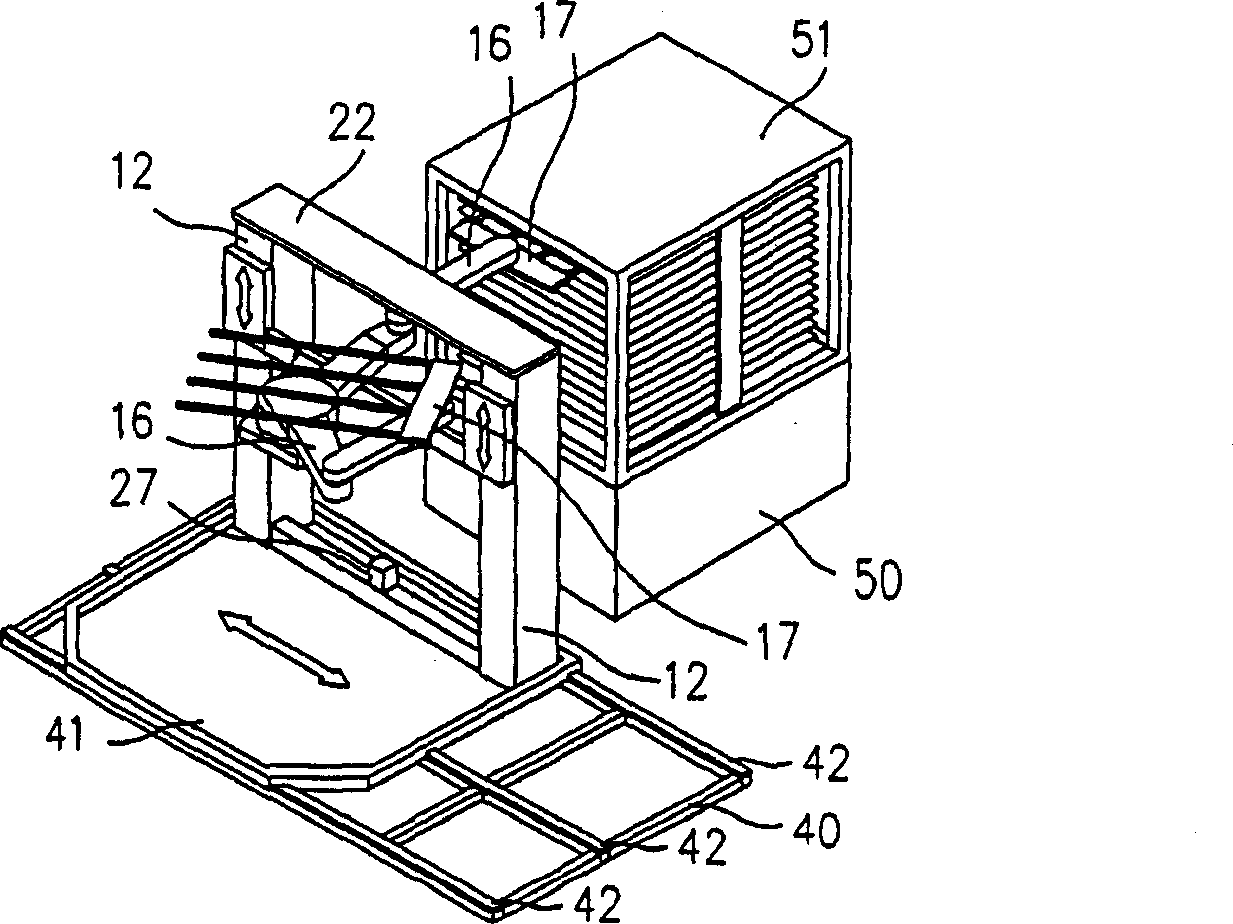

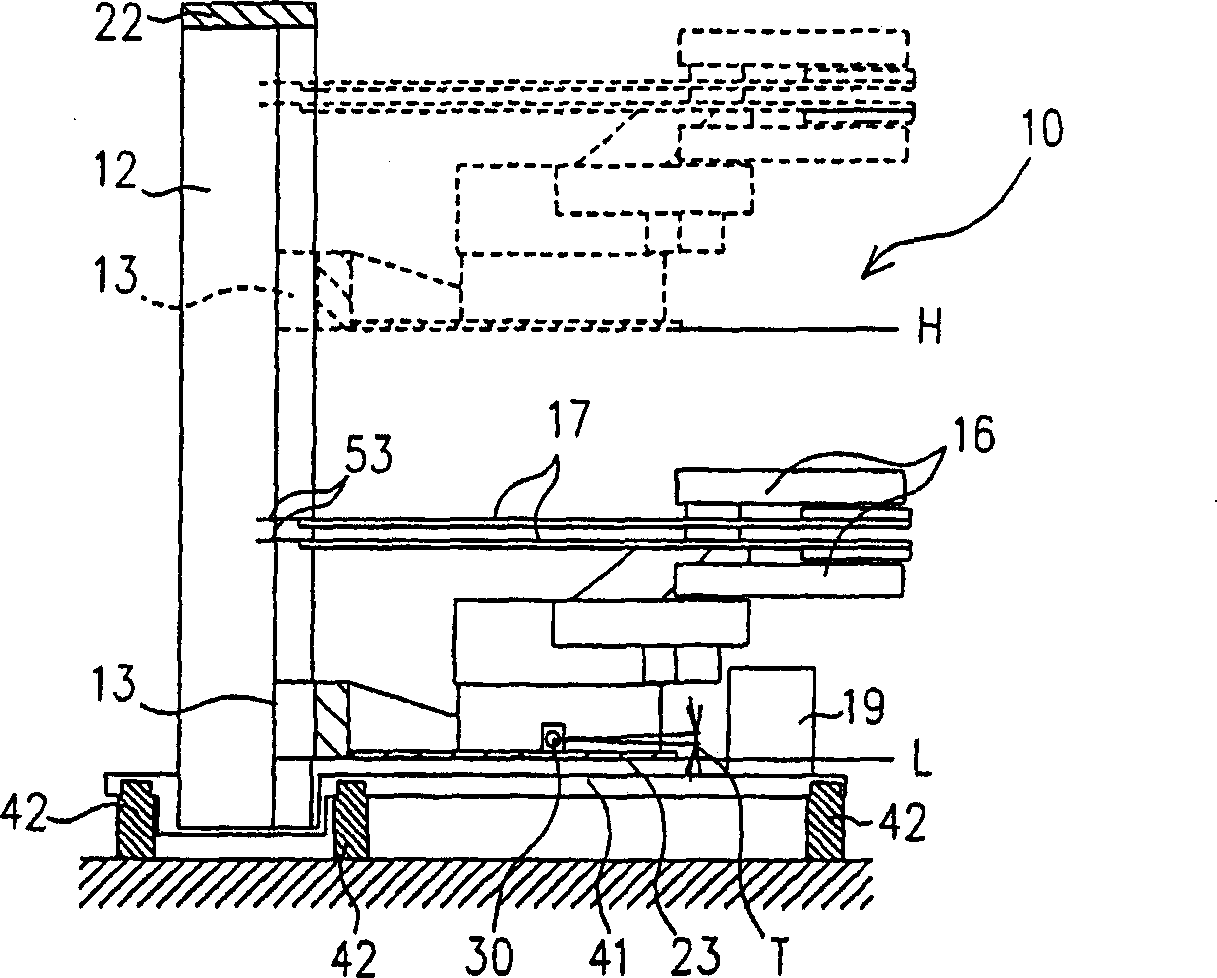

The invention relates to a transfer device for transferring thin plate-like articles, such as liquid crystal display panels and glass substrates, into a processing device. The invention provides, in a transfer device provided with a relatively large robot (14) having a turning arm (16) for transferring large-sized thin plate-like articles, a transfer device capable of stabilized lifting even if the height is 2 m or so and capable of transfer in which the amount of deflection with the turning arm (16) extended can be corrected; and a thin plate-like article transferring system. A transfer robot (14) having the turning arm (16) is mounted on a horizontal support block (13) cantilevered for lifting and lowering motion on two upright support bodies (12). Further, the amount of deflection with the arm extended is corrected by raising the level of the horizontal support block (13) according to the amount of deflection. The amount of deflection can also be corrected by changing the angle of installation at which the robot (14) is mounted on the horizontal support block (13).

Owner:RORZE CORP

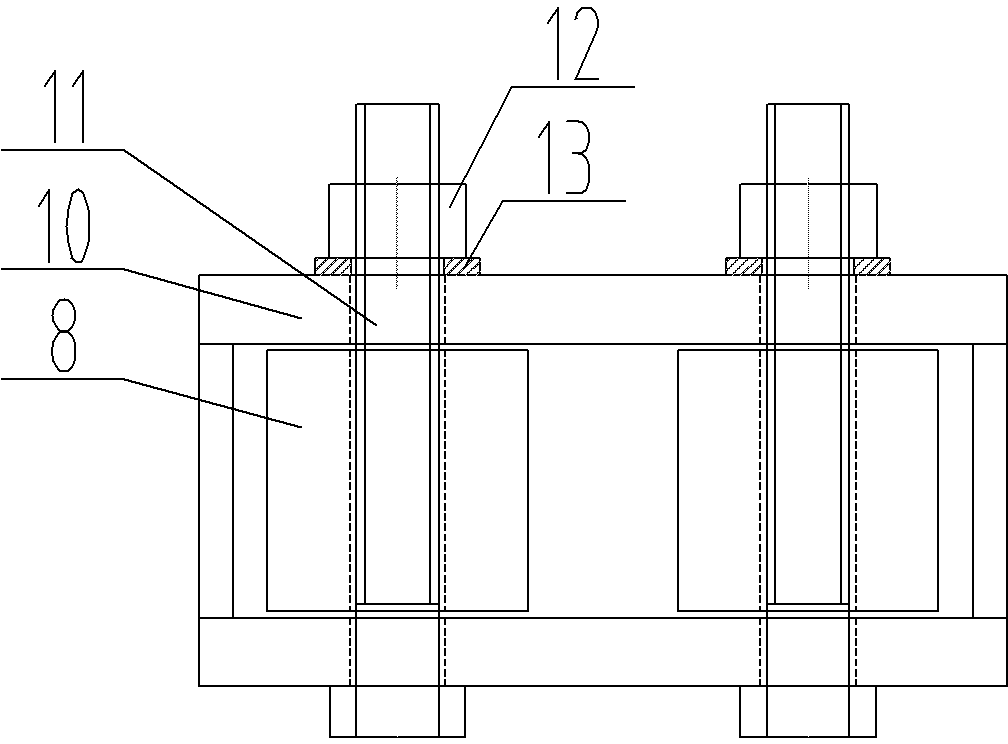

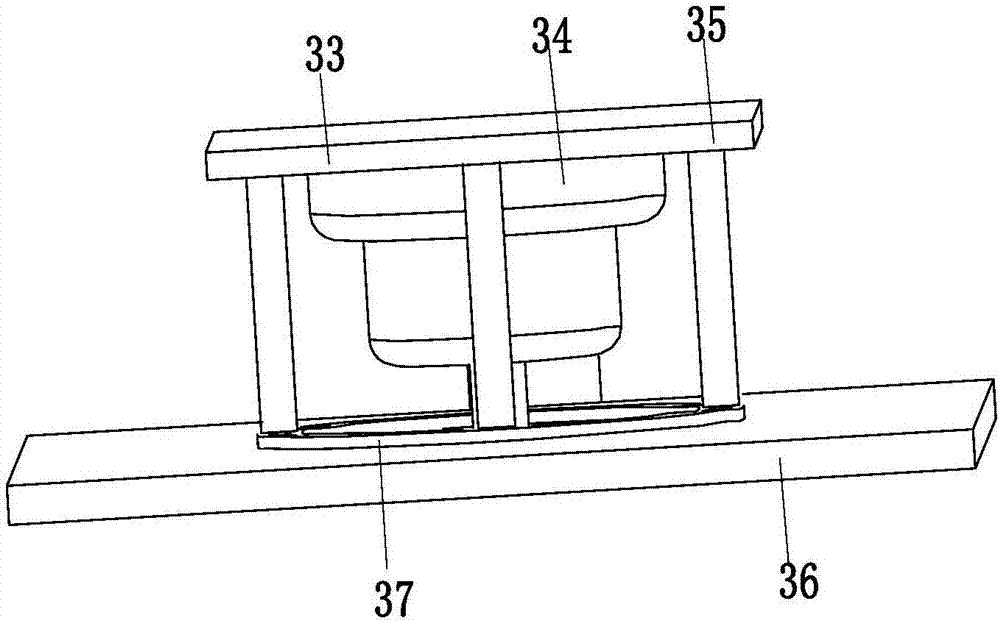

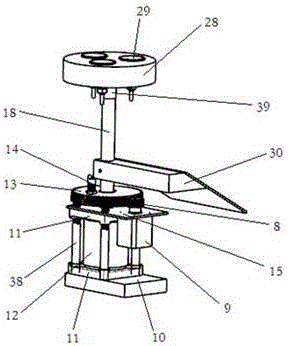

Accurate positioning storage bin

ActiveCN103028998AIncrease loading capacitySmall footprintMetal working apparatusMotor driveSmall footprint

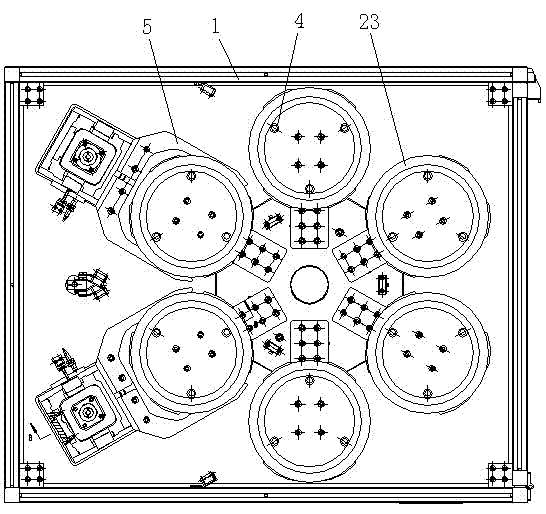

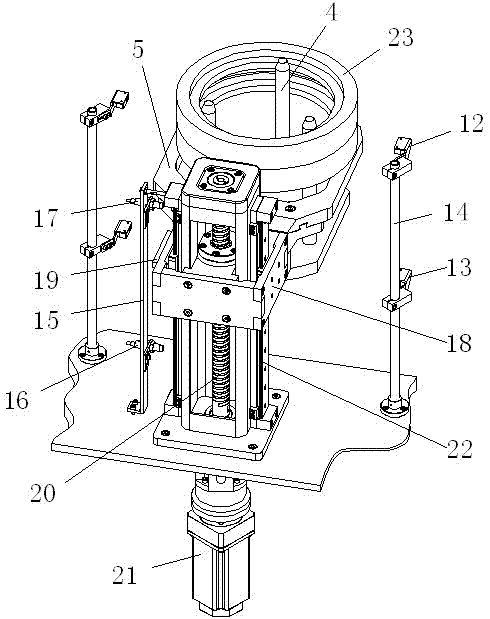

The invention discloses an accurate positioning storage bin. The accurate positioning storage bin comprises a storage bin frame, workpiece lifting mechanisms and a workpiece horizontal rotary conveying mechanism; the workpiece horizontal rotary conveying mechanism comprises a first motor which is arranged on the storage bin frame, a rotary disc which is connected with a first motor rotor and workpiece loading mechanisms which are arranged along the peripheral direction of the rotary disc at equal intervals; and two sets of workpiece lifting mechanisms are arranged and are distributed opposite to the two sets of workpiece loading mechanisms, and each workpiece lifting mechanism comprises a clamping jaw for conveying workpieces on the workpiece loading mechanisms and a drive device for driving the clamping jaw to lift and descend. According to the accurate positioning storage bin, the first motor drives the rotary disc so as to drive the workpiece loading mechanisms to rotate horizontally, so that the transmission error existing in conventional storage bin chain wheel and chain transmission is eliminated, the repeat positioning precision along the horizontal direction is high, and a manipulator of processing equipment can accurately take and store materials; and moreover, a plurality of workpiece loading mechanisms can be arranged on the same rotary disc, the loading capacity of the storage bin is large and the storage bin occupies a small area.

Owner:CHONGQING MACHINE TOOL GROUP

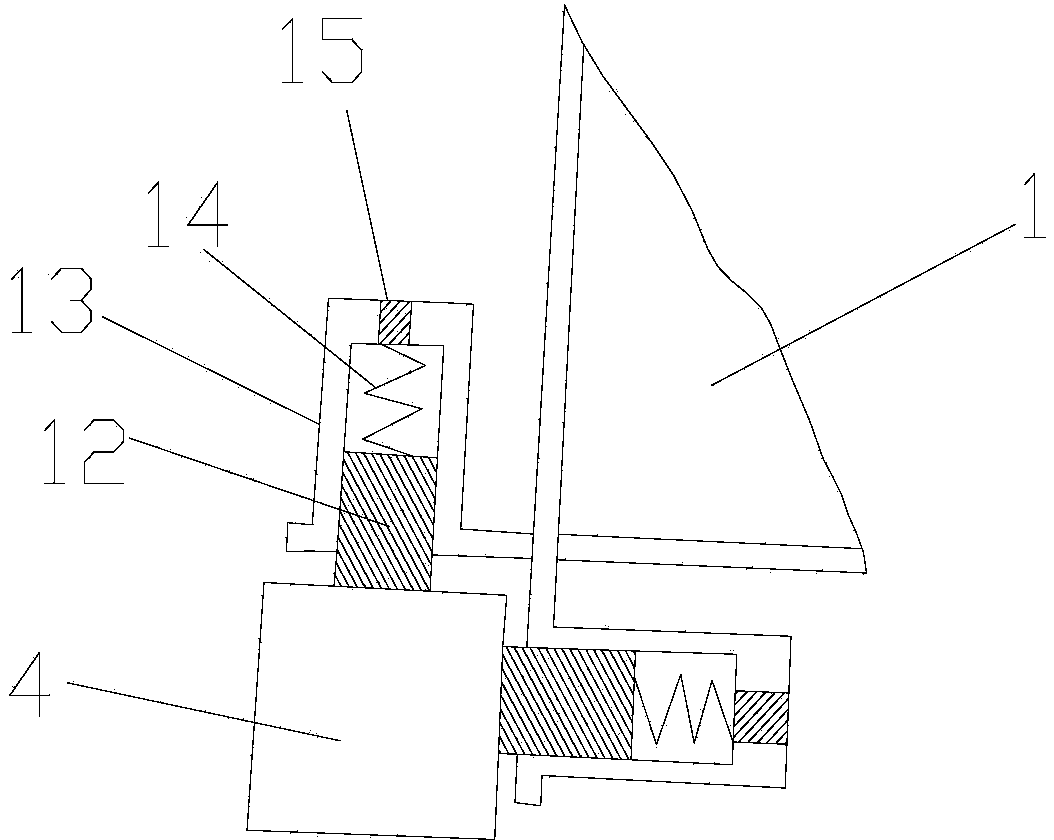

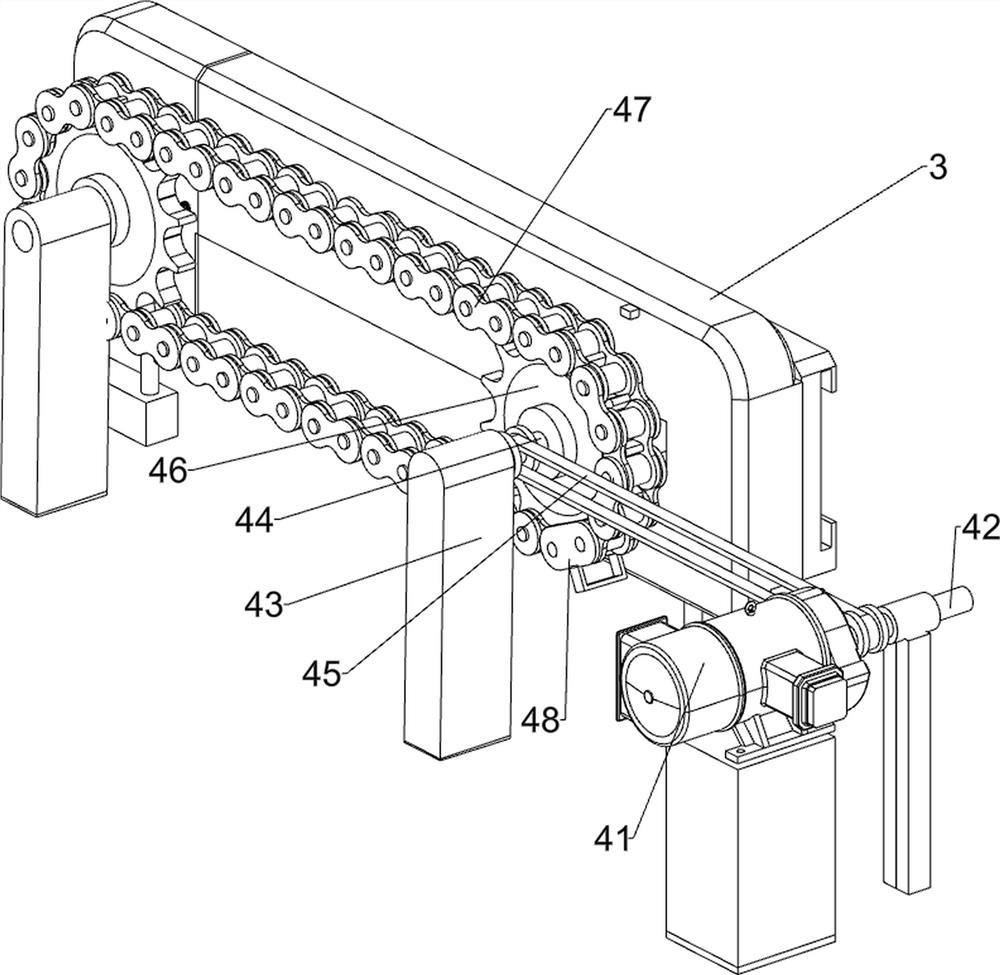

Self-unloading-type blanking device

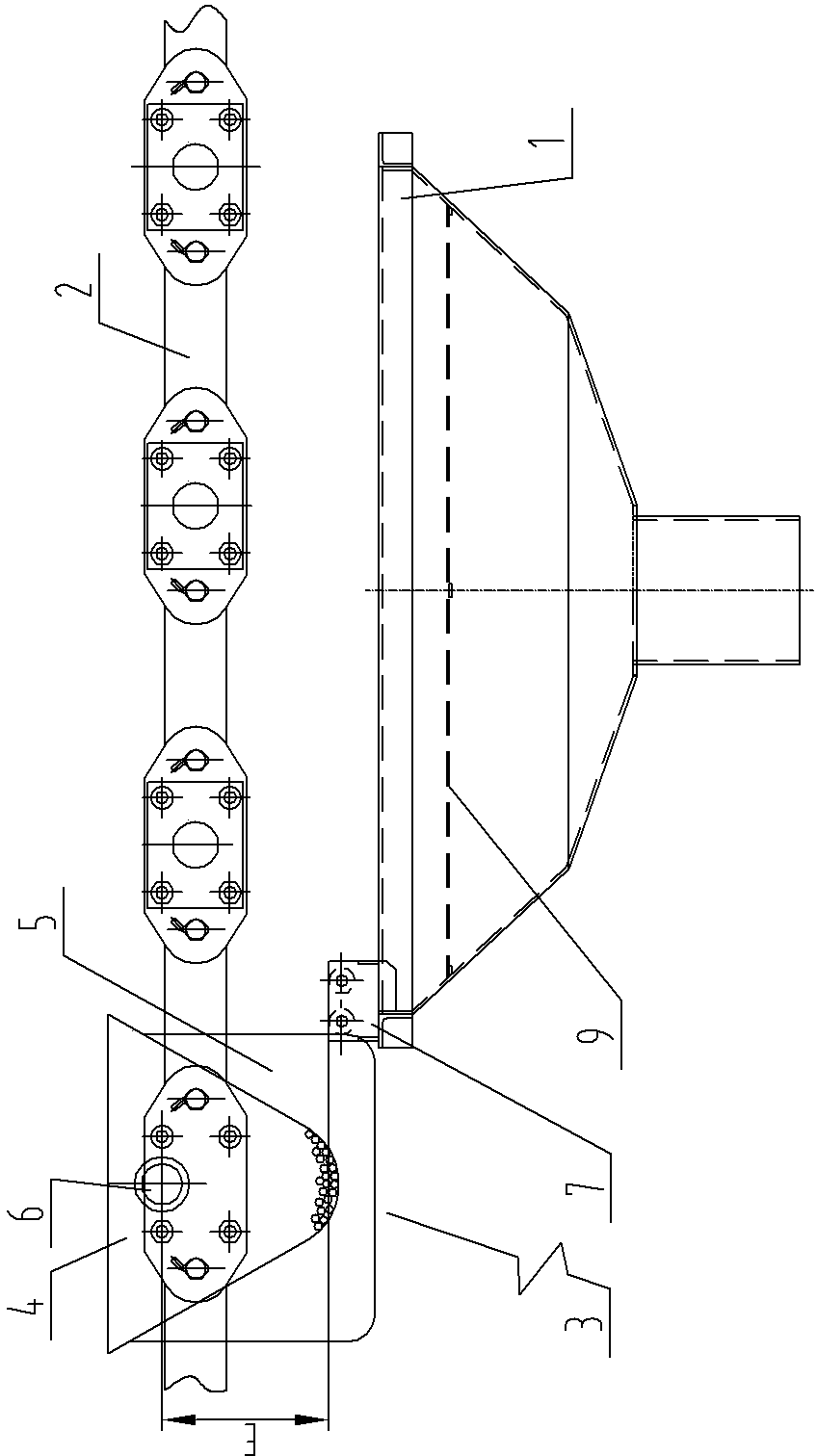

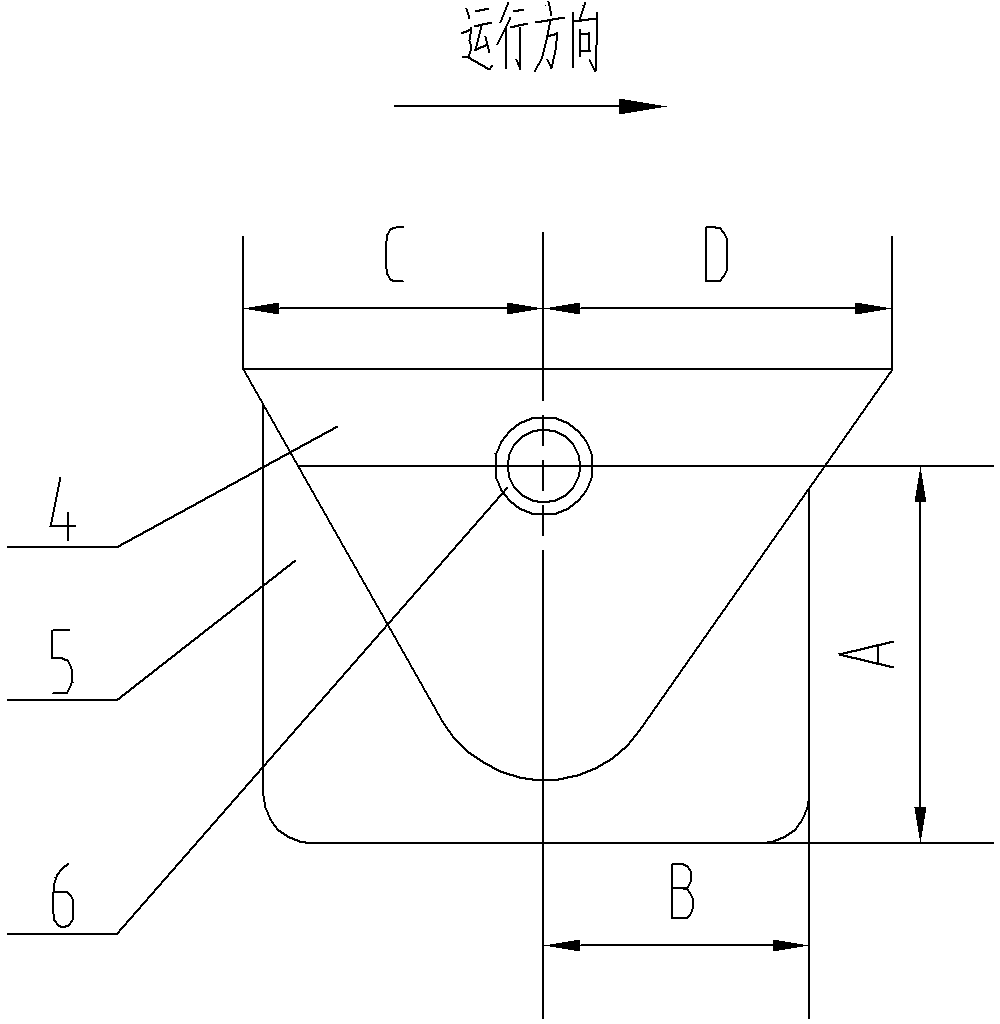

ActiveCN103466306AShipped accuratelyPlay the role of hanging weightConveyor partsSteel ballFixed position

The invention provides a self-unloading-type blanking device. By the self-unloading-type blanking device, steel balls are enabled to automatically fall towards a feeding device, and manual conveying and interfering are not needed; the self-unloading-type blanking device is timesaving, laborsaving and high in efficiency, and accurate conveying of the steel balls is guaranteed. The self-unloading-type blanking device comprises a feeding hopper, and a dedusting device is arranged below the feeding hopper. The self-unloading-type blanking device is characterized in that a conveying chain is arranged above the feeding hopper, a material mover is mounted on the conveying chain and comprises a material moving hopper, a guide plate and a turning bearing, the guide plate is arranged on the outer side of the material moving hopper, the turning bearing penetrates two sides of a front position on the upper portion of the material moving hopper, the turning bearing, the guide plate and the material moving hopper form the material mover in a fixed position relationship, the turning bearing is supported in a positioning groove of the conveying chain, and the material moving hopper is of an opening-closed structure in a big-end-up manner.

Owner:JIANGSU TAIHU BOILER

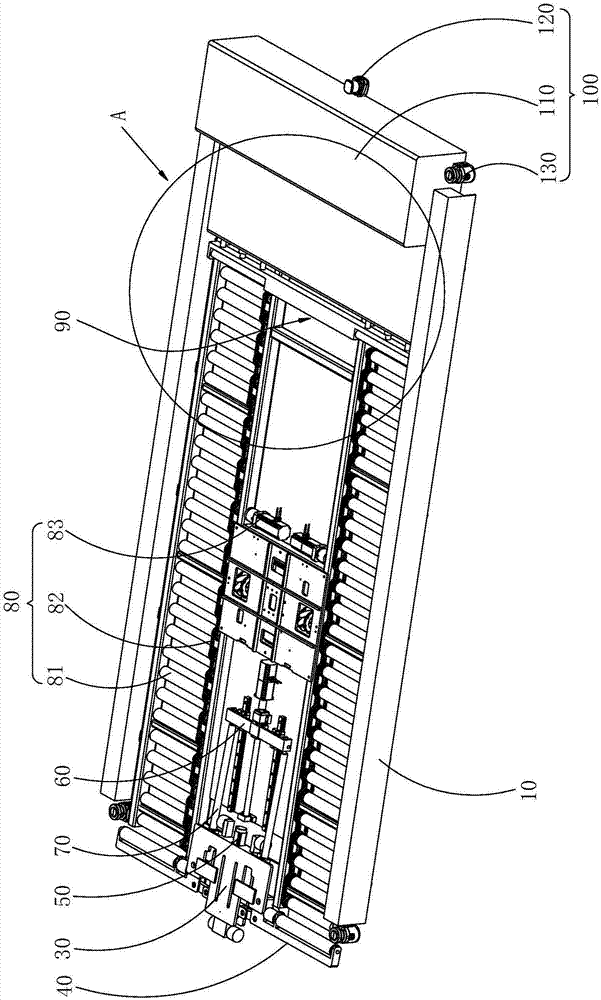

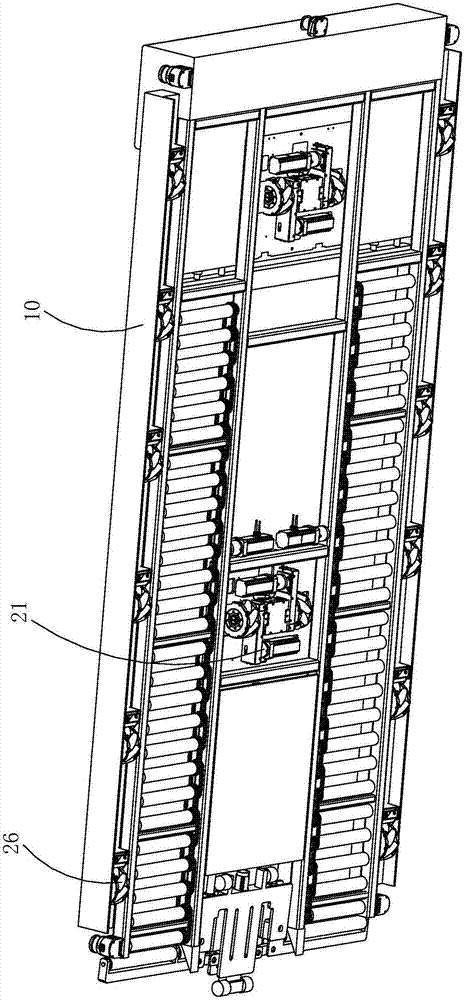

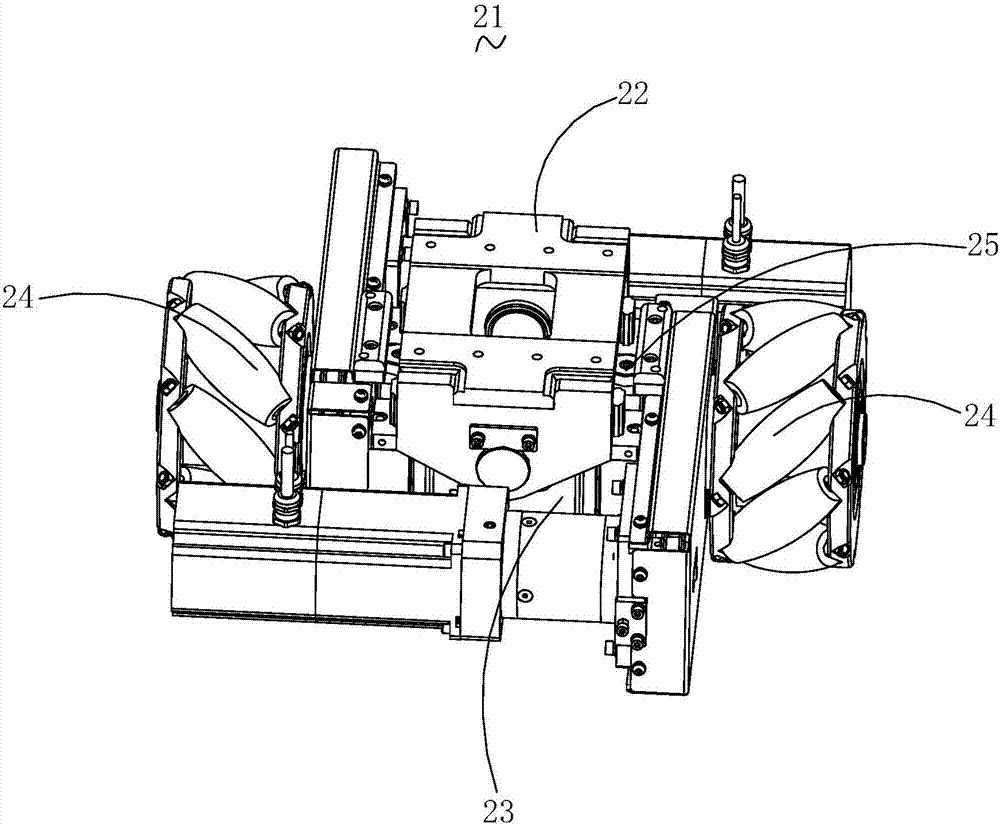

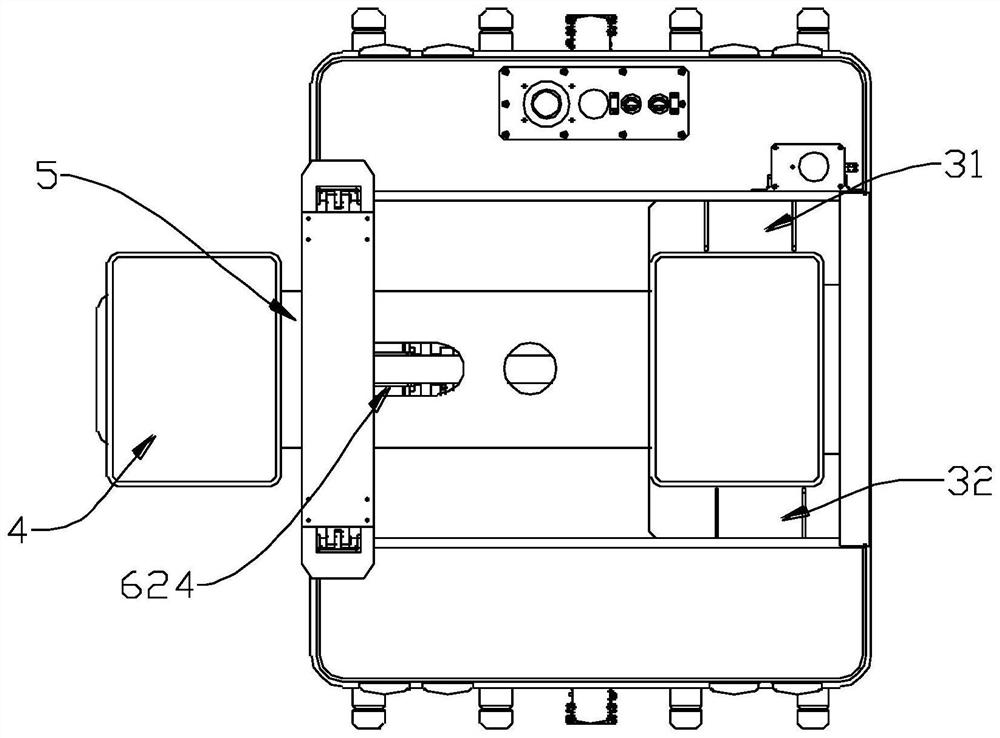

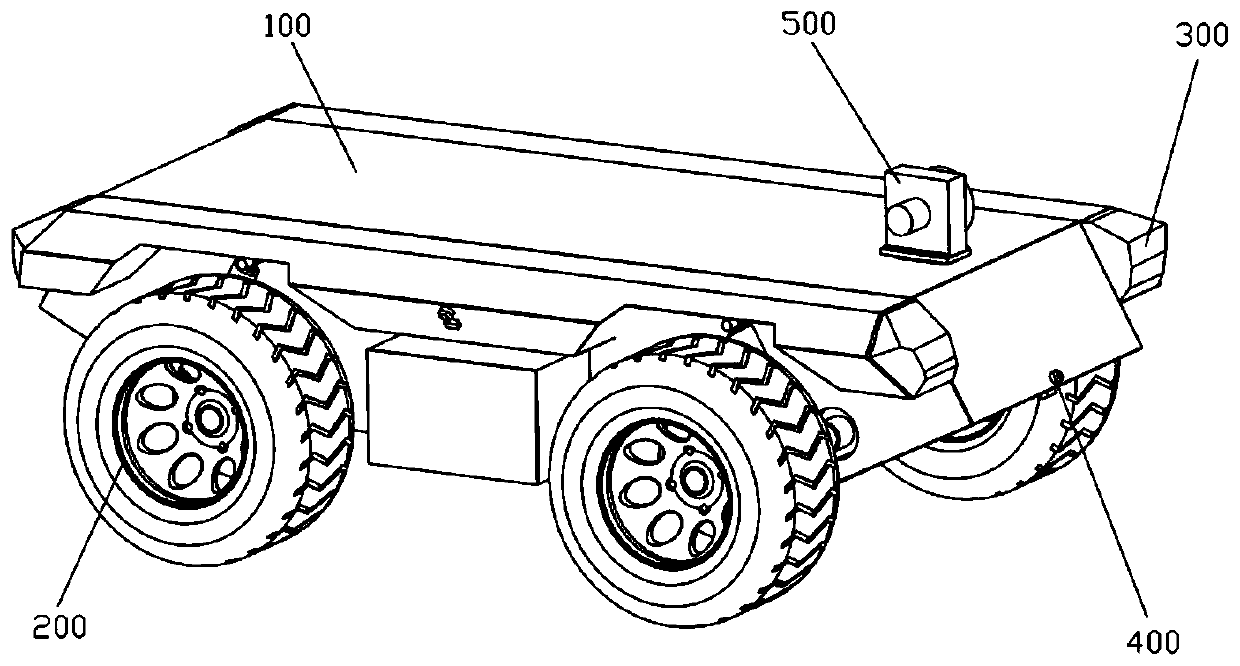

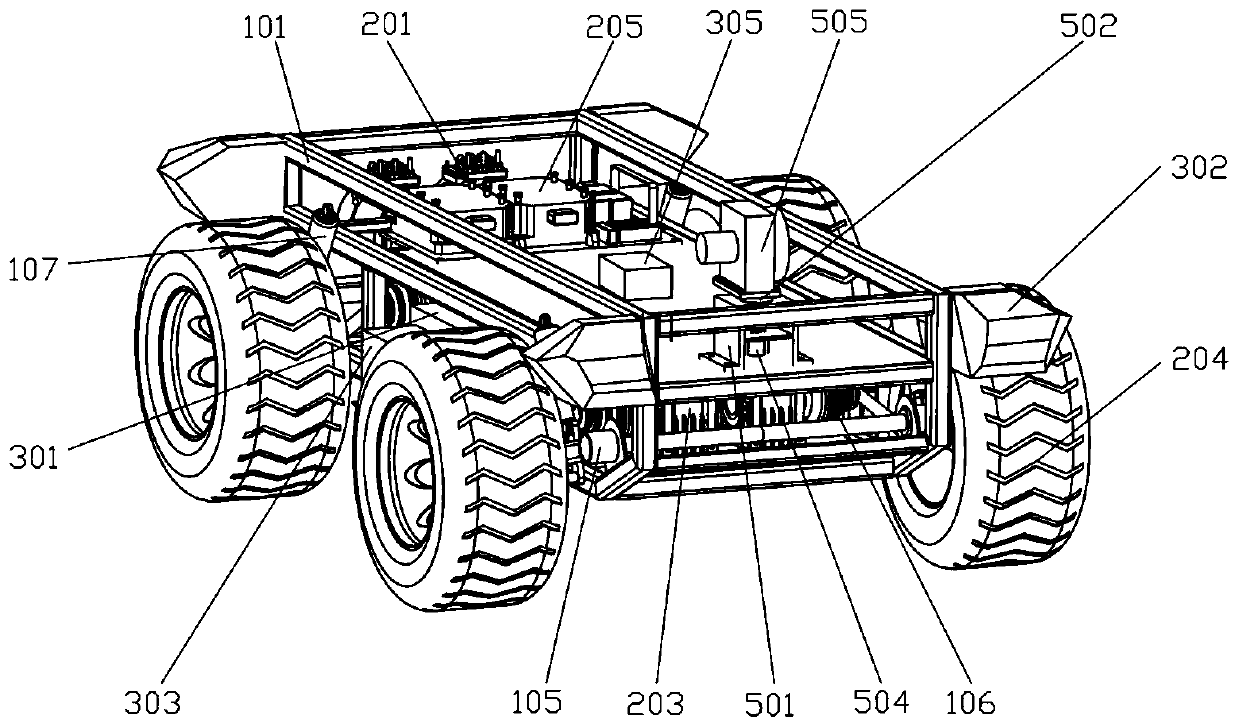

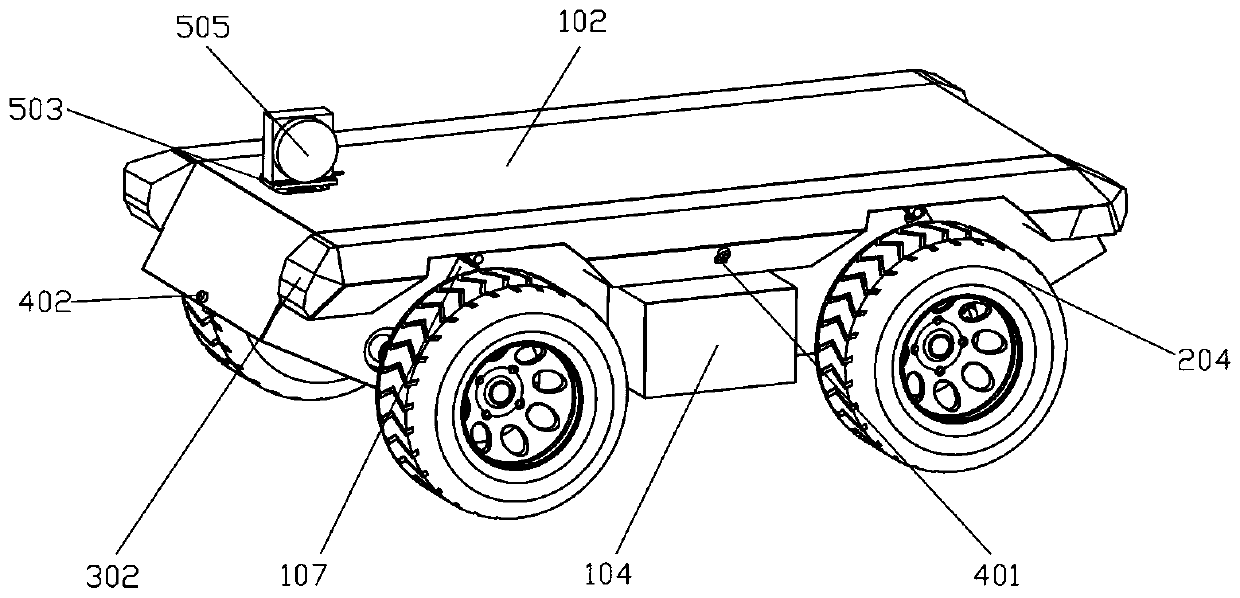

AGV conveying robot and positioning and orienting method used for robot

Provided is an AGV conveying robot and a positioning and orienting method used for the robot. The AGV conveying robot comprises a vehicle frame, and running devices, a clamping arm device, a front blocking device, a conveying device and an electronic control system installed on the vehicle frame correspondingly. The clamping arm device and the front blocking device are located on two sides of the vehicle frame correspondingly, and the conveying device is located on the top of the vehicle frame. The clamping device comprises a clamping arm base, two clamping arms arranged on two sides of the clamping arm base correspondingly, a pushing arm mechanism arranged on the clamping arm base, a pushing base mechanism installed on the vehicle frame and a connecting rod for connecting the clamping arm base. One end of each clamping arm is pivotally connected to a base body and a pushing arm mechanism, and the connecting rod is hinged with the pushing base mechanism. The clamping arms can be driven by the pushing arm mechanism to rotate around the clamping arm base, the clamping arm base is driven by the pushing base mechanism to stretch out and retract into the vehicle frame, and then matches conveying motion of the conveying device, so that the parking and picking automobiles can be achieved. According to the AGV conveying robot and the positioning and orienting method, a vehicle loading tray and a comb-shaped frame for parking vehicles that are essential in a traditional garage can be omitted, and the garage cost is reduced.

Owner:DONGGUAN SONGSHAN LAKE TECHXINST CO LTD

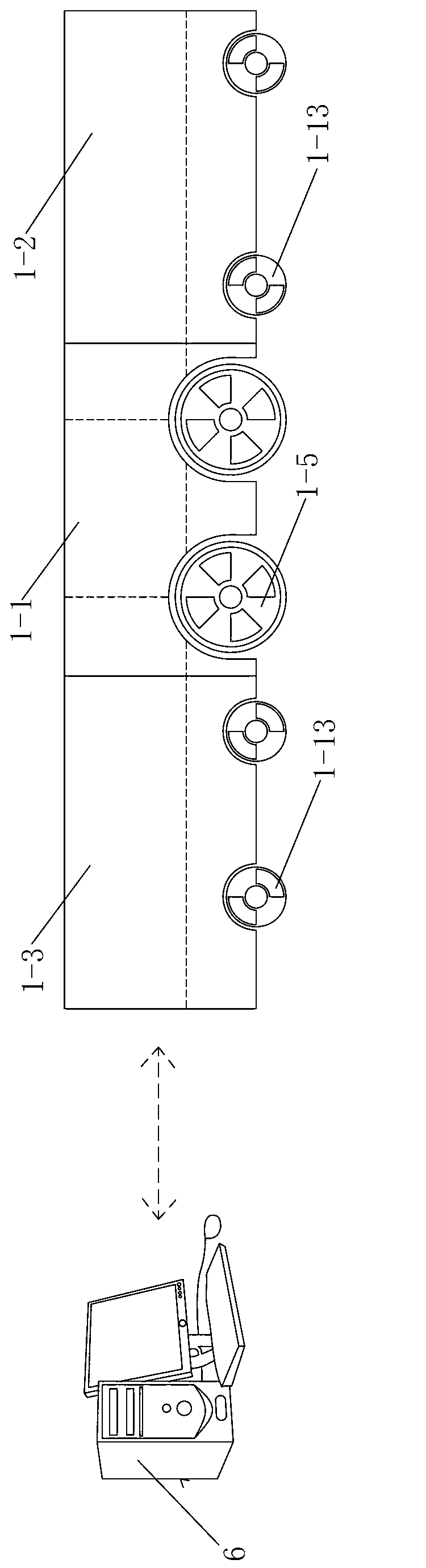

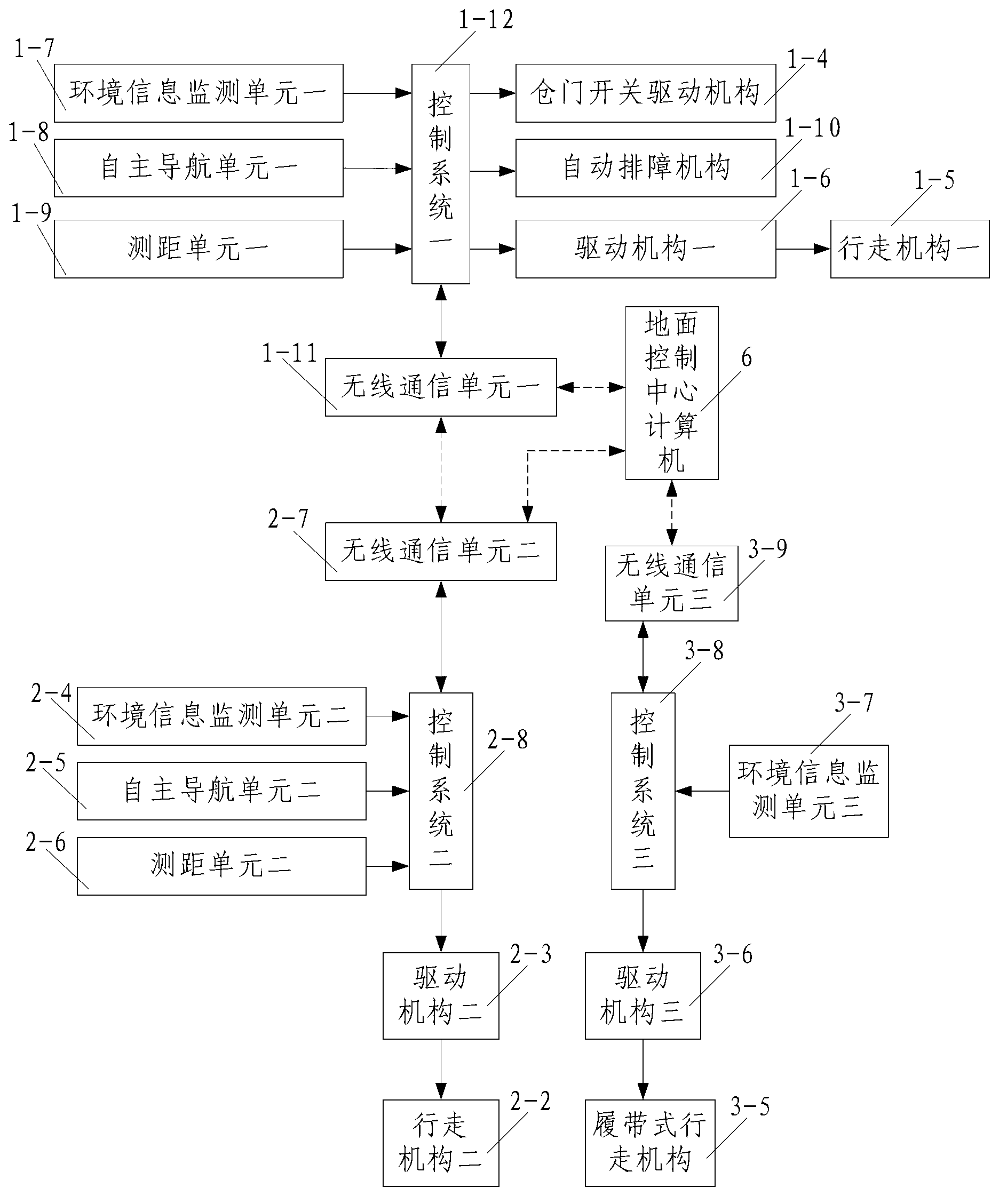

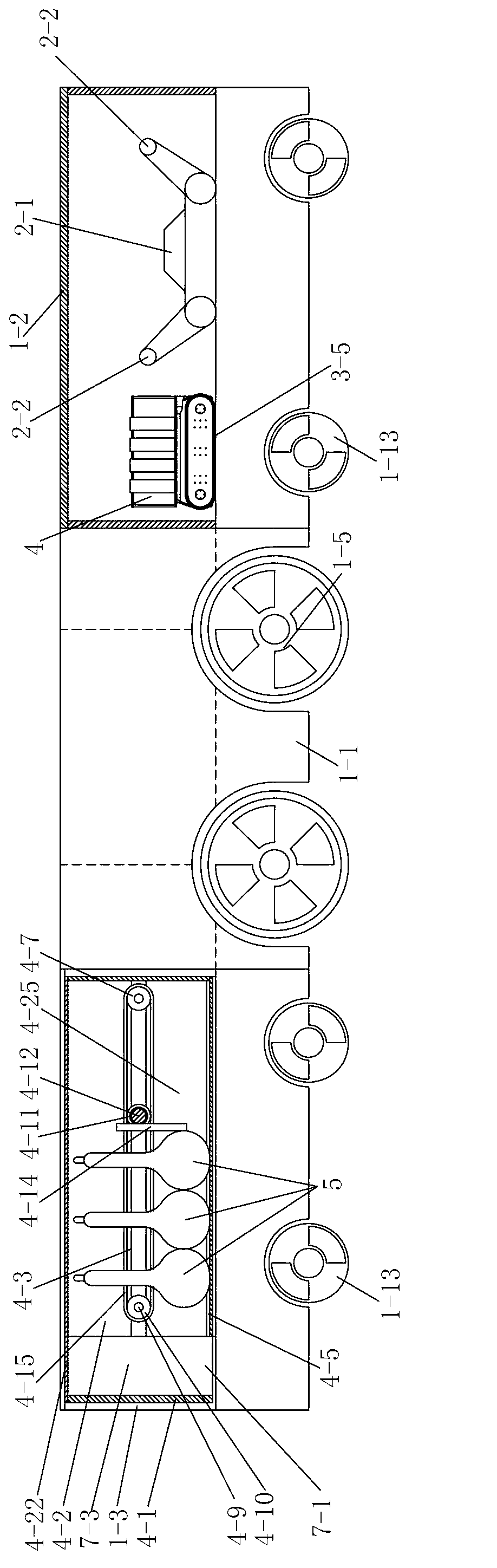

Building system and method of wireless communication network for emergency rescue in underground coal mine

ActiveCN103072600ANovel and reasonable designEasy to implementRailway traffic control systemsRescue robotNetwork link

The invention discloses a building system and method of a wireless communication network for emergency rescue in an underground coal mine. The system comprises a rescue commanding center computer and a rescue robot system. The rescue robot system comprises a carrying robot, a probe robot placed in a robot storage cabin, and a wireless communication relay placing system which places a communication network robot and is placed in a placing system storage cabin. The wireless communication relay placing system comprises a wireless communication relay placing device and a wireless communication relay. The method comprises the steps that first, the carrying robot detects and processes signals, the placing device in the placing system storage cabin casts the wireless communication relay and draws an emergency rescue wireless communication network link map; then, the communication network robot is placed to detect and process the signals and the wireless communication relay is cast to update the map till the underground emergency wireless communication network is built. The system and the method are reasonable in design, strong in practicality and high in popularization and application value.

Owner:XIAN UNIV OF SCI & TECH

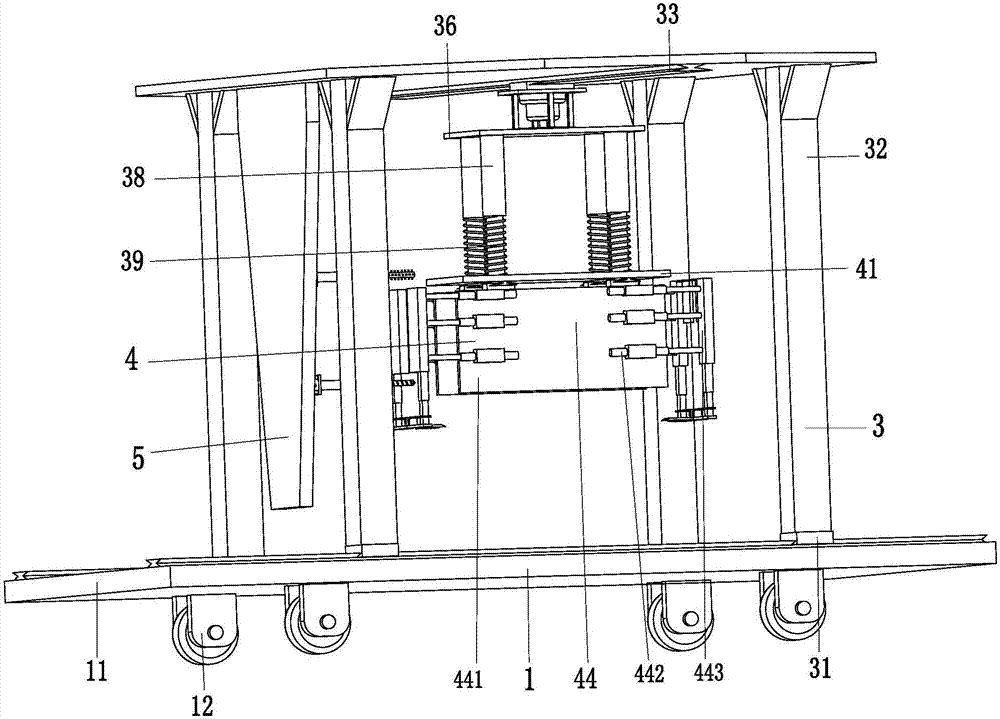

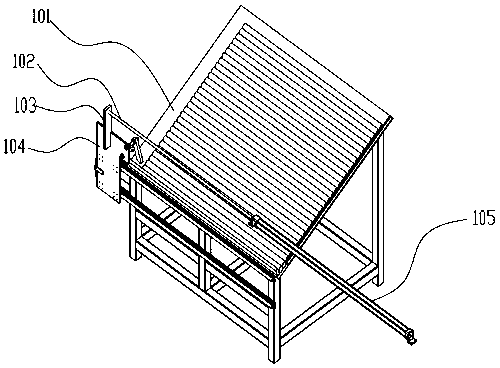

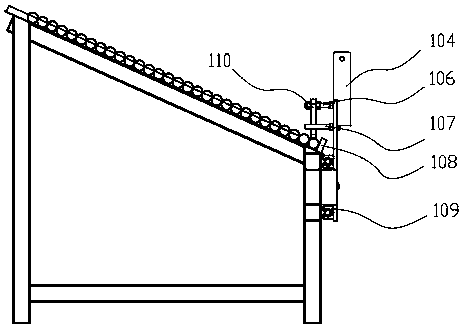

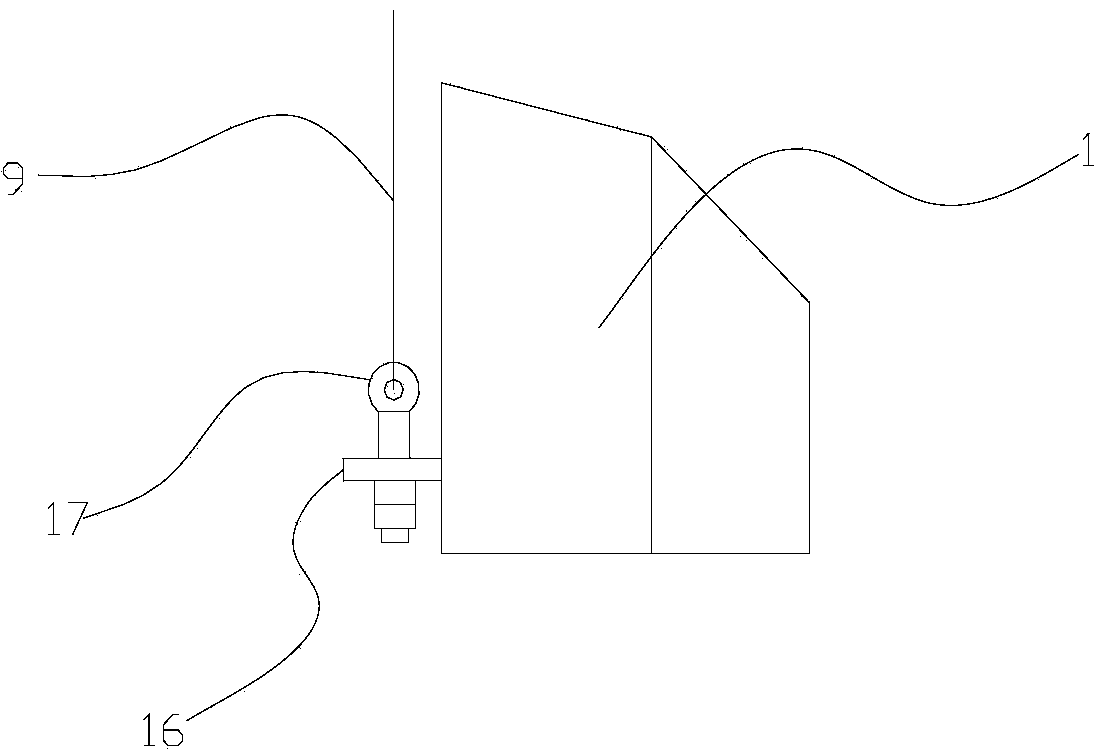

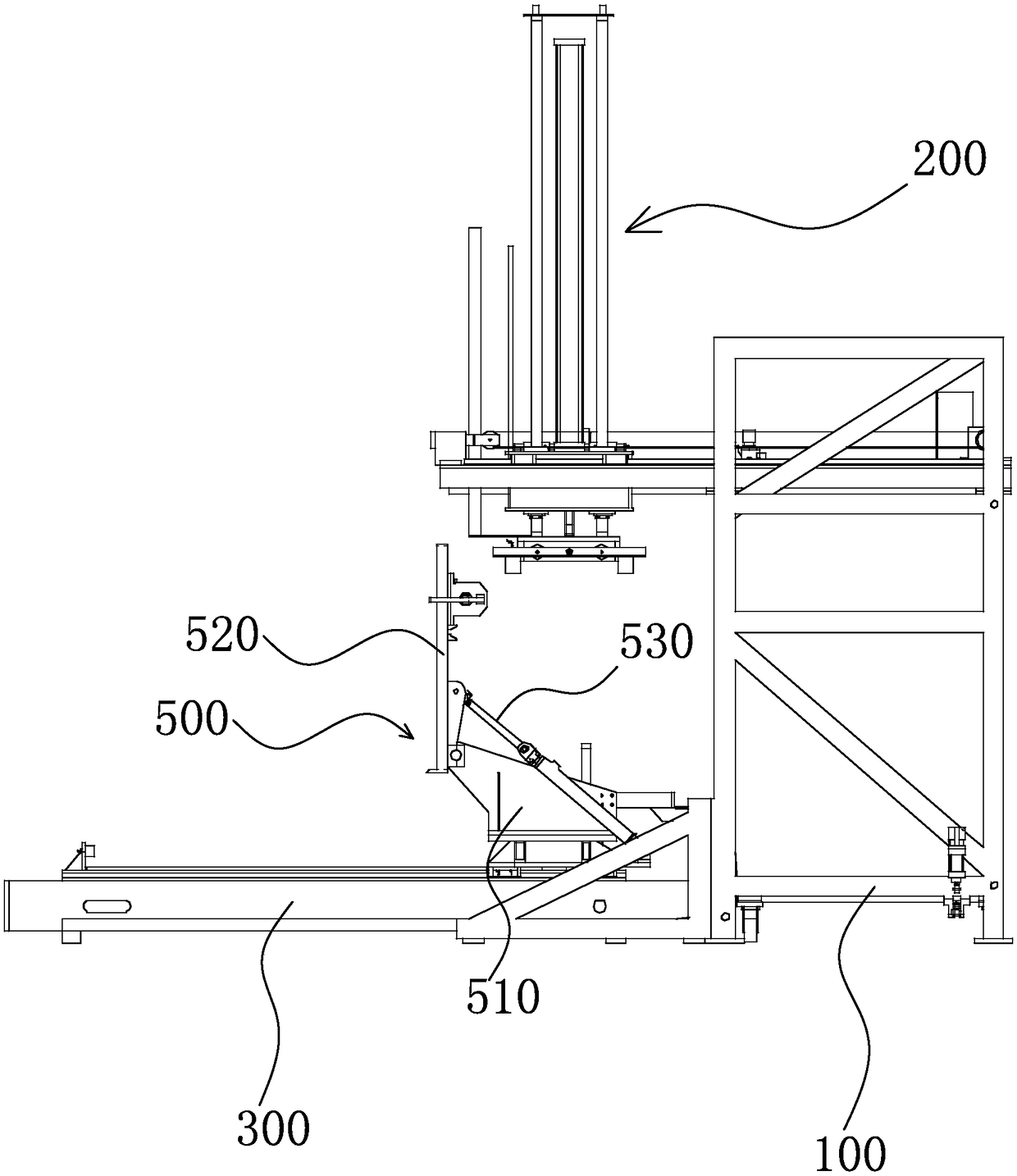

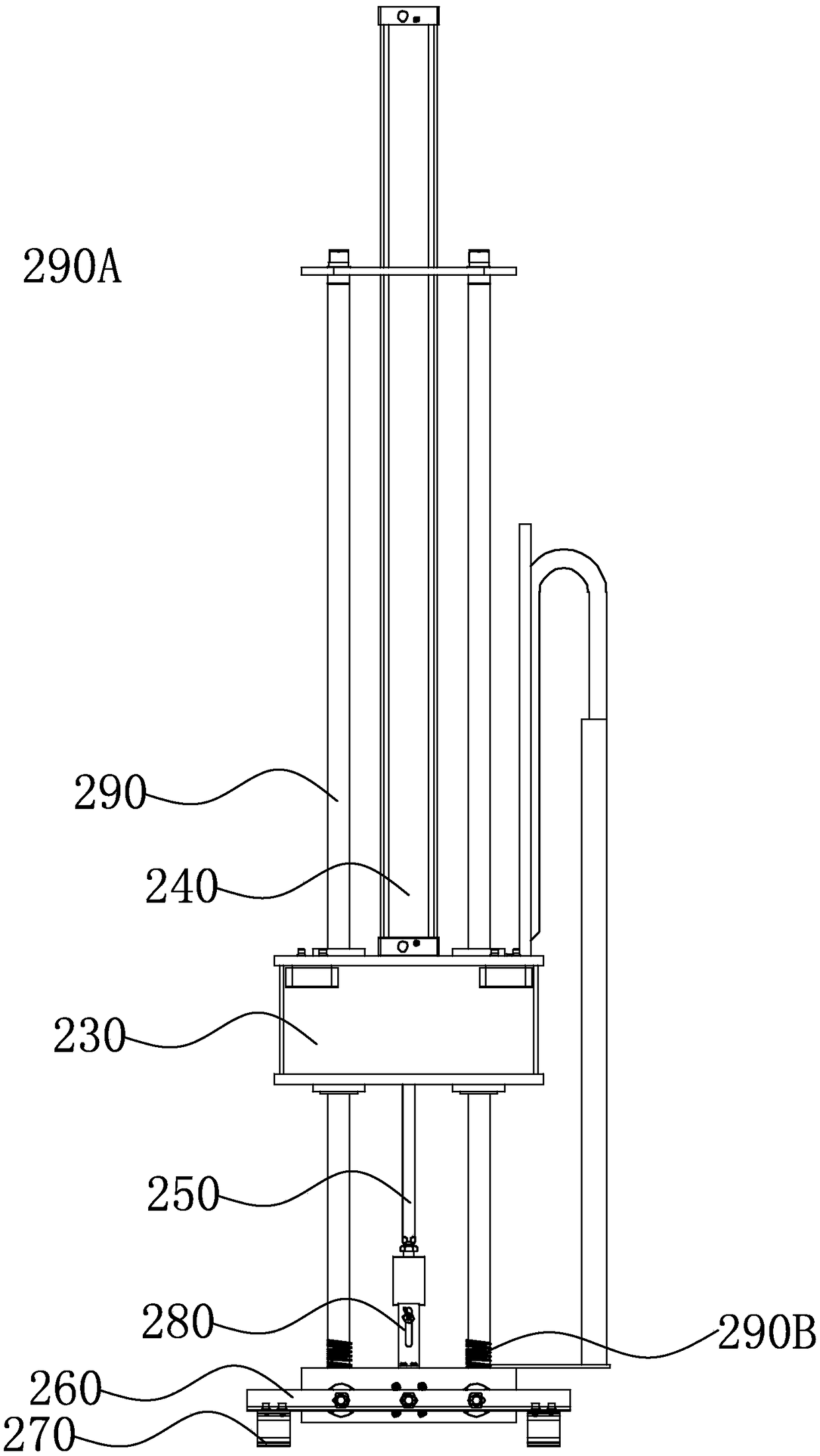

Automatic hoisting and mounting machine for special glass fiber reinforced plastic isolating piers for expressway maintenance

ActiveCN107324220ARealize automatic positioning and installationImprove work efficiencyCleaning using toolsTrolley cranesGlass fiberMechanical engineering

The invention relates to an automatic hoisting and mounting machine for special glass fiber reinforced plastic isolating piers for expressway maintenance. The automatic hoisting and mounting machine comprises a base, a hoisting frame device, a grabbing device and a clearing device, wherein the base comprises a supporting bottom plate and four universal wheels; the bottom of the hoisting frame device is connected with the top of the supporting bottom plate; the grabbing device is mounted on the hoisting frame device; the clearing device is positioned at the left side of the grabbing device; and the clearing device is mounted on the hoisting frame device. The automatic hoisting and mounting device can solve the problems that working efficiency is low, labor intensity is great, mounting holes of isolating piers cannot be effectively cleared, danger is easily generated in a carrying process of the isolating piers, the isolating piers cannot be positioned and mounted, and the like when the isolating piers are mounted in the prior art, realizes a function of automatically positioning and mounting the isolating piers, and has the advantages of being high in working efficiency, small in labor intensity, capable of completely clearing the mounting holes of the isolating piers, free of danger during mechanical carrying of the isolating piers, and capable of positioning and mounting the isolating piers.

Owner:成武盛阳热力有限公司

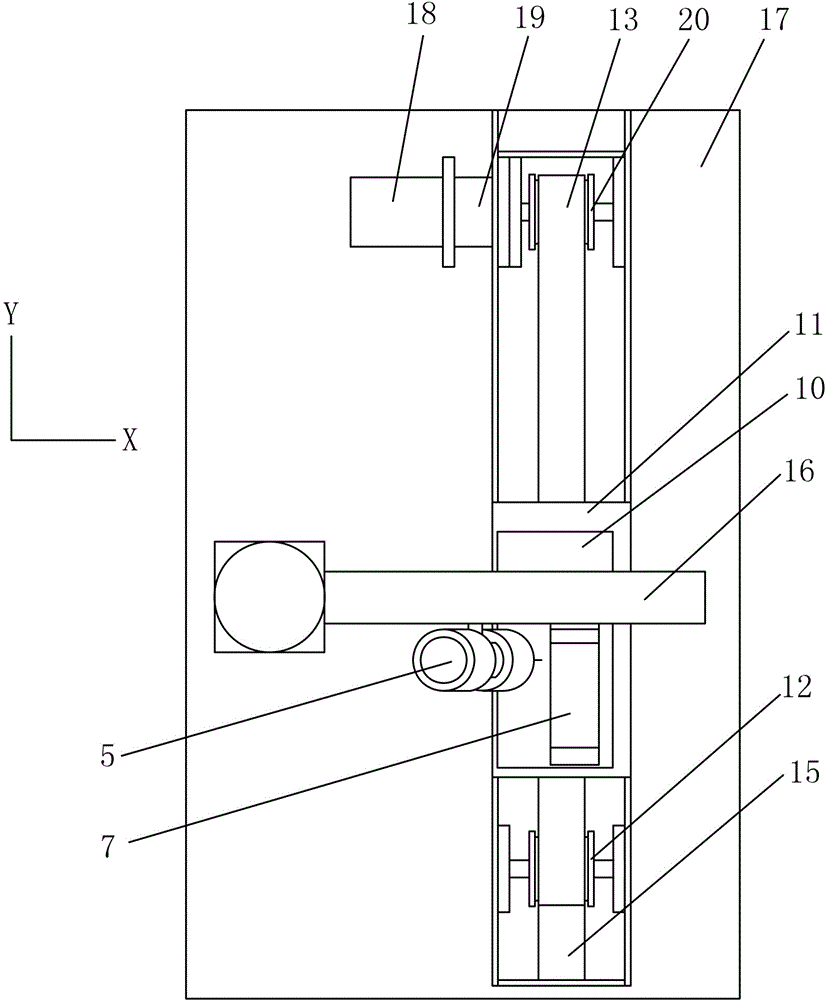

Method for inkjet laser printing on plastic and inkjet laser printing device applying same

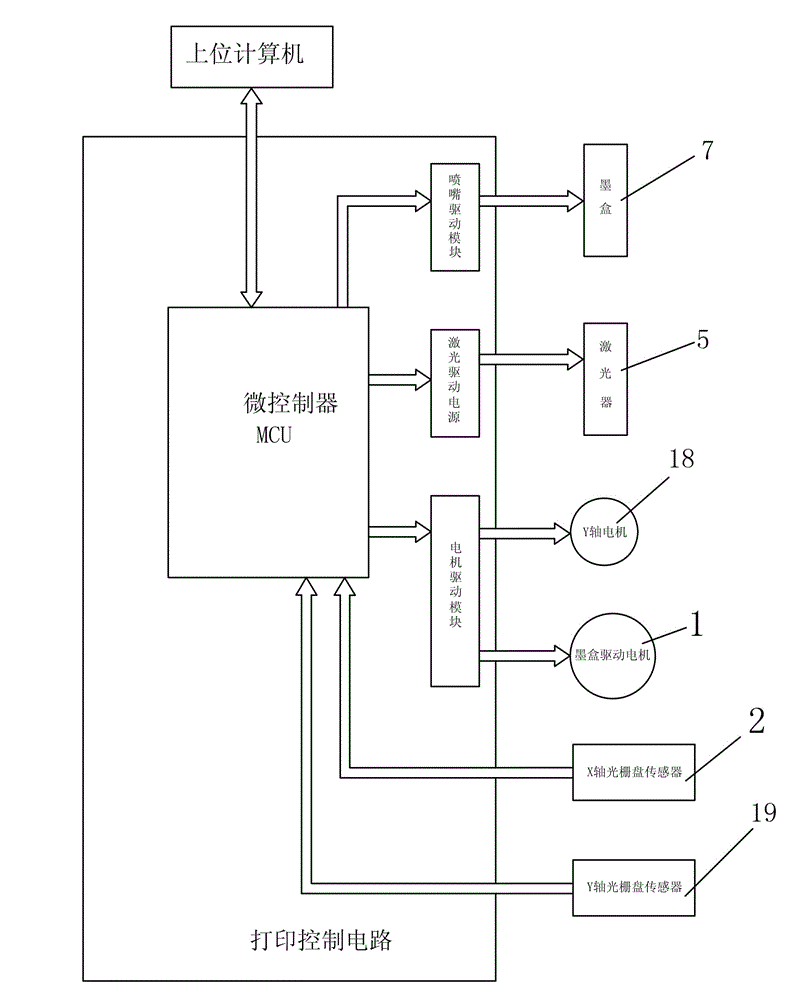

ActiveCN104085191AReduce pollutionAccurate printingTypewritersPower drive mechanismsWater basedSurface layer

The invention relates to a method for inkjet laser printing on plastic and an inkjet laser printing device applying the method. The inkjet laser printing device comprises a printing control circuit, an ink box moving mechanism arranged in the X-axis direction and a printing medium moving mechanism arranged in the Y-axis direction. The printing control circuit is electrically connected with a first drive part and a first printing part on the ink box moving mechanism, the printing control circuit is further electrically connected with a second drive part of the printing medium moving mechanism, a laser is further arranged on the ink box moving mechanism. The method for inkjet laser printing on the plastic and the inkjet laser printing device applying the method have the advantages that water-based ink droplets are raised in temperature quickly, are cured and are fused into a plastic surface layer through the laser, and the water-based ink can be applied to plastic medium to conduct jet printing, so that the limitation of oil-based ink required in a traditional plastic jet printing process is eliminated, and pollution to the air and environment caused by using the oil-based ink is reduced.

Owner:刘小欣 +1

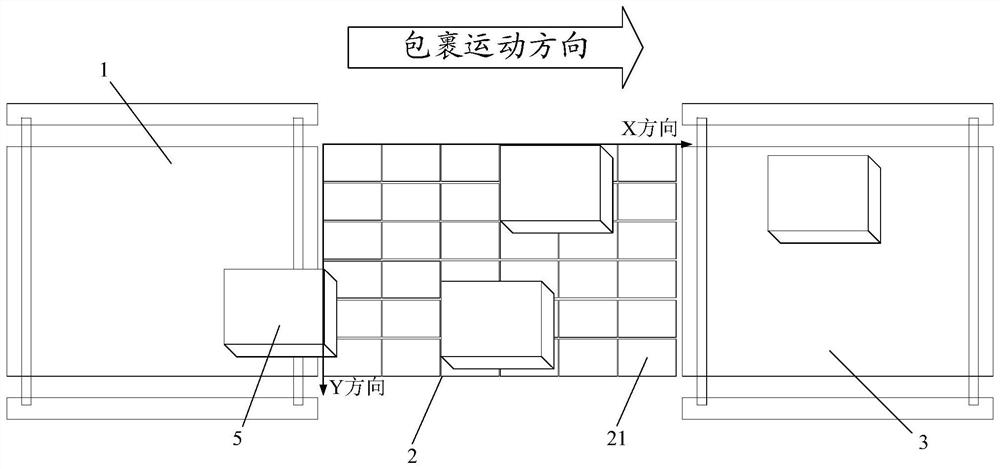

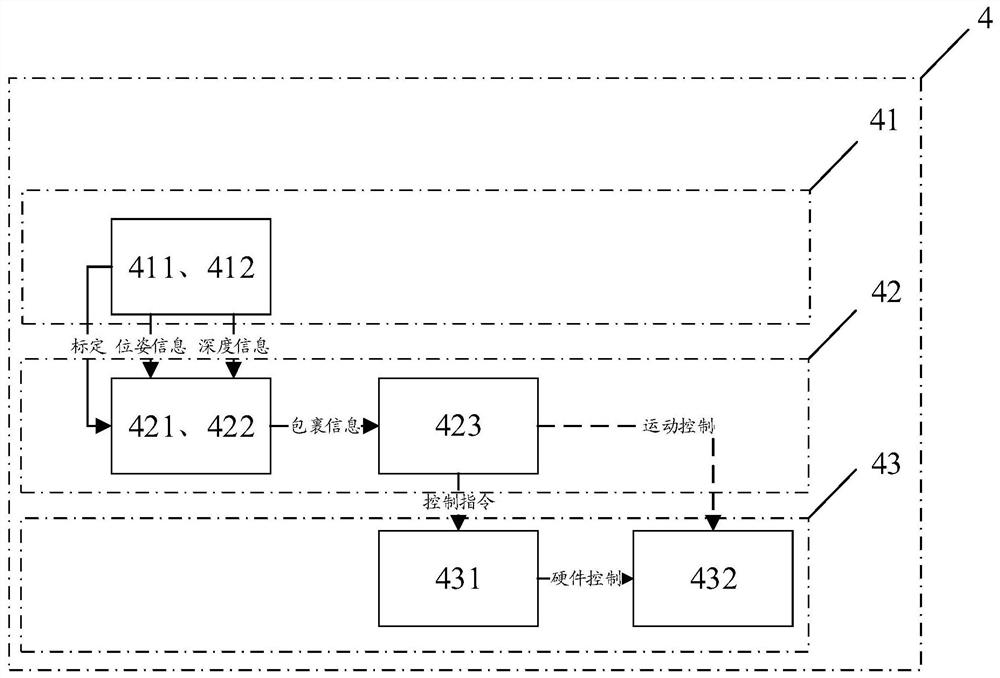

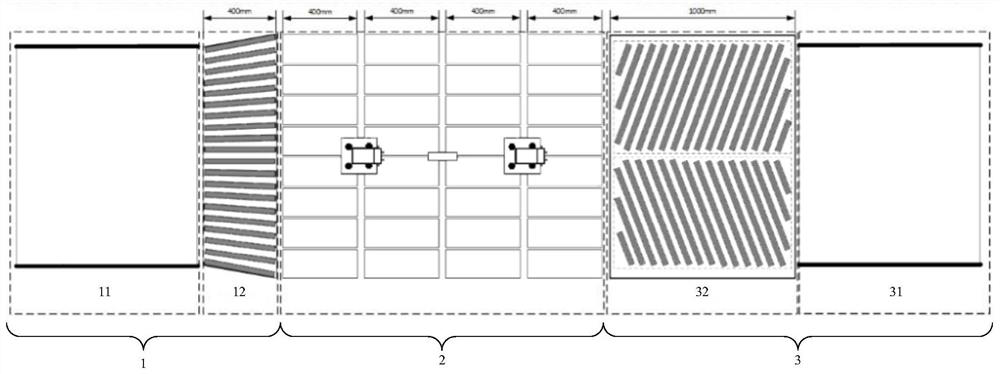

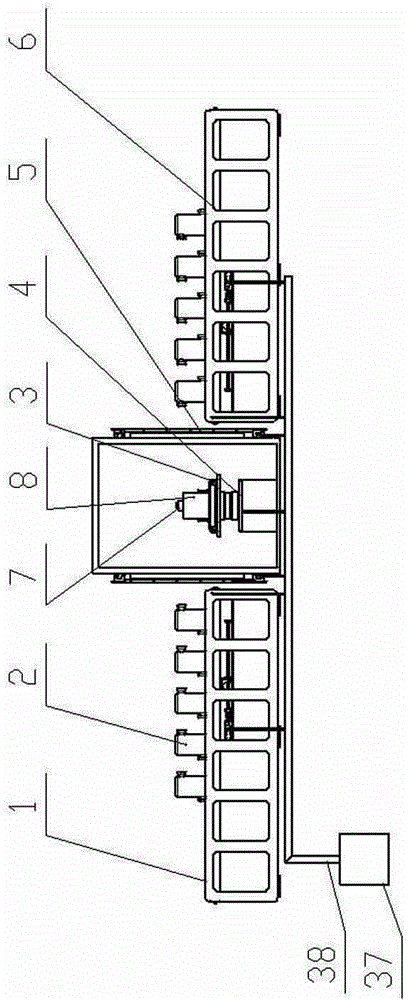

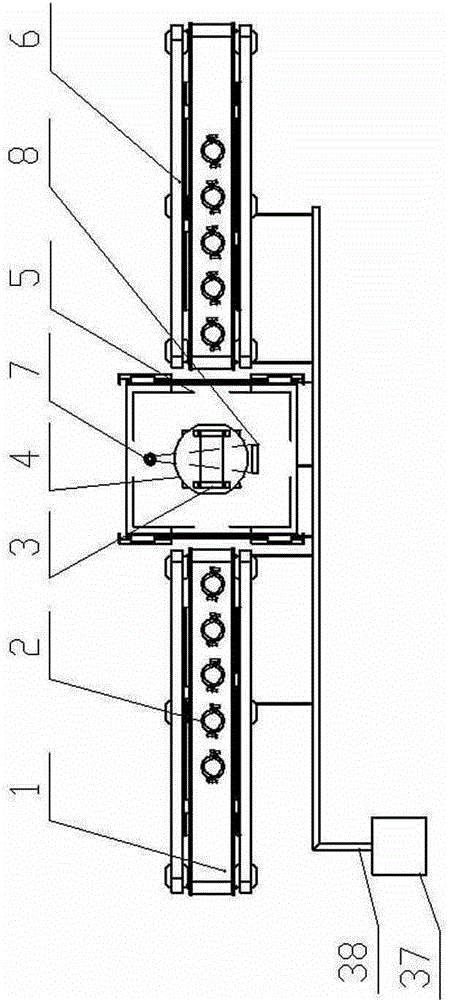

Parcel sorting method and system

ActiveCN111921873AOrdered outputHigh separation precisionSortingLogistics managementProcess engineering

The embodiment of the invention discloses a parcel sorting method and system. Parcels are positioned based on a visual imaging system to obtain imaging information of the parcels, then the coordinaterange correspondingly to each parcel is obtained through the data processing of a control device, according to the location distribution of each parcel on a separator, an appropriate scheduling strategy is used combined with the performance of the separator, and finally the scheduling strategy is sent to the control device to separate the parcels. The method is more accurate in control accuracy and processing throughout than a traditional way through the visual system, and it is not necessary to control the position situation of the parcels flowing into a first conveyor belt in advance by human intervention; and meanwhile the distribution labor cost of a current logistics company in the sorting process can be saved, after the integration of the whole device, the maintenance and improvementin the later stage are also convenient, and the degree of automation of the logistics can be improved.

Owner:HANGZHOU HIKROBOT TECH CO LTD

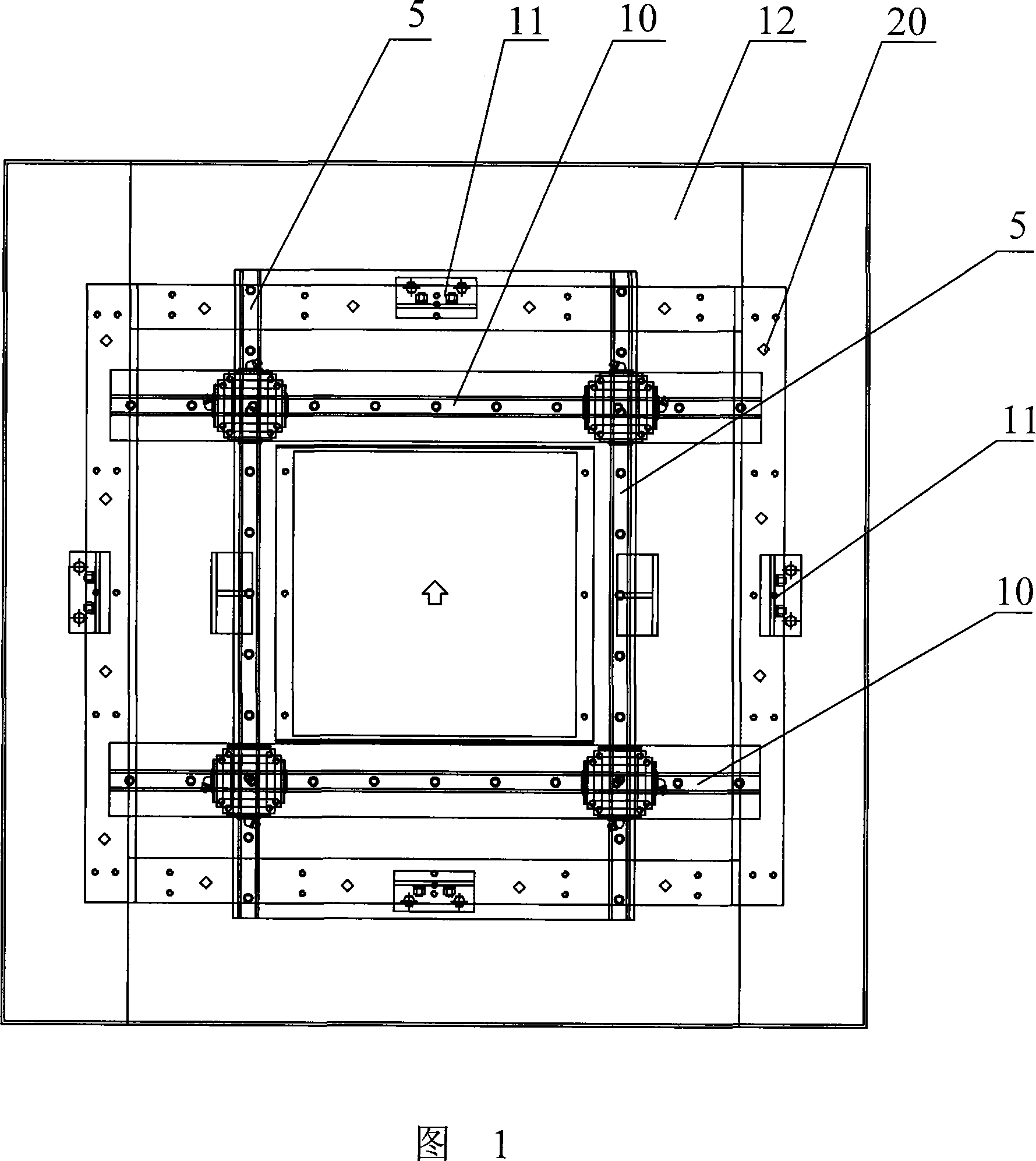

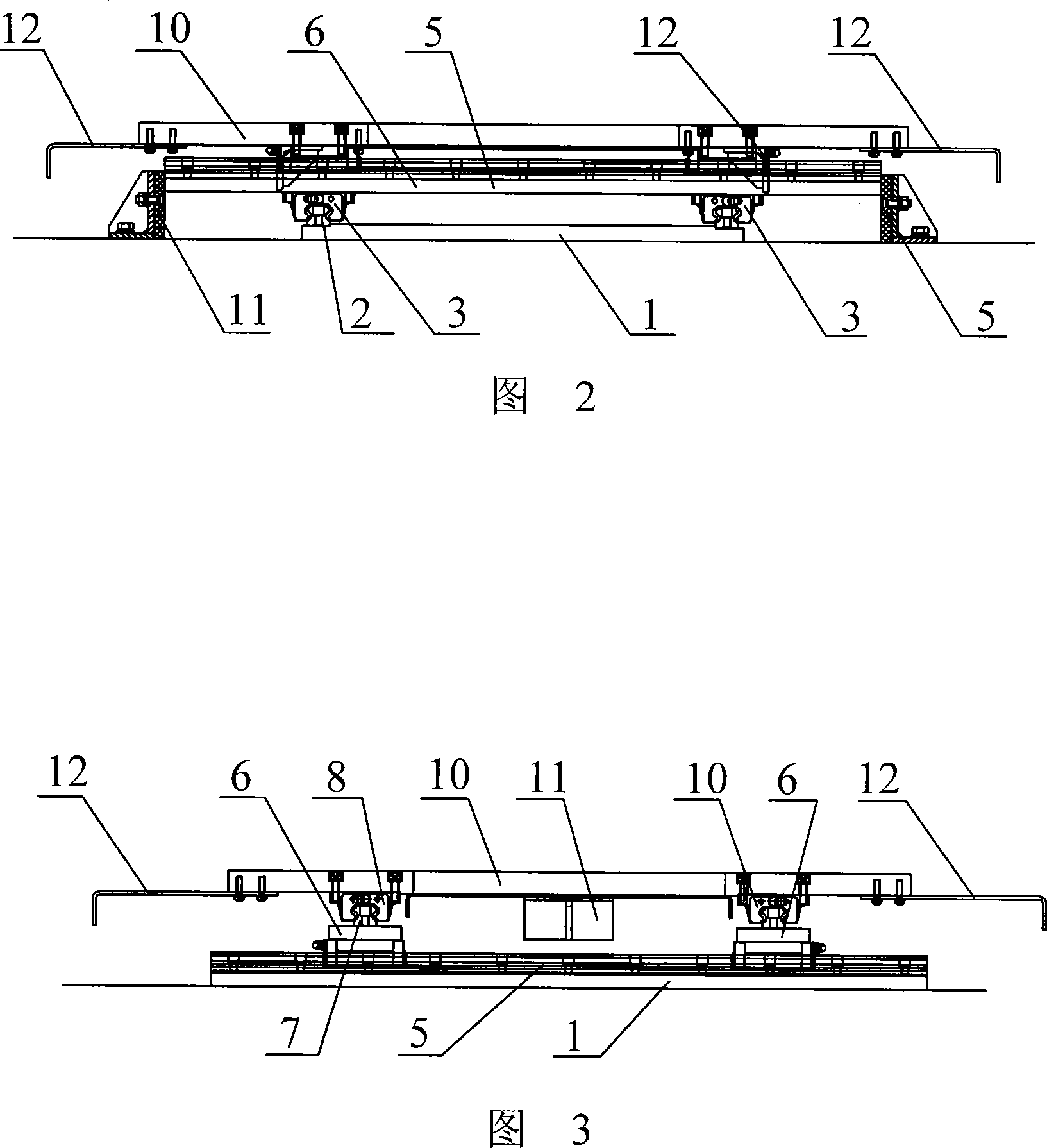

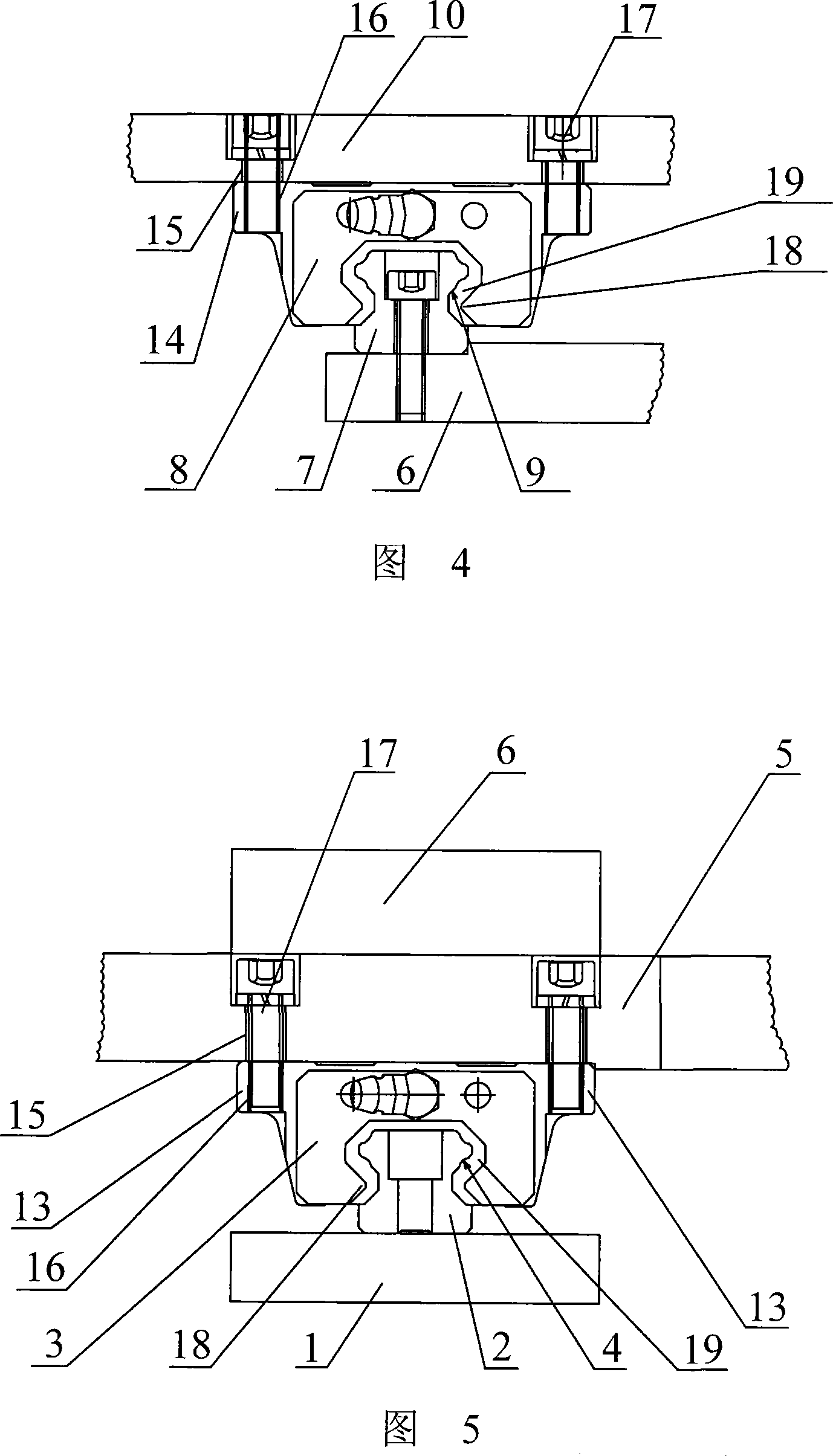

Adjustable sliding table top

InactiveCN101100238ASuitable for assemblyShipped accuratelyConveyor partsVehiclesTransverse grooveEngineering

The adjustable gliding table top includes one pedestal with parallel transverse raised strips, one transverse sliding carriage with bottom transverse grooves set on the transverse raised strips through the slide fit between the transverse raised strips and the transverse grooves, two or more longitudinal guide rails set on the transverse sliding carriage, one installation board with parallel longitudinal raised strips set on the longitudinal guide rails, one longitudinal sliding carriage with bottom longitudinal grooves set on the longitudinal raised strips through the slide fit between the longitudinal raised strips and the longitudinal grooves, and two or more transverse guide rails set on the longitudinal sliding carriage. The present invention has precise conveyance, smart structure, flexible running and simple manufacture process.

Owner:MIRACLE AUTOMATION ENG CO LTD

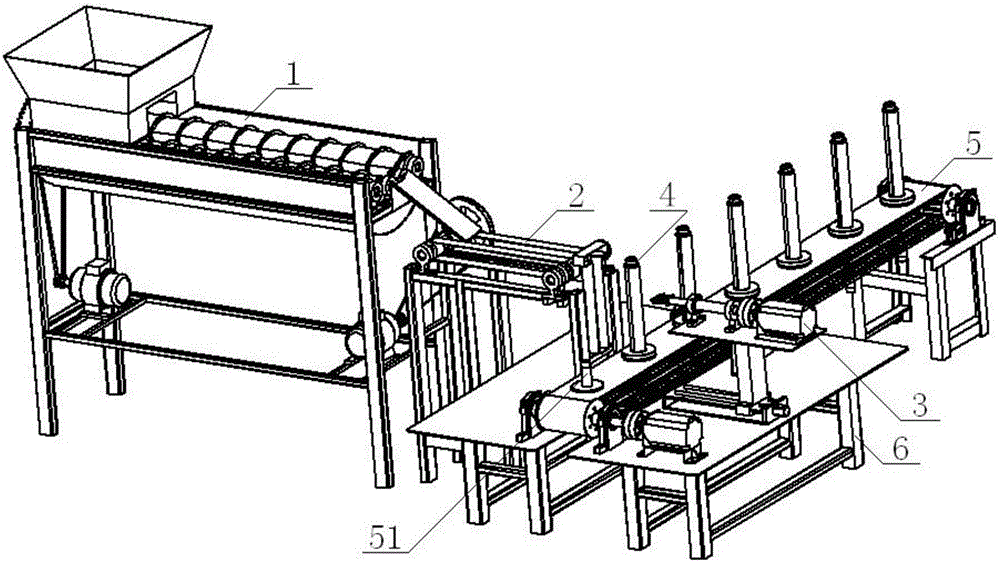

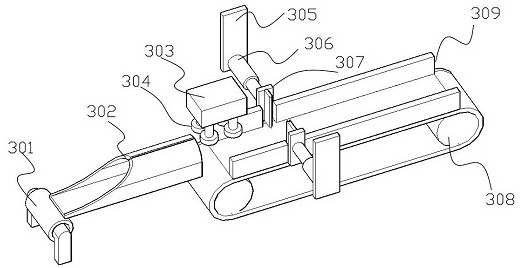

Glass fiber bobbin transporting device and control method thereof

A glass fiber bobbin transporting device comprises a feeding component, a bobbin positioning component, a bobbin overturning component, a bobbin and a synchronous toothed belt. The bobbin positioning component and the bobbin overturning component are arranged on the two sides of the synchronous toothed belt correspondingly. The feeding component is arranged on the side, far away from the synchronous toothed belt, of the bobbin positioning component and comprises an opposite-direction rotation roller, a bobbin bin and a bobbin discharging groove. The bobbin positioning component comprises a synchronous conveying belt and a guiding frame. The bobbin overturning component comprises a clamping pneumatic claw provided with a bobbin clamping frame, an overturning shaft and an overturning motor. In the transporting process, the bobbin is conveyed into the guiding frame sequentially through the opposite-direction rotation roller, the bobbin discharging groove and the synchronous conveying belt, a bobbin body is clamped through the bobbin clamping frame, then, the overturning motor drives the overturning shaft to overturn so that the bobbin can be rotated, the bobbin body is loosened through the bobbin clamping frame, and the bobbin falls onto the synchronous toothed belt. The design is high in work efficiency and low in labor cost.

Owner:WUHAN TEXTILE UNIV

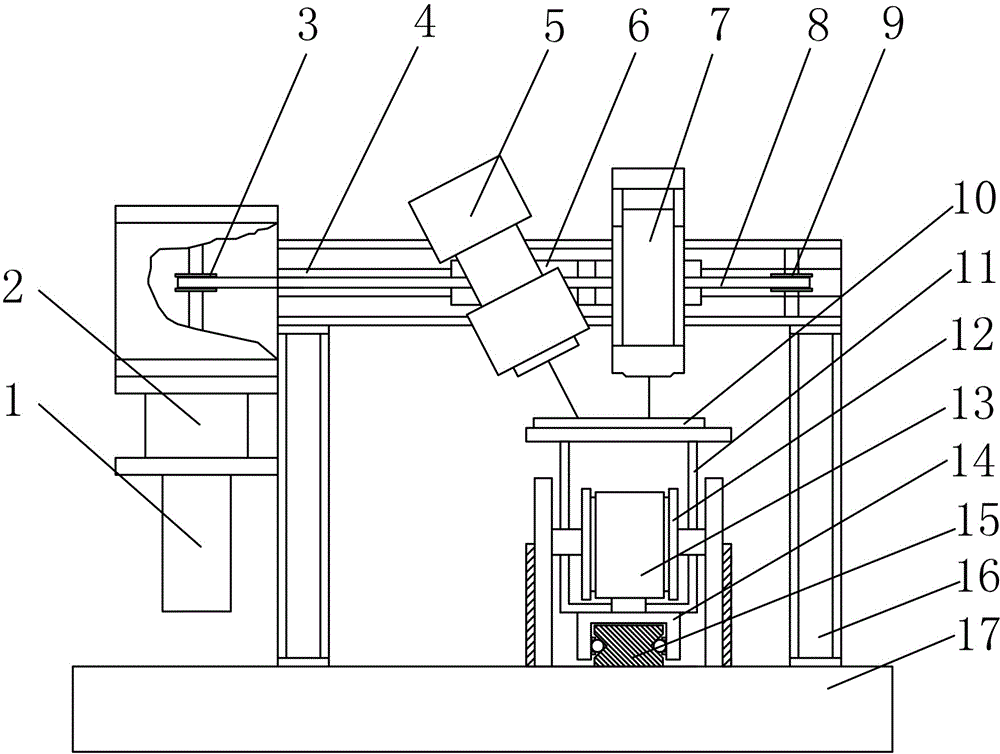

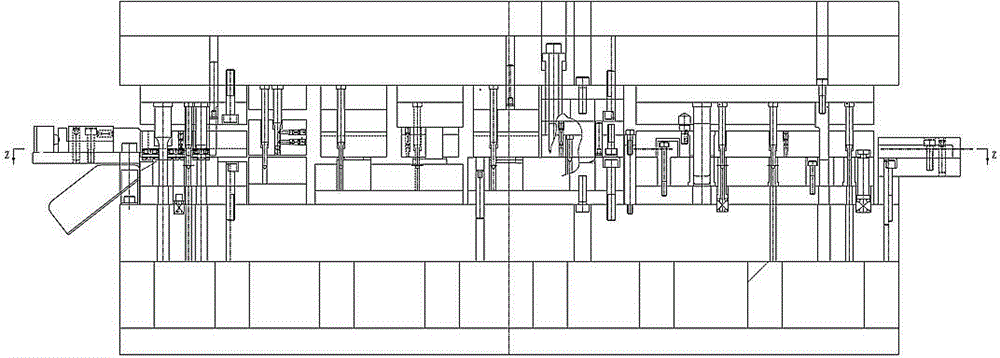

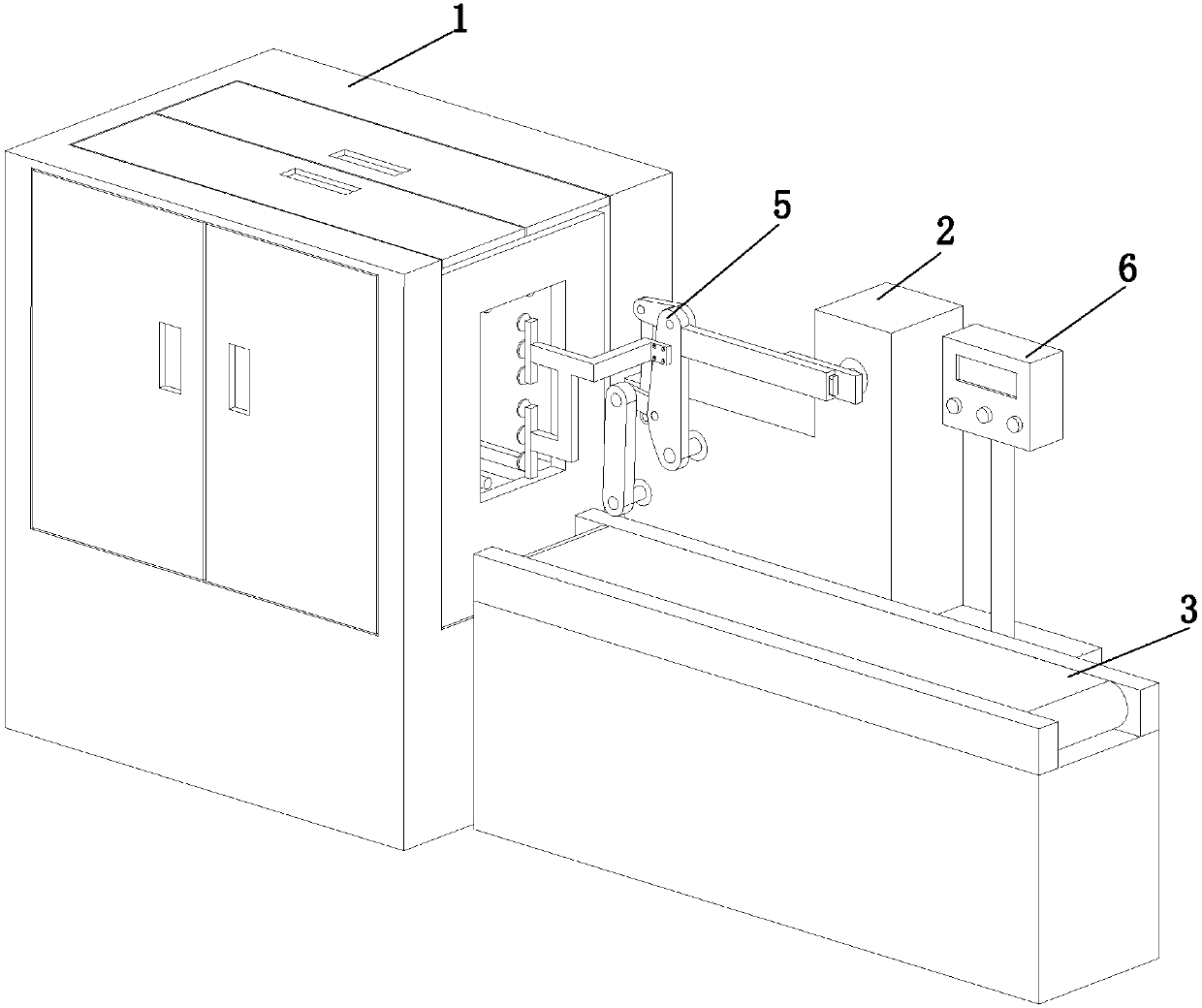

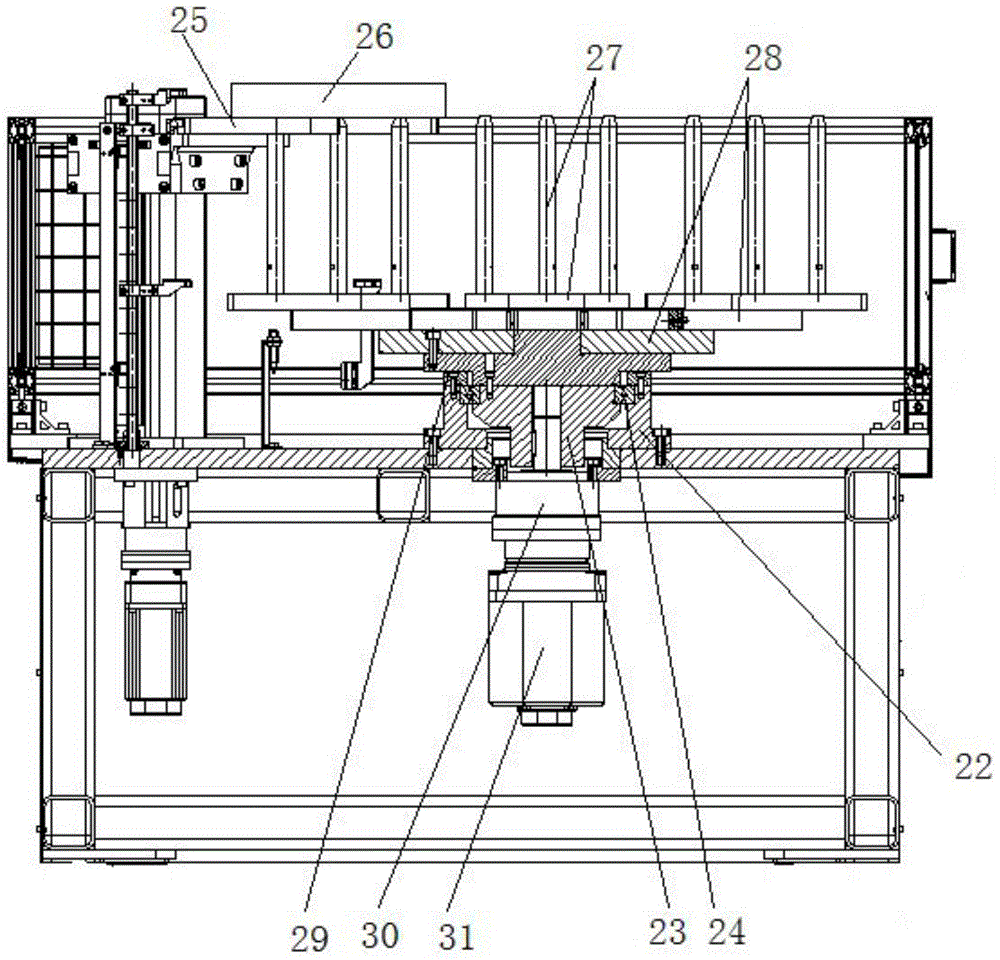

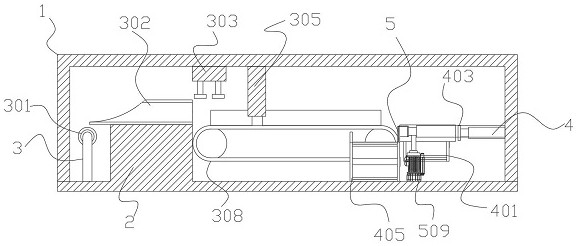

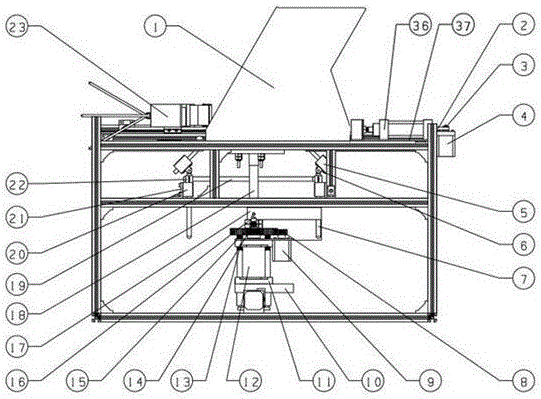

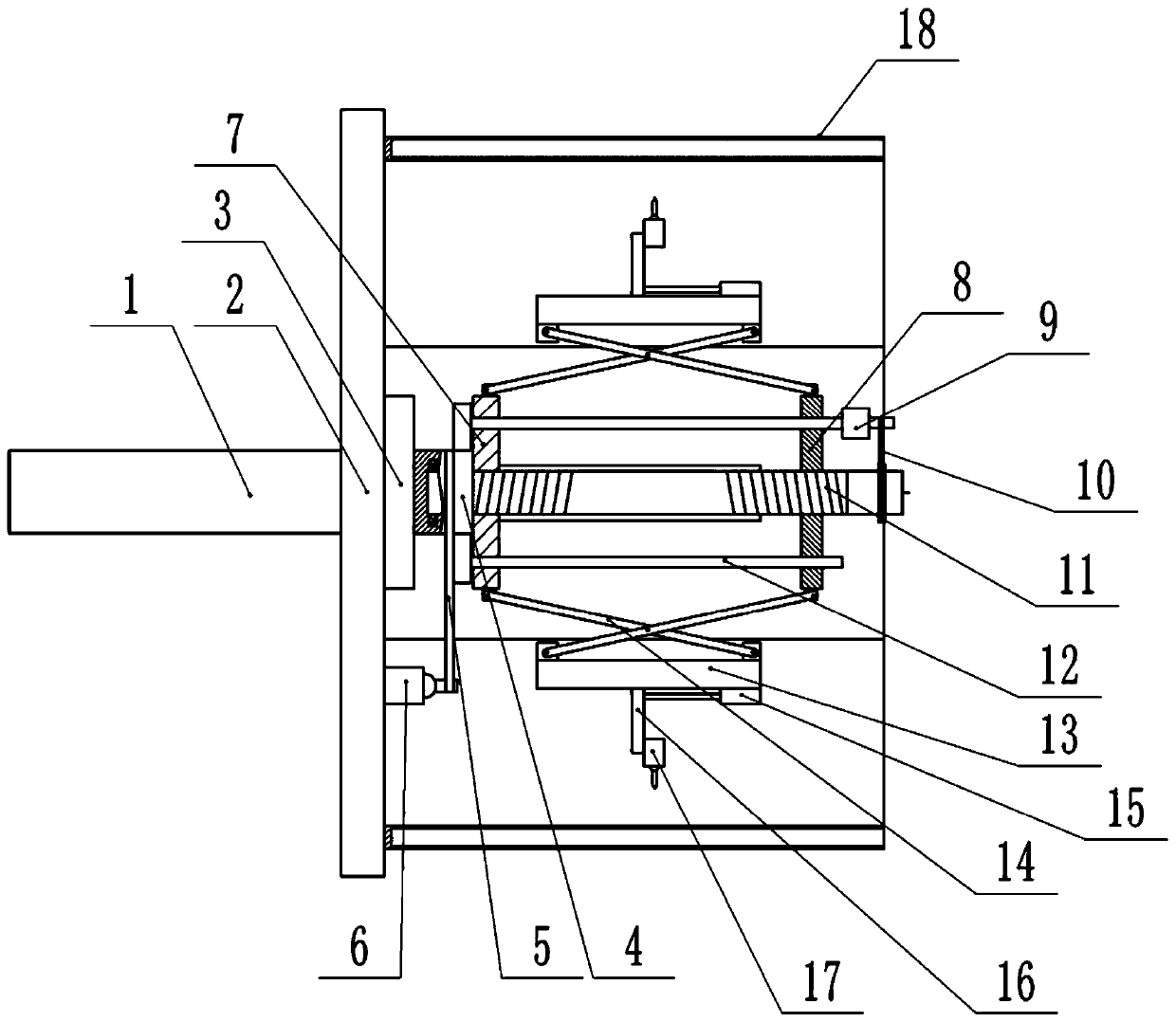

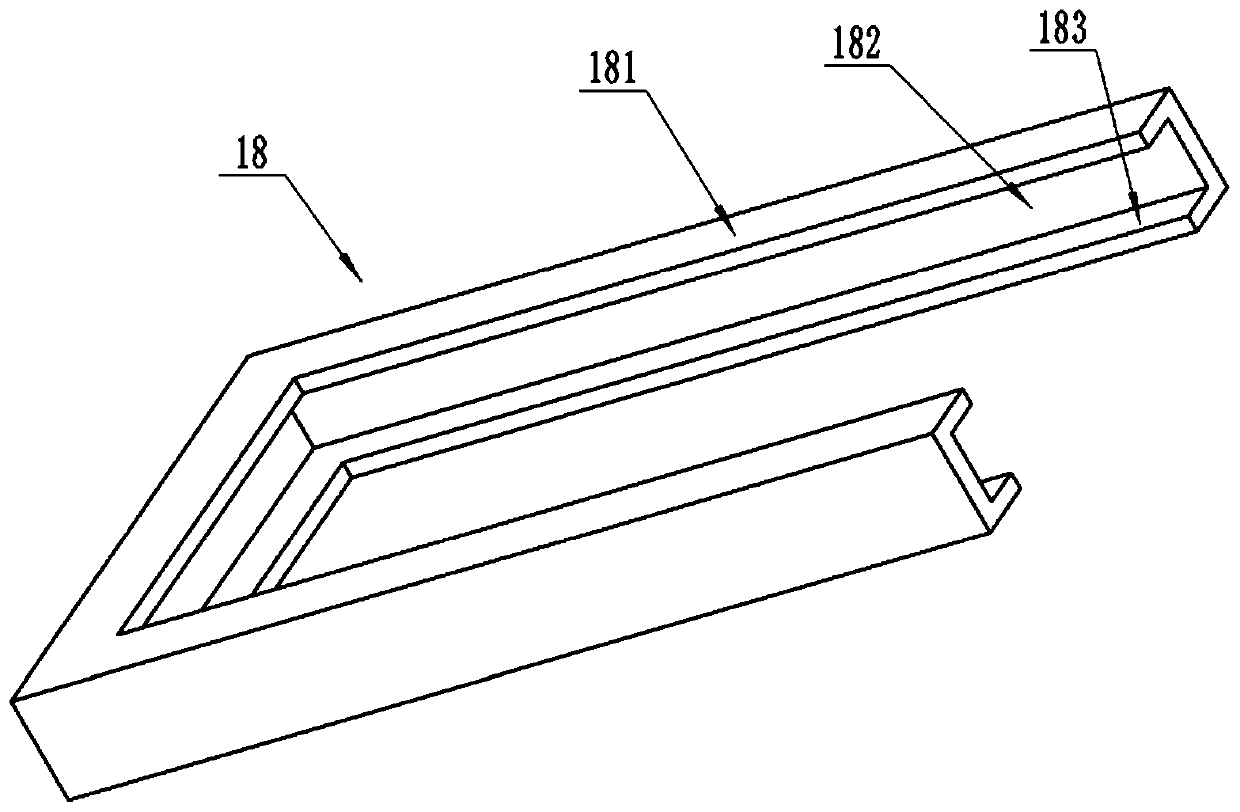

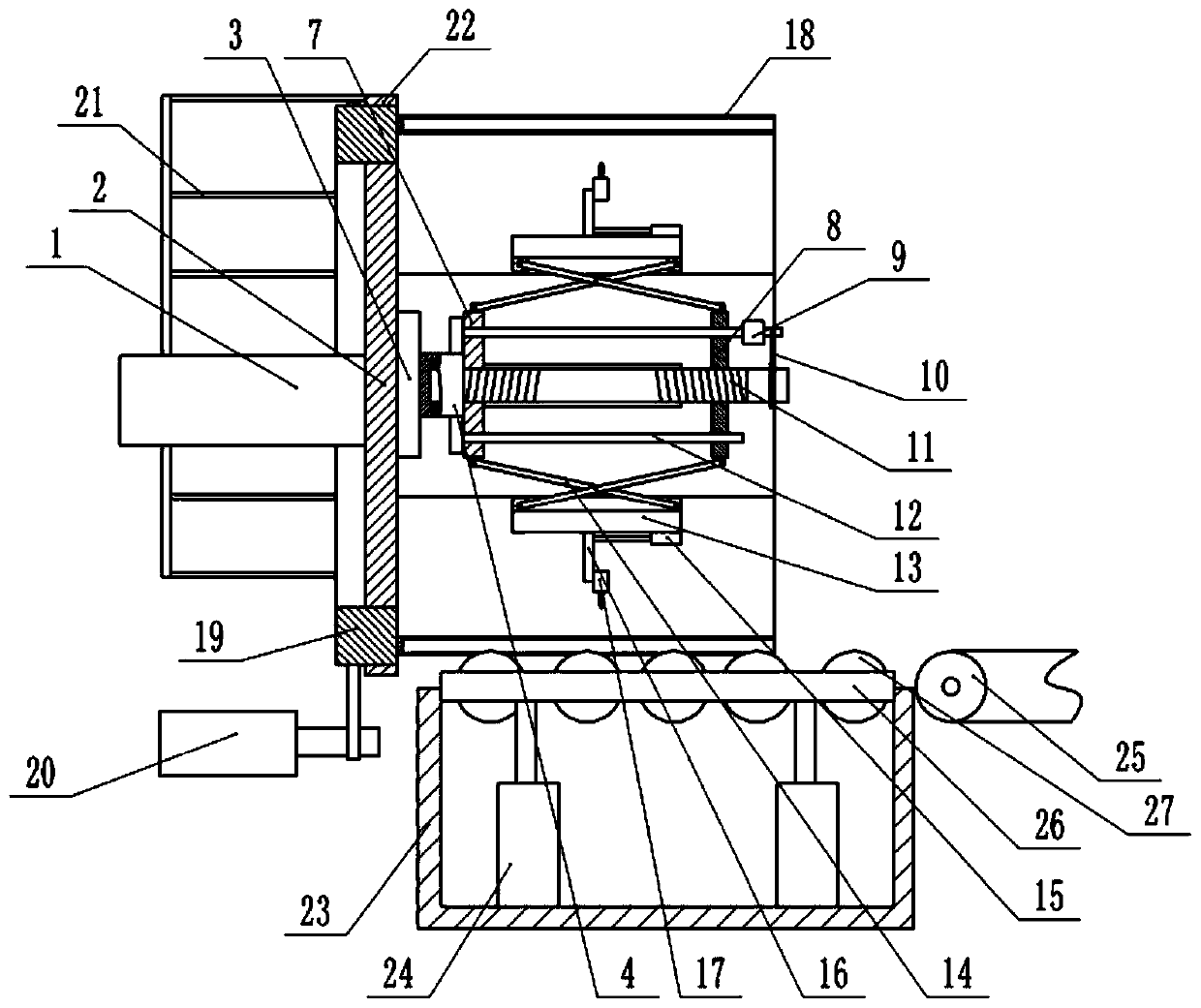

Online CT (computed tomography) nondestructive testing device

ActiveCN104458769AFast shippingShipped accuratelyMaterial analysis using wave/particle radiationFlat panel detectorComputed tomography

Disclosed is an online CT (computed tomography) nondestructive testing device. A testing platform is mounted in a protective lead room, an X-ray tube and a flat-panel detector are fixed on the left wall and the right wall of a lead room frame in the protective lead room respectively, a feeding conveying line and a discharging conveying line are mounted on the left side and the right side of the protective lead room, a platform conveying line is mounted on the testing platform, and control signal input ends and control signal output ends of components controlled by a control device are connected with an input end and an output end of the control device through cables. The device is high in conveying accuracy and automation degree and convenient to operate, a workpiece can be rapidly and accurately conveyed to the test position, the association degree between all actions is high, the workpiece can enter and exit the device by one key, an X-ray begins to acquire an image, the position of the workpiece can be manually adjusted through an imaging screen when deviating, the X-ray does not need to be closed, and the service life of the X-ray tube is prolonged.

Owner:DONGDAN AOLONG RADIATIVE INSTR GRP

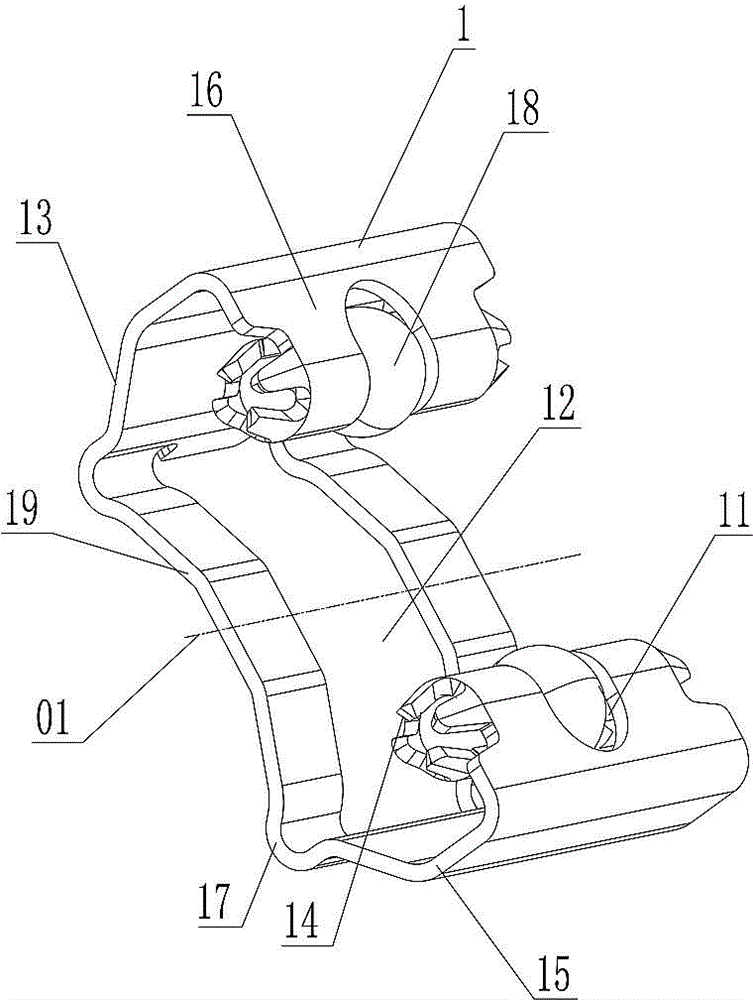

Continuous die for manufacturing automobile seat sliding way holder and method for manufacturing automobile seat sliding way holder

The invention relates to a continuous die for manufacturing an automobile seat sliding way holder and a method for manufacturing the automobile seat sliding way holder. A punching trimming die, a second trimming die, a performing die, an opposite side bending die, a rolling die, a groove bending die, a steel ball inlet die, a third trimming die and a cutting separating die are sequentially arranged. A steel ball inlet male die, an elastic nail assembly, a lower stripper plate, a guide column and a steel ball feeding device are arranged in the steel ball inlet die. The steel ball inlet male die is fixed to an upper die plate and matched with a steel ball channel. The elastic nail assembly is located in the lower stripper plate, the lower stripper plate is connected to the guide column in a floating and sleeving mode, the guide column and a lower die fixing plate are fixed, and the steel ball feeding device and a lower die plate are fixed. The manufacturing method comprises the steps of punching trimming, performing, bending, rolling, bending, steel ball feeding, trimming and cutting. The continuous die and the manufacturing method of the automobile seat sliding way holder are more reasonable and simpler, using is convenient and reliable, positioning is accurate, and efficiency is higher. The seat sliding way holder manufactured through the continuous die and the manufacturing method is high in precision and low in cost.

Owner:ZHEJIANG LONGSHENG AUTO PARTS TECH CO LTD

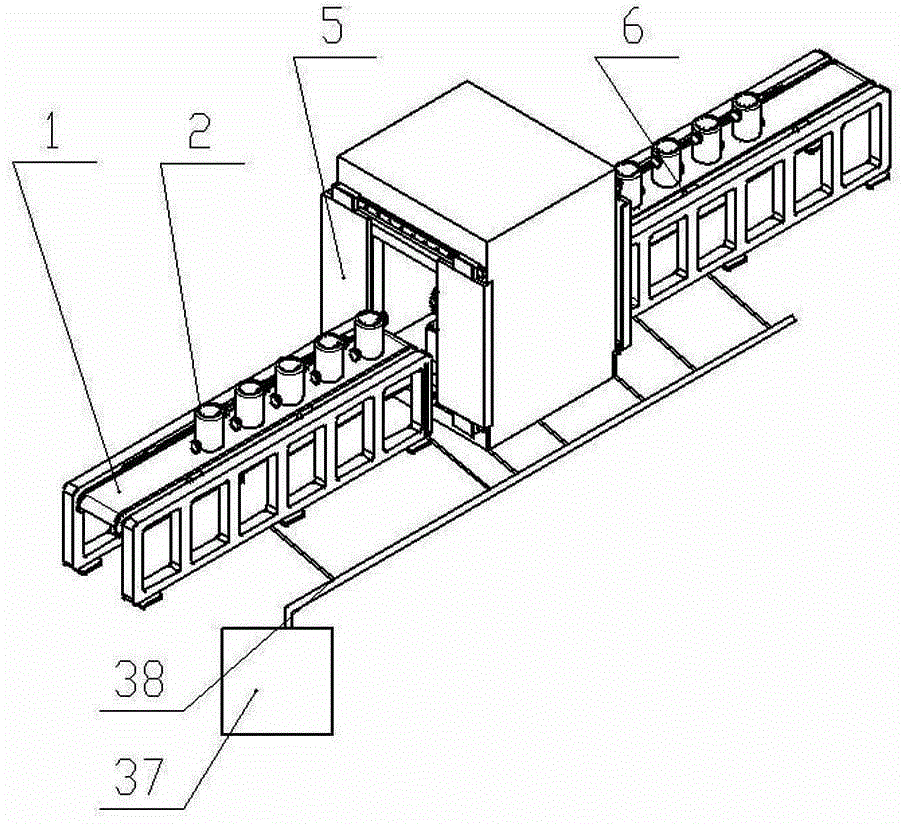

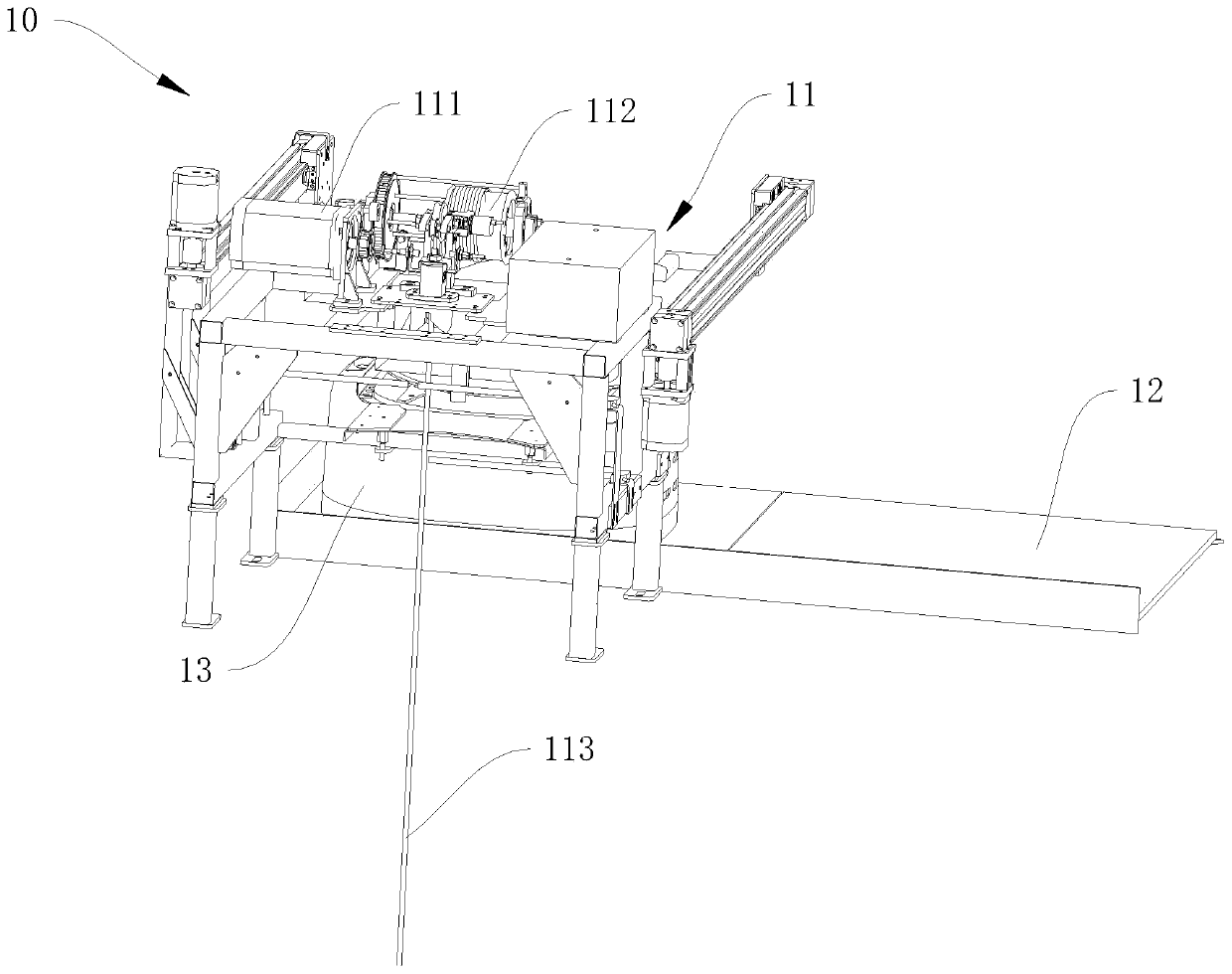

Automatic drilling machine

PendingCN108788222AImprove consistencyReduce biasAutomatic control devicesDrilling/boring measurement devicesMachiningDrilling machines

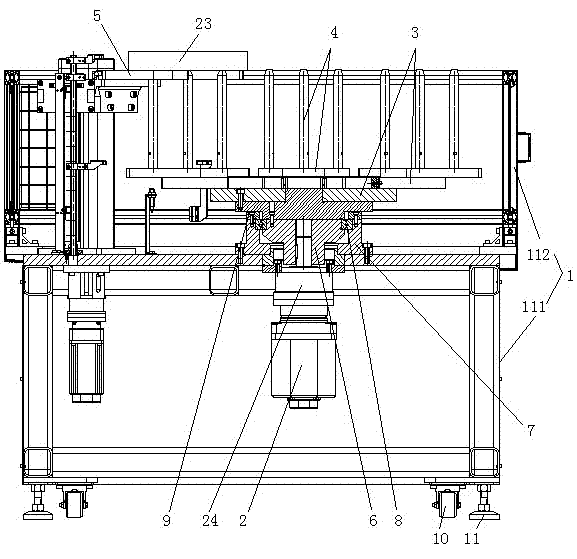

The invention relates to the technical field of pipe machining, in particular to an automatic drilling machine. The automatic drilling machine comprises a feeding device, a discharging device and a drilling device. The feeding device, the drilling device and the discharging device are sequentially connected. A series of working procedures of feeding, machining and discharging are achieved, drilling machining of a pipe is automatically completed, and the machining efficiency is high.

Owner:GUANGZHOU KINGHING CONSTR TECH

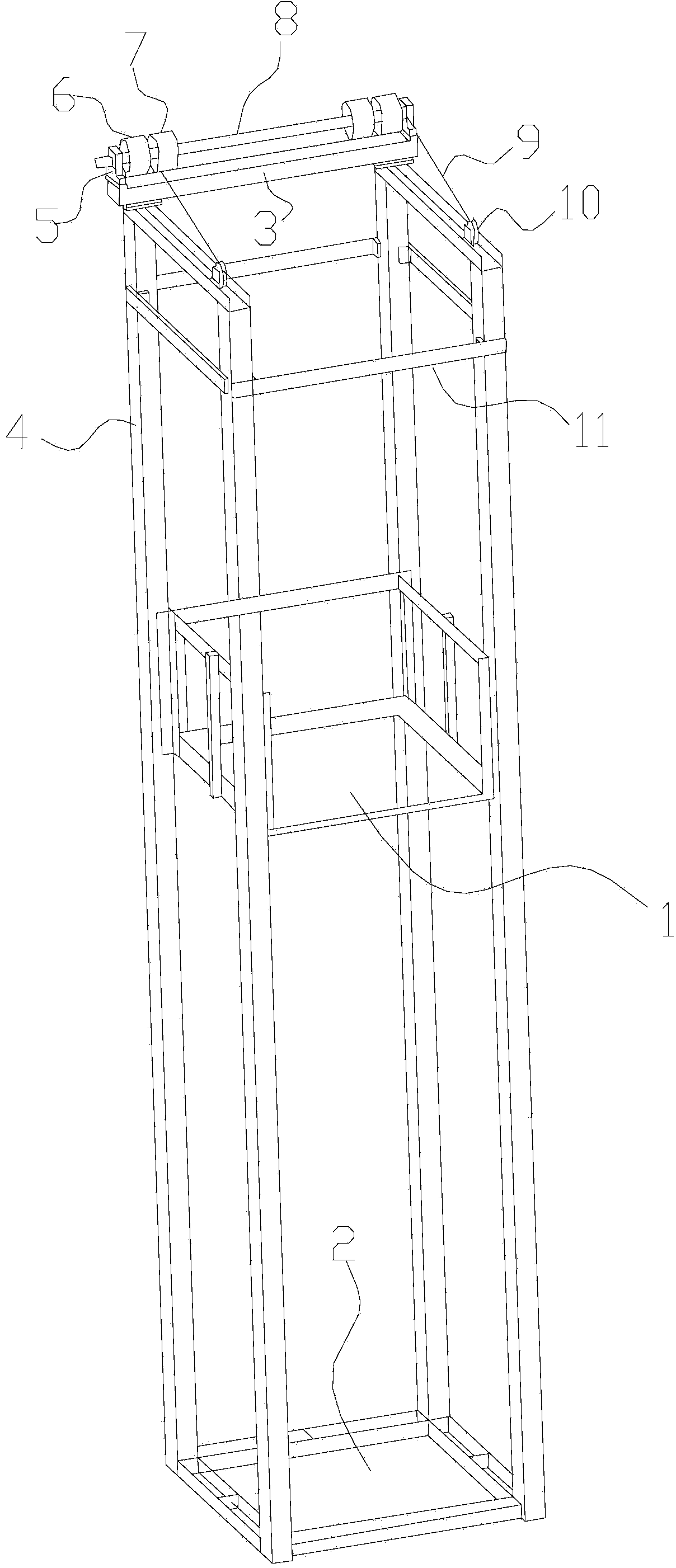

Octahedral guiding elevator

InactiveCN104355203AOvercome costsOvercome spaceElevatorsBuilding liftsEngineeringMechanical engineering

The invention provides an octahedral guiding elevator. The octahedral guiding elevator comprises a cuboid supporting frame, an elevator car, and a traction mechanism, wherein the cuboid supporting frame is supported by four upright posts; the elevator car is arranged in the supporting frame; the traction mechanism is used for drawing the elevator car to move; the elevator car comprises four side edge angles; mounting seats opposite to the two adjacent side surfaces of the upright posts are arranged at the extending parts on the two adjacent side surfaces of elevator car forming the side edge angles; guide grooves are formed in the mounting seats; guide parts are arranged in the guide grooves; the elevator car is matched with the upright post side surfaces through the guide parts to conduct lifting motion; two guide surfaces matched with the guide part are formed on each upright post; eight guide surfaces are formed on the four upright posts in total. The guide parts and the mounting seats are matched with each other, and the elevator car is guided in all directions to enable the elevator car to move up and down along the upright posts under external driving; an octahedral guiding elevator adopting the structure is an independent elevator product, and is stable and reliable in running, aesthetic in appearance, convenient to mount, and wide in application.

Owner:东莞市张越电子科技有限公司

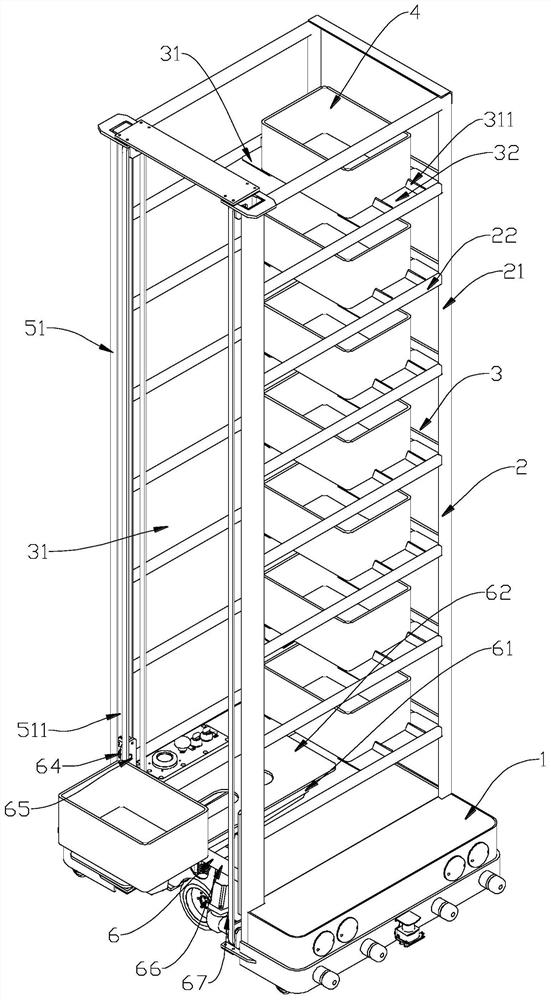

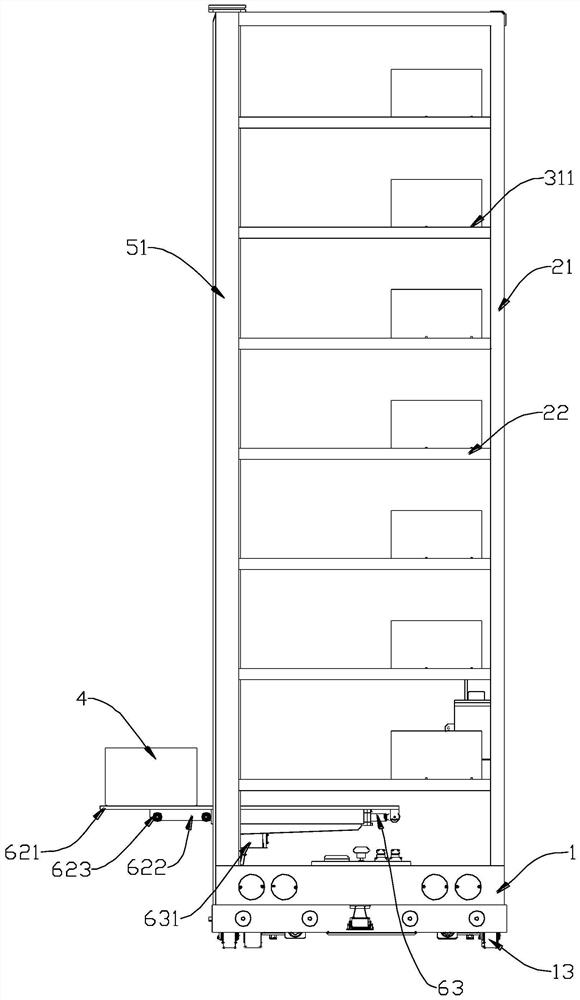

Multifunctional high-position order picker and operation method thereof

ActiveCN112079023AEfficient pickingProper selectionLifting devicesStorage devicesStructural engineeringMechanical engineering

Owner:杭州坤格智造科技有限公司

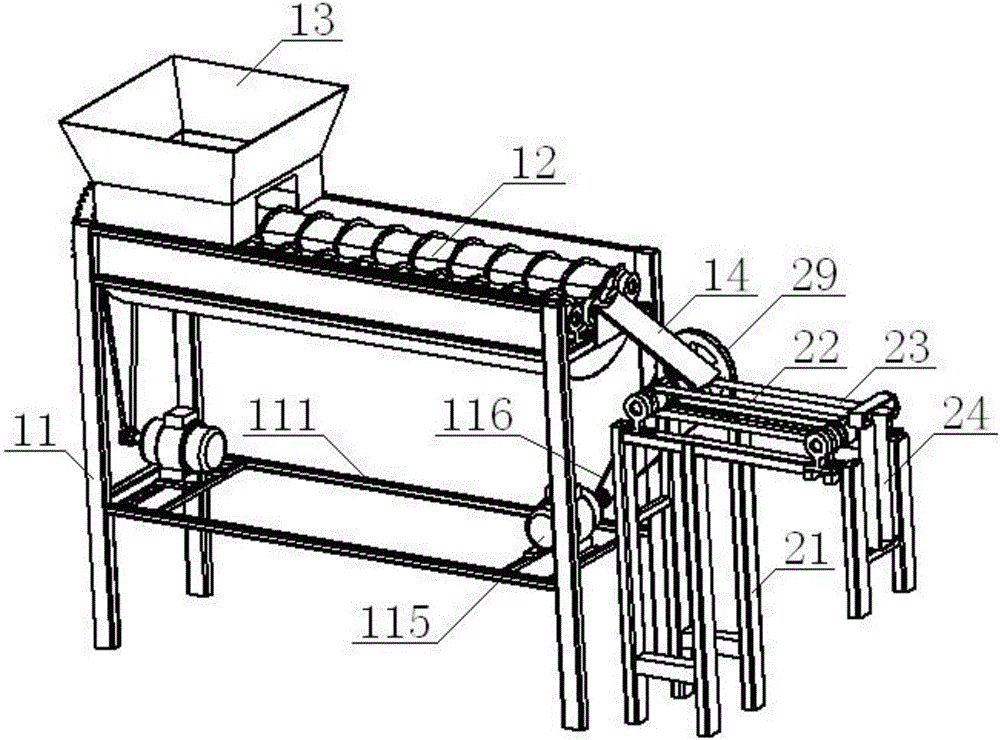

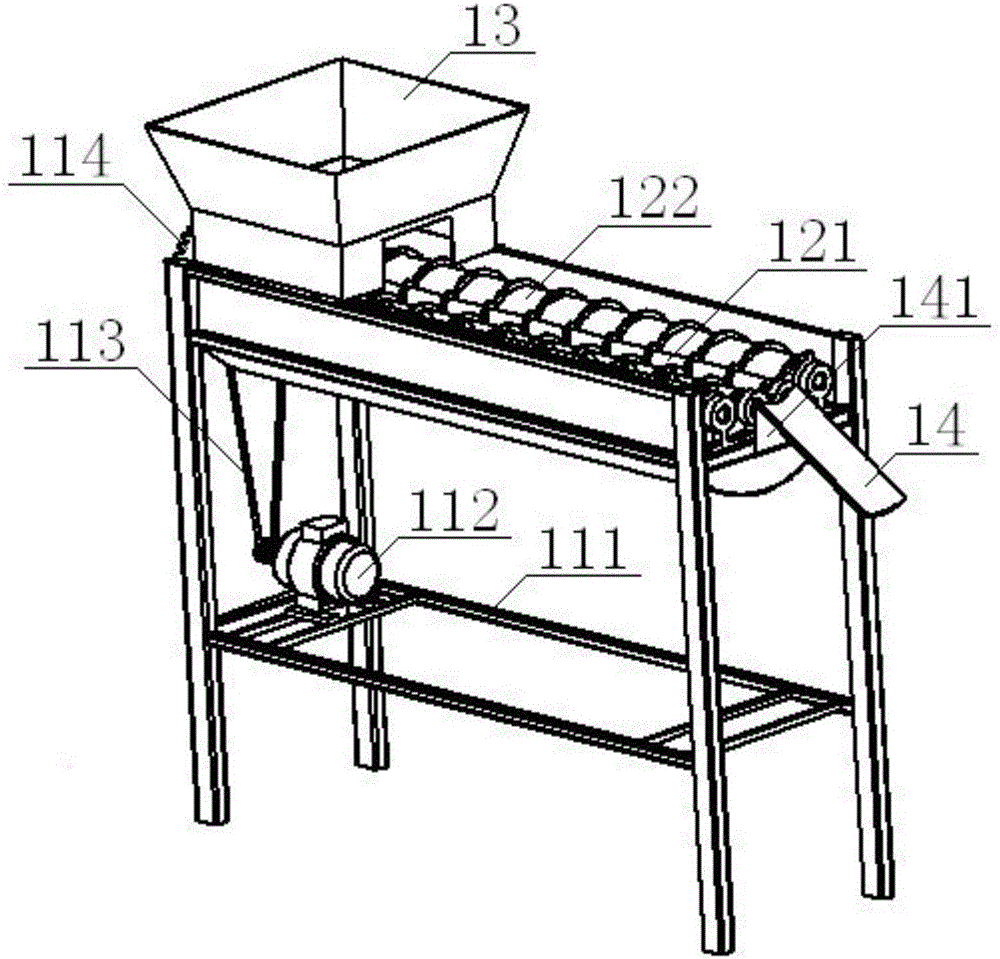

Automatic material moving device for wooden panels

PendingCN107601037AImprove work efficiencyReduce outputConveyor partsEngineeringMechanical engineering

The invention relates to the field of panel processing and particularly relates to an automatic material moving device for wooden panels. The automatic material moving device comprises a second work cabinet and a panel clamping device. The panel clamping device comprises a clamping part and a clamping driving part. The clamping part comprises an absorption assembly and a connecting rod assembly; the connecting assembly is arranged on the side portion, close to a transmission table, of the second work cabinet, the adsorption assembly is fixedly arranged on the connecting rod assembly, the connecting rod assembly comprises a second driving portion, a second driven portion and a third driven portion, the second driving portion is arranged in the middle of the upper half portion of the secondwork cabinet, the second driven portion and the third driven portion are separately arranged on the two sides of the second driving portion, and the second driven portion and the third driven portionare in transmission connection to the second driving portion. By way of adsorptive material loading, the device is simple and clear in structure and clear in mechanical movement principle, and can transfer to-be-loaded panels to appointed positions accurately, so that the labor output is reduced, and the work efficiency of material movement is increased.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

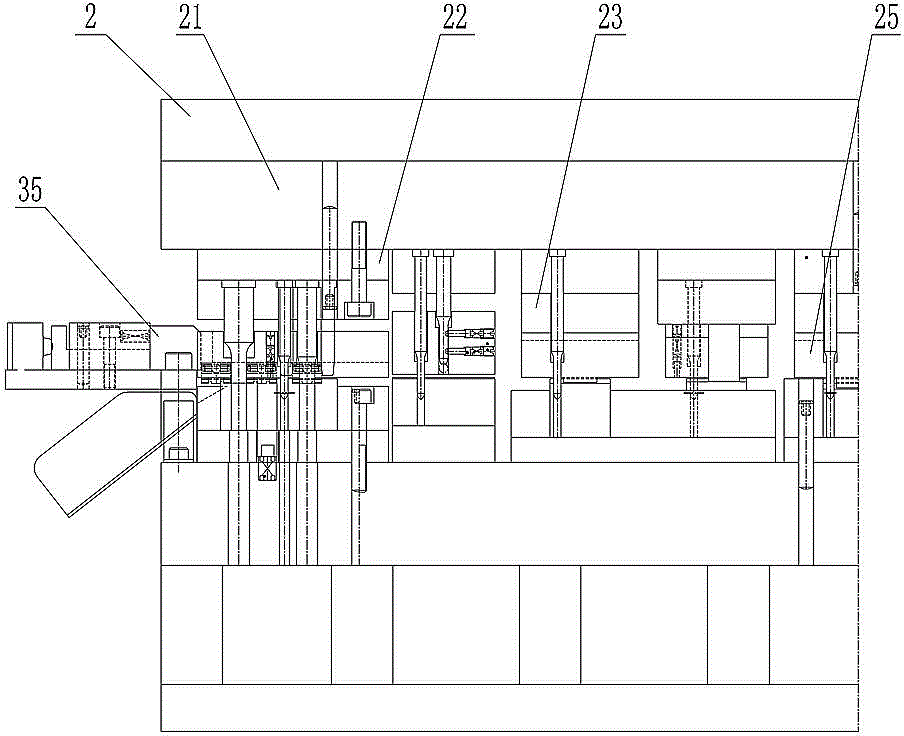

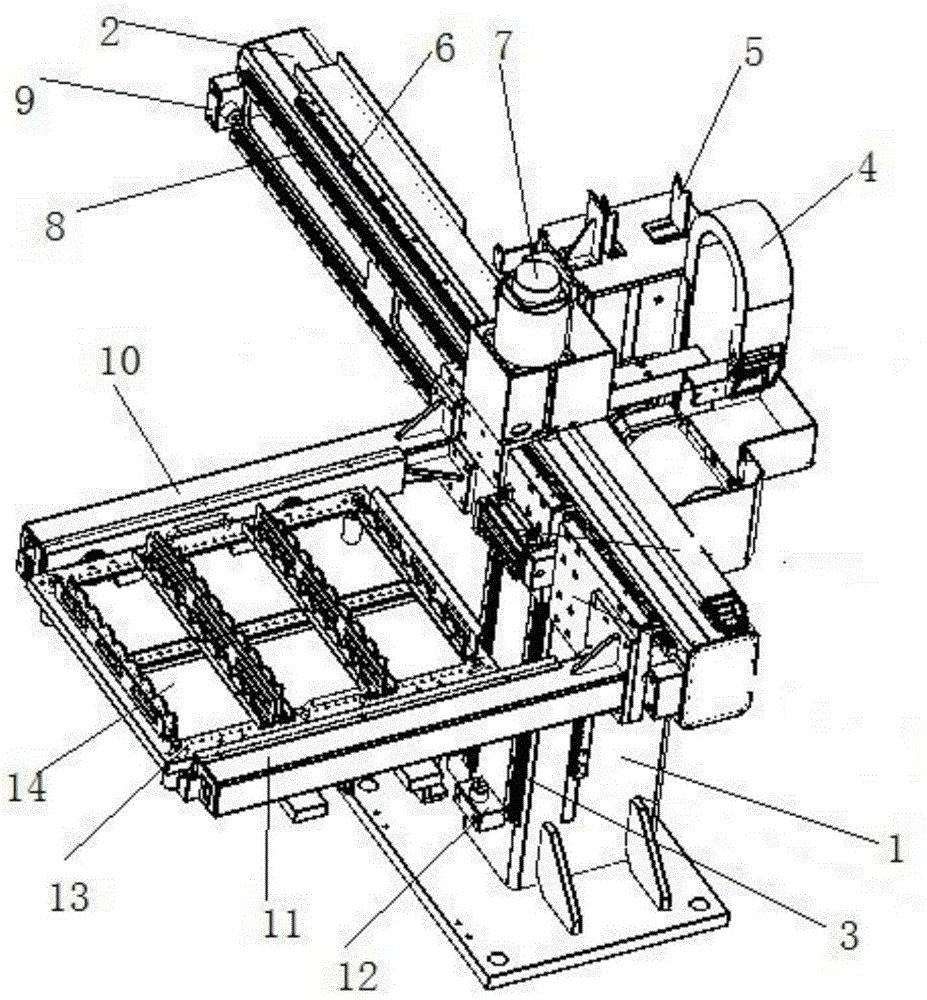

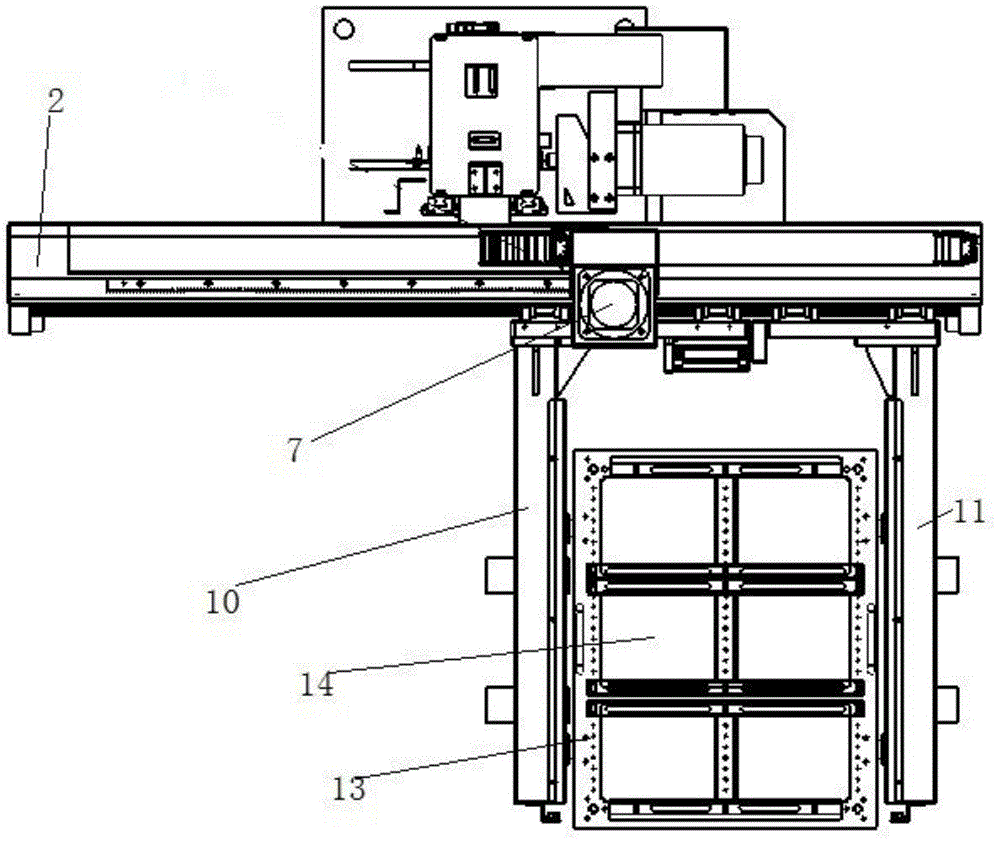

Novel material feeding and discharging palletizer stock bin capable of conducting accurate positioning operation

The invention discloses a novel material feeding and discharging palletizer stock bin capable of conducting accurate positioning operation. The novel material feeding and discharging palletizer stock bin capable of conducting accurate positioning operation comprises a vertical shaft, a horizontal shaft, a vertical shaft guiding rail, a vertical shaft bending column, a secondary positioning stand, a horizontal shaft gliding strip, a horizontal shaft common-range driving motor, a horizontal shaft guiding rail, a horizontal shaft limiting block, a left arm, a right arm, a stock bin stand, a workpiece elevating mechanism and a workpiece horizontal rotary transmission mechanism. The top of the vertical shaft is provided with the vertical shaft bending column and the secondary positioning stand. One side of the vertical shaft is provided with the vertical shaft guiding rail and a vertical shaft lower limiting block. The horizontal shaft is connected with the vertical shaft guiding rail through a gear in a matching mode. The horizontal shaft is provided with the horizontal shaft guiding rail and the horizontal shaft gliding strip. The horizontal shaft is fixedly provided with the left arm and the right arm. The left arm and the right arm are provided with a tray stand in a stand mode. According to the workpiece elevating mechanism, the accurate positioning can be carried out on the ascending position and the descending position of the workpiece. The transmission distance of the workpiece is free from the influence of the workpiece thickness and the transmission error of a driving device, the accurate transporting of the workpiece to an appropriate position is guaranteed, and smooth picking and placing of the workpiece by a manipulator are guaranteed.

Owner:宁夏巨能机器人股份有限公司

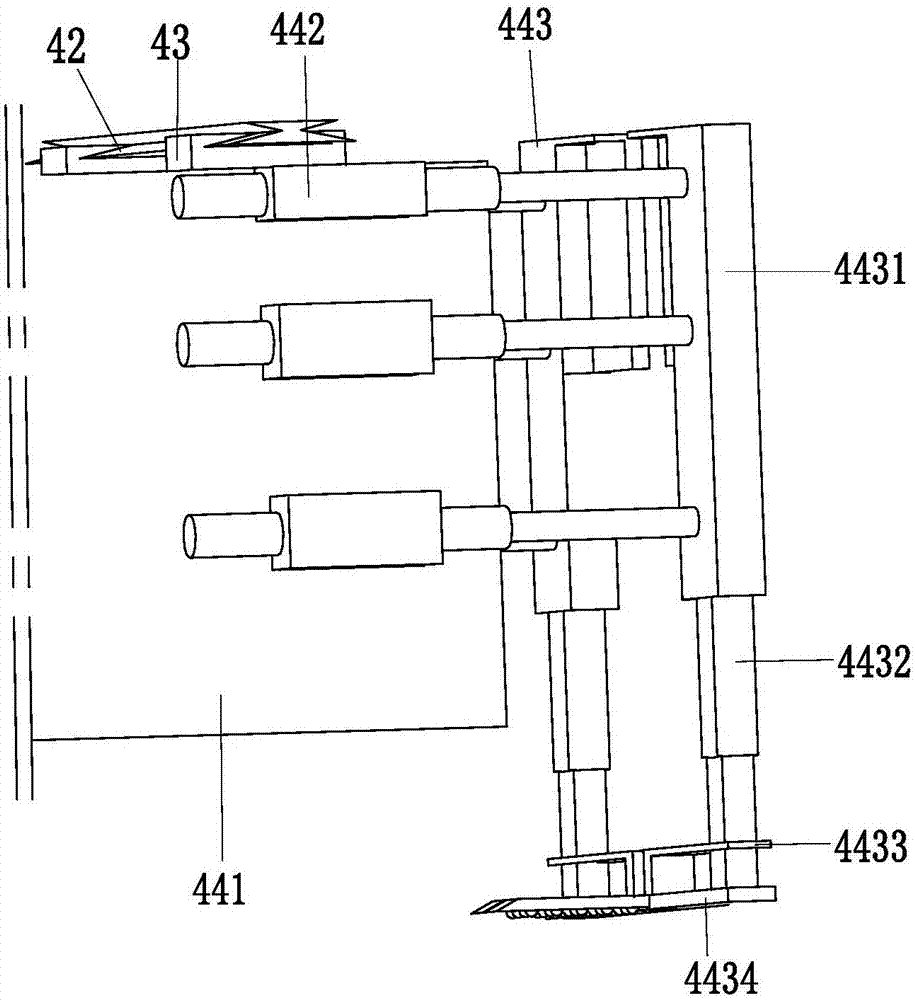

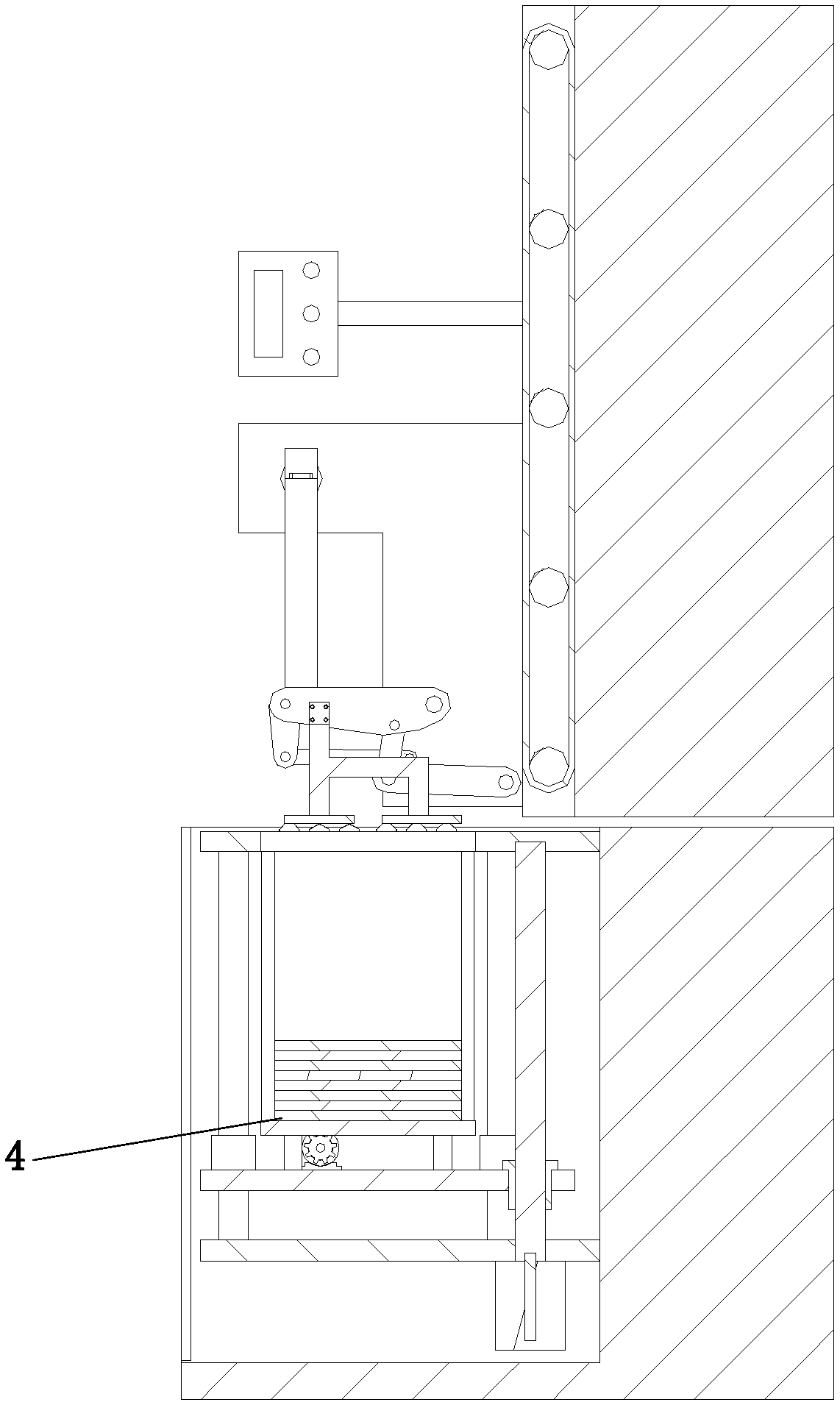

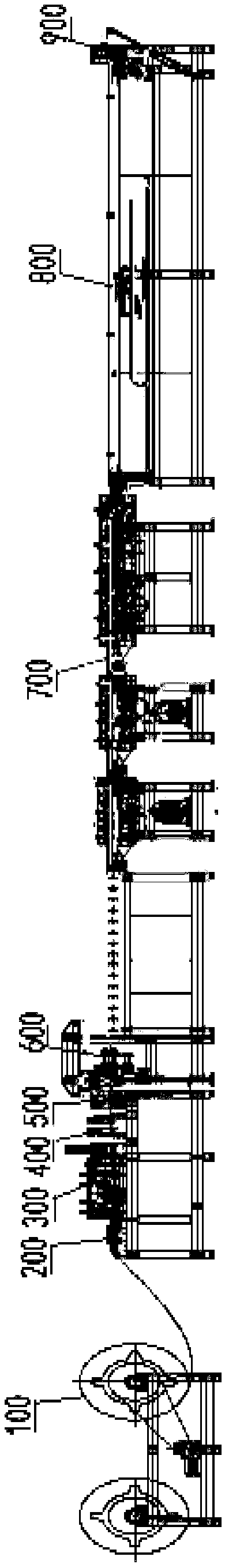

High-precision bending equipment and bending method thereof as well as air pipe production line

InactiveCN109277438AShipped accuratelyAffect qualityMetal-working feeding devicesPositioning devicesProduction lineEngineering

The invention discloses high-precision bending equipment and a bending method thereof as well as an air pipe production line, and belongs to the field of wind pipe manufacturing. The bending equipmentcomprises a bending machine, a feeding device and a grabbing device, wherein the feeding device and the grabbing device are used for feeding to the bending machine; the grabbing device is arranged inthe feeding direction of the feeding device, and is driven by a grabbing driving mechanism; the grabbing device comprises a mechanical arm and a lifting mechanism, wherein the lifting mechanism drives the mechanical arm to move up and down, so that a clamping end of the mechanical arm is higher than or lower than a feeding plane of the feeding device. The bending equipment is used for tight grasping and conveying plates through the mechanical arm, the bending machine can be used for accurately bending the plates, and the bending precision of the plates is high; the bending method is utilizedby the bending equipment for machining the plates, so that the bending precision of the machined finished plates is high; and the wind pipe production line further adopts the bending equipment, so that the shape precision and the sealing performance of the manufactured wind pipe are greatly improved.

Owner:安徽开天重工机械制造有限公司

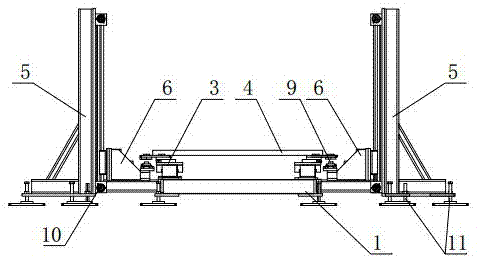

Automobile component conveyer

InactiveCN105438751AShipped accuratelyAchieve deliveryLifting framesMechanical conveyorsEngineeringMechanical engineering

Owner:MH ROBOT & AUTOMATION

Coconut cutting device for beverage processing

InactiveCN112238489AAchieve clampingAchieve reductionMetal working apparatusEngineeringStructural engineering

The invention relates to a cutting device, in particular to a coconut cutting device for beverage processing. According to the coconut cutting device for beverage processing, safety is high, coconutsdo not need to be fixed by the hands, and the coconuts can be intermittently discharged. The coconut cutting device for beverage processing comprises a base, a first supporting plate, a moving device,a clamping device, a cutting device body and second supporting plates; a first mounting frame is arranged at the top of the base; the first supporting plate is arranged at the top of the base; the moving device is arranged between the first supporting plate and the base; the clamping device is arranged at the top of the base; the cutting device body is arranged on the first supporting plate; andthe second supporting plates are symmetrically arranged at the top of the base and penetrate through the lower side of the first mounting frame. According to the coconut cutting device, the coconuts are clamped through the clamping device, then the coconuts are conveyed rightwards under cooperation of the moving device and the cutting device body, meanwhile, the coconuts are cut, and coconut juiceis collected.

Owner:周展

Packaging machine with protection structure for glass production

InactiveCN111674627AEasy to disassemble separatelyEasy to installConveyor wrappingWrapper twisting/gatheringIndustrial engineeringGlass production

The invention discloses a packaging machine with protection structure for glass production. The packaging machine comprises a shell, a bag packaging module, a boxing module and a box sealing module, wherein a boss is arranged at the bottom of the inner side of the shell, a feeding shaft is arranged on the left side of the bag packaging module, the bag packaging module is located above the boss, atransferring conveying belt is arranged on the rear side of the boxing module, the boxing module is located on the right side of the inner side of the shell, the boxing module comprises the transferring conveying belt, a piece pushing hydraulic rod, a piece pushing plate, a U-shaped groove, an auxiliary conveying belt and a limiting plate, the U-shaped groove is formed in the front side of the transferring conveying belt, the piece pushing hydraulic rod is arranged above the U-shaped groove, the auxiliary conveying belt is arranged on the left front side of the U-shaped groove, a second hydraulic rod is arranged on the right side of the box sealing module, and the box sealing module is located on the right side of the interior of the shell. According to the packaging machine with the protection structure for glass production, a user can complete automatic packaging of glasses through the bag packaging module and the box sealing module.

Owner:东莞市奇趣机器人科技有限公司

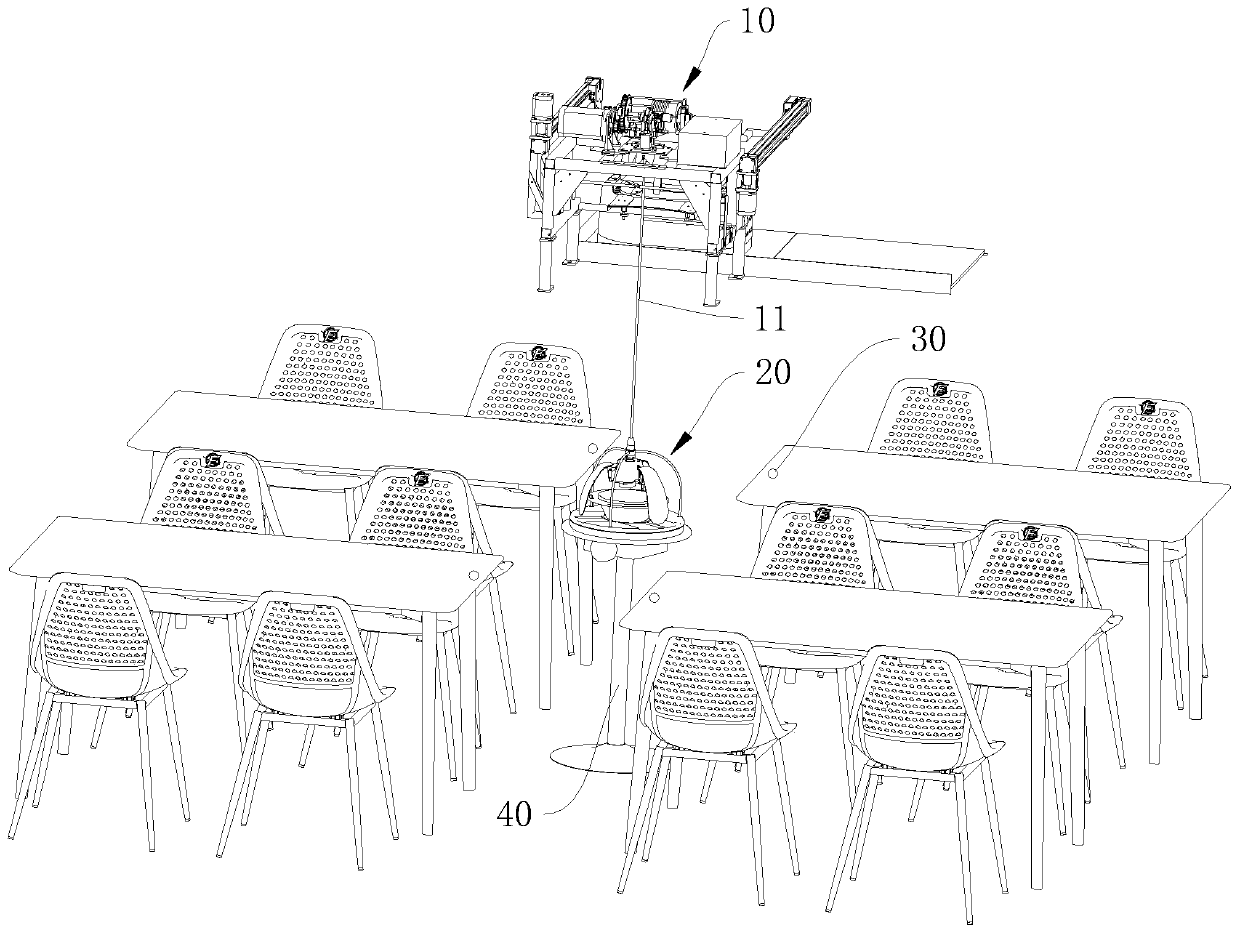

Robot restaurant and meal delivery method

InactiveCN111506085ASimple structureIncrease profitLogisticsPosition/course control in two dimensionsBiotechnologyAnimal science

The invention relates to a robot restaurant and a meal delivery method. The robot restaurant comprises dish serving equipment, distribution equipment and at least two control pieces. The dish servingequipment is used for obtaining food products according to the order information and is provided with a lifting mechanism, wherein the distribution equipment is in driving connection with the liftingmechanism; the distribution equipment comprises a tray, a stopping mechanism and a driving mechanism, wherein the tray is used for bearing food products, the stopping mechanism is provided with a stopping position for stopping the food products and an avoiding position for avoiding the food products, and the driving mechanism is used for driving the stopping mechanism to move between the stoppingposition and the avoiding position, wherein at least two control pieces are used for being arranged on different dining areas respectively, each control piece is in communication connection with the distribution equipment, and when the control piece on the dining area corresponding to the order information is triggered, the stopping mechanism can move to the avoiding position from the stopping position. According to the robot restaurant, the utilization rate of dish serving equipment is greatly increased, the structure of the robot restaurant is simplified, and the cost is reduced.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

Self-following type double-purpose fire-fighting robot

PendingCN111332386AEasy to operateReduce economic and human lossesFire rescuePosition/course control in two dimensionsAutomotive engineeringMechanical engineering

The invention discloses a self-following type double-purpose fire-fighting robot. The fire-fighting robot comprises a device body part, a driving mechanism, an electrical part, an information collection device and a traction mechanism, according to the invention, the main controller is adopted to control the normal operation of the whole machine; a firefighter can freely switch between a tractionmode and a remote control mode in the using process, fire-fighting materials are carried through the single-person traction trolley and transported through the single-person remote control trolley, operation is easy, time and labor are saved, rescue materials can be quickly and accurately transported, and economic and personnel losses are effectively reduced. The fire-fighting robot is low in manufacturing cost, simple in structure and high in maneuverability and flexibility, and has high stability, practicability and safety.

Owner:浙江丞士机器人有限公司 +1

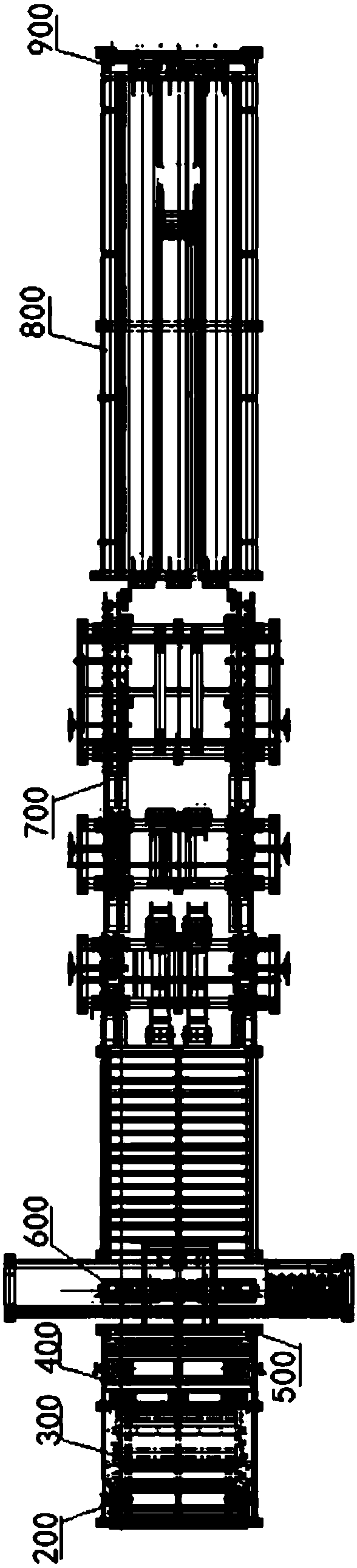

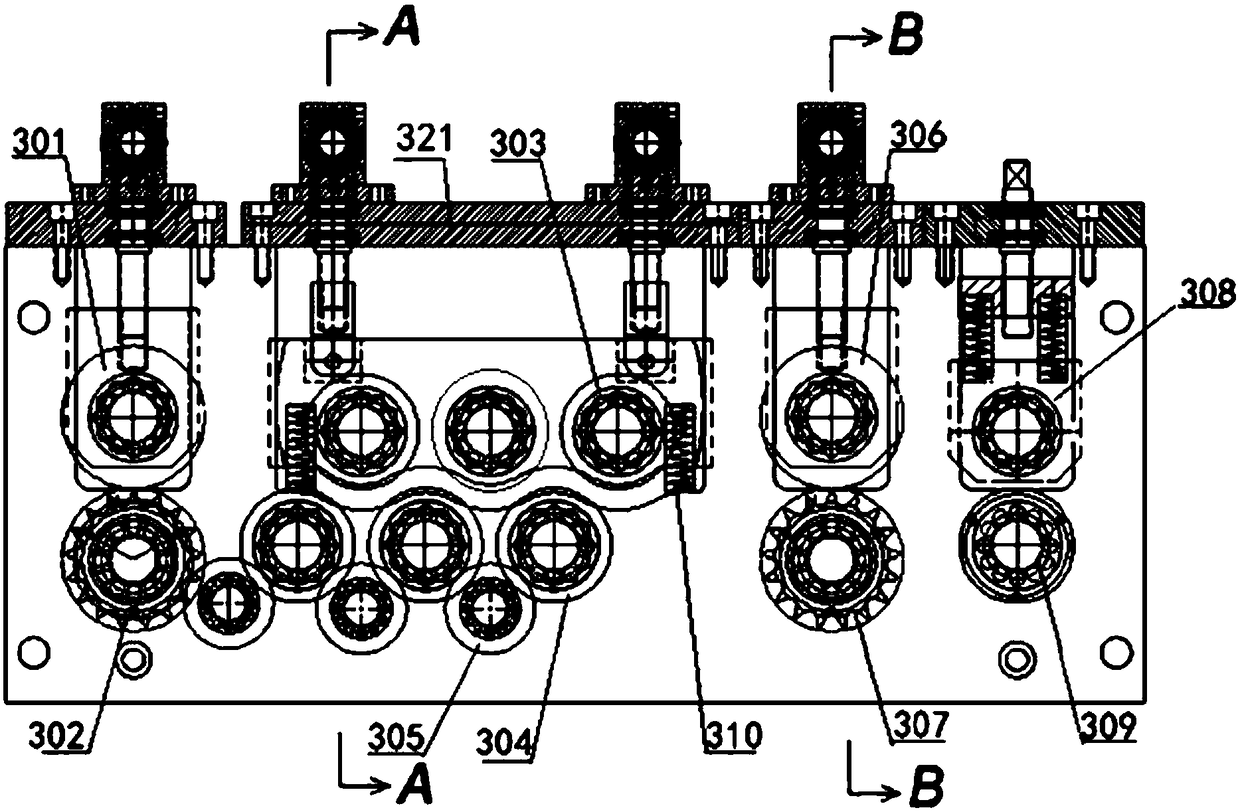

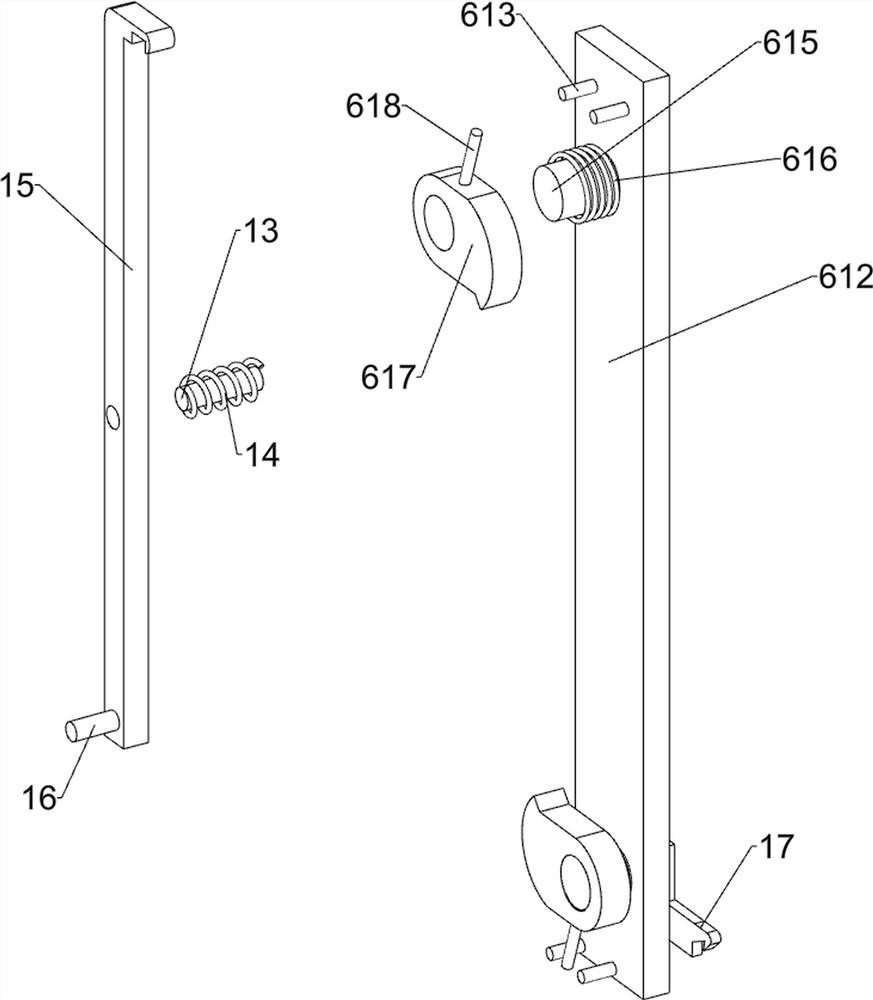

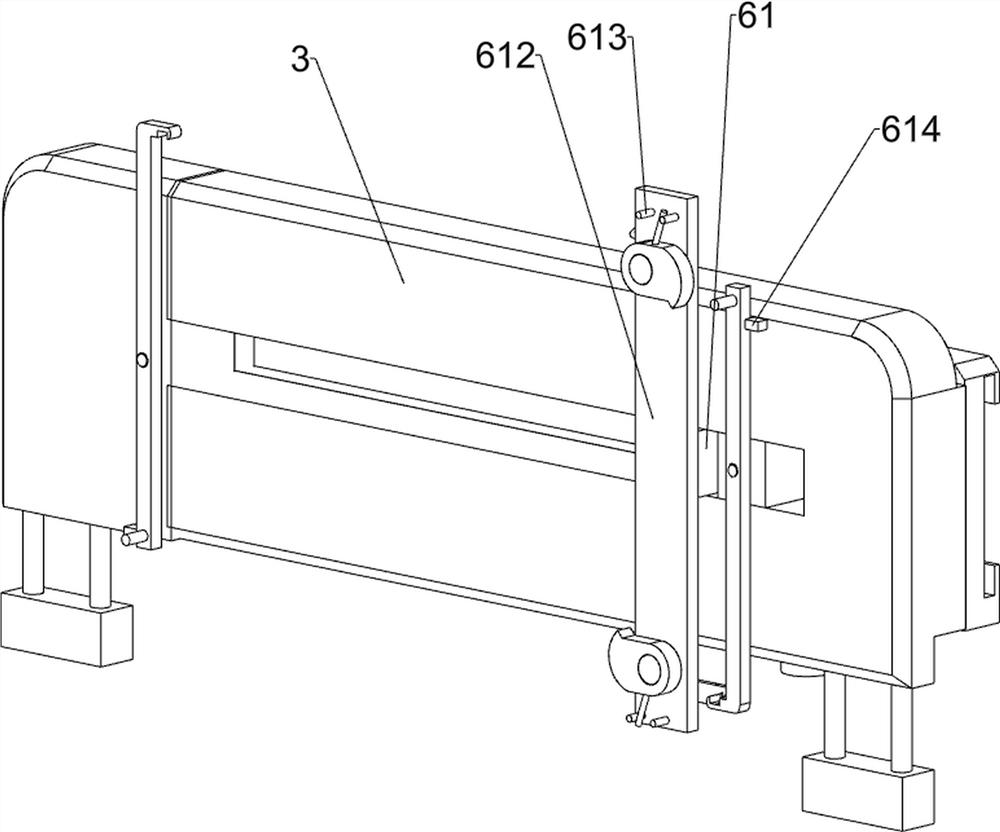

Novel transfer device

InactiveCN105151641AMovement precisionShipped accuratelyConveyorsStorage devicesEngineeringMechanical engineering

Owner:SUZHOU IRON TECH

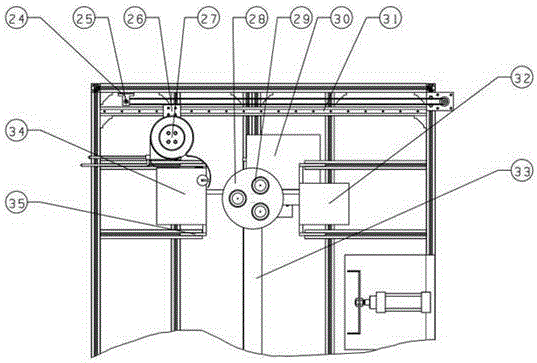

Full-automatic carton sealing machine structure and carton sealing method

The invention provides a full-automatic carton sealing machine structure. The structure comprises a carton obtaining device, a cylinder device, a bevel rotary table mechanism, ejector rod and turnover plate mechanisms and an adhesive sealing mechanism. The carton obtaining device comprises a carton collecting barrel and an elastic pressing plate, and the elastic pressing plate is arranged on one side of the carton collecting barrel which is arranged on the upper portion of a machine frame. A ball screw is arrange under an outlet of the carton collecting barrel, the whole bevel rotary table mechanism is mounted on the ball screw, the adhesive sealing mechanism is arranged opposite to the carton collecting barrel, and the adhesive sealing mechanism and the carton collecting barrel are located on the same plane. The ejector rod and turnover plate mechanisms are arranged on the two sides of the machine frame, a right turnover plate and a left turnover plate of the ejector rod and turnover plate mechanisms are flush with the bottom of the carton collecting barrel, an ejector rod body is vertically arranged on the lower portion of the corresponding turnover plate, the cylinder device is arranged on one side of the right turnover plate and comprises a cylinder body and a carrying plate, the cylinder body is arranged on the carrying plate, and the cylinder body is flush with the corresponding turnover plate. By means of the full-automatic carton sealing machine structure, the defects that an existing larger pipelined carton packaging machine is extremely large in occupied area, high in device cost and maintenance cost, complex in structure and operation, poor in start-stop flexibility and the like are overcome, the full-automatic carton sealing machine structure has the advantages that the comprehensive benefits of size, cost and efficiency can be optimized.

Owner:永丰余纸业(南京)有限公司

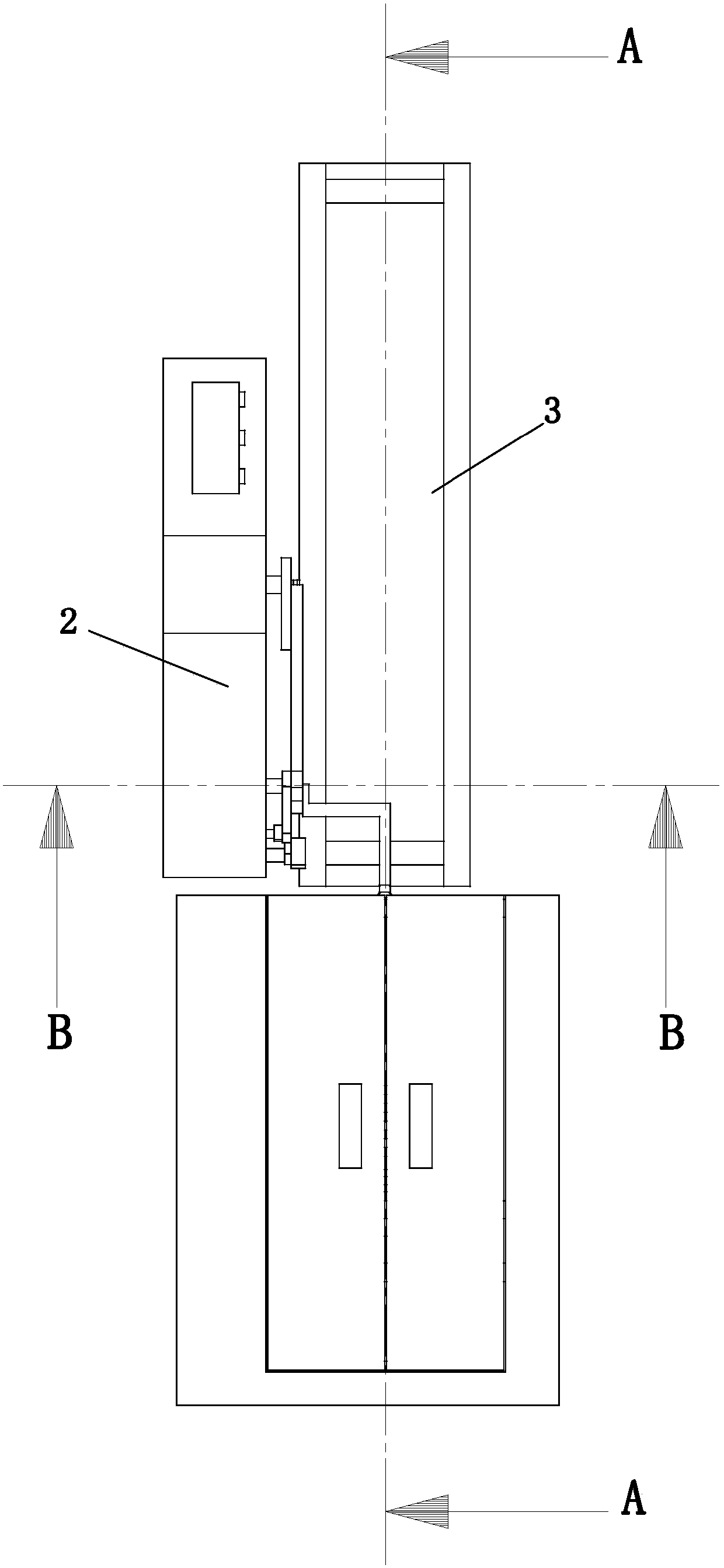

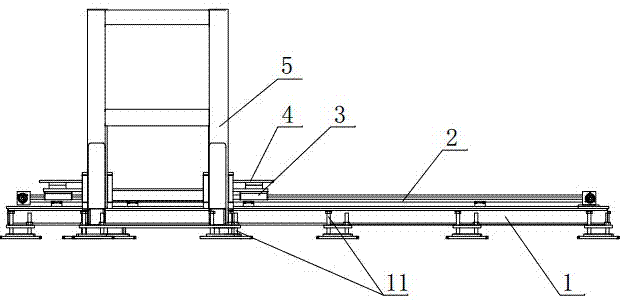

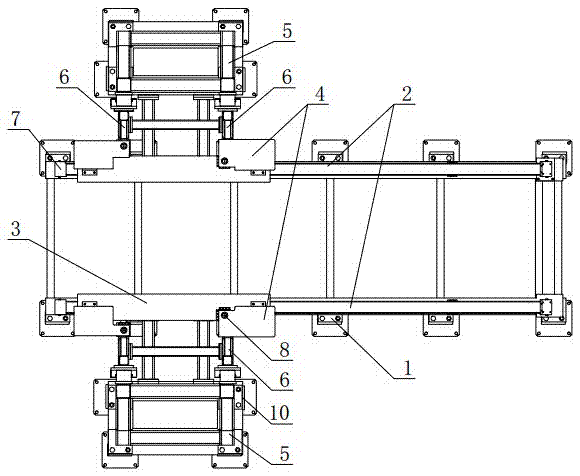

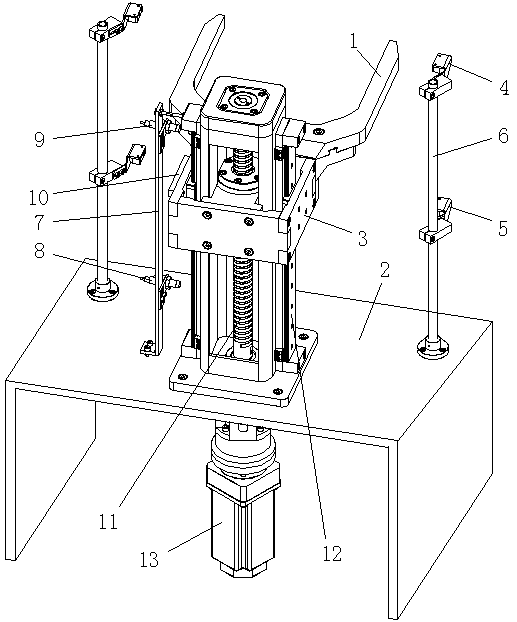

Workpiece up-and-down transportation device

The invention discloses a workpiece up-and-down transportation device which comprises a machine frame, a workpiece rising and falling transportation device, a workpiece rising and falling positioning device and a workpiece transportation limit position positioning device; the workpiece rising and falling transportation device comprises a holding jaw, a driving device and a bracket; the workpiece rising and falling positioning device comprises a first detection switch, a second detection switch and a fixed bracket; the workpiece transportation limit position positioning device comprises a travel switch mounting block, a first proximity switch, a second proximity switch and a travel collision block. According to the workpiece up-and-down transportation device, rising and falling positions of a workpiece are ensured through the workpiece rising and falling positioning device and the workpiece transportation limit position positioning device, and the delivery distance of the workpiece is not influenced by the thickness of the workpiece or transmission errors of the driving device, as a result the workpiece can be transported in place and the mechanical hand of a processing device can take and place the workpiece smoothly.

Owner:CHONGQING MACHINE TOOL GROUP

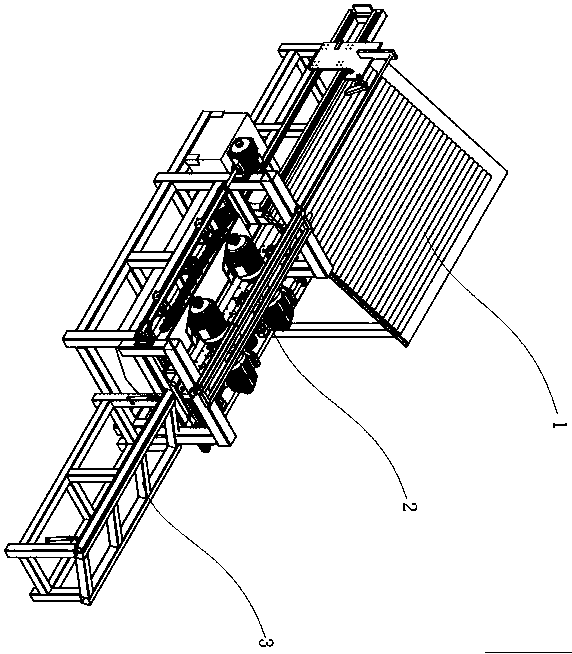

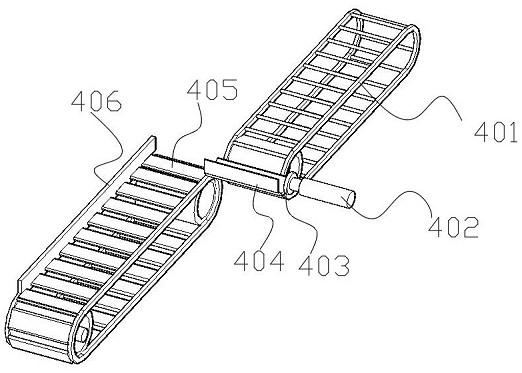

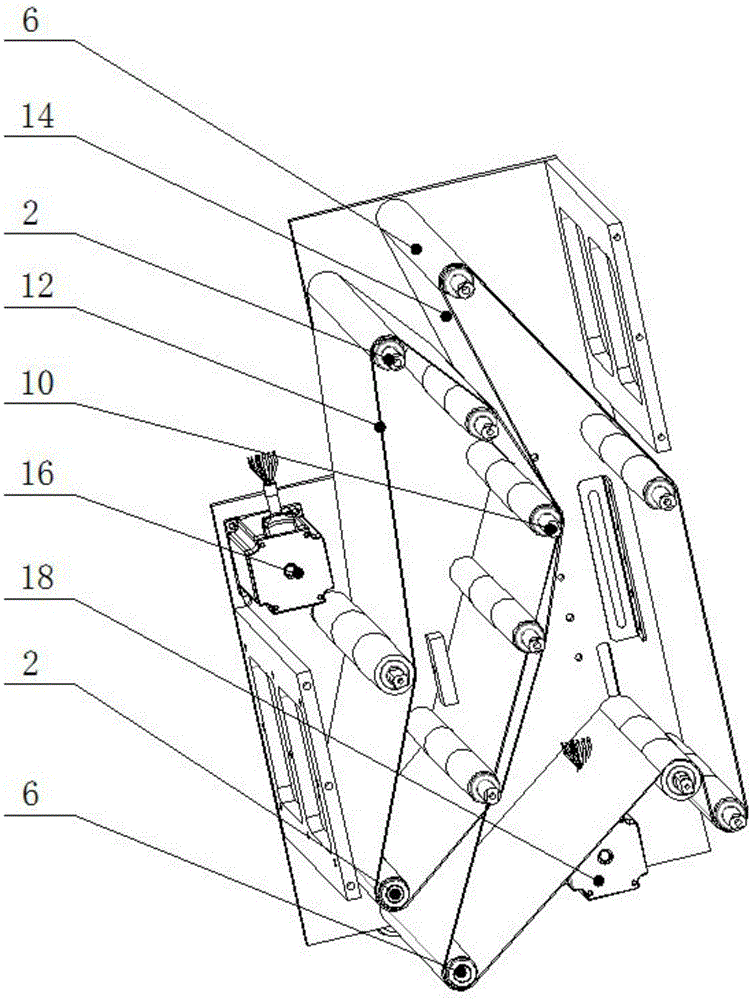

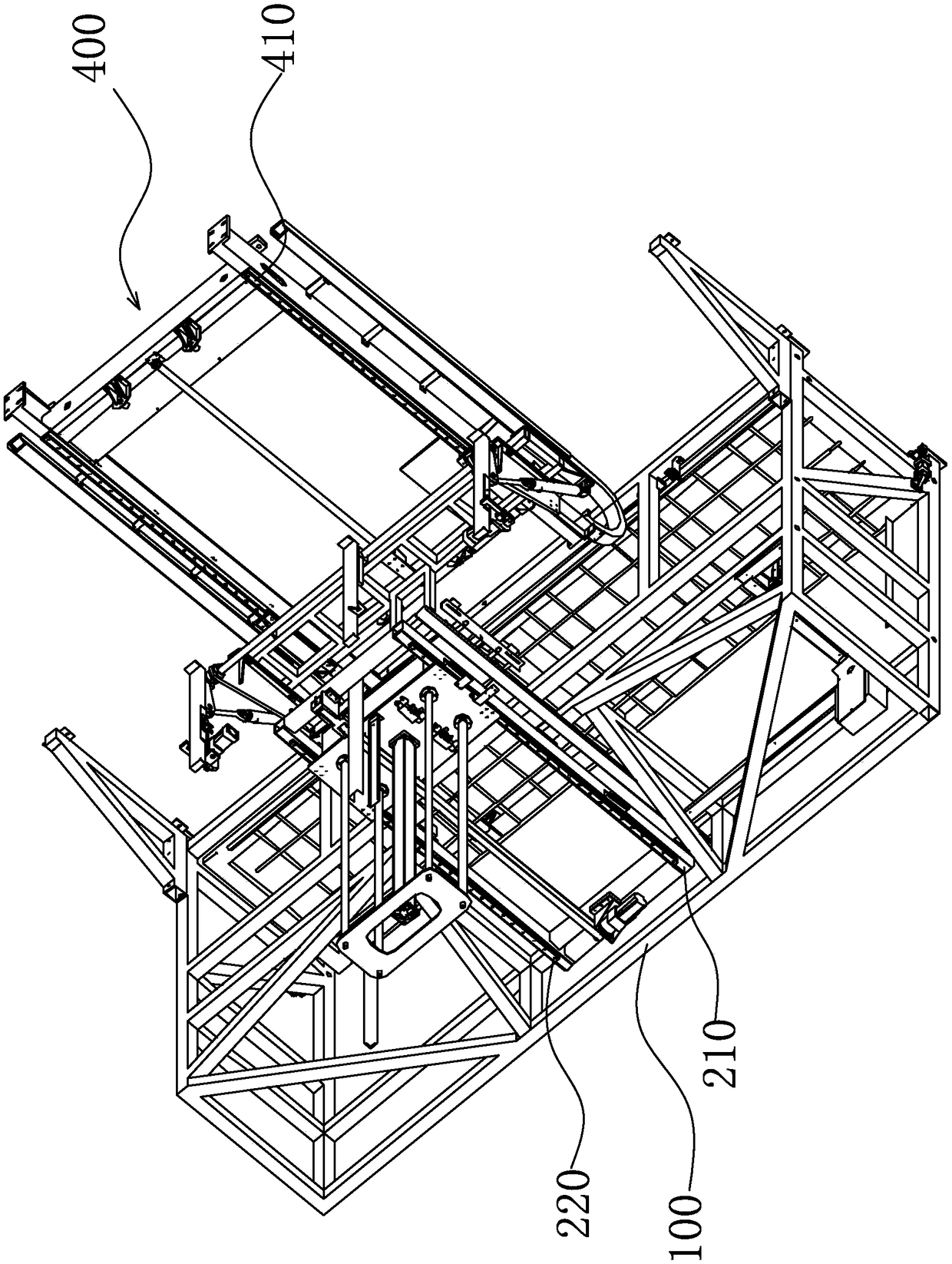

Mesh piece lifting, steering and feeding execution mechanism

PendingCN108750537AEasy to bendShipped accuratelyConveyorsConveyor partsEngineeringMechanical engineering

The invention provides a mesh piece lifting, steering and feeding execution mechanism which comprises a storage support, a feeding support and a steering assembly. The storage support is placed on thefloor and is used for storing a horizontal-state mesh plate; a lifting assembly is connected onto the storage support and can move along the vertical direction and the horizontal direction of the support; the feeding support is located in front of the storage support; a feeding assembly is arranged on the feeding support; one end of the steering assembly is fixedly connected onto the feeding support; and the other end of the steering assembly is movably connected onto the feeding assembly. According to the mesh piece lifting, steering and feeding execution mechanism provided by the invention,the horizontal-state mesh plate can be easily rotated to a vertical-state mesh plate, so that the mesh plate can be conveniently bent by the next mechanism; and in addition, through the execution mechanism, the mesh plate can be accurately lifted and conveyed to a bending mechanism, so that the working efficiency is improved, and the accurate operation implementation is ensured.

Owner:NINGBO XINZHOU RESISTANCE WELDER

Processing equipment for anti-deformation wooden door and processing method thereof

InactiveCN111438789AReduce weightReduce deformationWood working apparatusDrill holeStructural engineering

The invention relates to the field of wooden door processing, in particular to processing equipment for an anti-deformation wooden door and a processing method thereof. The method comprises the following steps of A, material preparation: preparing a sealing plate, two door panels and multiple wooden strips according to the actual size requirements of customers, wherein the length of the wooden strips is less than that of the door panels; B, filling: filling the multiple wooden strips between the two door panels, and making gaps between the adjacent wooden strips; C, after the filling, blockingthe gaps between edges of the two door panels by using the sealing plate; D, carrying out processing steps such as drilling and door casing corner cutting in the factory according to the actual needsof the customers, directly processing the wooden door into a finished product in the factory, and using the processing equipment for drilling during the drilling; and E, home installation: directly using installation tools to install the wooden door by the installer after being delivered to the customer's home. The solution makes the processed wooden door less susceptible to deformation.

Owner:简德宽

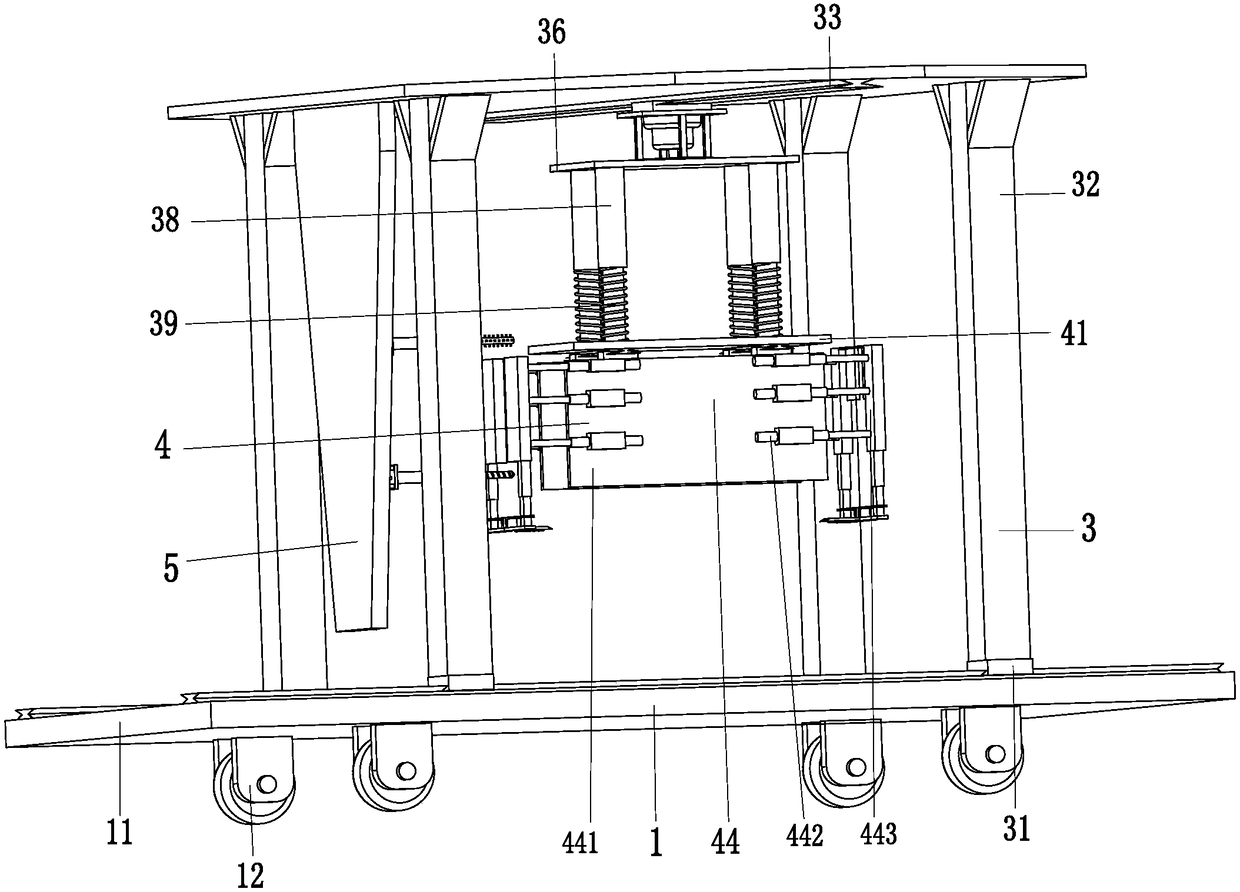

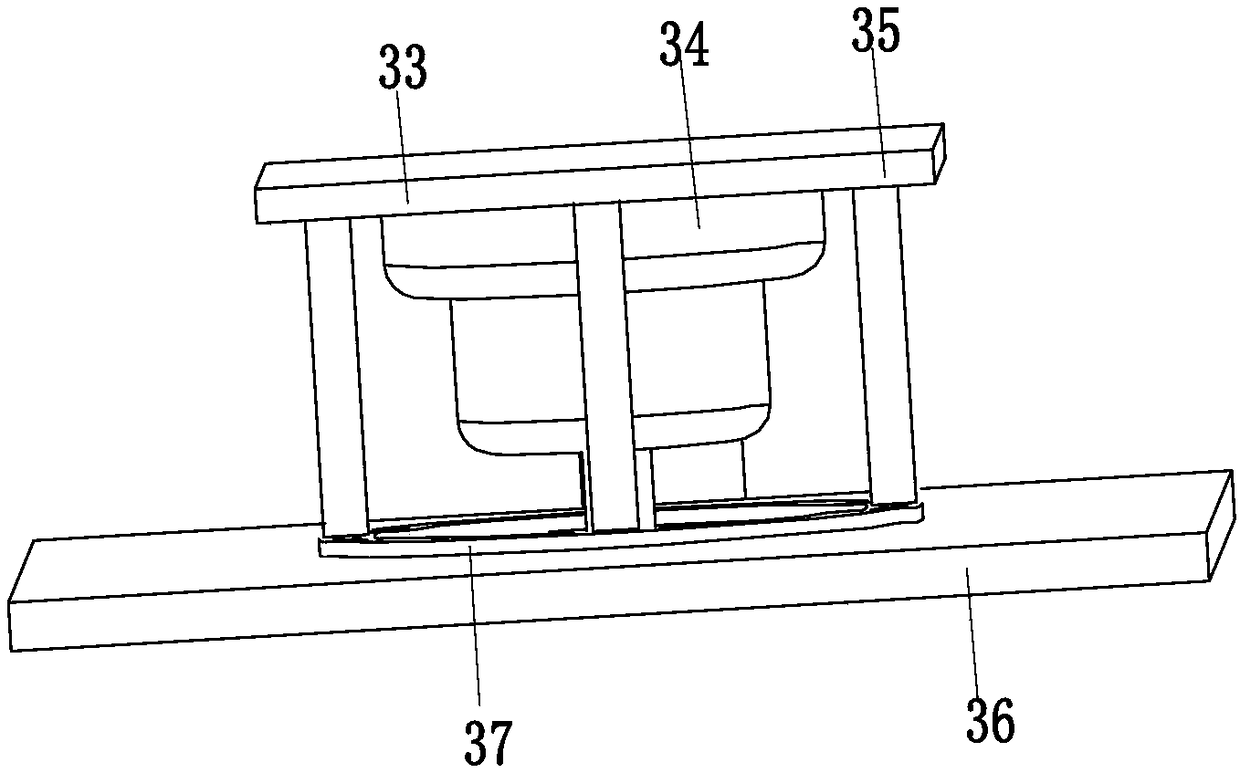

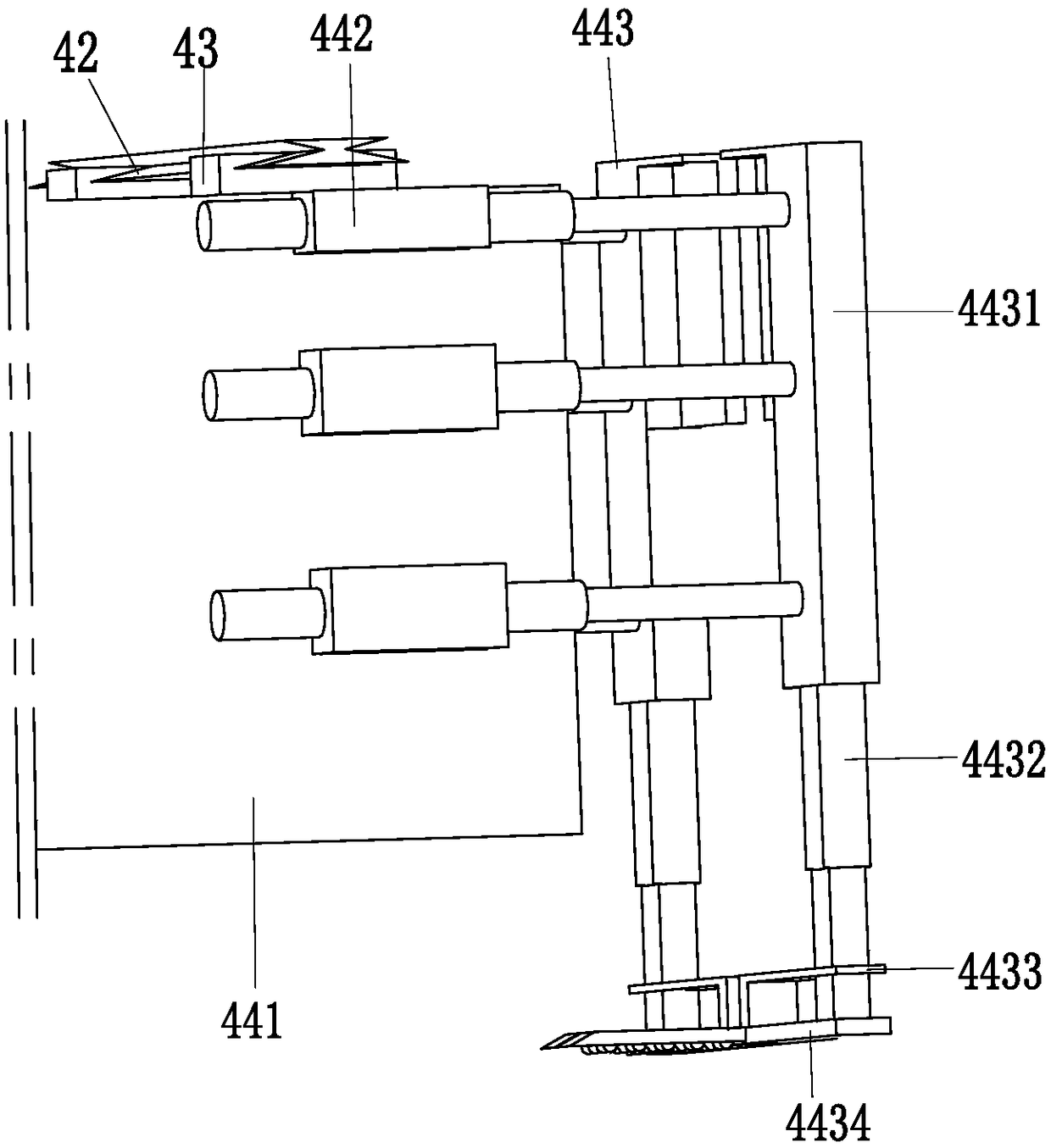

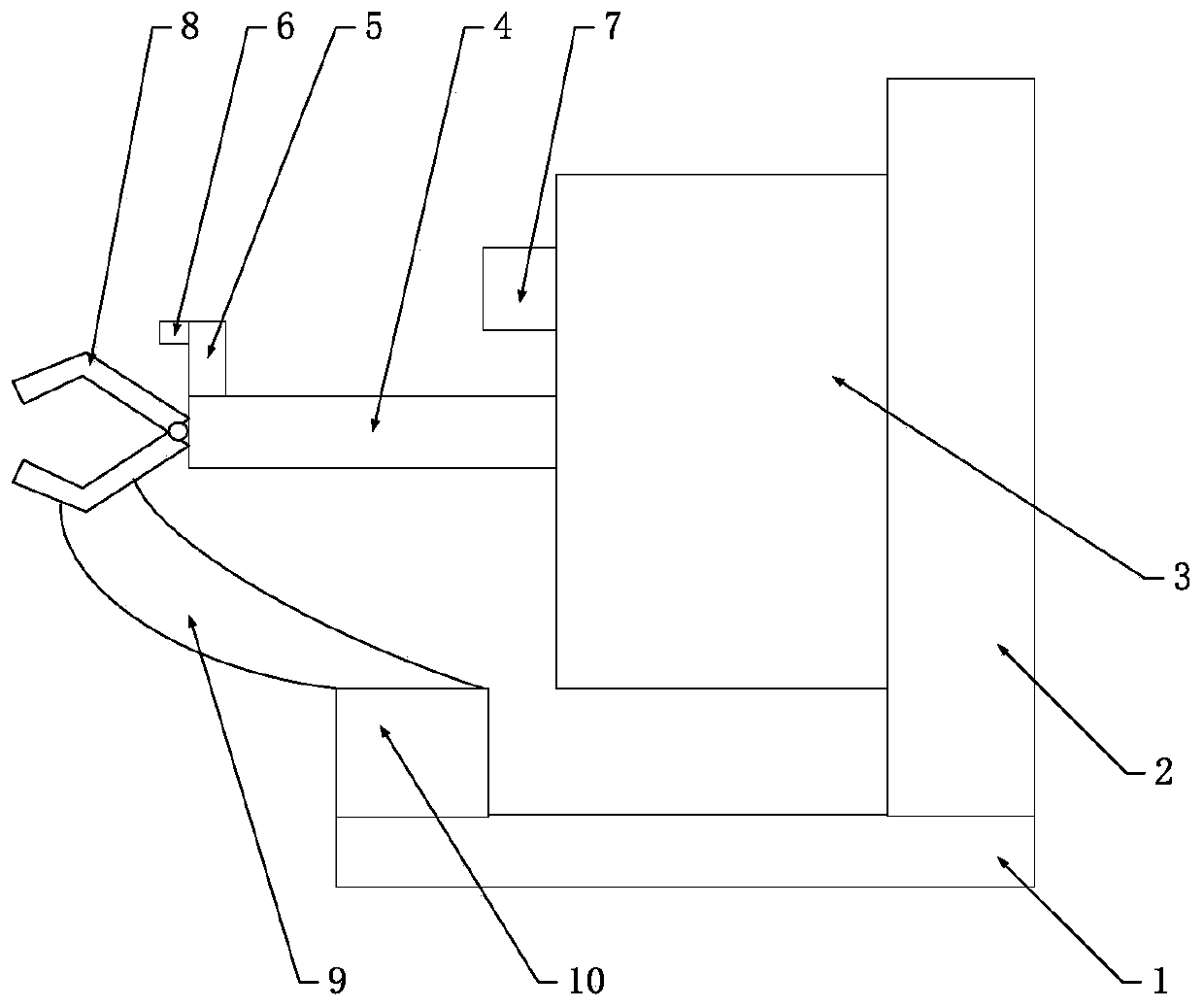

An automatic hoisting and installing machine for glass fiber reinforced plastic isolation pier for expressway maintenance

ActiveCN107324220BRealize automatic positioning and installationImprove work efficiencyCleaning using toolsTrolley cranesGlass fiberEngineering

The invention relates to an automatic hoisting and installation machine for fiberglass isolation piers dedicated to highway maintenance, which includes a base, a hanger device, a grabbing device, and a cleaning device. The base includes a supporting bottom plate and four universal wheels, and the crane The bottom of the rack device is connected to the top of the support base plate, the grabbing device is installed on the hanger device, the cleaning device is located on the left side of the grabbing device, and the cleaning device is installed on the hanger device. The invention can solve the existing problems of low work efficiency, high labor intensity, inability to effectively clean the installation holes of the isolation pier, easy dangers during the transportation of the isolation pier, and inability to position and install the isolation pier during the installation of the isolation pier. ; It realizes the function of automatic positioning and installation of isolation piers, and has the advantages of high work efficiency, low labor intensity, the ability to thoroughly clean the installation holes of the isolation piers, mechanized handling of the isolation piers without danger, and the ability to position and install the isolation piers.

Owner:成武盛阳热力有限公司

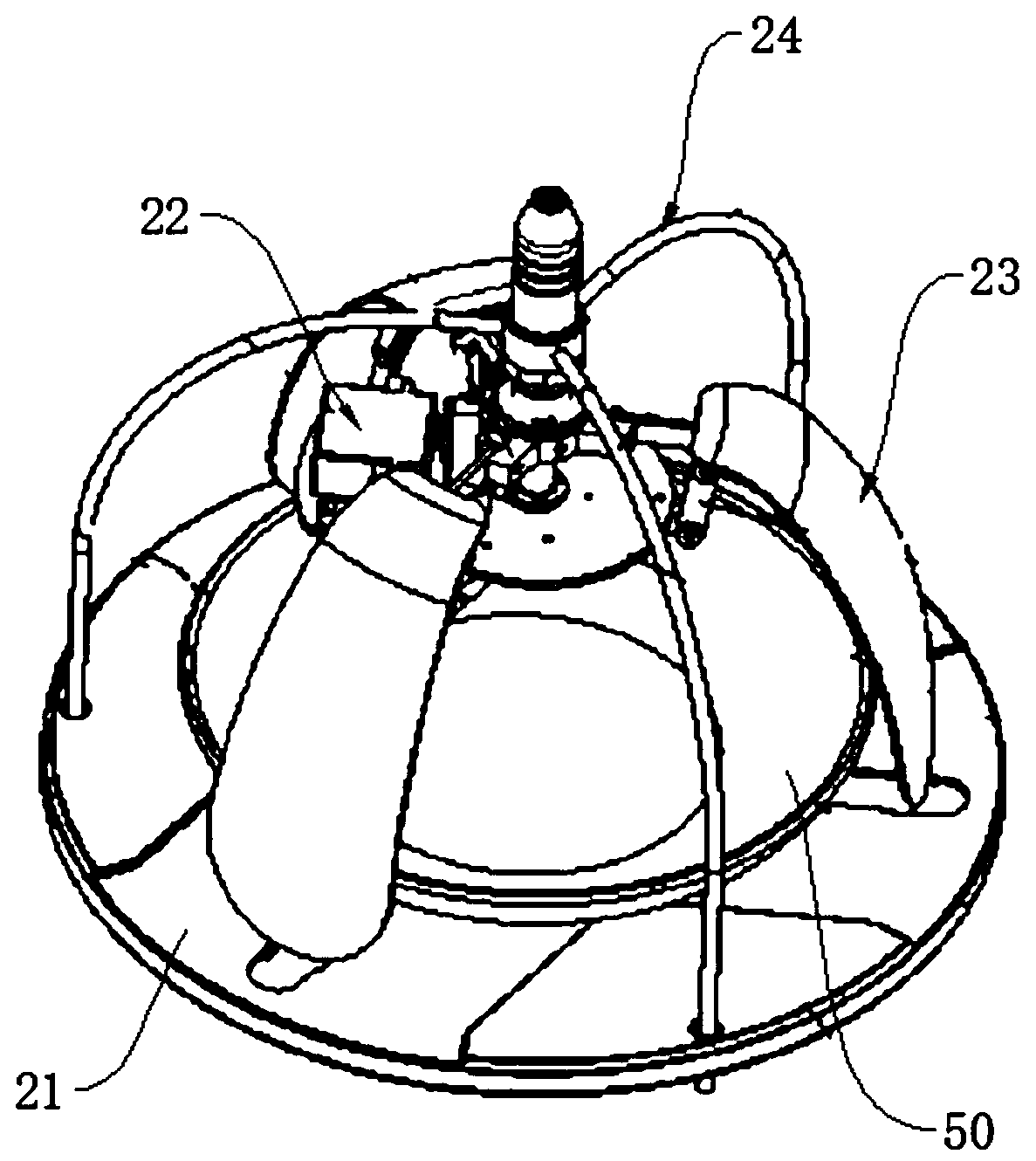

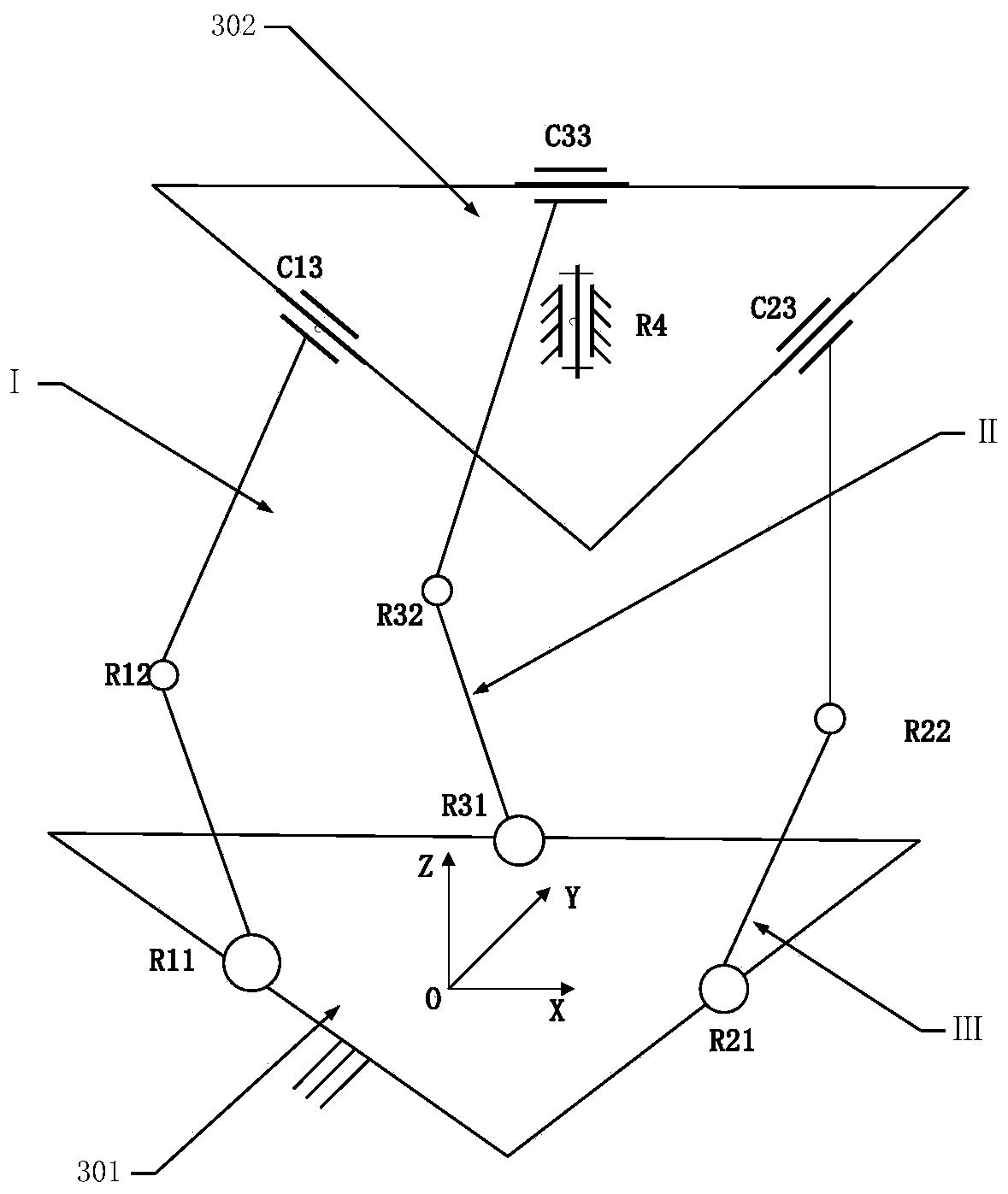

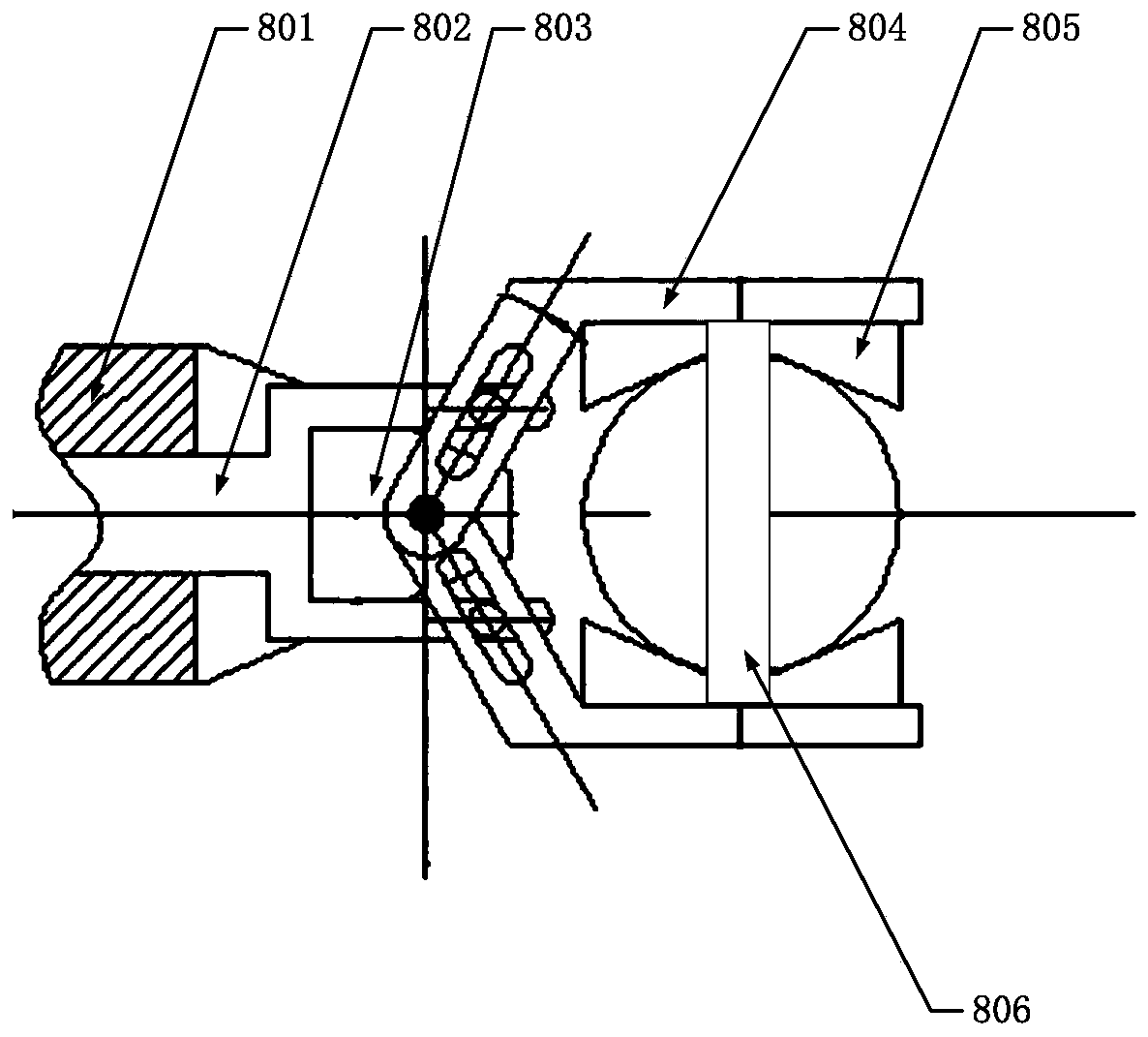

Parallel platform for fruit and vegetable picking manipulator

InactiveCN110800468AShipped accuratelyAvoid main branchesProgramme-controlled manipulatorGripping headsFruit treeControl engineering

The invention provides a parallel platform for a fruit and vegetable picking manipulator. The parallel platform comprises a static platform, a moving platform, a rotating pair R4, single open-chains I, II, III and four servo motors. The parallel platform further comprises a specific topological structure, wherein the topological structure of the parallel platform is 3-RRC+R, and the parallel platform has higher positioning performance under the PID feedback regulation effect, so that the leakage rate and the crushing rate can be effectively reduced; the single positioning time takes less time,so that the response time of mechanical actions is effectively shortened; and the three-dimensional imaging is applied to a target positioning system, so that the positioning of fruits can be effectively realized, and the parallel platform can adapt to the complexity of the operating environment of a fruit tree picking robot and the particularity of the operating targets.

Owner:熊浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com