Accurate positioning storage bin

A precise positioning and silo technology, applied in metal processing and other directions, can solve the problems of poor repeated positioning accuracy, inconvenient workpiece replacement, and less loaded workpieces, and achieve high repeated positioning accuracy, short installation and debugging time, accurate material removal and The effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

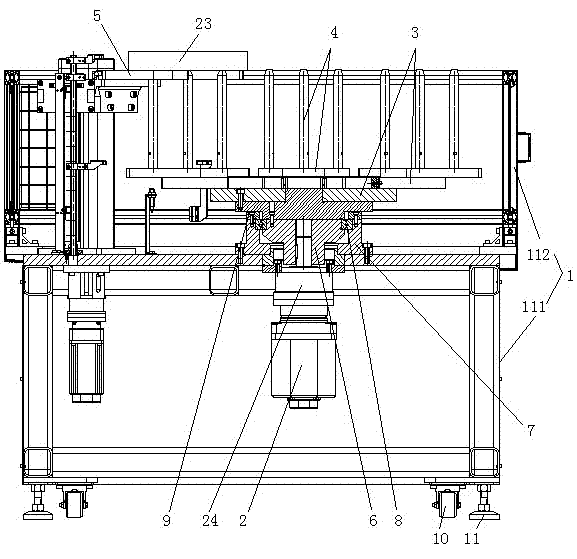

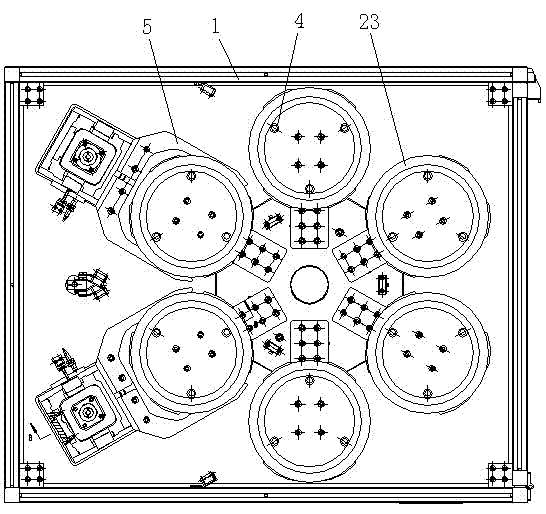

[0031] As shown in the figure, this embodiment accurately positions the silo, including a silo frame 1, a workpiece lifting mechanism and a workpiece horizontal rotating transport mechanism;

[0032] The workpiece horizontal rotary transport mechanism includes a first motor 2 arranged on the bin frame 1, a turntable 3 connected to the rotor of the first motor, and a workpiece loading mechanism 4 arranged at equal intervals along the circumferential direction of the turntable;

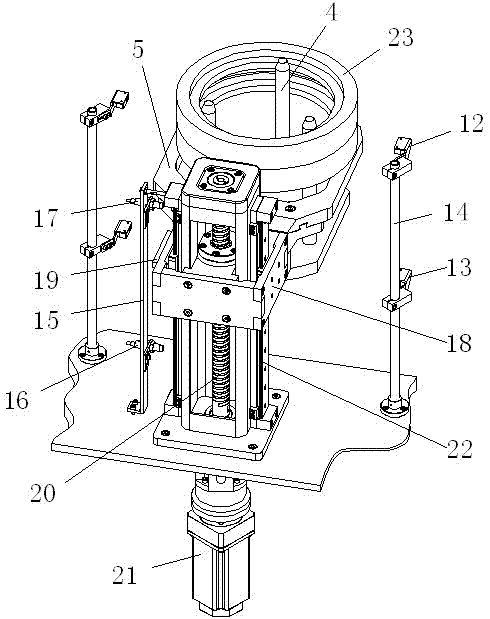

[0033] There are two sets of the workpiece lifting mechanism, and the two sets of workpiece lifting mechanisms are arranged correspondingly to the two sets of workpiece loading mechanisms 4. The workpiece lifting mechanism includes a jaw 5 for transporting the workpiece on the workpiece loading mechanism and a driving device for driving the jaw 5 to lift .

[0034] In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com