Patents

Literature

84results about How to "Accurate retrieving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Image Similarity Calculation System, Image Search System, Image Similarity Calculation Method, and Image Similarity Calculation Program

ActiveUS20080152225A1Accurately determineAccurate retrievingImage analysisCharacter and pattern recognitionPattern recognitionReference image

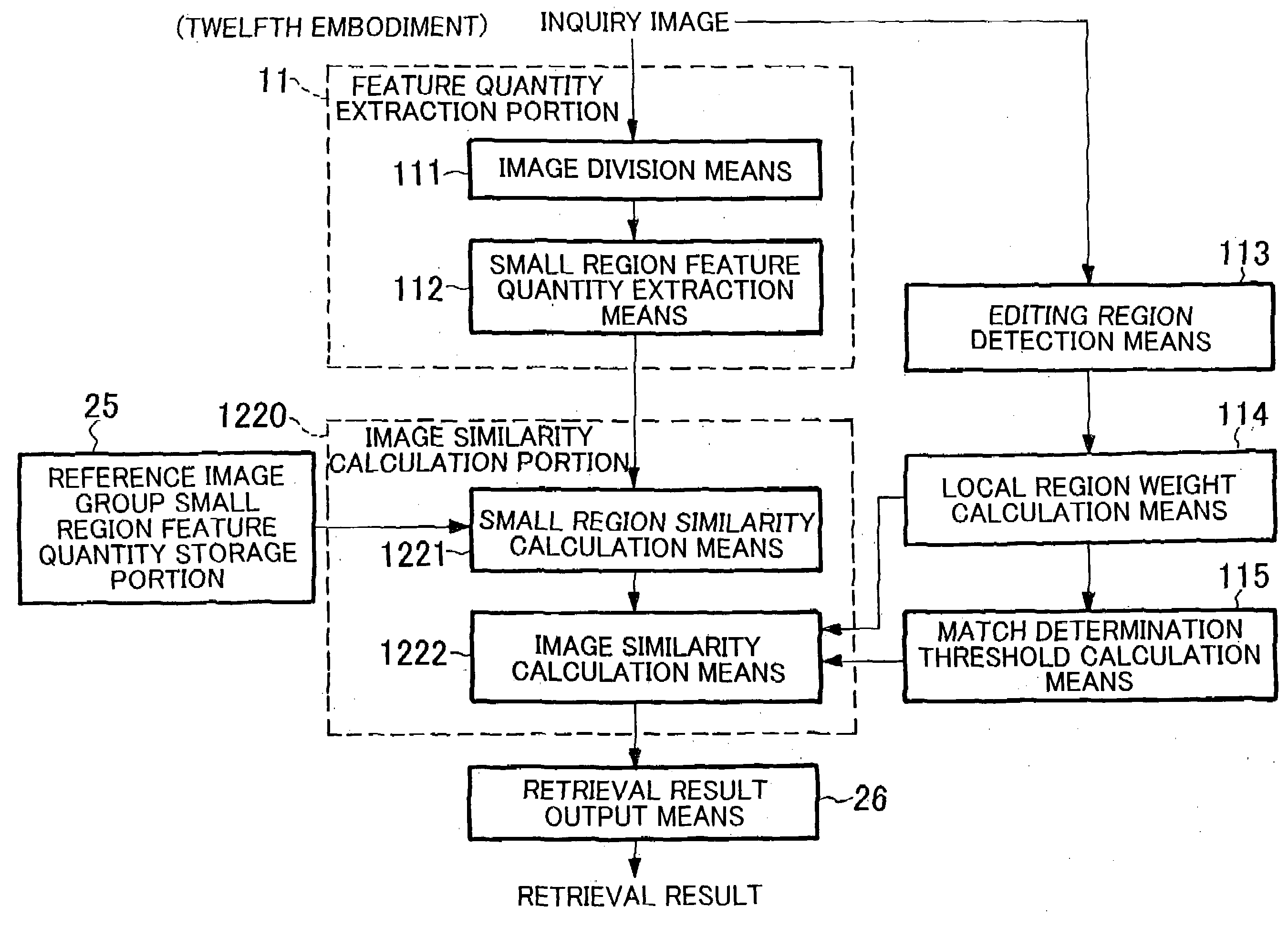

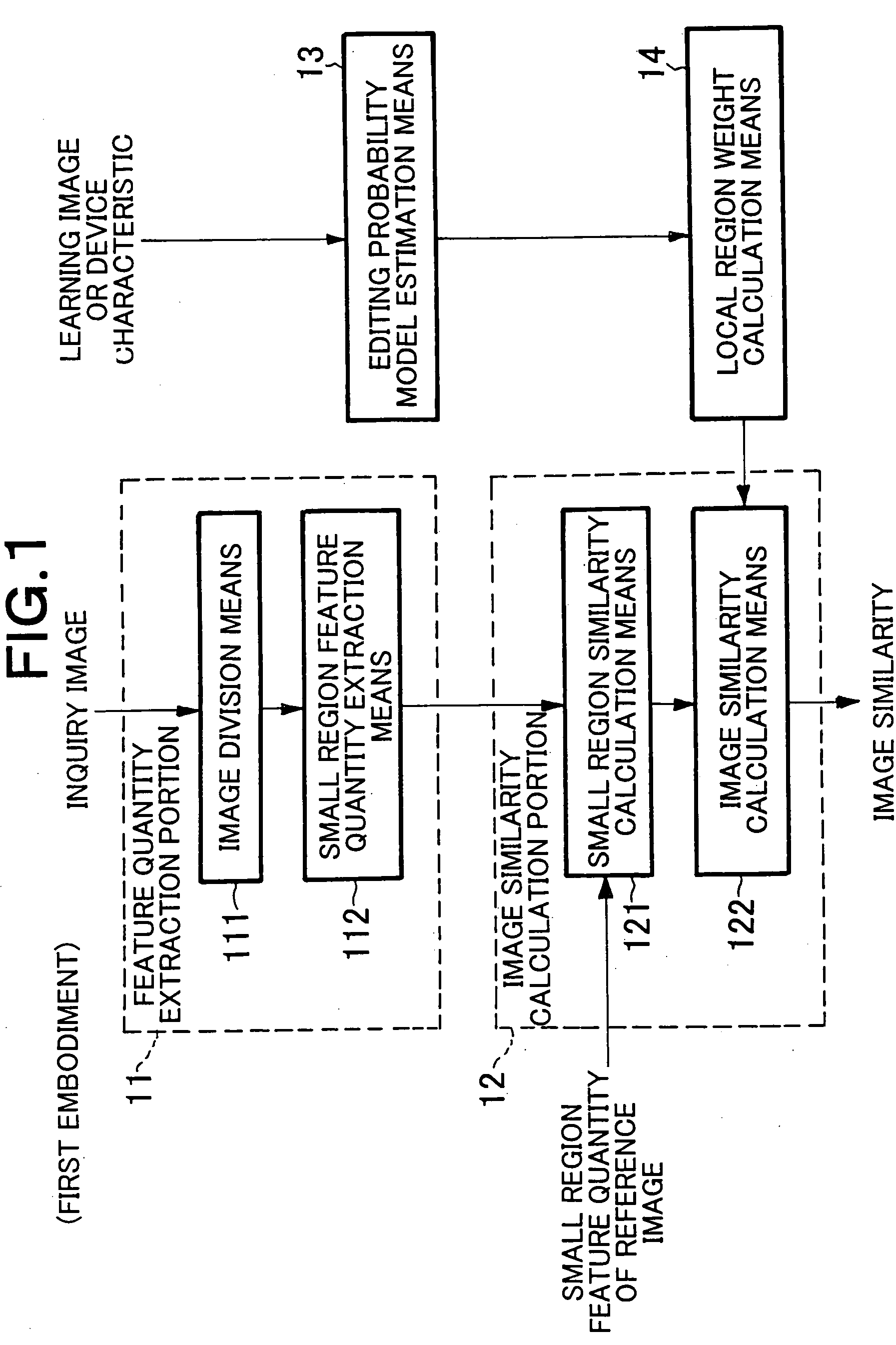

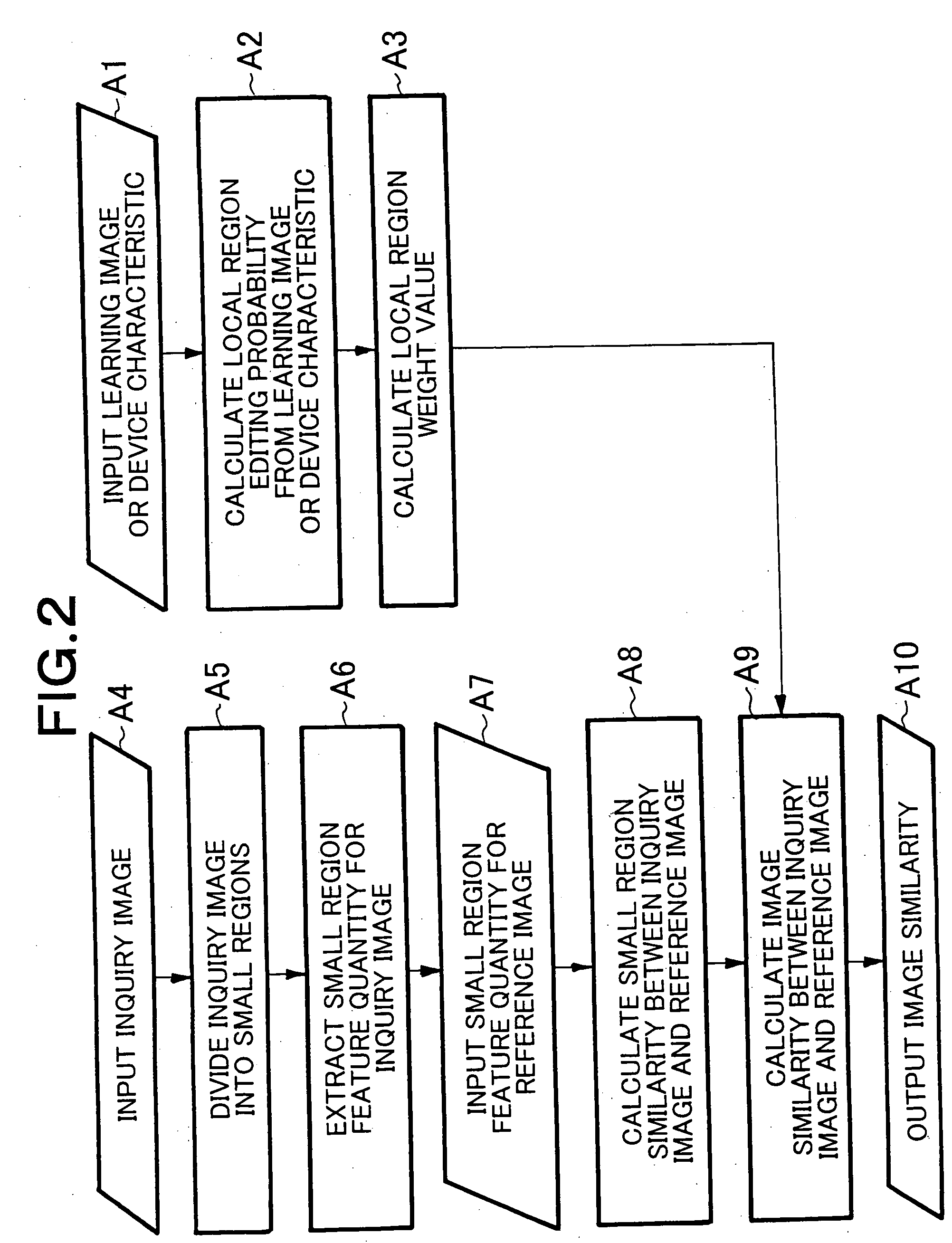

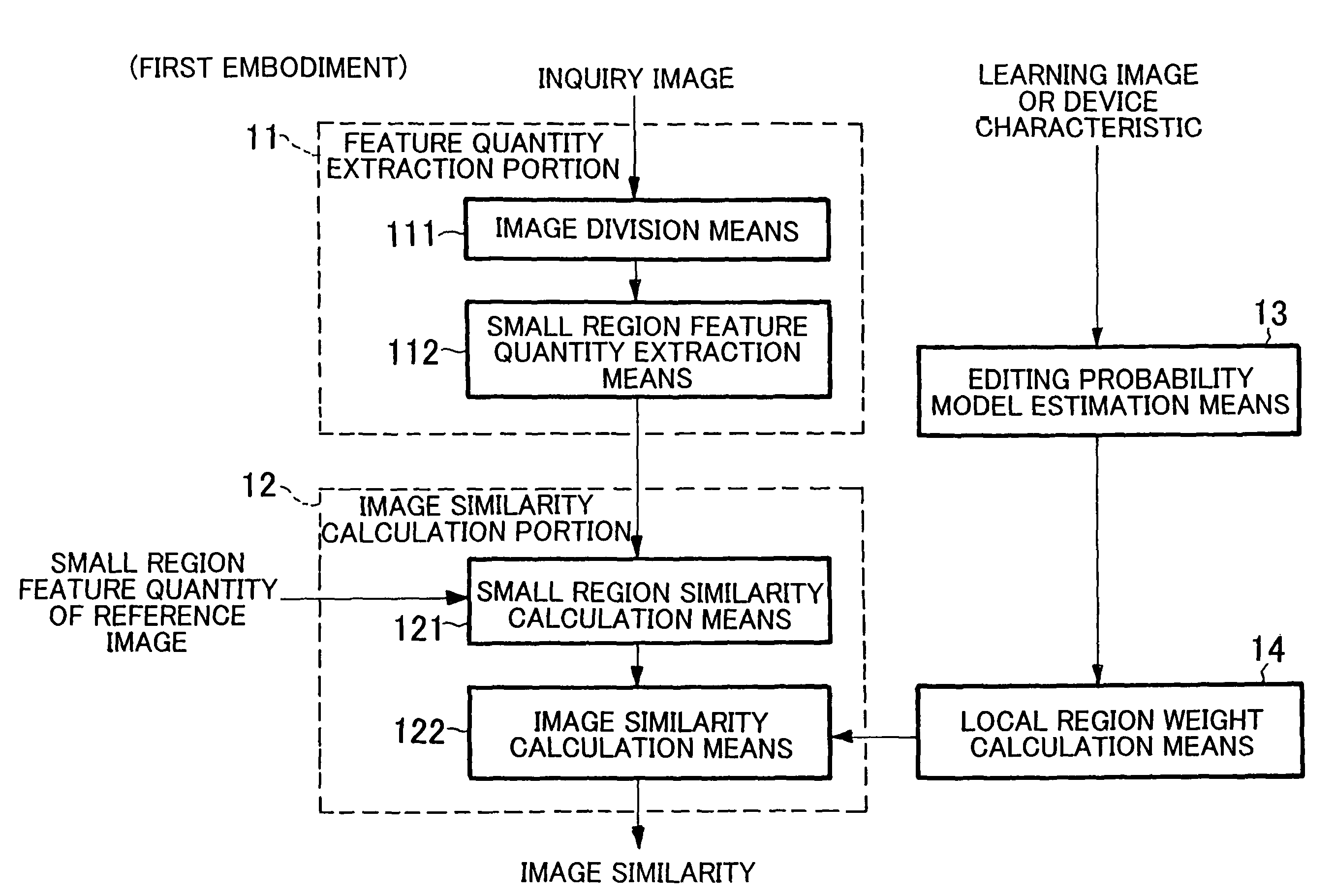

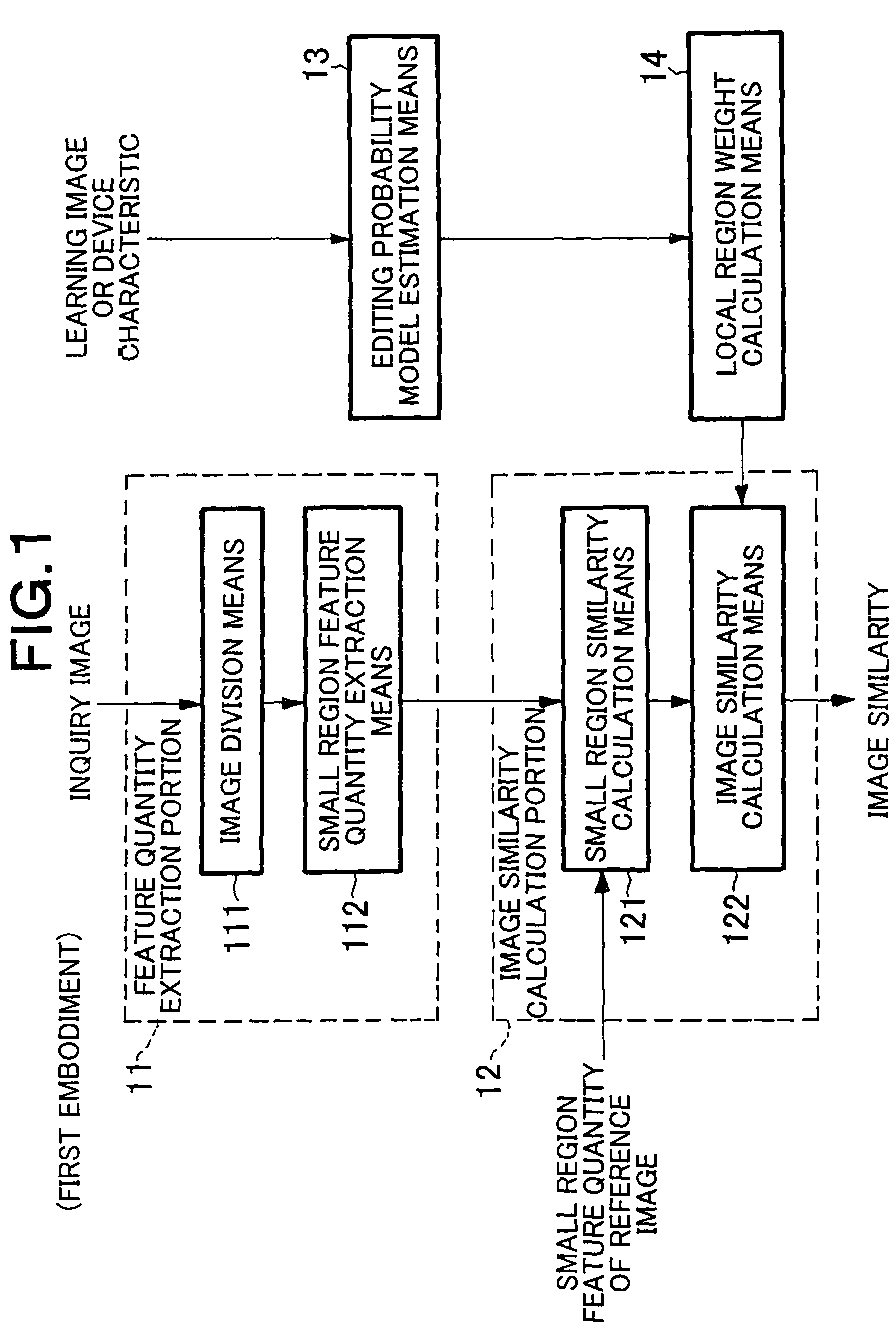

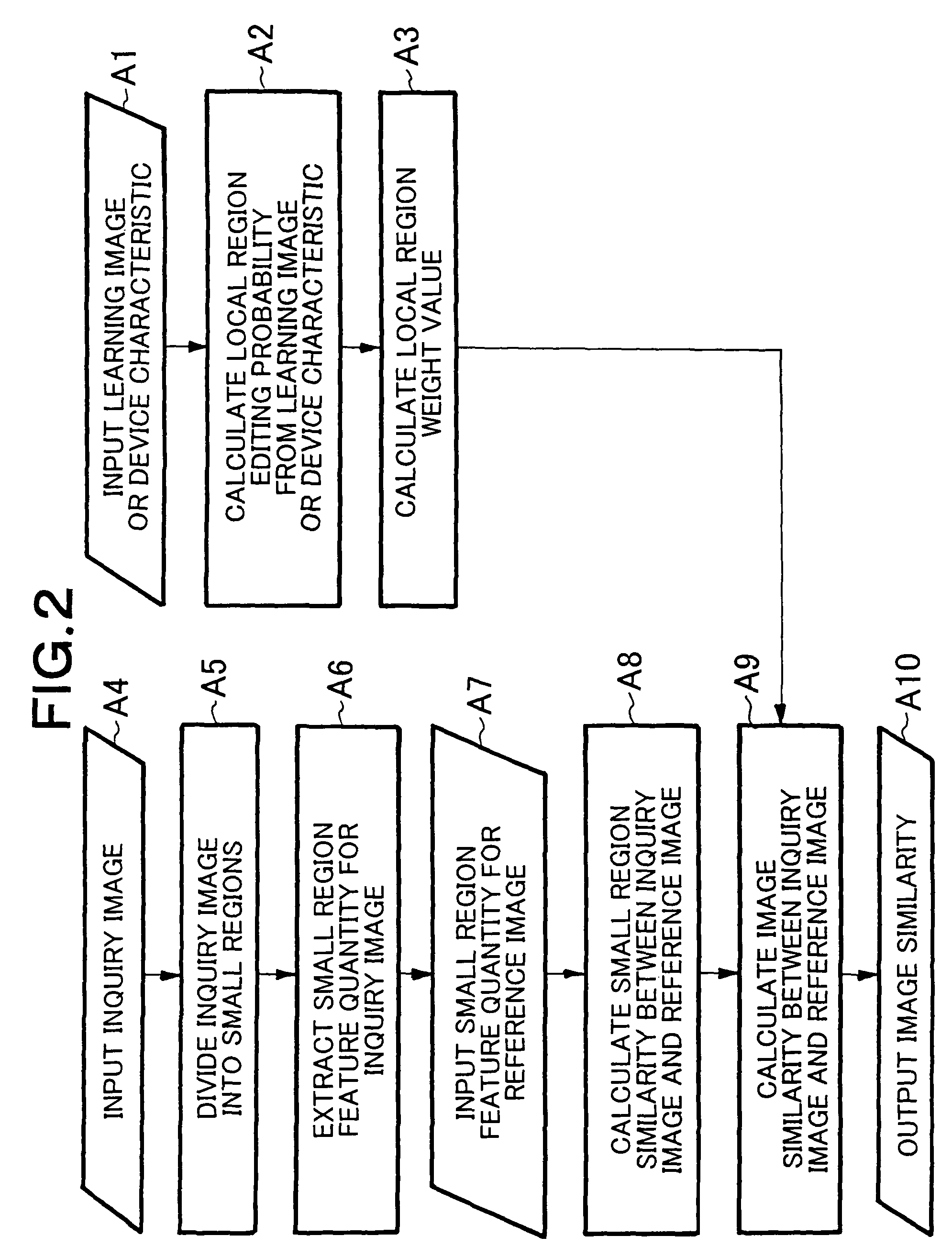

There is provided an image similarity calculation system which yields a large value for image similarity between an edited image and an original image. A local region weight calculation means 14 calculates a weight value for each local region in the image as a local region weight value, based on probability of editing each local region in the image. The local region weight calculation means 14 outputs the calculated local region weight value to an image similarity calculation means 122. A small region similarity calculation means 121 compares a feature quantity for each small region resulting from dividing an inquiry image with a feature quantity for each small region resulting from dividing a reference image. The small region similarity calculation means 121 calculates a similarity of feature quantities for the respective small regions. The image similarity calculation means 122 calculates an image similarity between the inquiry image and the reference image by applying a small-region-based weight value to the calculated similarity. This weight value is found from a local region weight value supplied from the local region weight calculation means 14.

Owner:NEC CORP

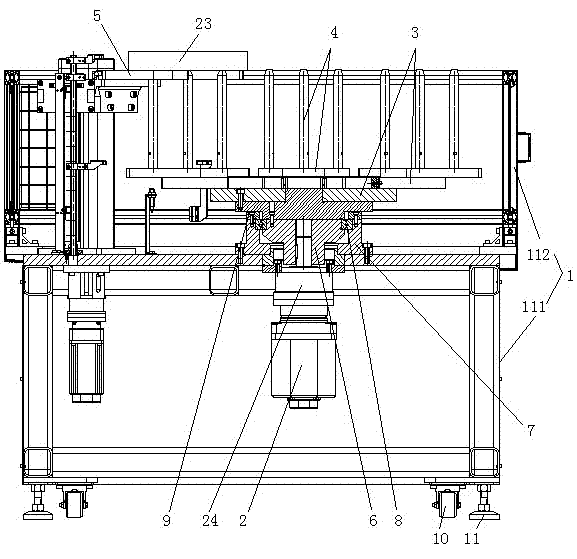

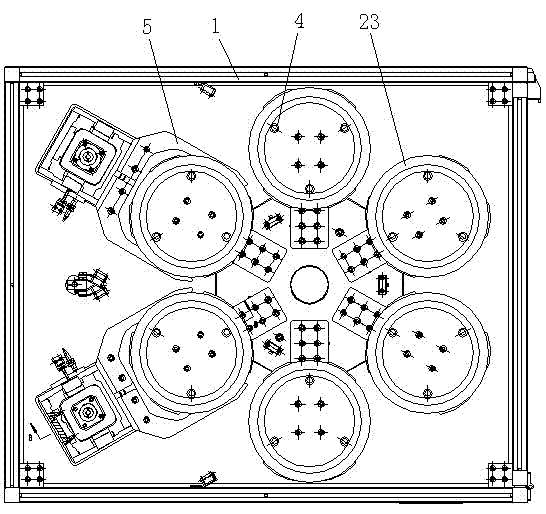

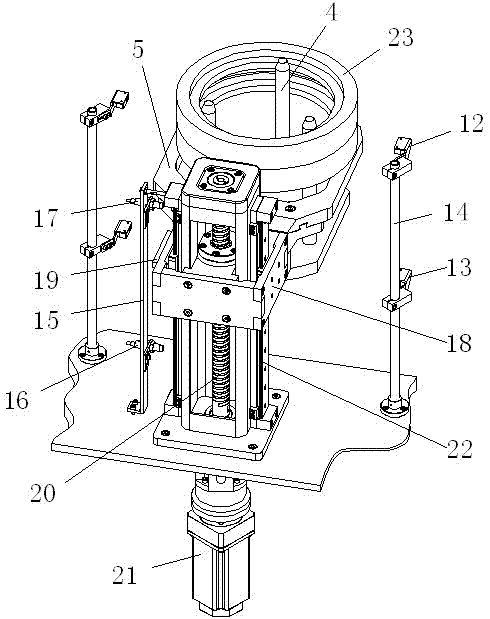

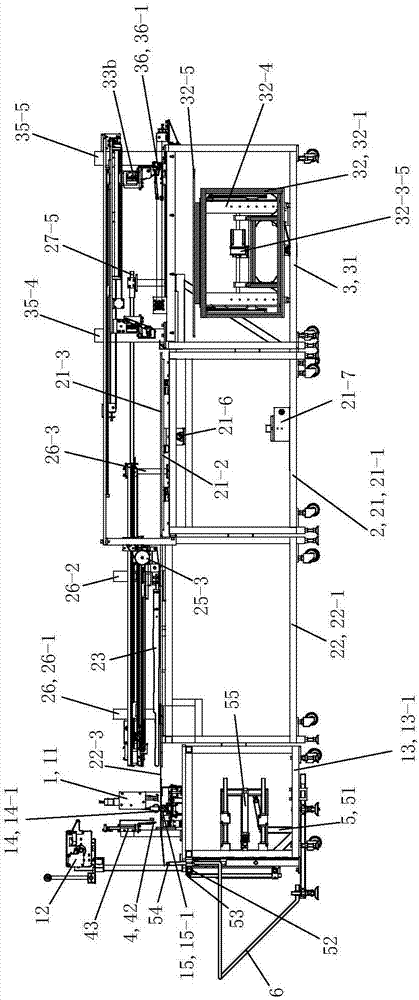

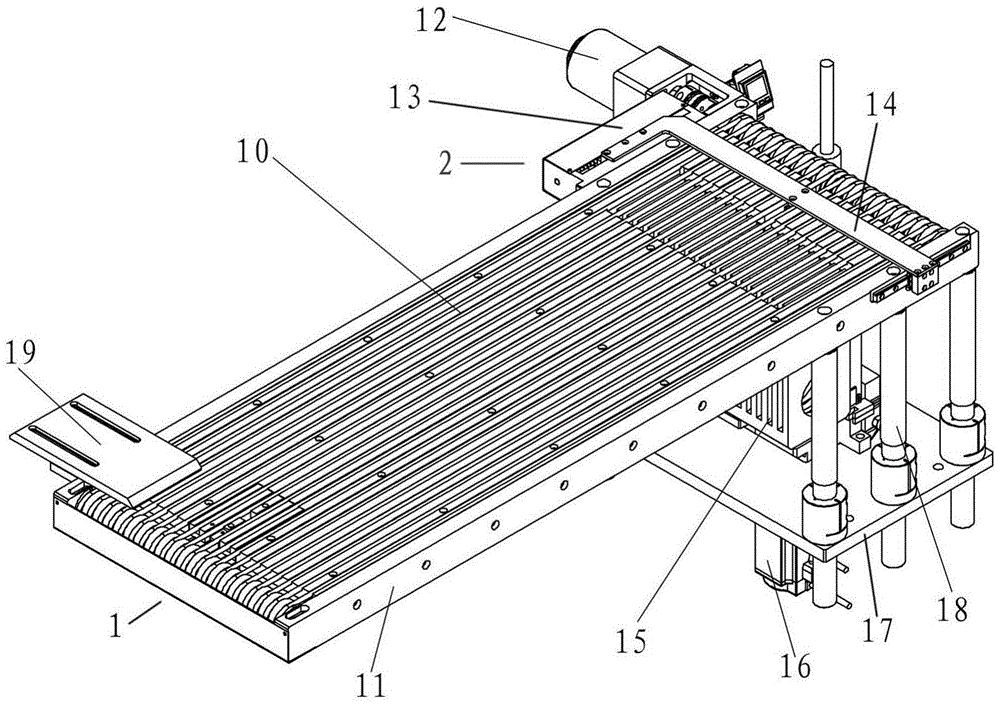

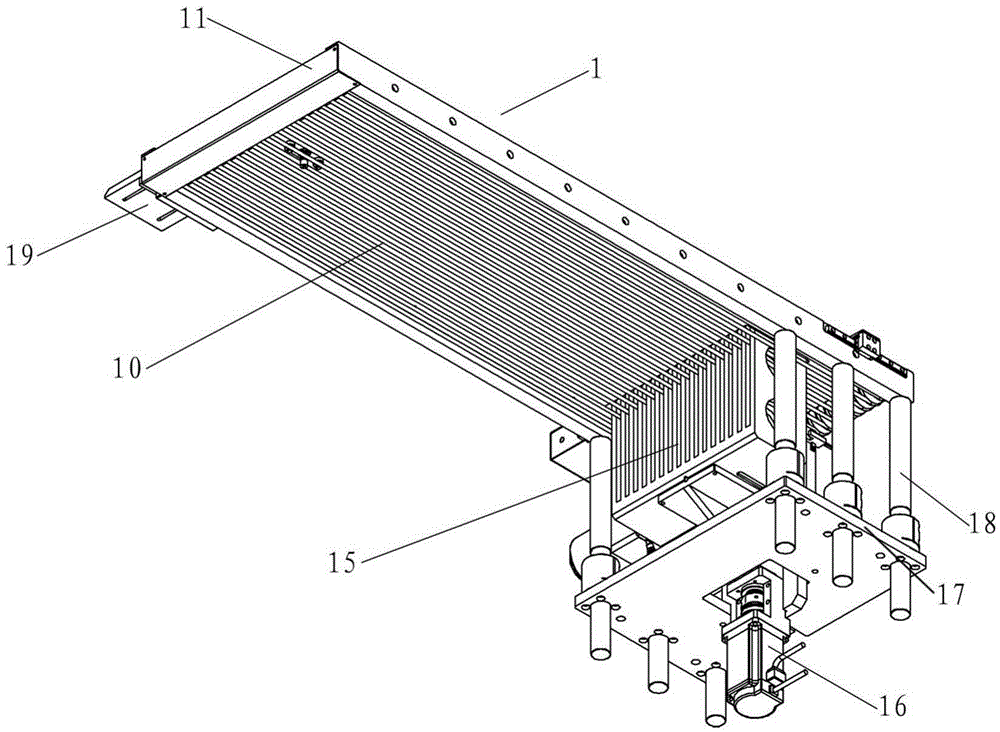

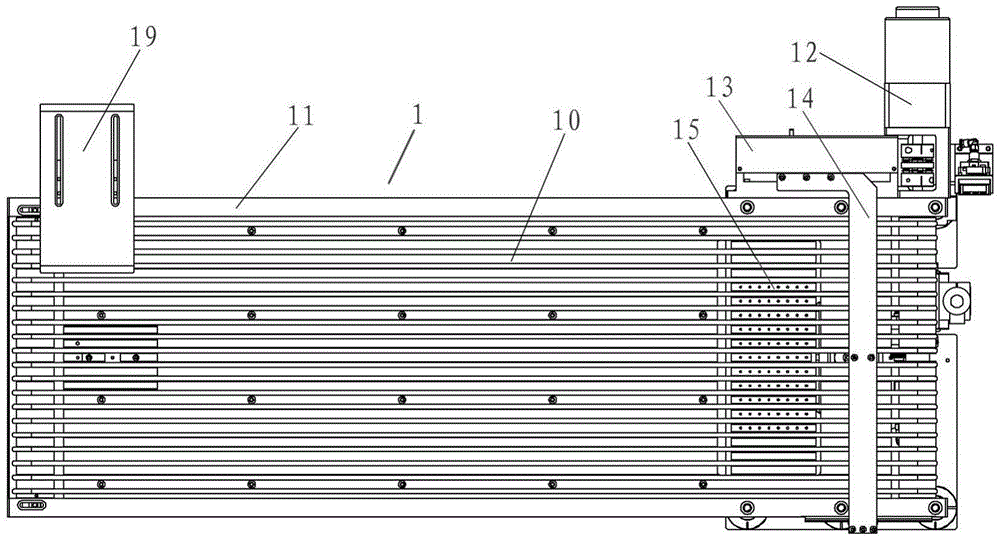

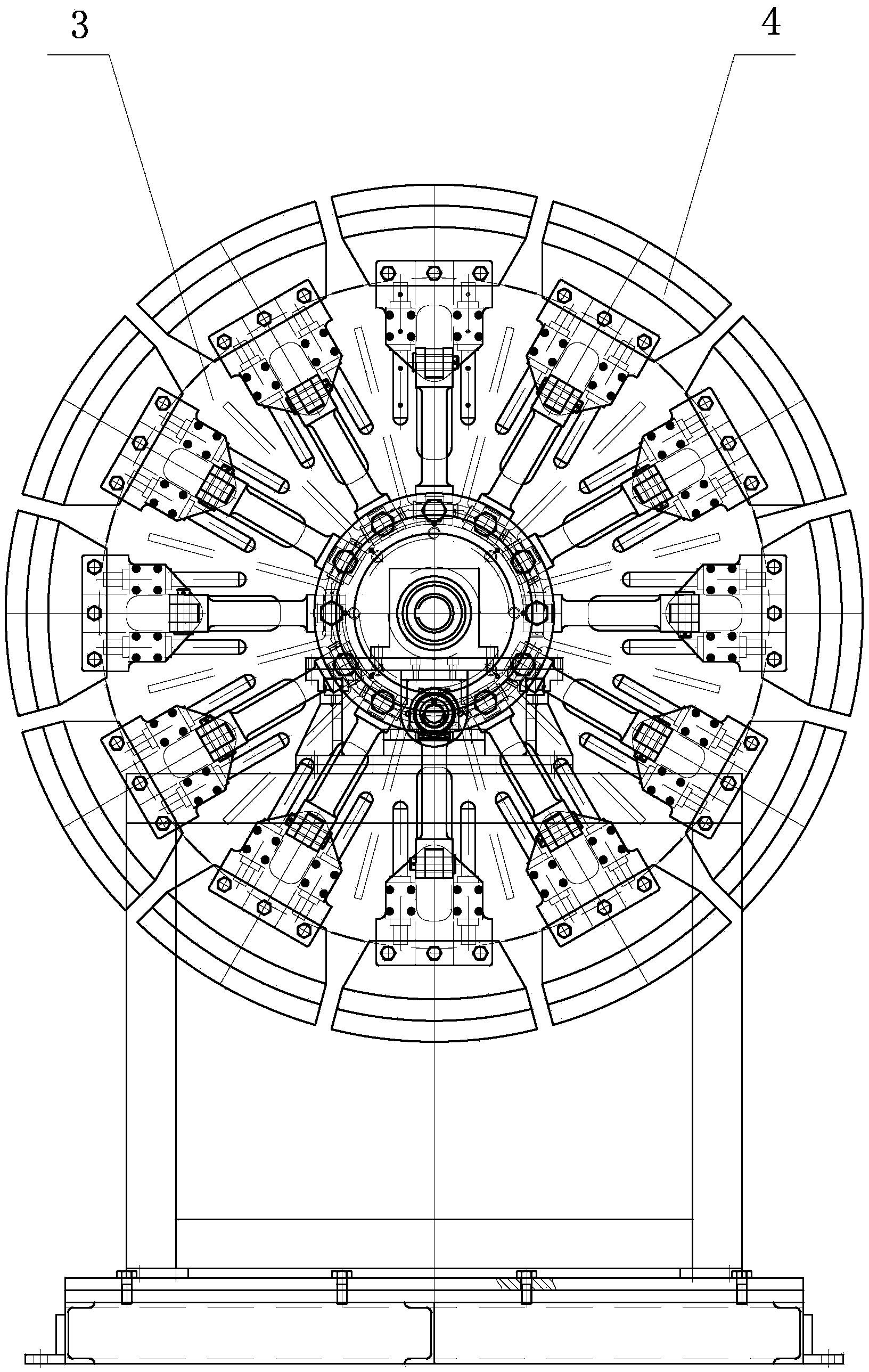

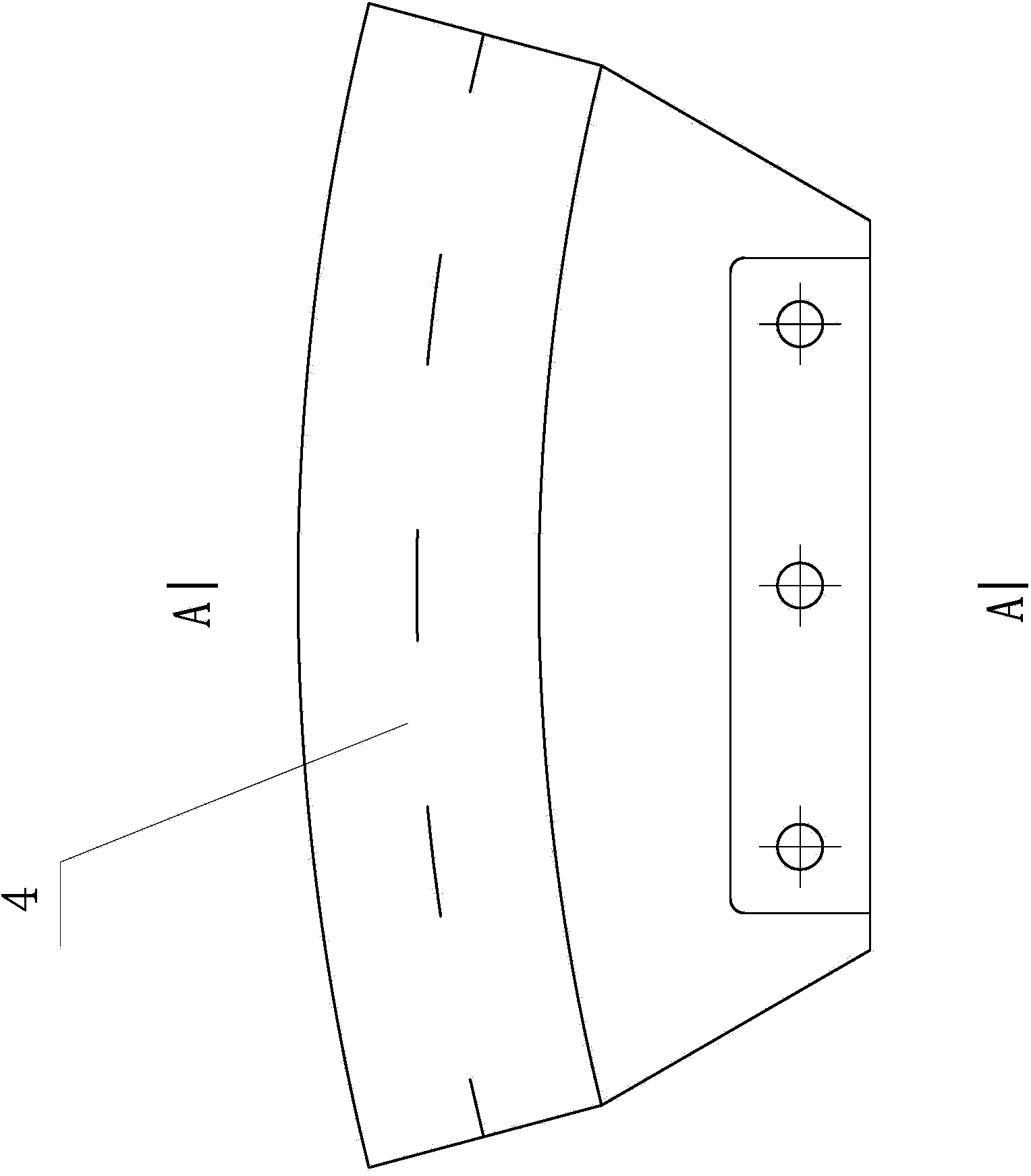

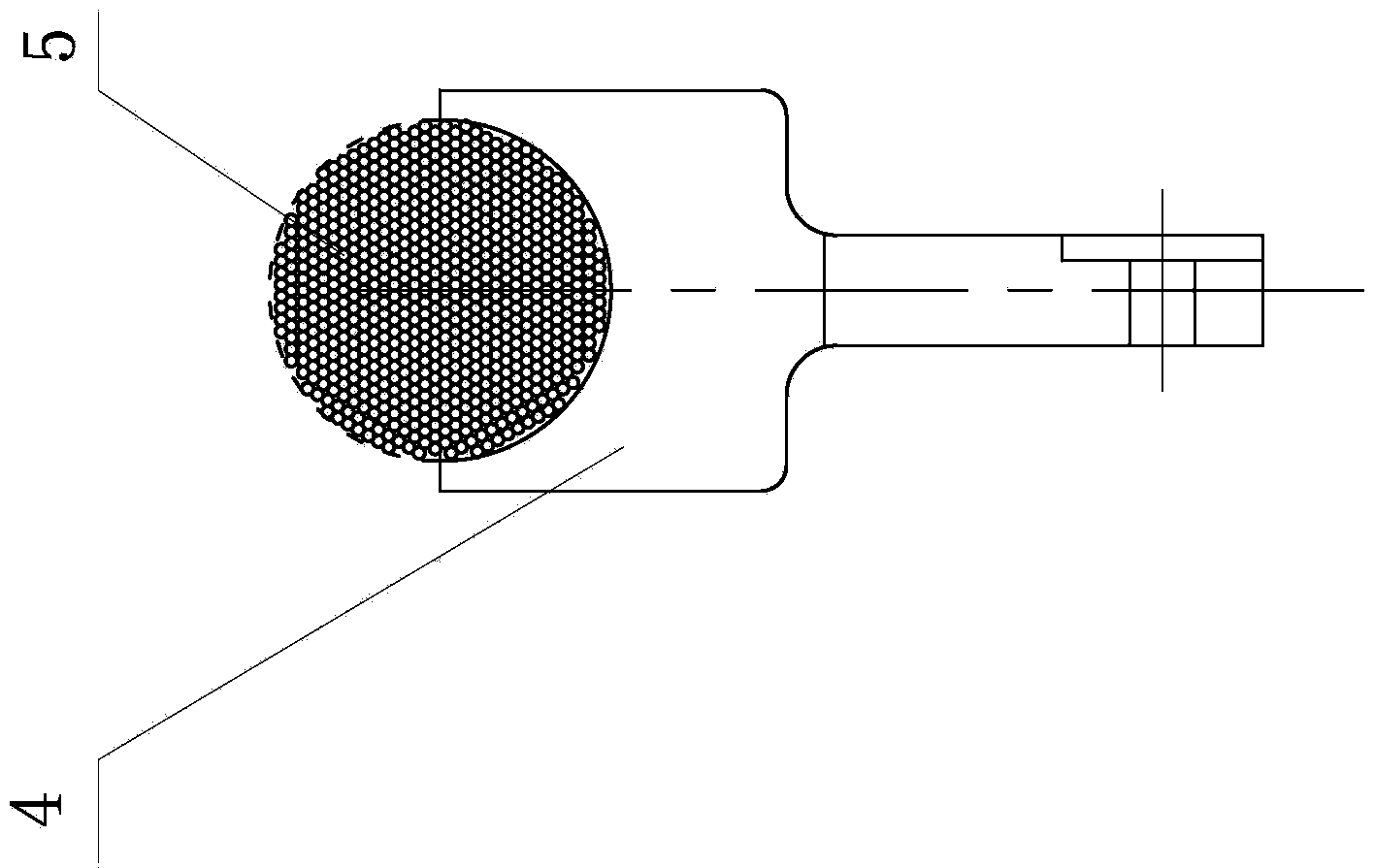

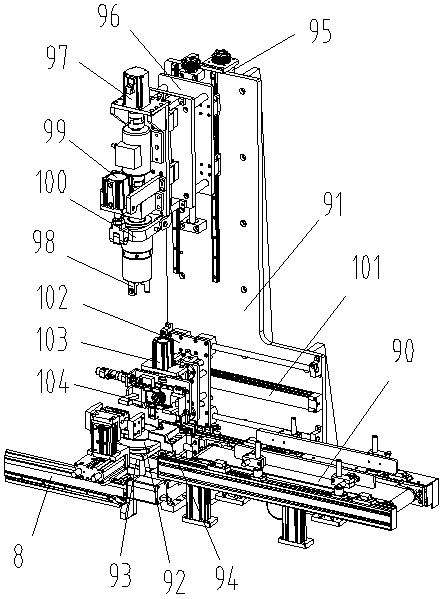

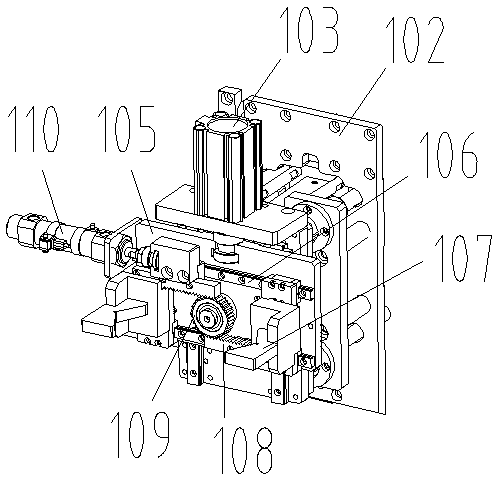

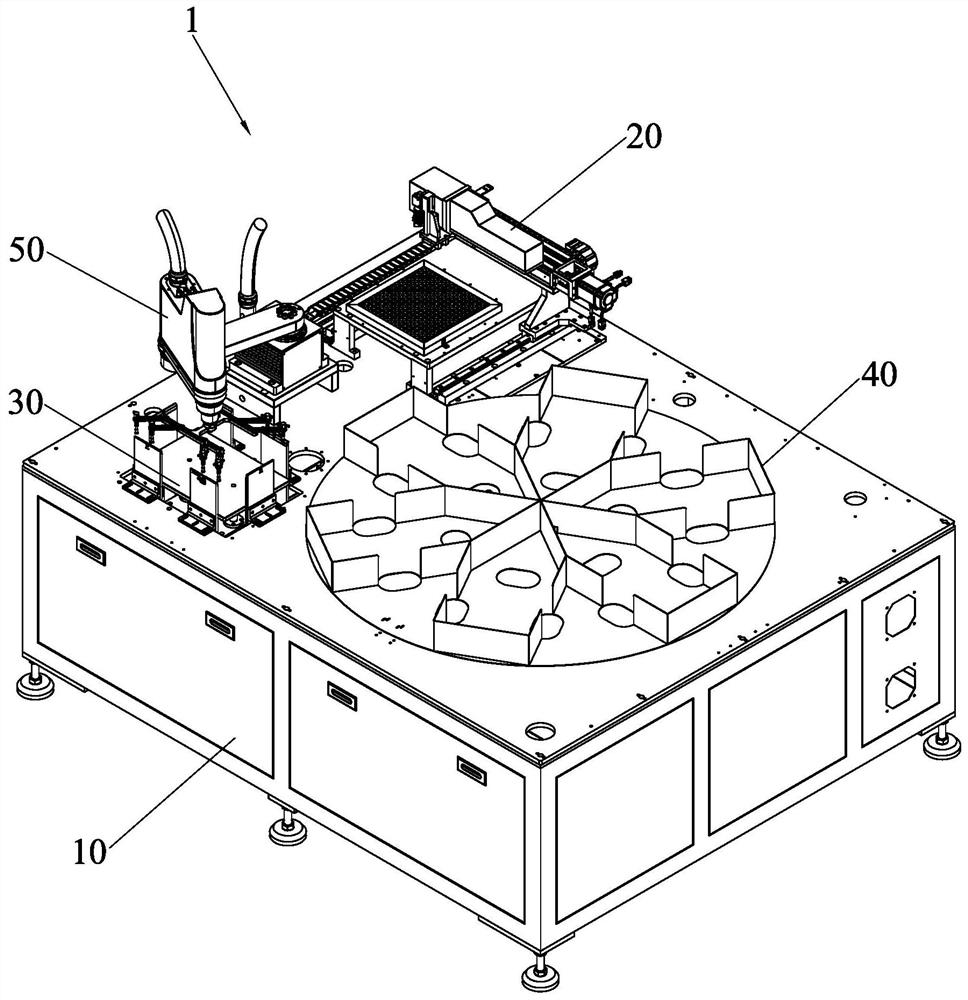

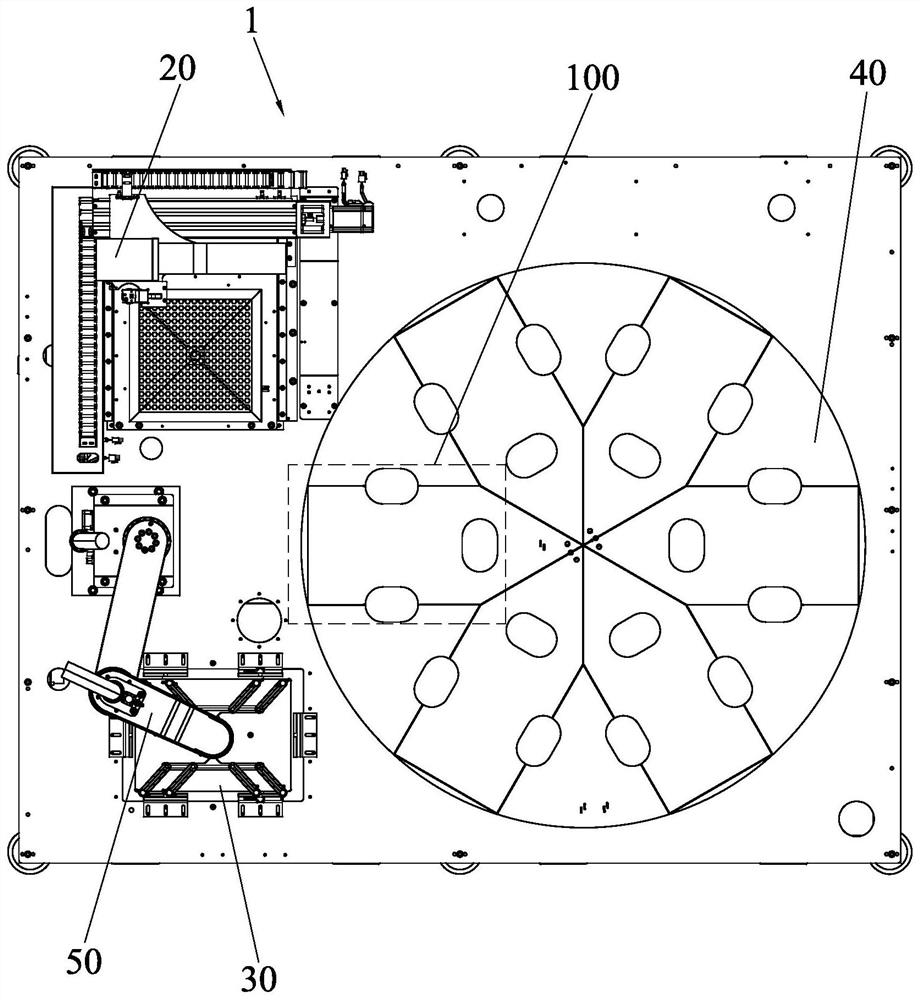

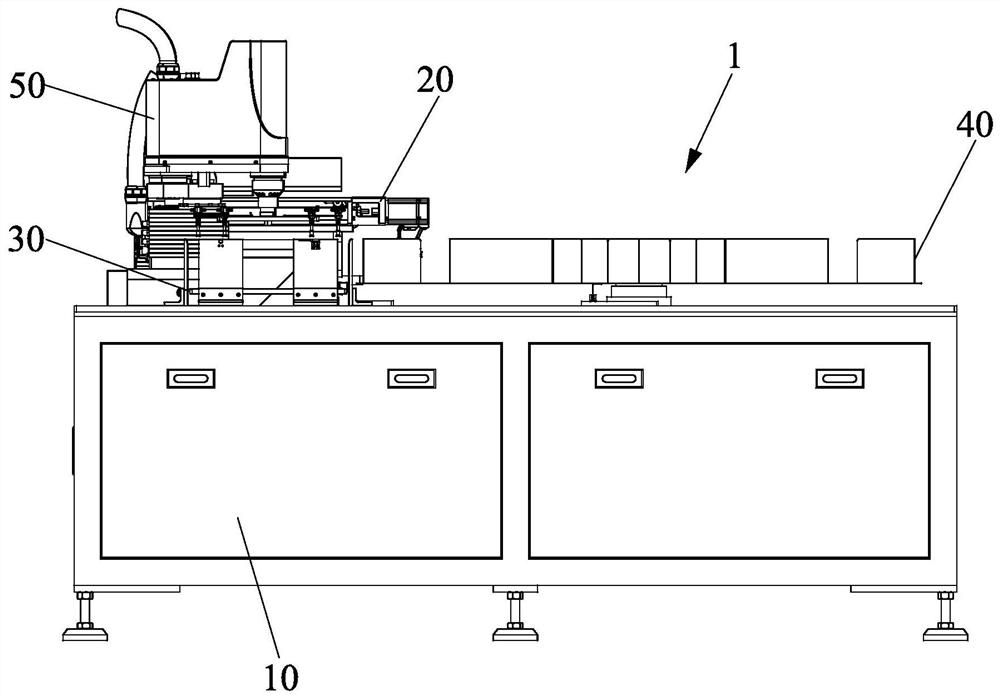

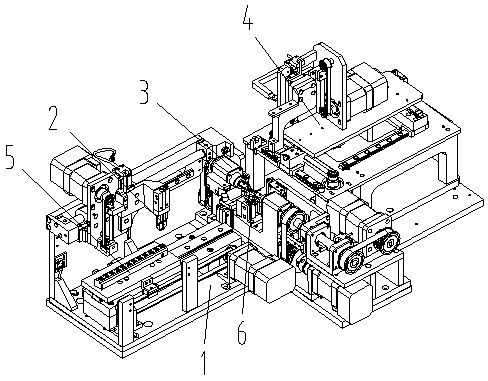

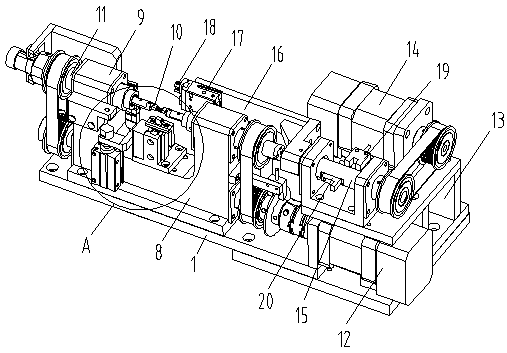

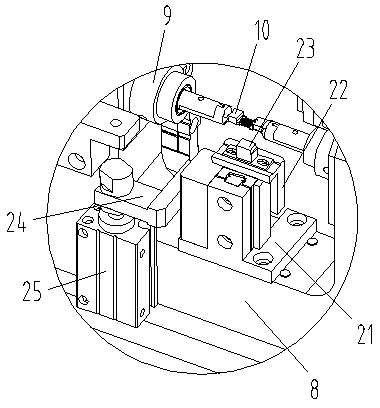

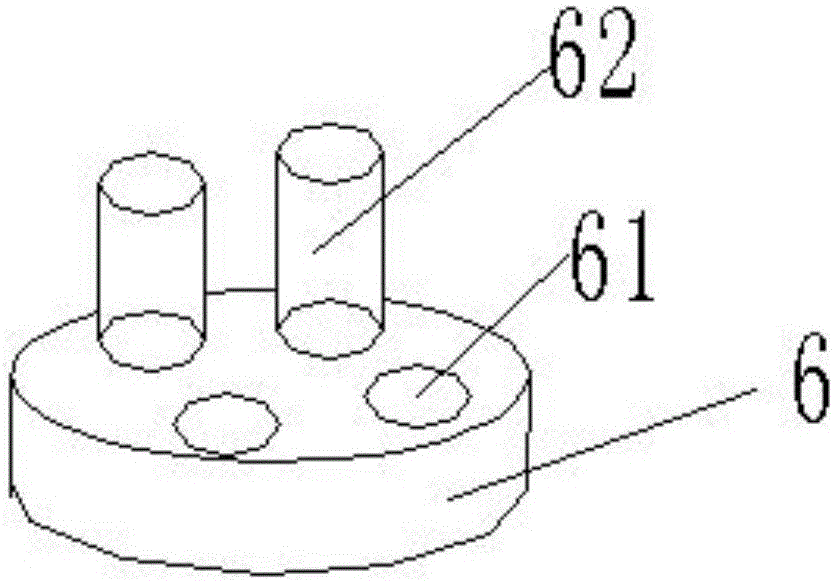

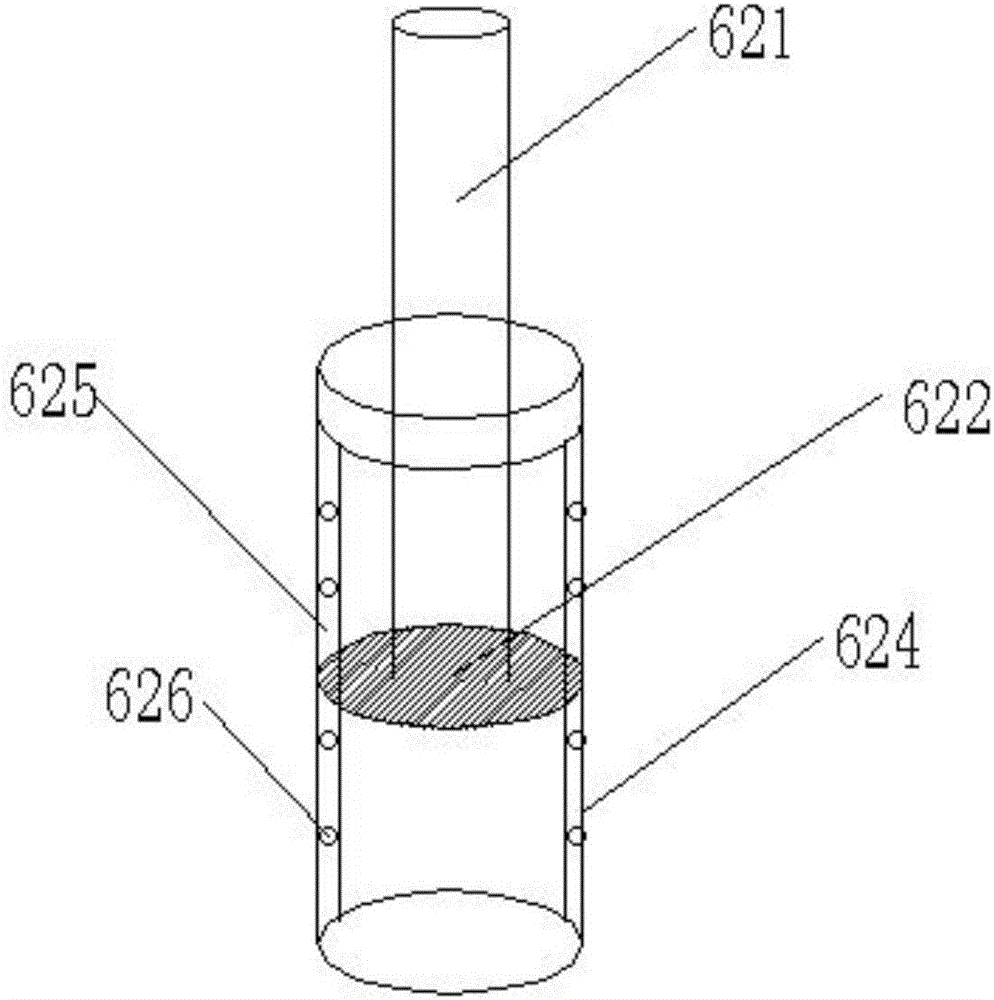

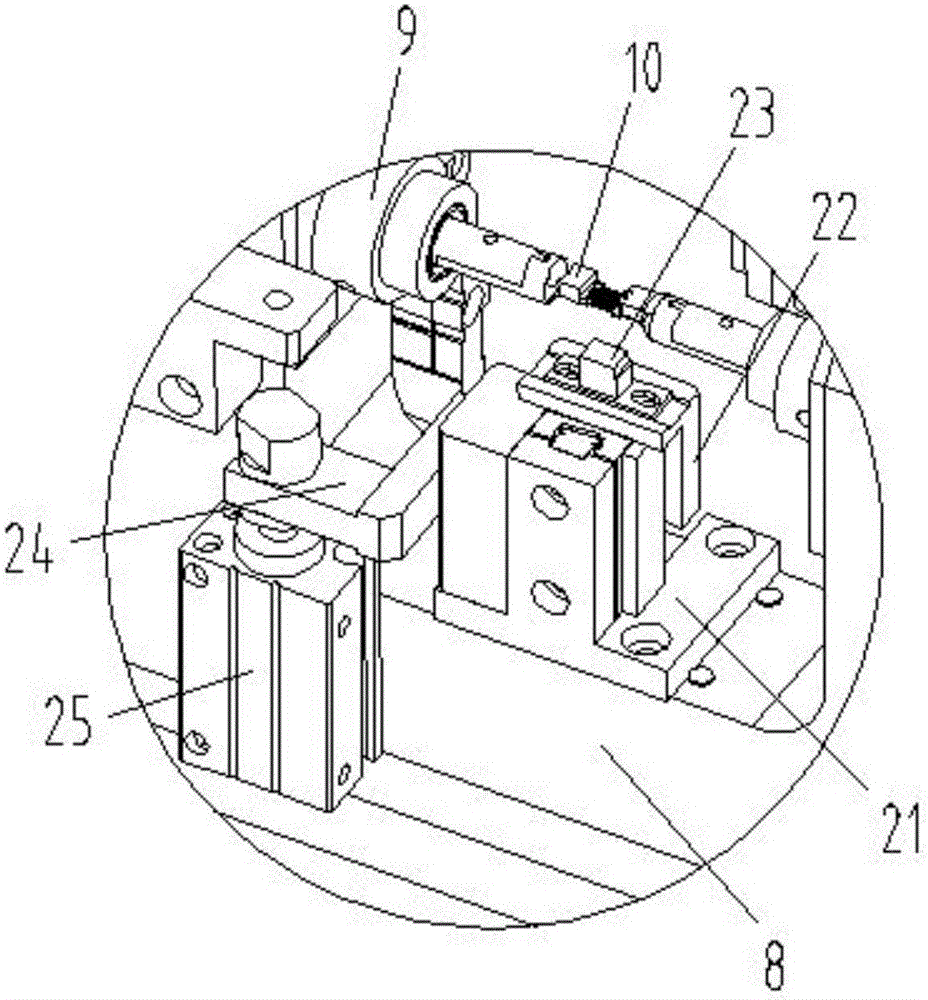

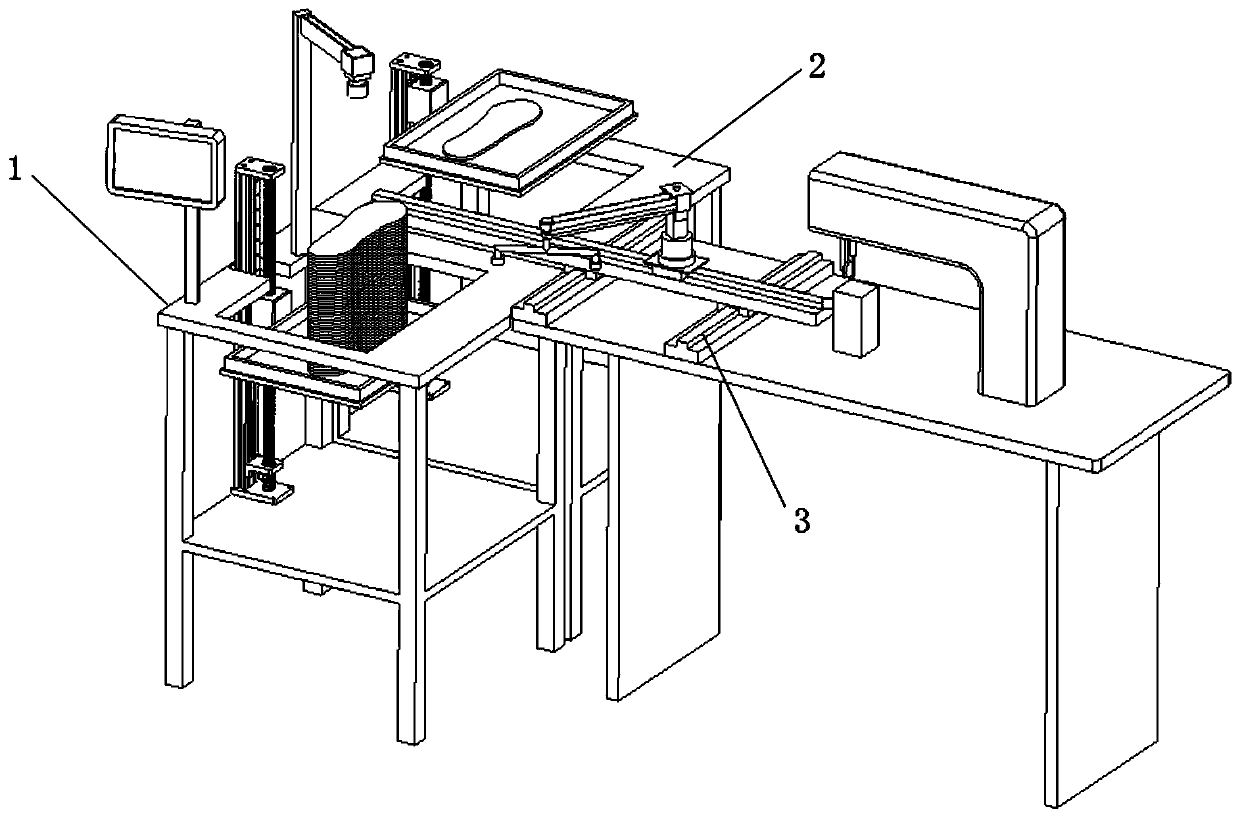

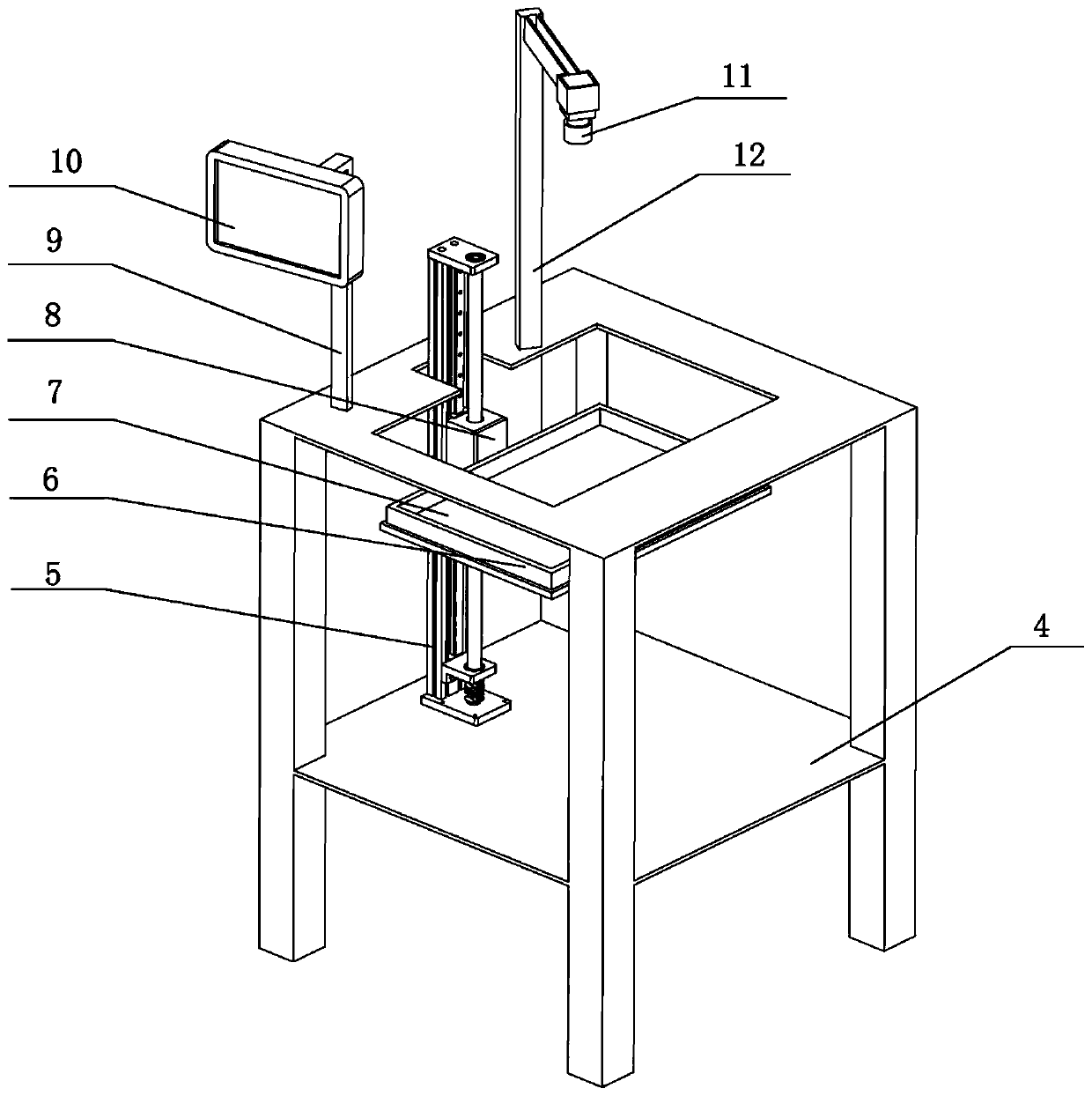

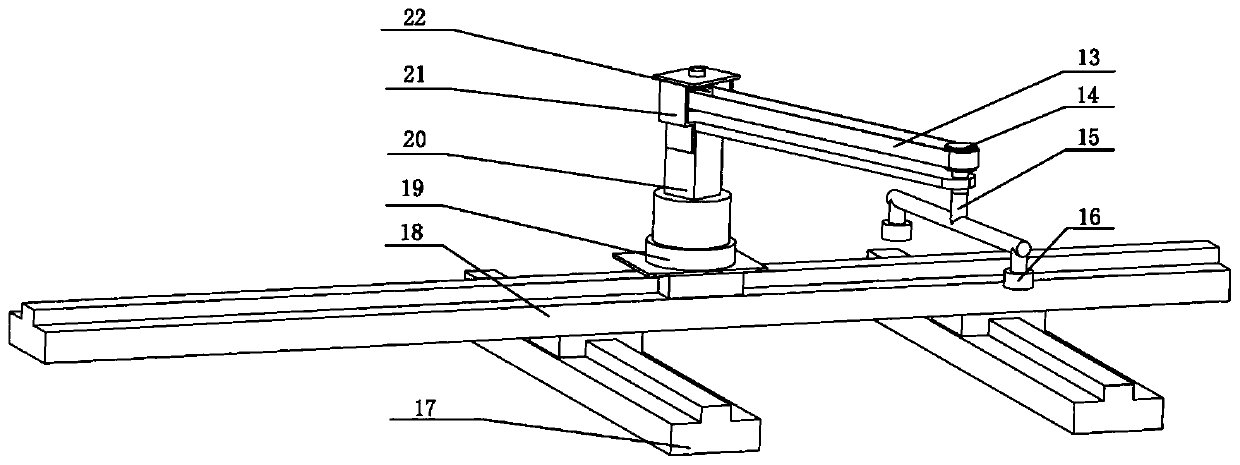

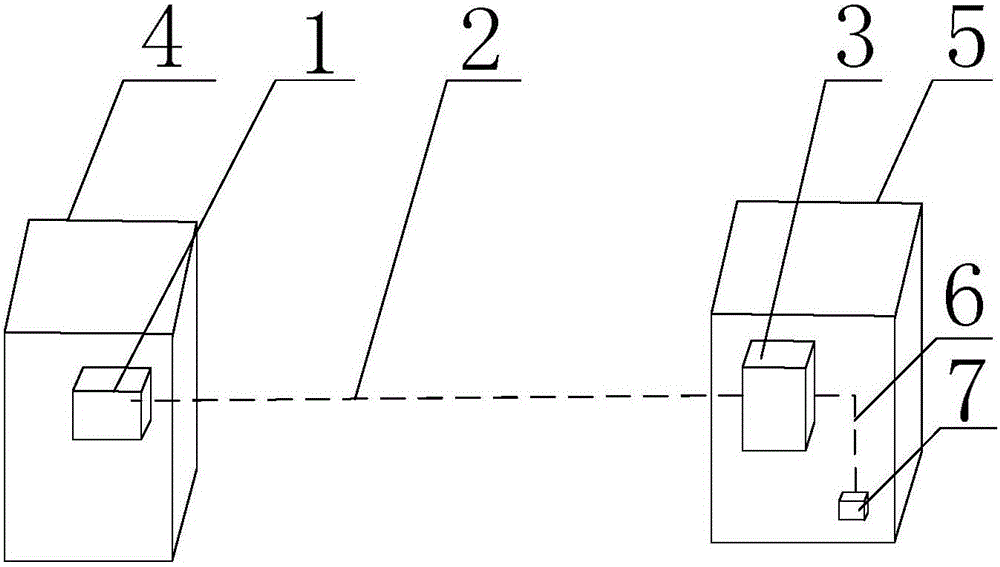

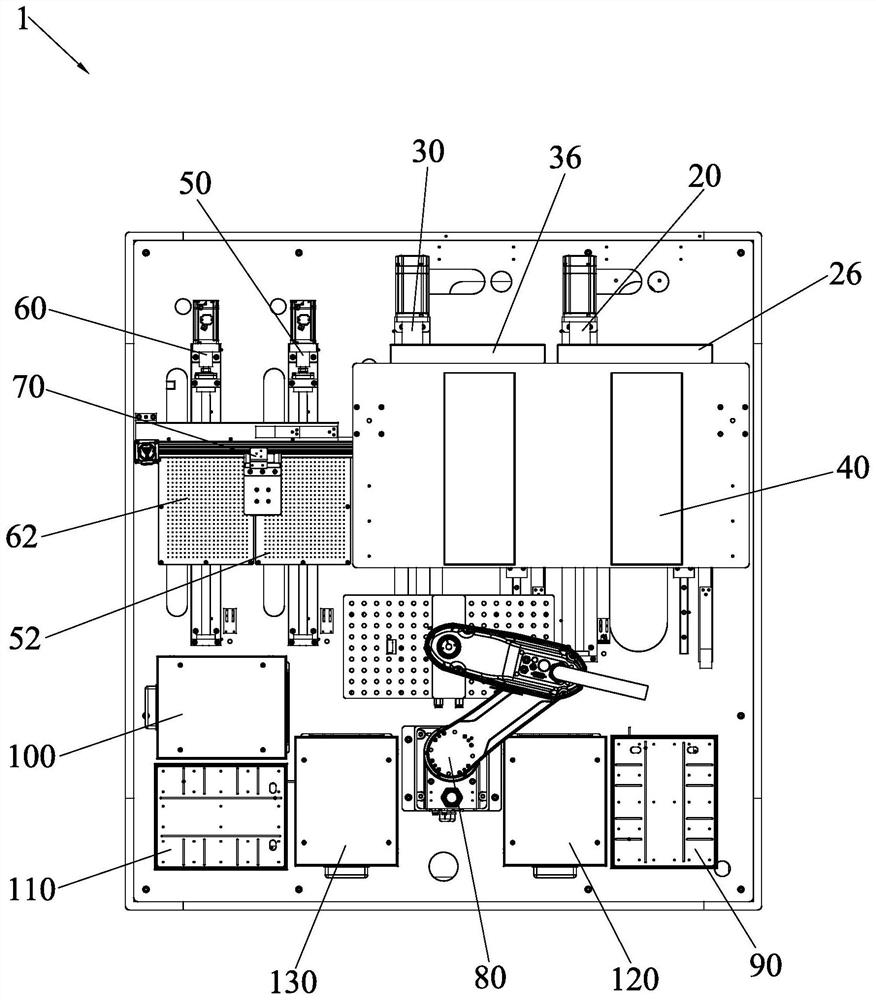

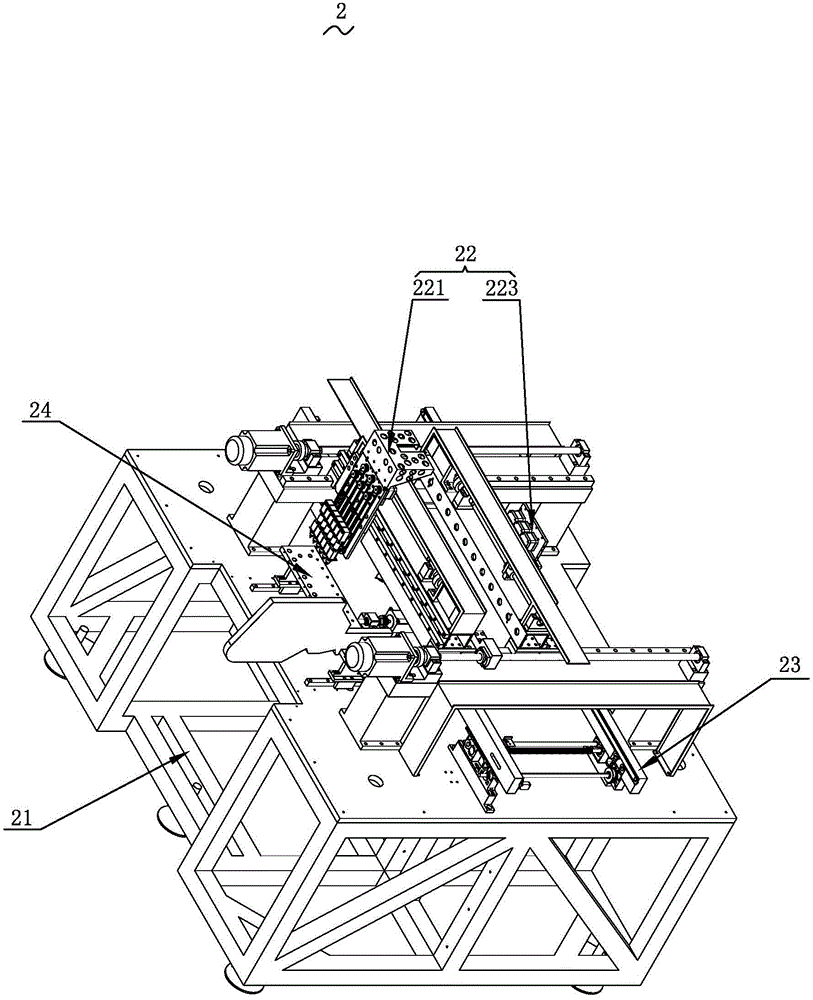

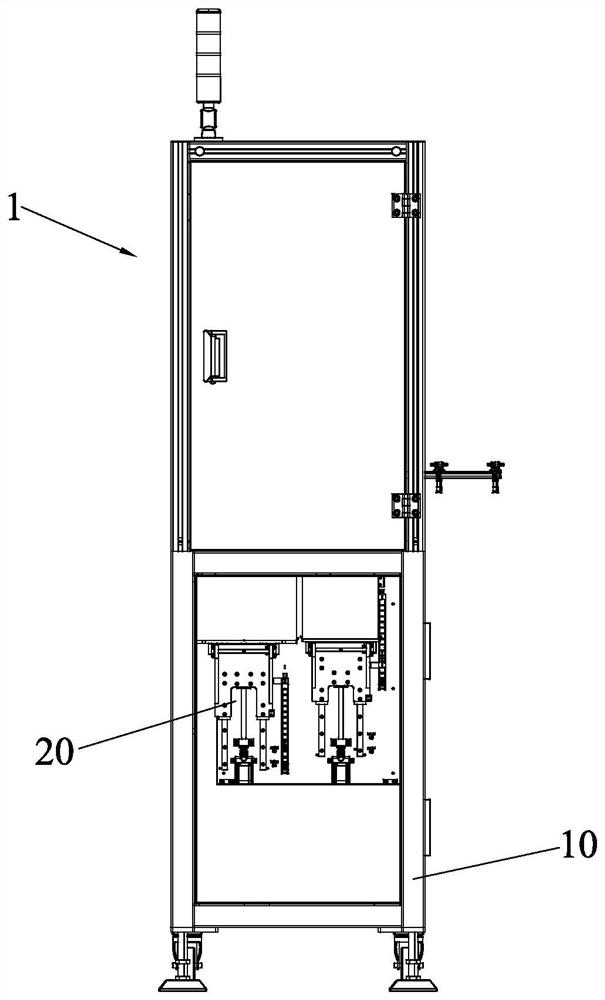

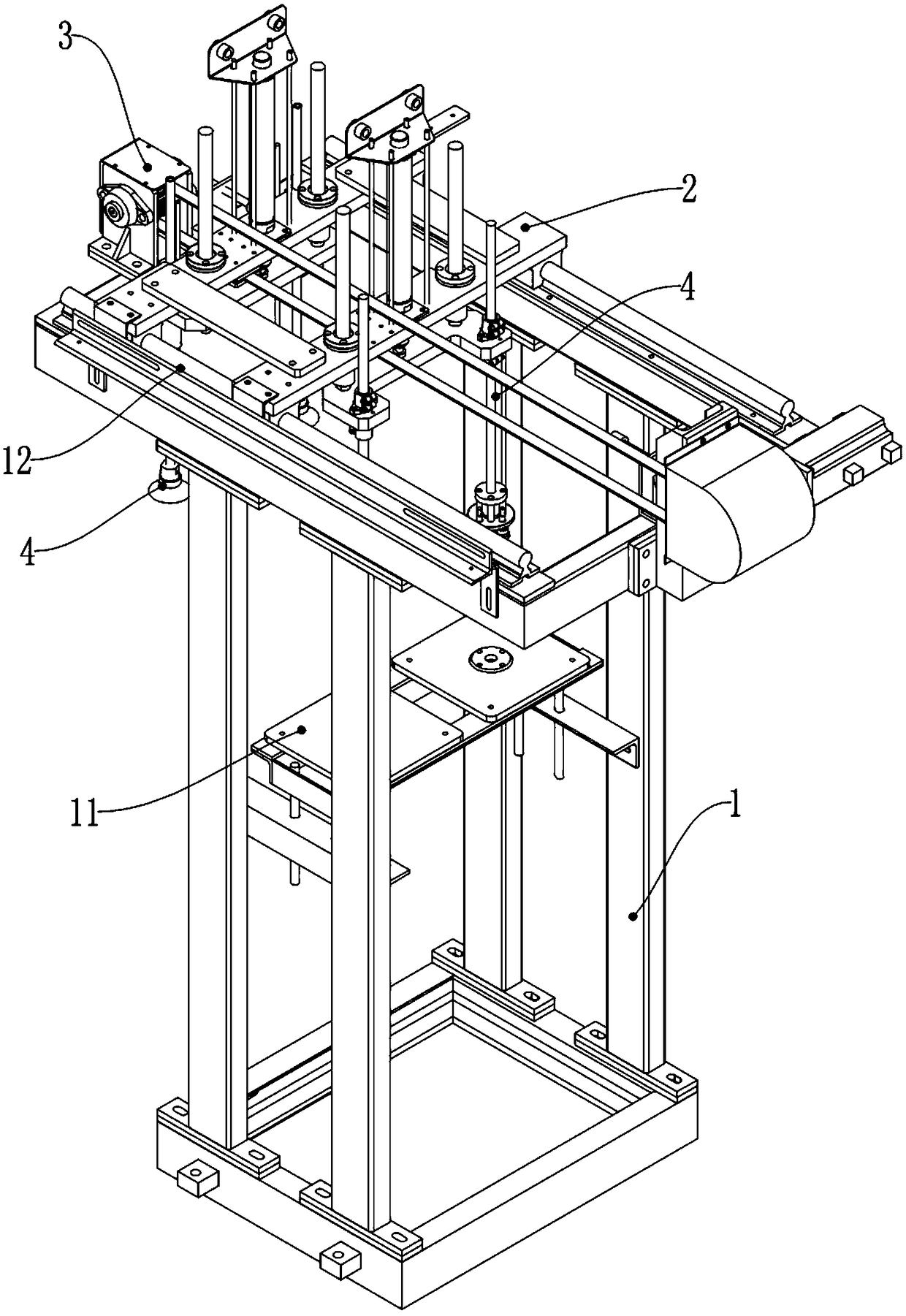

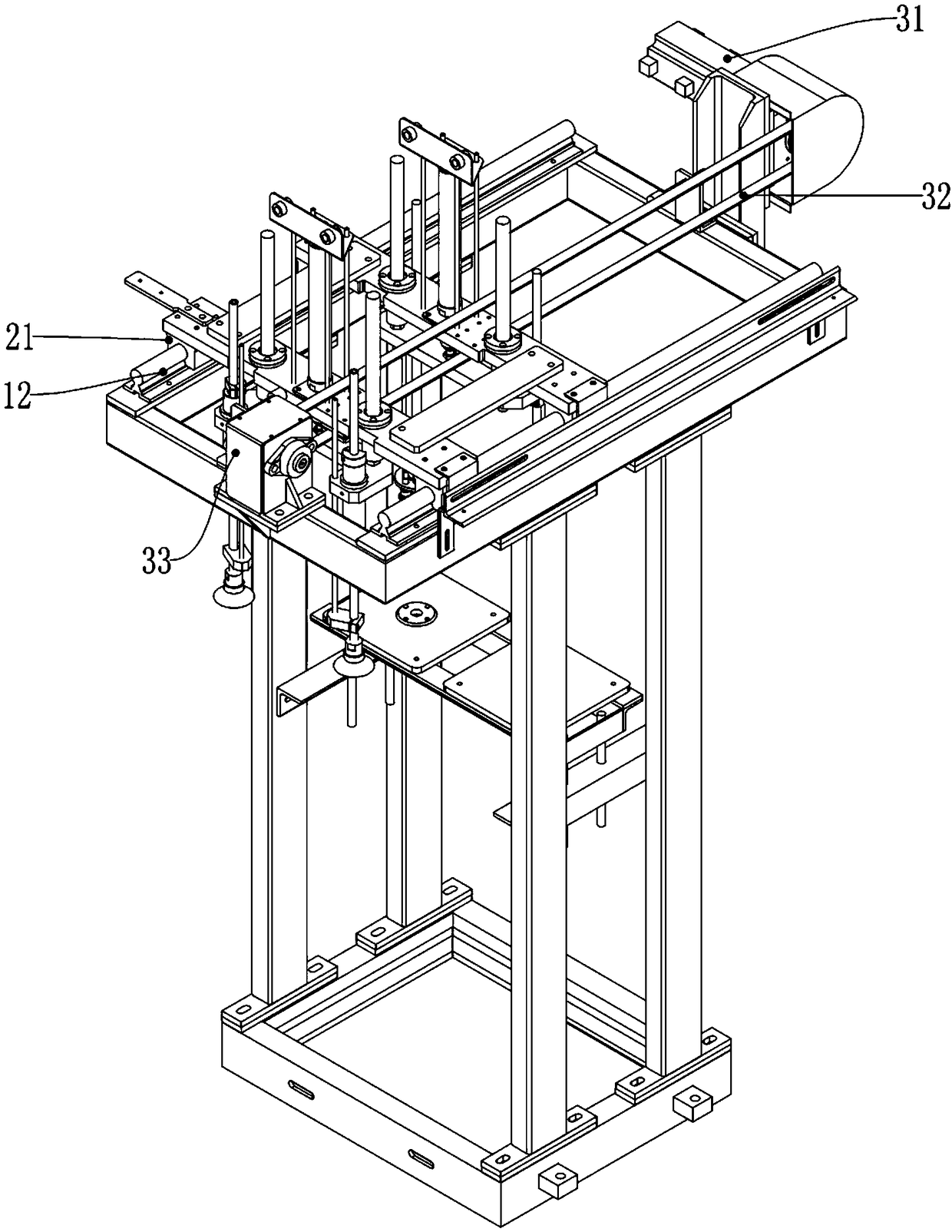

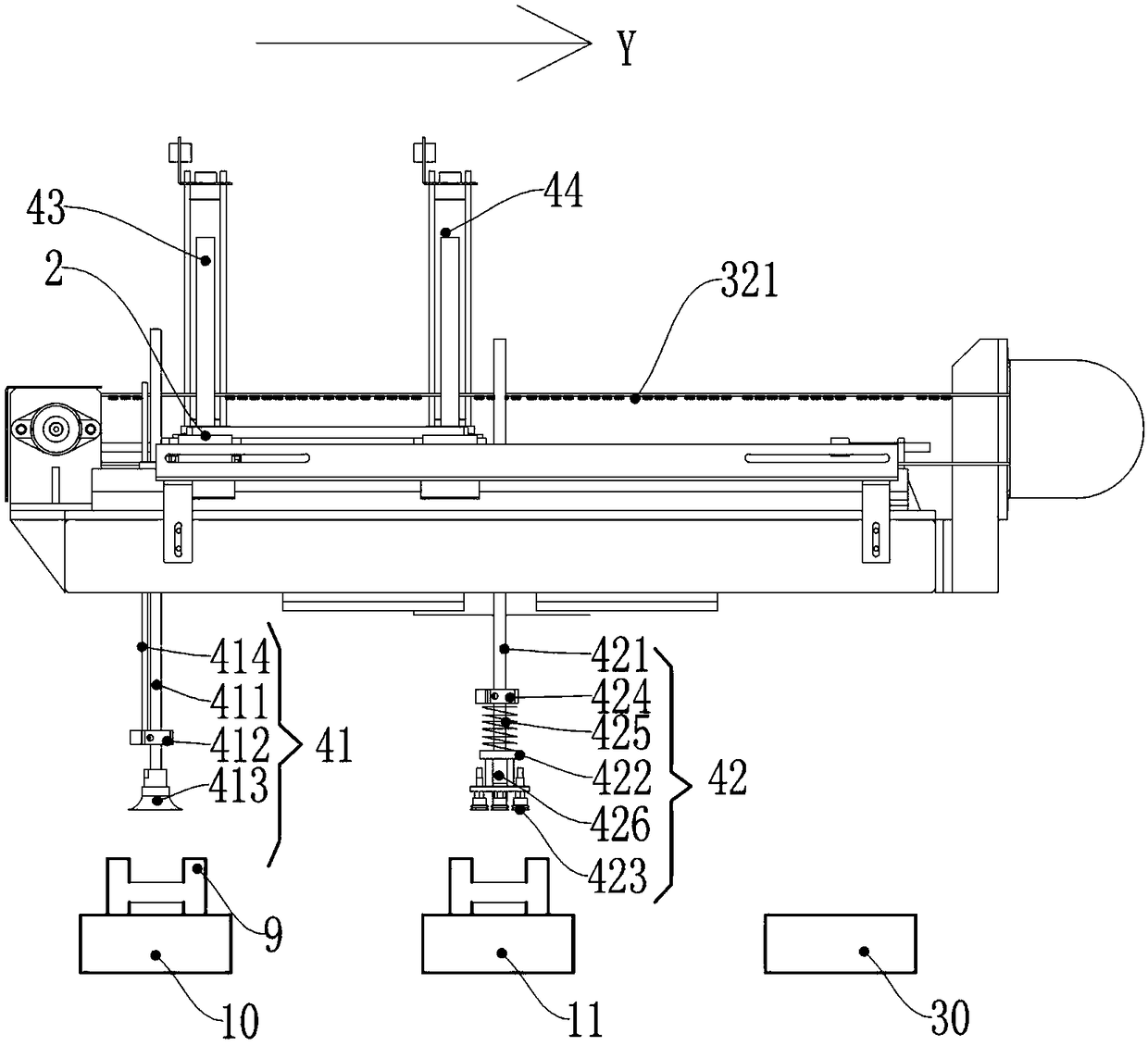

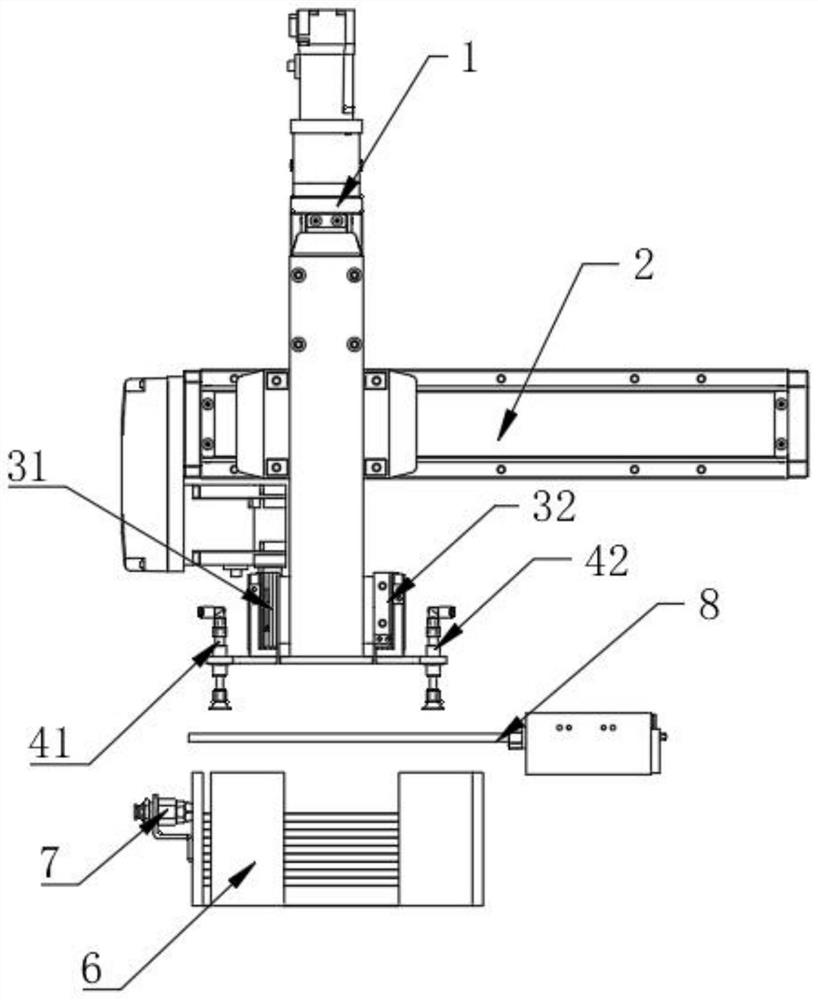

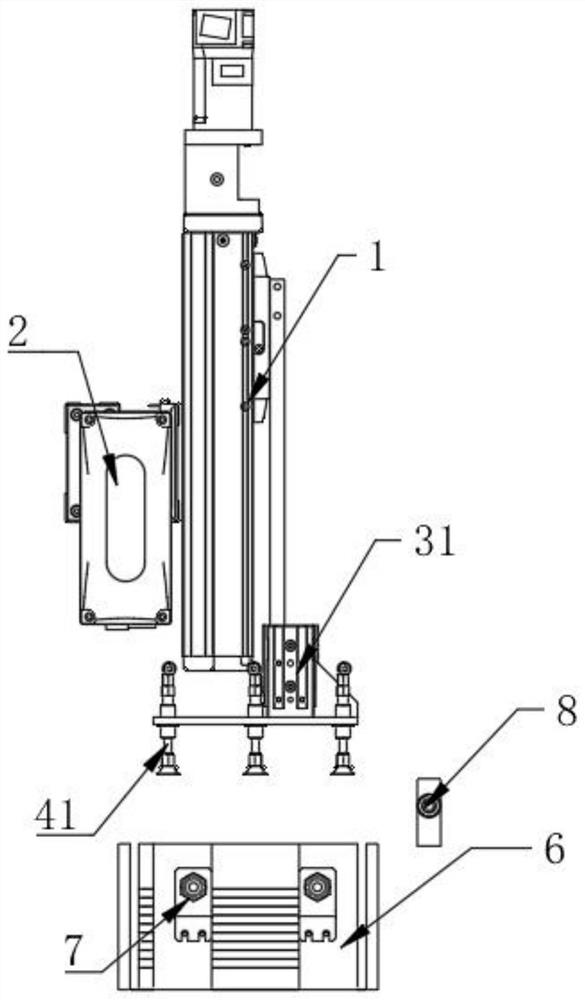

Accurate positioning storage bin

ActiveCN103028998AIncrease loading capacitySmall footprintMetal working apparatusMotor driveSmall footprint

The invention discloses an accurate positioning storage bin. The accurate positioning storage bin comprises a storage bin frame, workpiece lifting mechanisms and a workpiece horizontal rotary conveying mechanism; the workpiece horizontal rotary conveying mechanism comprises a first motor which is arranged on the storage bin frame, a rotary disc which is connected with a first motor rotor and workpiece loading mechanisms which are arranged along the peripheral direction of the rotary disc at equal intervals; and two sets of workpiece lifting mechanisms are arranged and are distributed opposite to the two sets of workpiece loading mechanisms, and each workpiece lifting mechanism comprises a clamping jaw for conveying workpieces on the workpiece loading mechanisms and a drive device for driving the clamping jaw to lift and descend. According to the accurate positioning storage bin, the first motor drives the rotary disc so as to drive the workpiece loading mechanisms to rotate horizontally, so that the transmission error existing in conventional storage bin chain wheel and chain transmission is eliminated, the repeat positioning precision along the horizontal direction is high, and a manipulator of processing equipment can accurately take and store materials; and moreover, a plurality of workpiece loading mechanisms can be arranged on the same rotary disc, the loading capacity of the storage bin is large and the storage bin occupies a small area.

Owner:CHONGQING MACHINE TOOL GROUP

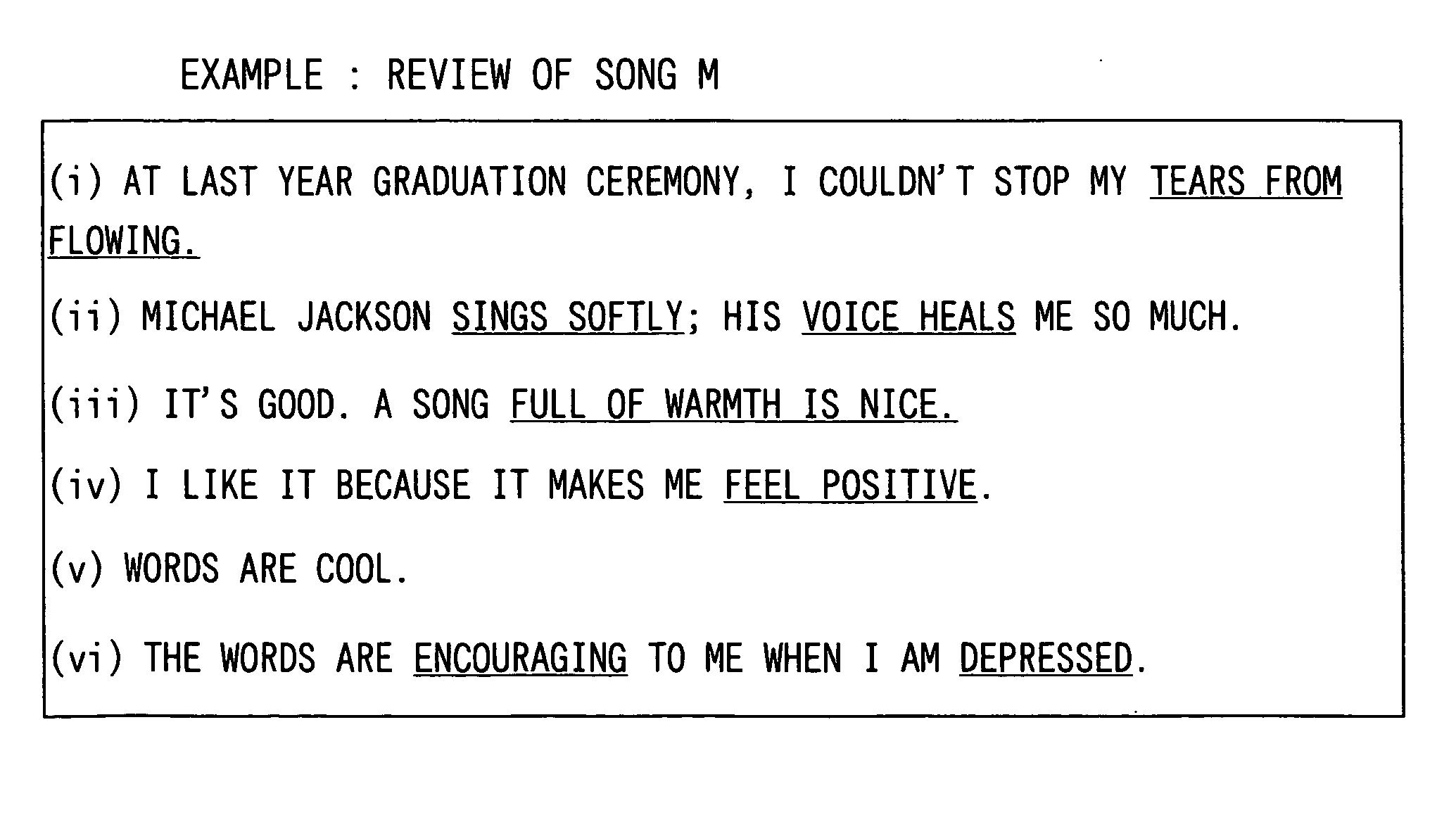

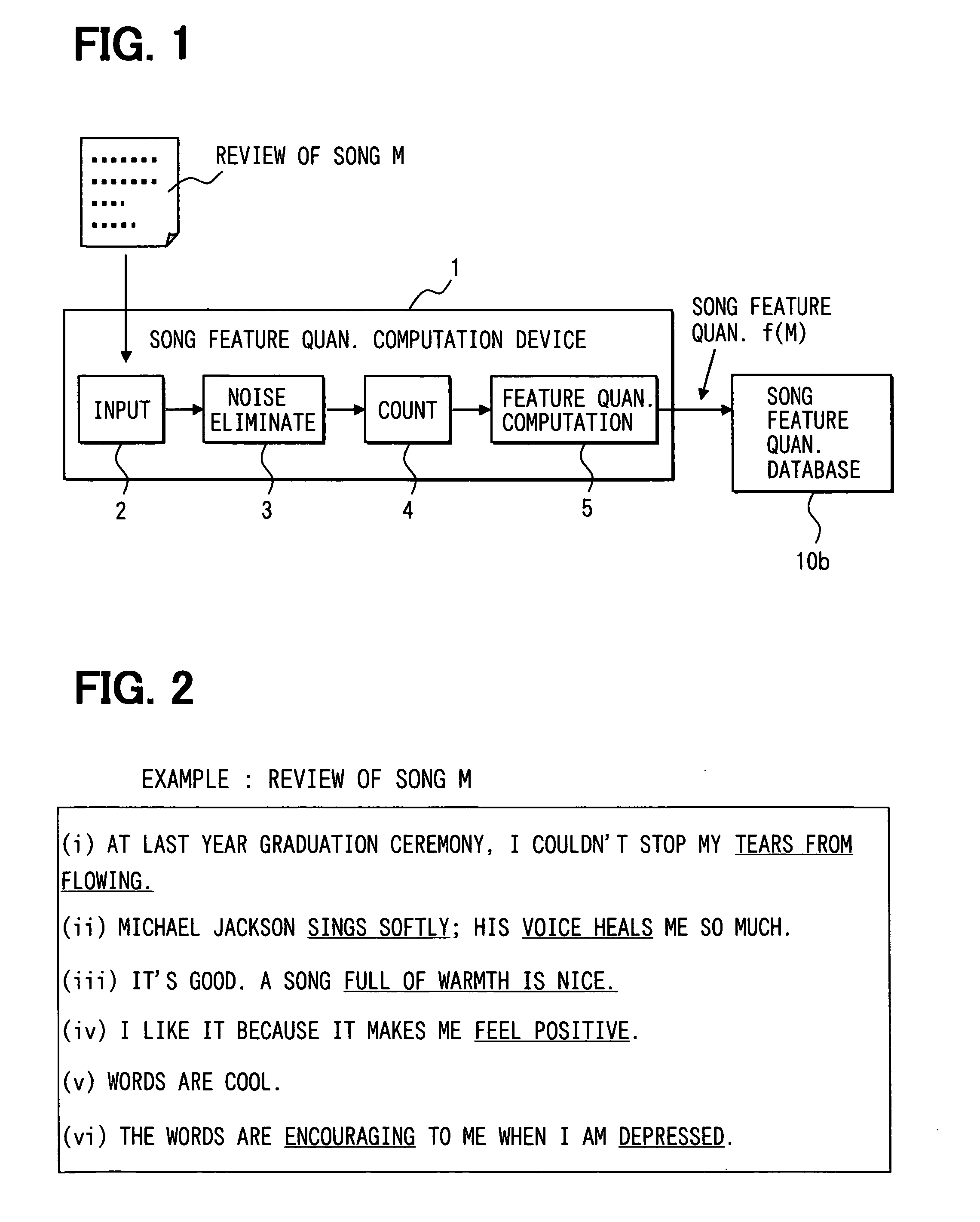

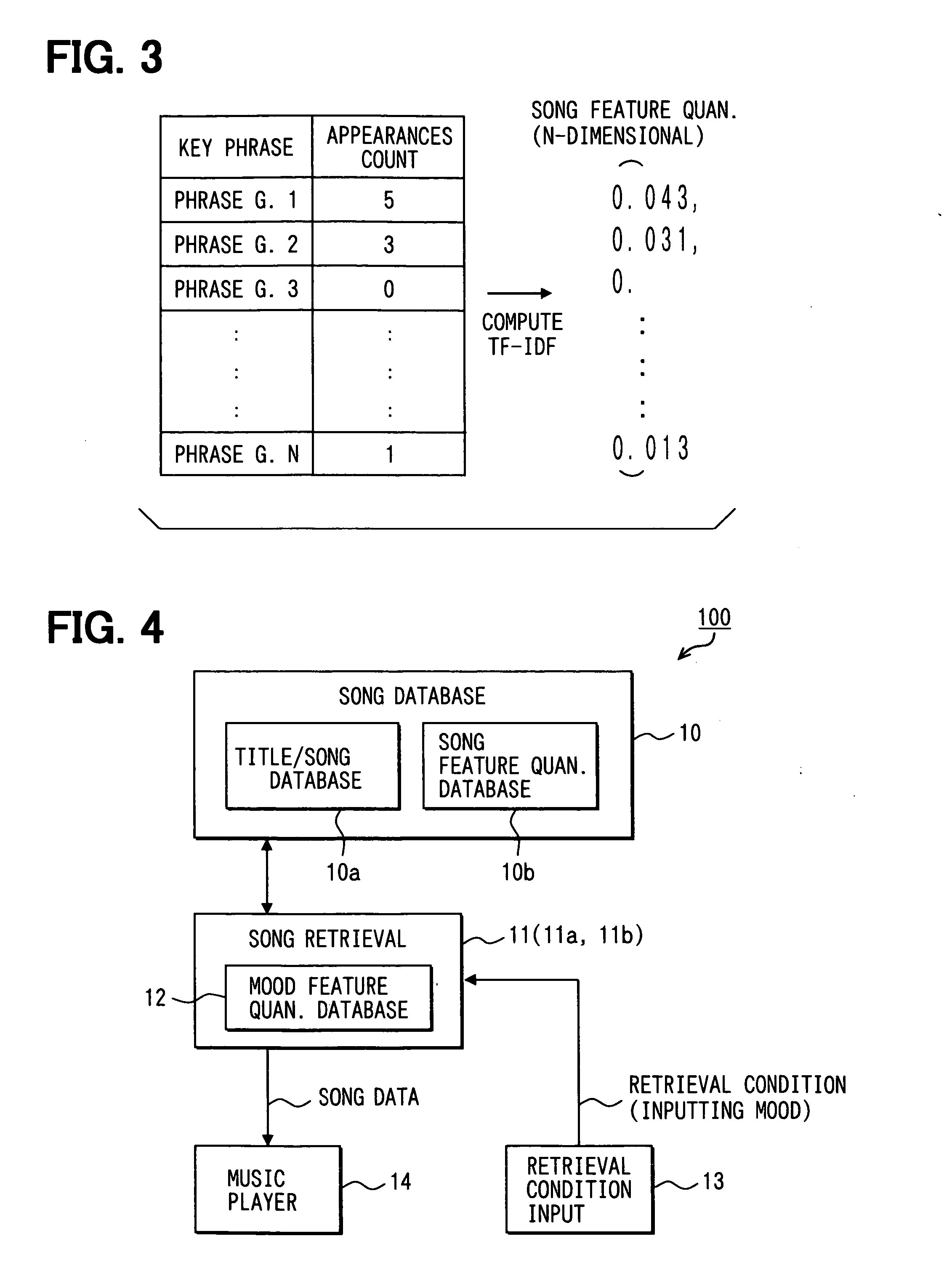

Song feature quantity computation device and song retrieval system

Several feature phrases including combinations of words are predetermined to indicate a feature of a song. TF-IDF values are computed based on appearances counts of the feature phrases. A song feature quantity is computed as a vector constituted by the TF-IDF values. This vector is an index indicating the feature of the song. Using the feature phrases results in proper exclusion of a comment not related to the feature of the song itself in computing the song feature quantity. This allows the song feature quantity to match, with a high accuracy, with a mood generated when the song is actually listened to.

Owner:DENSO CORP

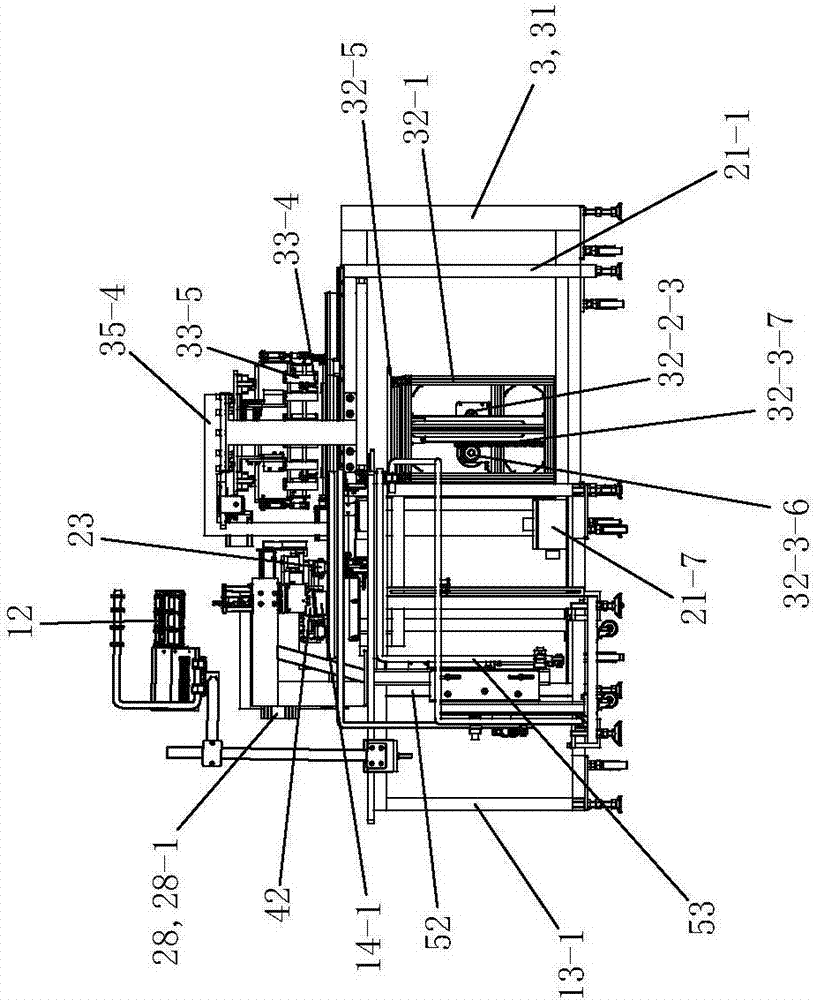

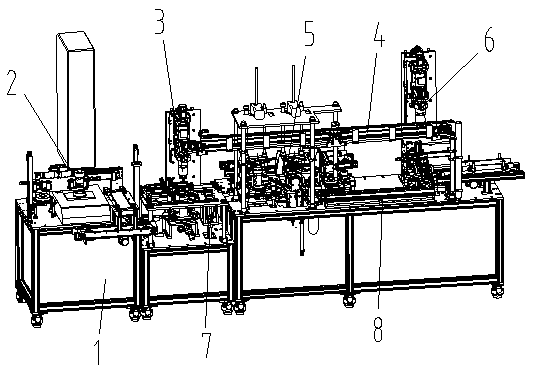

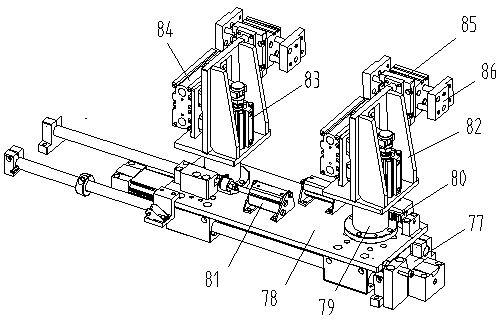

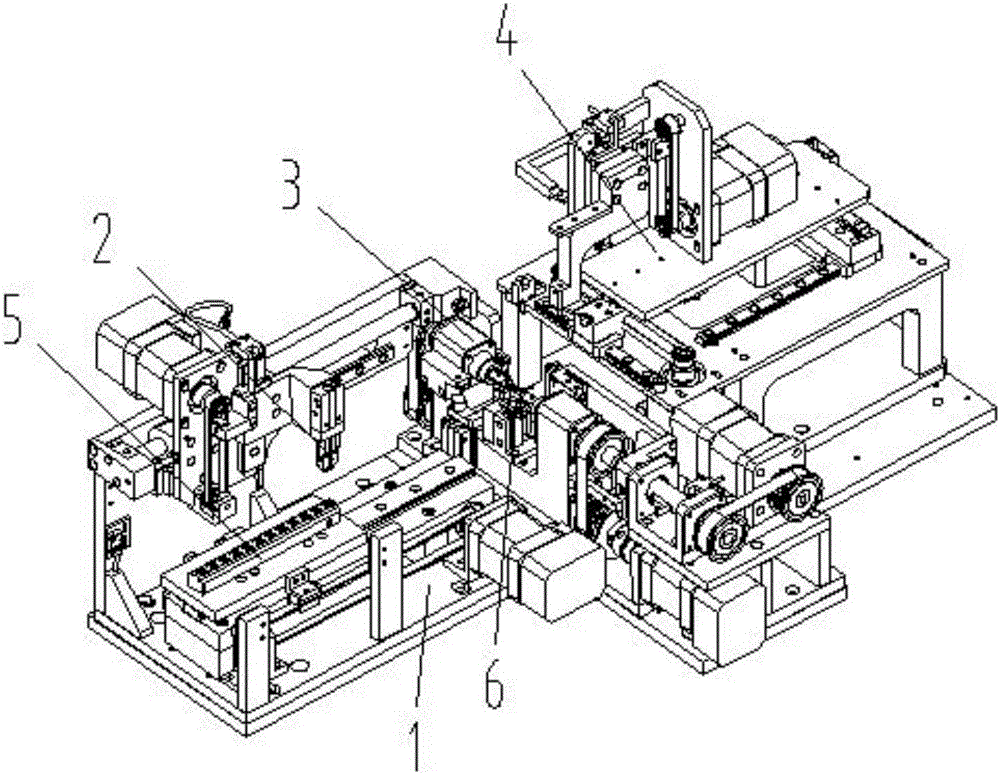

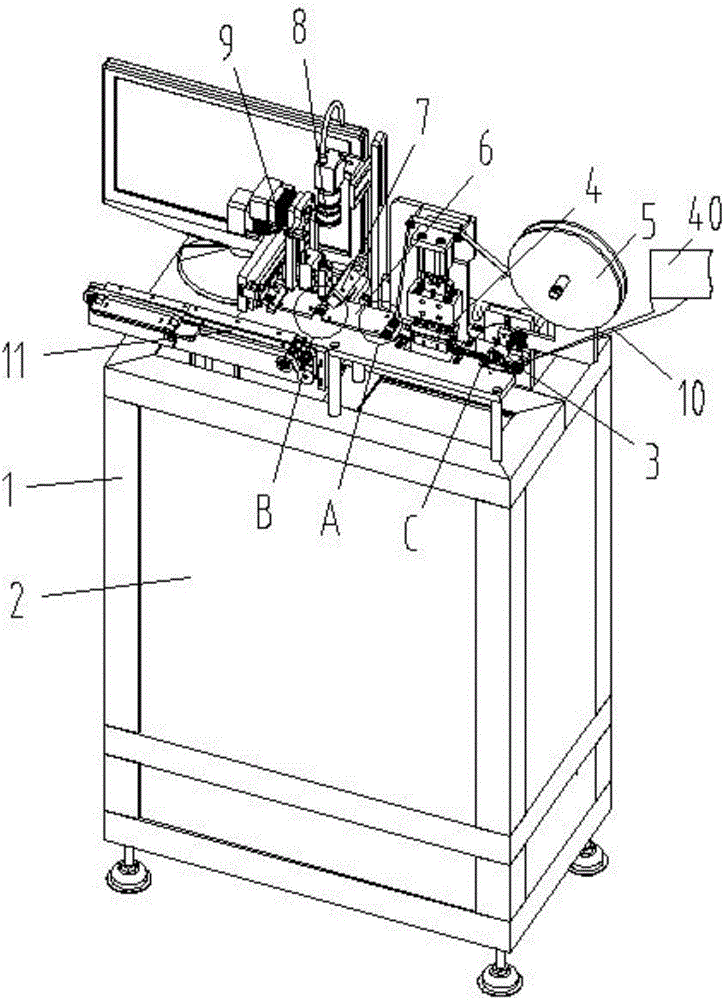

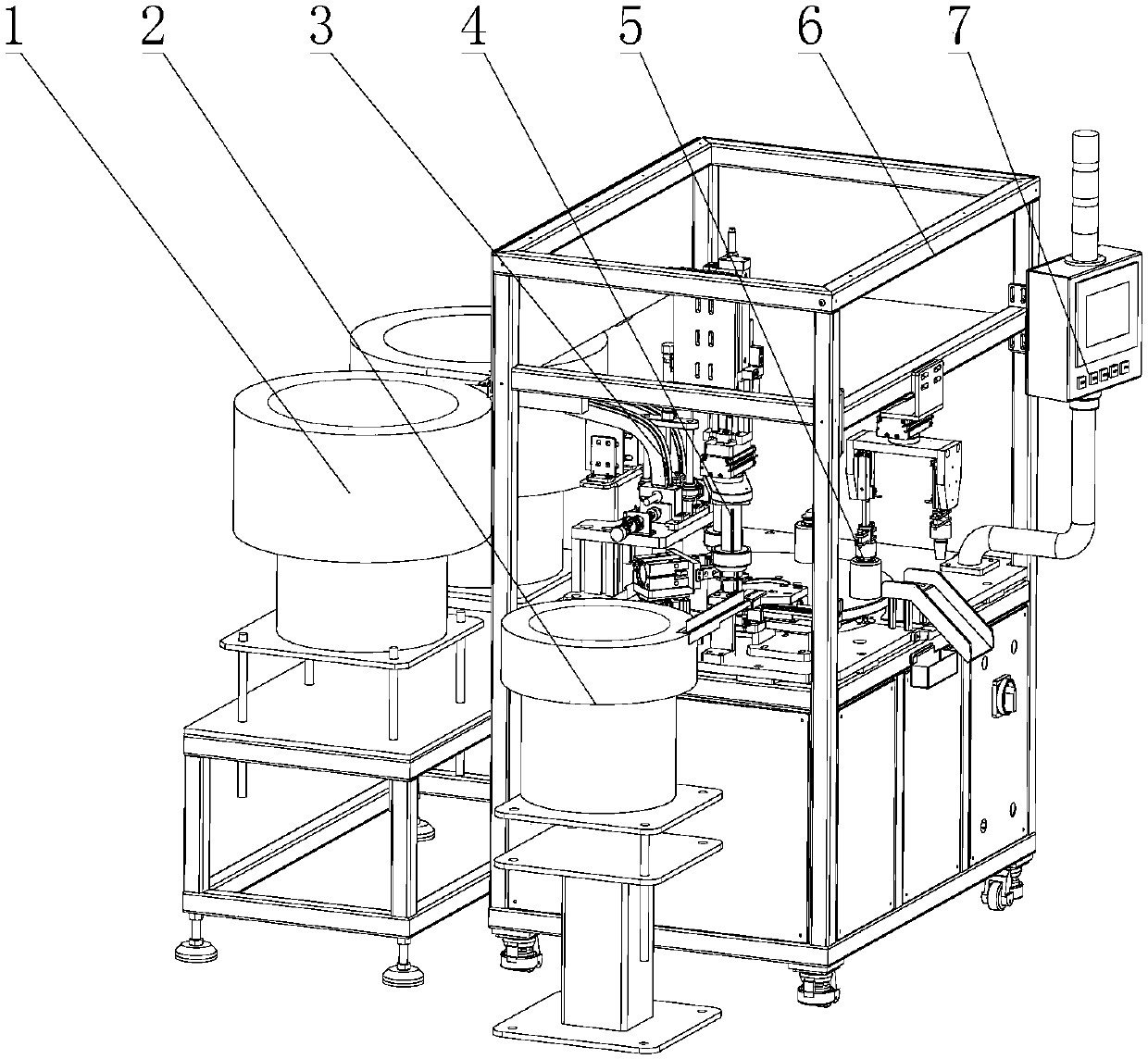

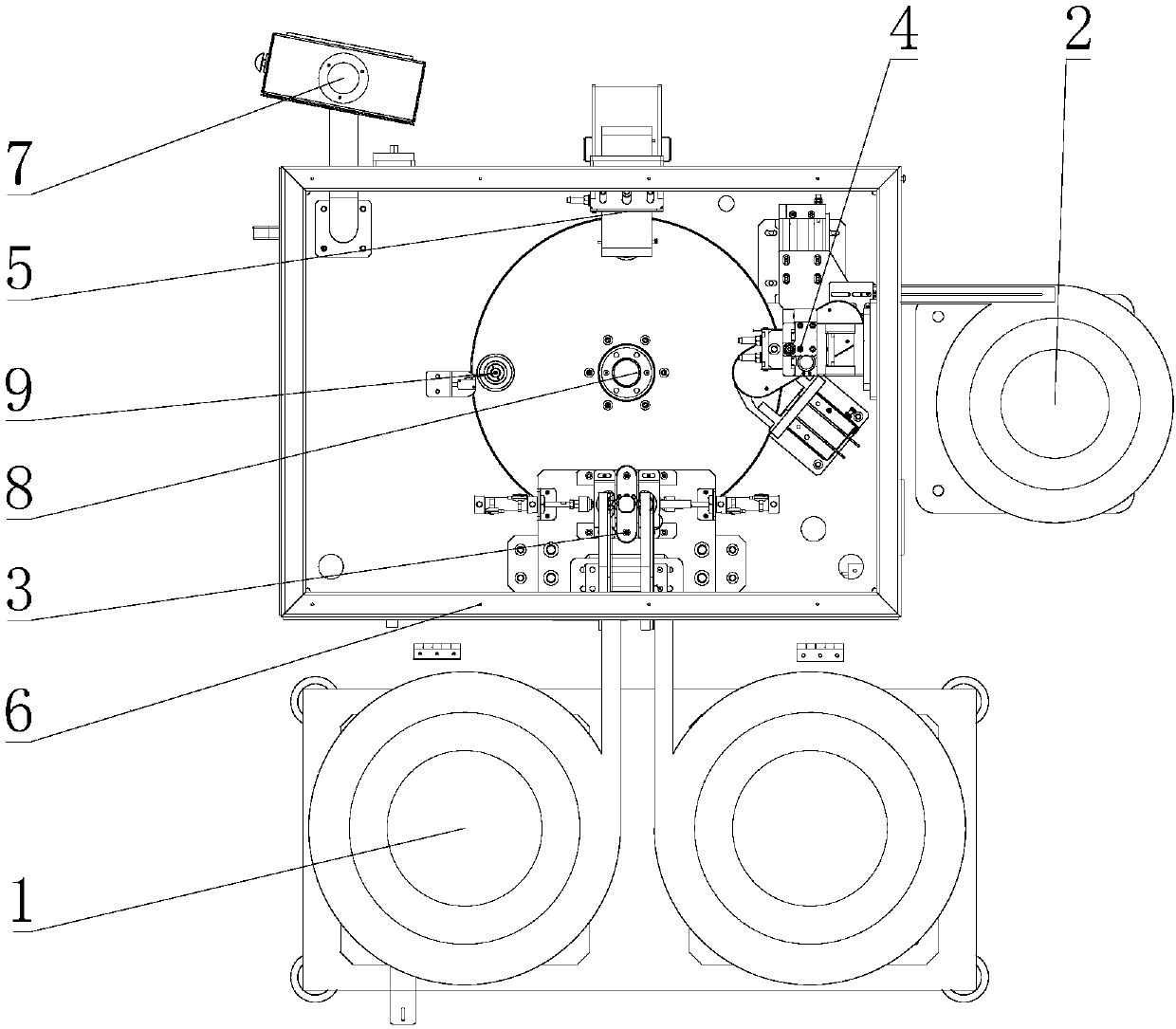

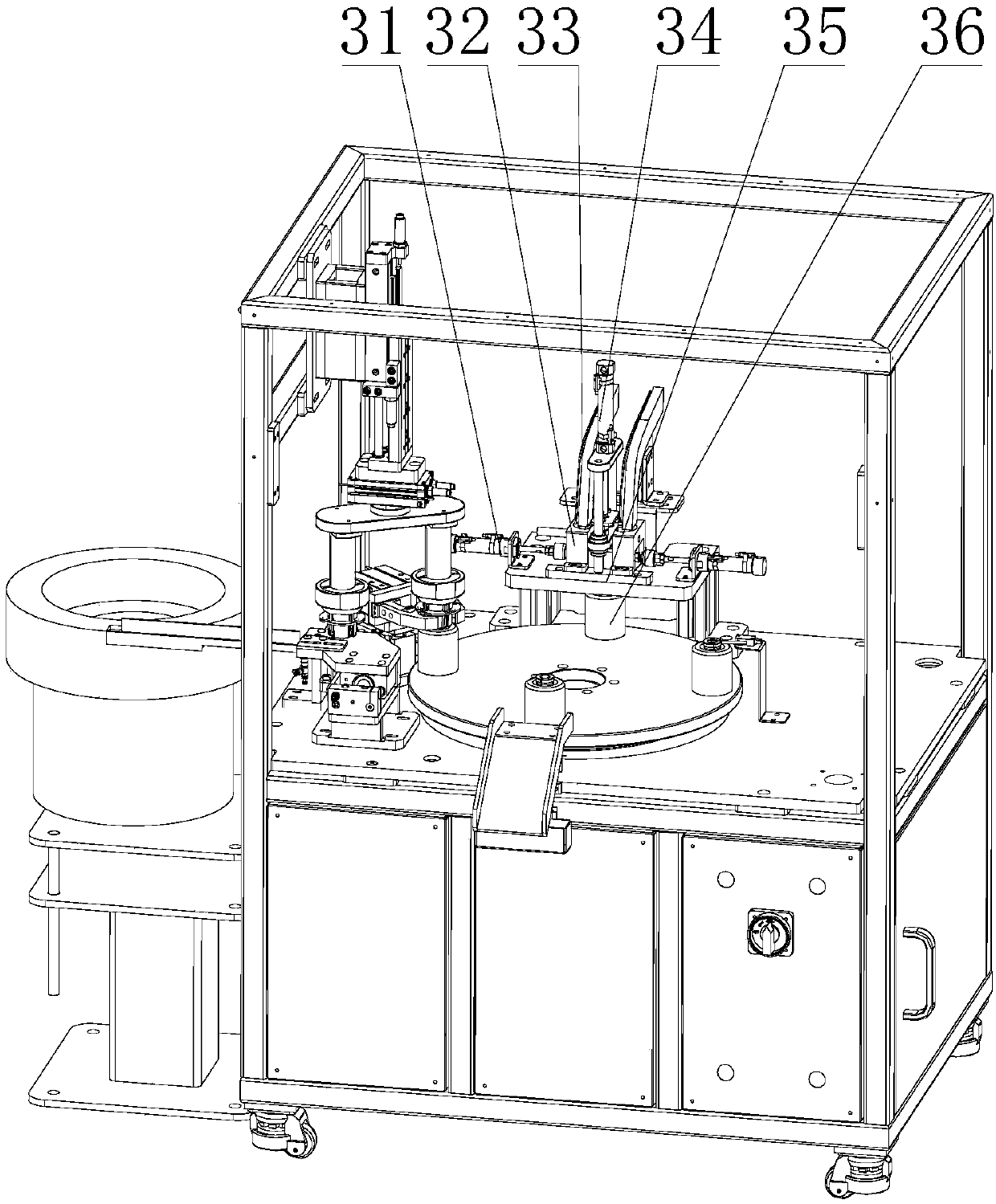

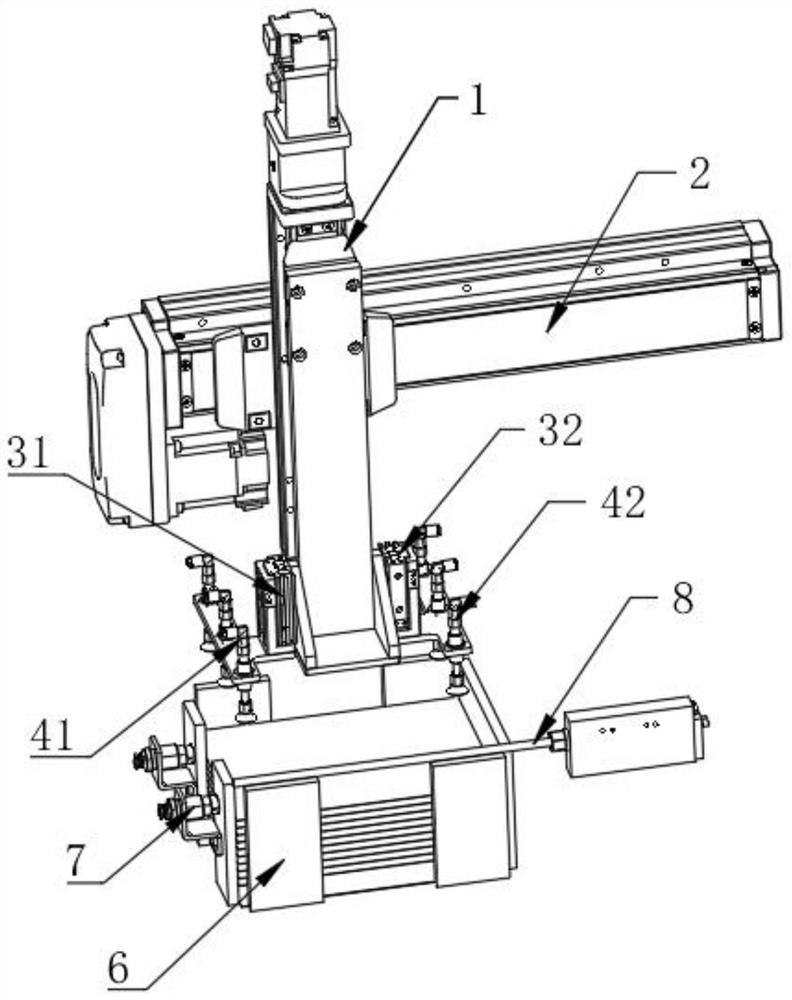

Fully-automatic round-head barrel hook forming machine

ActiveCN105414415AMeet production requirementsFulfill production requirementsWire articlesProduction lineControl system

The invention discloses a fully-automatic round-head barrel hook forming machine belonging to the field of wire bending machines. The fully-automatic round-head barrel hook forming machine comprises a steel wire feeding device, a handle tube feeding device, a forming device, a fetching and shaping device and a control system, wherein the handle tube feeding device is arranged in front of the forming device; the steel wire feeding device is arranged at the rear of the forming device; the fetching and shaping device is arranged in front of the forming device, is located below the handle tube feeding device and is composed of a grabbing mechanism, a locating mechanism and a shaping mechanism; and all the steel wire feeding device, the handle tube feeding device, the forming device and the fetching and shaping device are automatically controlled by the control system to sequentially finish the actions of handle tube feeding, steel wire feeding, barrel hook forming as well as fetching and shaping. By using the fully-automatic round-head barrel hook forming machine, a barrel hook not only can be fully-automatically produced, but also can be corrected and shaped after being formed to make preparation for the next installation of the barrel hook, so that the requirement of an automatic installation production line of the barrel hook is met, and the automatic level and production efficiency of vessels such as barrels and tanks are greatly increased.

Owner:CHANGZHOU PUHE PLASTIC

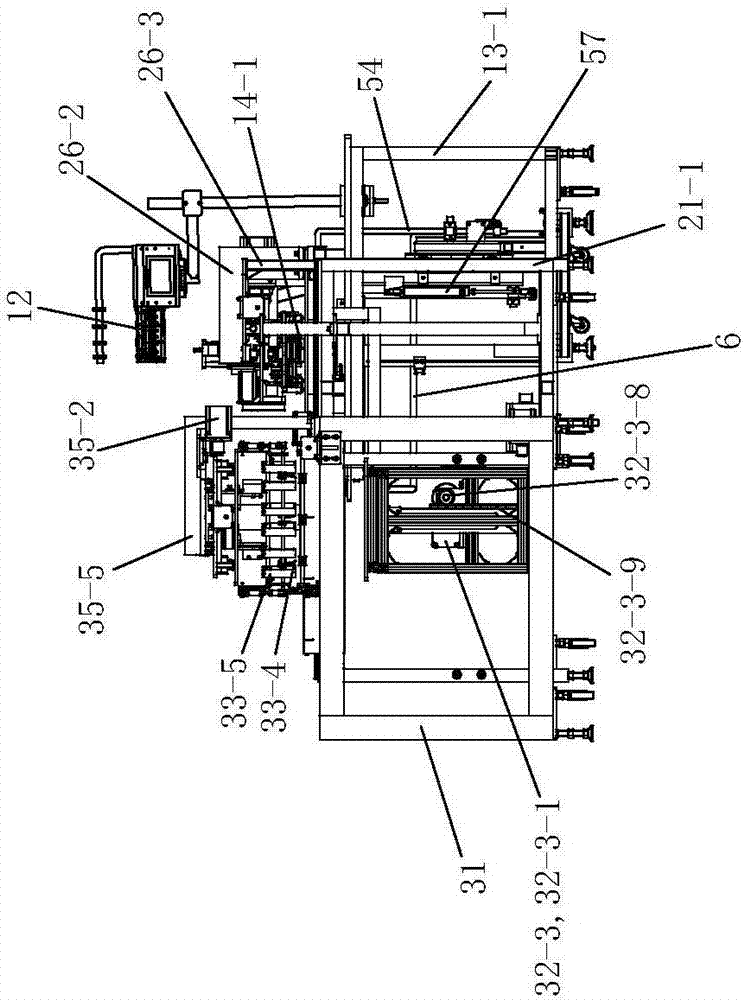

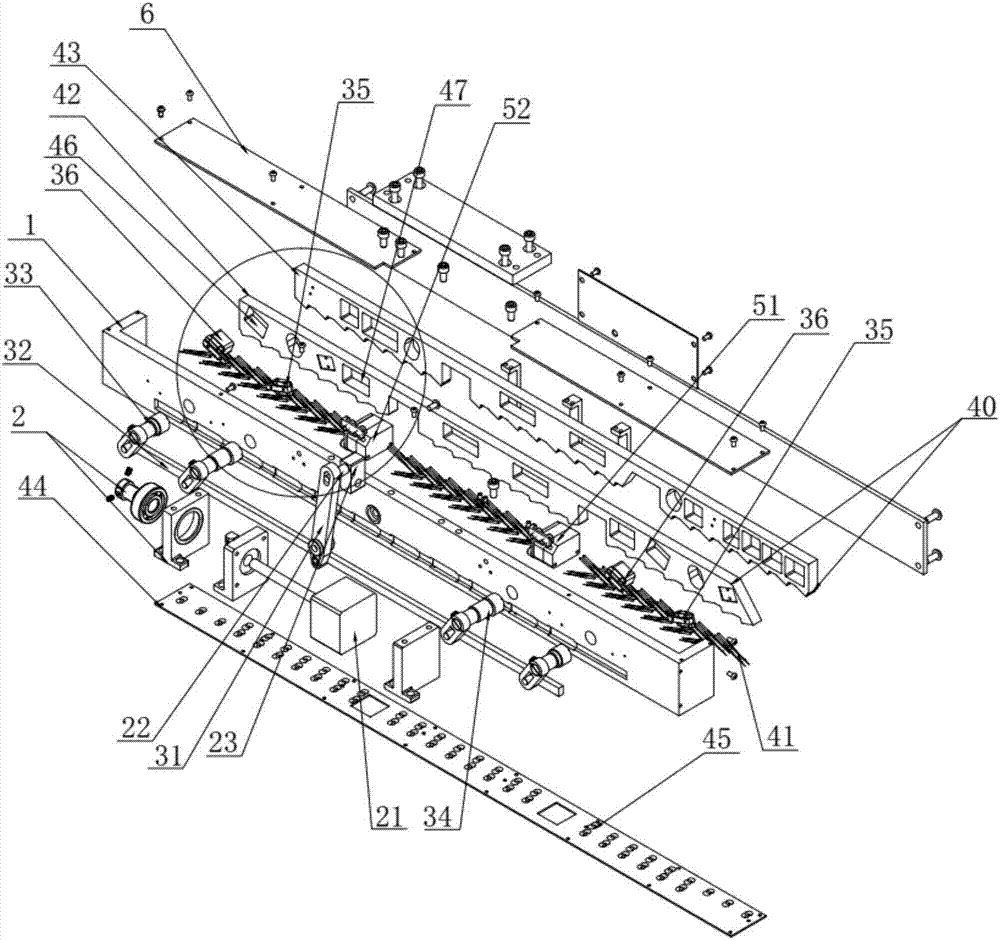

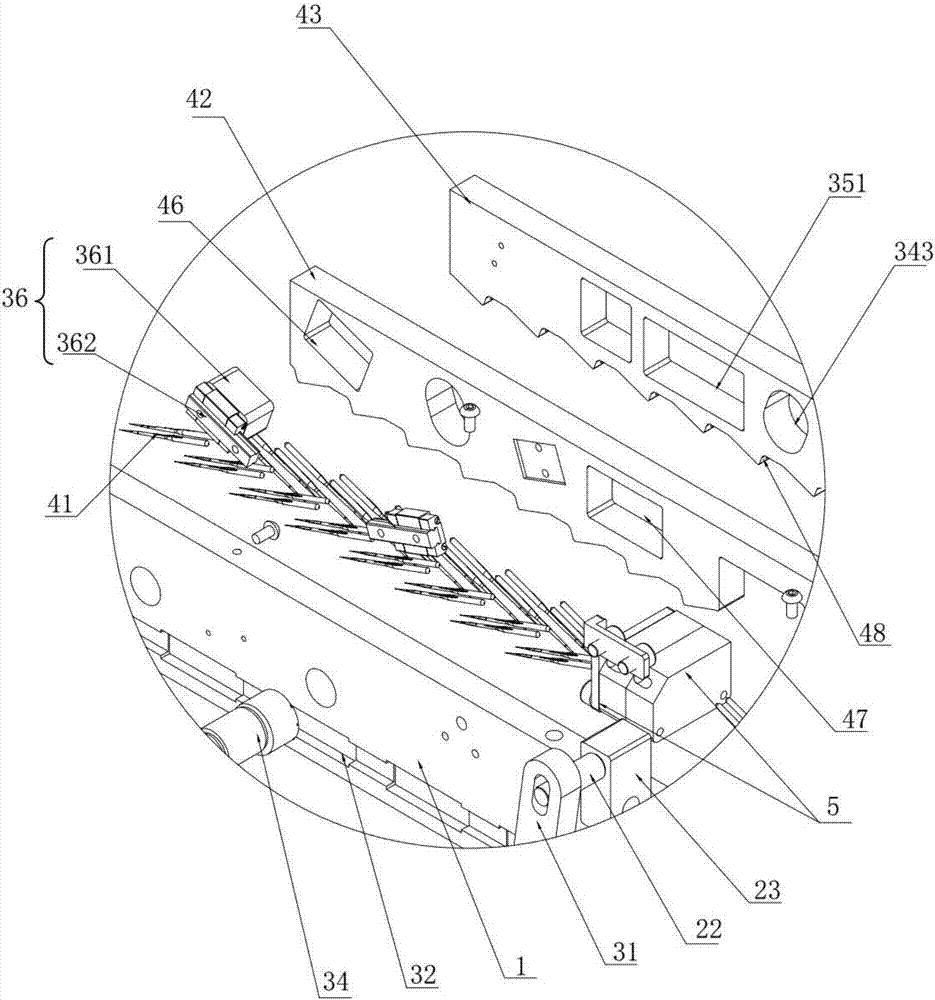

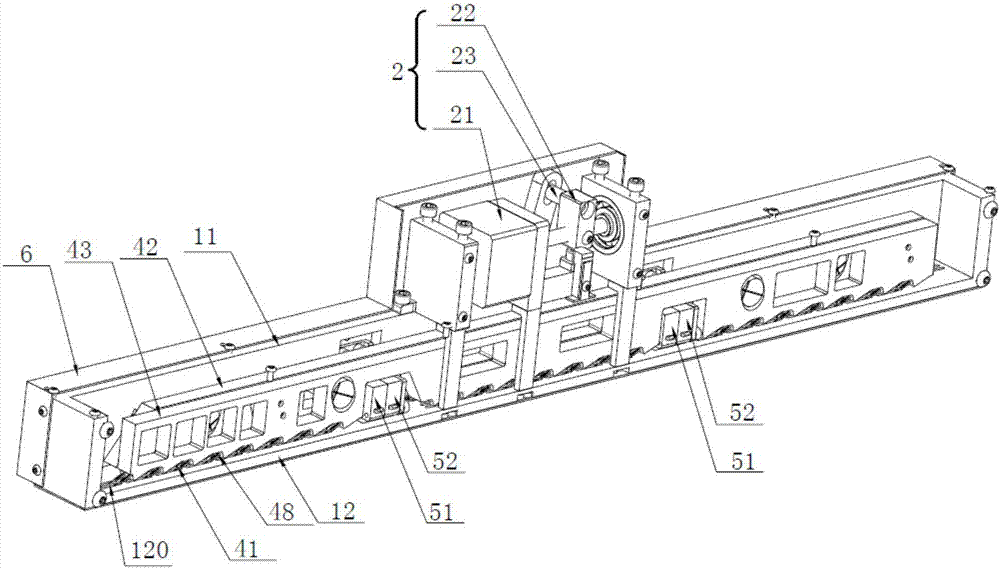

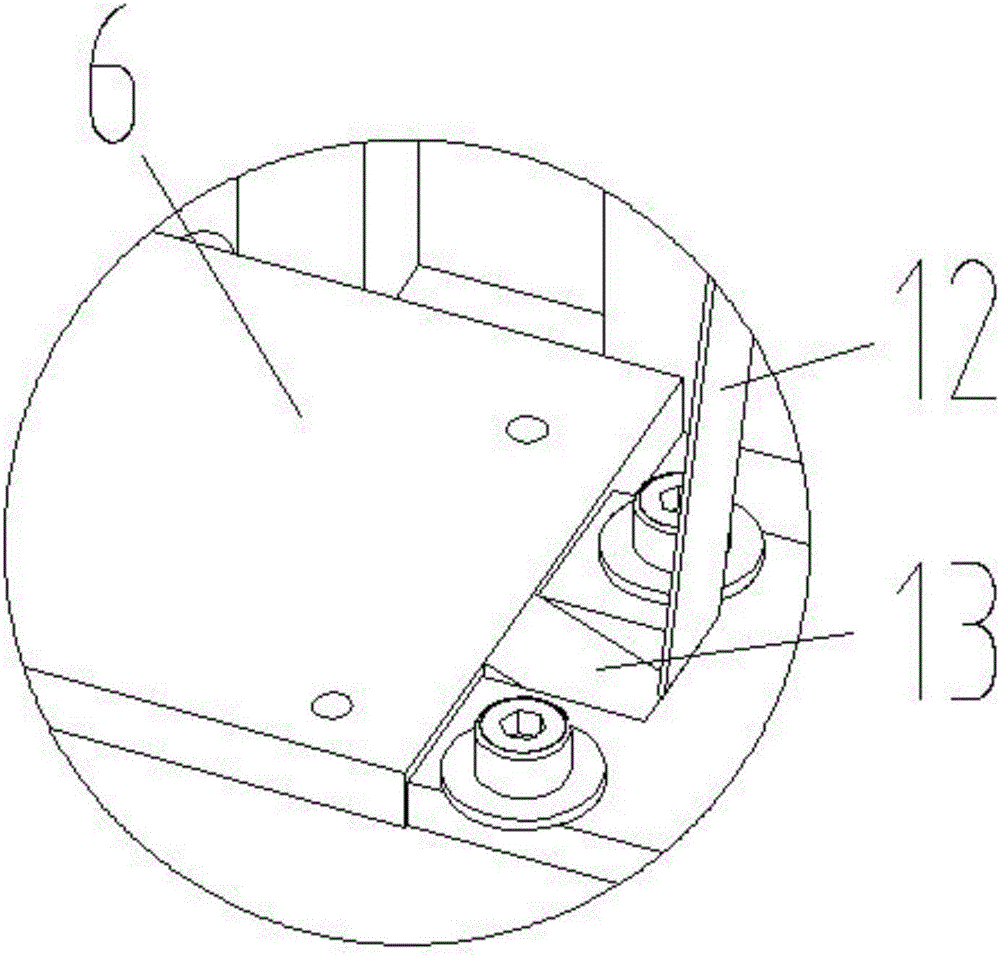

Full-automatic multi-trim-strip sewing equipment

ActiveCN107190425ASimple structureSewn flatWorkpiece carriersWork-feeding meansEngineeringSewing machine

The invention discloses full-automatic multi-trim-strip sewing equipment. The full-automatic multi-trim-strip sewing equipment comprises a sewing device, wherein the sewing device comprises a multi-needle sewing machine, a trim-strip feeding device, a first work platform, an upper tug assembly and a lower tug assembly. The full-automatic multi-trim-strip sewing equipment is characterized by further comprising a feeding device, and lower tugs of the lower tug assembly are driving wheels. The feeding device comprises a discharging table assembly, a feeding table assembly, pressing foot assemblies, and a pressing foot two-stage driving assembly. A discharging panel of the discharging table assembly is arranged on a discharging shelf in a way of moving front and back, and a feeding table panel of the feeding table assembly is fixedly arranged on a feeding table mounting shelf. The feeding table surface is communicated with a first panel and a discharging panel of the first work platform. The pressing foot assemblies comprise pressure feet. The pressure feet are arranged above the discharging panels, a feeding table panel, and the first panel in a way of moving left and right through the pressing foot two-stage driving assembly, and are used for delivering fabric of to-be-sewed trim-strips located on the discharging panel to the first panel through the feeding table panel after pressing the fabric.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

Image similarity calculation system, image search system, image similarity calculation method, and image similarity calculation program

ActiveUS7991232B2Accurately determineAccurate retrievingImage analysisCharacter and pattern recognitionPattern recognitionReference image

There is provided an image similarity calculation system which yields a large value for image similarity between an edited image and an original image. A local region weight calculation means 14 calculates a weight value for each local region in the image as a local region weight value, based on probability of editing each local region in the image. The local region weight calculation means 14 outputs the calculated local region weight value to an image similarity calculation means 122. A small region similarity calculation means 121 compares a feature quantity for each small region resulting from dividing an inquiry image with a feature quantity for each small region resulting from dividing a reference image. The small region similarity calculation means 121 calculates a similarity of feature quantities for the respective small regions. The image similarity calculation means 122 calculates an image similarity between the inquiry image and the reference image by applying a small-region-based weight value to the calculated similarity. This weight value is found from a local region weight value supplied from the local region weight calculation means 14.

Owner:NEC CORP

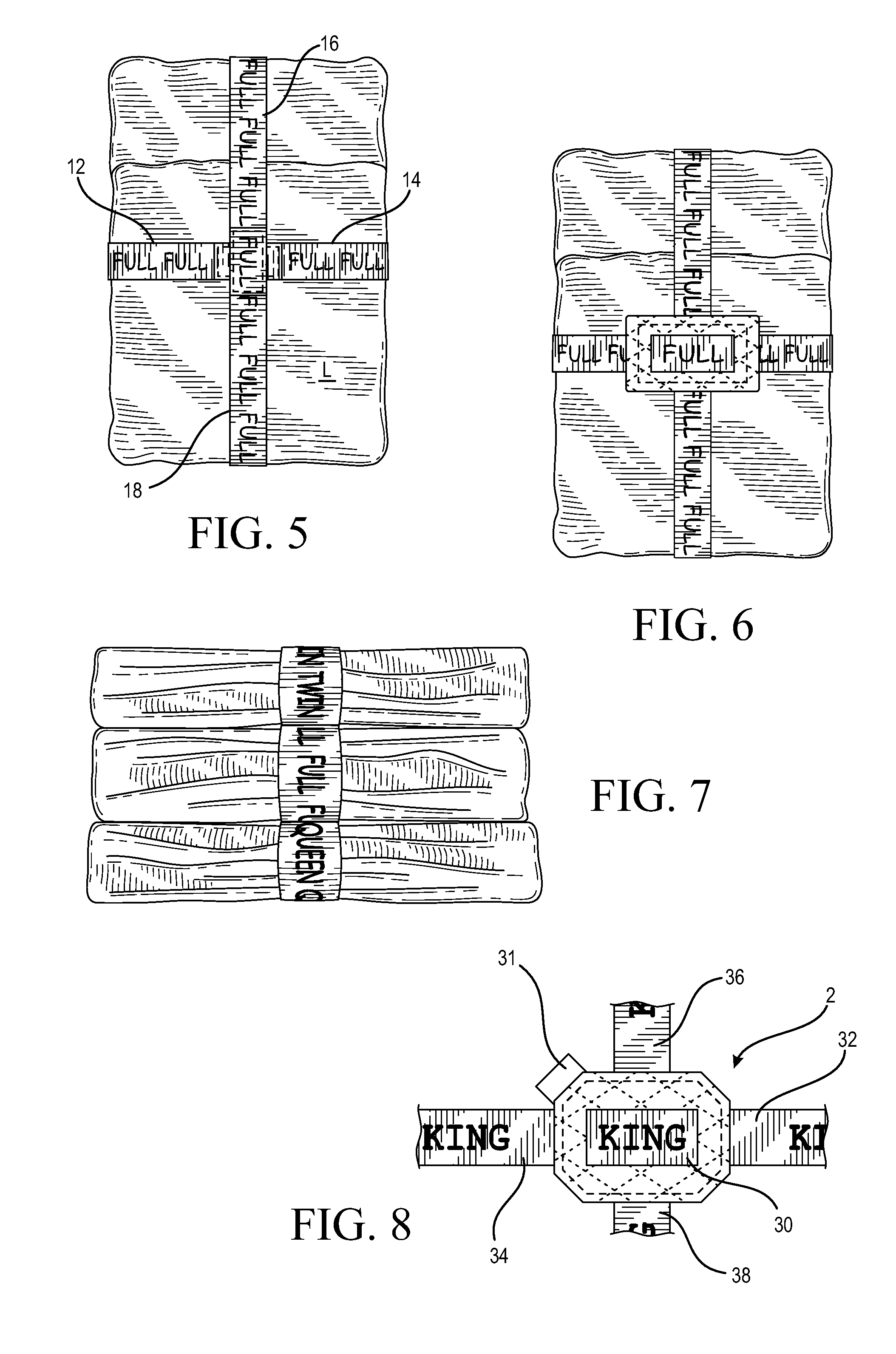

Bedding set organizer and method

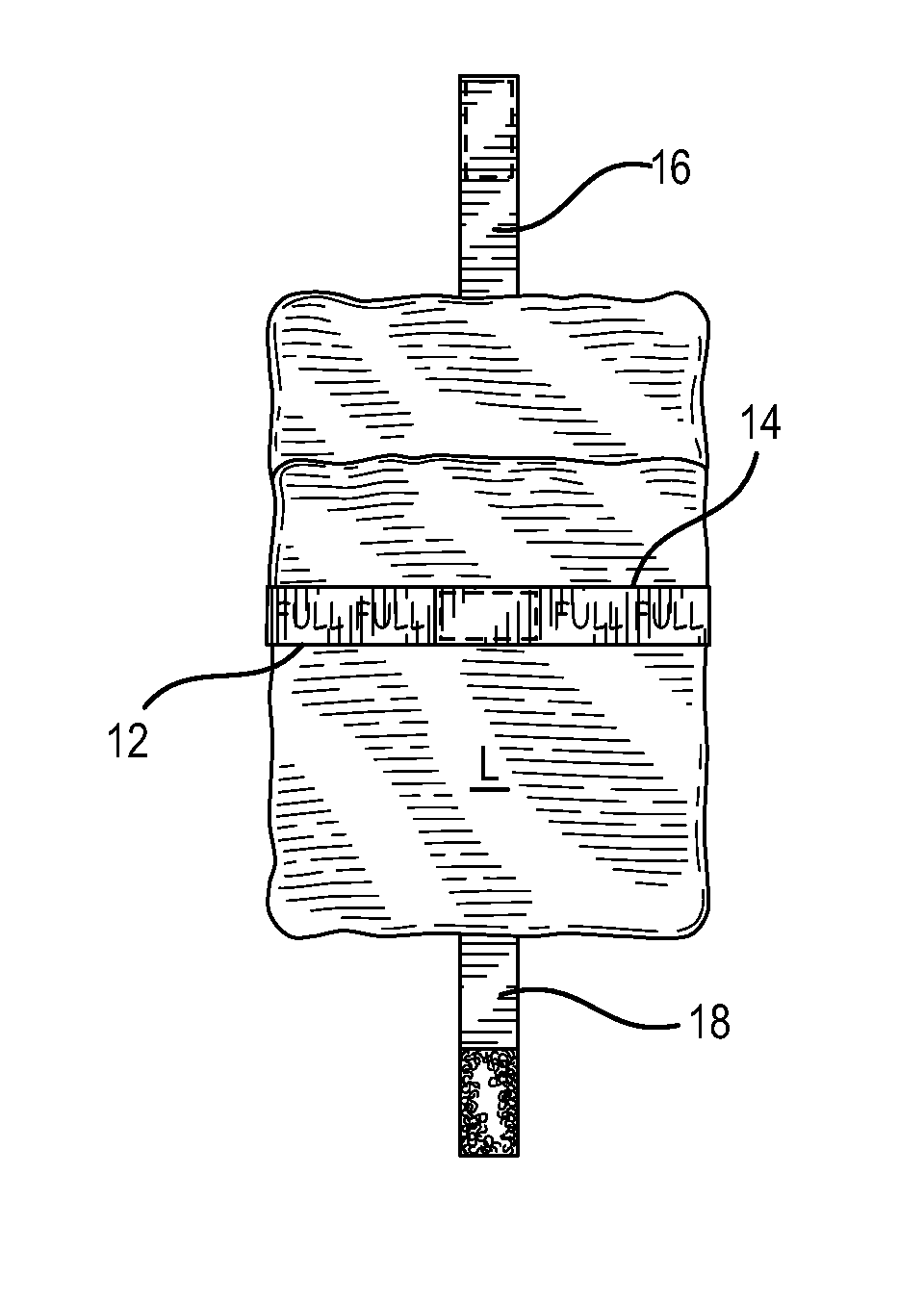

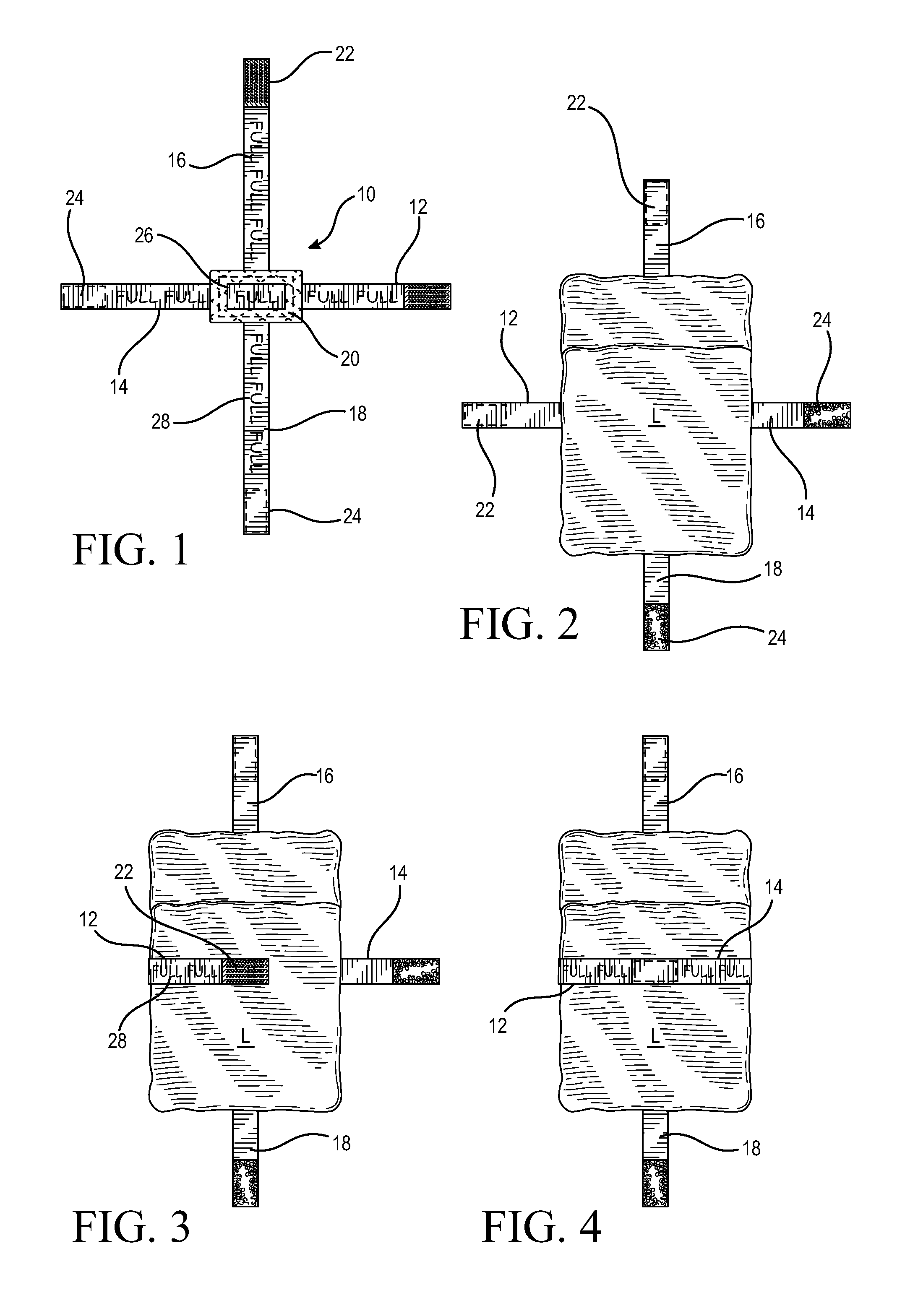

ActiveUS20120074021A1Minimizes required to retrieveAccurate retrievingStampsOther accessoriesEngineeringMechanical engineering

Owner:RAVARY ENTERPRISES

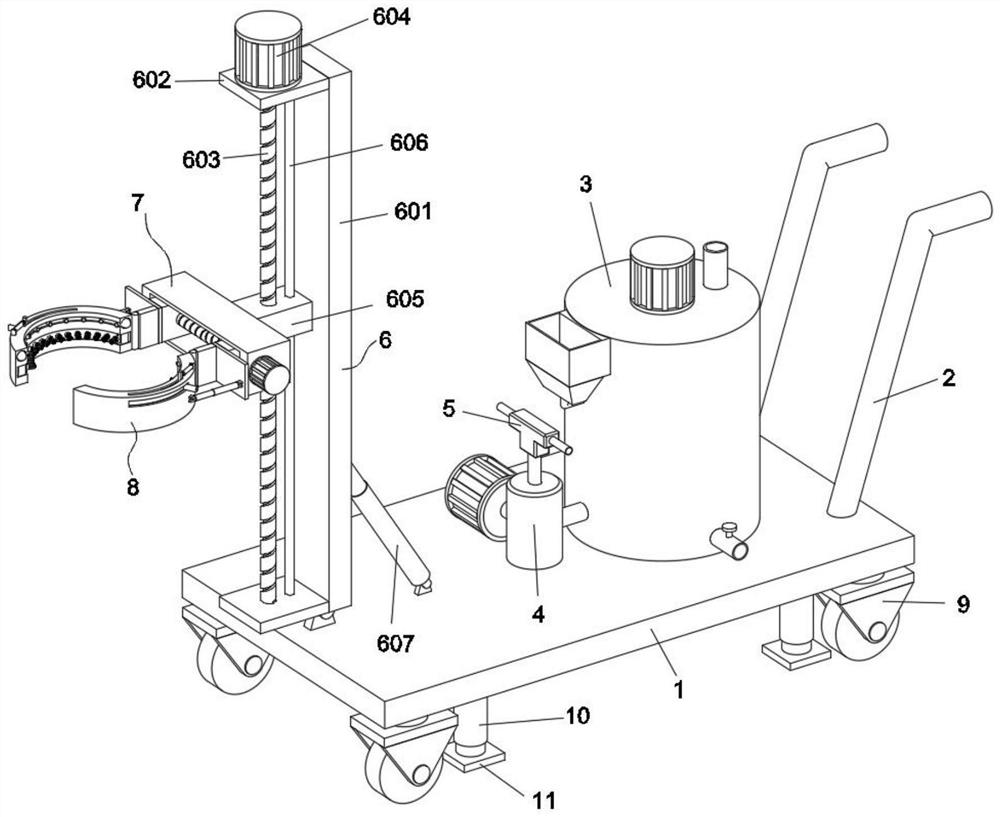

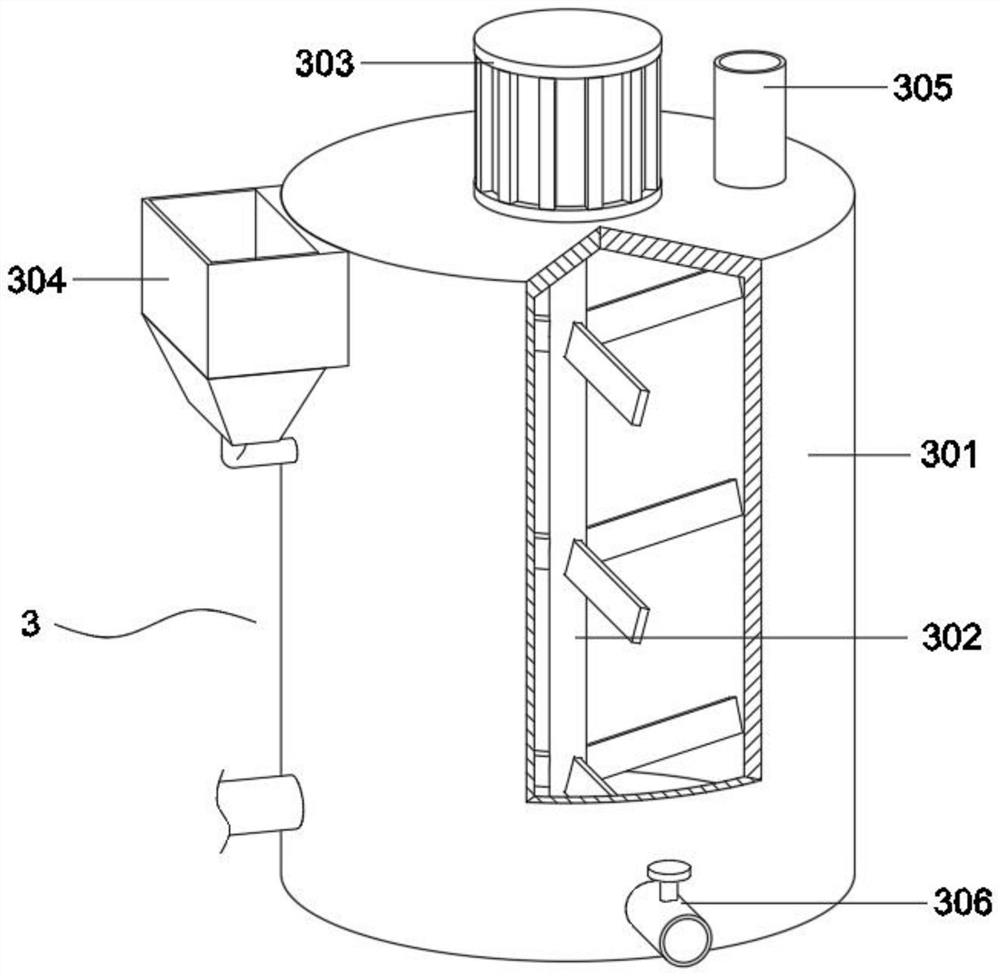

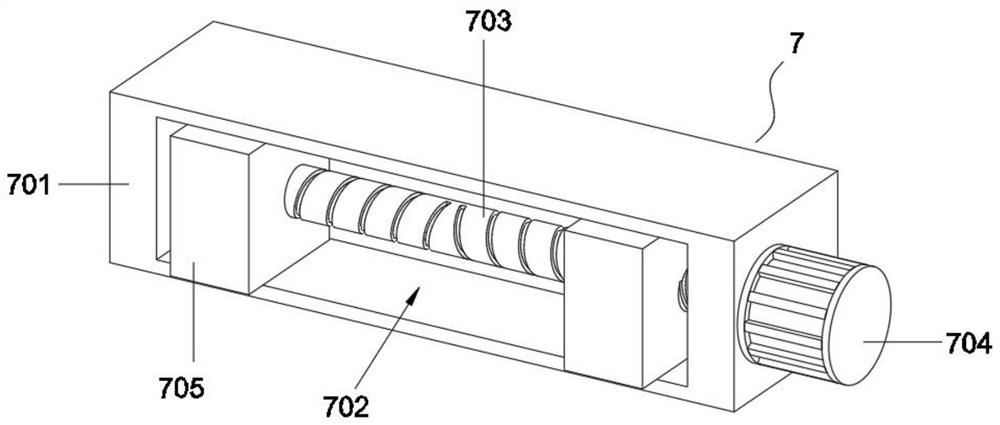

Trunk brushing device for municipal greening and using method thereof

ActiveCN112044639AConfiguration highEnsure deployment qualityClimate change adaptationSpraying apparatusTree trunkGreening

The invention relates to the technical field of municipal greening brushing equipment, in particular to a trunk brushing device for municipal greening and a using method thereof. The device comprisesa bottom plate, wherein a pushing handle is fixed to the right end of the upper surface of the bottom plate, a stirring box is fixed to the right side of the upper surface of the bottom plate, and a water pump is arranged on the left side of the stirring box; and a water inlet pipe of the water pump is communicated to the bottom of the stirring box, a water outlet pipe of the water pump is connected with a tee joint, a displacement assembly is arranged on the left side of the upper surface of the bottom plate, an adjusting assembly is arranged on the displacement assembly, a brushing assemblyis arranged on the left side of the adjusting assembly, the tee joint is connected with the brushing assembly through a connecting pipe, and universal wheels are fixed to the four corners of the bottom end of the bottom plate. According to the device, whitewashing liquid can be rapidly prepared, the situation that the effect is reduced due to the fact that the whitewashing liquid is placed for a long time is avoided, the angle of the displacement assembly can be adjusted, trees inclining by a certain angle can be brushed in a matched mode, the trees with different thicknesses can be brushed, and the application range is wide.

Owner:芜湖丽芳园园林景观建设有限公司

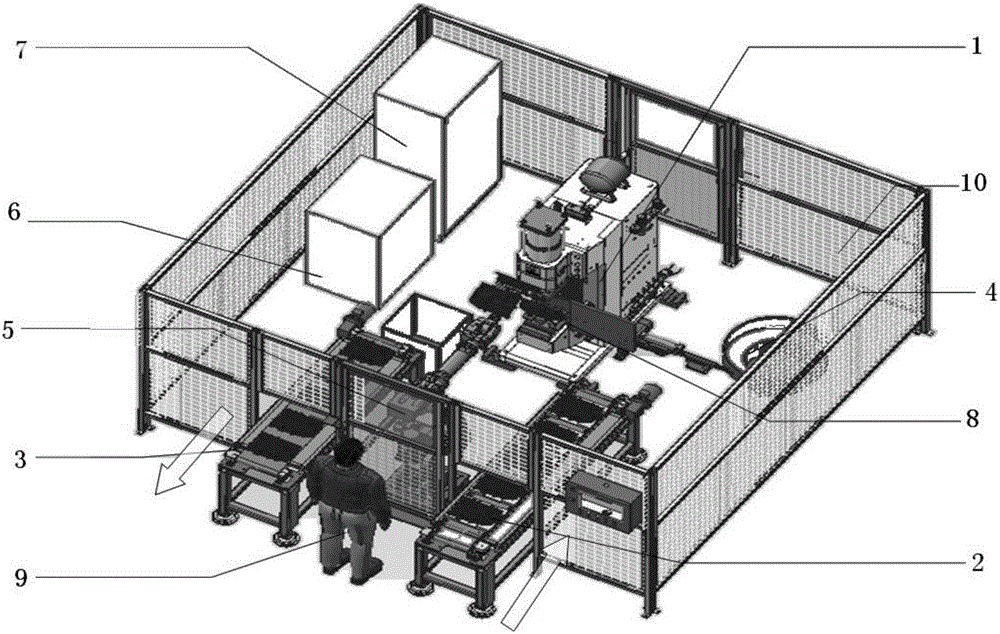

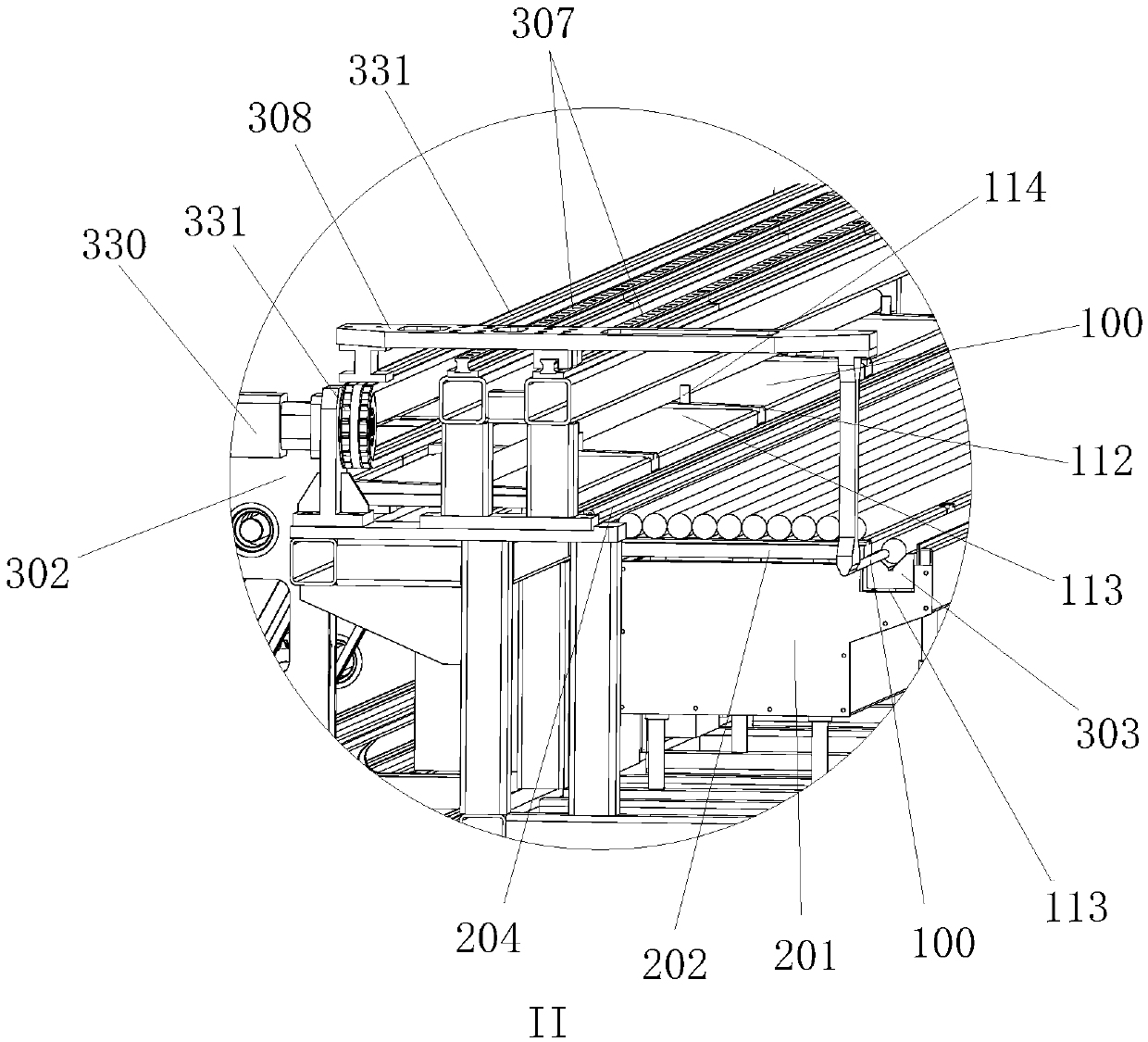

Feeding structure for feeding assembly line

ActiveCN104944103AImprove stabilityAccurate retrievingControl devices for conveyorsMechanical conveyorsStructural stabilityAssembly line

The invention provides a feeding structure for a feeding assembly line. The feeding structure comprises the assembly line, a conveying motor, a lifting motor, a lifting platform, a detection and correction device and a controller. The assembly line is composed of a plurality of belts, a rotating shaft and assembly line baffles. The rotating shaft is provided with fixing grooves matched with all the belts, and all the belts rotate in the fixing grooves. The position, at the tail end of the assembly line, of the rotating shaft is connected with the conveying motor, and the conveying motor drives the belts to rotate circularly through the rotating shaft. The lifting platform is in a multi-row column shape and can be contained in gaps between the belts. The lifting motor controls the lifting platform to ascend and penetrate through the gaps between the belts and utilizes vacuum suction to cooperate with feeding. The controller is connected with and controls the conveying motor, the lifting motor and the detection and correction device. The feeding structure for the feeding assembly line is good in stability, high in material fetching accuracy and capable of improving production efficiency.

Owner:SHENZHEN XINSANLI AUTOMATION EQUIP

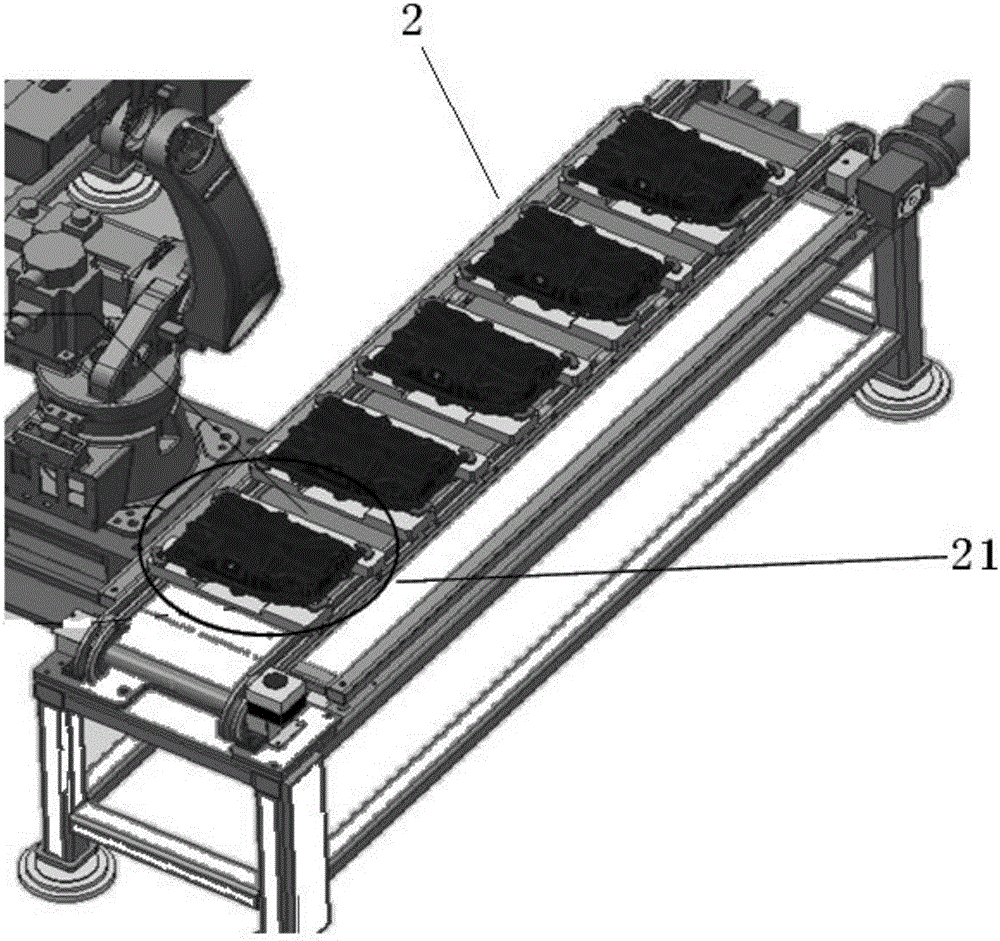

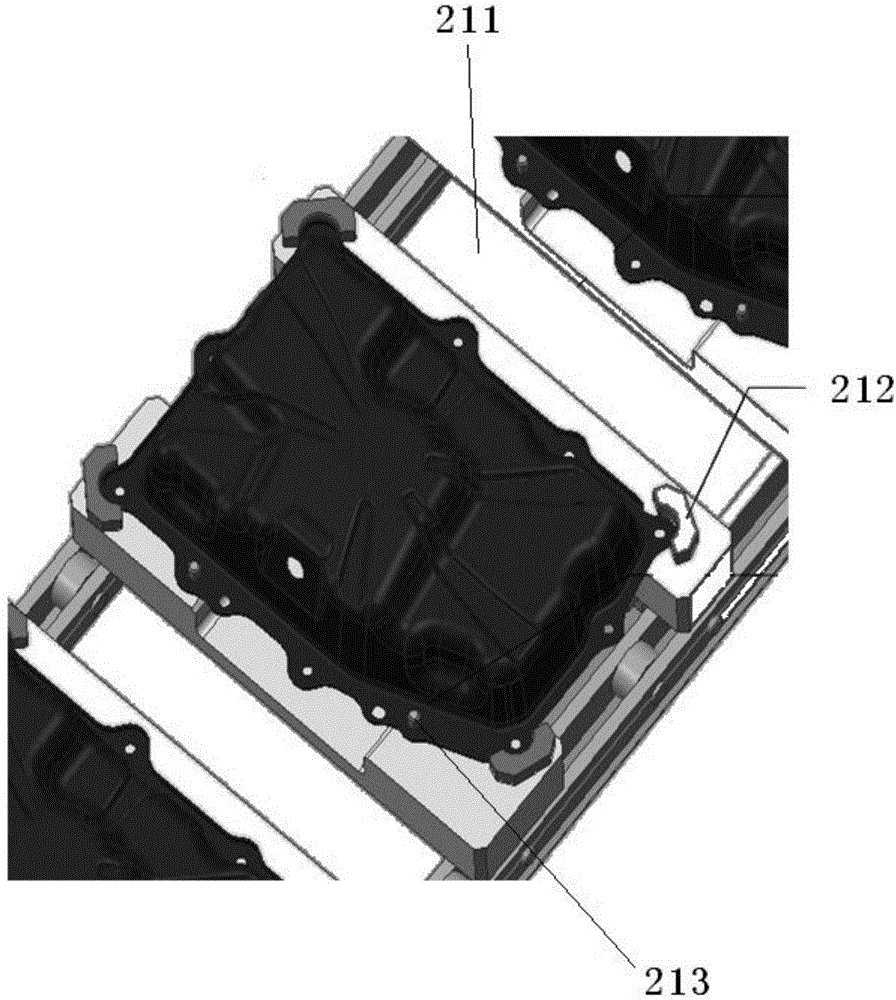

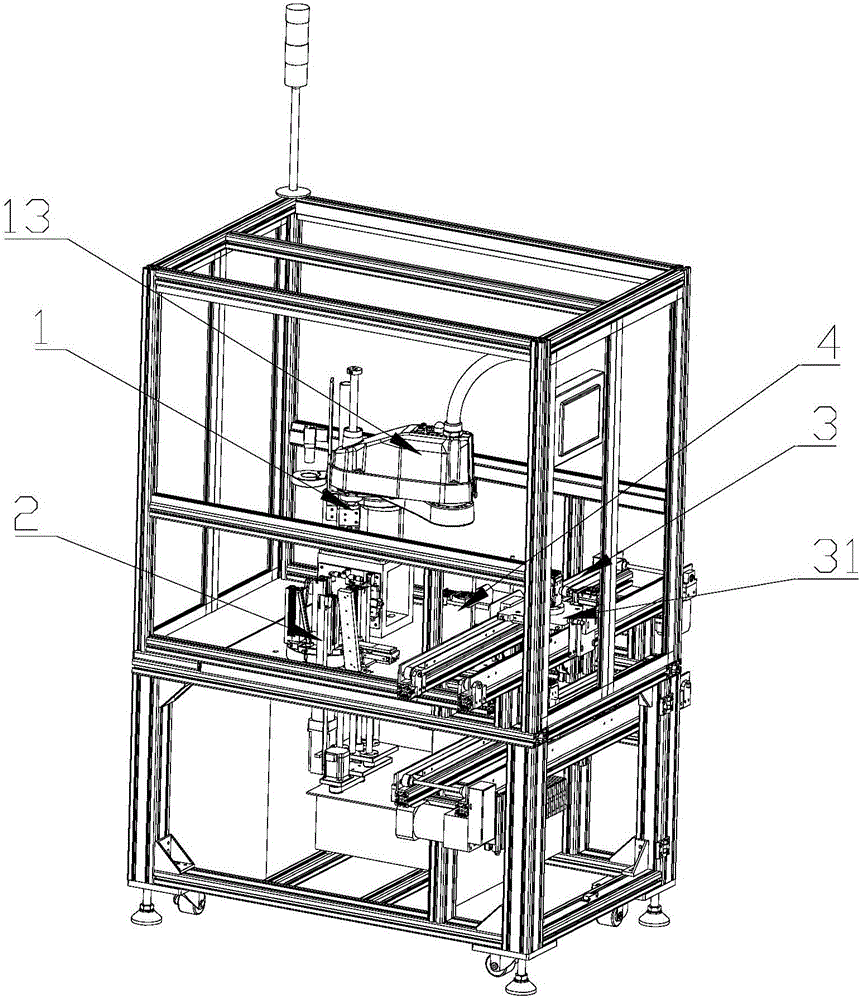

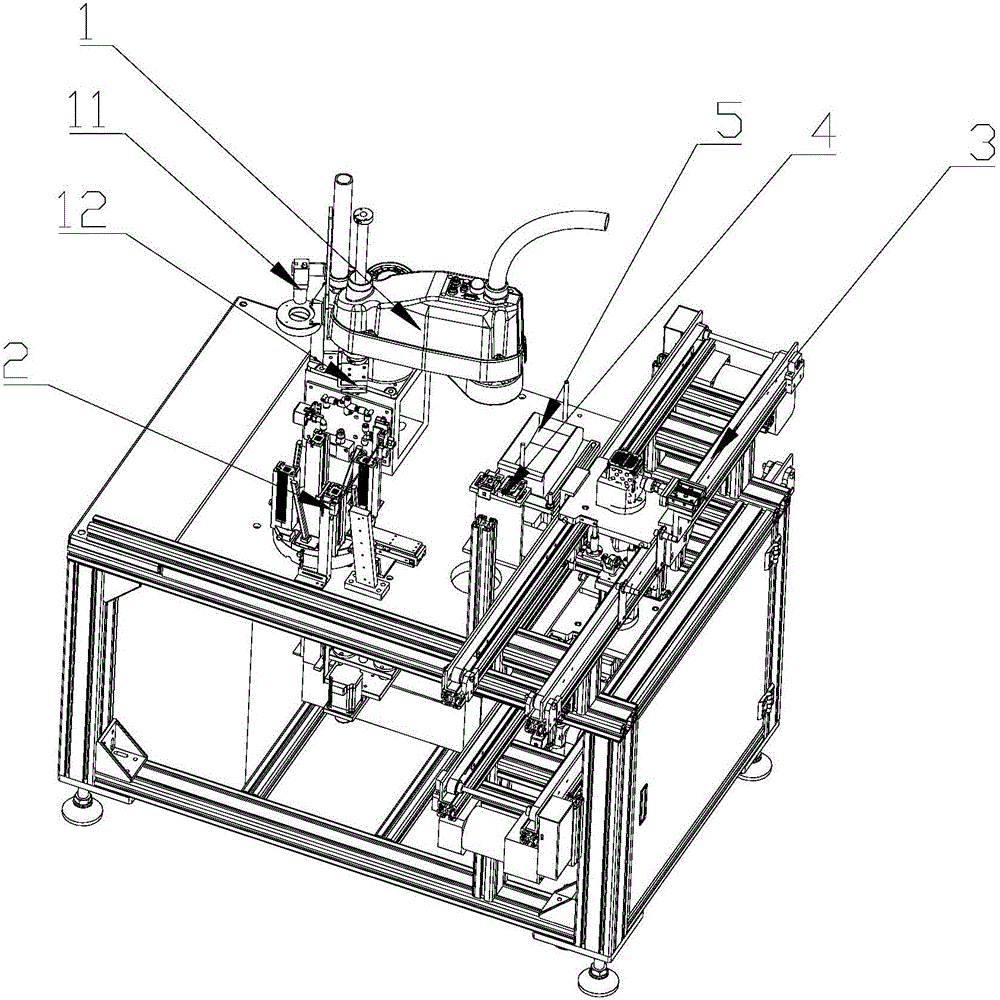

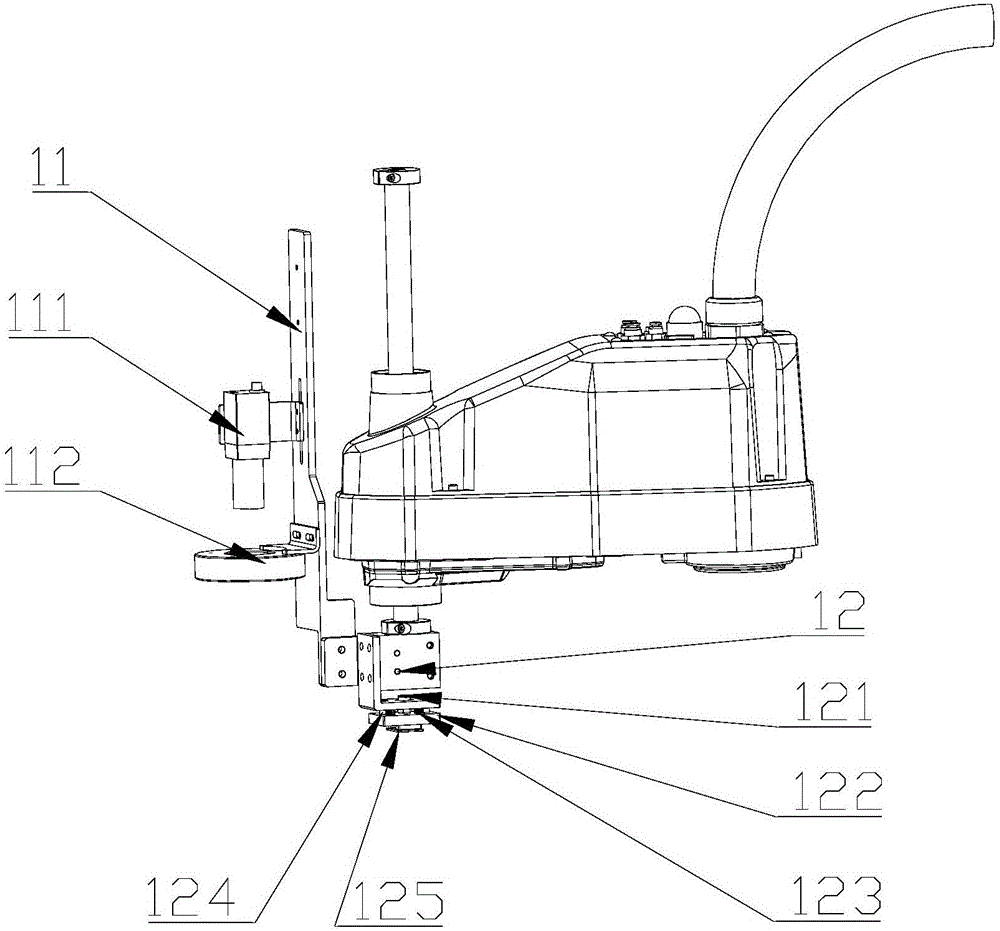

Automatic welding device for lower oil pans

ActiveCN106181008AHigh degree of automationAccurate retrievingStorage discharge weldingElectricityIntermediate frequency

The invention discloses an automatic welding device for lower oil pans. The device comprises an intermediate frequency energy storing welder, a feeding conveyor line, a discharging conveyor line, a nut feeding assembly, a robot, a robot electric cabinet, a control cabinet and a nut locating assembly, wherein the feeding conveyor line is used for conveying the oil pans to the position of the intermediate frequency energy storing welder; the robot is used for transferring the oil pans to the oil pan welding part of the intermediate frequency energy storing welder from the feeding conveyor line and is also used for transferring welded finished products to the discharging conveyor line, and the discharging conveyor line is used for outputting the finished products; the nut feeding assembly is arranged at one side of the intermediate frequency energy storing welder and used for conveying nuts to the position of the intermediate frequency energy storing welder; the nut locating assembly is arranged between the intermediate frequency energy storing welder and the nut feeding assembly and used for transferring the nuts from the nut feeding assembly to the oil pan welding part; and the intermediate frequency energy storing welder is connected with the control cabinet, and the intermediate frequency energy storing welder discharges electricity and finishes the welding of the oil pans and the nuts under the control of the control cabinet.

Owner:CHANGSHU JUNCHI SCI & TECH

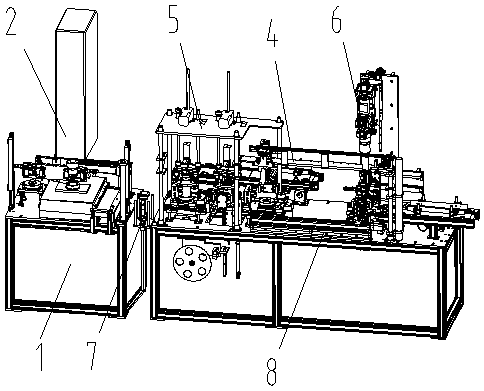

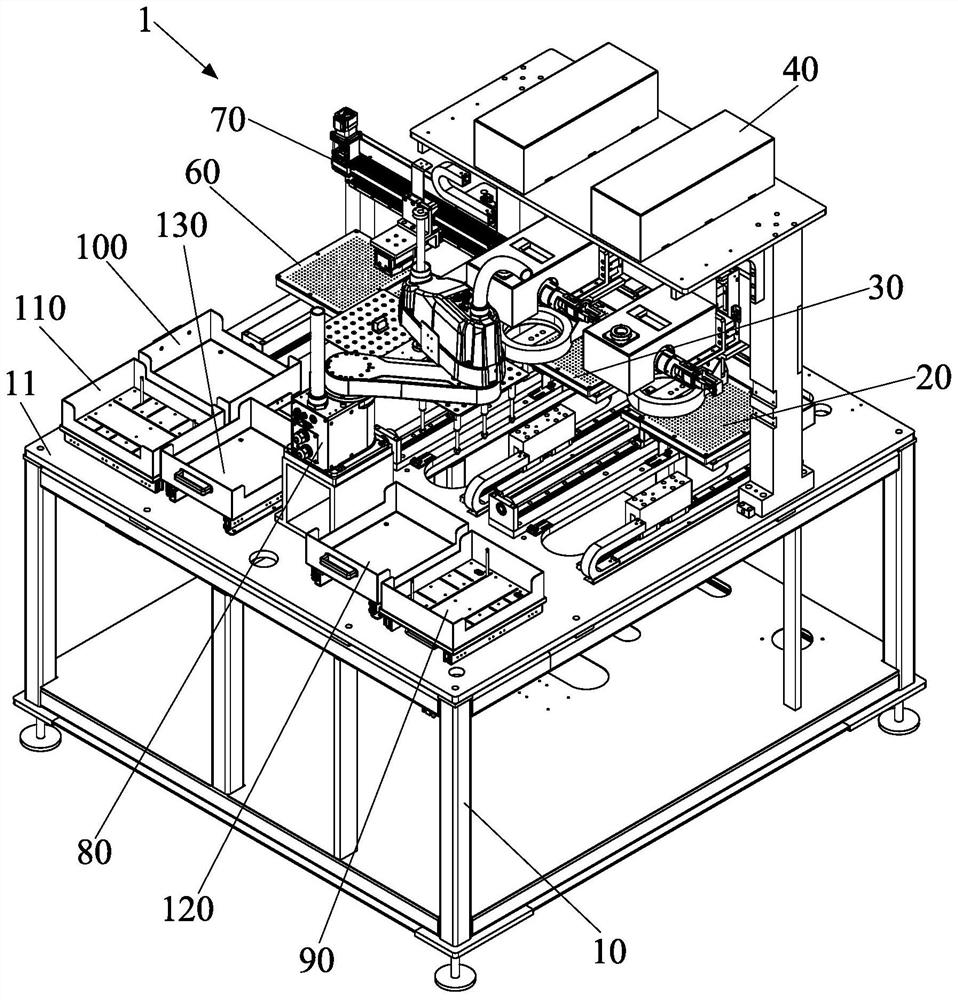

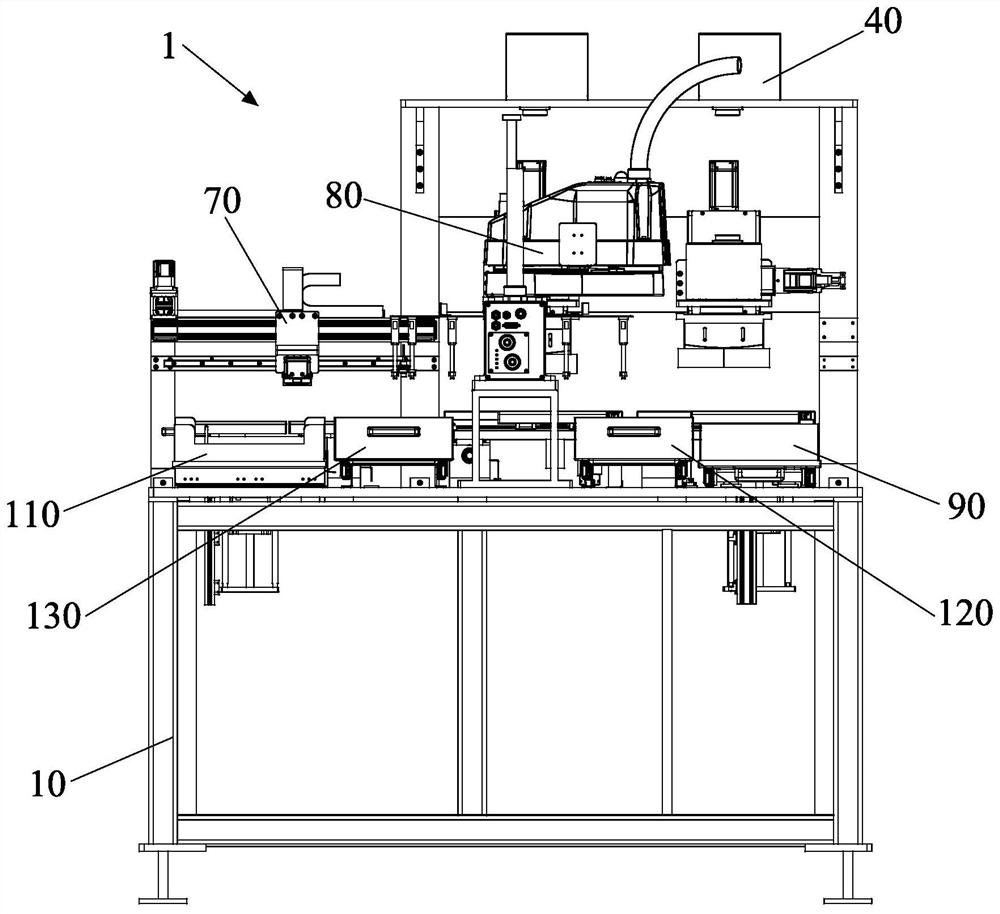

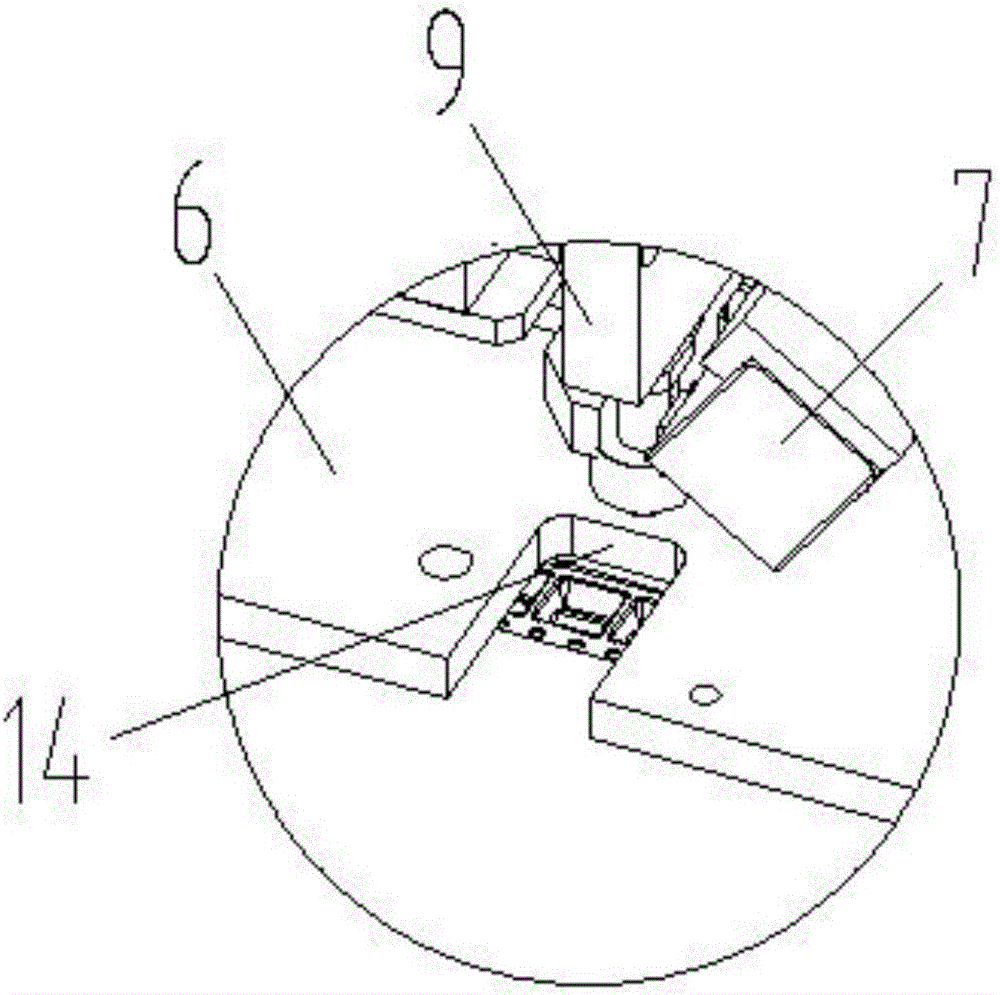

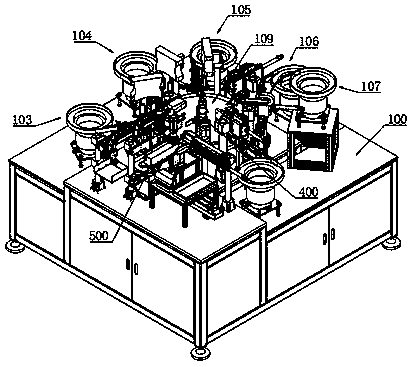

Automatic feeding assembly machine of integrated machine core component

ActiveCN105817882ARealize automatic feedingImplement automatic installationAssembly machinesMaterial supplySurface plate

The invention discloses an automatic feeding assembly machine of an integrated machine core component. According to the automatic feeding assembly machine of the integrated machine core component, a feeding mechanism achieves automatic material supply through components in a jacking mechanism jacking bin I and / or a bin II. A material absorbing mechanism absorbs materials to a work panel from the feeding mechanism, and automatic installation is achieved. After installation is finished, a line body transports workpieces machined through the work panel away, the full automation in the assembly process is achieved, the labor force is relieved, and the assembly efficiency is further improved. Material taking is more accurate through a vision detecting mechanism, the assembling efficiency and the assembling precision are improved, and the problem that a large amount of labor force is needed is greatly solved. The automatic feeding assembly machine is suitable for the field of automatic optical lens assembling.

Owner:GUANGDONG JINHONGDA AUTOMATION TECH CO LTD

Puncture type automatic material taking mechanism

ActiveCN106946033ARealize automatic prickingAccurate retrievingConveyor partsElectric machineryDrive motor

The invention discloses a puncture type automatic material taking mechanism which comprises a support, a puncture mechanism and a driving mechanism. The support comprises a base plate and a bottom plate located at the bottom of the base plate and connected with the base plate; the puncture mechanism comprises a material-taking sliding plate and a plurality of machine pins, the material-taking sliding plate is located on one side of the base plate and located on the bottom plate, the machine pins are mounted under the material-taking sliding plate, and a certain inclination angle is formed by the machine pins and the material-taking sliding plate in the horizontal direction; and the driving mechanism is located on the base plate and comprises a driving motor and a transmission mechanism connected with the puncture mechanism. During work, the driving motor drives the transmission mechanism to act, and the transmission mechanism drives the puncture mechanism to move to enable the machine pins located at the bottom of the material-taking sliding plate to puncture and take cloth. The multiple machine pins are adopted, the material puncturing mode is adopted, the material-taking sliding plate moves to drive the machine pins to move according to the thickness of the cloth, material taking is accurate, and the problems that cloth taking is not stable due to the fact that cloth is soft, breathable and different in thickness are well solved.

Owner:福恩达机器人(昆山)有限公司

Preparation method of circular-section steel wire ring for radial tire

The invention discloses a preparation method of a circular-section steel wire ring for a radial tire. According to the preparation method, a steel wire ring with a circular section is formed by winding a single attached steel wire on a concave semicircular tile of a steel wire ring winding disc on a steel wire winding device, in the winding process, the coiling of steel wires, the horizontal wire arrangement among the steel wires, the up and down wire tripping among the steel wires and the total winding amount of the steel wires are respectively controlled by servo systems correspondingly arranged on the steel wire winding device, all the servo systems are connected with a PLC (Programmable Logic Controller) through lines, thus realizing the automatic control; a circular-section steel wire ring production line is composed of the steel wire winding device and a steel wire unwinding device, as well as a cloth roller wire cleaning device, a preheating device, an extruder, a traction, storage and cooling device, a prebending device and a steel ring wrapped winding device. According to the preparation method, the coiling, wire discharge, wire tripping and winding amount of the steel wires are controlled by the servo systems with set parameters, and the preparation method has the characteristics of being precise for materials to take, close to wind, uniform for intervals, and stable for circular-section shape.

Owner:CHEMCHINA GUILIN TIRE

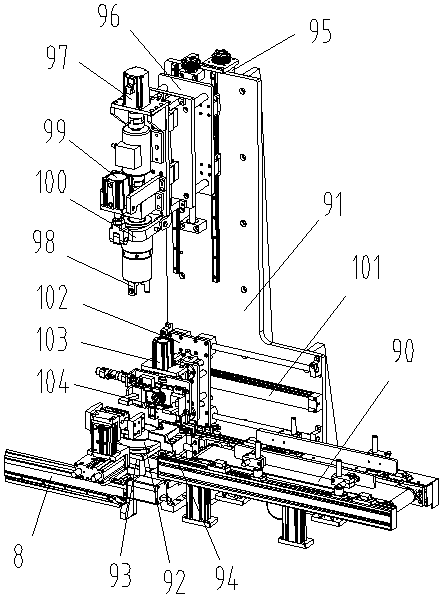

Cover tightening mechanism for insulation bottle production

InactiveCN109454439ARealize integrated automatic operationImprove assembly efficiencyWelding/cutting auxillary devicesAuxillary welding devicesDistribution controlEngineering

The invention relates to the field of machining equipment of insulation bottles, in particular to a cover tightening mechanism for insulation bottle production. The mechanism comprises a power distribution control box; a loading device, a covering device and a tightening device are arranged on the power distribution control box from left to right; the loading device comprises a loading lifting cylinder and a loading lifting base; the loading device is matched with the covering device through a taking device; the covering device is matched with the tightening device through a feeding device; and the taking device, the covering device, the feeding device, the tightening device and the loading lifting cylinder are connected to the power distribution control box. The cover tightening mechanismfor insulation bottle production uses the loading device for loading, realizes cooperation between the loading device and the covering device through the taking device, and meanwhile, can feed sleeved bottle bodies and bottle covers to the tightening device for tightening through the feeding device to realize integral automatic operation, so that the assembly efficiency is greatly improved, and meanwhile, the product quality is improved.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Laser punching equipment

PendingCN111687551AEasy to identifyImprove consistencyPrinted circuitsMetal working apparatusPunchingEngineering

The invention discloses a laser punching equipment. The laser punching equipment comprises a machine frame, a laser punching mechanism, a lifting platform mechanism, a material transfer mechanism andan upper camera. The laser punching mechanism comprises a laser workbench, a mobile module, a laser device and a camera module. The lifting platform mechanism is arranged on a machine frame workbench.The material transfer mechanism comprises a robot and a suction disk jig. A robot is arranged on the machine frame workbench. The suction disk jig is arranged at the bottom end of a rotary arm of therobot. The upper camera is arranged on the part, corresponding to the upper part of the lifting platform, of the machine frame and is used to recognize materials on a lifting platform. With the laserpunching equipment, the operational accuracy and the production efficiency can be improved, equipment operation is automatic, one person can operate multiple devices, the human cost is reduced, and intelligent manufacturing can be implemented.

Owner:厦门柔性电子研究院有限公司 +2

Convenient-to-clamp winding machine for transformer skeleton

Owner:XUZHOU SANHE AUTOMATIC CONTROL EQUIP

Assembling and detecting all-in-one machine for vacuum bottle

InactiveCN108673111AEasy to operateSimple structureFluid-tightness measurementMetal working apparatusDistribution controlBottle

The invention relates to an assembling and detecting all-in-one machine for a vacuum bottle. The assembling and detecting all-in-one machine for the vacuum bottle comprises a power distribution control box, and a gas tightness detecting device, a cap sleeving device and a tightening device are arranged on the power distribution control box from left to right; feeding devices matched with the gas tightness detecting device are arranged on the left side and the right side of the gas tightness detecting device; and a gas tightness detecting carrier is arranged on a detecting front-back left-rightmoving device, a detecting rotating motor is connected to a detecting rotating grabbing disc, and the detecting rotating grabbing disc is matched with a detecting grabbing disc opening and closing rotating arm. According to the assembling and detecting all-in-one machine for the vacuum bottle, cooperation of the gas tightness detecting device and the cap sleeving device is achieved through a reclaiming device, a bottle body and a bottle cap which are connected in a sleeving mode can be delivered to the tightening device to be tightened through the feeding devices, integrated automatic operation is achieved, the assembling efficiency is greatly improved, and meanwhile it can be guaranteed that the gas tightness of the processed vacuum bottle is good and the heat preservation effect is ideal.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

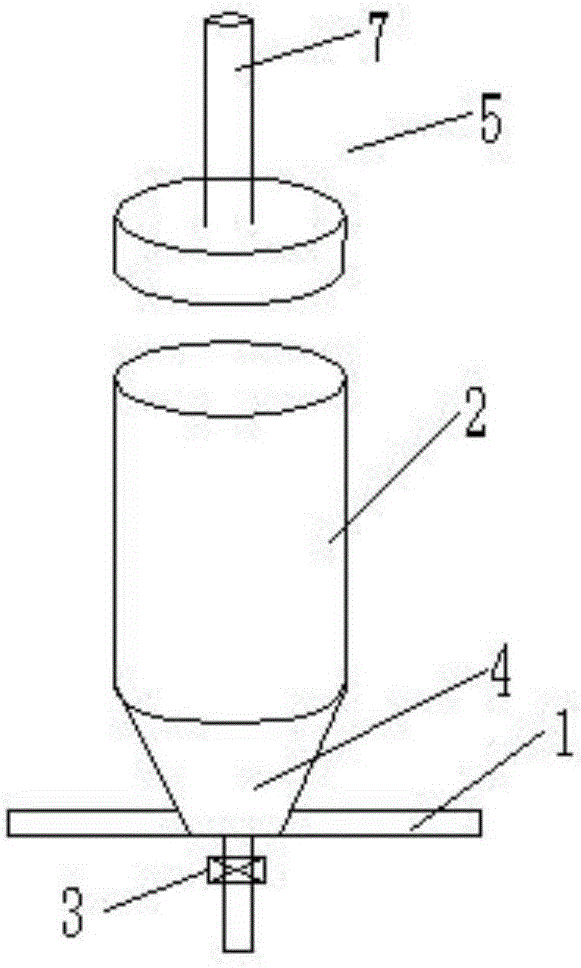

Automatic material taking and feeding type hopper for chinlon spinning

InactiveCN106809542AAccurate retrievingImprove feeding efficiencyLarge containersEngineeringMechanical engineering

The invention provides an automatic material taking and feeding type hopper for chinlon spinning. The hopper comprises a base, a storage hopper and a discharge valve. The storage hopper is fixedly arranged on the base and is cylindrical, a discharging port is formed in the lower portion of the storage hopper, and the diameter of the discharging port is smaller than that of a feeding port. The discharge valve is arranged on the discharging port, an automatic feeding device is arranged above the storage hopper and comprises a controller, a rotary device and a material taker, the material taker is arranged below the rotary device, and the material taker and the rotary device are both connected with the controller. The automatic material taking and feeding device is arranged, material taking is accurate, multiple kinds of materials can be added at the same time, and the feeding efficiency is greatly improved.

Owner:南通苏源化纤有限公司

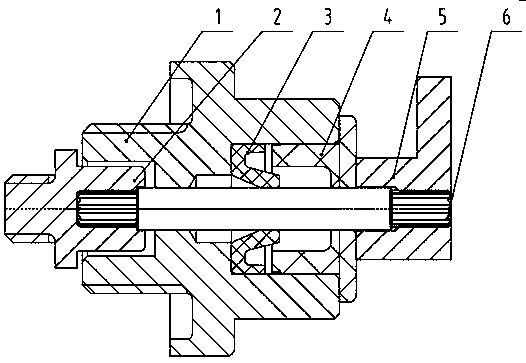

Winding machine for frameworks of transformers

The invention relates to a winding machine for frameworks of transformers. The winding machine is characterized in that a winding mechanism and a pay-off device are arranged on a support plate, the winding mechanism comprises a winding seat, the winding seat is arranged on the support plate, winding rotary shafts are arranged on the winding seat, the outer ends of the winding rotary shafts are connected to a winding motor, feed cylinders are connected with the inner ends of the winding rotary shafts and are provided with clamp blocks which are matched with the frameworks of the transformers, the pay-off device comprises a pay-off seat, copper wires of a pay-off plate are arranged on the pay-off seat, a wire outlet is formed in the pay-off seat, a wiring block which is matched with the wire outlet is arranged on the winding seat and is matched with the altitudes of the clamp blocks, and wiring openings which are matched with the wire outlet are formed in the wiring block. The winding machine has the advantages that the feed cylinders are arranged on the winding rotary shafts, the clamp blocks which are matched with the frameworks of the transformers are arranged on cylinder heads of the feed cylinders, vertically downward wire outlet holes are formed in the pay-off device and are matched with the wiring block, and accordingly the copper wires can be uniformly wound on the frameworks of the transformers and can be prevented from twining and knotting.

Owner:威海合益电子科技有限公司

Flexible automatic feeding and discharging device and method of roller machine

PendingCN110241522AIncrease productivityReduce dependenceSewing-machine control devicesWork-collecting devicesMotion controllerMulti axis

The invention belongs to the technical field of sewing of roller machines, and particularly discloses a flexible automatic feeding and discharging device and method of a roller machine. The device comprises a material feeding platform, a motion controller, a material taking and auxiliary sewing mechanism and a material discharging platform, the motion controller is used for converting coordinate information of material taking, auxiliary sewing and discharging into a multi-axis linkage signal, and a guide rail unit, a first rotation unit and a terminal rotation unit execute material taking and auxiliary sewing motion according to the signal and transfer materials to the material discharging platform. The method comprises the steps that the coordinate information of material taking, auxiliary sewing and discharging is extracted and converted into the multi-axis linkage signal, and the multi-axis linkage signal is transmitted to a material feeding unit, the material taking and auxiliary sewing mechanism and the material discharging platform to complete material feeding, material taking, auxiliary sewing and material discharging. The flexible automatic feeding and discharging device can effectively replace manual material feeding and discharging and auxiliary sewing, quickly adapt to the sewing contour change, and improve the sewing efficiency and quality.

Owner:HUAZHONG UNIV OF SCI & TECH +1

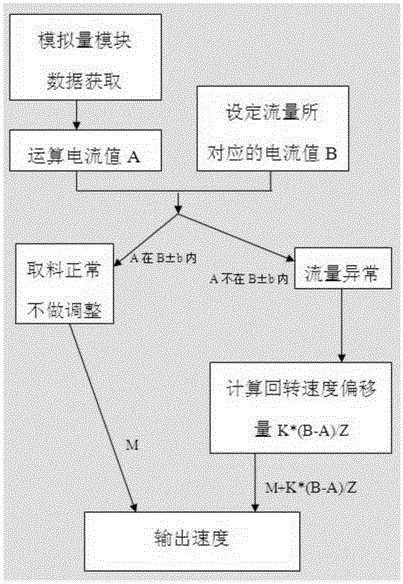

System and method for controlling instant material taking quantity of bucket wheel machine

InactiveCN105892395AControl the instantaneous amount of materialReclaiming safetyProgramme control in sequence/logic controllersPower flowControl system

The invention relates to a system and a method for controlling instant material taking quantity of a bucket wheel machine. The system comprises a current data conversion device, an analog input module and a PLC processor, wherein the current data conversion device is connected with the analog input module through a shielding signal cable; the analog input module is connected with the PLC processor through a communication device. The method comprises the following steps: step one, converting the current data of the material taking bucket wheel machine into analog data by the current data conversion device; step two, transmitting the analog data to the analog input module by the shielding signal cable; step three, transmitting signals to the PLC processor by the analog input module; step four, judging the rotation material taking speed needing to be adjusted in real time through the comparison of data returned by the analog input module and a current value corresponding to preset material taking flow by the PLC processor, and controlling the instant material taking quantity of the bucket wheel machine by adjusting the rotation material taking speed. According to the system and the method, the material taking unmanned operation is safer and more accurate, automatic and efficient.

Owner:INSTALLATION ENG CO LTD OF CCCC FIRST HARBOR ENG

Laser code marking and scanning equipment

PendingCN112548350AReduce labor costsImprove processing efficiencyLaser beam welding apparatusComputer hardwareLaser

The invention discloses laser code marking and scanning equipment. The laser code marking and scanning equipment comprises a machine frame, a code marking platform mechanism, a laser code marking mechanism, a code scanning platform mechanism, a code scanning mechanism, a material moving mechanism, a product feeding mechanism and a product receiving frame. The code marking platform mechanism, the code scanning platform mechanism, the material moving mechanism, the product feeding mechanism and the product receiving frame are integrated on the same machine frame to form the laser code marking and scanning equipment, and the laser code marking and scanning equipment has the functions of automatic feeding, laser code marking, code scanning and automatic material receiving at the same time. Compared with single laser code marking equipment and single code scanning equipment, the laser code marking and scanning equipment has the advantages that one code scanning process, one set of code scanning equipment and operators are reduced, the equipment and labor cost can be greatly reduced, and the processing efficiency can be improved.

Owner:厦门柔性电子研究院有限公司

Chip mounter with air pressure sampling board

ActiveCN105472902AWith mixed pasteIntelligentPrinted circuit assemblingElectrical componentsAtmospheric pressureElectrical and Electronics engineering

The invention relates to a chip mounter with an air pressure sampling board. The chip mounter comprises a mounter table, a chip mounter head and a material feed base. The chip mounter head and the material feed base are arranged in a way of relying on the mounter table. The material feed base feeds material to the chip mounter head. The bottom part of the chip mounter head comprises multiple suction nozzles for taking material from the material feed base. The chip mounter head internally comprises the air pressure sampling board which acquires air pressure of the suction nozzles, and compares and judges the acquired air pressure values and a preset value so as to control the chip mounter head to perform material throwing and / or remounting of chips. The chip mounter with the air pressure sampling board has advantages of being accurate in chip mounting and intelligent so that mixed mounting can be realized without leak mounting.

Owner:冷晓勇

Packaging machine capable of achieving bean screening

The invention relates to a packaging machine capable of achieving bean screening. The packaging machine comprises a rack and a power distribution control box. A packaging box conveying device matched with a packaging box vibration feeding plate is arranged on the rack. A bean feeding hopper and a film pressing mechanism are sequentially arranged above the packaging box conveying device. The bean feeding hopper is matched with a screening device. The screening device comprises a screening seat. A shaking device is arranged on the screening seat. The shaking device comprises a shaking motor arranged on the screening seat. The shaking motor is matched with a shaking movable seat through a shaking rotating handle. The shaking movable seat is connected with a shaking frame through a shaking connecting rod, and the middle portion of the shaking connecting rod is hinged to the shaking seat. The shaking frame is provided with a screen matched with beans, and a screening discharging sliding groove matched with the screen is formed in the end portion of the shaking seat. The screening discharging sliding groove is matched with the bean feeding hopper. The packaging machine can be in well butt joint with the bean feeding hopper while a good screening function is achieved, and the bean feeding efficiency is improved.

Owner:安徽茉莉花食品科技发展有限公司

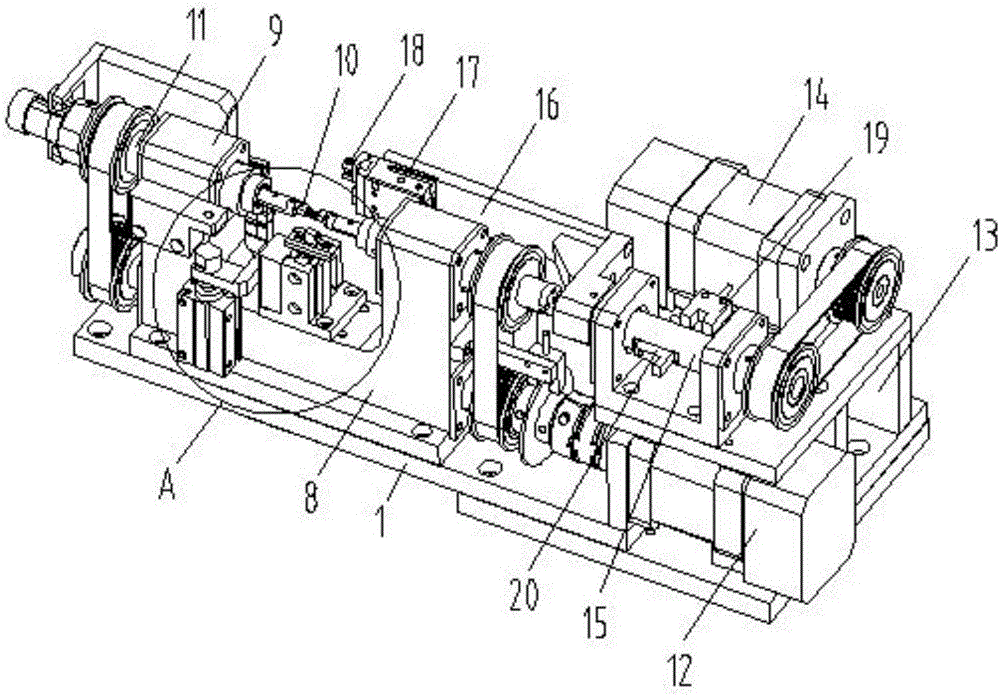

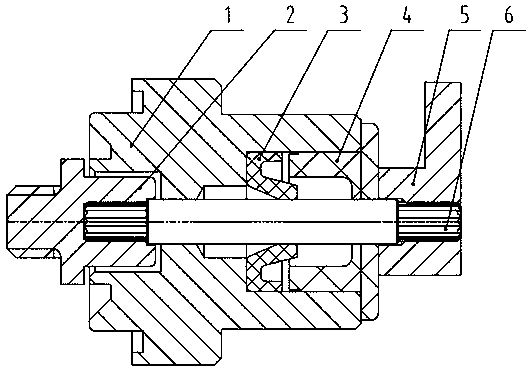

Transmission shaft assembling mechanism of direct transmission set assembling device

ActiveCN110802400AFast deliveryGuaranteed continuityAssembly machinesMetal working apparatusDrive shaftStructural engineering

The invention discloses a transmission shaft assembling mechanism of a direct transmission set assembling device. The transmission shaft assembling mechanism is characterized by comprising a vibrationdisc for transmission shafts, a first conveying pipe, a material receiving and positioning base for the transmission shafts and a transplanting mechanism for the transmission shafts, wherein the material receiving and positioning base for the transmission shafts comprises a base and a material receiving assembly, and the material receiving assembly comprises a material receiving protruding block,a material receiving sliding block, a transverse moving air cylinder for the material receiving sliding block and a jacking air cylinder for the transmission shafts; a jacking interval is formed between the lower surface of the material receiving sliding block and the lower side face of an inserting hole, and the height between the upper surface of the material receiving sliding block and the lower side face of the inserting hole is consistent with the length of the transmission shafts; and the upper end of the first conveying pipe communicates with a discharging port of the vibration disc for the transmission shafts, and the lower end of the first conveying pipe communicates with a blanking hole in the material receiving protruding block. The transmission shaft assembling mechanism of the direct transmission set assembling device has the beneficial effects that one-by-one sequential orderly output and precise positioning of the transmission shafts can be effectively guaranteed, and high-precision assembling of the transmission shafts can be better achieved.

Owner:深圳市睿荔科技有限公司

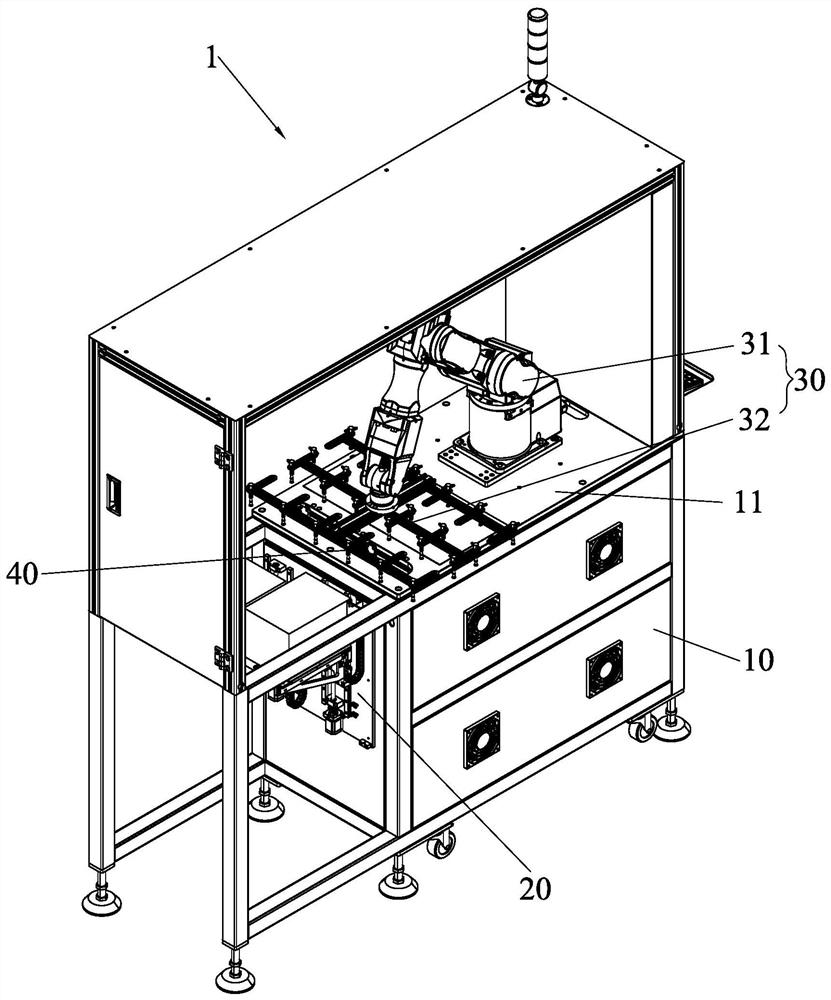

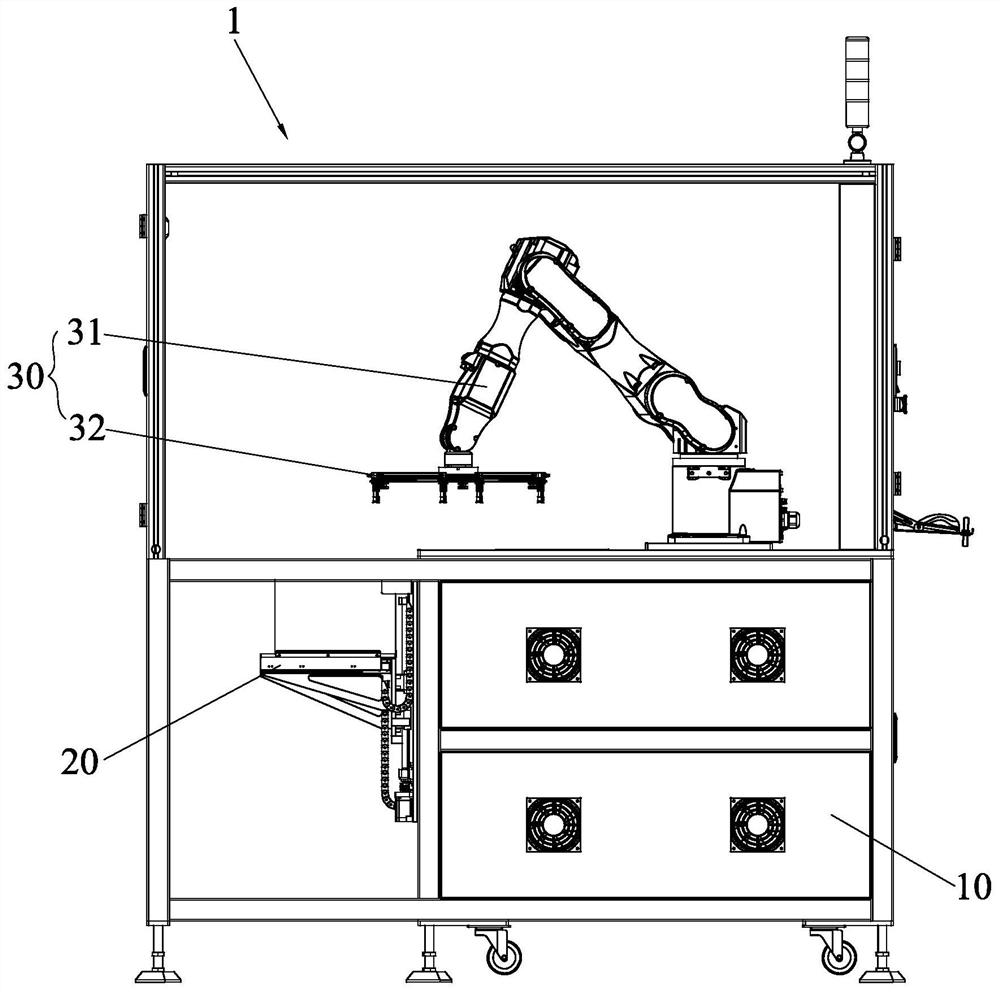

Automatic feeding and discharging equipment and automatic feeding and discharging method

PendingCN112794062ARealize intelligent manufacturingIncrease productivityControl devices for conveyorsReciprocating motionControl engineering

The invention discloses automatic feeding and discharging equipment and an automatic feeding and discharging method. The equipment comprises a rack, a feeding and discharging mechanism and a material moving mechanism, wherein the feeding and discharging mechanism and the material moving mechanism are arranged on the rack; the feeding and discharging mechanism comprises a feeding assembly and a discharging assembly; the feeding assembly and the discharging assembly are arranged on a mechanism mounting plate side by side; the feeding assembly comprises a Y-axis linear module, a Y-axis linear guide rail and a lifting bracket; the Y-axis linear module can drive a lifting bracket to reciprocate along the Y-axis linear guide rail; the discharging assembly and the feeding assembly are the same in structure; and the material moving mechanism comprises a robot and a material suction jig connected with the robot. By adopting the automatic feeding and discharging equipment disclosed by the invention, automatic feeding and discharging can be achieved; manual operation is replaced; intelligent manufacturing is achieved; production efficiency is improved; one person can operate a plurality of devices, so manpower investment is reduced; in addition, the equipment runs stably; and product quality is effectively guaranteed.

Owner:XIAMEN HONGXIN ELECTRON TECH +1

Machining device for punching and taking materials synchronously

PendingCN109175077AFully automatedAccurate retrievingMetal-working feeding devicesMetal working apparatusPunchingEngineering

The invention discloses a machining device for punching and taking materials synchronously. A Y-axis moving frame can be horizontally and movably installed on a machine frame; a Y-axis driver assemblyis fixed on the machine frame and an output end of the Y-axis driver assembly is connected to the Y-axis moving frame, so that the Y-axis moving frame is horizontally moved on the machine frame; a picking assembly is installed on the Y-axis moving frame; a material sucking grabbing part and a punching grabbing part can be installed on the Y-axis moving frame in a lifting mode; a punching shaft can be mounted on a punching lifting base plate in a lifting mode; a punching seat is fixed at the bottom end of the punching shaft, and the punching shaft can penetrate through a punching passing hole;a material receiving sucker is arranged on the punching seat; the material receiving sucker is connected with vacuum; the punching grabbing part and the material sucking grabbing part are sequentially and horizontally arranged above the position of a machining table and then reset; the material sucking grabbing part and the punching grabbing part can be lifted up and down on the position where amold containing body is located; when the punching grabbing part is vertically close to the mold containing body, the punching shaft penetrates through the punching passing hole in the mold containingbody. According to the machining device, the device is used for grabbing and punching workpieces, and has the functions of full automation, accurate material taking, material placing and punching automation.

Owner:智鑫隆科技(广东)有限公司

Automatic prestressed clip combining and ring sleeving device

ActiveCN109551193ARealize automatic material sortingStable positionMetal working apparatusEngineeringManipulator

The invention discloses an automatic prestressed clip combining and ring sleeving device, which comprises an automatic clip feeding and combining mechanism, an O-ring feeding and sleeving mechanism, afinished product discharging manipulator and a four-station rotary tool platform. Through two vibrating feeding machines, half-piece clips are fed into slideways, the clips in the two-side slidewaysare in the combined state through a guide mechanism, and the clips are pushed to the middle position by push rod cylinders placed on the two sides, so that the clips are truly combined together, and the combined clip enters a clamp on the tool platform under the action of the self-gravity and pressure rod cylinders at the upper part; single O-rings are successively conveyed to ring taking groovesby the feeding machines, two-station ring taking jaws move one O-ring to the combined clip arranged in the clamp after taking the O-ring, and the leather ring sleeves a leather ring groove on the clip. A workbench is rotated, and rotation is performed once each time after a cycle (the whole process is finished). At the discharging station, the discharging manipulator takes out the clips sleeved with O-rings. The automatic prestressed clip combining and ring sleeving device successfully solves the technical difficulties about clip combining and how to feed the O-ring one by one, has high efficiency, good stability, ingenious equipment structure design and compact layout, and is suitable for popularization and use.

Owner:常州中科科创智能技术有限公司

Device for taking green ceramic chips layer by layer one by one

PendingCN113291792AAchieve separationEliminate environmental problemsConveyor partsMaterial storageStatic electricity

The invention discloses a device for taking green ceramic chips layer by layer one by one. The device comprises a material storage bin and a material taking paw X-direction shaft located above the material storage bin, wherein a material taking paw Z-direction shaft is installed on the material taking paw X-direction shaft, a mounting frame is arranged on a sliding base of the material taking paw Z-direction shaft, supporting plates are arranged on two sides of the mounting frame respectively, a first material sheet layer separation mechanism and a second material sheet layer separation mechanism are installed on two sides of the installation frame respectively, a first suction cup paw and a second suction cup paw are installed on the supporting plate respectively, and a compressed gas blowing nozzle and a blowing type static electricity eliminator are installed on the storage bin through a support. The problems of abnormal material taking, low material taking efficiency and the like caused by interlayer adhesion when the raw ceramic chips are taken layer by layer are solved, accurate and reliable material taking work of single raw ceramic chips is achieved, and the efficiency and accuracy of single raw ceramic chip taking are improved.

Owner:上海思恩装备科技股份有限公司

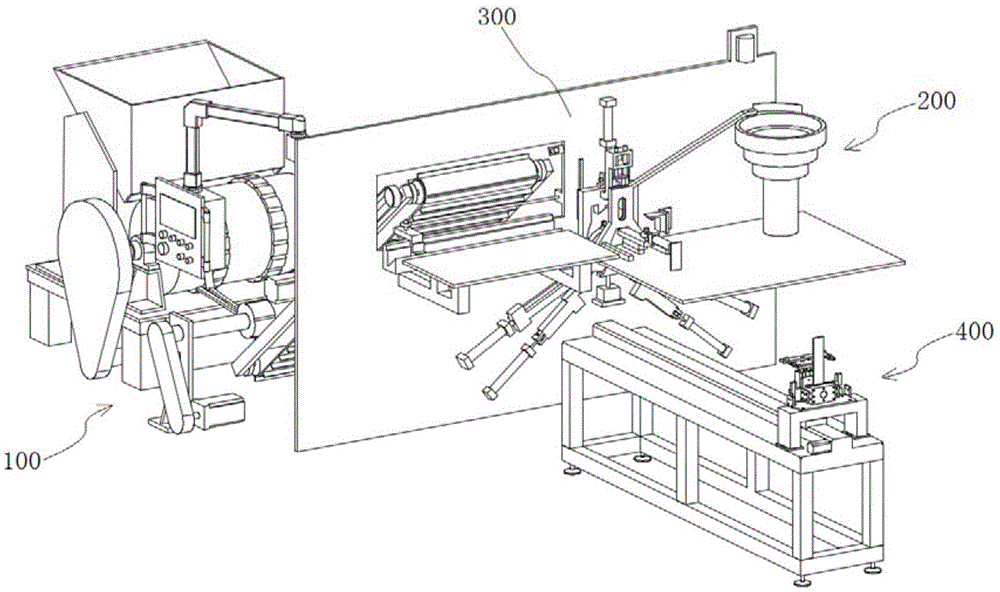

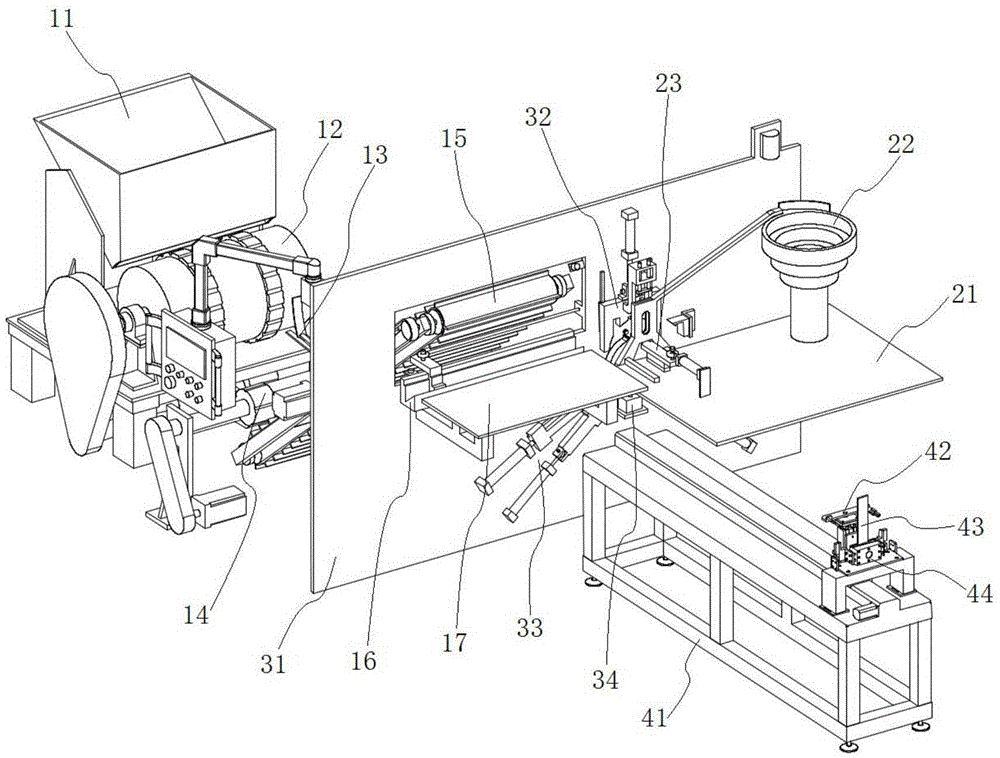

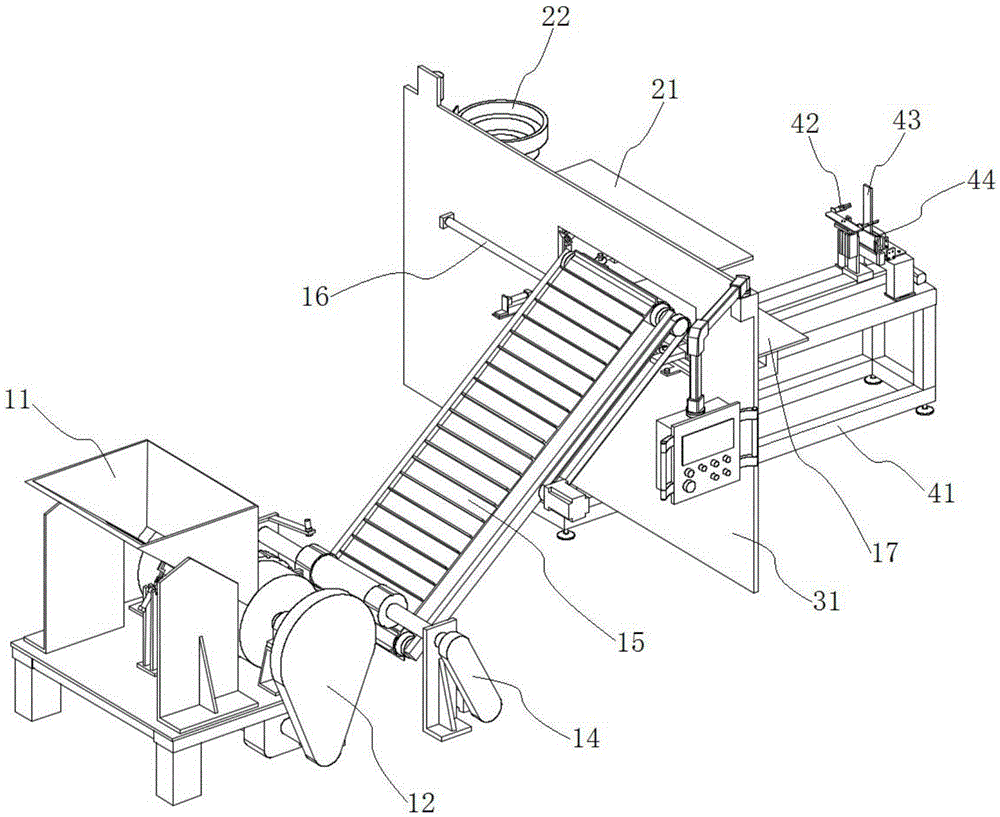

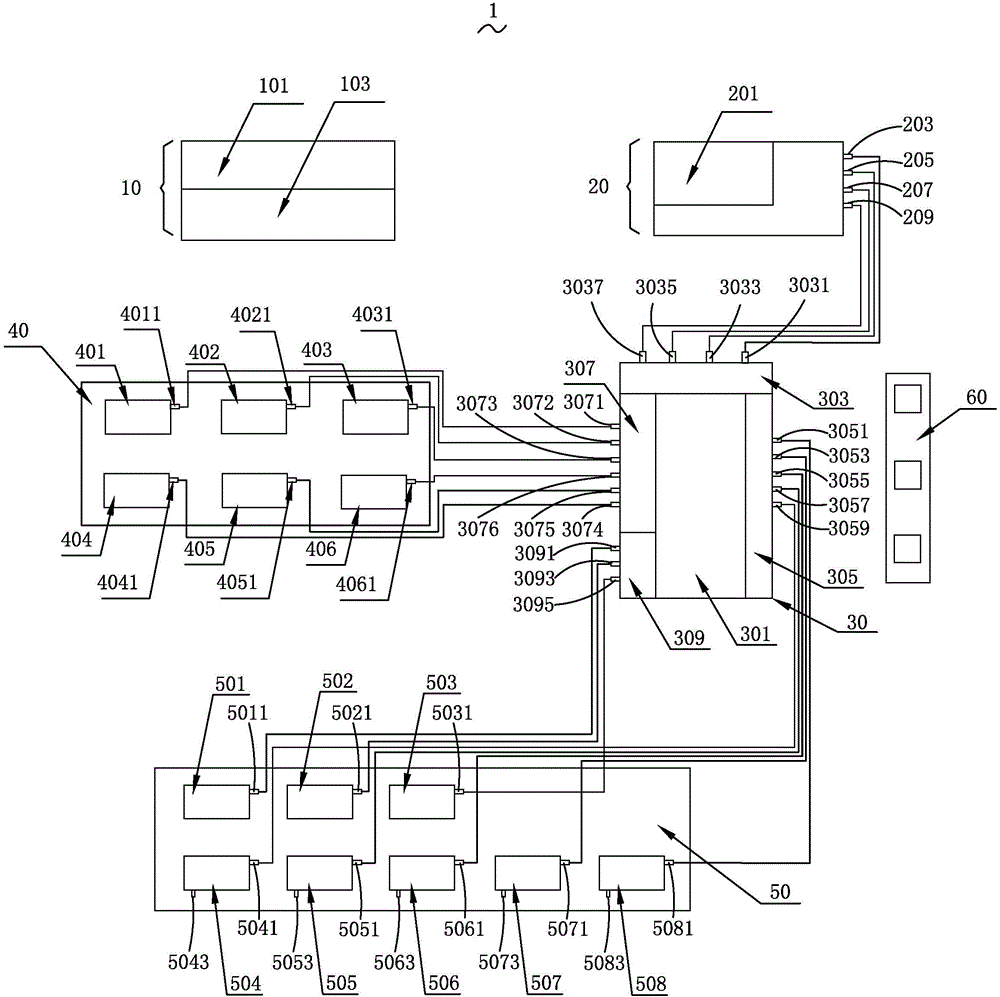

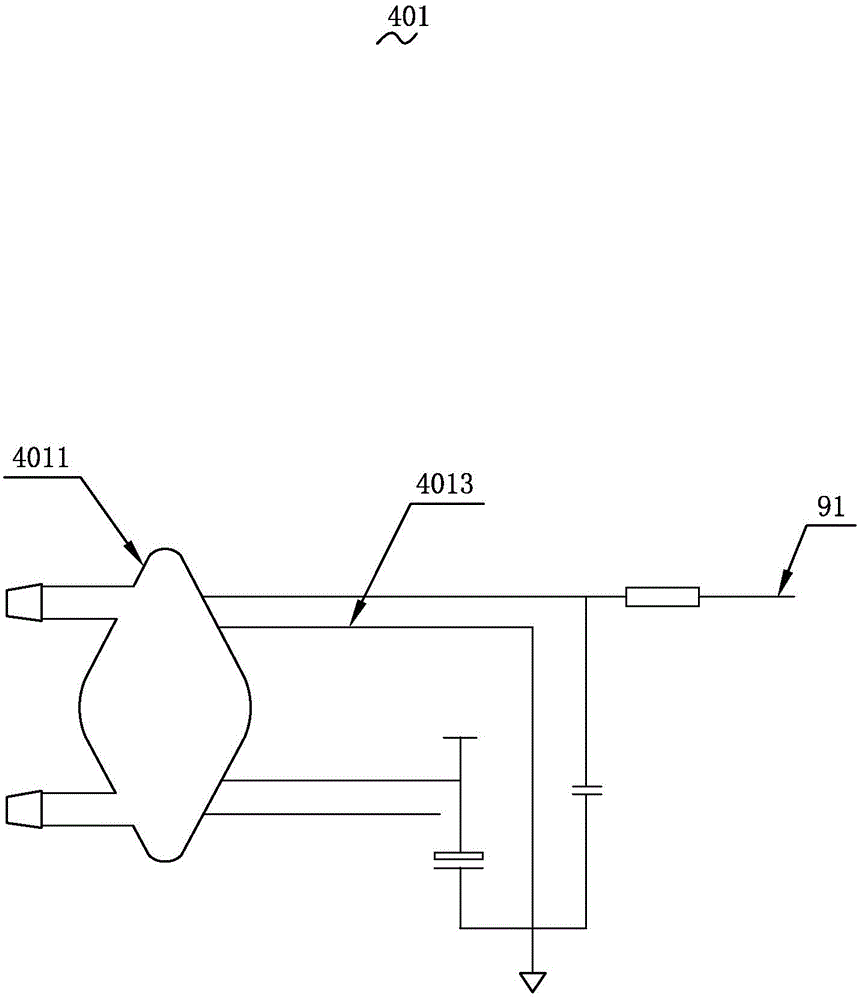

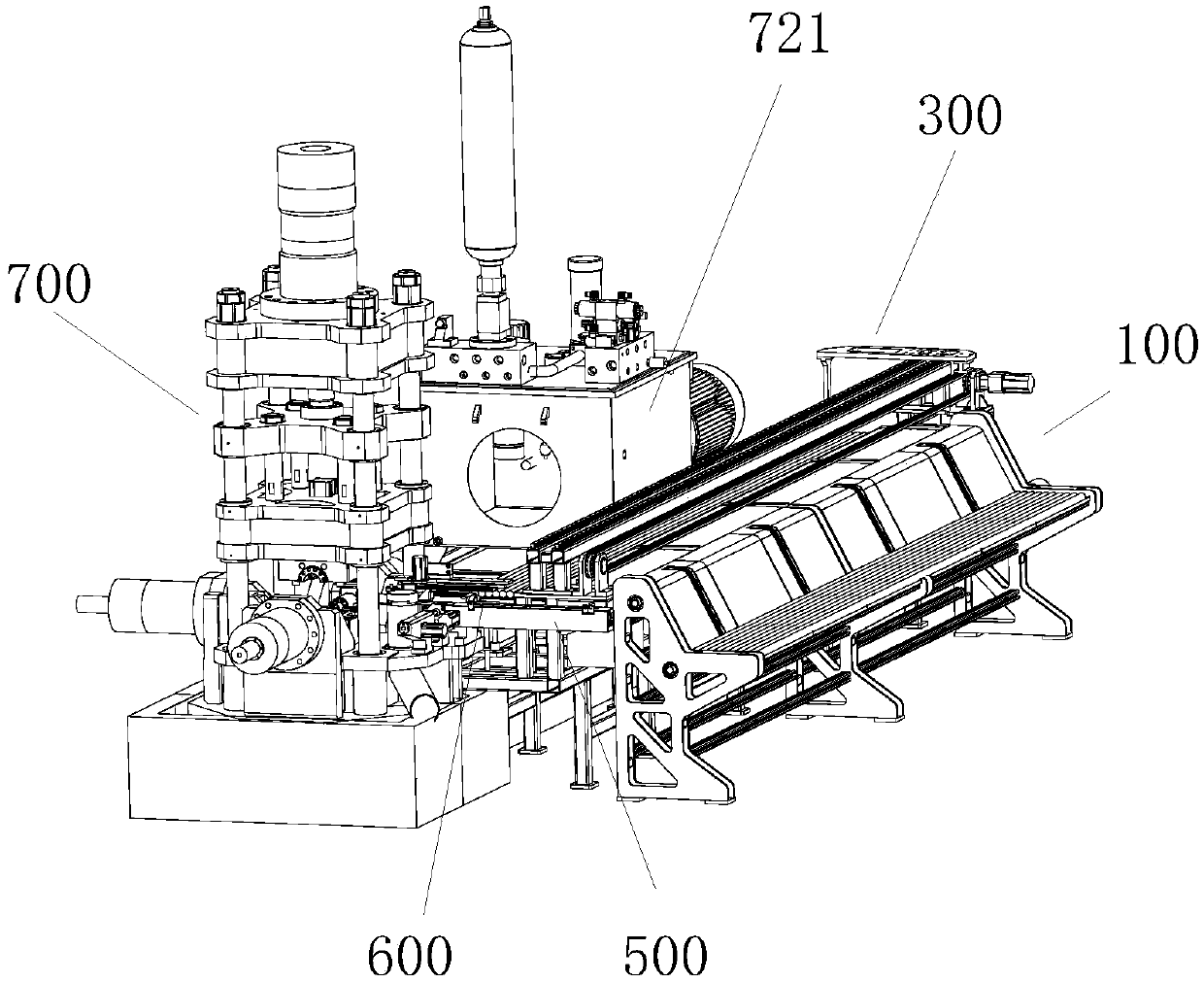

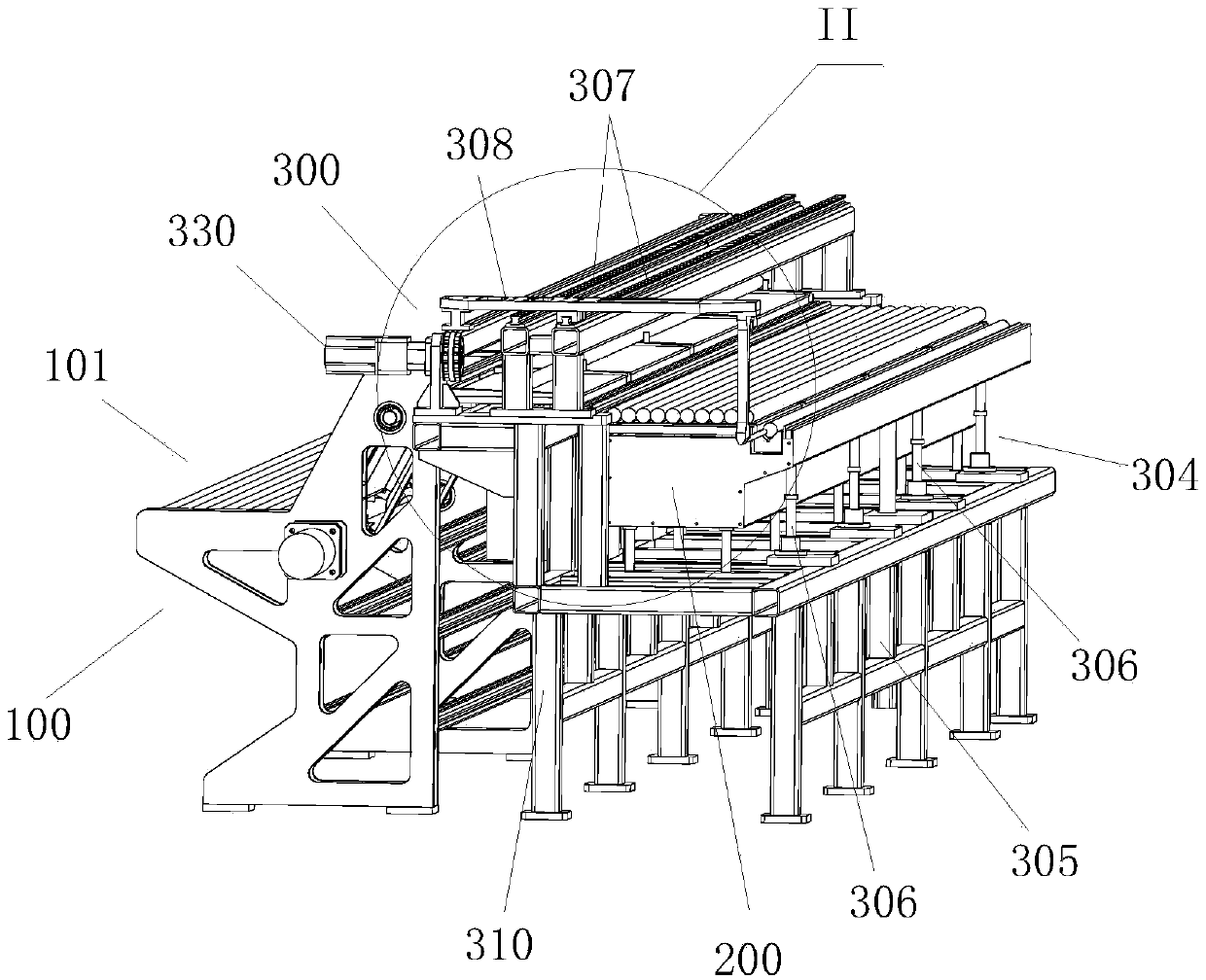

A bar processing control system

ActiveCN107983894BSmooth feedingPrecise feedingForging/hammering/pressing machinesHandling devicesMachine controlControl system

The invention relates to the field of rod automatic machining, and discloses a rod machining control system. The rod machining control system comprises a rod transportation system and a rod machiningsystem; the rod transportation system comprises a transportation device (100), a heating device (200), a feeding device (300) and a cutting device (400); copper rods are transported to the heating device (200) for heating through the transportation device (100), and them, are fed in the feeding device (300) for feeding; the transportation device (100) comprises a transportation platform (101) anda transportation mechanism; a transportation block (150) is driven through a transportation chain (106) to feed the copper rods from a lower support table (102) to an upper support table (103); the copper rods are fed in the rod machining system after passing through the heating device (200), the feeding device (300) and the cutting device (400); and workpiece manufacturing and automatic withdrawal are finished by a feeding manipulator (500), a machining mold (700) and a taking manipulator (600). The device is high in automation degree, stable in loading and machining and high in production efficiency.

Owner:叶腾斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com