System and method for controlling instant material taking quantity of bucket wheel machine

A technology of control system and bucket wheel machine, applied in general control system, control/regulation system, program control, etc., can solve the problem of low efficiency of reclaiming materials, and achieve the effect of efficient unmanned operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will be described in detail in conjunction with the embodiments of the present invention with reference to the accompanying drawings.

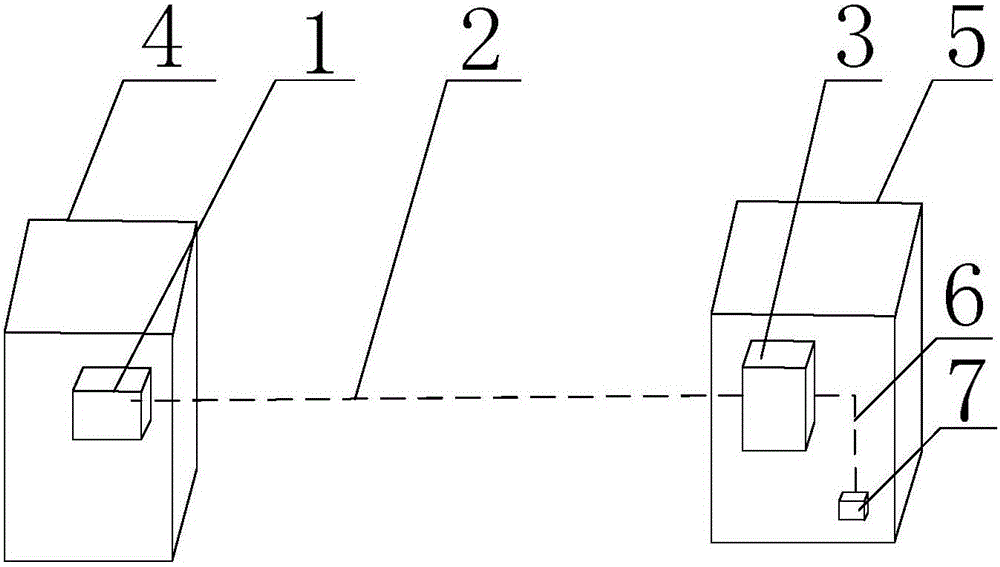

[0020] The control system of bucket wheel machine’s instantaneous feeding quantity, current data changing device 1, analog input module 3 and PLC processor 7, current data changing device 1 and analog input module 3 are connected through shielded signal cable 2, analog input The module 3 and the PLC processor 7 are connected through the communication device 6; the current data replacement device 1 is installed inside the high-voltage cabinet 4 of the bucket wheel motor of the reclaimer, and the analog input module 3 and the PLC processor 7 are installed in the PLC control inside of cabinet 5;

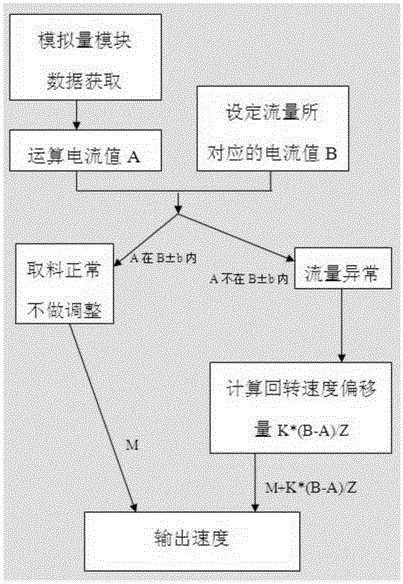

[0021] The current data replacement device 1 converts the current data of the bucket wheel motor of the reclaimer into analog data, and the shielded signal cable 2 transmits the analog data to the analog input module 3; the analog i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com