An automatic pick-and-feed hydraulic rubber extrusion molding machine

An extrusion molding machine and automatic technology, which is applied in the field of automatic feeding and feeding hydraulic rubber extrusion molding machines, can solve problems such as burns, and achieve the effects of convenient repair, smooth transmission, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

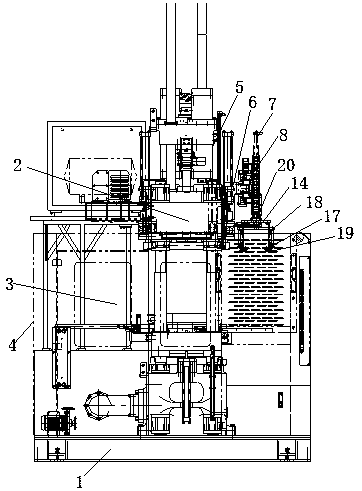

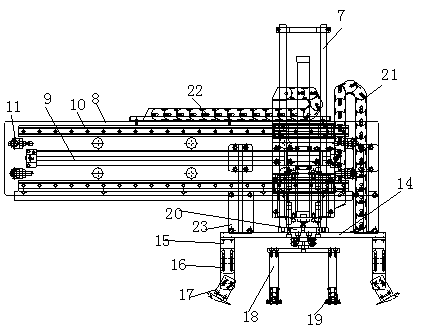

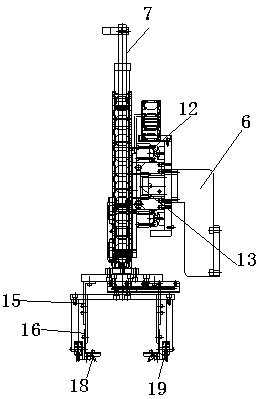

[0022] Example 1, such as figure 1 , 2 , shown in 3, a kind of hydraulic rubber extruding molding machine of automatic pick-and-feed type is characterized in that: comprise machine base 1, the oil pressure supply structure on machine base 1, the upper part of oil pressure supply structure is provided with mold forming unit 2. A material preparation structure is provided on the upper part of the mold forming unit 2, an upper driving mechanism is provided on the upper part of the material preparation structure, and an electric control operating system 3 and an outer cover 4 are also provided on the machine base;

[0023] The upper support column 5 of the material preparation structure is provided with a robot automatic feeding device; The movable plate is provided with a multi-directional adjustment seat structure in the longitudinal movable plate, and the vertical telescopic cylinder 7 is connected to the multi-directional adjustment seat structure, and the lower end of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com