An automatic clamping and conveying device for the underbody of a vehicle body

A technology for handling devices and underbody panels, which is applied in transportation, packaging, motor vehicles, etc., and can solve problems such as cuts, hidden dangers of employees, lagging production line requirements, ergonomic injuries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

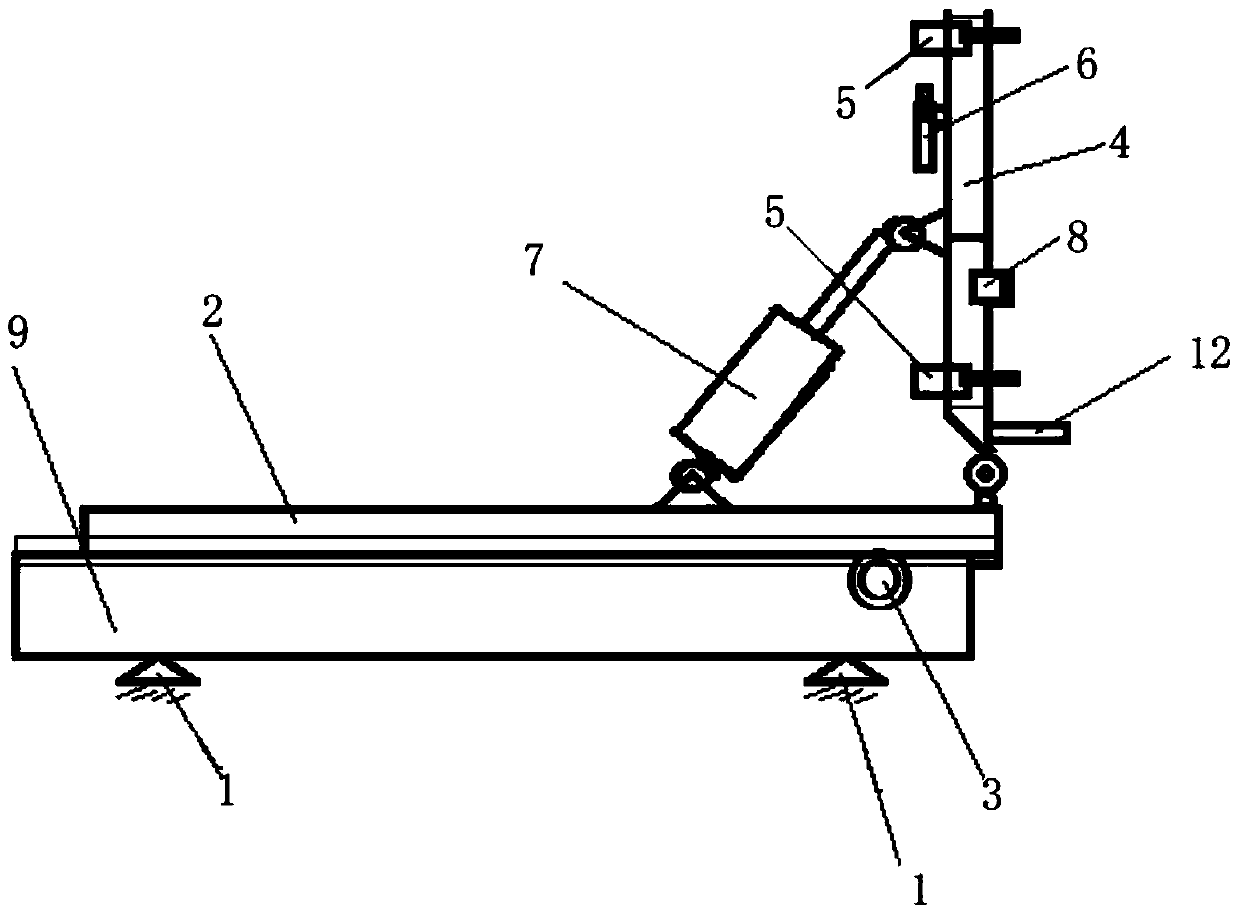

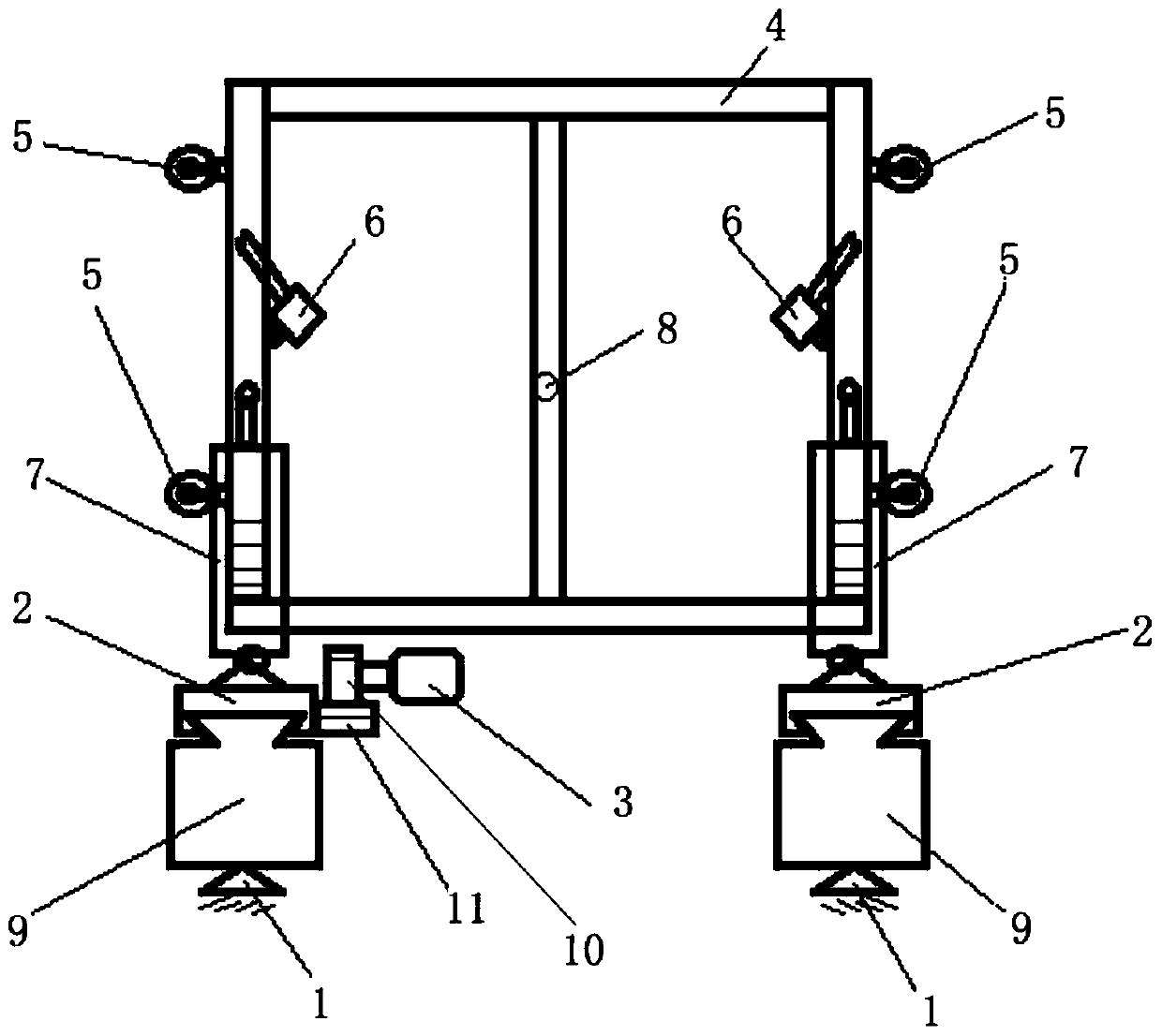

[0023] The following with attached Figure 1 to Figure 2 An automatic clamping and conveying device for the vehicle body bottom plate of the present invention will be further described in detail.

[0024] A kind of automatic clamping and handling device for vehicle body bottom plate of the present invention, please refer to Figure 1 to Figure 2 , comprising a base 1 and two moving guide rails 2 slidingly arranged on the base 1, the moving guide rails 2 are connected with a mobile driving device, the main support 4 is erected on the two moving guide rails 2, and the main support 4 The left and right ends of the bottom are respectively rotatably connected to the rear ends of the two moving guide rails 2, the main support 4 is connected to the rotary drive device, and at least two clamping devices 5 are arranged on the left and right sides of the rear side of the main support 4, The left and right sides of the main bracket 4 are respectively provided with block release devices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com