An automatic on-line equipment for structural layers of assembled composite panels

A composite board and automatic on-line technology, applied in the direction of lamination, lamination system, layered products, etc., can solve the problems of prolonging the construction period, increasing the burden on the environment, delaying the construction process, etc., and achieve the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

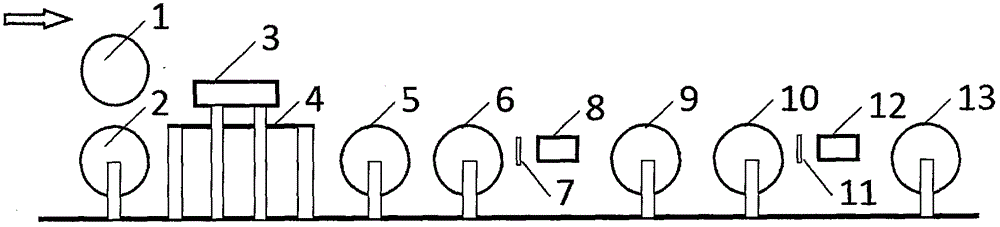

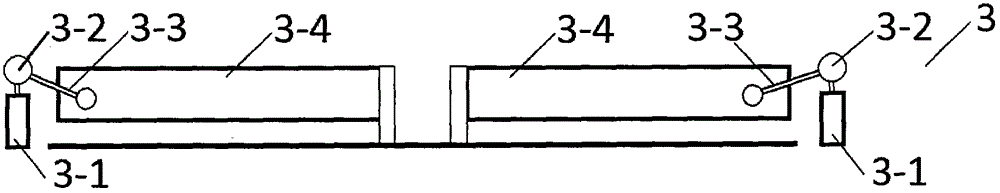

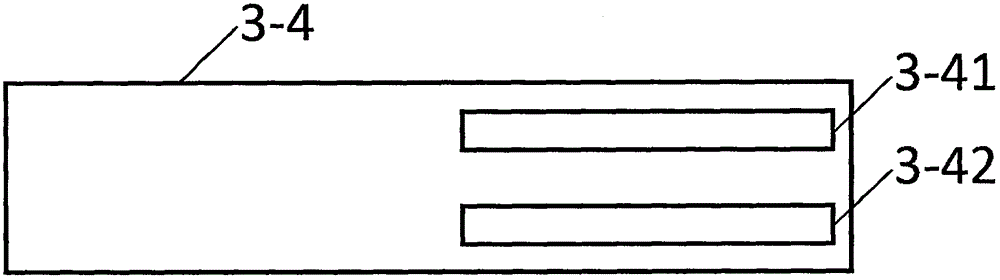

[0025] like figure 1 As shown, an automatic on-line equipment for the structural layer of assembled composite panels, which includes an equipment driving mechanism, and is arranged along the conveying direction of the structural layer: a pair of pressure rollers, a pair of sizing machines 3 and a metal fence 4 below them, Conveying roller 5, conveying roller 6, photosensitive head 7, a pair of swing arm 8, conveying roller 9, conveying roller 10, photosensitive head 11, a pair of swing arm 12, conveying roller 13; Wherein, pressure roller comprises upper pressure roller 1 and The lower pressure roller 2, each sizing machine 3 includes a shaking motor 3-1, a rotating disk 3-2, a rocking arm 3-3 and a gluing box 3-4, and each swing arm includes a swing arm horizontal section 8-11, a swing arm Arm inclined section 8-12, support point 8-2, hinge point 8-3 and telescopic cylinder 8-4; the upper pressing roller is divided into left and right parts, between the two parts is the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com