Cover tightening mechanism for insulation bottle production

A thermos bottle and cap cover technology, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy shaking of the bottle body and bottle cap, poor tightening effect, and affecting the quality of the thermos bottle. , to achieve the effect of wide coordination, simple structure and good docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

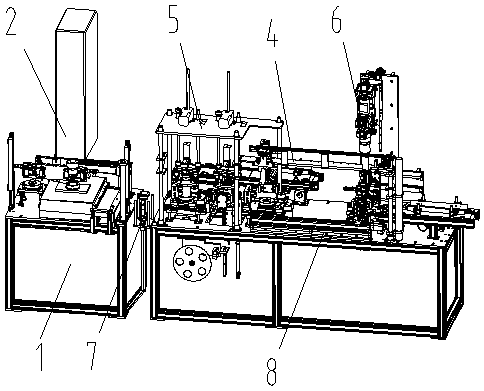

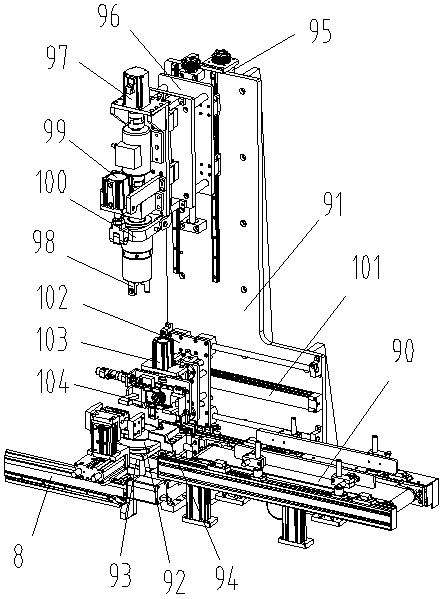

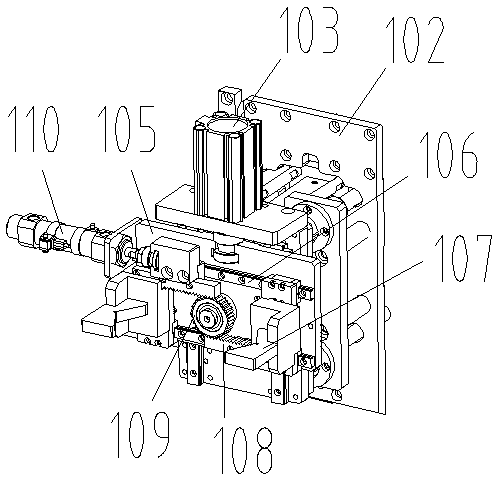

[0042] Such as Figure 1-Figure 12 As shown, the specific structure of the present invention is: a kind of cap tightening mechanism that is used for thermos bottle production, and it comprises power distribution control box 1, and described power distribution control box 1 is provided with feeding device, from left to right, Covering device 5 and screwing device 6, described feeding device 7 comprises feeding lifting cylinder 46 and feeding lifting seat 47, and feeding device 7 cooperates with cover device 5 through taking-off device 4, described sleeve The cover device 5 cooperates with the screwing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com