Fine dried noodle tabletting equipment

A technology of sheeting and equipment, which is applied in the directions of dough sheeting machine/rolling machine/rolling pin, dough processing, baking, etc. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

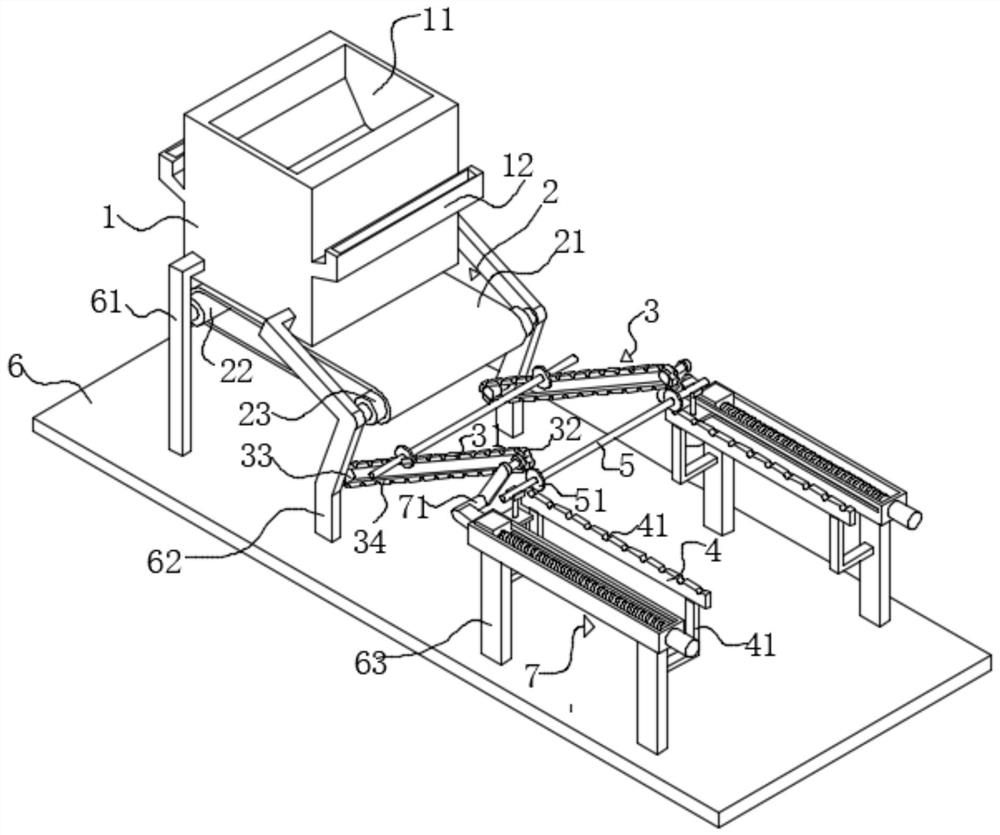

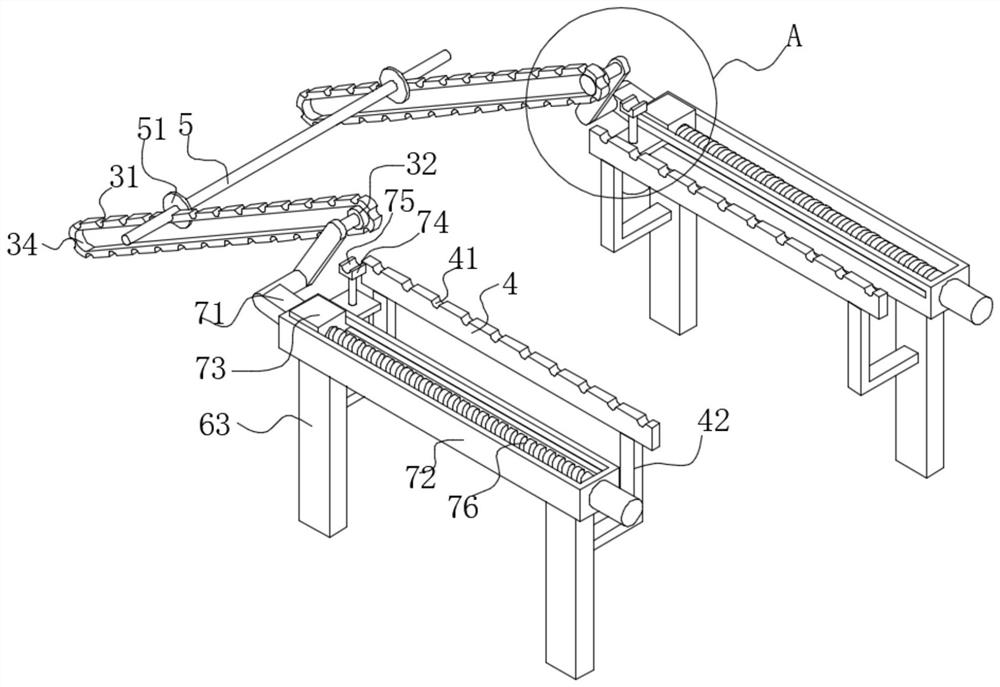

[0026] see figure 1 , the present embodiment, a kind of dried noodle tabletting equipment, comprises frame 6, the tabletting box 1 that is arranged on frame 6, the conveying mechanism 2 that is arranged at the bottom of tabletting box 1, the transshipment mechanism that is arranged at the end of conveying mechanism 2 3. The hanging rod frame 4 arranged at the end of the transfer mechanism 3, and the hanging rod 5 for hanging the noodles.

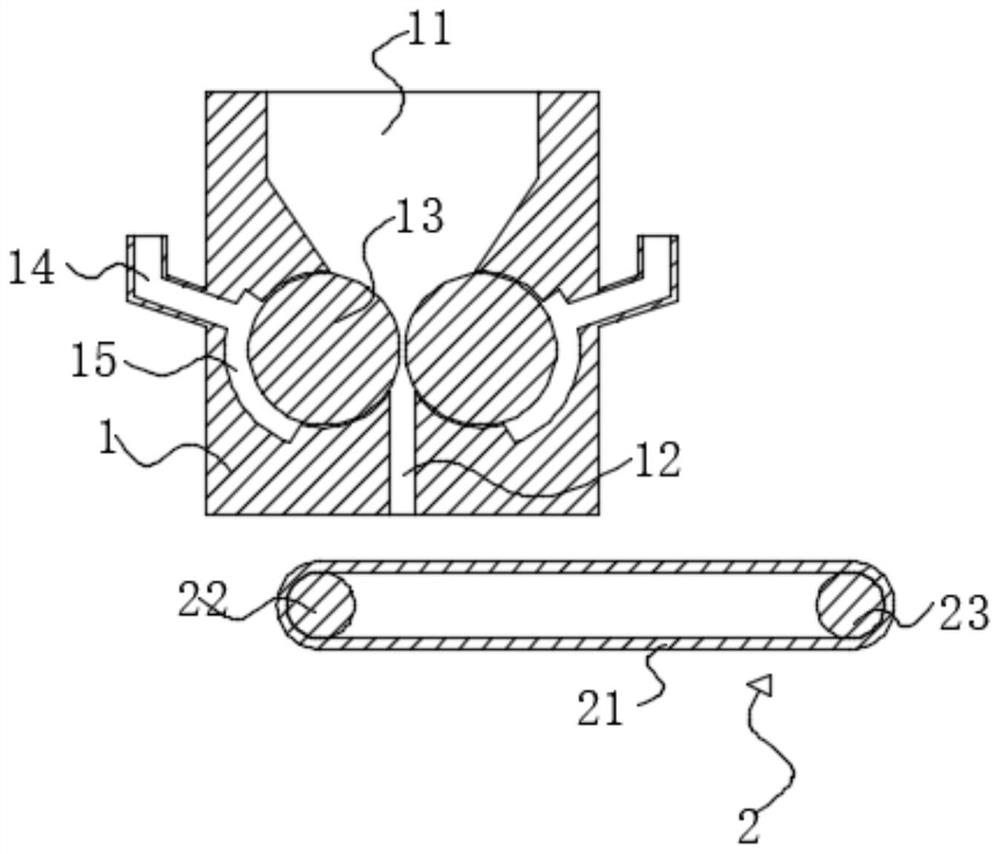

[0027] Participate figure 2 , in this embodiment, the tablet pressing box 1 is fixedly installed on the base through the first bracket 61 and the second bracket 62, and the tablet pressing box 1 has a top opening and a substantially funnel-shaped hopper 11, the hopper 11 For placing the dough, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com