Municipal garbage treating device

A processing device and municipal waste technology, applied in grain processing, transportation and packaging, presses, etc., can solve the problems of odor, harm to organisms, difficult to squeeze, etc., to prevent the spread of odor, long service life, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

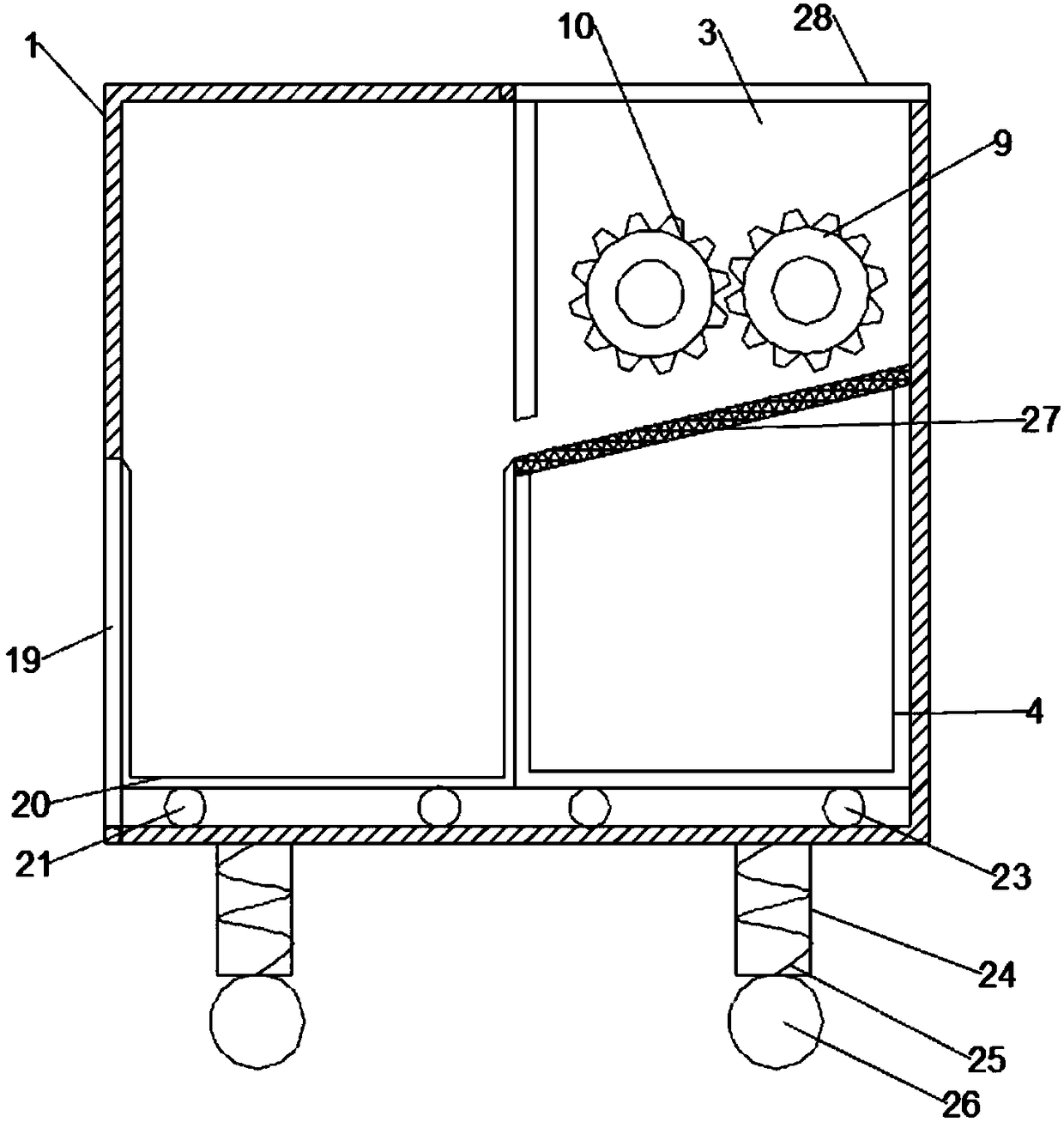

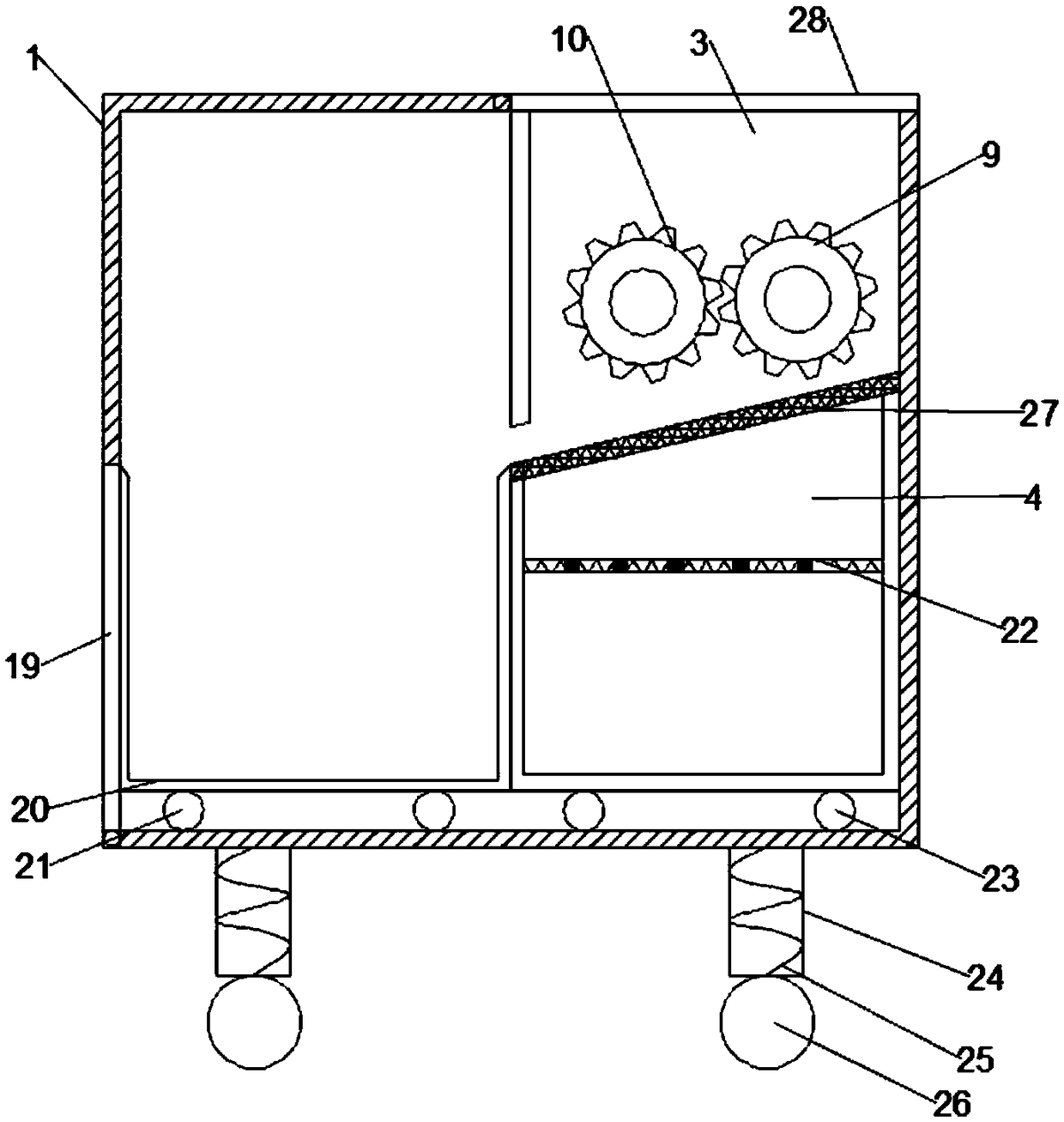

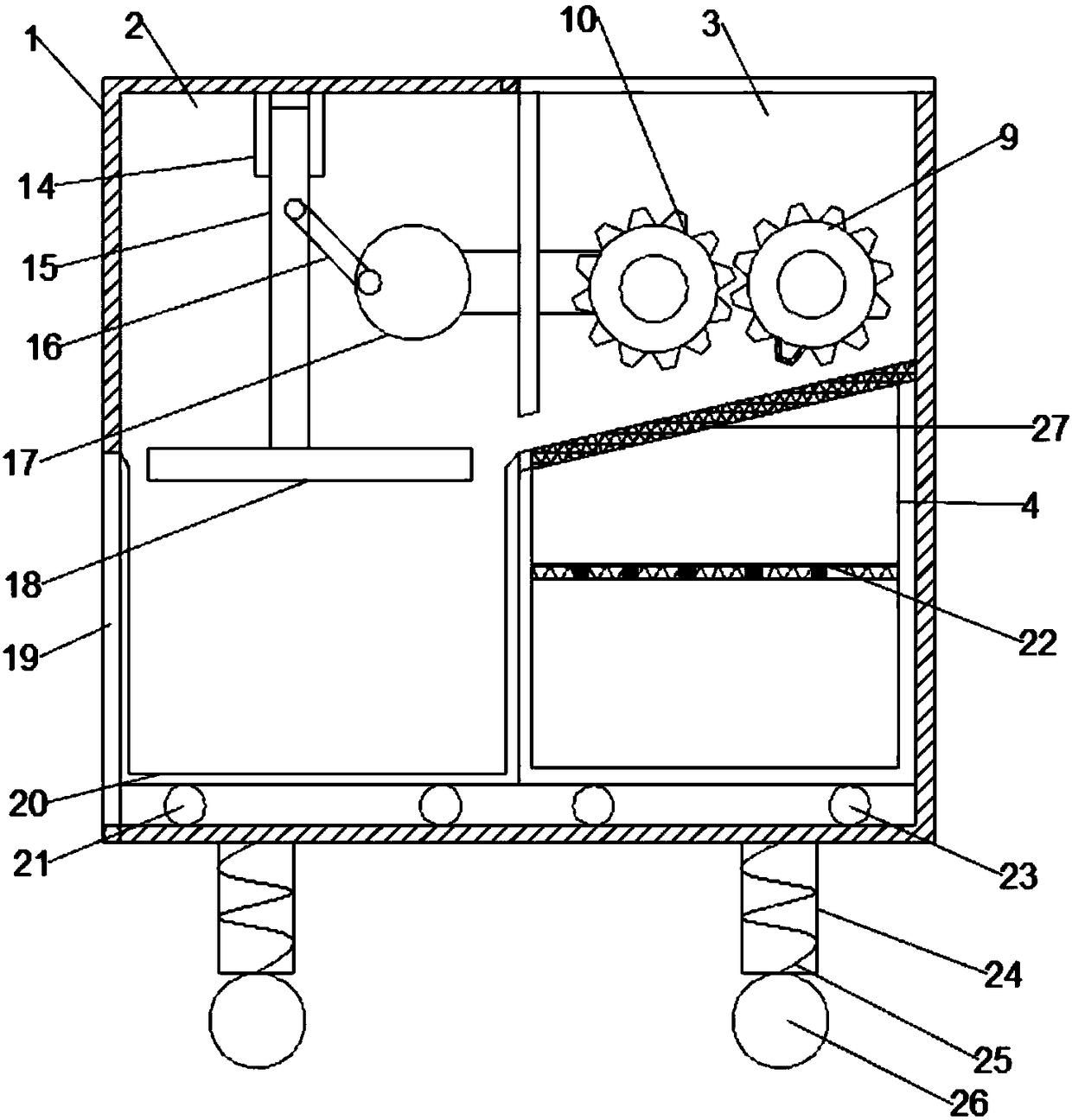

[0024] see Figure 1~5 , in an embodiment of the present invention, a municipal waste treatment device includes a device main body 1, a crushing area 3, a first collection vehicle 4 and a second collection vehicle 20, and the top right end of the device main body 1 is provided with a second hinged door 28 , the length of the second hinged door 28 is the same as the length of the top of the crushing area 3, and the upper right side of the inside of the device main body 1 is provided with a crushing area 3, and the inner surface of the rear wall of the crushing area 3 is closer to that of the device body 1. A motor 5 is fixedly connected under the top, and a second crushing roller 10 is fixedly connected to the front end of the output shaft of the motor 5. The right side of the second crushing roller 10 is provided with a first crushing roller 9 that meshes with each other. The width of crushing roller 10 and the first crushing roller 9 are all the same as the width of the secon...

Embodiment 2

[0026] see Figure 1~5, in an embodiment of the present invention, a municipal waste treatment device includes a device main body 1, a crushing area 3, a first collection vehicle 4 and a second collection vehicle 20, and the top right end of the device main body 1 is provided with a second hinged door 28 , the length of the second hinged door 28 is the same as the length of the top of the crushing area 3, and the upper right side of the inside of the device main body 1 is provided with a crushing area 3, and the inner surface of the rear wall of the crushing area 3 is closer to that of the device body 1. A motor 5 is fixedly connected under the top, and a second crushing roller 10 is fixedly connected to the front end of the output shaft of the motor 5. The right side of the second crushing roller 10 is provided with a first crushing roller 9 that meshes with each other. The width of crushing roller 10 and the first crushing roller 9 are all the same as the width of the second...

Embodiment 3

[0029] see Figure 1~5 , in an embodiment of the present invention, a municipal waste treatment device includes a device main body 1, a crushing area 3, a first collection vehicle 4 and a second collection vehicle 20, and the top right end of the device main body 1 is provided with a second hinged door 28 , the length of the second hinged door 28 is the same as the length of the top of the crushing area 3, and the upper right side of the inside of the device main body 1 is provided with a crushing area 3, and the inner surface of the rear wall of the crushing area 3 is closer to that of the device body 1. A motor 5 is fixedly connected under the top, and a second crushing roller 10 is fixedly connected to the front end of the output shaft of the motor 5. The right side of the second crushing roller 10 is provided with a first crushing roller 9 that meshes with each other. The width of crushing roller 10 and the first crushing roller 9 are all the same as the width of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com