Patents

Literature

56results about How to "Guaranteed normal whereabouts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

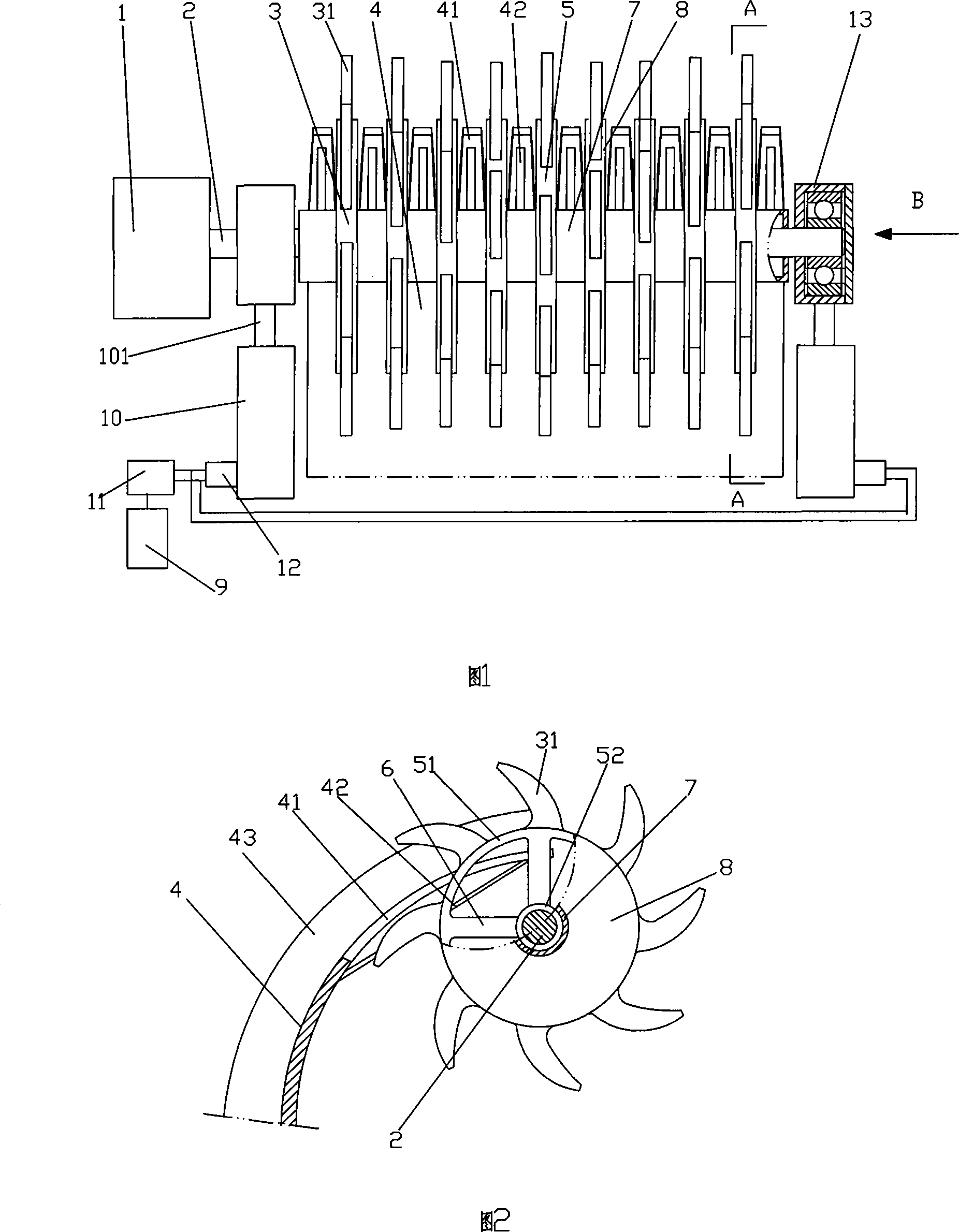

Device for cleaning waters floating material

The invention discloses a water area flotage cleaning device, which comprises a power device, a catcher, a separator and a flotage processing and recycling device, wherein the catcher comprises a rotary shaft and at least one catching gear, the power device matches with the rotary shaft to drive the rotary shaft, the catcher gear is arranged relative to the rotary shaft radial direction and is fixed and matched with the rotary shaft, the separator and the non-rotary part of the catcher are relatively fixed, the separator is arranged from the upper side to the lower side, the upper side is set in a comb gear shape, the comb gear shape is composed of at least two separating gears arranged in axial direction, the adjacent separate gears are arranged on both sides of the catcher gear with a gap to the catcher gears. The invention has simple and compact structure, high mechanic degree, small energy consumption, short flow, small occupancy area, easy operations, high work efficiency, environment protection property, convenient maintenance, simple process, and can maximally save labors, resources and process cost.

Owner:CHONGQING UNIV

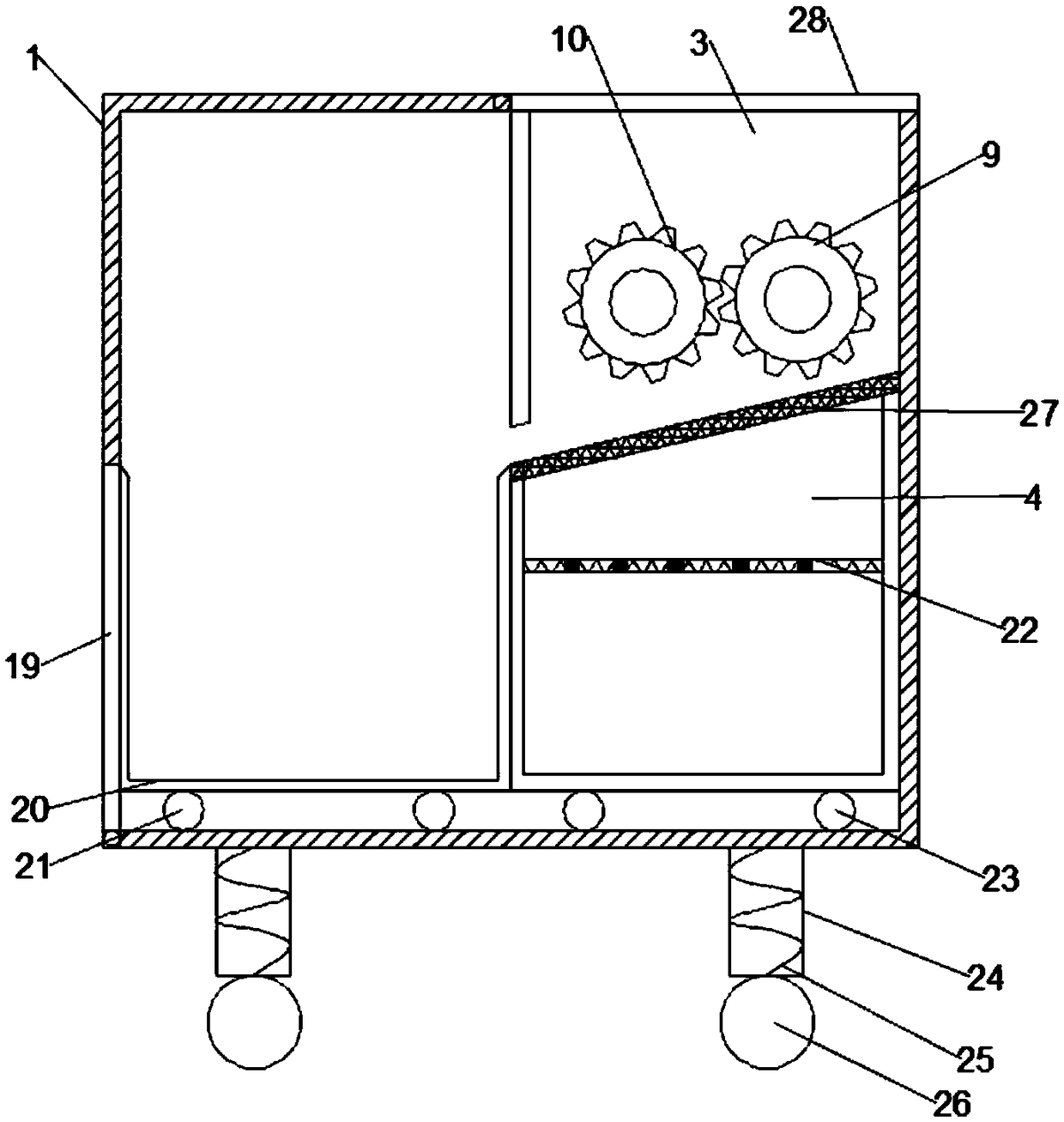

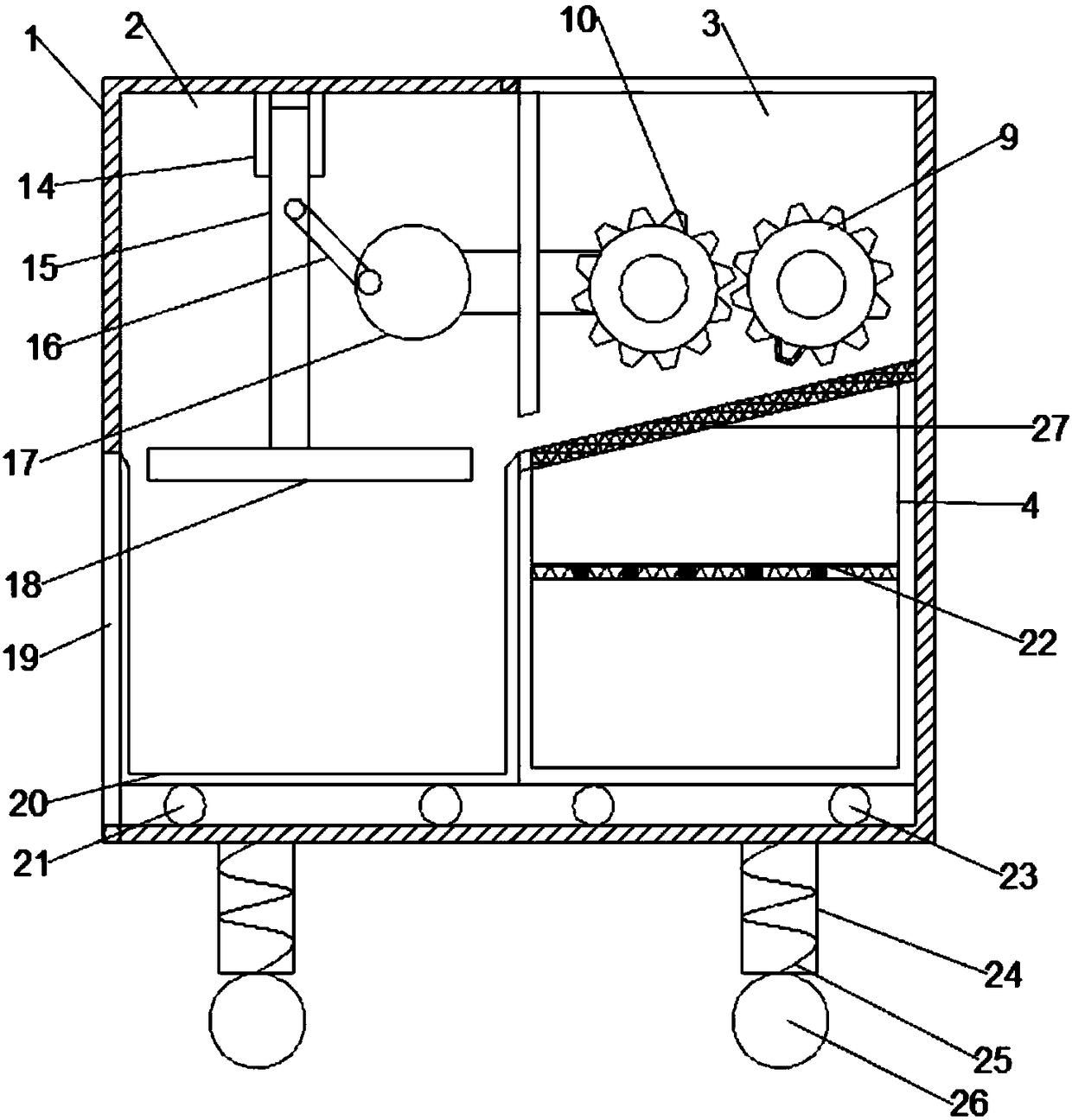

Municipal garbage treating device

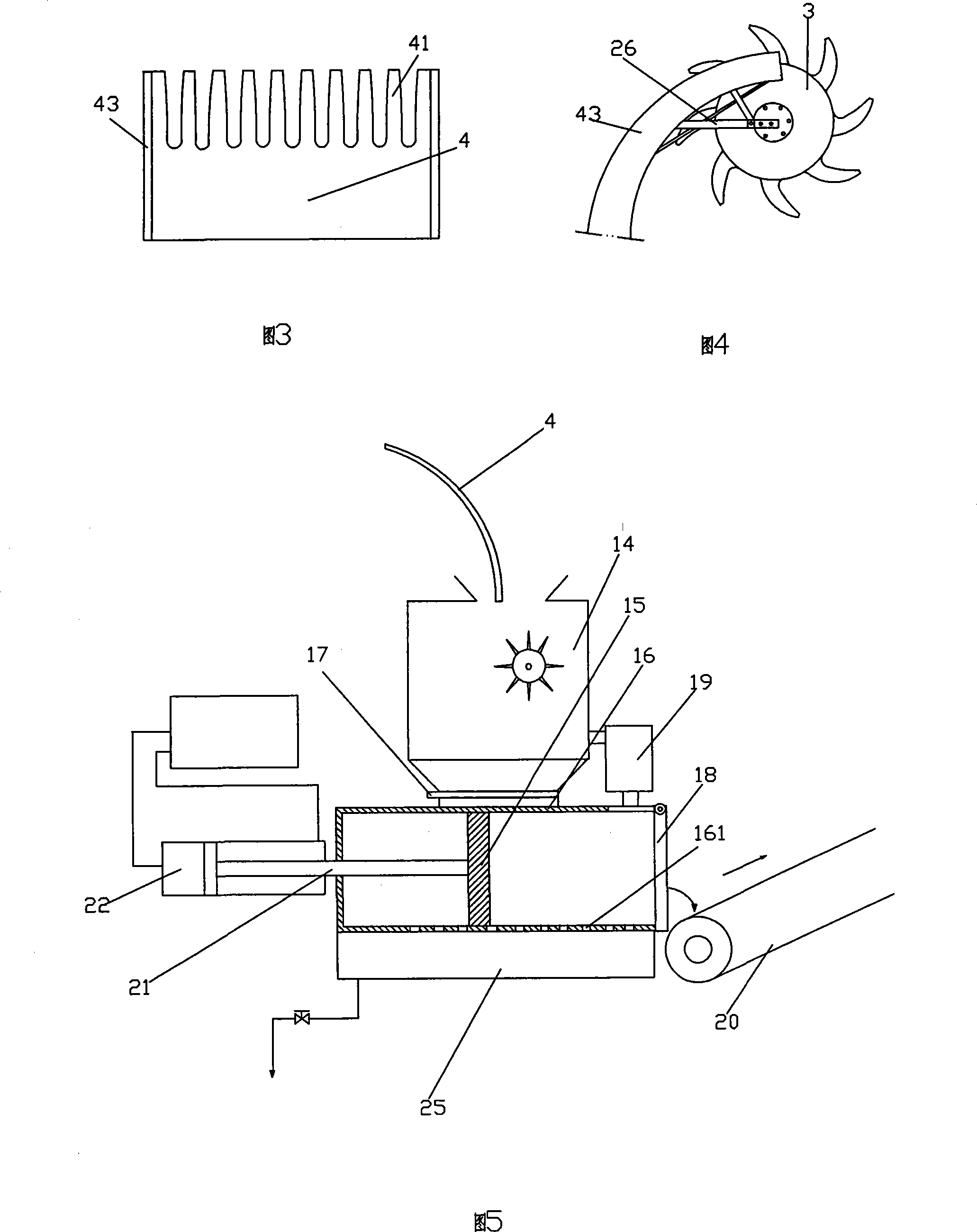

InactiveCN109174900APrevent proliferationPlay a role of buffer protectionSolid waste disposalTransportation and packagingSolid particleEngineering

The invention discloses a municipal garbage treating device. The device comprises a device main body, a pulverizing area, a first collecting vehicle and a second collecting vehicle, wherein a motor isfixedly connected on the inner surface, which is below the top of the device main body, of the rear wall of the pulverizing area; a second pulverizing roller is fixedly connected at the front end ofan output shaft of the motor; a first pulverizing roller meshed with the second pulverizing roller is arranged at the right side of the second pulverizing roller; a first isolating plate is arranged below the pulverizing area; the first collecting vehicle is placed below the first isolating plate; the second collecting vehicle is arranged at the left side of the first collecting vehicle; and a first driving wheel which is fixedly connected on the output shaft of the motor and arranged at the rear side of the second pulverizing roller is connected with a second driving wheel via a conveyor belt. The device disclosed by the invention has the advantages that the device has a simple structure and various functions; garbage in the second collecting vehicle can be squeezed to separate solid particles from liquid; primary treatment is carried out on the liquid; and the device is convenient to move.

Owner:YANCHENG BILLION CONNAUGHT MACHINERY CO LTD

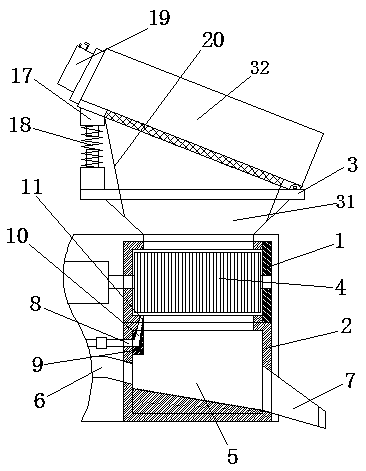

Filtering device for pharmaceutical equipment

ActiveCN113332782AEffective toggleGuaranteed filtering effectMoving filtering element filtersMarine engineeringStructural engineering

The invention discloses a filtering device for pharmaceutical equipment, and belongs to the technical field of pharmaceutical equipment. The filtering device comprises a shell for filtering medicines; and multiple vibration cleaning assemblies which are used for improving the cleaning effect of the filtering structure are installed in the shell. According to the invention, the screw stabilizing assembly is arranged inside, so the condition of motion eccentricity of the lifting screw caused by long-term work can be effectively avoided, and a good rotation effect of the threaded rotary drum matched with the screw stabilizing assembly is ensured; meanwhile, vibration can be effectively conducted into the vibration dredging shaft through the flexible vibration guide rubber, and the vibration dredging shaft can vibrate, so the design is ingenious; on one hand, the flexible vibration guide rubber can effectively reduce vibration of the stable sleeve and guarantee the using effect of the stable sleeve; on the other hand, vibration can be effectively utilized, the vibration dredging shaft of vibration can effectively dredge the interior of the feeding pipe, blockage in the feeding pipe is avoided, unavoidable invalid vibration can be utilized, waste is turned into wealth, and the use effect is improved.

Owner:南通灵德制药设备有限公司

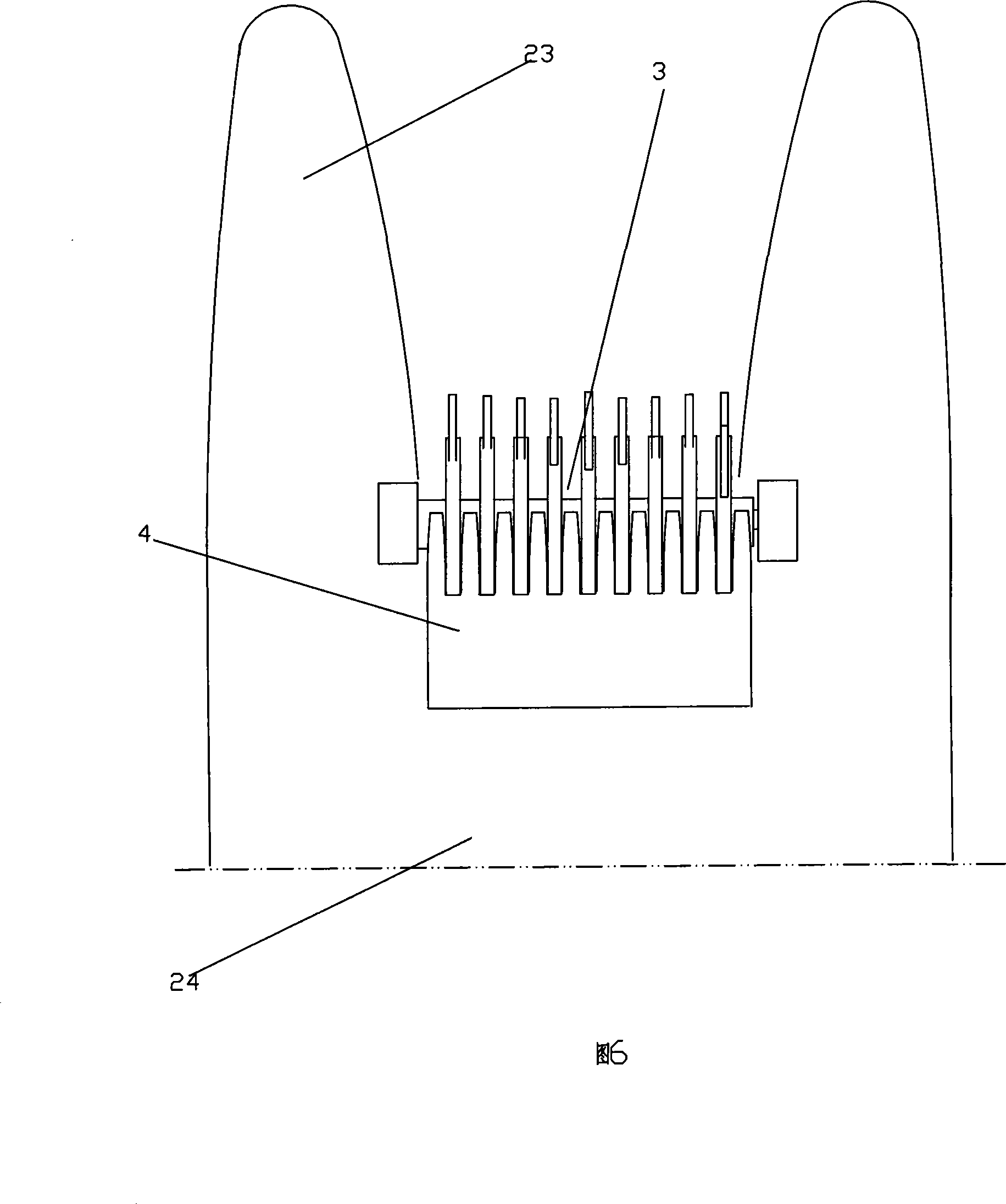

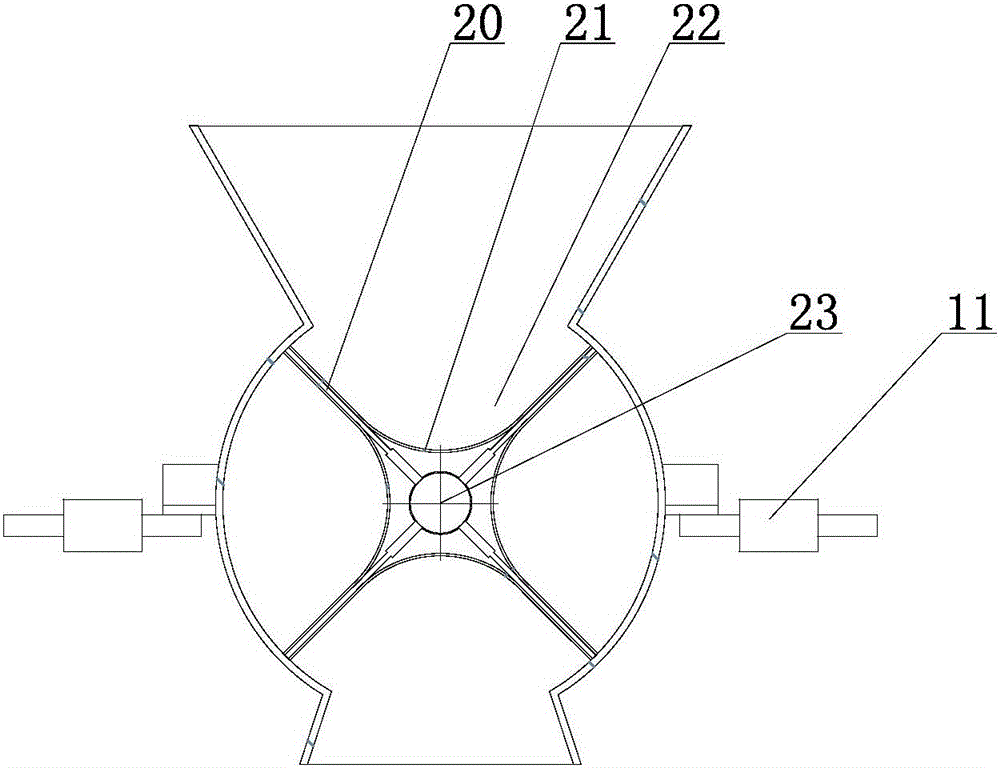

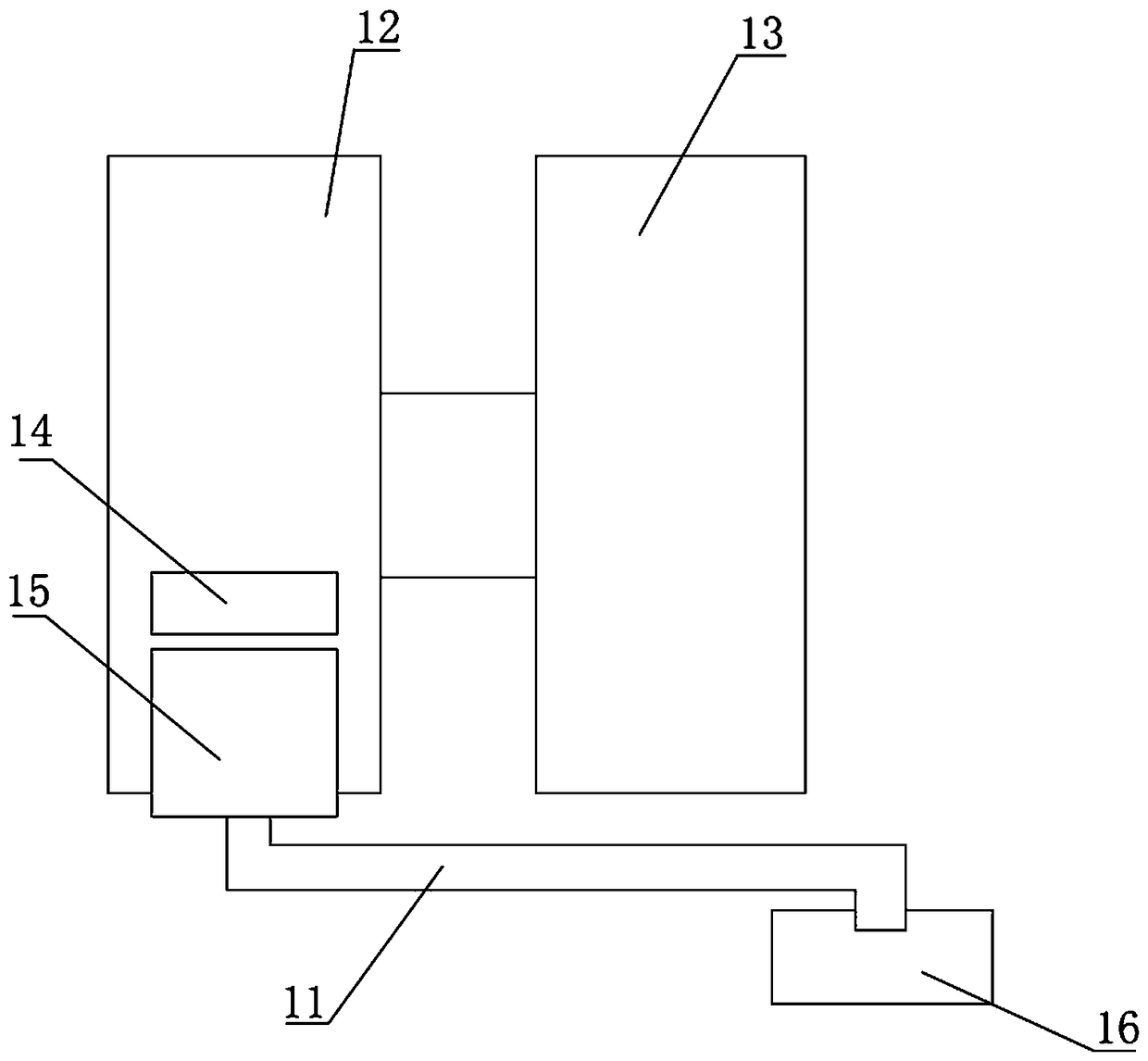

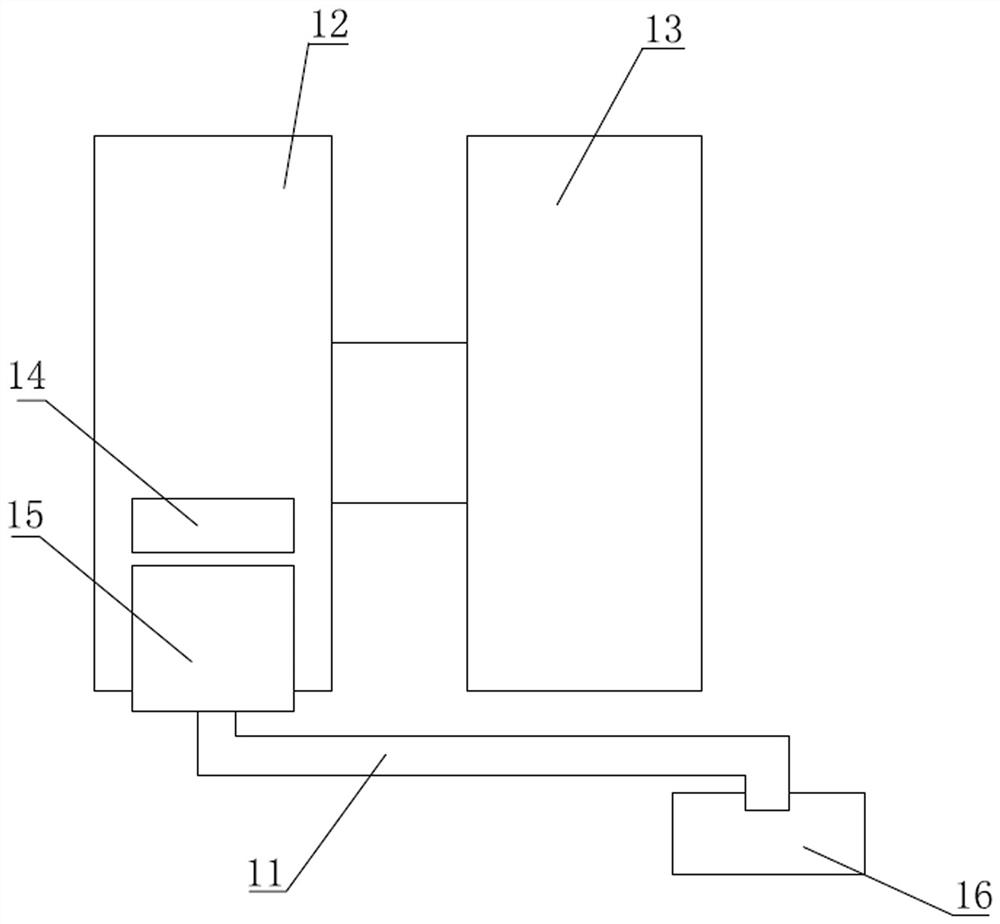

Fully-automatic equal-weight powder distribution system

InactiveCN106738277AGuaranteed weighing accuracyEnsure consistencyFeeding arrangmentsDistribution systemFully automatic

The invention mainly relates to production equipment for refractory bricks, in particular to a fully-automatic equal-weight powder distribution system. The fully-automatic equal-weight powder distribution system comprises a rack, a raw material bin, an automatic weighing material bin and a mold material distribution bin, wherein the raw material bin, the automatic weighing material bin and the mold material distribution bin are mounted on the rack from top to bottom. A feeding auger is arranged at the bottom inside the raw material bin. The discharging end of the feeding auger penetrates out of the raw material bin with an outlet facing downwards. The outlet directly faces a feeding opening of the automatic weighing material bin. The mold material distribution bin is connected with a displacement mechanism and can move in the horizontal direction under the action of the displacement mechanism. When the mold material distribution bin moves to the position below the automatic weighing material bin, a feeding opening of the mold material distribution bin directly faces a discharging opening of the automatic weighing material bin. The automatic weighing material bin and the mold material distribution bin can be opened and closed automatically. By means of the fully-automatic equal-weight powder distribution system, weight consistency of powder used for producing the refractory bricks through pressing can be guaranteed each time, and thus consistency of finished products is controlled; and meanwhile, dust of the powder can be controlled, labor intensity of workers can be lowered, and labor cost can be saved.

Owner:淄博桑德机械设备有限公司

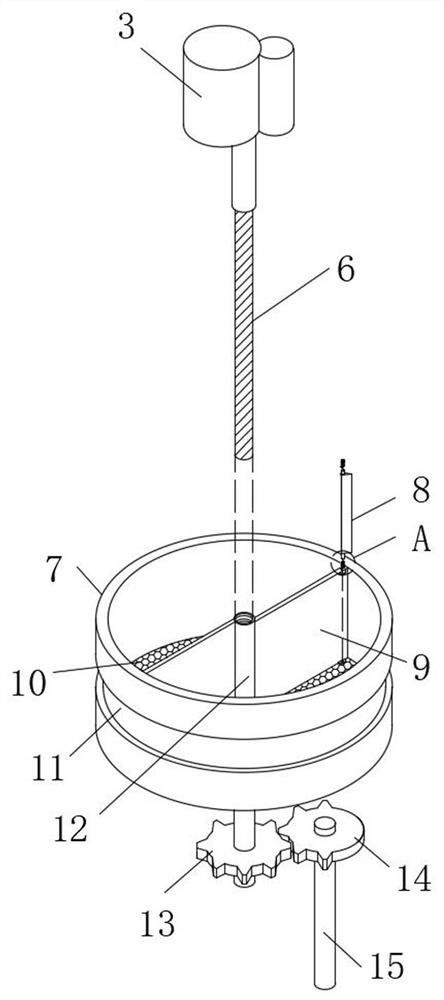

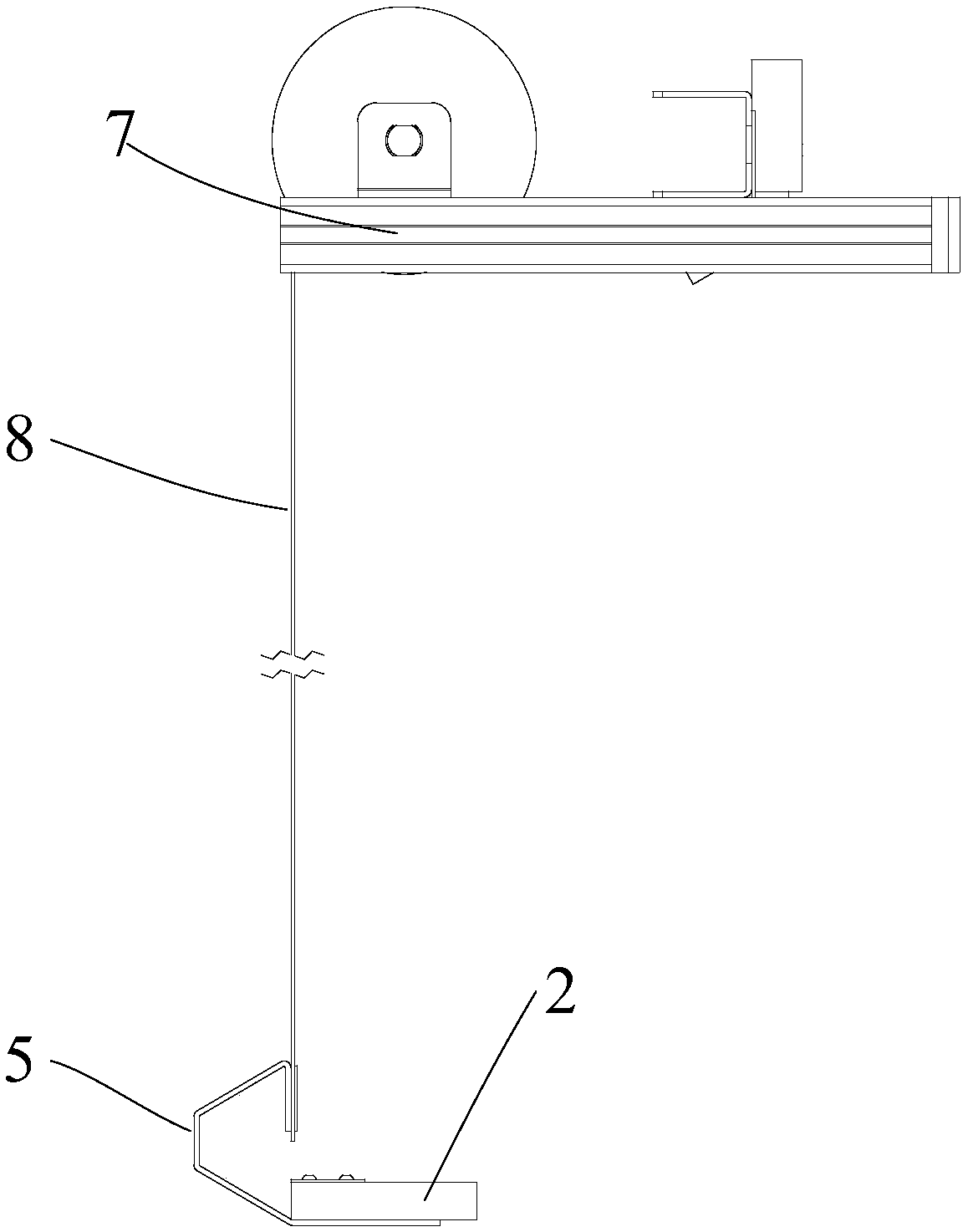

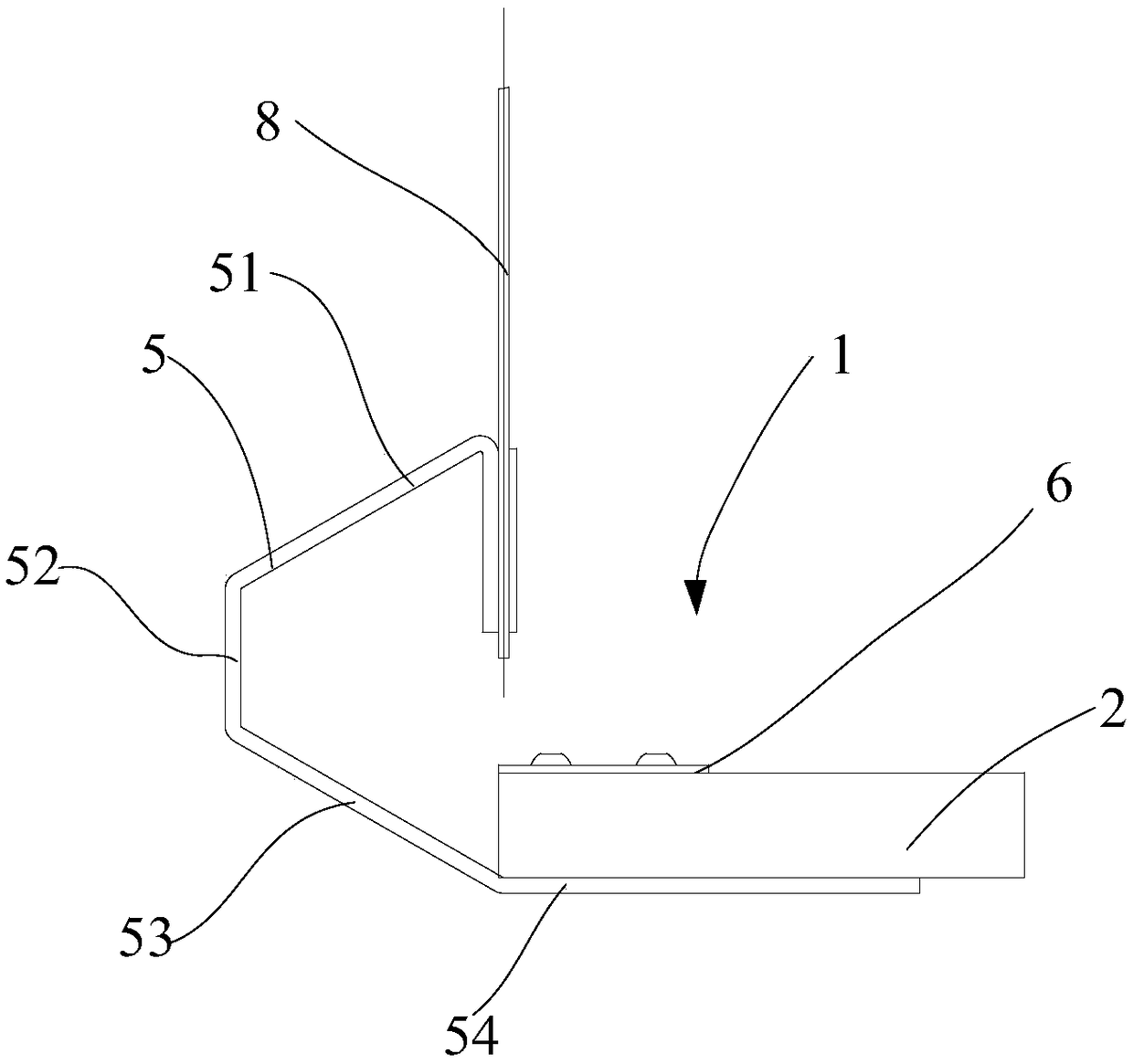

Tobacco stem falling number metering device and tobacco shred metering system comprising the device

ActiveCN109222205ARealize automatic collectionEasy to controlTobacco treatmentAir separationEngineering

The invention discloses a tobacco stem falling number metering device and a tobacco shred metering system comprising the device. The tobacco stem falling number metering device includes a mounting bracket, A measure mechanism and a splitter mechanism are arrange on that mounting bracket, The metering mechanism comprises a collecting funnel and a metering pipe, wherein the lower end of the meteringpipe is provided with a baffle plate, the rotating cylinder drives the baffle plate to be slidably connected with the lower end face of the metering pipe, the air inlet of the rotating cylinder is provided with an electromagnetic valve, the photoelectric switch and the emission plate are arranged on the inner wall of the metering pipe, and the splitting mechanism comprises a splitting funnel anda conical shunt; The invention can timely and efficiently precisely measure the amount of tobacco stem falling, thereby realizing timely and accurate adjustment of the parameters of the air separationdevice, meeting the requirements of production lean management and reducing tobacco waste while improving the air separation effect of the tobacco stem, and the invention has simple structure, smallmodification to the original equipment and low reconstruction cost.

Owner:CHINA TOBACCO HENAN IND

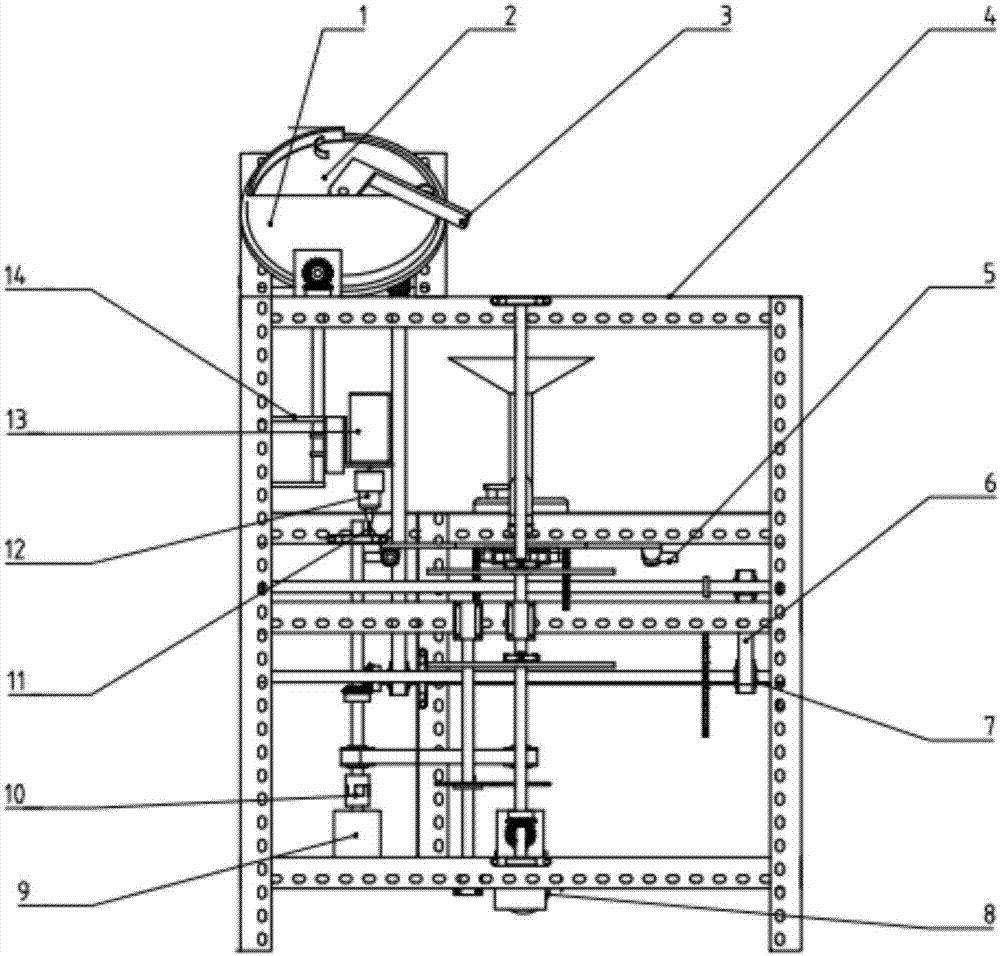

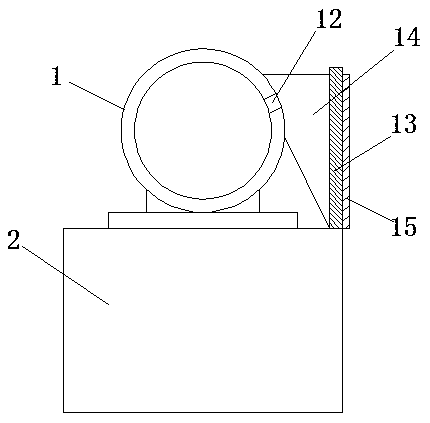

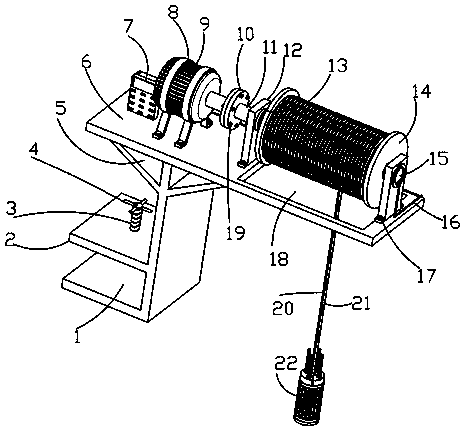

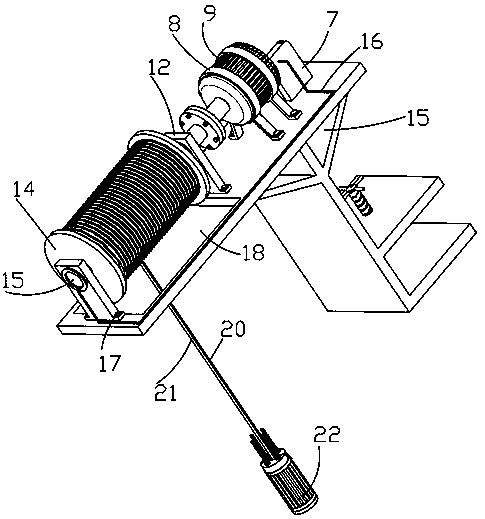

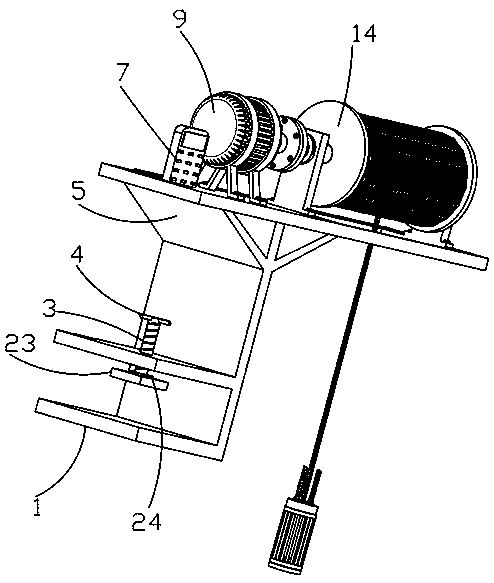

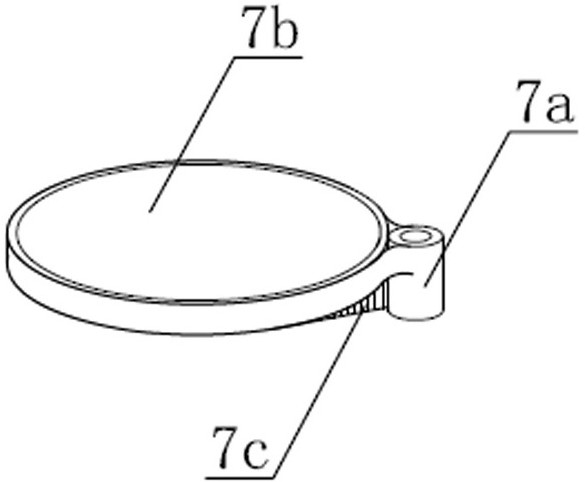

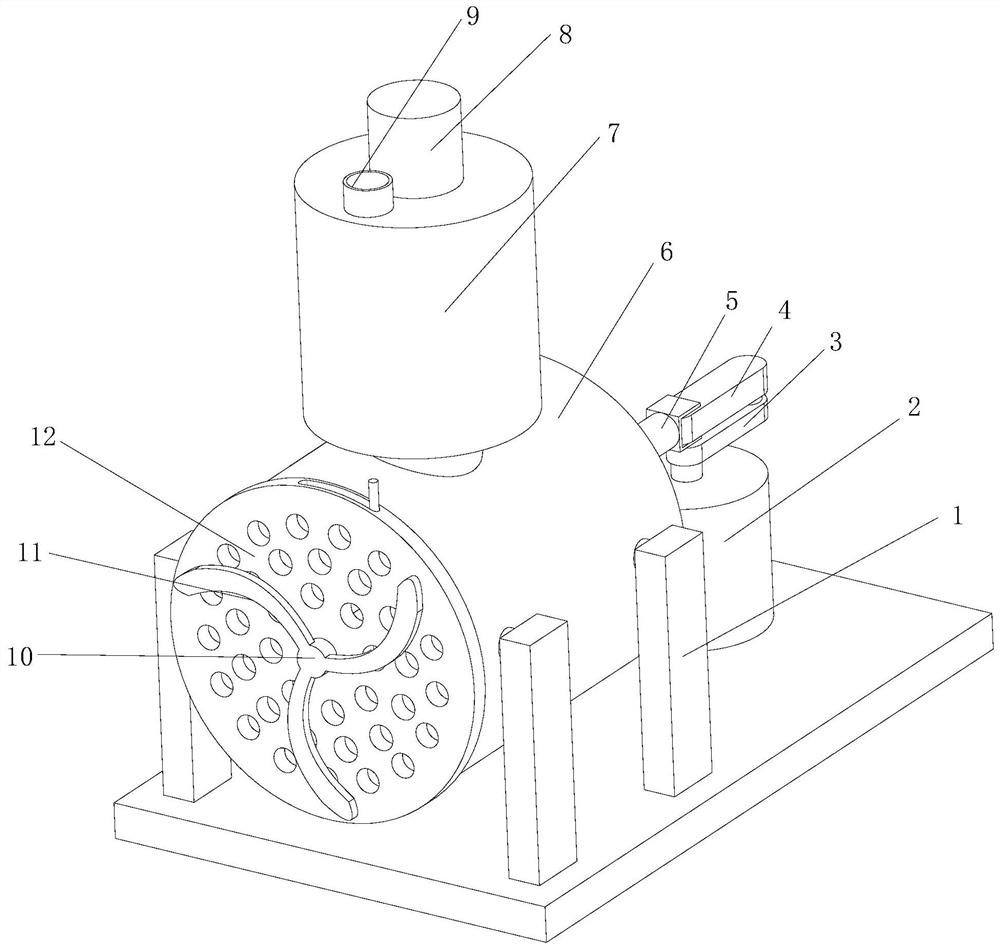

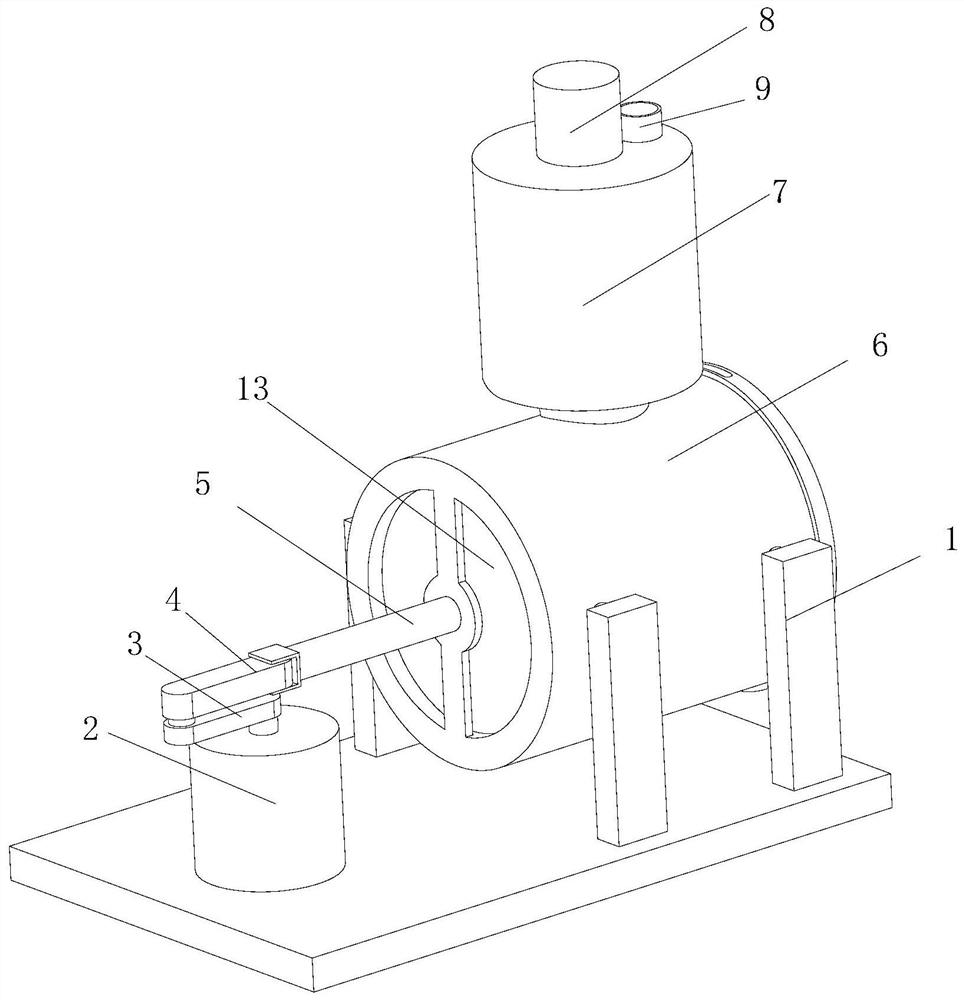

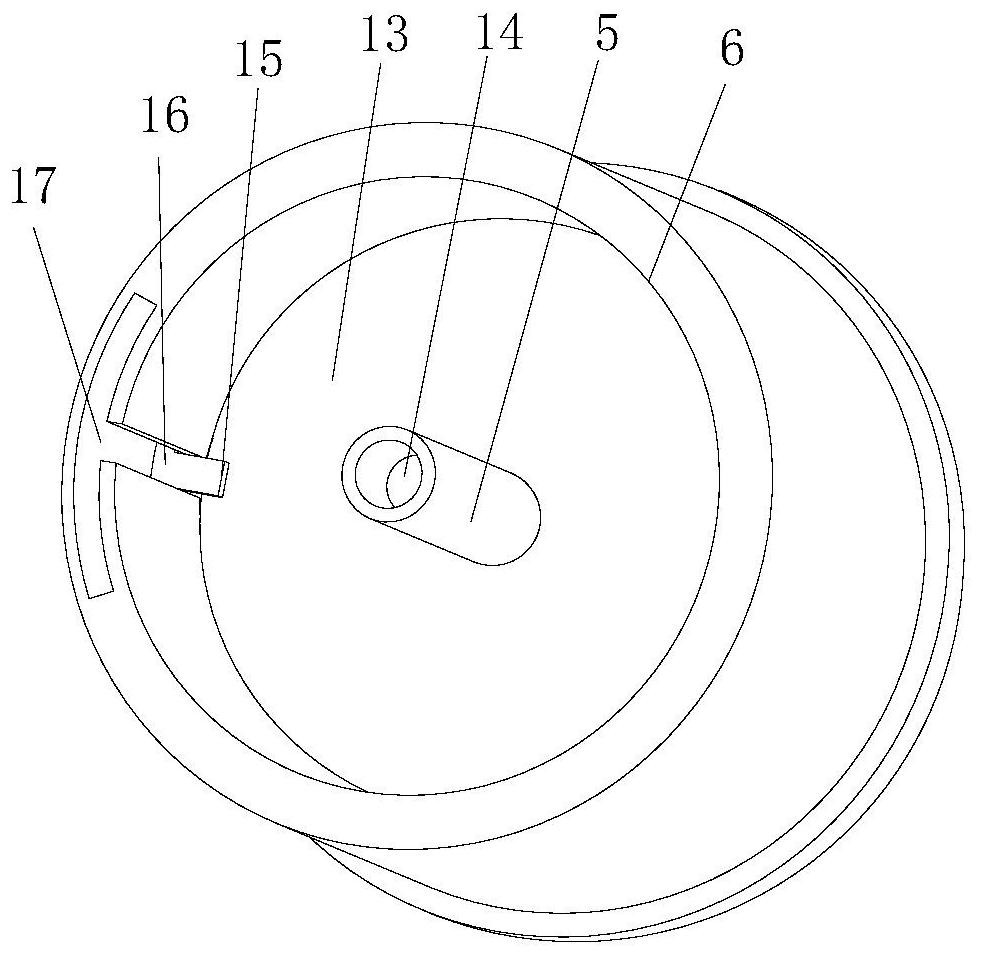

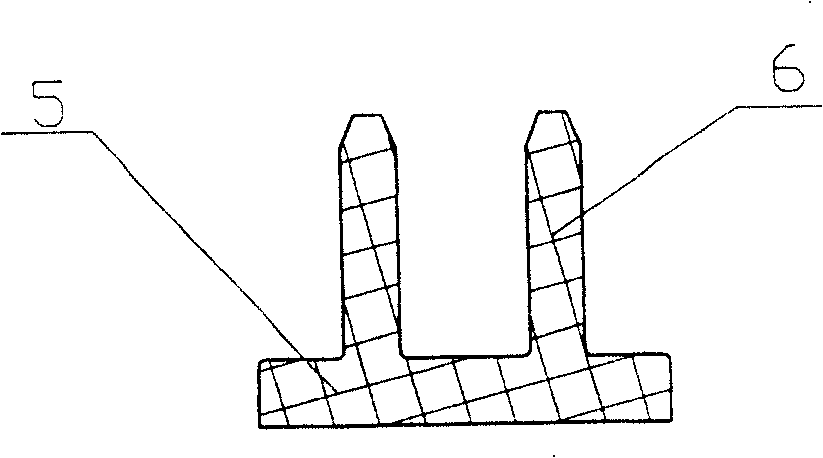

Perforating and threading integrated machine and method for bracelets

InactiveCN107443466ASave human effortShorten the timeJewelleryMetal working apparatusEngineeringRaw material

The invention discloses a perforating and threading integrated machine and method for bracelets. By adoption of the perforating and threading integrated machine and method for the bracelets, the problem that in the prior art, perforating and threading integrated manufacturing cannot be achieved is solved; and the effects of automatic feeding, perforating and threading are achieved, and bracelet perforating and threading tasks can be completed with few manpower resources in a short time. According to the scheme, a feeding mechanism of a bracelet perforating machine comprises a circular ring which is arranged obliquely, a separation disc which can rotate around the central axis of the circular ring is arranged in the circular ring, and a separation blocking piece is arranged on the outer side of the circular ring; a separation plate is arranged on the surface of the separation disc and intersects with the diameter of the separation disc; a discharging hopper is arranged on one side of the separation plate and located below the lateral portion of the circular ring, and a transverse pipe with an opening is arranged at the bottom of the discharging hopper; and a sliding block is arranged in the transverse pipe and connected with a crank, and the crank rotates to drive the sliding block, so that bracelet raw materials in the transverse pipe are pushed to advance and fall down from the opening.

Owner:QINGDAO UNIV

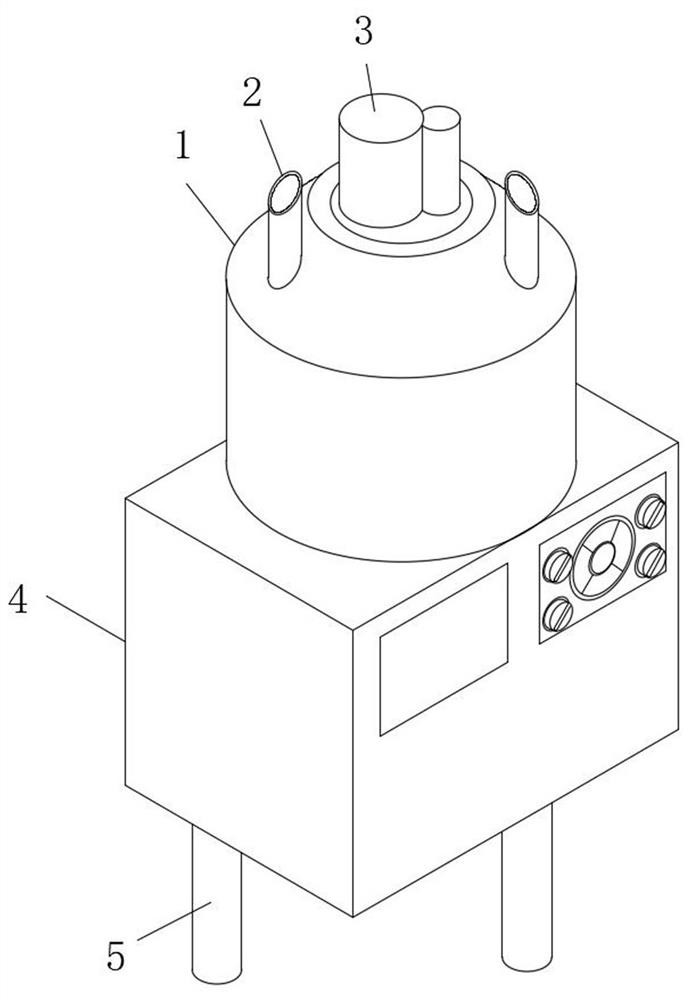

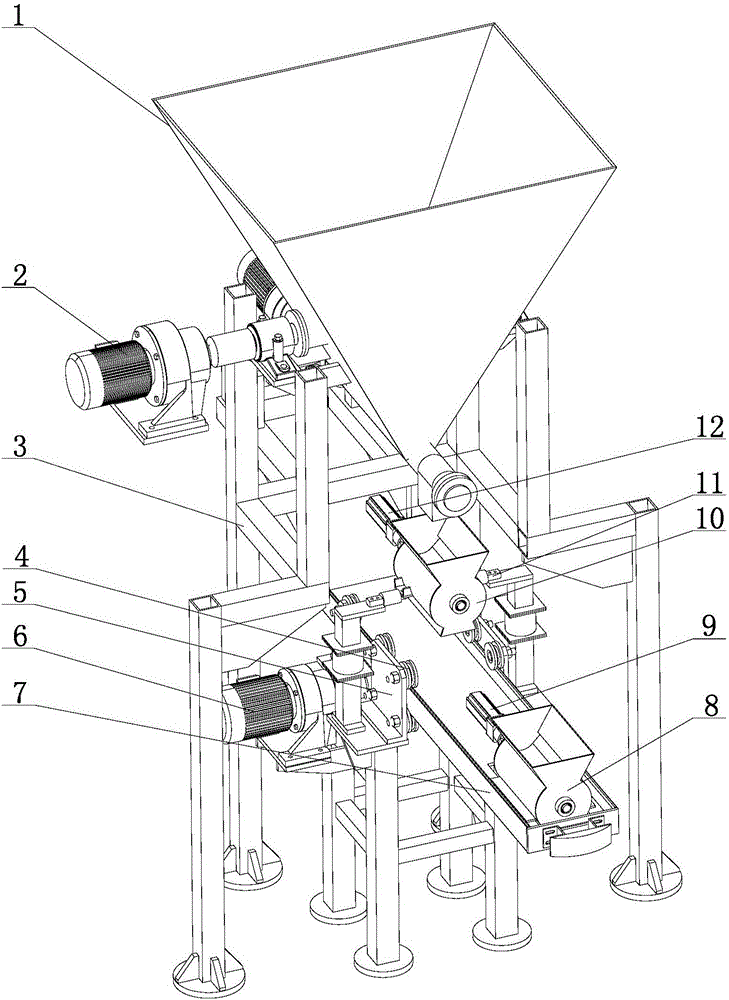

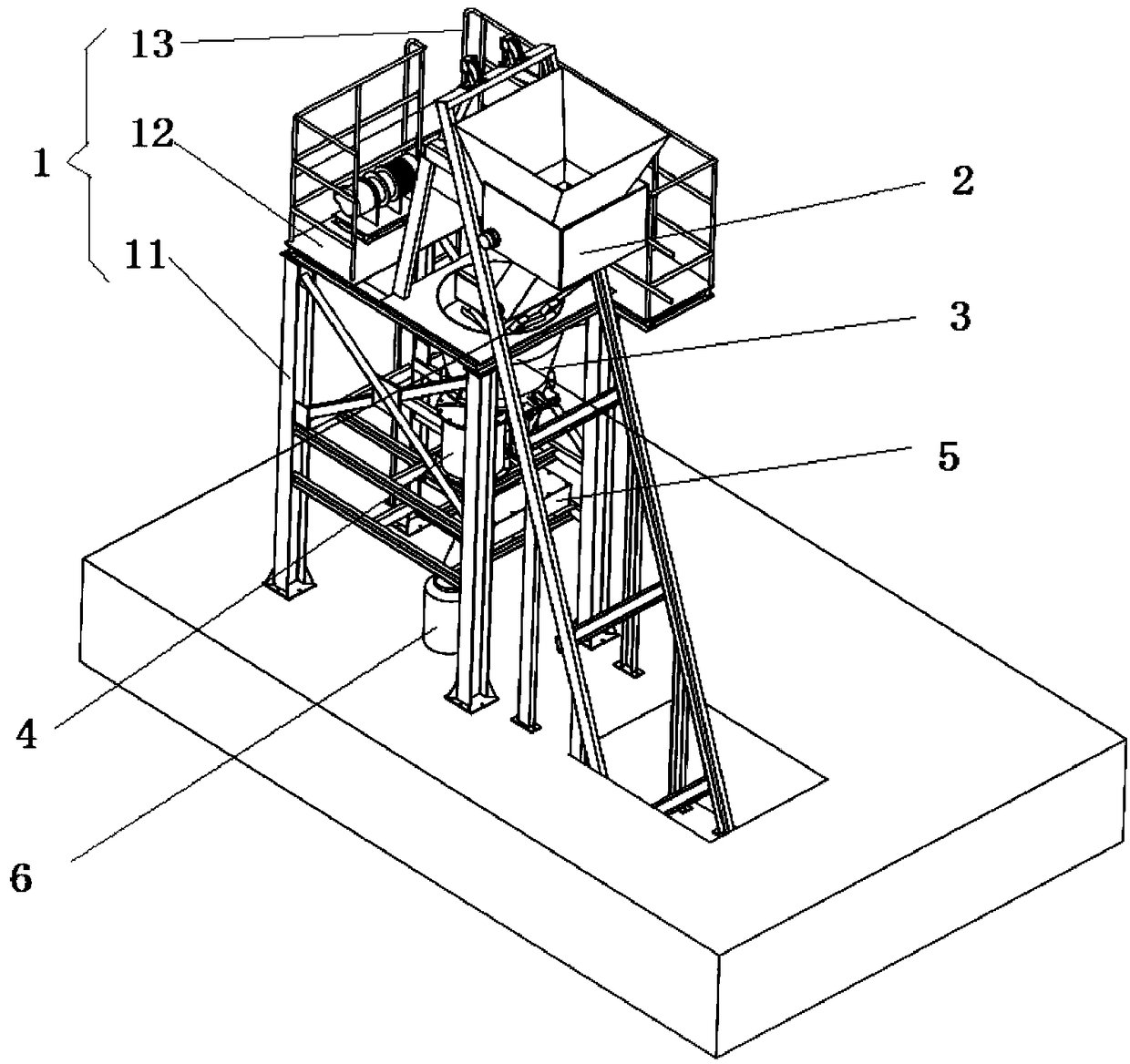

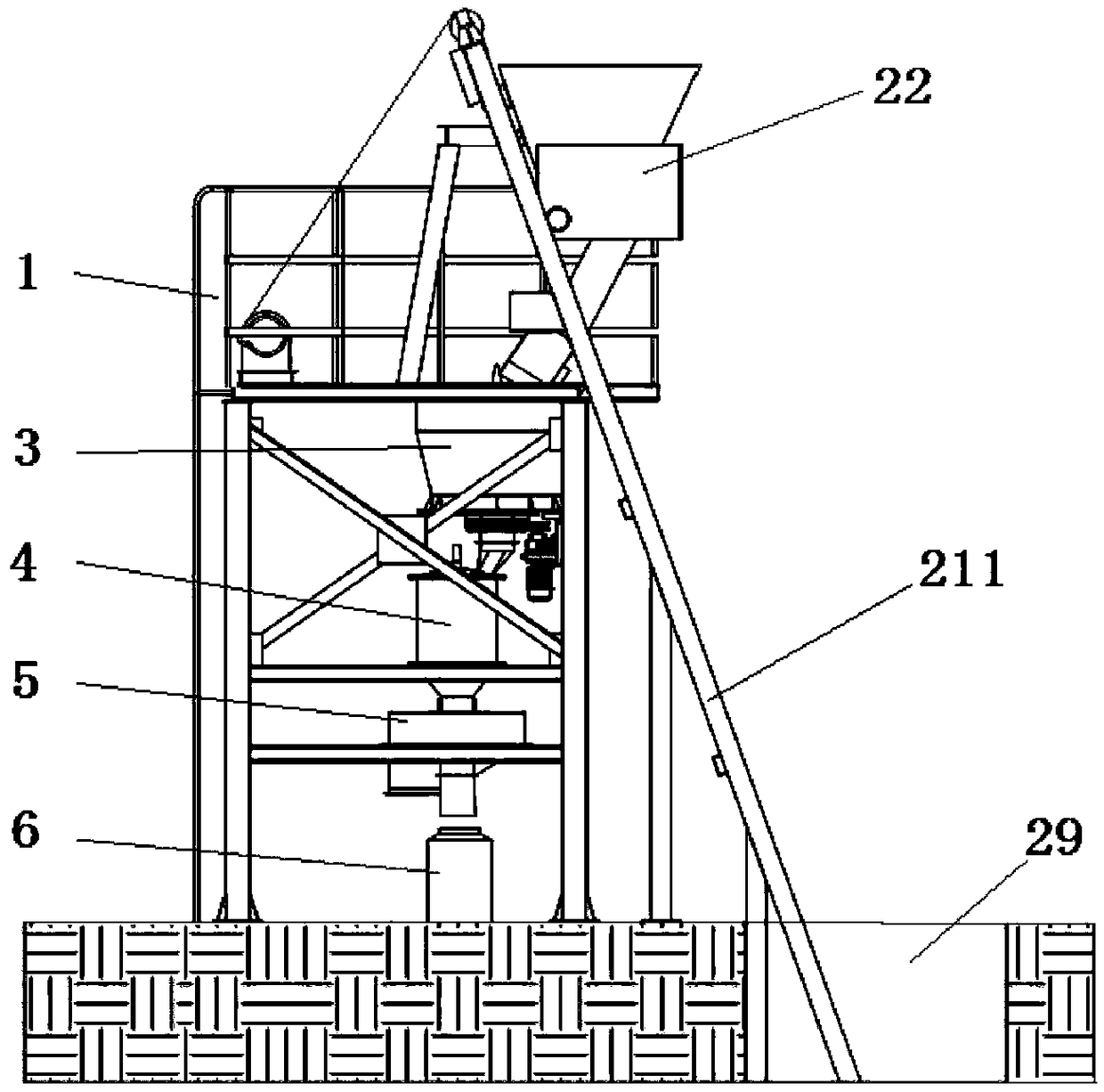

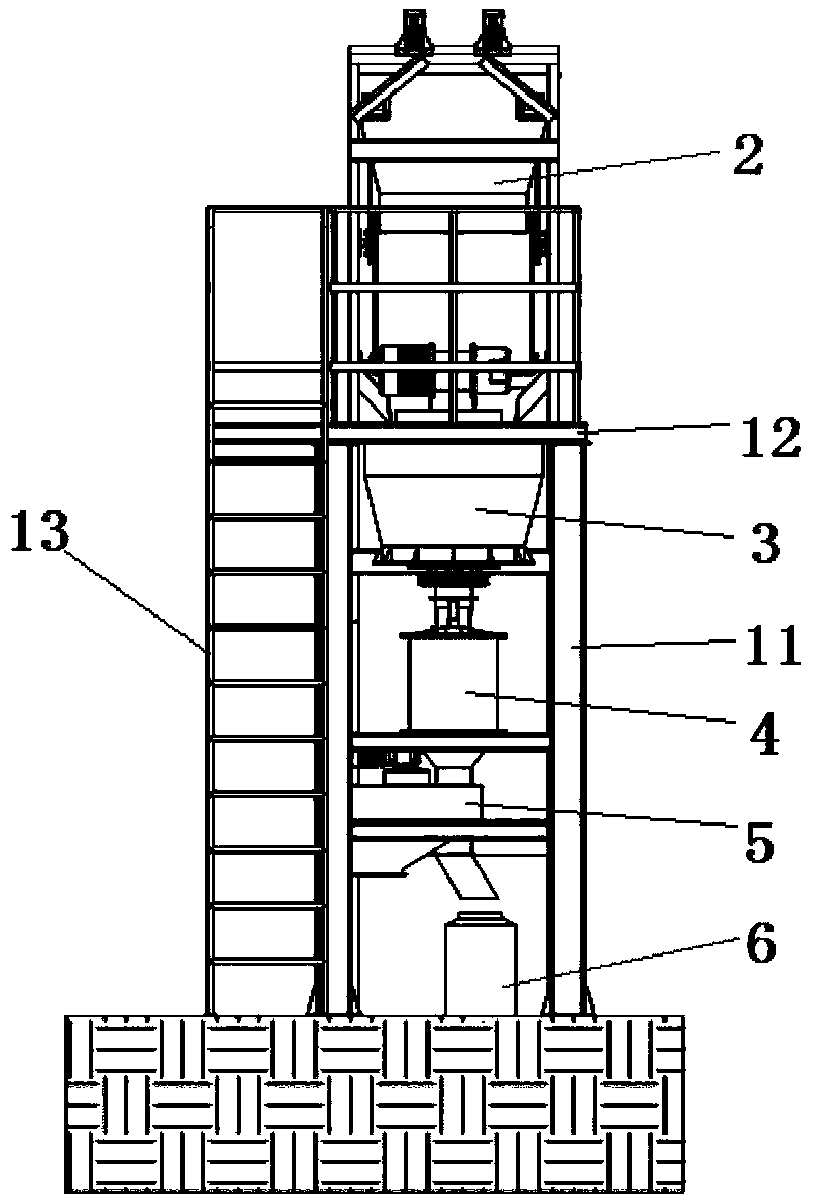

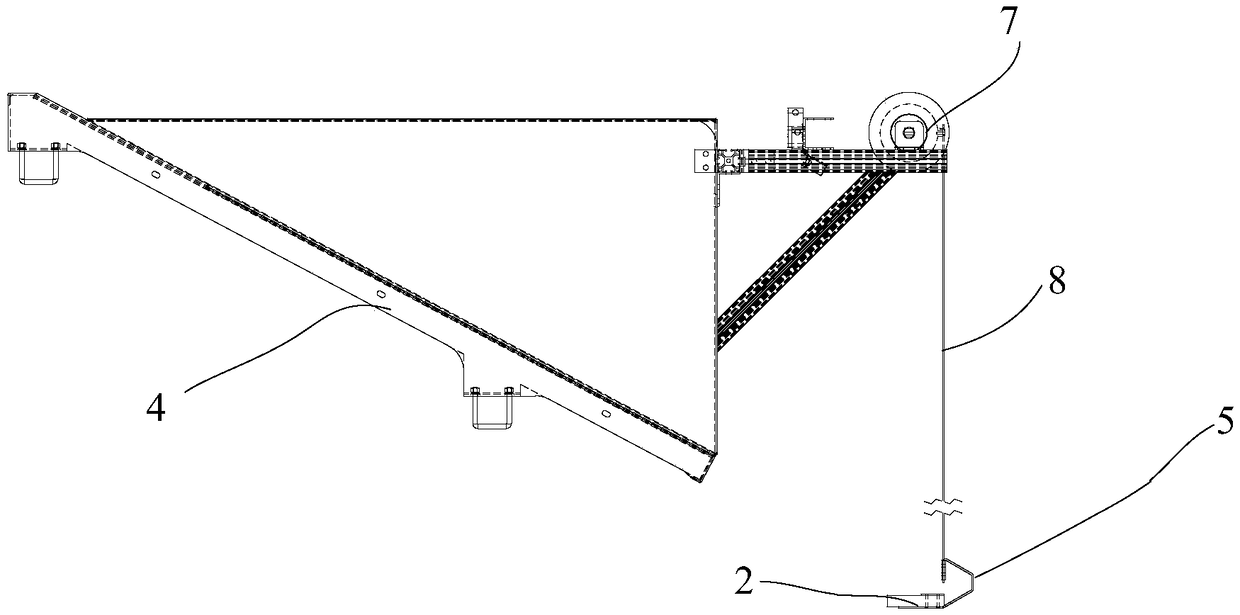

Solid mineral sample preparation system

ActiveCN108970720AWon't pile upGuaranteed representationWithdrawing sample devicesGrain treatmentsEngineeringCrusher

The invention relates to the field of solid mineral sample preparation, and particularly discloses a solid mineral sample preparation system. The system comprises a lifting platform, an loading device, a feeder, a crusher, a fixed mass division machine and a collection device, wherein a cavity is formed in a material bin of the feeder, a first feeding opening is formed in the top of the material bin, a first discharging opening is formed in the bottom of the material bin, and the cavity is communicated with the first feeding opening and the first discharging opening; the feeder further comprises a rotating shaft which is installed on the material bin, is rotatably connected with the material bin and penetrates the first discharging opening; the feeder further comprises a driving device which is connected with the rotating shaft; the feeder further comprises a feeding knife, one end of the feeding knife is fixed onto the rotating shaft, the other end of the feeding knife is attached tothe inner wall of the material bin, the feeding knife is located on the bottom of the cavity, and the feeding knife rotates to scrape a material in contact with the feeding knife from the material binside walls to the discharging opening, so that the material, away from the discharging opening, on the bottom of the material bin does not pile up, and discharging is even; the feeding knife rotatescontinuously, and the material in the material bin decreases layer by layer, so that discharging is continuous and stable, and the representativeness of a prepared sample can be ensured.

Owner:英飞智信(北京)科技有限公司

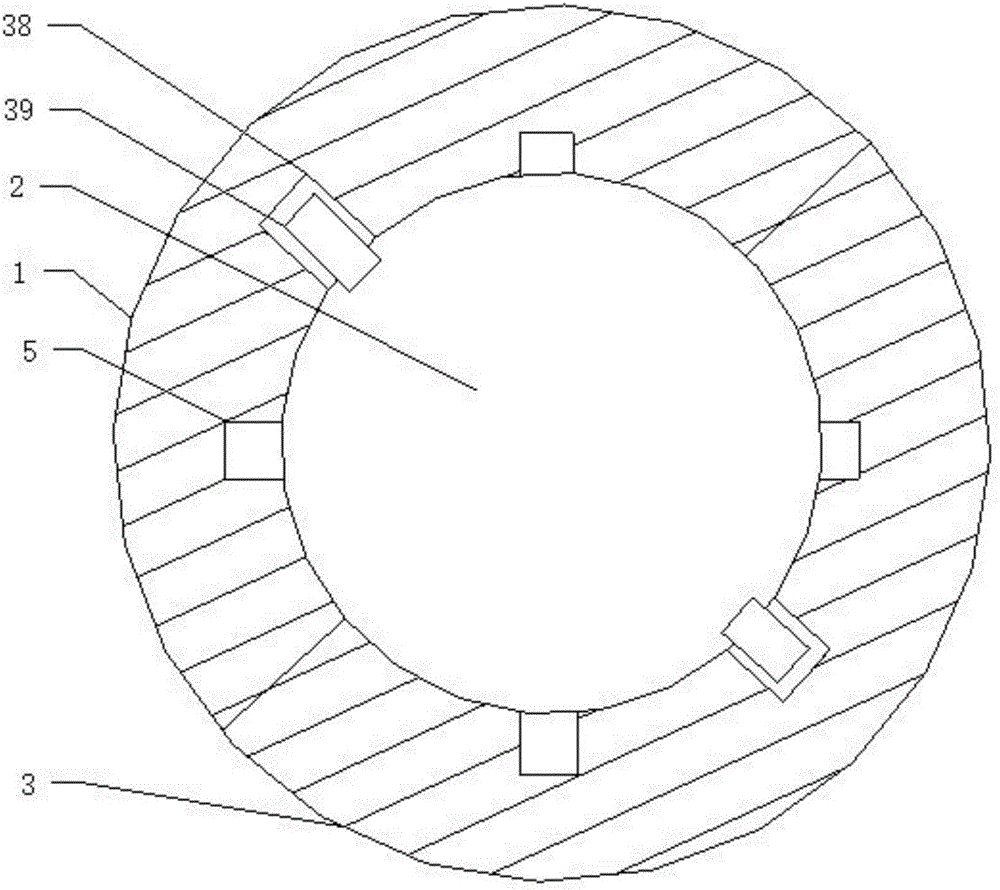

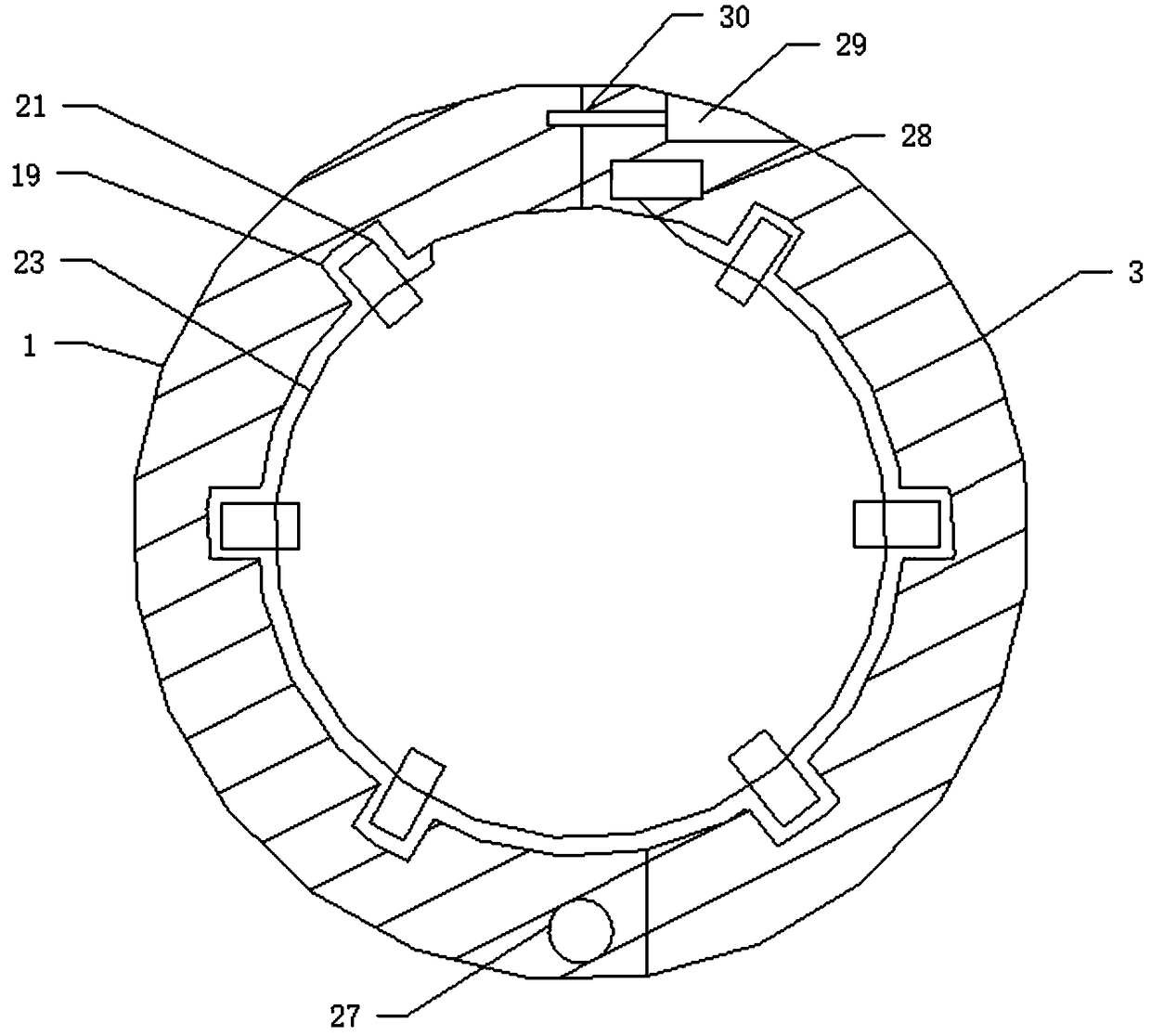

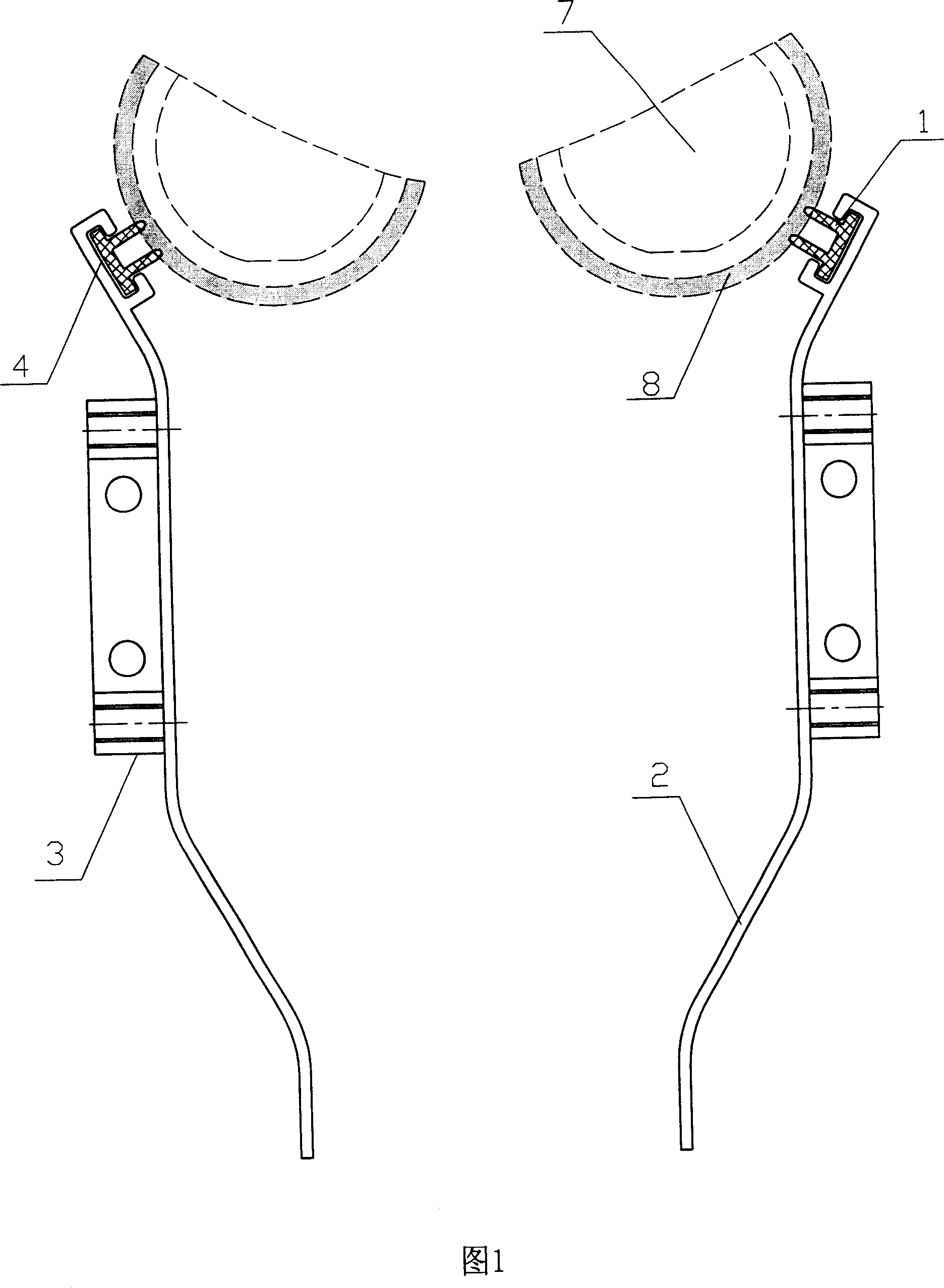

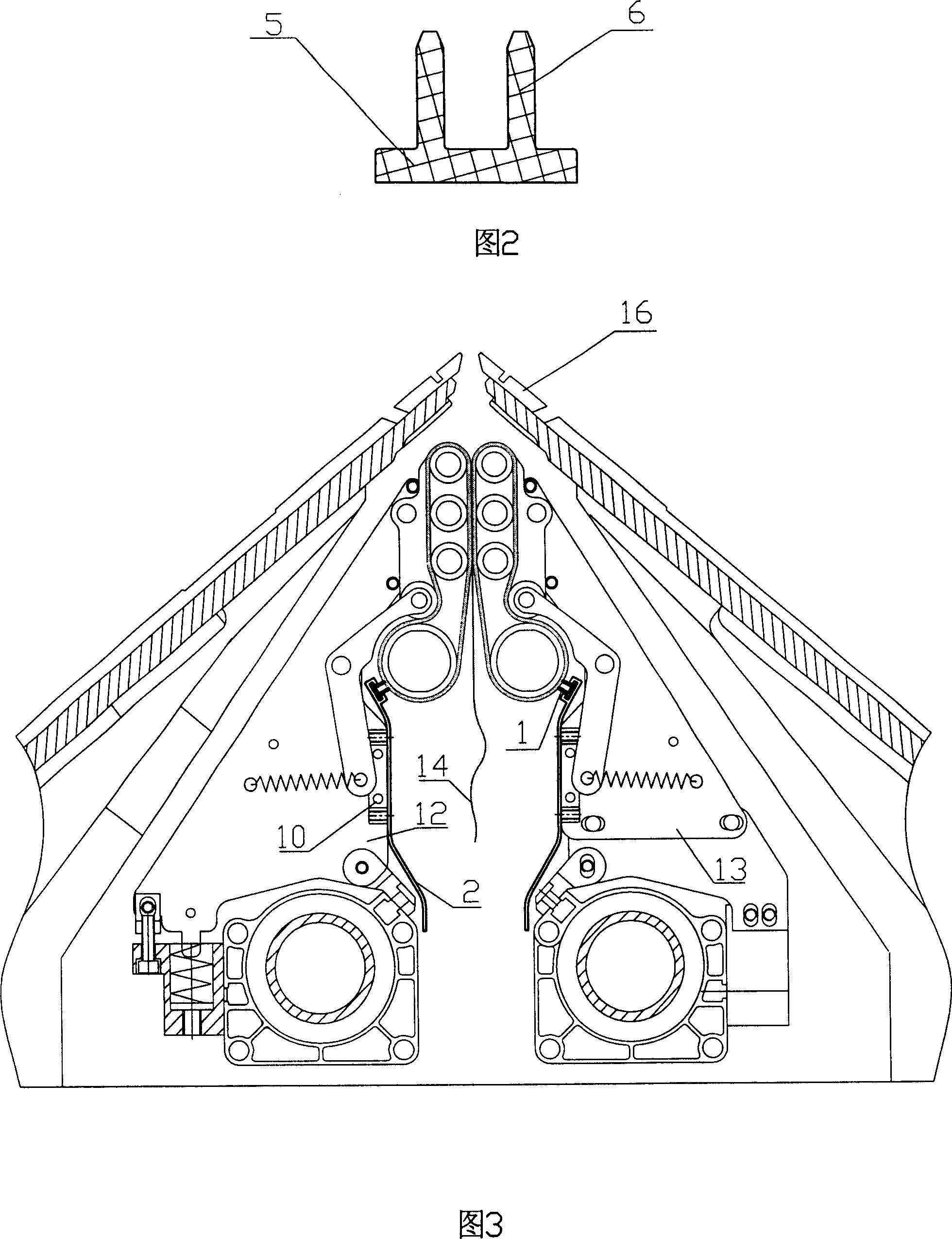

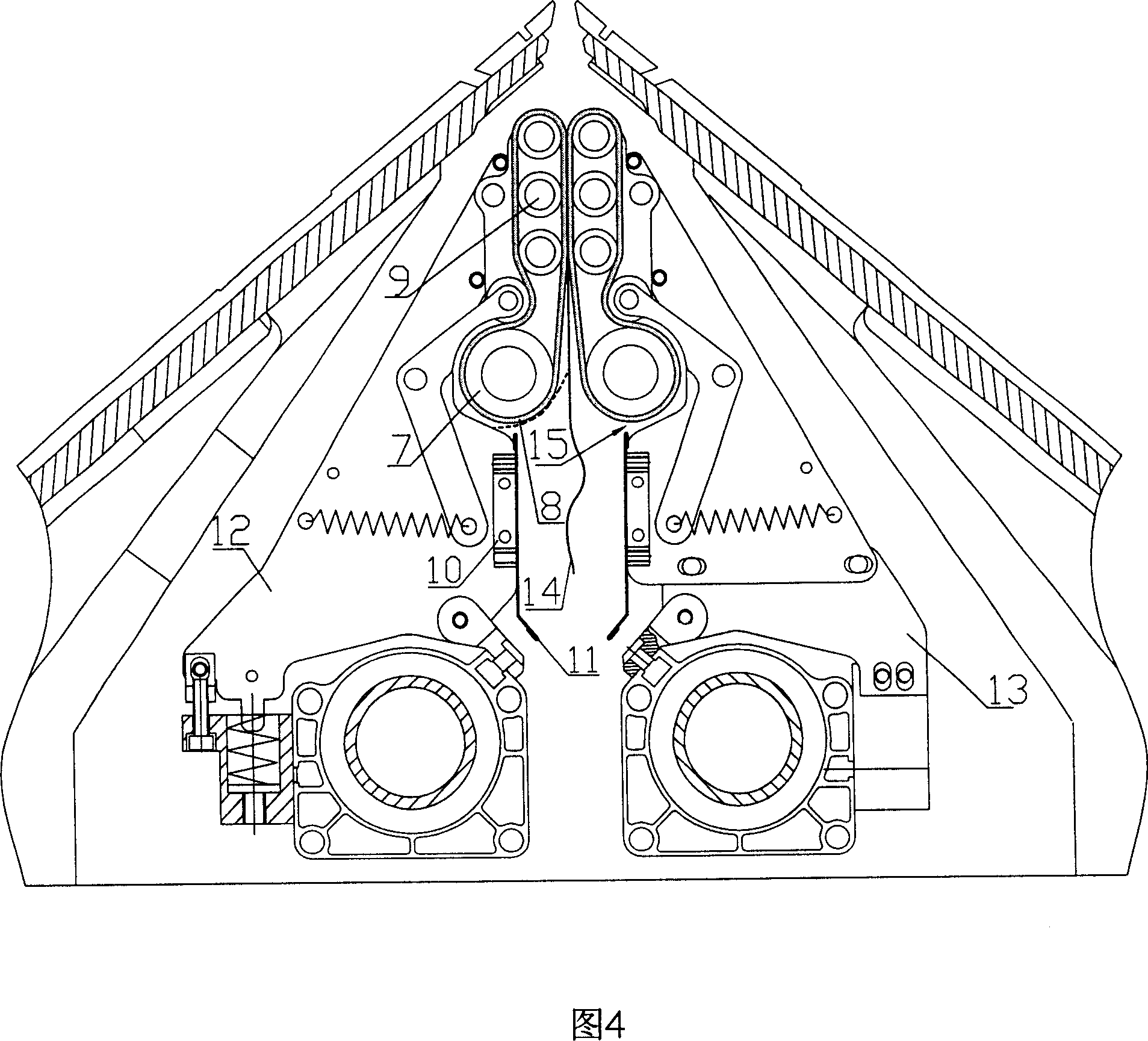

An automatic electrical power utility pole climbing assisting device capable of drying utility poles

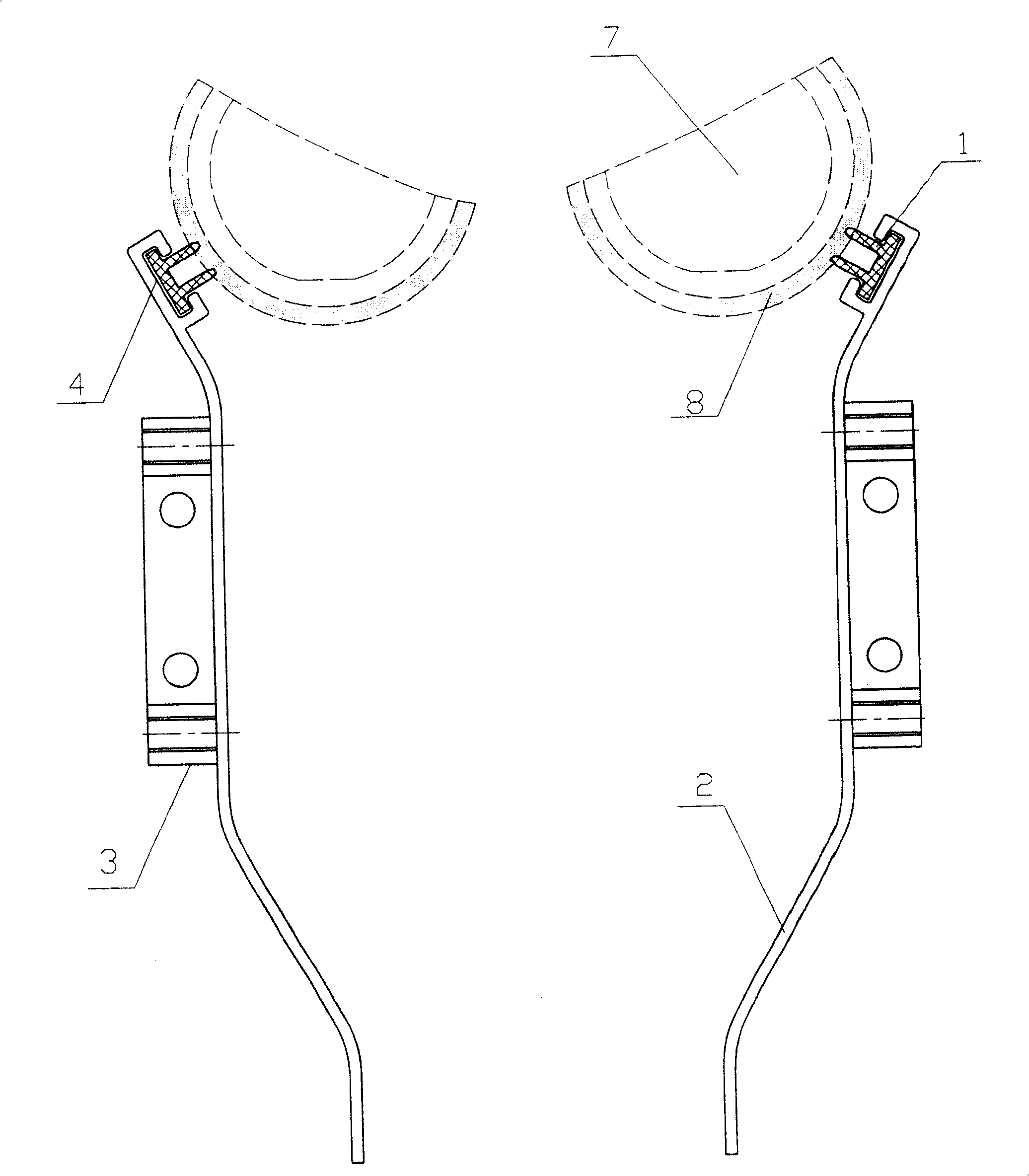

ActiveCN106390393ARepair in timePrevent the problem of not being able to climbDrying gas arrangementsClimbingRear quarterPower utility

The invention provides an automatic electrical power utility pole climbing assisting device capable of drying utility poles. The device comprises a first side plate and a second side plate, which are arc-shaped; a side plate cavity is formed between the first side plate and the second side plate; each of the first side plate and the second side plate is provided with a first side plate groove correspondingly communicating with the side plate cavity; each first side plate groove is inside provided with two intersecting first support shafts rotating corresponding to each other; each first support shaft is provided with a rotary fixed runner; each second side plate groove is inside provided with a heat dissipation pipe correspondingly communicating with the side plate cavity; the first side plate is inside provided with a heating cavity correspondingly communicating with the heat dissipation pipes. Heating wires in the heating cavity can generate heat which can be transmitted into the heat dissipation pipes, so that the heat dissipation pipes can dry utility poles and the problem is solved that in humid weather, the automatic electrical power utility pole climbing assisting device capable of drying utility poles slips in a utility pole climbing process and cannot be used for climbing.

Owner:畅达峰电力科技有限公司

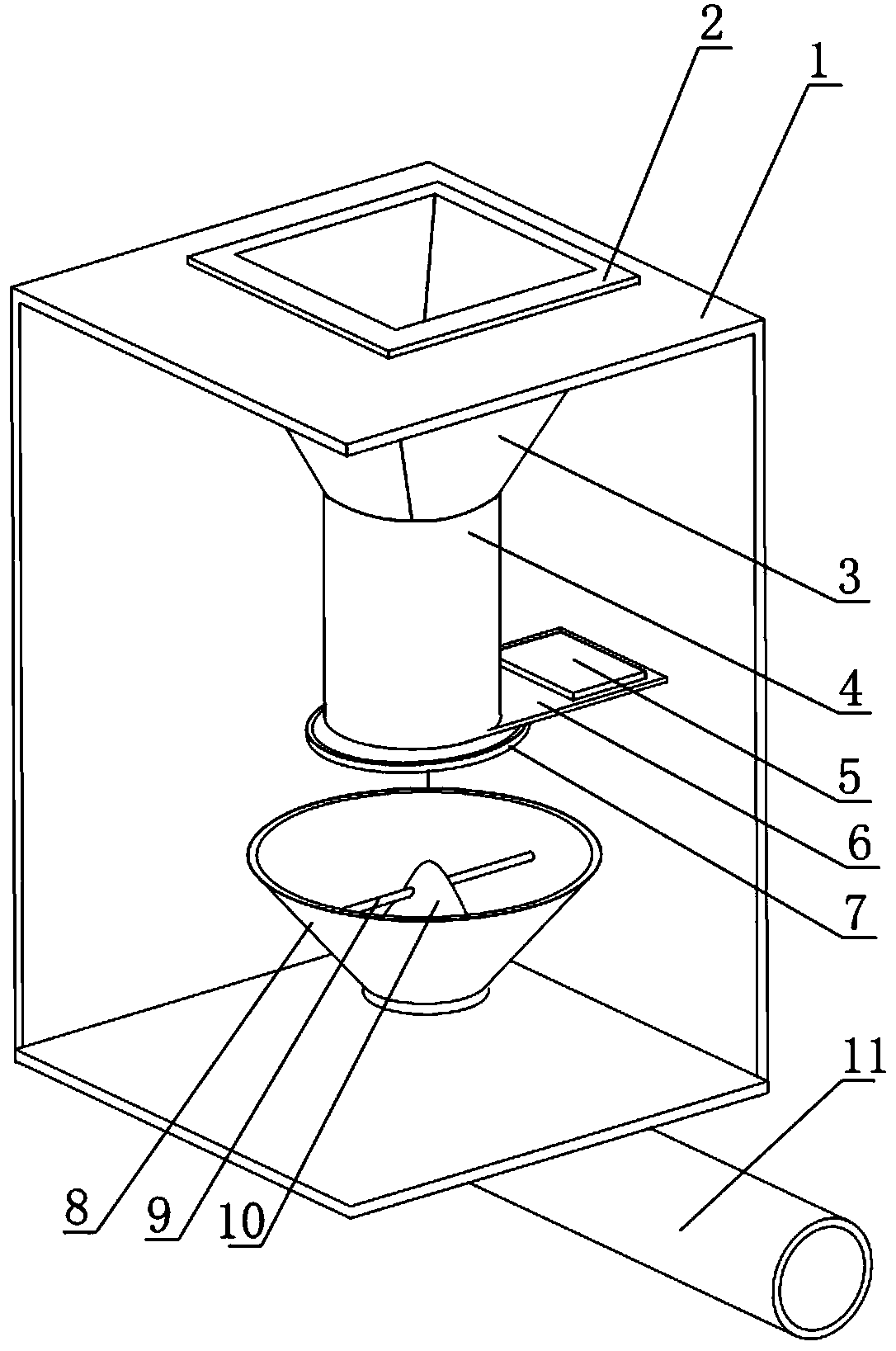

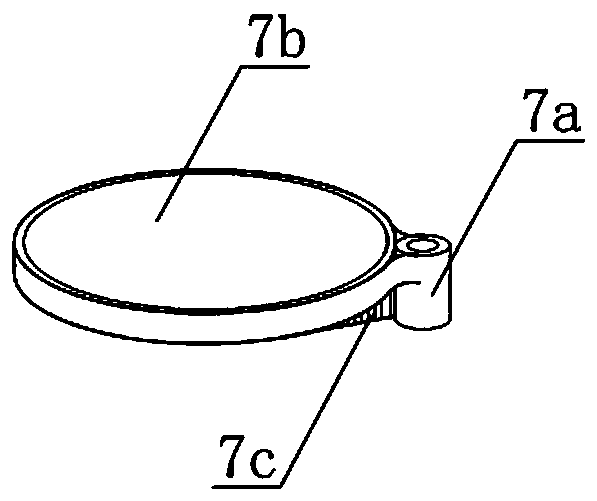

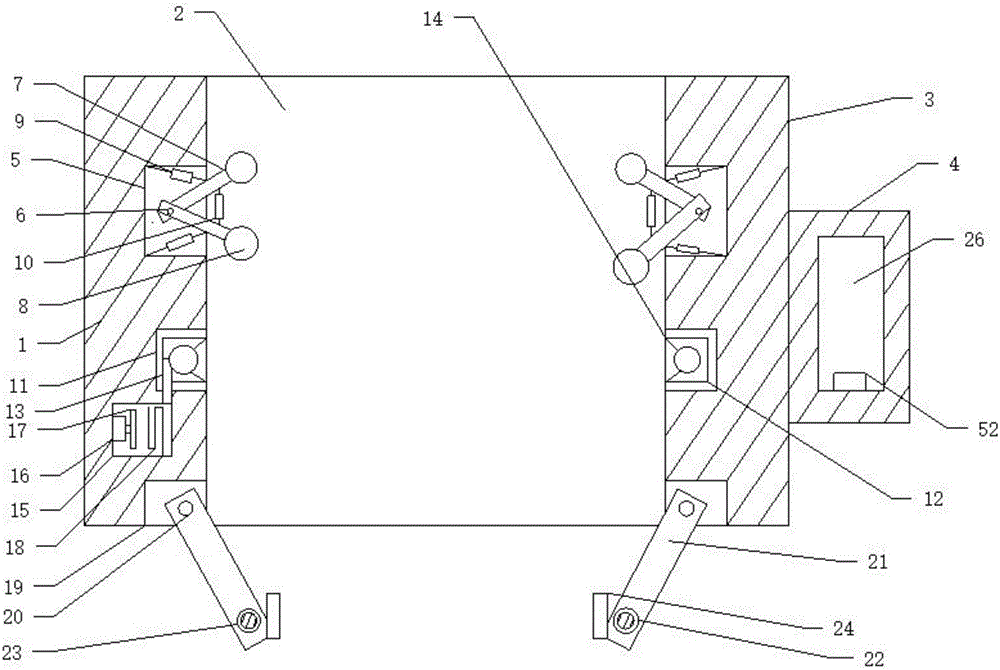

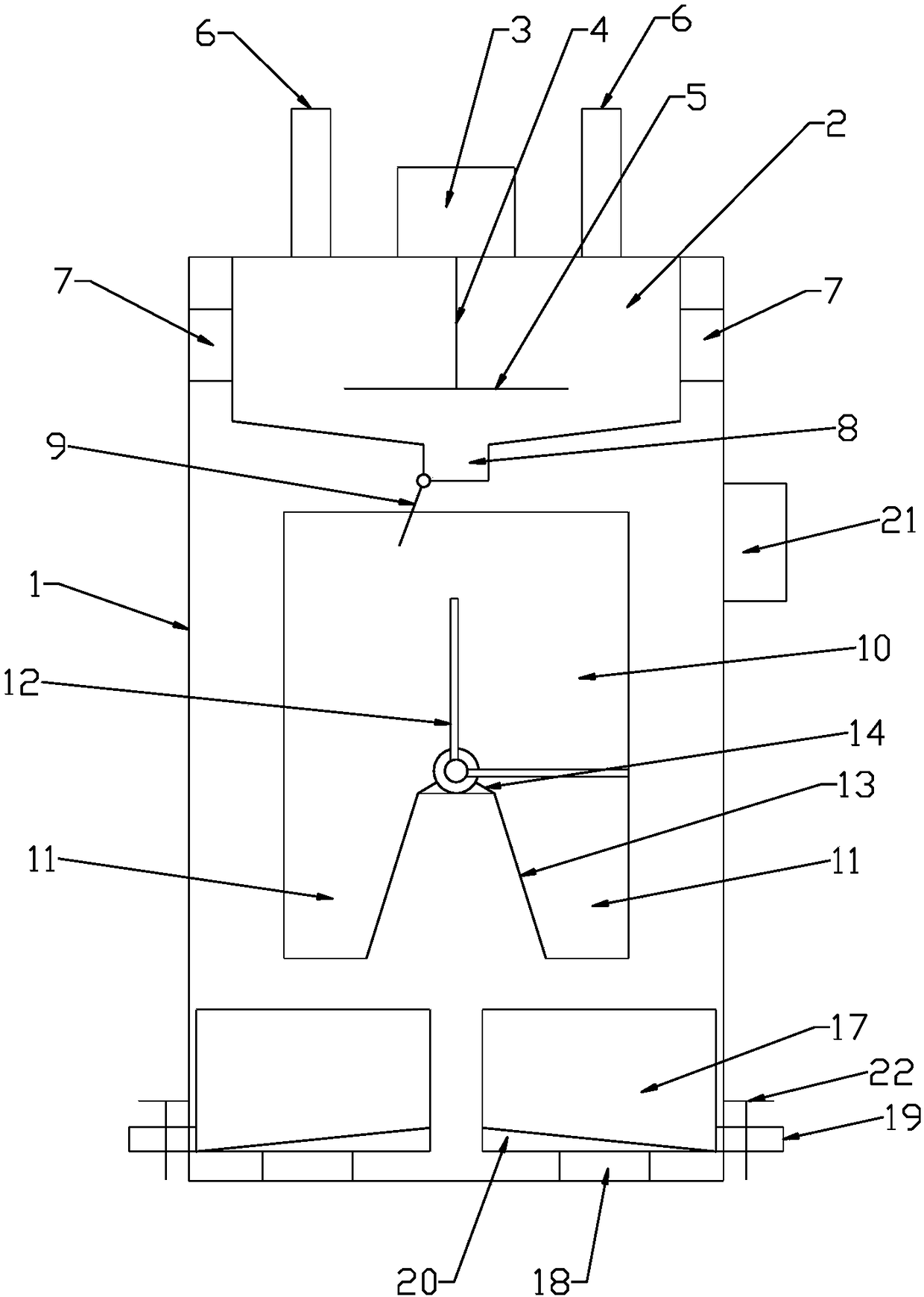

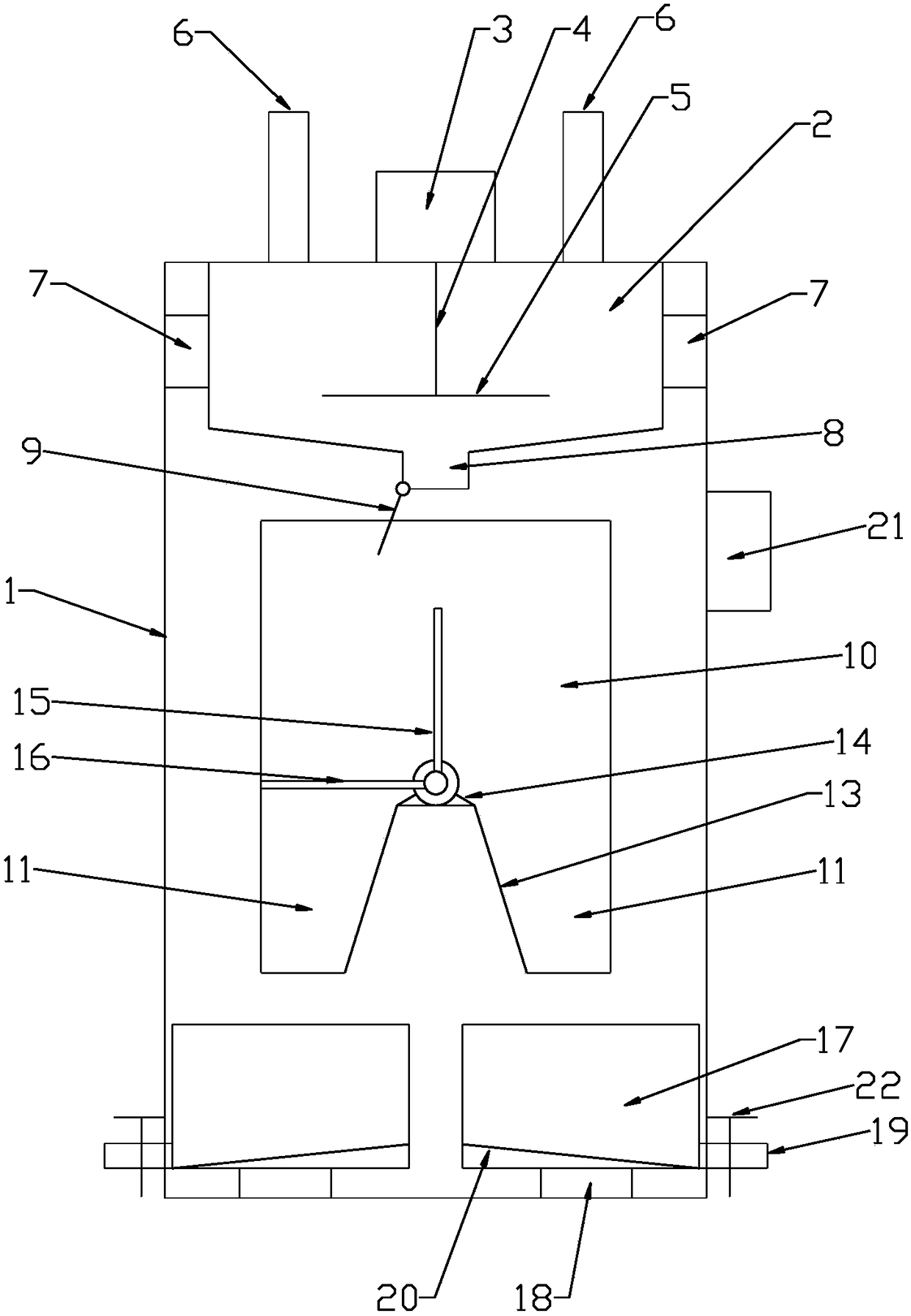

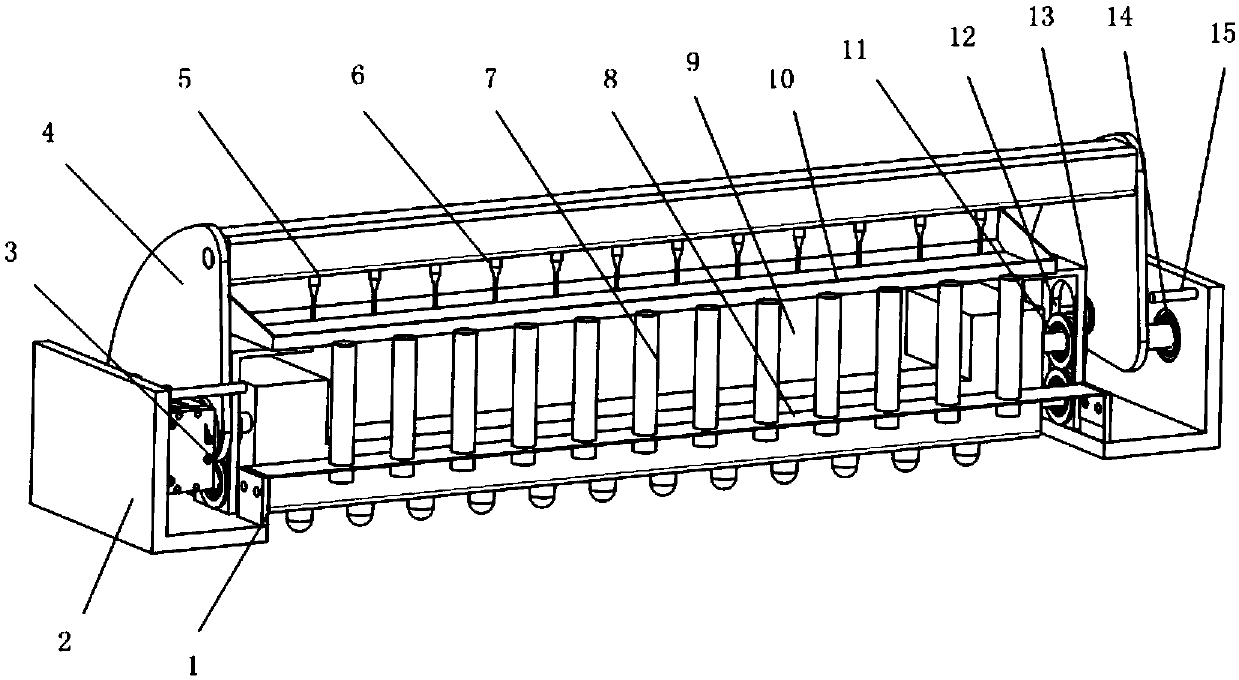

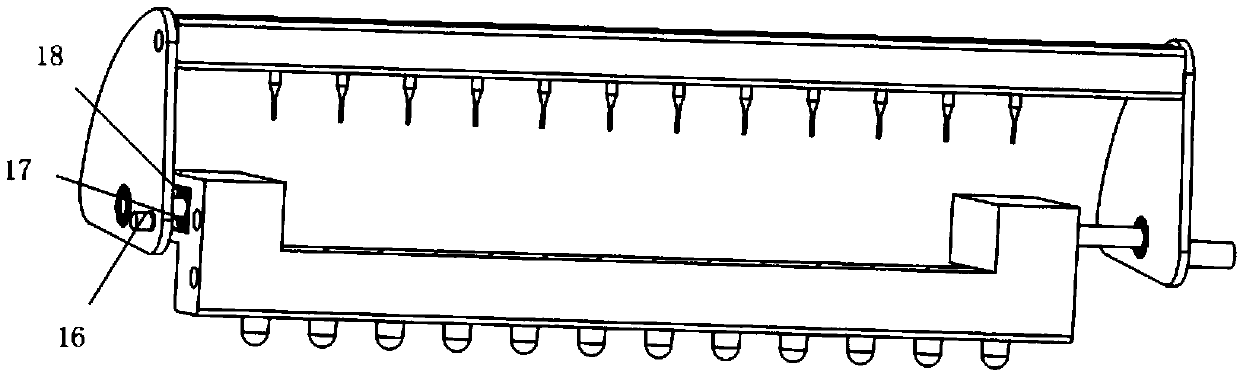

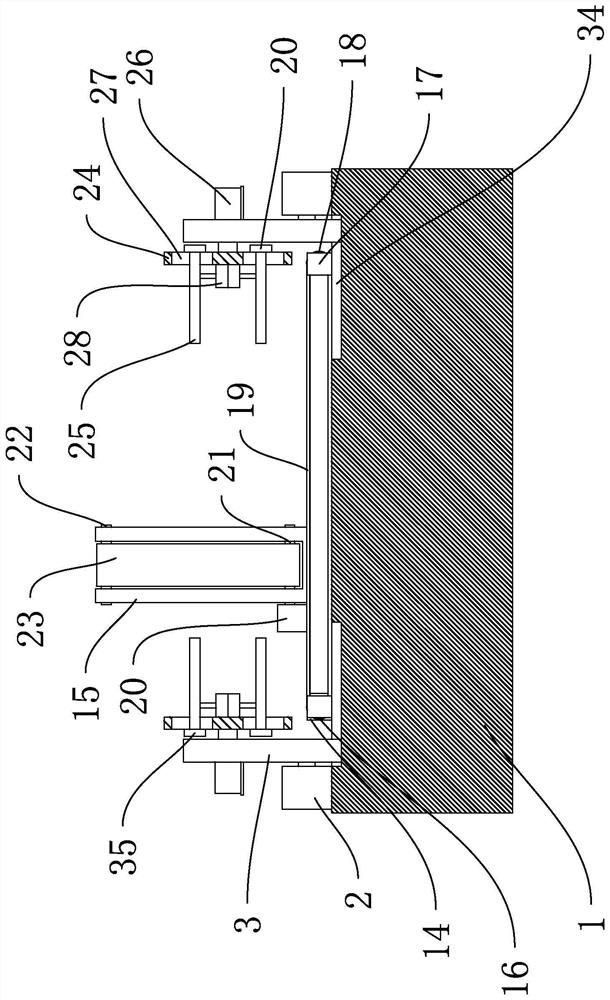

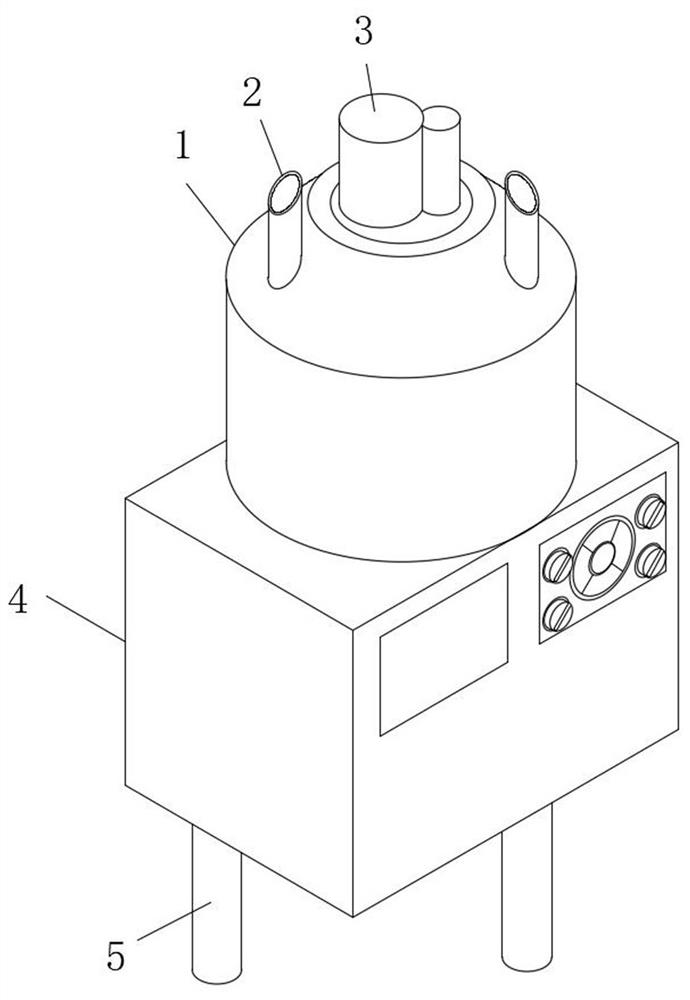

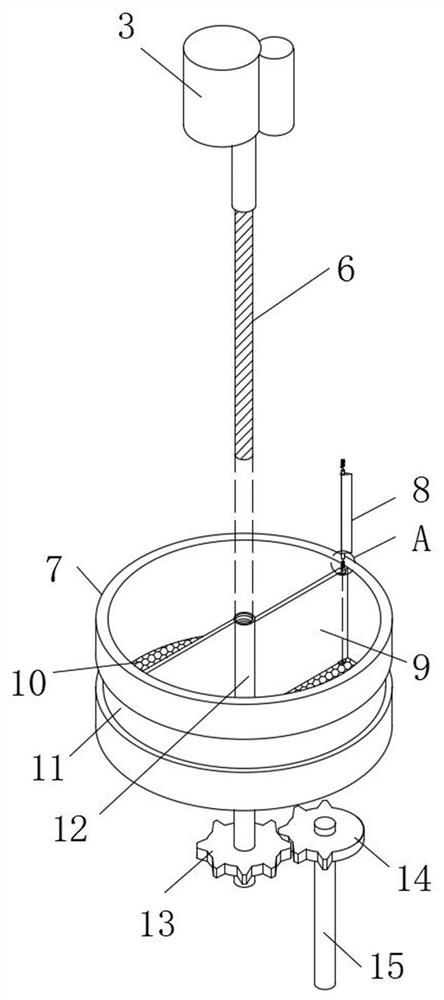

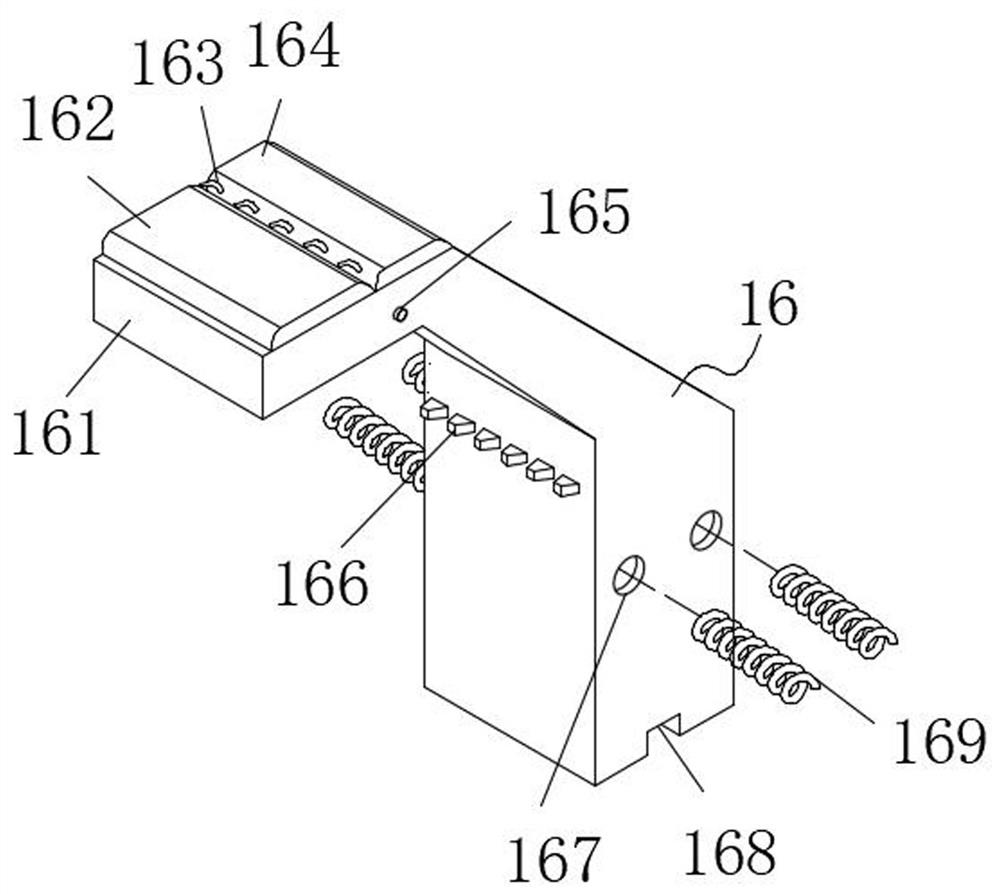

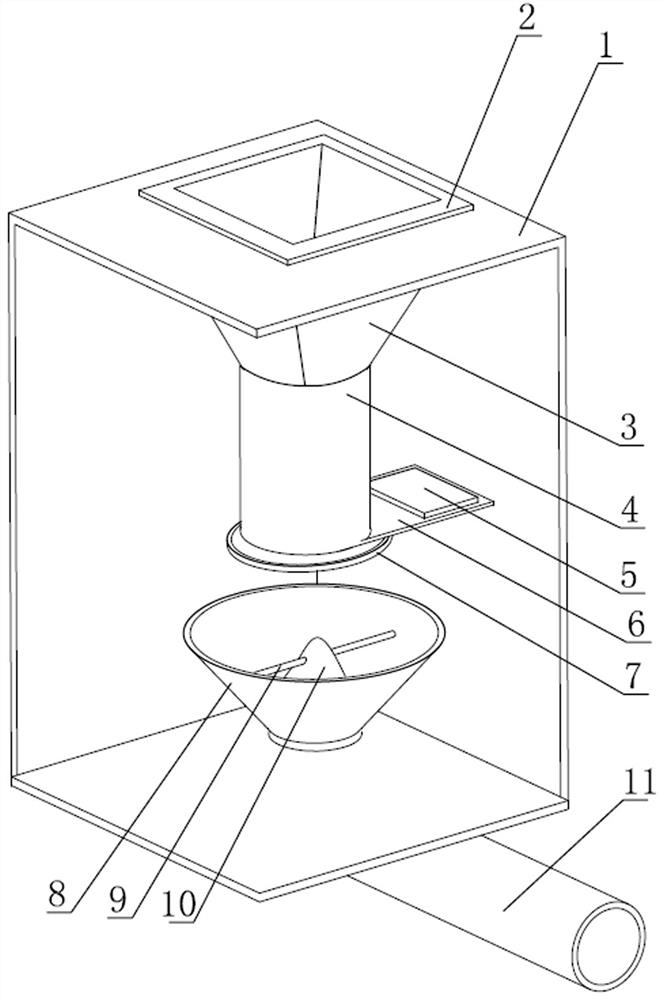

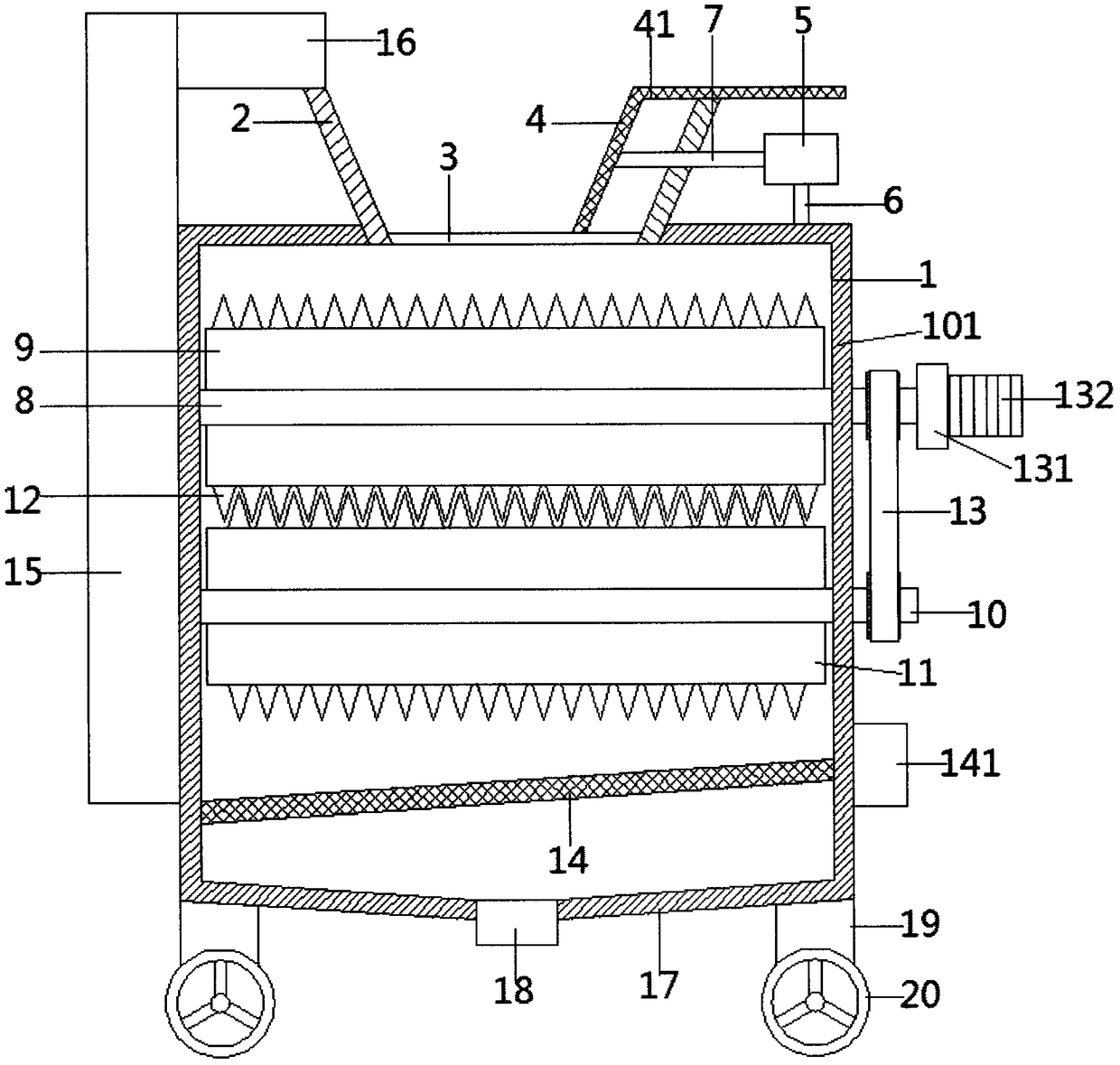

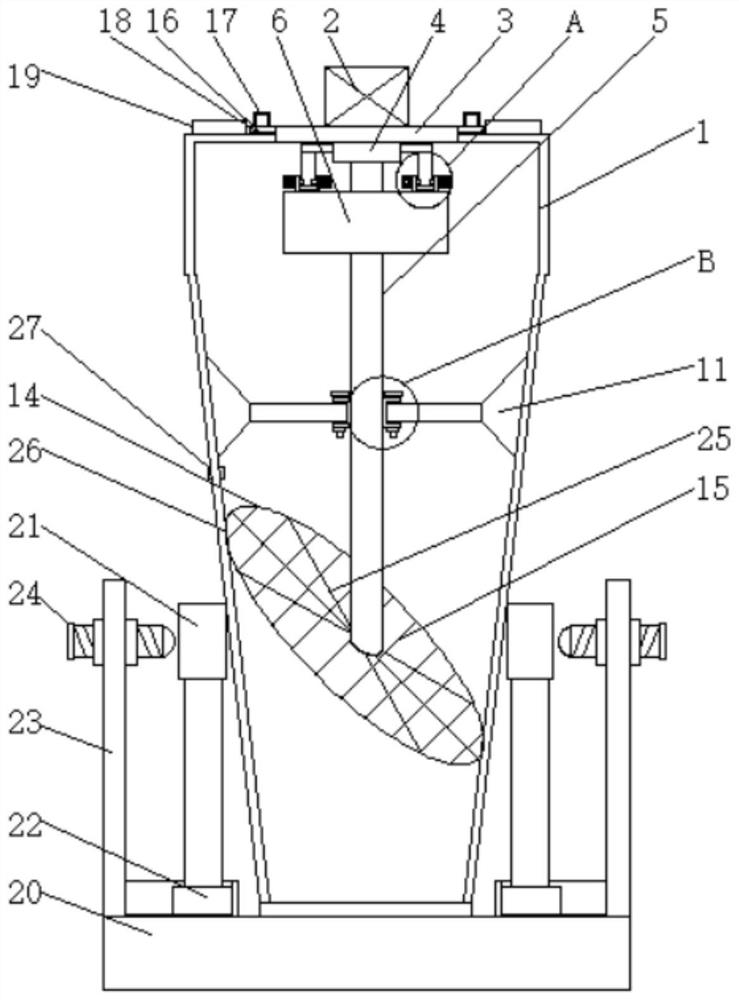

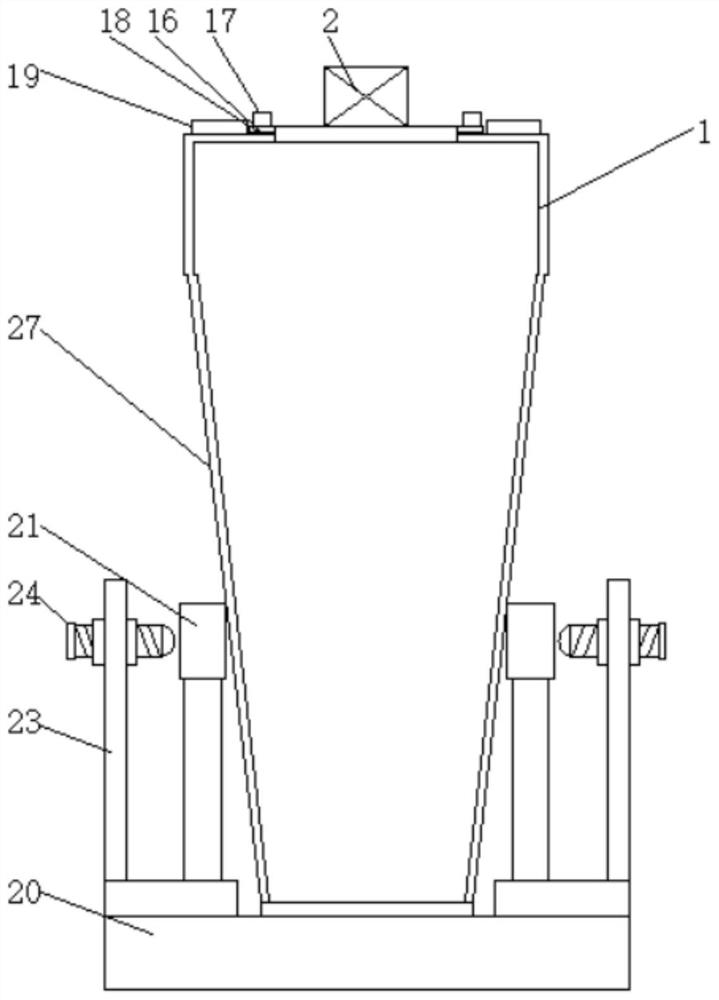

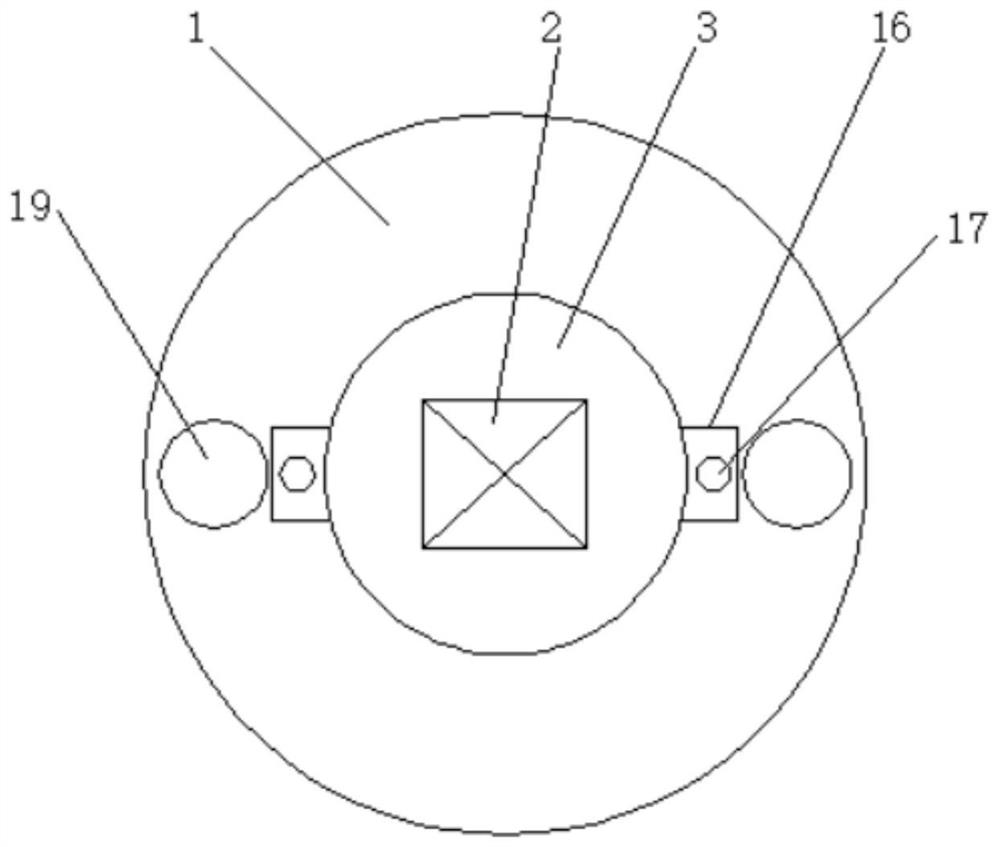

Fertilizer dividing and packaging equipment

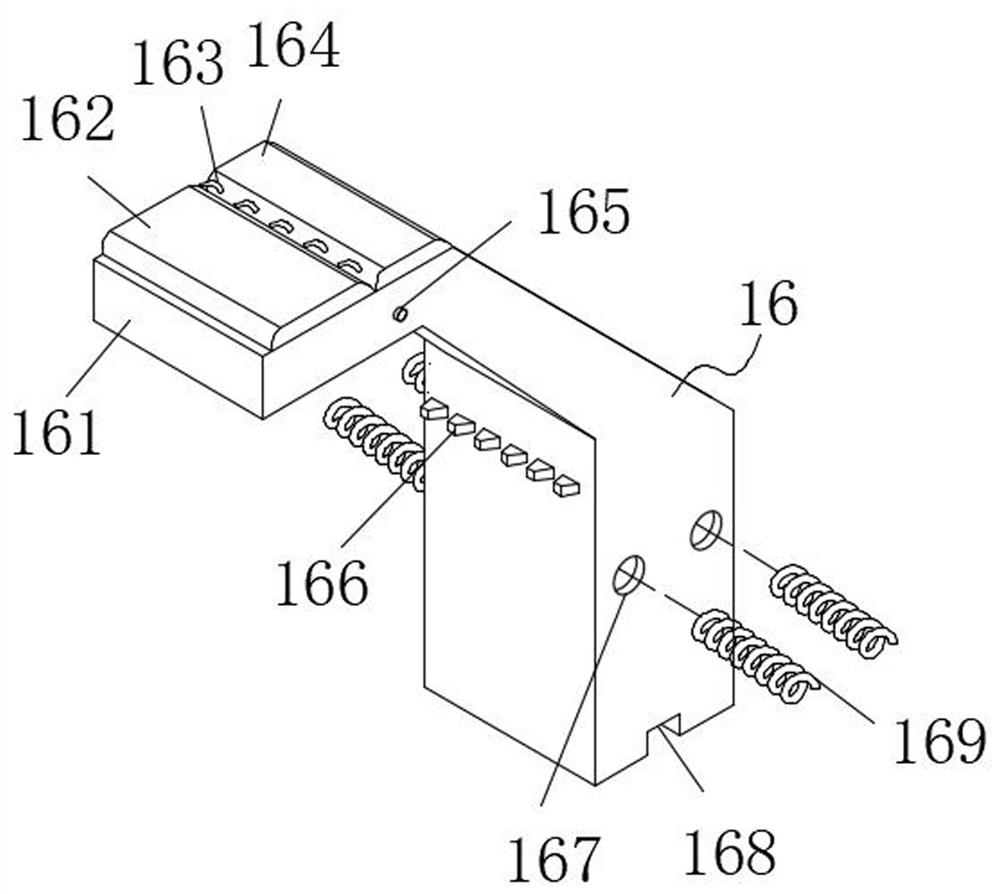

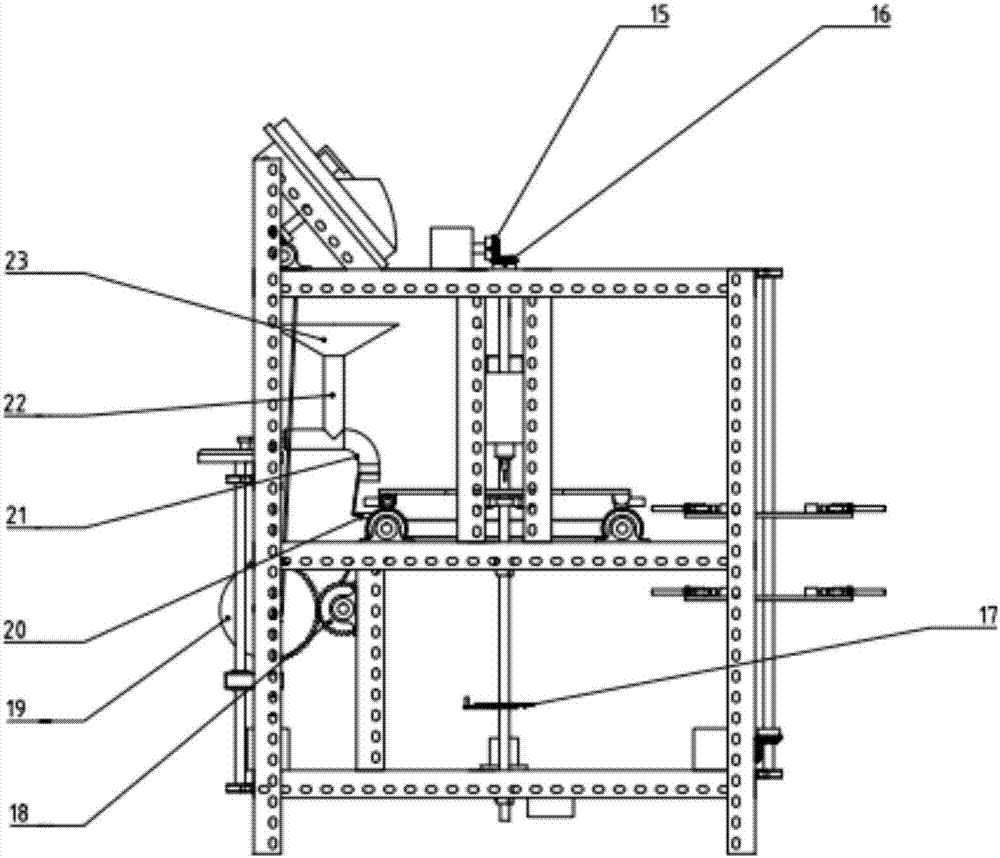

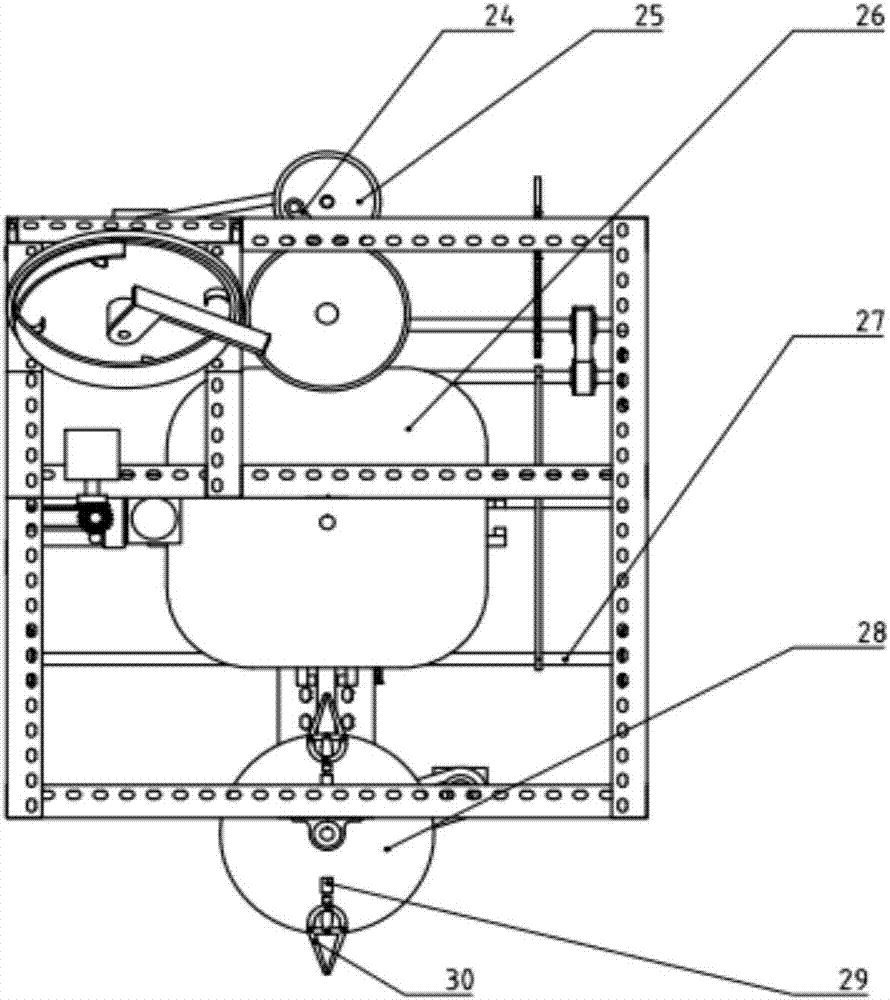

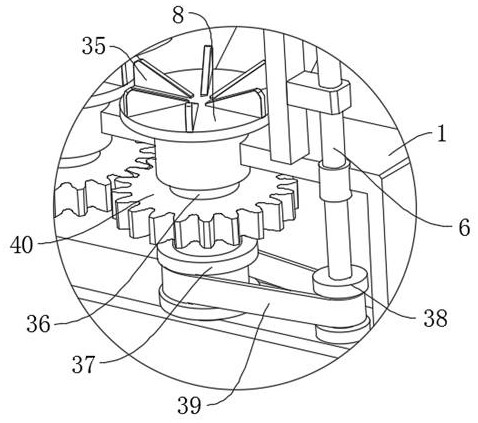

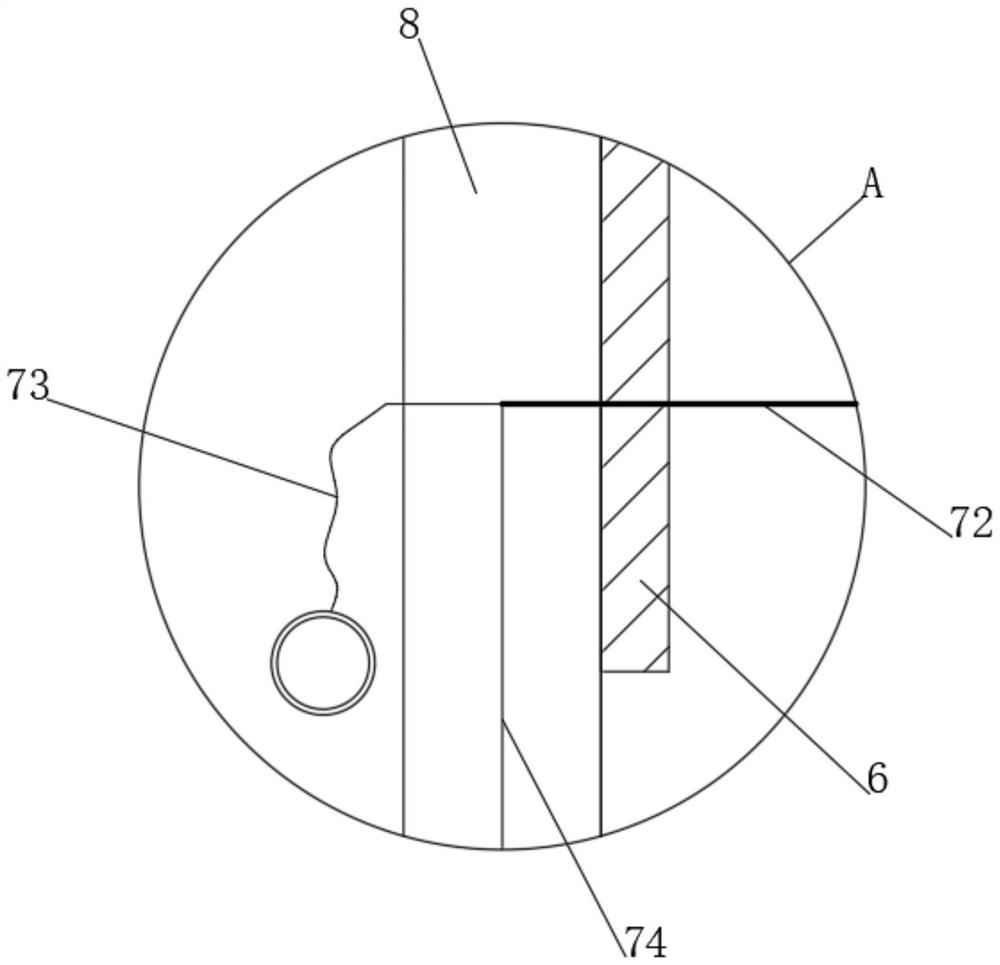

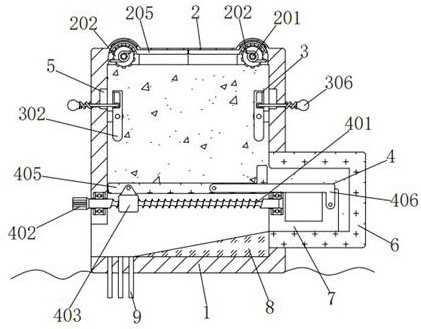

PendingCN108945602AGuaranteed normal whereaboutsAvoid strandedPackagingBiochemical engineeringElectric machinery

The invention relates to the technical field of fertilizer packaging, in particular to fertilizer dividing and packaging equipment. The fertilizer dividing and packaging equipment comprises a box. A stirring device is arranged on the upper portion in the box, and a receiving deice is arranged on the lower portion in the box. The fertilizer dividing and packaging equipment is characterized in thata dividing device is arranged on the position, between the stirring device and the receiving device, in the box, and the stirring device comprises a stirring box; a first motor is arranged on the box,and a rotary shaft of the first motor is connected with a stirring shaft; the stirring shaft stretches into the stirring box, and stirring blades are arranged on the stirring shaft; and a feeding pipe communicating with the interior of the stirring box is arranged on the box, and vibrating devices are evenly arranged between the stirring box and the inner side wall of the box in the peripheral direction. By adopting the fertilizer dividing and packaging equipment, corresponding discharging openings can be adjusted to be opened at the right moment according to the discharging situation, alternate discharging of the two discharging openings is achieved, and the working efficiency is improved; and meanwhile, the hidden danger caused by long-time stacking of fertilizers in a storing bin is also avoided, and smooth discharging of the discharging openings is ensured.

Owner:德阳市澳源农业科技有限公司

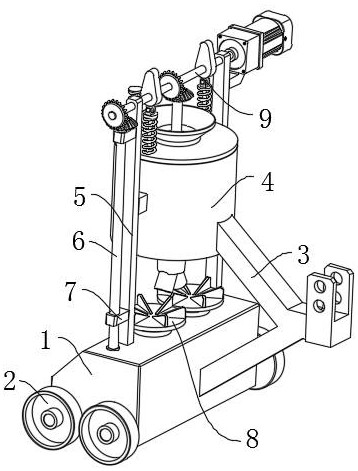

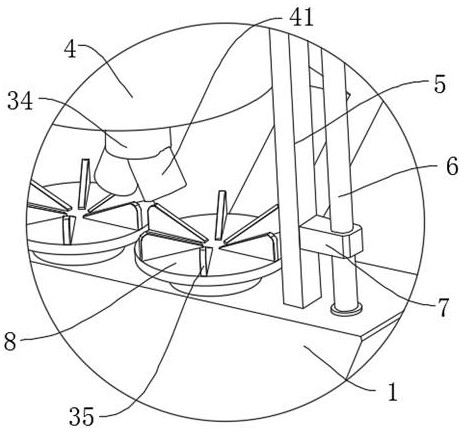

Fertilizing device for corn and soybean compound planting

PendingCN114793578AReduce labor intensityImprove fertilization efficiencyFertiliser distributersCentrifugal wheel fertilisersFertilizerAgricultural engineering

The invention relates to the field of agricultural planting, in particular to a corn and soybean compound planting fertilizing device which comprises a machine shell, a throwing part is installed at the upper end of the machine shell in a penetrating mode, a fertilizer falling part is installed above the machine shell and located above the throwing part, and a driving part is connected to the upper portion of the fertilizer falling part. The driving part is connected with the throwing part, moving wheels are installed on the front end face and the rear end face of the machine shell, and a traction frame is installed between the middle of the side face of the machine shell and the fertilizer falling part. According to the device, the labor intensity of workers is effectively reduced, the fertilization efficiency is improved, meanwhile, the fertilization uniformity is guaranteed, normal falling of fertilizer is guaranteed, and it is guaranteed that the fertilizer is fully pushed by the spiral blades.

Owner:滨州市国盛农业科技有限公司

Uniform-speed discharging and mixing material bin used in pneumatic wet spray machine

PendingCN109877965AExtended use timeGuaranteed normal whereaboutsDischarging apparatusMixing operation control apparatusSlurryEngineering

The invention relates to a uniform-speed discharging and mixing material bin used in a pneumatic wet spray machine. The uniform-speed discharging and mixing material bin comprises a material mixing bin, a material discharging bin arranged at the bottom of the material mixing bin and feeding bins arranged at the top of the material mixing bin; a feeding pulling bin is arranged in the material mixing bin, the material mixing bin and the material discharging bin are provided with an air outlet channel and a through hole, and an air source is connected so that the air source is directly, slantly and upwards blown to the feeding bins of the feeding pulling bin; in the rotating process of the feeding pulling bin, each feed bin can be pneumatically cleaned, so that depositing or accumulation of materials in the feed bins is effectively prevented, the materials are saved as much as possible, the use time of the feeding pulling bin is prolonged, and the number of cleaning and repairing is reduced; the feeding bins adopt vibration type material screening and discharging, and the materials in large particle sizes are prevented from entering the material mixing position and blocking or clamping rotation of the feeding pulling bin; a pressure relief valve is arranged so that the pressure balance in the material mixing bin can be ensured, and normal falling of the slurry materials is ensured; and a hole cover is arranged so that slurry in the material mixing bin can be prevented from being splashed outwards in the rotating process.

Owner:平顶山鸿顺源工贸有限公司

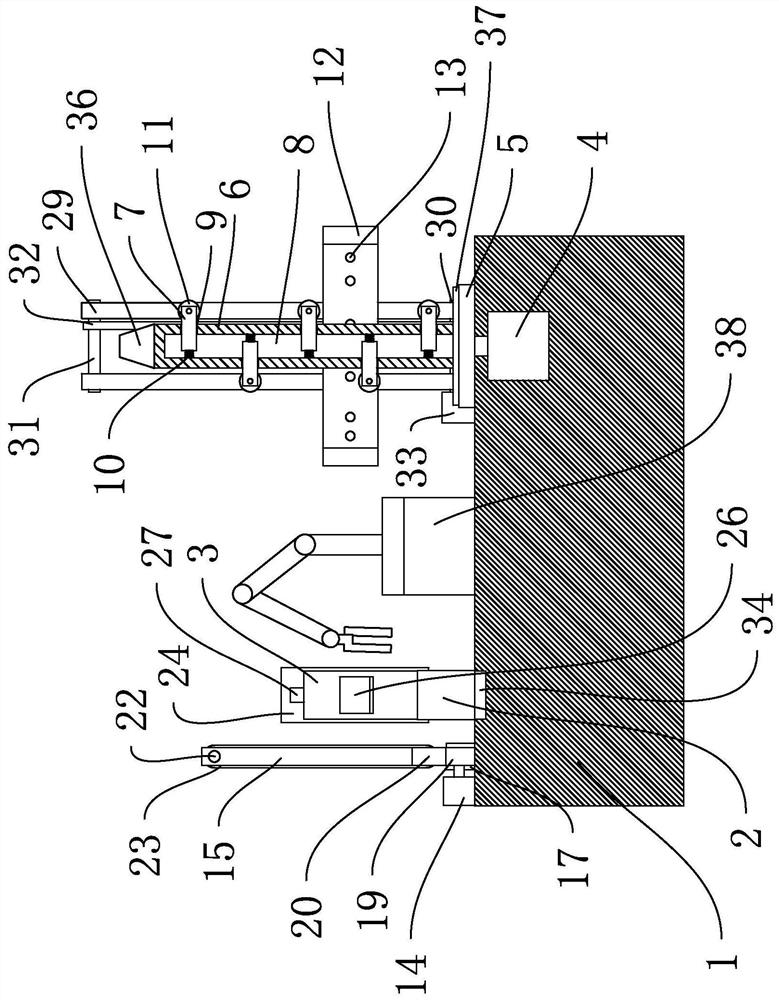

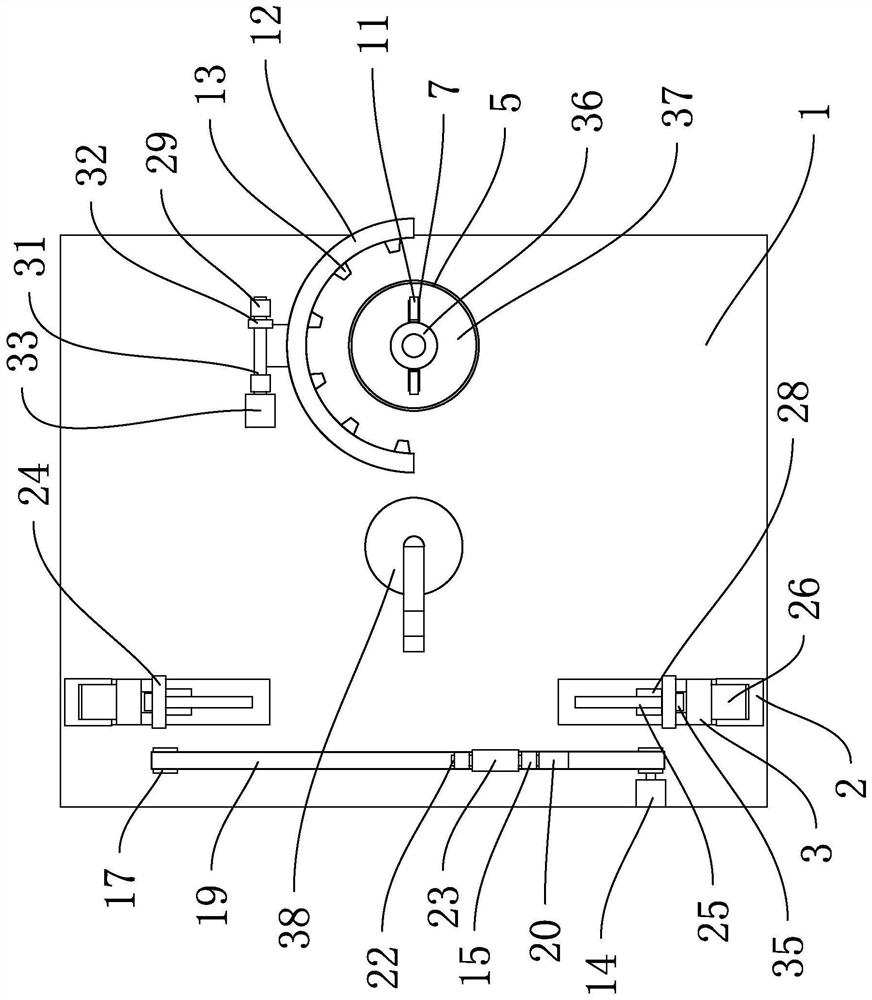

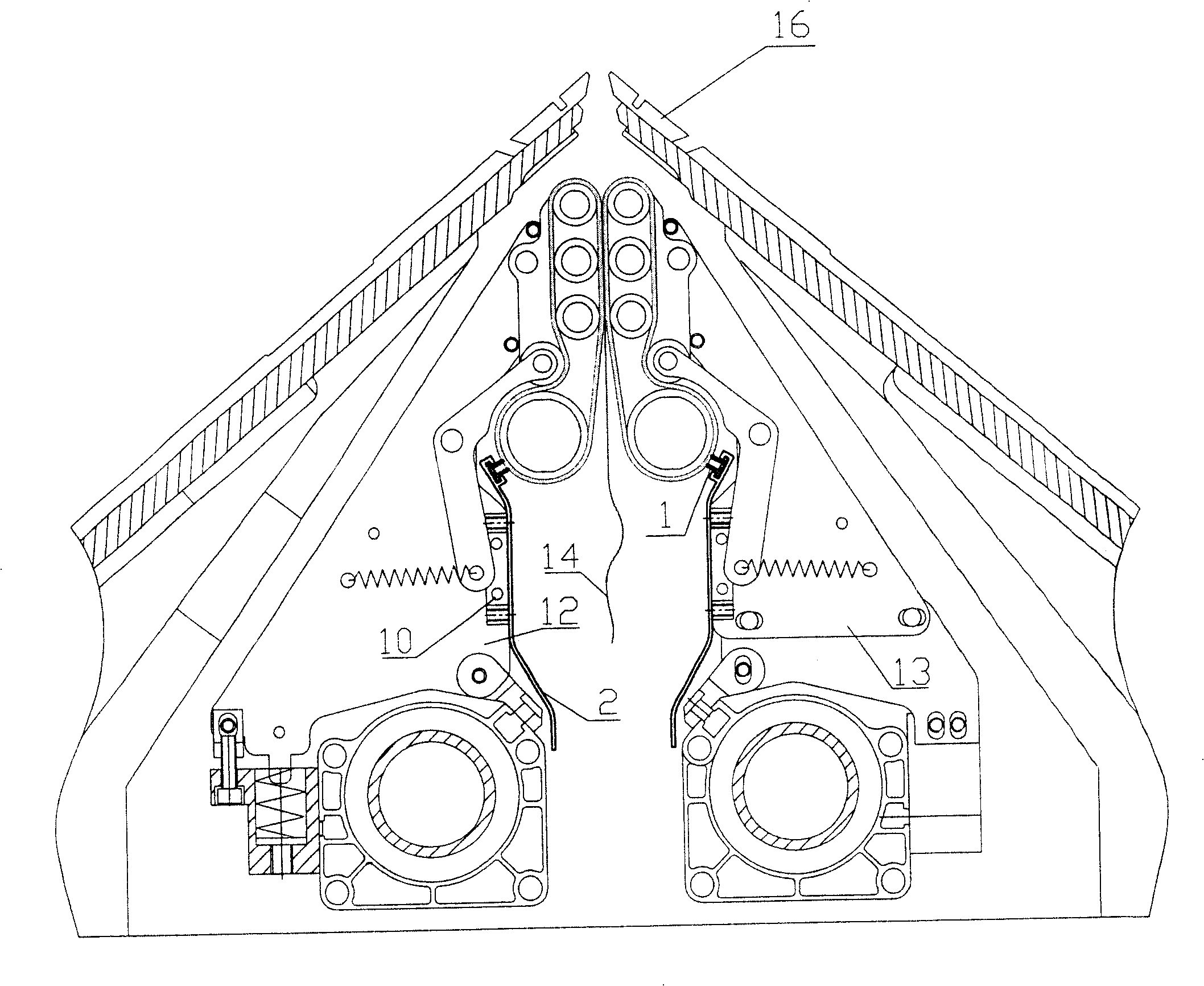

Sowing and hole pressing integrated device of plug-seedling sowing machine

ActiveCN109588086AReduce wearGuaranteed normal whereaboutsPlantingDibble seedersAgricultural engineeringCam

The invention discloses a sowing and hole pressing integrated device of a plug-seedling sowing machine to solve the condition of first hole pressing and then sowing in the sowing process of the vegetable plug-seedling sowing machine. The device mainly comprises a seed pipe support plate, a rack, a rotary cylinder, a sector-shaped part, an air supply chamber, a seed suction needle, a seed pipe, a seed pipe mounting plate, a hole pressing device, a seed groove, a seed pressing device guide plate connecting rod, a concave wheel, a hole pressing device guide plate, a bearing assembly, a rubber collision part, a rotary cylinder connecting rod, a hole pressing device connecting rod, a cam and the like. The device integrates a sowing device and a hole pressing device and can save space. The device is simple in structure, convenient to operate, reliable in performance and capable of effectively improving working efficiency.

Owner:HEBEI AGRICULTURAL UNIV.

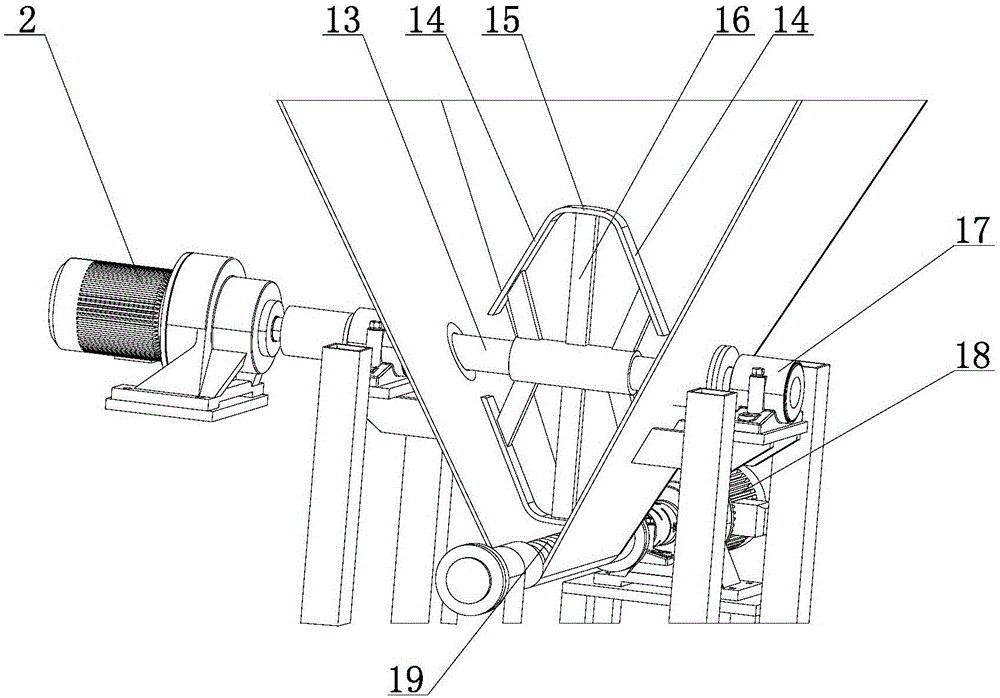

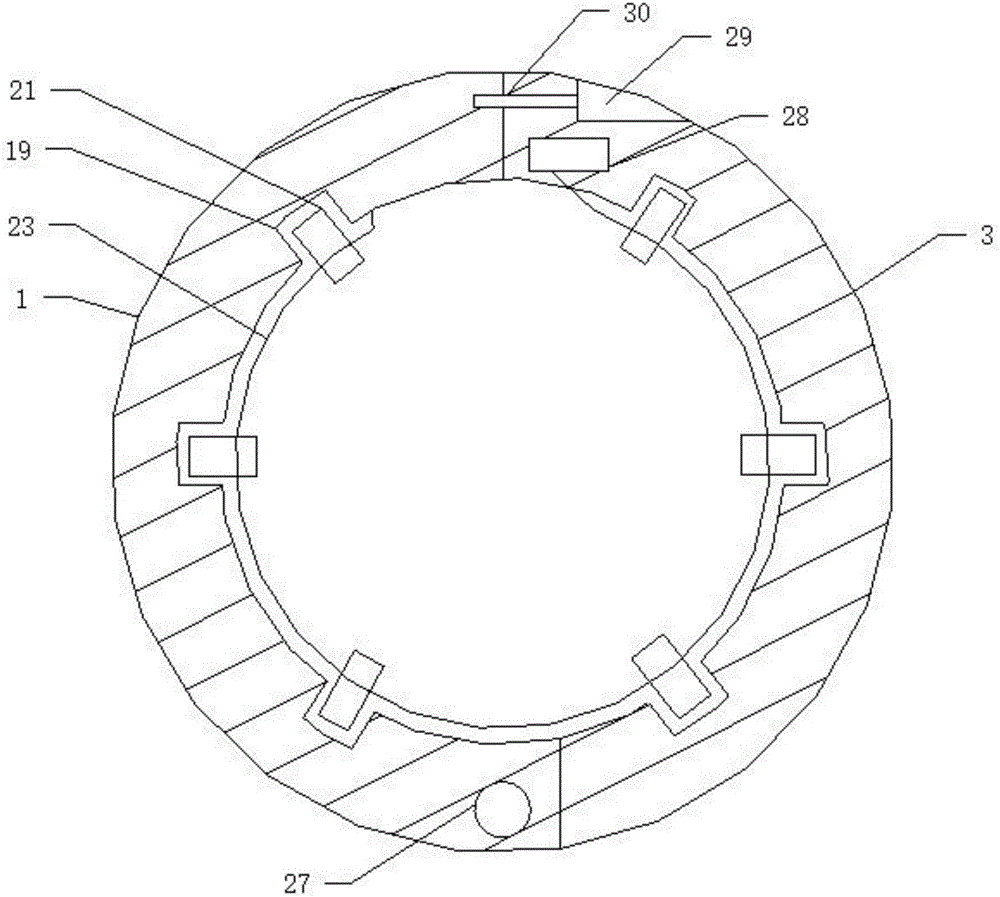

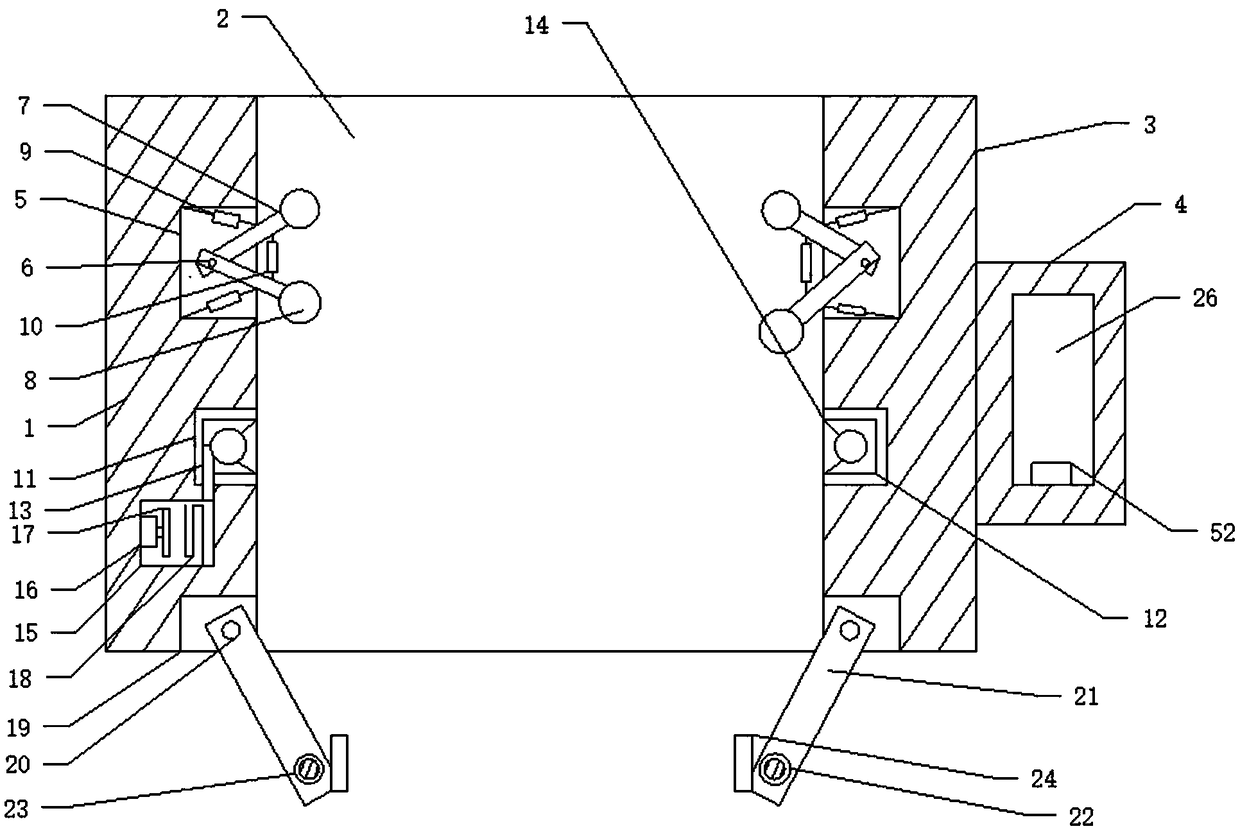

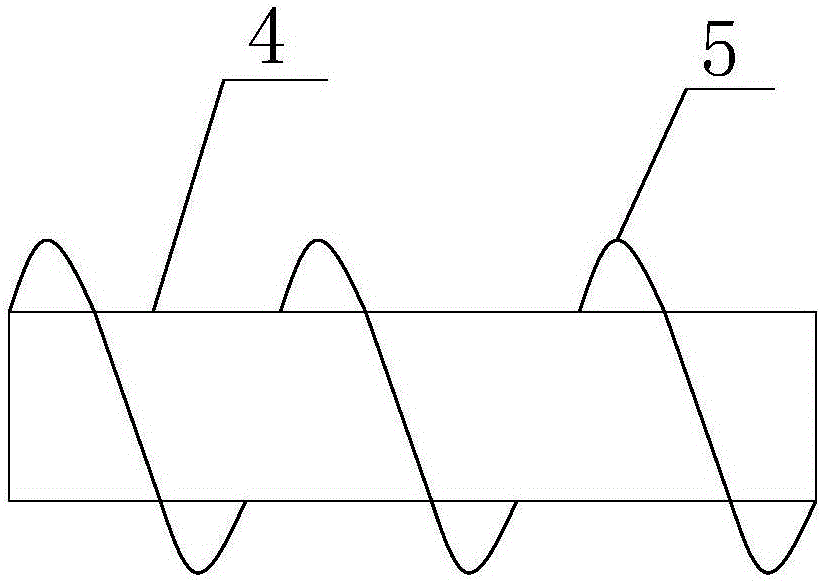

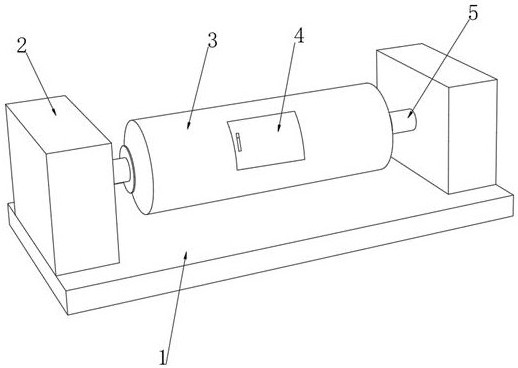

Surface treatment system of pipe fitting for swivel chair

ActiveCN112405252APrevent disengagementGuaranteed full polishingGrinding drivesBelt grinding machinesPolishingPipe fitting

The invention provides a surface treatment system of a pipe fitting for a swivel chair, belongs to the technical field of machinery, and solves the technical problems that existing pipe fitting polishing and paint spraying are not firm in fixation, incomplete in work and the like. The surface treatment system of the pipe fitting for the swivel chair comprises a rack, a polishing mechanism and a paint spraying mechanism; the polishing mechanism is fixed to the rack, and comprises a polishing structure and an adjusting structure arranged on the rack in a mirroring mode; a fixing structure is arranged on the adjusting mechanism; the paint spraying mechanism is fixed to the rack and located behind the polishing mechanism, and comprises a first driving motor fixed to the rack; a rotating tableis fixedly connected to an output shaft of the first driving motor; a positioning column is fixed to the rotating table; a plurality of telescopic structures are arranged on the positioning column; apaint spraying frame is movably arranged on the rack; a plurality of paint spraying heads are fixed to the paint spraying frame; and a transfer mechanism is arranged between the polishing mechanism and the paint spraying mechanism. The surface treatment system has the advantages that pipe fitting fixing is firm, and polishing and paint spraying are conducted in all directions.

Owner:ZHEJIANG KYLIGHT PIPES MFG

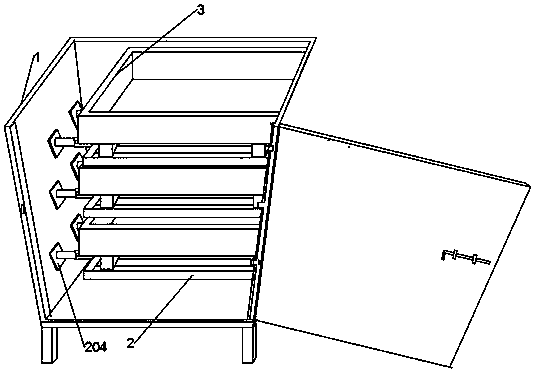

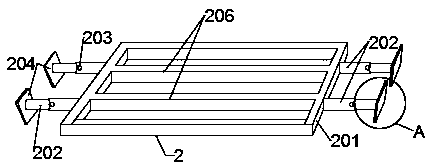

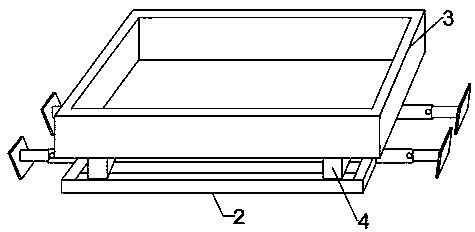

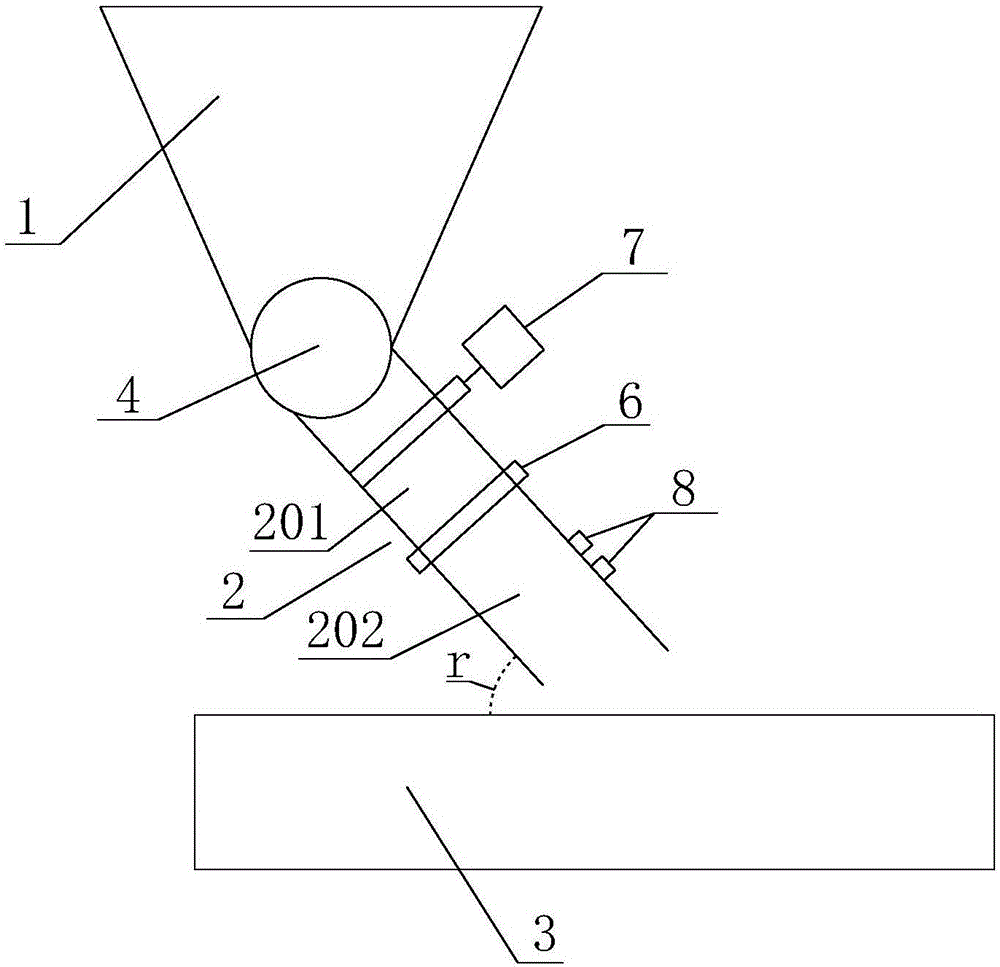

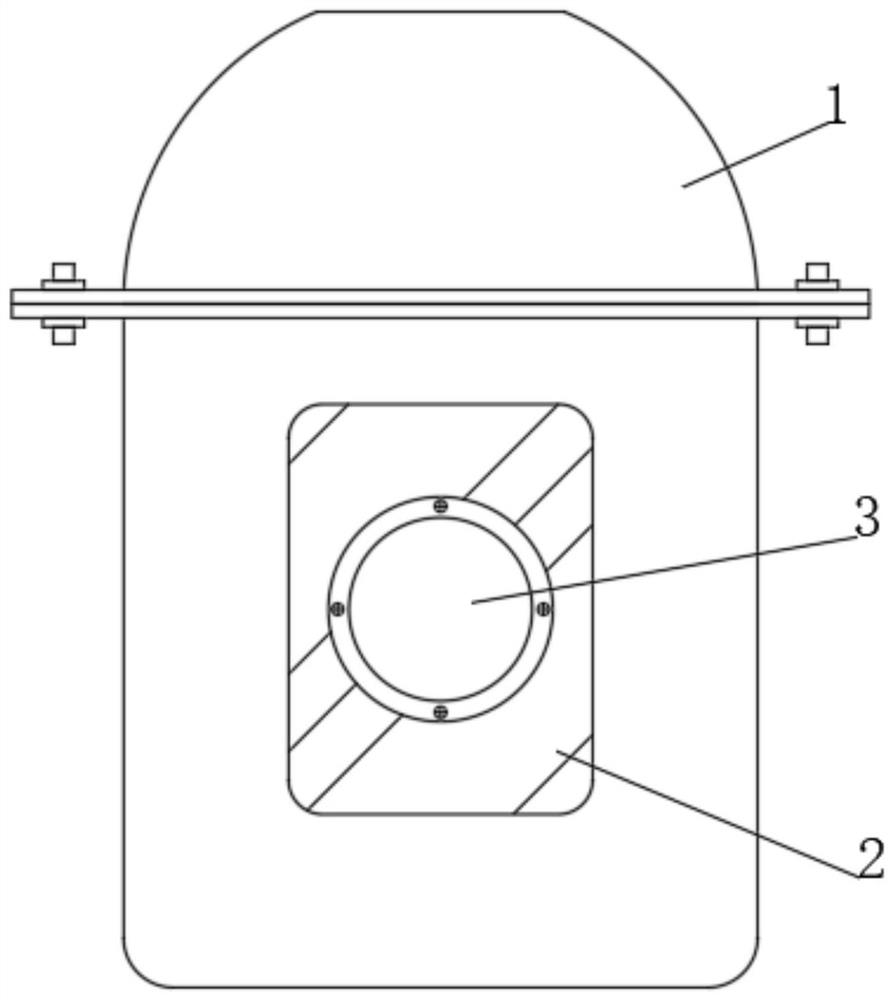

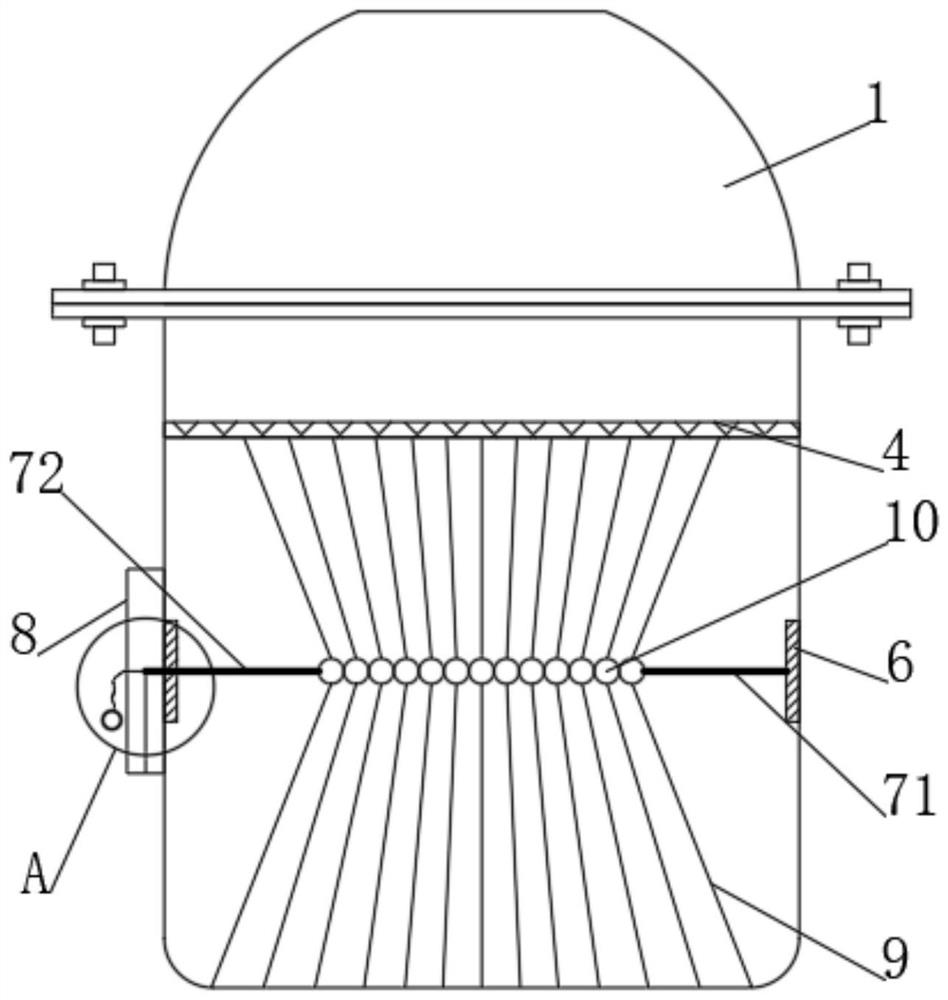

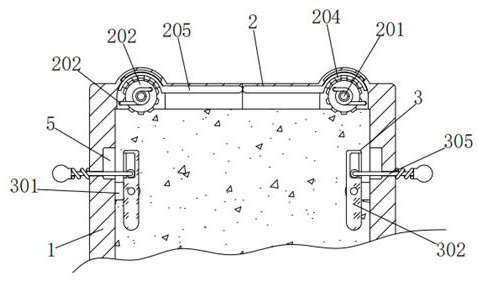

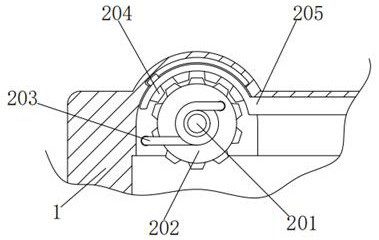

Layer-height-adjustable bean sprout cultivation device

InactiveCN107821148AAvoid damageGuaranteed normal whereaboutsAgriculture gas emission reductionCultivating equipmentsBiology

The invention discloses a layer-height-adjustable bean sprout cultivation device. One surface of a square cultivation hopper (1) is hinged with an openable and closable door; the square cultivation hopper (1) is internally provided with one or more cultivation tray brackets (2) from bottom to top; and each cultivation tray bracket (2) is provided with a cultivation tray (3). The layer-height-adjustable bean sprout cultivation device is characterized in that each cultivation tray bracket (2) comprises a rectangular frame (201) which is horizontally placed; each rectangular frame (201) is provided with two pairs of telescopic rods (202) capable of extending towards the left and right sides of the rectangular frame (201); each of the telescopic rods (202) is provided with a locating screw (203) for controlling the flexible quantity; the extension end of each of the telescopic rods (202) is provided with an inclined supporting plate (204) capable of increasing the area of contacting with the inner wall of the square cultivation hopper (1); and each inclined supporting plate (204) is provided with an elastic rubber layer (205) beneficial to clinging to the inner wall of the square cultivation hopper (1). A plurality of layers can be directly arranged inside an original bean sprout cultivation hopper structure under the condition that the original bean sprout cultivation hopper structure is not changed, and the height of each layer can be regulated.

Owner:贵州温育银芽蔬菜食品有限公司

Automatic climber for power telegraph pole

InactiveCN108635776ASwipe up and down normallyNormal climbingDrying gas arrangementsClimbingEngineeringMechanical engineering

The invention discloses an automatic auxiliary climber for drying a power telegraph pole. The automatic climber comprises a first arc-shaped side plate and a second arc-shaped side plate, wherein a side plate cavity is formed between the first side plate and the second side plate, a first side plate groove correspondingly communicated with the side plate cavity is formed in the first side plate and the second side plate respectively, two crossed correspondingly rotating first supporting shafts are arranged in the first side plate groove, a rotating fixed turning wheel is arranged on the firstsupporting shafts respectively, a heat dissipating tube correspondingly communicated with the side plate cavity is arranged in a second side plate groove, a heating cavity correspondingly communicatedwith the heat dissipating tube is also arranged in the first side plate, heating wires arranged in the heating cavity can be utilized to produce heat, accordingly heat can be delivered to the heat dissipating tube, accordingly the heat dissipating tube can be utilized to dry the power telegraph pole, and the problem is further prevented that the automatic auxiliary climber for drying slips and cannot be used for climbing in the power telegraph pole climbing process due to humid weather.

Owner:国网江西省电力有限公司九江供电分公司 +2

Feeding mechanism of biomass combustion furnace

InactiveCN106642190AGuarantee the safety of useFalling smoothlyLump/pulverulent fuel feeder/distributionSpiral bladeBiomass combustion

The invention relates to the technical field of a biomass combustion furnace, and particularly relates to a feeding mechanism of a biomass combustion furnace. The feeding mechanism comprises a feed bin, feed channels and a chain grate, a feed roller is arranged between the feed bin and the feed channels, the feed roller is driven by a feed machine to rotate, spiral blades are arranged on the feed roller, the feed channels are composed of a first channel and a second channel, the first channel and the second channel are connected through an expansion section. The feeding mechanism is simple in structure, the operating cost is decreased, and the maintenance is made easy. The biomass fuel in the feed bin can be smoothly discharged to the chain grate through the design of the feed roller of the spiral blades, and the blockage of biomass fuel is prevented. Through the arrangements of the first channel and the second channel on the feed channels and the connection of the first channel and the second channel by the expansion section, the operation of the feed channels in high-temperature environment is guaranteed, the application range of the current mechanism is increased, and the mechanism is more practical.

Owner:成都渔夫科技有限公司

Filtration device for pharmaceutical equipment

ActiveCN113332782BEffective toggleGuaranteed filtering effectMoving filtering element filtersStructural engineeringMechanical engineering

Owner:南通灵德制药设备有限公司

Intelligent measuring device for hydraulic engineering

InactiveCN111307244AEasy to measureEasy maintenanceMachines/enginesLevel indicatorsClassical mechanicsElectric machinery

The invention relates to the technical field of hydraulic engineering auxiliary instruments, in particular to an intelligent measuring device for hydraulic engineering. The intelligent measuring device comprises an L-shaped supporting plate; the L-shaped supporting plate is provided with a transverse plate; a fixing structure is arranged on the transverse plate; the L-shaped supporting plate is provided with a mounting plate; the mounting plate is provided with a measurement display panel, a mounting frame and a supporting plate; a driving motor is arranged on the mounting frame, the driving motor is provided with a flange, and the supporting plate is provided with a first bearing and a conductive slip ring; the conductive slip ring is provided with a second cable; the conductive slip ringis provided with a first cable; the first cable is electrically connected with the measurement display panel; a rotating rod is arranged on the first bearing, a rotary flange is arranged, and the twoflanges are provided with second bolts; a winding roller is arranged between the rotating rod and the conductive sliding ring, a steel rope is arranged on the winding roller, the first cable is fixedto the outer end of the steel rope and provided with a liquid level sensor, and a protection frame is arranged at the bottom of the steel rope. The downward moving distance provided by the steel ropeon the winding roller is larger in a deep water area, and the liquid level sensor can conveniently move to the deep water area for measurement.

Owner:杨国丽

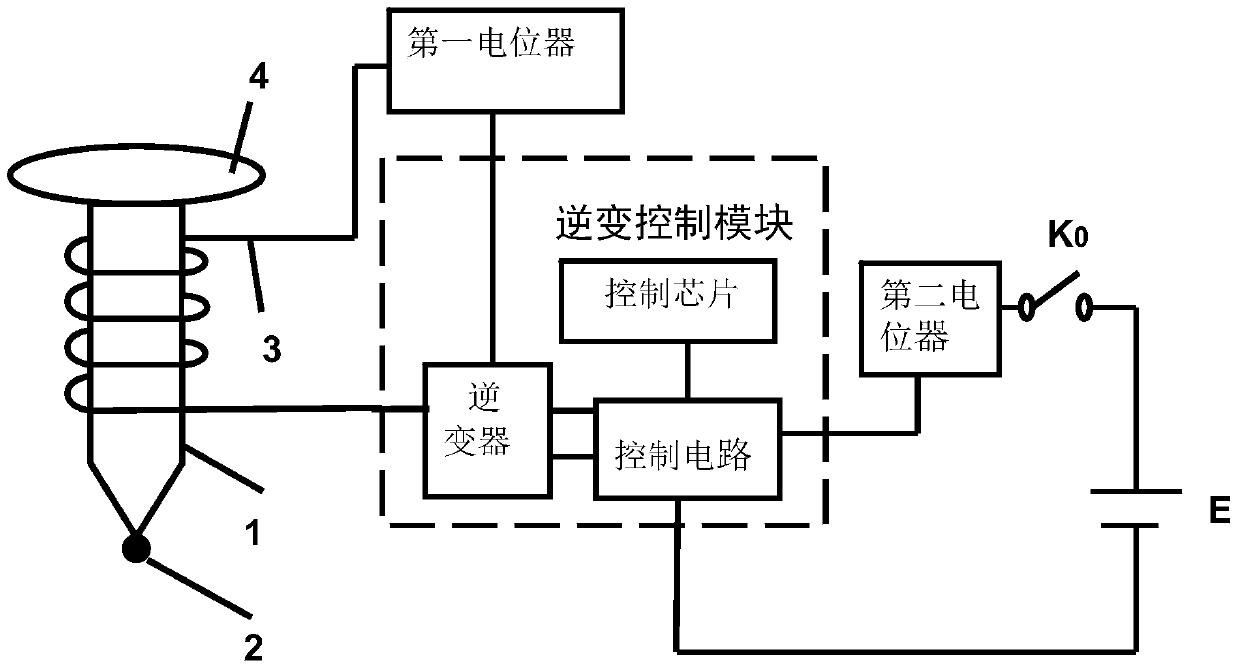

Device for releasing pellets in liquid viscosity coefficient experiment

The invention provides a device releasing a small ball in a liquid viscosity coefficient experiment, which belongs to the field of application of an alternating current electromagnet and comprises a magnetic field generating device, a control module, a first potentiometer, a second potentiometer, a switch K0 and a direct current power source E; an anode of the direct current power source E is connected with a power source input end of an inversion control module by the switch K0 and the second potentiometer; a cathode of the direct current power source E is connected with a grounding end of the inversion control module of which an output end is connected with the magnetic field generating device by the first potentiometer; the magnetic field generating device mainly comprises a metal core and a coil winding the metal core; a lower end of the metal core is a sharp end. The sharp end of the metal core wound by the metal coil adsorbs the small ball, when an alternating current in the metal coil is slowly reduced, the metal core is demagnetized to enable the small steel ball stained with glycerol to fall along the axis of a graduate, thus solving the problem of large error and inconvenience in operation in the existing liquid viscosity coefficient experiment.

Owner:GUANGXI NORMAL UNIV

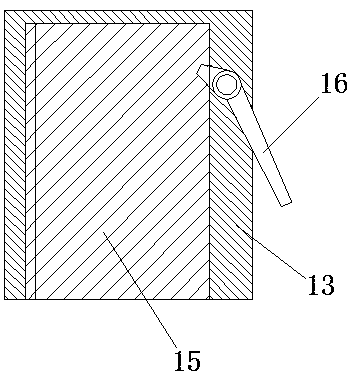

Winding-proof cloth-baffle device for flat knitting machine

InactiveCN1936139AHinder the rotation togetherGuaranteed normal whereaboutsWeft knittingEngineeringLeather belt

The invention relates to a athwart braider winding-proof blocking device that includes blocking board and installation board. The upper part of blocking board is bent to certain pitch to overreach the bottom location of great gross, and adhesive tape, which is contacted to batching strap, or close to batching belt and the clearance below the thickness of fabric, is set near great gross. Thus, the adhesive tape could effectively avoid fabric rotating with batching belt and ensure normal falling of the fabric.

Owner:冯加林

Tobacco stem falling stem metering device and shredded tobacco metering system including the device

ActiveCN109222205BRealize automatic collectionEasy to controlTobacco treatmentAgricultural engineeringProcess engineering

The invention discloses a metering device for falling tobacco stems and a shredded tobacco metering system including the device. The metering device for falling tobacco stems includes a mounting frame, on which a metering mechanism and a flow diversion mechanism are arranged up and down, and the metering mechanism includes a collection funnel connected up and down. And the metering tube, the lower end of the metering tube is provided with a baffle, and the rotary cylinder drives the baffle to slide and connect with the lower end of the metering tube. Including a diverter funnel and a conical diverter; the invention can accurately measure the amount of tobacco stem fall in a timely and efficient manner, and then realize timely and accurate adjustment of the parameters of the air separation device, while improving the air separation effect of shredded tobacco and tobacco stems, The production lean management requirement is met, the cut tobacco waste is reduced, and the invention has a simple structure, little modification to the original equipment, and low modification cost.

Owner:CHINA TOBACCO HENAN IND

Buffer mechanism and sorting system

PendingCN109230240AHas a buffering effectImprove buffering effectConveyorsSortingEngineeringFalling Objects

The embodiment of the invention discloses a buffer mechanism and a sorting system. The buffer mechanism is used for buffering a falling object. The buffer mechanism comprises a suspension device and asponge plate. The sponge plate is connected with the suspension device. The sponge plate is suspended in the air through the suspension device, the sponge plate is located below a falling opening allowing the object to fall, and the sponge plate is used for bearing the object in order to reduce the falling speed of the object. The sponge plate has a buffer effect, and by means of the suspended sponge plate, it is guaranteed that the object can continue to fall, and the buffer effect is further improved.

Owner:深圳市朗耀电子商务有限公司

Vertical-type efficient pulverizer for chemical production

The invention discloses a vertical-type efficient pulverizer for chemical production. The vertical-type efficient pulverizer comprises a pulverizer body. The outer wall of the pulverizer body is provided with a sound reducing layer. The upper side of the pulverizer body is provided with a feeding hopper. Sliding rails are arranged on the front side and the rear side of the bottom end of the interior of the feeding hopper. The sliding rails are slidably connected with adjusting plates. The top end of each adjusting plate is horizontally connected with a cover plate. The right end of the upper side of the pulverizer body is provided with an air cylinder. The bottom end of the air cylinder is fixed to the upper surface of the pulverizer body through a fixing frame. The left end of the air cylinder is connected with a telescopic rod. The telescopic rod penetrates through the feeding hopper and is fixedly connected with the right side walls of the adjusting plates. According to the vertical-type efficient pulverizer for chemical production, the feeding quantity can be controlled, blockage is avoided, and the working load of the pulverizer is further reduced, materials are pulverized through meshing of pulverizing teeth on two extruding rollers arranged in an up-down mode, the pulverizing effect is good, the two extruding rollers are driven by one motor, energy consumption is reduced, the pulverized materials can be screened and pulverized circularly, and the pulverizing quality is ensured; and in addition, moving is convenient, and convenience is high.

Owner:余姚市滨腾电器有限公司

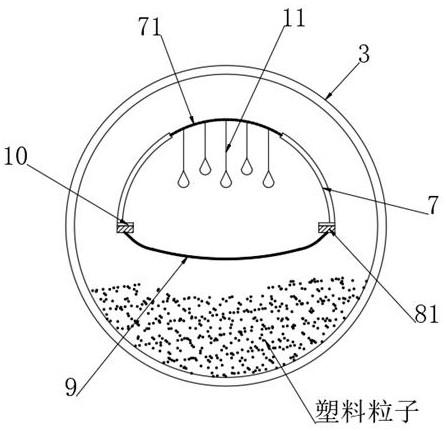

A kind of dynamic drying equipment for powdery plastic particles

ActiveCN113465326BSpeed up entryDisperse fastDrying gas arrangementsDrying chambers/containersReciprocating motionMaterials science

The invention discloses a powder-turning dynamic drying equipment for plastic particles, which belongs to the field of drying equipment. The powder-turning dynamic drying equipment for plastic particles is equipped with a powder-turning clutch bag to dry some plastic particles while rotating. After reaching the top under the action of centrifugal force, part of it enters the inner fixed cylinder and falls into the top powder clutch bag. When multiple electromagnetic plates are energized at intervals, the driving bar is pulled to reciprocate, so that the end of the top powder bag first The plastic particles are close to each other so that the plastic particles gather in the middle, and then they are quickly stretched and straightened, thereby generating a large bumping force on the plastic particles on it, and the plastic particles are quickly dispersed upwards and fully contacted with the hot air. In a bumpy dynamic, compared with the existing technology, the drying efficiency and drying uniformity are significantly improved, and when the traction bar moves back and forth, the multiple longitudinal rods are constantly stressed at intervals, effectively accelerating the plastic particles into the inner fixed cylinder Inside.

Owner:HAIMEN JINQILIN REDWOOD INVESTMENT DEV

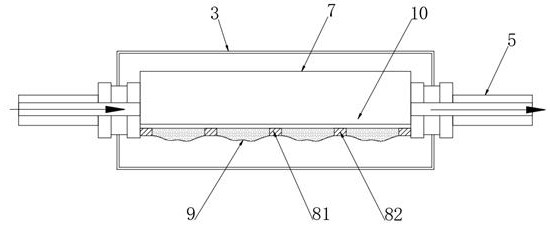

A secondary fiber separation device for pulverized coal system

The invention discloses a pulverized coal system fiber secondary separation device. The device comprises a fiber screen shell body, a brush, a screen, a base and a back flushing nitrogen pipeline; a motor is installed at the central position of the fiber screen shell body; a cover is installed below the motor; a bearing is installed below the cover; a rotary shaft is connected with the bottom of the bearing; a reduction box is connected with the outer side of the rotary shaft; fixed blocks are installed on both sides of the reduction box; a fixed rod is installed in each of the fixed blocks; and limiting blocks are installed on both the left side and the right side of each fixed rod. With the pulverized coal system fiber secondary separation device, separation treatment can be convenientlyconducted to pulverized coal by a user, the secondary separation structure is simple and manufacturing is easy. The device is applicable to a pulverized coal gasification device, placing stability ofthe device is effectively improved, the screen is convenient to disassemble, inspect and clean, the effect of capturing fiber and other impurities is remarkable, deficiency of existing technology canbe offset, a pulverized coal system can be cleaned more thoroughly and more efficiently, and a good foundation is laid for stable operation of the device.

Owner:ANHUI JINMEI ZHONGNENG CHEM IND

A feed processing device for raising hedgehogs

ActiveCN112352984BReduce accumulationReduce residualSievingFeeding-stuffElectric machineryEngineering

Owner:SUZHOU SHUAIZE INFORMATION TECH CO LTD

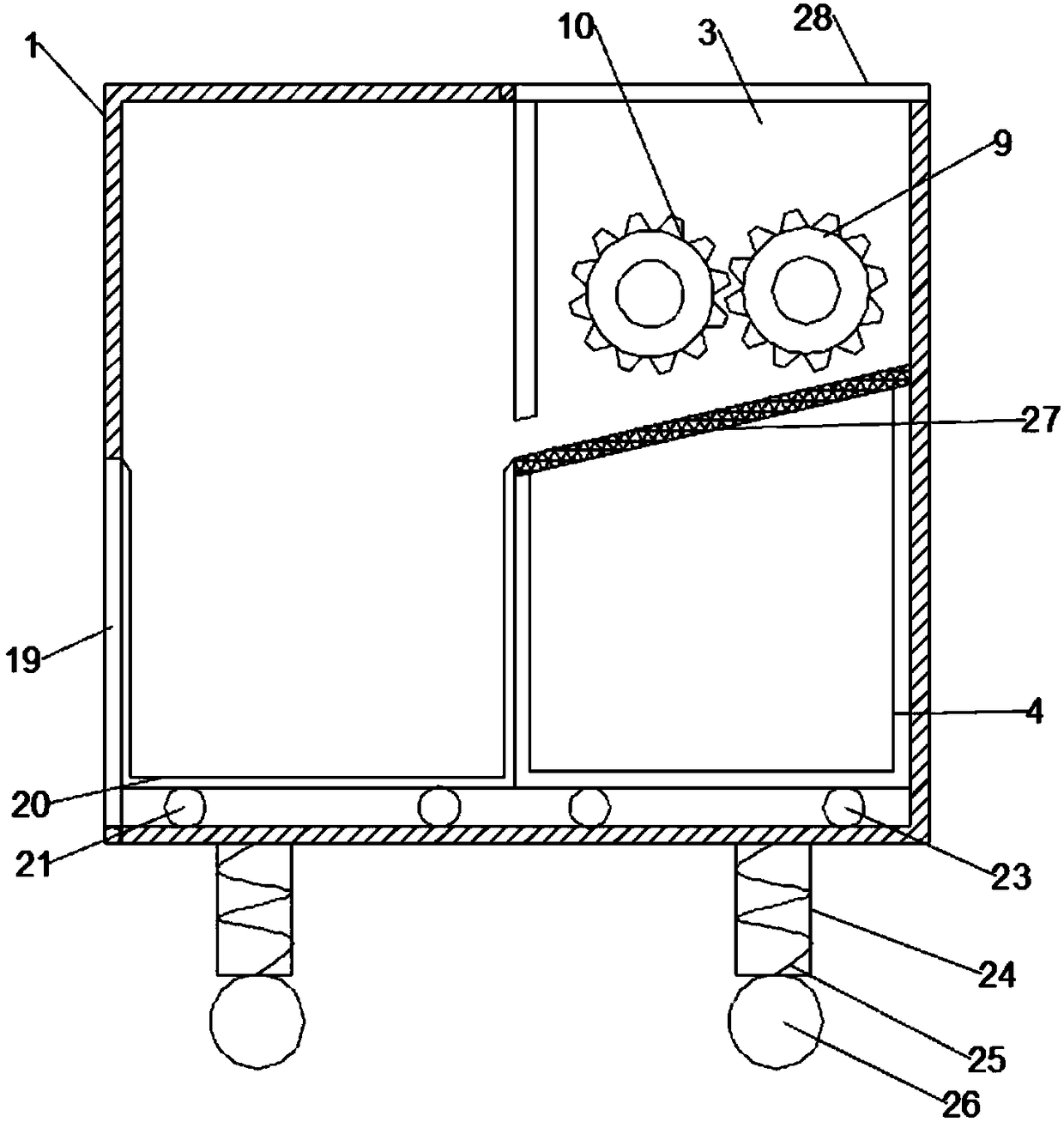

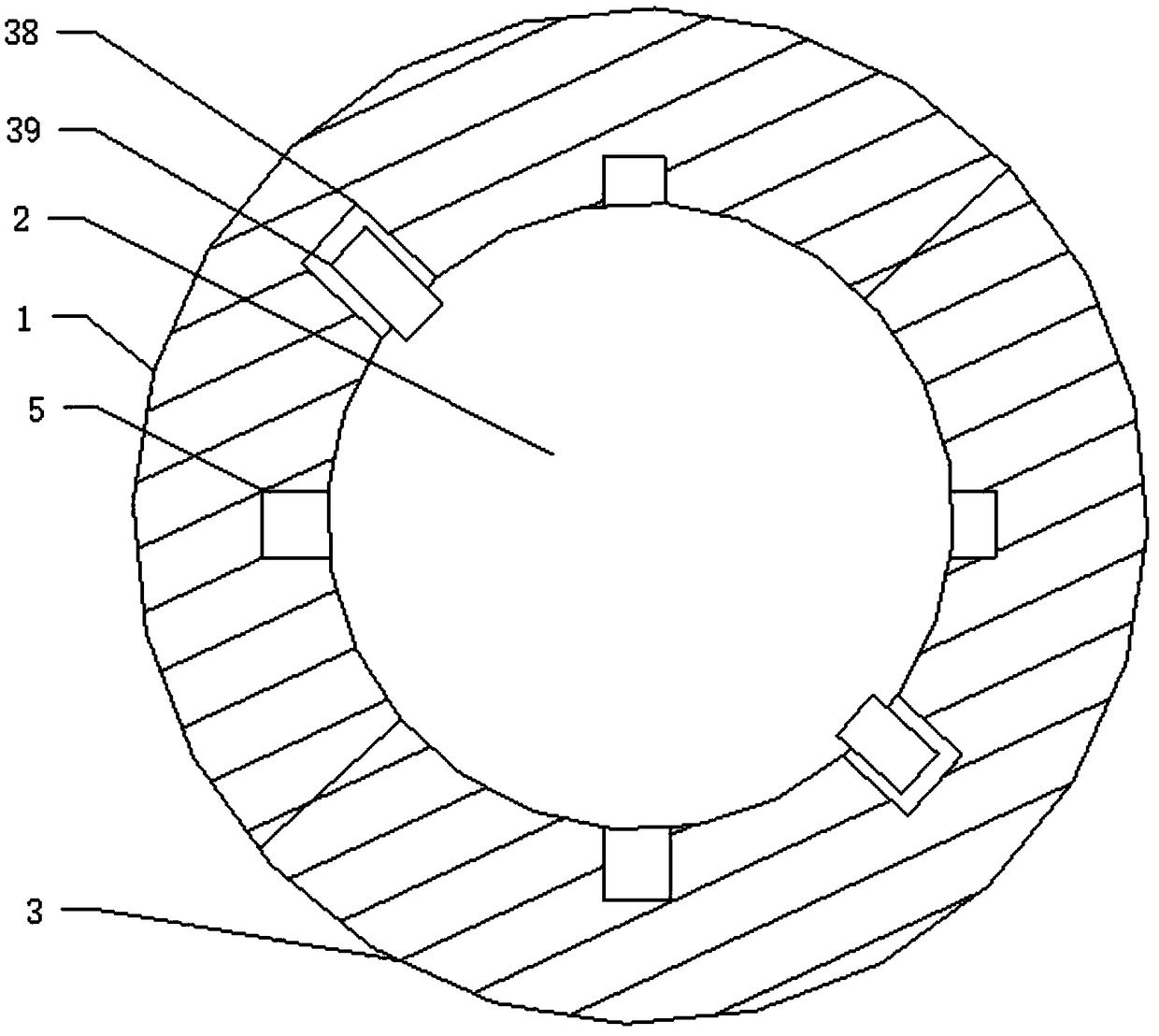

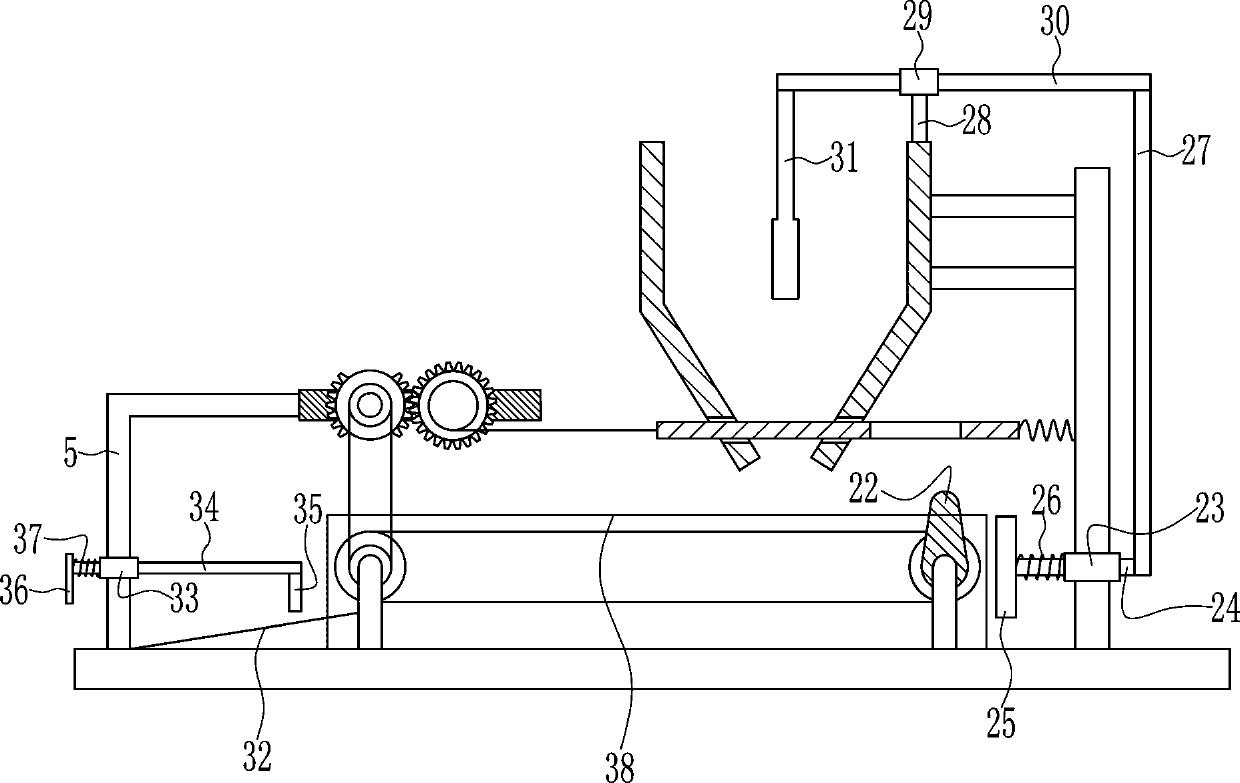

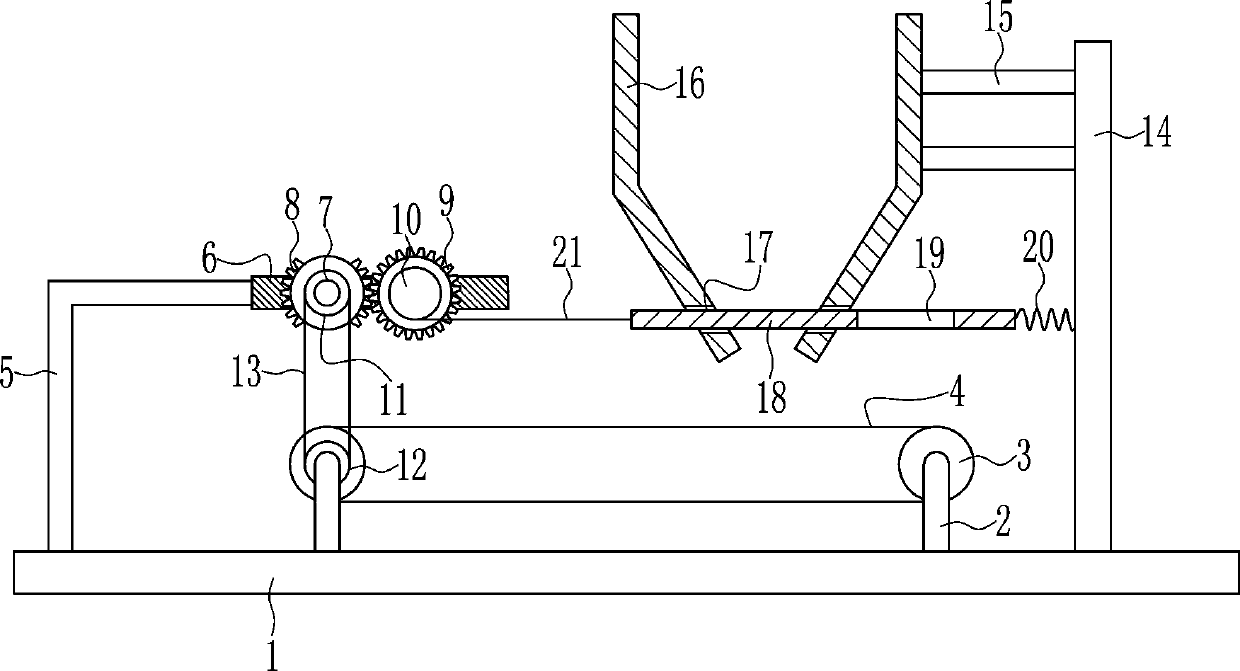

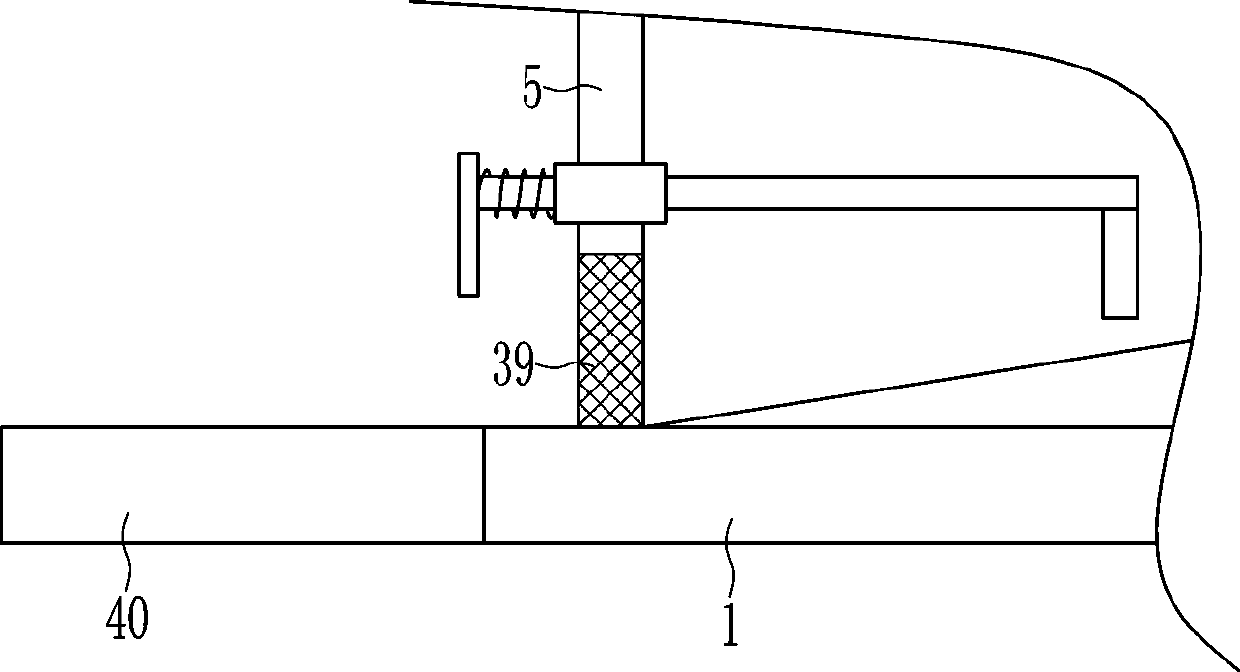

Batch-batch sand feeding equipment for construction concrete preparation

ActiveCN108422559BAvoid cakingGuaranteed normal whereaboutsMixing operation control apparatusPretreatment controlDrive wheelTransmission belt

The invention relates to blanking equipment, in particular to sand batch blanking equipment for preparation of architectural engineering concrete. Technically, the invention aims to provide the sand batch blanking equipment for preparation of architectural engineering concrete with the characteristics of batch blanking, no caking of sand after long time accumulation and convenient screening of fine sand. The sand batch blanking equipment for preparation of architectural engineering concrete comprises a first mounting plate, first support rods, driven wheels, a transmission belt, an L-shaped support rod, a second mounting plate, a driving wheel, a sector gear, etc. The first support rods are disposed on the left and right side at the top of the first mounting plate symmetrically. Through the left and right reciprocating motion of a stirring plate, the equipment can avoid caking of sand accumulated for a long time in a blanking frame, ensures normal falling of sand, improves the runningstability of the equipment, also can be applied to wall painting with high requirements for building materials, and reaches the effect of enhancing the equipment practicability.

Owner:ZHEJIANG AOCHUAN HYDRAULIC

A magnetic swing type large particle impurity interception device in exhaust gas

ActiveCN112044179BGuaranteed swing rangePlay a shearing roleDispersed particle separationEngineeringMechanical engineering

The invention discloses a magnetic swing type waste gas large particle impurity interception device, which belongs to the field of waste gas treatment. A magnetic swing type waste gas large particle impurity interception device can be used in waste gas through the setting of a magnetic suction moving ball and an interception moving rope. The vertical direction of the movement swings back and forth, thereby shearing the exhaust gas flow. Cooperating with the wire control rope and the auxiliary swing block, it can effectively ensure the swing range of the magnetic suction ball and effectively improve the interception of larger particles of impurities in the exhaust gas. At the same time, under the action of the expanded inner core in the intercepting moving rope, the outer convex deformation layer is continuously shrinking and stretching during repeated swings, so as to effectively ensure that the larger particle impurities intercepted on it can fall, which is convenient for magnetic absorption The moving ball and multiple intercepting moving ropes can continuously intercept impurities in the exhaust gas, effectively reducing the occurrence of poor interception effect due to excessive interception of impurities. Compared with the existing technology, the overall interception efficiency is significantly improved.

Owner:江苏鸿捷环保设备有限公司

Winding-proof cloth-baffle device for flat knitting machine

InactiveCN100449047CHinder the rotation togetherGuaranteed normal whereaboutsWeft knittingEngineeringLeather belt

The invention relates to a athwart braider winding-proof blocking device that includes blocking board and installation board. The upper part of blocking board is bent to certain pitch to overreach the bottom location of great gross, and adhesive tape, which is contacted to batching strap, or close to batching belt and the clearance below the thickness of fabric, is set near great gross. Thus, the adhesive tape could effectively avoid fabric rotating with batching belt and ensure normal falling of the fabric.

Owner:冯加林

Novel smart city garbage management system

InactiveCN111746985AEnsure the surrounding environmentImprove stickinessRefuse receptaclesTorsion springIntelligent city

The invention discloses a novel smart city garbage management system. The novel smart city garbage management system comprises a shell, opening and closing mechanisms are installed on the left side and the right side of the top of the inner wall of the shell, each opening and closing mechanism comprises a round rod, a gear, a torsion spring, a convex block and a bent plate, and the rear end surface of each round rod is fixedly connected with the upper part of the inner wall of the shell. According to the novel smart city garbage management system, the two bent plates are controlled to rotate through the opening and closing mechanisms, so that the opening and closing of a garbage feeding port are realized, garbage is prevented from running out due to being too full, the surrounding environment is guaranteed, and the use viscosity is improved; after the height of the internal garbage reaches a certain height, the bent plates are limited and cannot rotate, so that the storage of the garbage is limited, the service life is prolonged, the stirring of the internal garbage is realized, the garbage is prevented from being adhered and stuck, the falling of the garbage is guaranteed, the working difficulty is reduced, and normal use is guaranteed; and water in the garbage is leaked through a filter plate in an adjusting mechanism, so that the garbage is prevented from being soaked, the smell is reduced, the influence on the breath of passing people is reduced, and the popularization is facilitated.

Owner:陆开群

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com