Batch-batch sand feeding equipment for construction concrete preparation

A technology for construction engineering and concrete, which is applied to the field of batch cutting equipment for the preparation of concrete in construction engineering, can solve the problems of inability to cut materials in batches, easy to agglomerate, difficult to screen fine sand, etc., so as to ensure normal falling and avoid caking block, improve the effect of running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

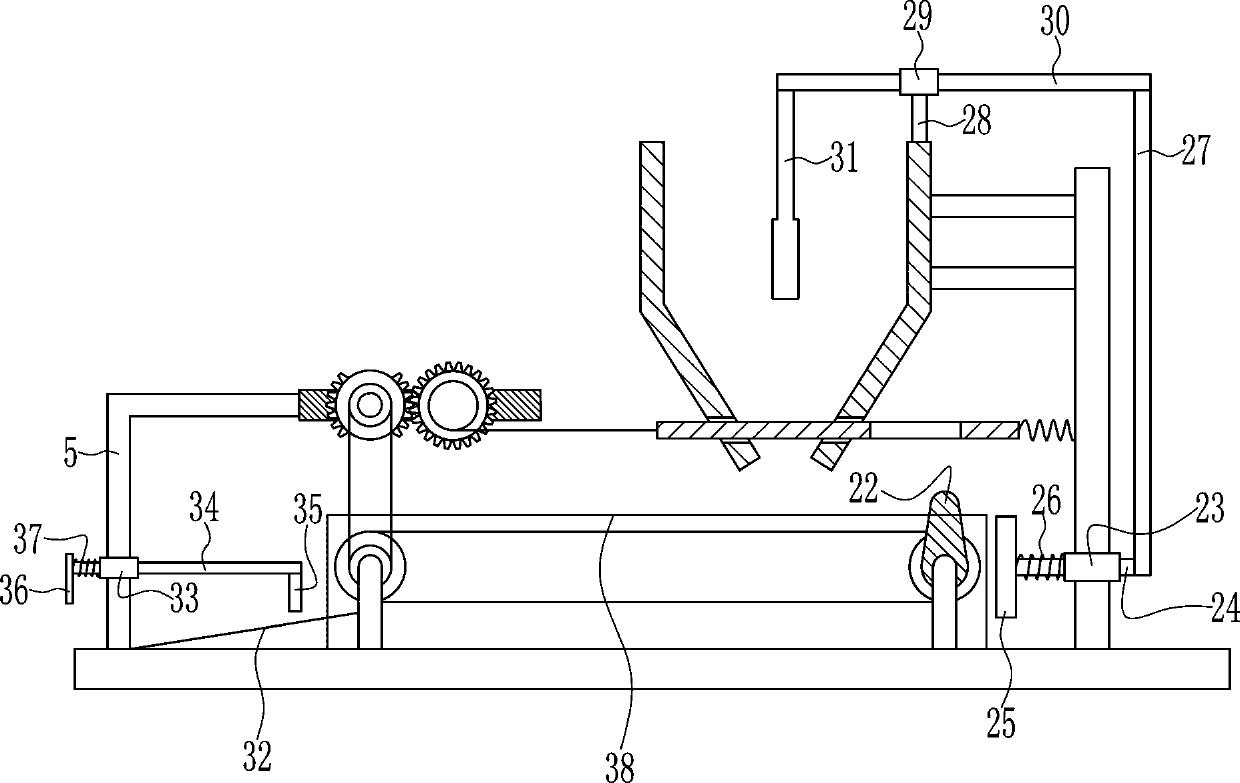

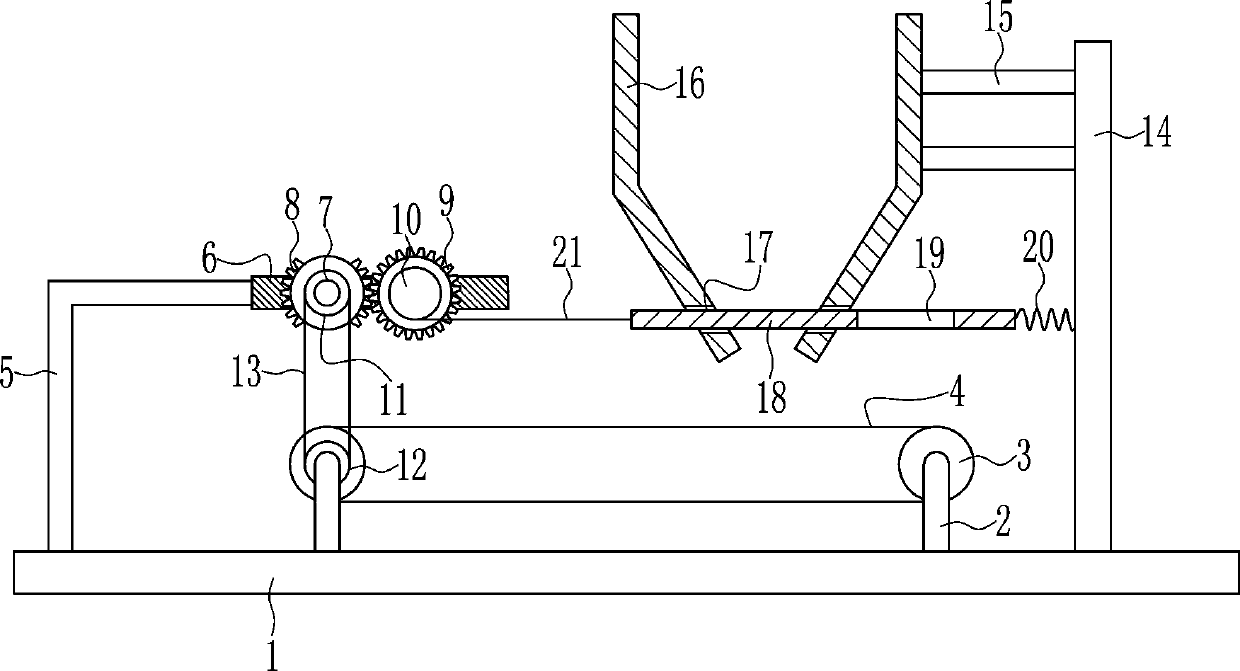

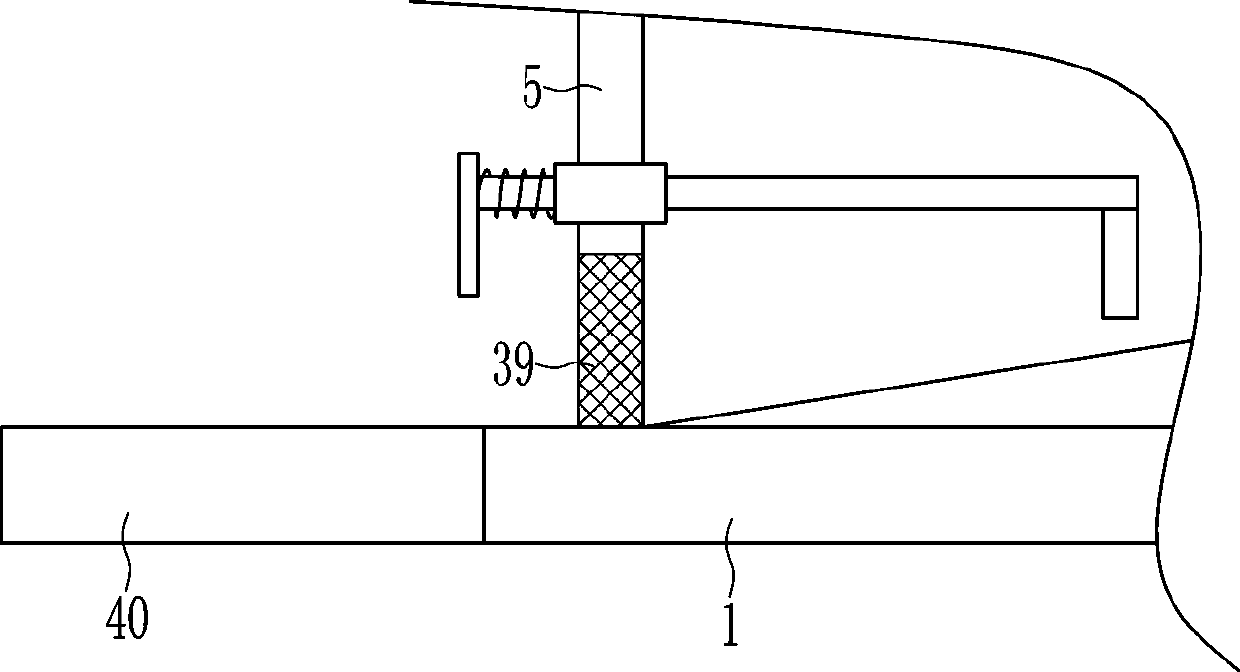

[0026] A kind of equipment for batch-batch sand feeding for concrete preparation in construction engineering, such as Figure 1-3As shown, it includes the first mounting plate 1, the first pole 2, the driven wheel 3, the transmission belt 4, the L-shaped pole 5, the second mounting plate 6, the driving wheel 7, the sector gear 8, the transmission gear 9, the winding Wheel 10, first pulley 11, second pulley 12, flat belt 13, third mounting plate 14, third pole 15, blanking frame 16, guide plate 18, first spring 20 and stay wire 21, first mounting plate 1 The top left and right is symmetrically provided with the first support rod 2, the top of the first support rod 2 is rotatably connected with the driven wheel 3, the left and right driven wheels 3 are wound with a transmission belt 4, and the left side of the first mounting plate 1 is provided with an L-shaped Strut 5, the right end of the L-shaped strut 5 is provided with a second mounting plate 6, and the left side of the fro...

Embodiment 2

[0028] A kind of equipment for batch-batch sand feeding for concrete preparation in construction engineering, such as Figure 1-3 As shown, it includes the first mounting plate 1, the first pole 2, the driven wheel 3, the transmission belt 4, the L-shaped pole 5, the second mounting plate 6, the driving wheel 7, the sector gear 8, the transmission gear 9, the winding Wheel 10, first pulley 11, second pulley 12, flat belt 13, third mounting plate 14, third pole 15, blanking frame 16, guide plate 18, first spring 20 and stay wire 21, first mounting plate 1 The top left and right is symmetrically provided with the first support rod 2, the top of the first support rod 2 is rotatably connected with the driven wheel 3, the left and right driven wheels 3 are wound with a transmission belt 4, and the left side of the first mounting plate 1 is provided with an L-shaped Strut 5, the right end of the L-shaped strut 5 is provided with a second mounting plate 6, and the left side of the fr...

Embodiment 3

[0031] A kind of equipment for batch-batch sand feeding for concrete preparation in construction engineering, such as Figure 1-3 As shown, it includes the first mounting plate 1, the first pole 2, the driven wheel 3, the transmission belt 4, the L-shaped pole 5, the second mounting plate 6, the driving wheel 7, the sector gear 8, the transmission gear 9, the winding Wheel 10, first pulley 11, second pulley 12, flat belt 13, third mounting plate 14, third pole 15, blanking frame 16, guide plate 18, first spring 20 and stay wire 21, first mounting plate 1 The top left and right is symmetrically provided with the first support rod 2, the top of the first support rod 2 is rotatably connected with the driven wheel 3, the left and right driven wheels 3 are wound with a transmission belt 4, and the left side of the first mounting plate 1 is provided with an L-shaped Strut 5, the right end of the L-shaped strut 5 is provided with a second mounting plate 6, and the left side of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com