Tobacco stem falling stem metering device and shredded tobacco metering system including the device

A technology of measuring device and tobacco stems, which is applied in the fields of tobacco, tobacco processing, and application, can solve the problems such as the inability to adjust the data of the secondary air separation equipment in time, the inability to accurately measure the falling stems in time, and the inability to provide the composition data of tobacco shreds, etc. To achieve the effect of easy and precise control, simple structure, and ensure the stable performance of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

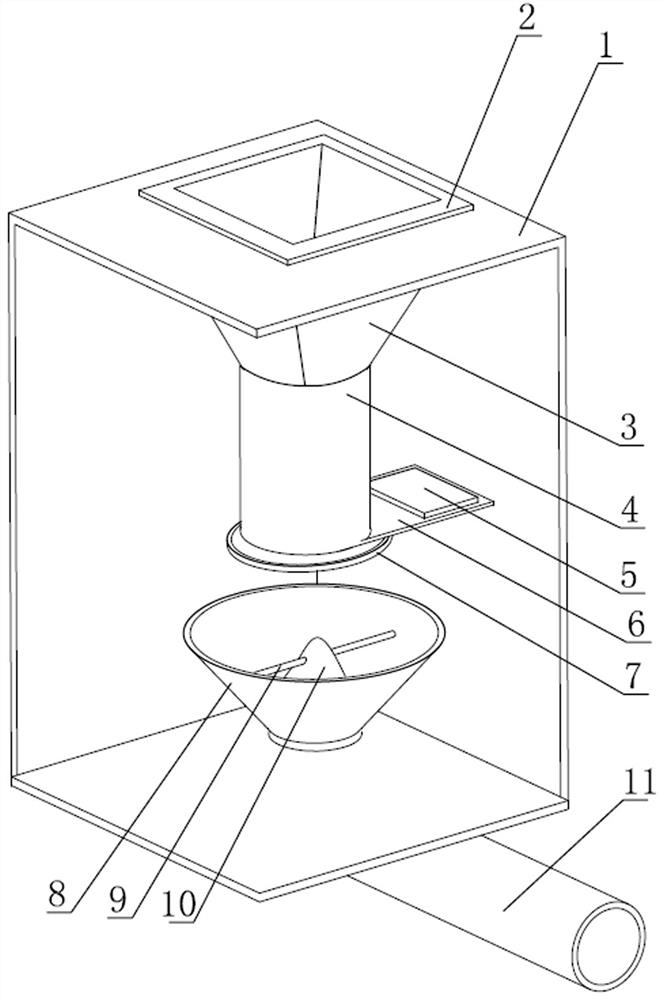

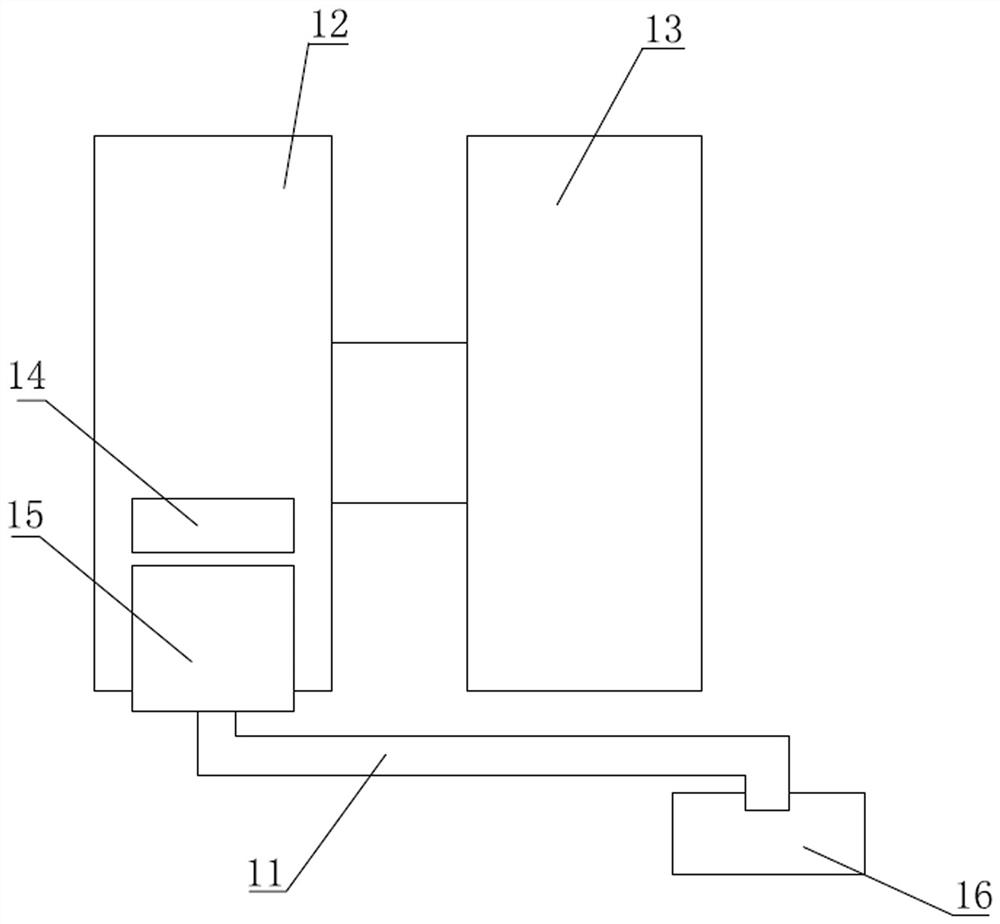

[0027] like figure 1 As shown in the figure, the present invention discloses a tobacco stem falling stem metering device, which includes an installation frame, the installation frame is located below the tobacco stem outlet of the upstream equipment, and the installation frame is provided with a metering mechanism and a diversion mechanism; the installation frame preferably adopts a rectangular metal shell Body 1, the casing 1 is fixedly arranged on the outer wall of the upstream equipment, and the metering mechanism and the diversion mechanism are arranged in the casing 1;

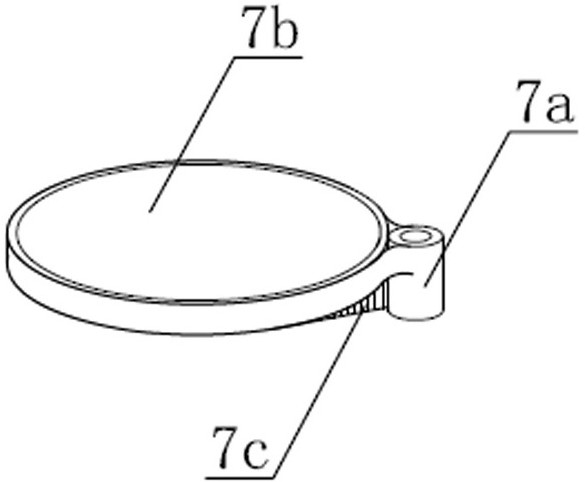

[0028] The metering mechanism includes a collection funnel 3 and a metering tube 4 arranged up and down. The collection funnel 3 adopts a quadrangular pyramid-shaped structure, and the diameter of the collection funnel 3 decreases sequentially from top to bottom. The frame, the rectangular frame 2 is fixedly connected to the upper end face of the housing 1; the measuring tube 4 is a pipeline that runs thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com