Uniform-speed discharging and mixing material bin used in pneumatic wet spray machine

A mixing bin and mixing material technology, applied in the direction of mixing operation control, mixing operation control device, unloading device, etc., can solve problems affecting equipment production efficiency and waste, reduce cleaning and maintenance times, save materials, and prolong use the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments. This embodiment provides detailed implementation methods and specific operation processes on the premise of the technical solution of the present invention.

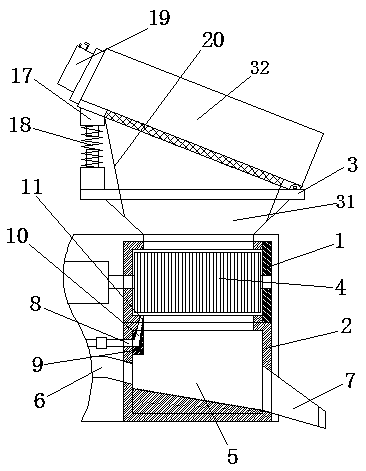

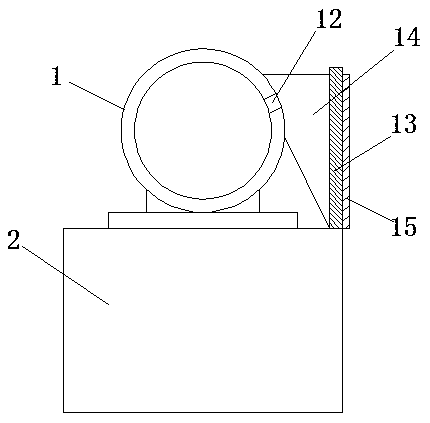

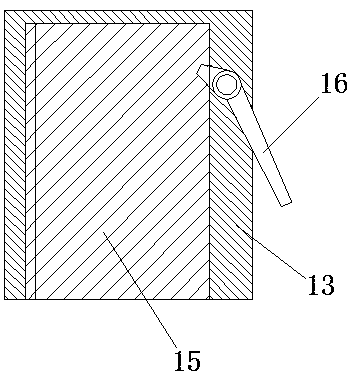

[0019] As shown in the figure, the present invention is a uniform feeding mixing bin used in a pneumatic wet spraying machine, including a mixing bin 1, a discharge bin 2 arranged at the bottom of the mixing bin 1 and a The feeding bin 3 at the top, the mixing bin 1 is provided with a feeding dial 4, and the feeding dial 4 includes a central axis roller 41, end plates 42 vertically arranged at both ends of the central axis roller 41 and two A plurality of baffles 43 evenly arranged on the circumference of the central shaft roller 41 between the end plates 42, any two adjacent baffles 43 and two end plates 42 form a feed bin 44, and the discharge bin 2 There is a through discharge channel 5 inclined downward, one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com