Intelligent measuring device for hydraulic engineering

A technology of intelligent measurement and water conservancy engineering, applied in the direction of measuring device, lubrication indicator device, liquid/fluid solid measurement, etc., can solve the inconvenience of practical use and other problems, achieve the effect of convenient fixed installation, ensure measurement stability, and reduce operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

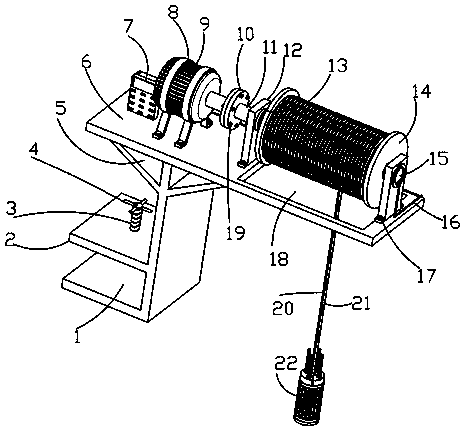

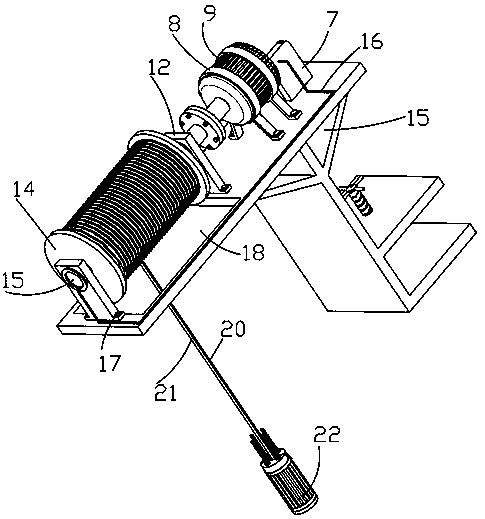

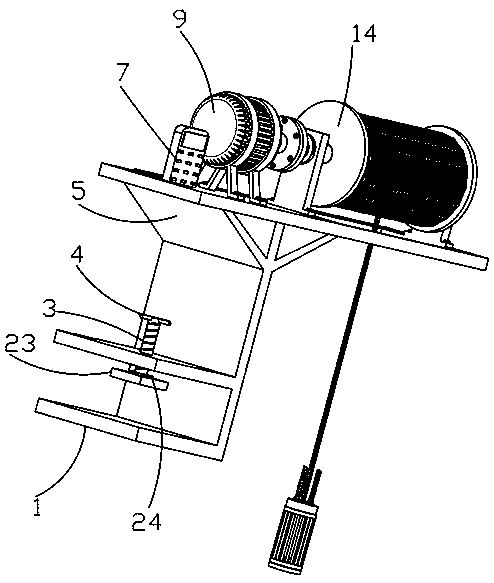

[0028] Such as Figure 1-4 The shown intelligent measuring device for water conservancy projects includes an L-shaped support plate 1, a measurement display panel 7, a drive motor 9, a conductive slip ring 15 and a liquid level sensor 28, and the middle end of the left side wall of the L-shaped support plate 1 A horizontal plate 2 is fixedly connected at the horizontal plate 2, and a fixed structure is provided on the horizontal plate 2. The fixed structure includes a compression threaded rod 3, a push rod 4, a second bearing 24 and a pressure plate 23. The threaded hole at the middle end of the horizontal plate 2 is connected with The compression threaded rod 3 is threadedly connected, the top of the compression threaded rod 3 is evenly fixedly connected with the push rod 4 along the circumferential direction, the bottom of the compression threaded rod 3 is fixedly connected with the inner ring of the second bearing 24, and the outer ring of the second bearing 24 It is fixedl...

Embodiment 2

[0030] Embodiment 2 is a further improvement to Embodiment 1.

[0031] Such as Figure 1-4The shown intelligent measuring device for water conservancy projects includes an L-shaped support plate 1, a measurement display panel 7, a drive motor 9, a conductive slip ring 15 and a liquid level sensor 28, and the middle end of the left side wall of the L-shaped support plate 1 The horizontal plate 2 is fixedly connected with the horizontal plate 2, and a fixed structure is arranged on the horizontal plate 2. The L-shaped support plate 1 is fixedly connected with a mounting plate 5, and the top of the mounting plate 5 is provided with a measurement display panel 7, a mounting frame 8 and a supporting plate 12 in sequence from the left. , the mounting frame 8 is fixedly installed with a drive motor 9, the output end of the drive motor 9 is fixedly connected with a flange 10, and the first bearing 13 and a conductive slip ring 15 are respectively fixedly connected in the horizontal ho...

Embodiment 3

[0033] Such as Figure 1-4 The shown intelligent measuring device for water conservancy projects includes an L-shaped support plate 1, a measurement display panel 7, a drive motor 9, a conductive slip ring 15 and a liquid level sensor 28, and the middle end of the left side wall of the L-shaped support plate 1 The horizontal plate 2 is fixedly connected with the horizontal plate 2, and a fixed structure is arranged on the horizontal plate 2. The L-shaped support plate 1 is fixedly connected with a mounting plate 5, and the top of the mounting plate 5 is provided with a measurement display panel 7, a mounting frame 8 and a supporting plate 12 in sequence from the left. , the mounting frame 8 is fixedly installed with a drive motor 9, the output end of the drive motor 9 is fixedly connected with a flange 10, and the first bearing 13 and a conductive slip ring 15 are respectively fixedly connected in the horizontal hole of the support plate 12, and the conductive slip ring 15 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com